Oil-in-Water Nanoemulsion Can Modulate the Fermentation, Fatty Acid Accumulation, and the Microbial Population in Rumen Batch Cultures

Abstract

1. Introduction

2. Materials and Methods

2.1. Oil-in-Water Nanoemulsion Preparation and Evaluation

2.2. The In Vitro Fermentation Trials

2.2.1. Source of the Rumen Inoculum

2.2.2. Trials Design and Management

2.2.3. Substrate and Incubation Fluid Sampling

2.3. Samples Chemical Analysis

2.3.1. Control Substrate Basic Analysis

2.3.2. Fermentation Characteristics

2.3.3. Fatty Acid Methyl Esters Analysis

2.3.4. Rumen Bacteria Quantification

2.4. Statistical Analysis

3. Results

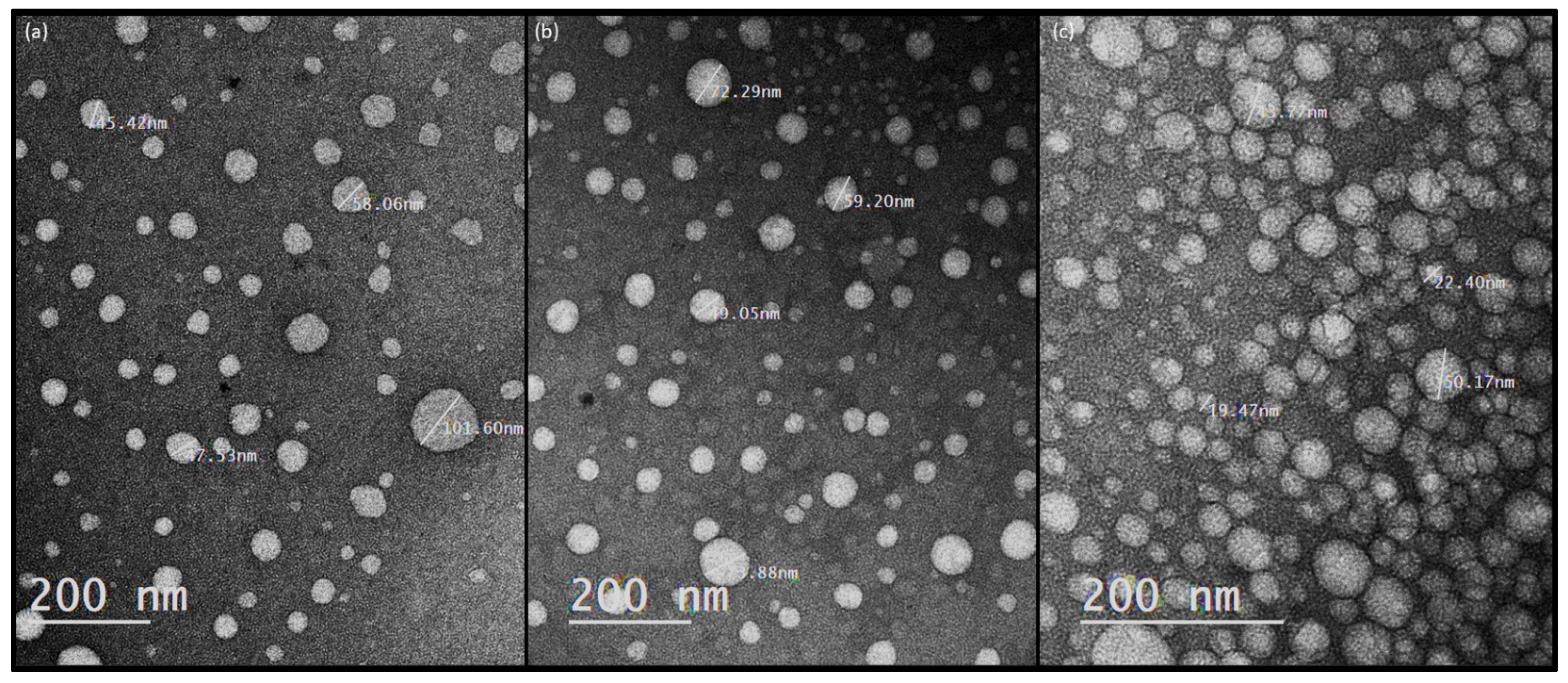

3.1. Oil-in-Water Nanoemulsion Evaluation

3.2. First Stage of Trials

3.2.1. Olive Oil Supplementation

3.2.2. Corn Oil Supplementation

3.2.3. Linseed Oil Supplementation

3.3. Second Stage of Trials

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shingfield, K.J.; Bonnet, M.; Scollan, N.D. Recent Developments in Altering the Fatty Acid Composition of Ruminant-Derived Foods. Animal 2013, 7, 132–162. [Google Scholar] [CrossRef] [PubMed]

- Meyer, B.J. Are We Consuming Enough Long Chain Omega-3 Polyunsaturated Fatty Acids for Optimal Health? Prostaglandins Leukot Essent Fat. Acids 2011, 85, 275–280. [Google Scholar] [CrossRef]

- O’Donnell, J.A. Future of Milk Fat Modification by Production or Processing: Integration of Nutrition, Food Science, and Animal Science. J. Dairy Sci. 1993, 76, 1797–1801. [Google Scholar] [CrossRef]

- Khattab, M.S.A.; Abd-El-Gawad, A.E.; Abo El-Nor, S.H.A.; El-Sherbiny, M. The Effect of Diet Supplemented with Vegetable Oils and/or Monensin on the Vaccenic Acid Production in Continuous Culture Fermenters. Anim. Nutr. 2015, 1, 320–323. [Google Scholar] [CrossRef] [PubMed]

- Cockbain, A.J.; Toogood, G.J.; Hull, M.A. Omega-3 Polyunsaturated Fatty Acids for the Treatment and Prevention of Colorectal Cancer. Gut 2011, 61, 135–149. [Google Scholar] [CrossRef]

- Koba, K.; Yanagita, T. Health Benefits of Conjugated Linoleic Acid (CLA). Obes. Res. Clin. Pract. 2014, 8, e525–e532. [Google Scholar] [CrossRef] [PubMed]

- Kliem, K.E.; Humphries, D.J.; Reynolds, C.K.; Morgan, R.; Givens, D.I. Effect of Oilseed Type on Milk Fatty Acid Composition of Individual Cows, and Also Bulk Tank Milk Fatty Acid Composition from Commercial Farms. Animal 2017, 11, 354–364. [Google Scholar] [CrossRef]

- Ramirez Ramirez, H.A.; Harvatine, K.J.; Kononoff, P.J. Short Communication: Forage Particle Size and Fat Intake Affect Rumen Passage, the Fatty Acid Profile of Milk, and Milk Fat Production in Dairy Cows Consuming Dried Distillers Grains with Solubles. J. Dairy Sci. 2016, 99, 392–398. [Google Scholar] [CrossRef]

