The Stability of Refined Rapeseed Oil Fortified by Cold-Pressed and Essential Black Cumin Oils under a Heating Treatment

Abstract

:1. Introduction

2. Result and Discussion

2.1. Material Characterization

2.1.1. Black Cumin Essential Oil

2.1.2. The Fatty Acids Profile and Iodine Value in Blends and Refined Rapeseed Oil

2.1.3. Tocochromanols in Blends and Refined Rapeseed Oil

2.2. Heated Blends and Their Deterioration

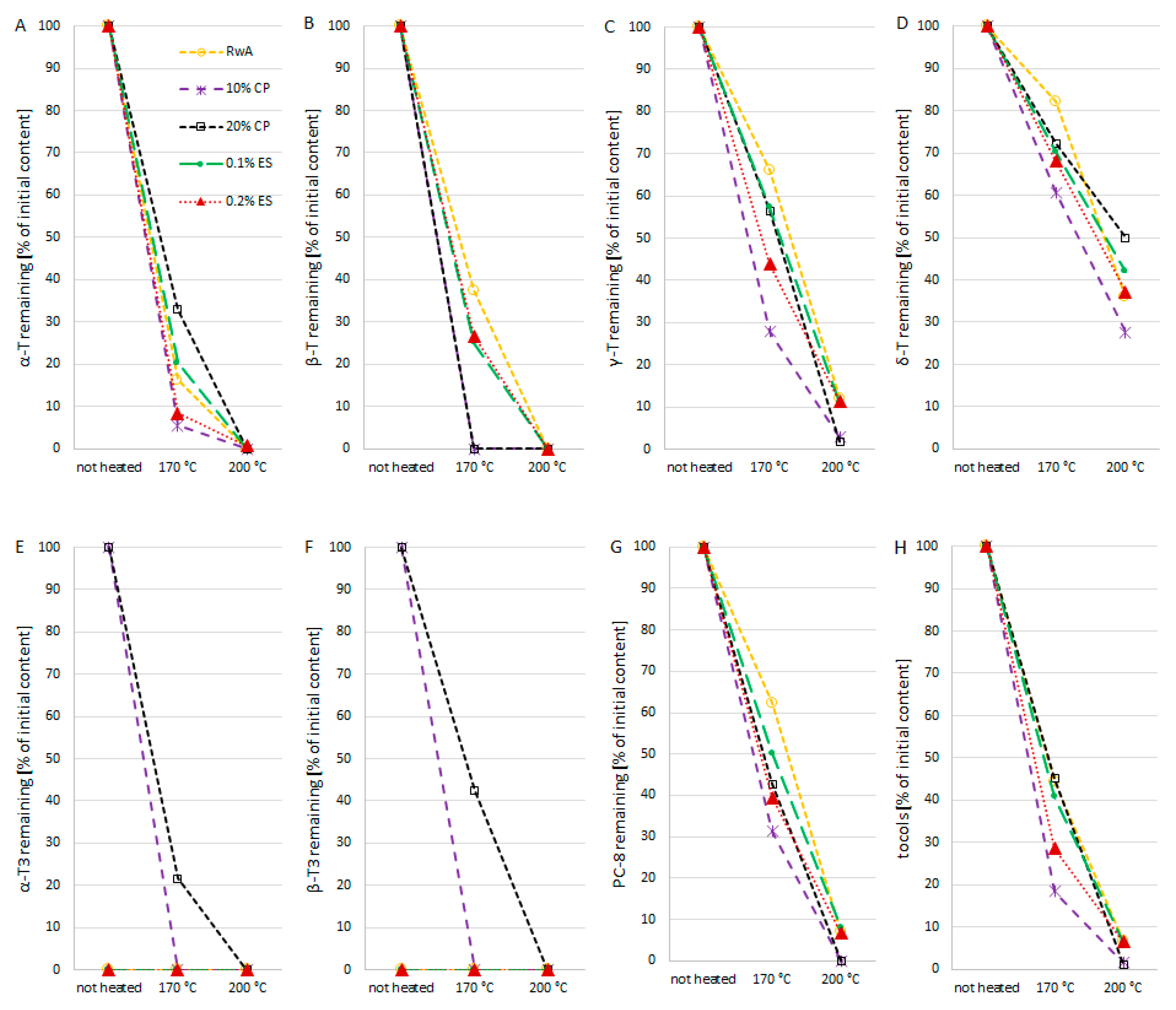