- Bionaz, M.; Vargas-Bello-Pérez, E.; Busato, S. Advances in fatty acids nutrition in dairy cows: From gut to cells and effects on performance. J. Anim. Sci. Biotechnol. 2020, 11, 110. [Google Scholar] [CrossRef]

- Alvarez-Hess, P.S.; Williams, S.R.O.; Jacobs, J.L.; Hannah, M.C.; Beauchemin, K.A.; Eckard, R.J.; Wales, W.J.; Morris, G.L.; Moate, P.J. Effect of dietary fat supplementation on methane emissions from dairy cows fed wheat or corn. J. Dairy Sci. 2019, 102, 2714–2723. [Google Scholar] [CrossRef] [PubMed]

- Cancino-Padilla, N.; Catalán, N.; Siu-Ting, K.; Creevey, C.J.; Huws, S.A.; Romero, J.; Vargas-Bello-Pérez, E. Long-Term Effects of Dietary Supplementation with Olive Oil and Hydrogenated Vegetable Oil on the Rumen Microbiome of Dairy Cows. Microorganisms 2021, 9, 1121. [Google Scholar] [CrossRef]

- Brzozowska, A.M.; Oprządek, J. Metabolism of Fatty Acids in Tissues and Organs of the Ruminants-a Review. Anim. Sci. Pap. Rep. 2016, 34, 211–220. [Google Scholar]

- Mason, T.G.; Wilking, J.N.; Meleson, K.; Chang, C.B.; Graves, S.M. Nanoemulsions: Formation, Structure, and Physical Properties. J. Phys. Condens. Matter 2006, 18, 635–666. [Google Scholar] [CrossRef]

- El-Sherbiny, M.; Cieslak, A.; Pers-Kamczyc, E.; Szczechowiak, J.; Kowalczyk, D.; Szumacher-Strabel, M. Short Communication: A Nanoemulsified Form of Oil Blends Positively Affects the Fatty Acid Proportion in Ruminal Batch Cultures. J. Dairy Sci. 2016, 99, 399–407. [Google Scholar] [CrossRef] [PubMed]

- El-Sherbiny, M.; Cieślak, A.; Szczechowiak, J.; Kołodziejski, P.; Szulc, P.; Szumacher-Strabel, M. Effect of nanoemulsified oils addition on rumen fermentation and fatty acid proportion in a rumen simulation technique. J. Anim. Feed Sci. 2016, 25, 116–124. [Google Scholar] [CrossRef]

- Kentish, S.; Wooster, T.J.; Ashokkumar, M.; Balachandran, S.; Mawson, R.; Simons, L. The Use of Ultrasonics for Nanoemulsion Preparation. Innov. Food Sci. Emerg. Technol. 2008, 9, 170–175. [Google Scholar] [CrossRef]

- Yousef, M.A.; Farouk, M.H.; Azzaz, H.H.; Khattab, M.S.A.; Abd El Tawab, A.M.; El-Sherbiny, M. Feeding Corn Oil in a Nanoemulsified Form Alters the Unsaturated Fatty Acids in the Milk of Zaraibi Dairy Goats. Animals 2022, 12, 2559. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis, 18th ed.; AOAC International: Washington, DC, USA, 2005; ISBN 0935584544. [Google Scholar]

- van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Minuti, A.; Palladino, A.; Khan, M.J.; Alqarni, S.; Agrawal, A.; Piccioli-Capelli, F.; Hidalgo, F.; Cardoso, F.C.; Trevisi, E.; Loor, J.J. Abundance of ruminal bacteria, epithelial gene expression, and systemic biomarkers of metabolism and inflammation are altered during the peripartal period in dairy cows. J. Dairy Sci. 2015, 98, 8940–8951. [Google Scholar] [CrossRef]

- Li, M.; Penner, G.B.; Hernandez-Sanabria, E.; Oba, M.; Guan, L.L. Effects of sampling location and time, and host animal on assessment of bacterial diversity and fermentation parameters in the bovine rumen. J. Appl. Microbiol. 2009, 107, 1924–1934. [Google Scholar] [CrossRef]

- Potu, R.B.; AbuGhazaleh, A.A.; Hastings, D.; Jones, K.; Ibrahim, S.A. The effect of lipid supplements on ruminal bacteria in continuous culture fermenters varies with the fatty acid composition. J. Microbiol. 2011, 49, 216–223. [Google Scholar] [CrossRef]

- Denman, S.E.; McSweeney, C.S. Development of a real-time PCR assay for monitoring anaerobic fungal and cellulolytic bacterial populations within the rumen. FEMS Microbiol. Ecol. 2006, 58, 572–582. [Google Scholar] [CrossRef]

- Yu, Y.; Lee, C.; Kim, J.; Hwang, S. Group-specific primer and probe sets to detect methanogenic communities using quantitative real-time polymerase chain reaction. Biotechnol. Bioeng. 2005, 89, 670–679. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.F.; Cao, W.W.; Cerniglia, C.E. PCR detection of Ruminococcus spp. in human and animal faecal samples. Mol. Cell. Probes 1997, 11, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Poeker, S.A.; Geirnaert, A.; Berchtold, L.; Greppi, A.; Krych, L.; Steinert, R.E.; de Wouters, T.; Lacroix, C. Understanding the prebiotic potential of different dietary fibers using an in vitro continuous adult fermentation model (PolyFermS). Sci. Rep. 2018, 8, 4318–4330. [Google Scholar] [CrossRef] [PubMed]

- AbuGhazaleh, A.A.; Ishlak, A. Effects of incremental amounts of fish oil on trans fatty acids and Butyrivibrio bacteria in continuous culture fermenters. J. Anim. Physiol. Anim. Nutr. 2014, 98, 271–278. [Google Scholar] [CrossRef]

- Khiaosa-Ard, R.; Leiber, F.; Soliva, C.R. Methods of Emulsifying Linoleic Acid in Biohydrogenation Studies in Vitro May Bias the Resulting Fatty Acid Profiles. Lipids 2010, 45, 651–657. [Google Scholar] [CrossRef]

- Bauchart, D.; Legay-Carmier’, F. Lipid Metabolism of Liquid-Associated and Solid-Adherent Bacteria in Rumen Contents of Dairy Cows Offered Lipid-Supplemented Diets. Br. J. Nutr. 1990, 63, 563–578. [Google Scholar] [CrossRef]

- Martínez Marín, A.L.; Gomez-Cortes, P.; Gomez Castro, G.; Juarez, M.; Perez Alba, L.; Perez Hernandez, M.; de la Fuente, M.A. Time-dependent variations in milk fatty acid content of goats fed 3 different plant oils. J. Dairy Sci. 2013, 96, 3238–3246. [Google Scholar] [CrossRef]

- Ozturk, B.; Argin, S.; Ozilgen, M.; McClements, D.J. Nanoemulsion Delivery Systems for Oil-Soluble Vitamins: Influence of Carrier Oil Type on Lipid Digestion and Vitamin D3 Bioaccessibility. Food Chem. 2015, 187, 499–506. [Google Scholar] [CrossRef]

- Kozłowska, M.; Cieślak, A.; Jóźwik, A.; El-Sherbiny, M.; Stochmal, A.; Oleszek, W.; Kowalczyk, M.; Filipiak, W.; Szumacher-Strabel, M. The effect of total and individual alfalfa saponins on rumen methane production. J. Sci. Food Agric. 2020, 100, 1922–1930. [Google Scholar] [CrossRef] [PubMed]

- Chan, E.-S.; Lim, T.-K.; Ravindra, P.; Mansa, R.F.; Islam, A. The effect of low air-to-liquid mass flow rate ratios on the size, size distribution and shape of calcium alginate particles produced using the atomization method. J. Food Eng. 2012, 108, 297–303. [Google Scholar] [CrossRef]

- Islam, K.N.; Ali, M.E.; Bakar, M.Z.B.A.; Loqman, M.Y.; Islam, A.; Islam, M.S.; Rahman, M.M.; Ullah, M. A novel catalytic method for the synthesis of spherical aragonite nanoparticles from cockle shells. Powder Technol. 2013, 246, 434–440. [Google Scholar] [CrossRef]

- Teo, S.H.; Ng, C.H.; Islam, A.; Abdulkareem-Alsultan, G.; Joseph, C.G.; Janaun, J.; Taufiq-Yap, Y.H.; Khandaker, S.; Islam, G.J.; Znad, H.; et al. Sustainable toxic dyes removal with advanced materials for clean water production: A comprehensive review. J. Clean. Prod. 2022, 332, 130039. [Google Scholar] [CrossRef]

| Item | Control Substrate |

|---|---|

| Ingredients, g/kg of DM | |

| Corn grain | 75.5 |

| Cotton seed meal | 116 |

| Sunflower seed meal | 85.5 |

| Wheat bran | 175 |

| Molasse | 35.5 |

| Mineral–vitamin mixture | 12.5 |

| Berseem clover | 500 |

| Chemical composition, g/kg of DM | |

| Organic Matter | 911 |

| Ash | 89.0 |

| Crude Protein | 169 |

| Either Extract | 34.0 |

| Neutral detergent fiber | 349 |

| Acid detergent fiber | 199 |

| Item | Control Substrate | Supplements 1 | |||||

|---|---|---|---|---|---|---|---|

| OO | NOO | CO | NCO | LO | NLO | ||

| C14:0 | 0.74 | 0.02 | 0.02 | 0.08 | 0.12 | 0.10 | 0.09 |

| C16:0 | 21.6 | 16.6 | 15.7 | 13.4 | 10.2 | 5.20 | 4.98 |

| C18:0 | 2.89 | 2.70 | 2.49 | 2.01 | 1.82 | 3.80 | 3.52 |

| C18:1 cis-9 | 21.8 | 61.2 | 62.9 | 29.7 | 31.2 | 18.7 | 19.3 |

| C18:2 cis-9, cis-12 | 44.9 | 16.5 | 15.5 | 52.6 | 53.9 | 16.2 | 16.9 |

| C18:3 cis-9, cis-12, cis-15 | 7.71 | 0.66 | 0.78 | 0.88 | 0.84 | 55.2 | 53.7 |

| Other FA 2 | 0.36 | 2.32 | 2.61 | 1.33 | 1.92 | 0.80 | 1.51 |

| SFA 3 | 25.6 | 19.8 | 18.8 | 15.5 | 12.1 | 9.50 | 9.20 |

| UFA 4 | 74.7 | 80.2 | 81.2 | 84.5 | 87.9 | 90.5 | 90.8 |

| MUFA 5 | 52.6 | 63.1 | 64.9 | 29.7 | 31.2 | 19.0 | 19.8 |

| PUFA 6 | 21.8 | 17.2 | 16.3 | 54.8 | 56.7 | 71.5 | 71.0 |

| Targeted Rumen Bacteria | Primer Sequence (5′ to 3′) | Reference |

|---|---|---|

| Anaerovibrio lipolytica | F: GAAATGGATTCTAGTGGCAAACG R: ACATCGGTCATGCGACCAA | [20] |

| Butyrivibrio fibrisolvens | F: ACACACCGCCCGTCACA R: TCCTTACGGTTGGGTCACAGA | [21] |

| Butyrivibrio proteoclasticus | F: TCCTAGTGTAGCGGTGAAATG R: TTAGCGACGGCACTGAATGCCTA | [22] |

| Fibrobacter succinogenes | F: GTTCGGAATTACTGGGCGTAAA R: CGCCTGCCCCTGAACTATC | [23] |

| Megasphaera elsdenii | F: AGATGGGGACAACAGCTGGA R: CGAAAGCTCCGAAGAGCCT | [24] |

| Ruminococcus albus | F: CCCTAAAAGCAGTCTTAGTTCG R: CCTCCTTGCGGTTAGAACA | [25] |

| Ruminococcus flavefaciens | F: CGAACGGAGATAATTTGAGTTTACTTAGG R: CGGTCTCTGTATGTTATGAGGTATTACC | [26] |

| Streptococcus bovis | F: TTCCTAGAGATAGGAAGTTTCTTCGG R: ATGATGGCAACTAACAATAGGGGT | [24] |

| Item | Form 1 | Levels 2, % | SEM | Contrast 3 | p-Value 4 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | L | Q | F | L | FxL | |||

| Rumen Basic Parameters | |||||||||||

| pH | NOO | 6.35 a | 6.32 a | 6.11 bx | 5.98 bx | 0.066 | <0.001 | <0.001 | <0.001 | 0.002 | 0.123 |

| OO | 6.35 a | 6.28 b | 5.69 cy | 5.23 dy | 0.001 | 0.009 | |||||

| TGP, mL/g DM | NOO | 264 d | 275 cx | 286 bx | 298 ax | 2.745 | <0.001 | 0.002 | 0.004 | 0.015 | 0.214 |

| OO | 264 a | 269 ay | 253 by | 248 cy | <0.001 | <0.001 | |||||

| Ammonia-N, mmol/L | NOO | 12.3 a | 12.6 a | 12.5 ax | 10.9 bx | 0.189 | <0.001 | 0.011 | <0.001 | 0.002 | 0.041 |

| OO | 12.3 a | 12.1 a | 10.6 by | 9.47 cy | <0.001 | <0.001 | |||||

| IVDMD 5, % | NOO | 55.3 a | 56.2 ax | 54.8 ax | 49.6 bx | 0.832 | 0.004 | 0.019 | 0.003 | 0.012 | 0.110 |

| OO | 55.3 a | 54.6 ay | 48.9 by | 41.7 cy | <0.001 | 0.006 | |||||

| Volatile Fatty Acids (VFA), mmol/L | |||||||||||

| Total VFA | NOO | 114 b | 120 ax | 119 ax | 101 cx | 1.877 | <0.001 | <0.001 | 0.002 | 0.022 | 0.236 |

| OO | 114 a | 111 ay | 98.7 by | 87.7 cy | <0.001 | <0.001 | |||||

| Acetate (A) | NOO | 61.7 b | 67.3 ax | 60.9 bx | 53.7 cx | 1.286 | <0.001 | 0.002 | <0.001 | 0.009 | 0.098 |

| OO | 61.7 a | 62.1 ay | 54.1 by | 42.3 cy | 0.003 | 0.009 | |||||

| Propionate (P) | NOO | 21.8 a | 22.3 ax | 20.9 bx | 19.3 cx | 0.279 | <0.001 | 0.015 | <0.001 | <0.001 | 0.114 |

| OO | 21.8 a | 21.1 ay | 19.2 by | 17.4 cy | 0.004 | 0.007 | |||||

| Butyrate | NOO | 19.6 a | 19.5 ax | 18.9 bx | 16.2 cx | 0.348 | <0.001 | 0.018 | <0.001 | 0.012 | 0.074 |

| OO | 19.6 a | 18.7 by | 16.9 cy | 13.8 dy | <0.001 | <0.001 | |||||

| A:P ratio | NOO | 2.83 b | 3.02 a | 2.91 a | 2.78 cx | 0.029 | <0.001 | 0.007 | 0.011 | 0.031 | 0.099 |

| OO | 2.83 b | 2.94 a | 2.82 b | 2.43 cy | 0.008 | 0.009 | |||||

| Fatty Acid Methyl Esters, g/100 g FA | |||||||||||

| C14:0 | NOO | 2.89 a | 1.78 by | 1.58 cy | 1.63 cy | 0.095 | <0.001 | <0.001 | 0.002 | 0.009 | 0.127 |

| OO | 2.89 a | 2.54 bx | 2.22 cx | 2.82 ax | <0.001 | <0.001 | |||||

| C14:1 cis-9 | NOO | 2.12 a | 1.43 by | 1.11 cy | 1.07 cy | 0.066 | <0.001 | 0.014 | 0.005 | 0.019 | 0.178 |

| OO | 2.12 a | 1.64 bx | 1.56 cx | 1.44 dx | <0.001 | 0.009 | |||||

| C16:0 | NOO | 21.3 a | 18.7 by | 16.9 cy | 15.4 dy | 0.364 | <0.001 | <0.001 | 0.002 | <0.001 | 0.022 |

| OO | 21.3 a | 21.1 ax | 20.3 ax | 19.5 bx | <0.001 | <0.001 | |||||

| C16:1 cis-9 | NOO | 0.67 c | 0.78 b | 0.83 bx | 0.89 ax | 0.014 | 0.008 | 0.017 | <0.001 | 0.004 | 0.415 |

| OO | 0.67 b | 0.81 a | 0.72 by | 0.69 by | 0.003 | 0.031 | |||||

| C18:0 | NOO | 32.6 a | 26.7 by | 22.3 dy | 24.9 cy | 0.778 | <0.001 | <0.001 | <0.001 | <0.001 | 0.211 |

| OO | 32.6 b | 33.9 abx | 34.7 ax | 26.8 cx | <0.001 | 0.017 | |||||

| C18:1 trans-10 | NOO | 0.89 ab | 0.81 by | 0.84 by | 0.92 ax | 0.016 | <0.001 | 0.002 | <0.001 | 0.004 | 0.166 |

| OO | 0.89 b | 0.92 bx | 1.12 ax | 0.82 cy | <0.001 | 0.001 | |||||

| C18:1 trans-11 | NOO | 4.32 a | 3.85 by | 3.52 cy | 3.11 dy | 0.158 | <0.001 | <0.001 | <0.001 | 0.003 | 0.147 |

| OO | 4.32 d | 5.22 bx | 6.11 ax | 4.56 cx | <0.001 | <0.001 | |||||

| C18:1 cis-9 | NOO | 5.66 d | 20.8 cx | 24.1 bx | 29.8 ax | 1.444 | <0.001 | <0.001 | <0.001 | <0.001 | 0.087 |

| OO | 5.66 d | 11.3 cy | 12.8 by | 13.7 ay | <0.001 | 0.004 | |||||

| C18:2 cis-9 cis-12 | NOO | 3.09 d | 7.19 cx | 8.33 bx | 8.79 ax | 0.386 | <0.001 | <0.001 | 0.002 | <0.001 | 0.009 |

| OO | 3.09 d | 3.99 cy | 4.22 by | 4.78 ay | <0.001 | <0.001 | |||||

| C18:2 cis-9 trans-11 | NOO | 0.26 b | 0.29 aby | 0.31 ay | 0.27 by | 0.016 | <0.001 | 0.006 | 0.002 | 0.008 | 0.097 |

| OO | 0.26 c | 0.43 bx | 0.52 ax | 0.41 bx | 0.002 | 0.011 | |||||

| C18:2 trans-10 cis-12 | NOO | 0.19 a | 0.15 cy | 0.15 cy | 0.17 by | 0.017 | 0.011 | 0.079 | <0.001 | 0.007 | 0.124 |

| OO | 0.19 d | 0.29 cx | 0.35 bx | 0.42 ax | <0.001 | 0.002 | |||||

| C18:3 cis-9 cis-12 cis-15 | NOO | 0.48 c | 1.87 ax | 1.66 bx | 1.66 bx | 0.092 | <0.001 | <0.001 | <0.001 | <0.001 | 0.112 |

| OO | 0.48 c | 0.82 by | 0.93 ay | 0.89 ay | <0.001 | 0.006 | |||||

| Other FA 6 | NOO | 25.5 a | 15.6 cy | 18.4 bx | 11.4 dy | 0.879 | <0.001 | 0.011 | 0.007 | 0.003 | 0.072 |

| OO | 25.5 a | 17.0 cx | 14.4 dy | 23.2 bx | 0.017 | 0.024 | |||||

| SFA 7 | NOO | 69.4 a | 48.3 by | 44.4 cy | 42.3 dy | 1.793 | <0.001 | <0.001 | <0.001 | 0.009 | 0.112 |

| OO | 69.4 a | 63.2 bx | 60.7 cx | 59.2 cx | <0.001 | <0.001 | |||||

| UFA 8 | NOO | 30.6 d | 51.7 cx | 55.6 bx | 57.7 ax | 1.393 | <0.001 | <0.001 | <0.001 | <0.001 | 0.278 |

| OO | 30.6 d | 36.8 cy | 39.3 by | 40.8 ay | <0.001 | 0.004 | |||||

| MUFA 9 | NOO | 24.7 d | 33.8 cx | 35.9 bx | 37 ax | 0.804 | <0.001 | <0.001 | 0.002 | 0.001 | 0.114 |

| OO | 24.7 c | 26.9 by | 29.2 ay | 30.3 ay | <0.001 | 0.003 | |||||

| PUFA 10 | NOO | 5.89 d | 17.9 cx | 19.7 bx | 20.7 ax | 0.998 | <0.001 | <0.001 | <0.001 | <0.001 | 0.088 |

| OO | 5.89 c | 9.88 by | 10.1 aby | 10.4 ay | <0.001 | 0.002 | |||||

| Item | Form 1 | Levels 2, % | SEM | Contrast 3 | p-Value 4 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | L | Q | F | L | FxL | |||

| Rumen Basic Parameters | |||||||||||

| pH | NCO | 6.55 a | 6.54 ax | 6.55 ax | 5.98 bx | 0.066 | <0.001 | 0.022 | <0.001 | <0.001 | 0.411 |

| CO | 6.55 a | 6.34 by | 5.87 cy | 5.33 dy | <0.001 | 0.009 | |||||

| TGP, mL/g DM | NCO | 274 c | 290 bx | 301 ax | 309 ax | 3.259 | <0.001 | 0.005 | 0.004 | 0.008 | 0.088 |

| CO | 274 a | 272 ay | 261 by | 243 cy | <0.001 | 0.007 | |||||

| Ammonia-N, mmol/L | NCO | 13.7 a | 13.7 a | 13.9 ax | 12.8 bx | 0.236 | <0.001 | 0.004 | <0.001 | 0.003 | 0.336 |

| CO | 13.7 a | 13.5 a | 12.6 by | 9.22 cy | <0.001 | 0.003 | |||||

| IVDMD 5, % | NCO | 56.6 a | 56.9 a | 57.3 ax | 50.6 bx | 0.940 | <0.001 | 0.003 | <0.001 | <0.001 | 0.250 |

| CO | 56.6 a | 56.7 a | 49.2 by | 39.8 cy | <0.001 | <0.001 | |||||

| Volatile Fatty Acids (VFA), mmol/L | |||||||||||

| Total VFA | NCO | 122 b | 130 ax | 128 abx | 110 cx | 2.293 | <0.001 | 0.022 | <0.001 | <0.001 | 0.009 |

| CO | 122 a | 124 ay | 111 by | 83.5 cy | <0.001 | <0.001 | |||||

| Acetate (A) | NCO | 65.3 a | 66.2 a | 64.9 ax | 60.1 bx | 0.884 | <0.001 | 0.002 | <0.001 | <0.001 | 0.412 |

| CO | 65.3 a | 65.2 a | 61.1 by | 48.8 cy | 0.003 | 0.031 | |||||

| Propionate (P) | NCO | 24.7 a | 25.1 a | 24.8 ax | 20.2 bx | 0.489 | <0.001 | 0.002 | <0.001 | <0.001 | 0.122 |

| CO | 24.7 a | 24.9 a | 21.7 by | 16.2 cy | <0.001 | <0.001 | |||||

| Butyrate | NCO | 19.1 a | 19.5 ax | 19.5 ax | 17.1 bx | 0.283 | <0.001 | 0.003 | <0.001 | 0.004 | 0.369 |

| CO | 19.1 a | 18.9 ay | 17.3 by | 14.1 cy | <0.001 | <0.001 | |||||

| A:P ratio | NCO | 2.64 b | 2.64 b | 2.62 by | 2.98 a | 0.025 | 0.005 | 0.019 | <0.001 | 0.004 | 0.258 |

| CO | 2.64 c | 2.62 c | 2.82 bx | 3.01 a | 0.012 | 0.029 | |||||

| Fatty Acid Methyl Esters, g/100 g FA | |||||||||||

| C14:0 | NCO | 3.32 a | 2.43 by | 2.12 cy | 1.87 d | 0.087 | 0.002 | 0.011 | <0.001 | 0.005 | 0.149 |

| CO | 3.32 a | 2.55 bx | 2.28 cx | 1.92 d | <0.001 | 0.009 | |||||

| C14:1 cis-9 | NCO | 2.88 a | 1.67 by | 1.43 cy | 1.22 dy | 0.101 | <0.001 | 0.008 | 0.011 | <0.001 | 0.228 |

| CO | 2.88 a | 1.83 bx | 1.53 cx | 1.33 dx | 0.002 | 0.021 | |||||

| C16:0 | NCO | 22.3 a | 19.1 by | 17.6 cy | 14.9 dy | 0.383 | <0.001 | <0.001 | <0.001 | 0.009 | 0.018 |

| CO | 22.3 a | 20.2 bx | 19.3 cx | 17.4 dx | <0.001 | 0.002 | |||||

| C16:1 cis-9 | NCO | 0.77 c | 0.82 b | 0.91 a | 0.95 a | 0.010 | 0.003 | 0.014 | 0.002 | <0.001 | 0.111 |

| CO | 0.77 c | 0.83 b | 0.87 ab | 0.92 a | 0.004 | 0.032 | |||||

| C18:0 | NCO | 33.2 a | 25.4 by | 24.2 cy | 23.3 dy | 0.609 | <0.001 | <0.001 | 0.011 | 0.005 | 0.142 |

| CO | 33.2a | 30.7 bx | 31.2 abx | 29.9 bx | 0.003 | 0.014 | |||||

| C18:1 trans-10 | NCO | 0.79 | 0.83 y | 0.81 y | 0.78 y | 0.016 | <0.001 | 0.001 | 0.002 | 0.013 | 0.122 |

| CO | 0.79 c | 0.97 ax | 1.08 ax | 0.81 bx | 0.002 | 0.007 | |||||

| C18:1 trans-11 | NCO | 5.14 a | 4.01 by | 3.12 cy | 2.89 dy | 0.176 | <0.001 | <0.001 | 0.001 | 0.007 | 0.189 |

| CO | 5.14 b | 5.54 abx | 6.12 ax | 4.09 cx | <0.001 | 0.003 | |||||

| C18:1 cis-9 | NCO | 5.89 d | 16.7 cx | 18.3 bx | 20.1 ax | 0.868 | <0.001 | <0.001 | 0.002 | 0.003 | 0.322 |

| CO | 5.89 d | 10.2 ay | 9.12 by | 8.13 cy | <0.001 | 0.006 | |||||

| C18:2 cis-9 cis-12 | NCO | 3.12 d | 10.19 cx | 11.33 bx | 13.79 ax | 0.589 | <0.001 | <0.001 | 0.001 | 0.005 | 0.002 |

| CO | 3.12 c | 6.77 ay | 6.32 ay | 5.66 by | <0.001 | 0.002 | |||||

| C18:2 cis-9 trans-11 | NCO | 0.32 a | 0.18 cy | 0.19 cy | 0.22 by | 0.017 | <0.001 | 0.004 | 0.004 | 0.012 | 0.211 |

| CO | 0.32 c | 0.42 bx | 0.49 ax | 0.38 bx | 0.002 | 0.008 | |||||

| C18:2 trans-10 cis-12 | NCO | 0.26 a | 0.17 by | 0.18 by | 0.18 by | 0.012 | <0.001 | <0.001 | 0.002 | <0.001 | 0.078 |

| CO | 0.26 c | 0.31 bx | 0.39 ax | 0.32 bx | 0.002 | 0.008 | |||||

| C18:3 cis-9 cis-12 cis-15 | NCO | 0.51 c | 1.97 ax | 1.89 ax | 1.79 bx | 0.091 | <0.001 | 0.002 | <0.001 | 0.003 | 0.125 |

| CO | 0.51 b | 0.97 ay | 0.99 ay | 1.02 ay | 0.012 | 0.112 | |||||

| Other FA 6 | NCO | 21.5 a | 16.5 dy | 17.9 cy | 18.0 by | 0.550 | <0.001 | <0.001 | <0.001 | 0.006 | 0.116 |

| CO | 21.5 b | 18.7 cx | 20.3 bx | 28.1 ax | <0.001 | <0.001 | |||||

| SFA 7 | NCO | 67.4 a | 49.7 by | 46.3 by | 42.7 cy | 1.409 | <0.001 | <0.001 | 0.018 | 0.013 | 0.021 |

| CO | 67.4 a | 60.1 bx | 59.2 bx | 58.1 bx | <0.001 | 0.011 | |||||

| UFA 8 | NCO | 32.6 d | 50.3 cx | 53.7 bx | 57.3 ax | 1.106 | <0.001 | 0.002 | 0.019 | 0.014 | 0.114 |

| CO | 32.6 d | 39.9 cy | 40.8 by | 41.9 ay | <0.001 | 0.019 | |||||

| MUFA 9 | NCO | 26.4 d | 29.8 cx | 32.6 bx | 37.1 ax | 0.539 | <0.001 | 0.001 | <0.001 | 0.002 | 0.412 |

| CO | 26.4 d | 28.4 cy | 29.9 by | 31.8 ay | <0.001 | 0.009 | |||||

| PUFA 10 | NCO | 6.24 b | 20.5 ax | 21.1 ax | 20.2 ax | 0.960 | <0.001 | 0.006 | <0.001 | <0.001 | 0.041 |

| CO | 6.24 d | 11.5 ay | 10.9 by | 10.1 cy | <0.001 | <0.001 | |||||

| Item | Form 1 | Levels 2, % | SEM | Contrast 3 | p-Value 4 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | L | Q | F | L | FxL | |||

| Rumen Basic Parameters | |||||||||||

| pH | NLO | 6.26 a | 6.24 ax | 6.04 bx | 5.80 cx | 0.075 | <0.001 | <0.001 | <0.001 | <0.001 | 0.073 |

| LO | 6.26 a | 6.12 by | 5.61 cy | 5.12 dy | <0.001 | <0.001 | |||||

| TGP, mL/g DM | NLO | 261 d | 274 cx | 285 bx | 294 ax | 3.425 | <0.001 | 0.089 | 0.004 | <0.001 | 0.222 |

| LO | 261 a | 262 ay | 249 by | 238 cy | <0.001 | 0.066 | |||||

| Ammonia-N, mmol/L | NLO | 12.6 a | 12.8 a | 12.8 ax | 11.5 bx | 0.239 | 0.008 | 0.344 | <0.001 | 0.002 | 0.041 |

| LO | 12.6 a | 12.4 a | 11.2 by | 9.06 cy | 0.013 | <0.001 | |||||

| IVDMD 5, % | NLO | 54.3 a | 54.8 a | 54.4 ax | 48.6 bx | 1.015 | <0.001 | 0.002 | <0.001 | 0.006 | 0.534 |

| LO | 54.3 a | 53.9 a | 47.6 by | 39.5 cy | <0.001 | <0.001 | |||||

| Volatile Fatty Acids (VFA), mmol/L | |||||||||||

| Total VFA | NLO | 114 b | 121 ax | 120 ax | 102 cx | 2.373 | <0.001 | <0.001 | 0.009 | 0.001 | 0.166 |

| LO | 114 a | 114 ay | 102 by | 83.0 cy | <0.001 | <0.001 | |||||

| Acetate (A) | NLO | 61.6 b | 64.7 ax | 61.0 bx | 55.2 cx | 1.221 | <0.001 | 0.003 | 0.001 | 0.022 | 0.211 |

| LO | 61.6 a | 61.7 ay | 55.9 by | 44.2 cy | <0.001 | 0.007 | |||||

| Propionate (P) | NLO | 22.6 a | 23.0 a | 22.2 ax | 19.2 bx | 0.441 | 0.014 | 0.059 | <0.001 | 0.008 | 0.088 |

| LO | 22.6 a | 22.3 a | 19.8 by | 16.3 cy | 0.003 | <0.001 | |||||

| Butyrate | NLO | 18.8 a | 18.9 a | 18.6 ax | 16.2 bx | 0.357 | <0.001 | 0.001 | <0.001 | 0.002 | 0.356 |

| LO | 18.8 a | 18.2 a | 16.6 by | 13.5 cy | <0.001 | 0.002 | |||||

| A:P ratio | NLO | 2.73 | 2.82 | 2.75 | 2.88 x | 0.011 | 0.082 | 0.195 | 0.021 | 0.144 | 0.321 |

| LO | 2.73 | 2.77 | 2.82 | 2.71 y | 0.122 | 0.221 | |||||

| Fatty Acid Methyl Esters, g/100 g FA | |||||||||||

| C14:0 | NLO | 3.01 a | 2.04 by | 1.79 cy | 1.70 cy | 0.093 | <0.001 | 0.011 | 0.002 | 0.018 | 0.144 |

| LO | 3.01 a | 2.47 bx | 2.18 cx | 2.30 bx | <0.001 | 0.003 | |||||

| C14:1 cis-9 | NLO | 2.43 a | 1.50 by | 1.23 cy | 1.11 cy | 0.095 | 0.007 | 0.009 | 0.007 | 0.011 | 0.175 |

| LO | 2.43 a | 1.68 bx | 1.50 cx | 1.34 dx | <0.001 | <0.001 | |||||

| C16:0 | NLO | 21.1 a | 18.3 by | 16.7 cy | 14.7 dy | 0.417 | <0.001 | 0.004 | 0.004 | 0.007 | 0.022 |

| LO | 21.1 a | 20.0 ax | 19.2 ax | 17.9 bx | <0.001 | <0.001 | |||||

| C16:1 cis-9 | NLO | 0.70 c | 0.78 b | 0.84 abx | 0.89 ax | 0.012 | <0.001 | <0.001 | <0.001 | 0.001 | 0.478 |

| LO | 0.70 b | 0.80 a | 0.77 ay | 0.78 ay | <0.001 | <0.001 | |||||

| C18:0 | NLO | 31.9 a | 25.3 by | 22.5 by | 23.4 by | 0.762 | <0.001 | <0.001 | <0.001 | 0.008 | 0.544 |

| LO | 31.9 a | 31.3 ax | 31.9 ax | 27.5 bx | <0.001 | <0.001 | |||||

| C18:1 trans-10 | NLO | 0.81 | 0.80 y | 0.80 y | 0.82 | 0.018 | 0.111 | 0.217 | 0.007 | 0.023 | 0.345 |

| LO | 0.81 c | 0.92 bx | 1.07 ax | 0.79 c | 0.002 | 0.067 | |||||

| C18:1 trans-11 | NLO | 4.59 a | 3.81 by | 3.22 by | 2.91 cy | 0.188 | <0.001 | <0.001 | 0.001 | 0.012 | 0.236 |

| LO | 4.59 b | 5.22 ax | 5.93 ax | 4.20 bx | <0.001 | <0.001 | |||||

| C18:1 cis-9 | NLO | 5.60 c | 18.2 bx | 20.6 abx | 24.2 ax | 1.300 | <0.001 | <0.001 | <0.001 | 0.002 | 0.611 |

| LO | 5.60 b | 10.4 ay | 10.63 ay | 10.59 ay | <0.001 | <0.001 | |||||

| C18:2 cis-9 cis-12 | NLO | 3.03 c | 8.43 bx | 9.54 abx | 10.9 ax | 0.558 | 0.004 | 0.009 | <0.001 | 0.004 | 0.222 |

| LO | 3.03 b | 5.22 ay | 5.11 ay | 5.06 ay | <0.001 | 0.005 | |||||

| C18:2 cis-9 trans-11 | NLO | 0.28 | 0.23 y | 0.24 y | 0.24 y | 0.018 | 0.199 | 0.254 | 0.001 | 0.002 | 0.411 |

| LO | 0.28 c | 0.41 abx | 0.49 ax | 0.38 bx | 0.002 | 0.009 | |||||

| C18:2 trans-10 cis-12 | NLO | 0.22 a | 0.16 by | 0.16 by | 0.17 by | 0.016 | 0.018 | 0.119 | <0.001 | 0.002 | 0.225 |

| LO | 0.22 b | 0.29 bx | 0.36 ax | 0.36 ax | <0.001 | <0.001 | |||||

| C18:3 cis-9 cis-12 cis-15 | NLO | 0.48 c | 1.86 ax | 1.72 abx | 1.67 bx | 0.104 | 0.011 | 0.156 | <0.001 | 0.006 | 0.105 |

| LO | 0.48 b | 0.87 ay | 0.93 ay | 0.93 ay | 0.002 | 0.008 | |||||

| Other FA 6 | NLO | 25.8 a | 18.6 cy | 20.6 bx | 17.3 cy | 0.731 | 0.008 | 0.017 | <0.001 | <0.001 | 0.022 |

| LO | 25.8 b | 20.3 cx | 19.9 cy | 27.9 ax | 0.003 | 0.008 | |||||

| SFA 7 | NLO | 63.2 a | 47.8 by | 42.3 cy | 40.1 dy | 1.688 | <0.001 | <0.001 | <0.001 | <0.001 | 0.333 |

| LO | 63.2 a | 58.8 bx | 57.3 bx | 53.9 cx | <0.001 | <0.001 | |||||

| UFA 8 | NLO | 36.8 d | 52.2 cx | 57.7 bx | 59.9 ax | 1.138 | <0.001 | <0.001 | <0.001 | <0.001 | 0.211 |

| LO | 36.8 c | 41.2 by | 42.7 by | 46.1 ay | <0.001 | 0.009 | |||||

| MUFA 9 | NLO | 28.5 d | 32.9 cx | 36.8 bx | 38.7 ax | 0.701 | <0.001 | <0.001 | <0.001 | <0.001 | 0.009 |

| LO | 28.5 c | 30.3 by | 31.5 by | 34.2 ay | <0.001 | <0.001 | |||||

| PUFA 10 | NLO | 8.32 c | 19.3 bx | 20.9 abx | 21.2 ax | 1.036 | <0.001 | <0.001 | <0.001 | <0.001 | 0.568 |

| LO | 8.32 c | 10.9 by | 11.2 aby | 11.9 ay | <0.001 | 0.066 | |||||

| Item | Treatments 1 | SEM | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CON | OO3% | CO3% | LO3% | NOO3% | NCO3% | NLO3% | ||||

| Rumen Basic Parameters | ||||||||||

| pH | 6.37 b | 6.28 c | 6.35 b | 6.25 c | 6.46 a | 6.46 a | 6.42 a | 0.020 | 0.002 | |

| TGP, mL/g DM | 265 b | 254 c | 257 c | 249 d | 268 ab | 270 a | 264 b | 1.914 | <0.001 | |

| Ammonia-N, mmol/L | 11.3 b | 10.5 c | 11.4 ab | 10.9 c | 11.7 a | 11.8 a | 11.1 b | 0.112 | 0.006 | |

| IVDMD 2, % | 56.3 b | 54.6 c | 55.3 bc | 53.5 d | 56.9 ab | 57.1 a | 56.6 ab | 0.329 | 0.002 | |

| Volatile Fatty Acids (VFA), mmol/L | ||||||||||

| Total VFA | 105 b | 100 c | 106 b | 99 c | 110 a | 112 a | 108 ab | 1.479 | 0.001 | |

| Acetate (A) | 62.8 b | 60.7 c | 63.1 b | 60.1 c | 65.2 a | 66.7 a | 63.2 b | 0.321 | <0.001 | |

| Propionate (P) | 23.2 ab | 21.1 c | 22.7 b | 21.5 c | 23.7 a | 23.8 a | 23.5 a | 0.188 | 0.016 | |

| Butyrate | 18.9 b | 18.1 c | 18.7 b | 17.2 d | 19.3 a | 19.4 a | 19.2 a | 0.109 | <0.001 | |

| A:P ratio | 2.71 b | 2.88 a | 2.78 ab | 2.80 ab | 2.75 b | 2.80 ab | 2.69 c | 0.010 | 0.023 | |

| Fatty Acid Methyl Esters, g/100 g FA | ||||||||||

| C14:0 | 2.71 a | 1.89 b | 1.77 bc | 1.81 b | 1.64 c | 1.52 d | 1.66 c | 0.097 | 0.001 | |

| C14:1 cis-9 | 1.98 a | 1.11 bc | 0.98 c | 1.23 ab | 0.94 cd | 0.87 d | 0.99 c | 0.094 | 0.009 | |

| C16:0 | 20.9 a | 18.7 b | 18.3 bc | 19.2 b | 16.4 d | 15.9 d | 17.1 c | 0.428 | 0.003 | |

| C16:1 cis-9 | 0.93 bc | 0.68 d | 0.95 b | 0.87 c | 0.81 cd | 1.04 a | 0.97 b | 0.029 | 0.017 | |

| C18:0 | 29.6 b | 31.9 a | 31.4 ab | 32.3 a | 27.1 c | 25.8 d | 26.4 d | 0.678 | 0.001 | |

| C18:1 trans-10 | 1.69 c | 1.98 b | 2.13 a | 2.27 a | 1.09 d | 1.17 d | 1.25 e | 0.120 | <0.001 | |

| C18:1 trans-11 | 4.46 c | 5.76 b | 6.12 a | 5.89 b | 3.18 e | 3.42 d | 3.54 d | 0.315 | <0.001 | |

| C18:1 cis-9 | 6.22 e | 13.7 c | 12.2 c | 11.7 d | 25.4 a | 20.3 b | 19.3 b | 1.586 | <0.001 | |

| C18:2 cis-9 cis-12 | 3.87 e | 3.92 de | 4.56 c | 4.06 d | 8.31 b | 10.15 a | 9.88 a | 0.718 | 0.002 | |

| C18:2 cis-9 trans-11 | 0.21 e | 0.39 c | 0.51 a | 0.47 b | 0.19 e | 0.28 d | 0.26 d | 0.031 | 0.006 | |

| C18:2 trans-10 cis-12 | 0.13 d | 0.28 b | 0.31 ab | 0.35 a | 0.14 d | 0.16 c | 0.15 c | 0.023 | 0.001 | |

| C18:3 cis-9 cis-12 cis-15 | 0.38 e | 0.39 e | 0.43 e | 0.51 d | 1.12 c | 1.65 b | 1.97 a | 0.163 | <0.001 | |

| Other FA 3 | 26.9 a | 19.3 c | 20.3 b | 19.3 c | 13.7 e | 17.7 d | 16.5 d | 1.006 | <0.001 | |

| SFA 4 | 61.2 a | 59.1 b | 59.4 b | 58.3 b | 49.1 c | 47.2 d | 48.3 c | 1.505 | 0.013 | |

| UFA 5 | 38.8 e | 40.9 d | 40.6 d | 41.7 c | 50.9 b | 52.8 a | 51.7 a | 1.505 | 0.001 | |

| MUFA 6 | 30.6 c | 30.6 c | 28.7 e | 29.4 d | 35.1 a | 33.6 b | 33.3 b | 0.588 | <0.001 | |

| PUFA 7 | 8.21 e | 10.3 d | 11.9 c | 12.3 c | 15.8 b | 19.2 a | 18.4 a | 1.021 | <0.001 | |

| Item 1 | Treatments 2 | SEM | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|---|

| CON | OO3% | CO3% | LO3% | NOO3% | NCO3% | NLO3% | |||

| Anaerovibrio lipolytica | 1.01 b | 0.93 c | 0.98 c | 0.87 d | 1.08 a | 1.12 a | 1.03 b | 0.024 | 0.001 |

| Butyrivibrio fibrisolvens | 1.22 b | 1.17 c | 1.18 c | 1.15 d | 1.26 ab | 1.32 a | 1.21 b | 0.016 | 0.011 |

| Butyrivibrio proteoclasticus | 2.77 b | 2.71 c | 2.75 b | 2.69 c | 2.83 ab | 2.91 a | 2.79 b | 0.021 | 0.001 |

| Fibrobacter succinogenes | 3.56 c | 3.45 d | 3.52 c | 3.42 d | 3.76 a | 3.77 a | 3.68 b | 0.040 | <0.001 |

| Megasphaera elsdenii | 0.49 b | 0.33 d | 0.37 c | 0.31 d | 0.49 b | 0.54 a | 0.48 b | 0.025 | <0.001 |

| Ruminococcus flavefaciens | 0.63 b | 0.58 c | 0.61 bc | 0.57 c | 0.67 b | 0.71 a | 0.64 b | 0.014 | 0.003 |

| Ruminococcus albus | 0.056 ab | 0.051 bc | 0.054 b | 0.047 c | 0.055 ab | 0.059 a | 0.054 b | 0.001 | 0.009 |

| Streptococcus bovis | 0.028 a | 0.021 bc | 0.023 b | 0.019 c | 0.027 a | 0.031 a | 0.027 a | 0.021 | 0.010 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Sherbiny, M.; Khattab, M.S.A.; Abd El Tawab, A.M.; Elnahr, M.; Cieślak, A.; Szumacher-Strabel, M. Oil-in-Water Nanoemulsion Can Modulate the Fermentation, Fatty Acid Accumulation, and the Microbial Population in Rumen Batch Cultures. Molecules 2023, 28, 358. https://doi.org/10.3390/molecules28010358

El-Sherbiny M, Khattab MSA, Abd El Tawab AM, Elnahr M, Cieślak A, Szumacher-Strabel M. Oil-in-Water Nanoemulsion Can Modulate the Fermentation, Fatty Acid Accumulation, and the Microbial Population in Rumen Batch Cultures. Molecules. 2023; 28(1):358. https://doi.org/10.3390/molecules28010358

Chicago/Turabian StyleEl-Sherbiny, Mohamed, Mostafa S. A. Khattab, Ahmed M. Abd El Tawab, Mostafa Elnahr, Adam Cieślak, and Małgorzata Szumacher-Strabel. 2023. "Oil-in-Water Nanoemulsion Can Modulate the Fermentation, Fatty Acid Accumulation, and the Microbial Population in Rumen Batch Cultures" Molecules 28, no. 1: 358. https://doi.org/10.3390/molecules28010358

APA StyleEl-Sherbiny, M., Khattab, M. S. A., Abd El Tawab, A. M., Elnahr, M., Cieślak, A., & Szumacher-Strabel, M. (2023). Oil-in-Water Nanoemulsion Can Modulate the Fermentation, Fatty Acid Accumulation, and the Microbial Population in Rumen Batch Cultures. Molecules, 28(1), 358. https://doi.org/10.3390/molecules28010358