2.2.1. Tocochromanol Loss

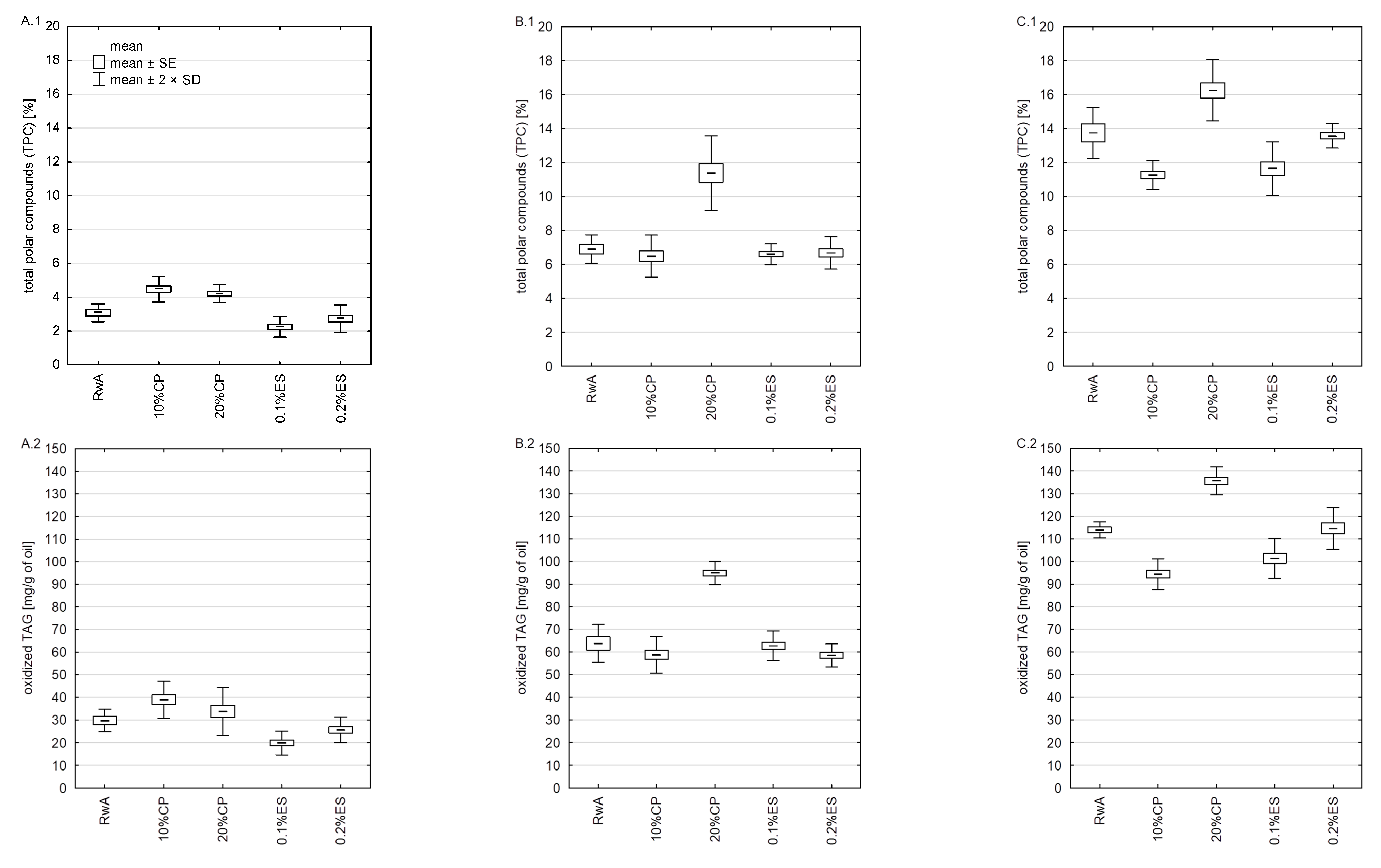

2.2.2. Total Polar Compounds (TPC)

2.2.3. TAG Polymers Composition and Content

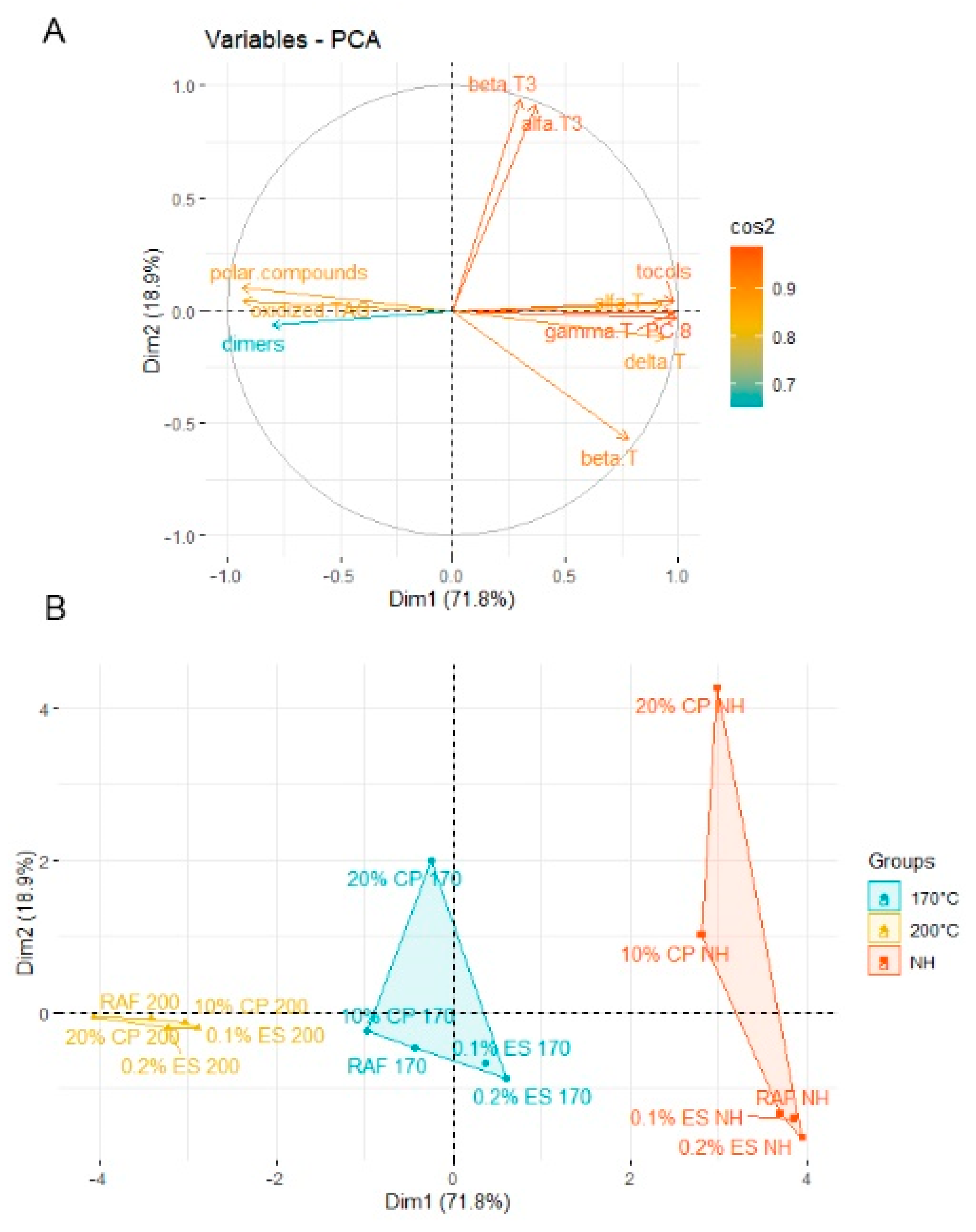

3. Principal Component Analysis (PCA)

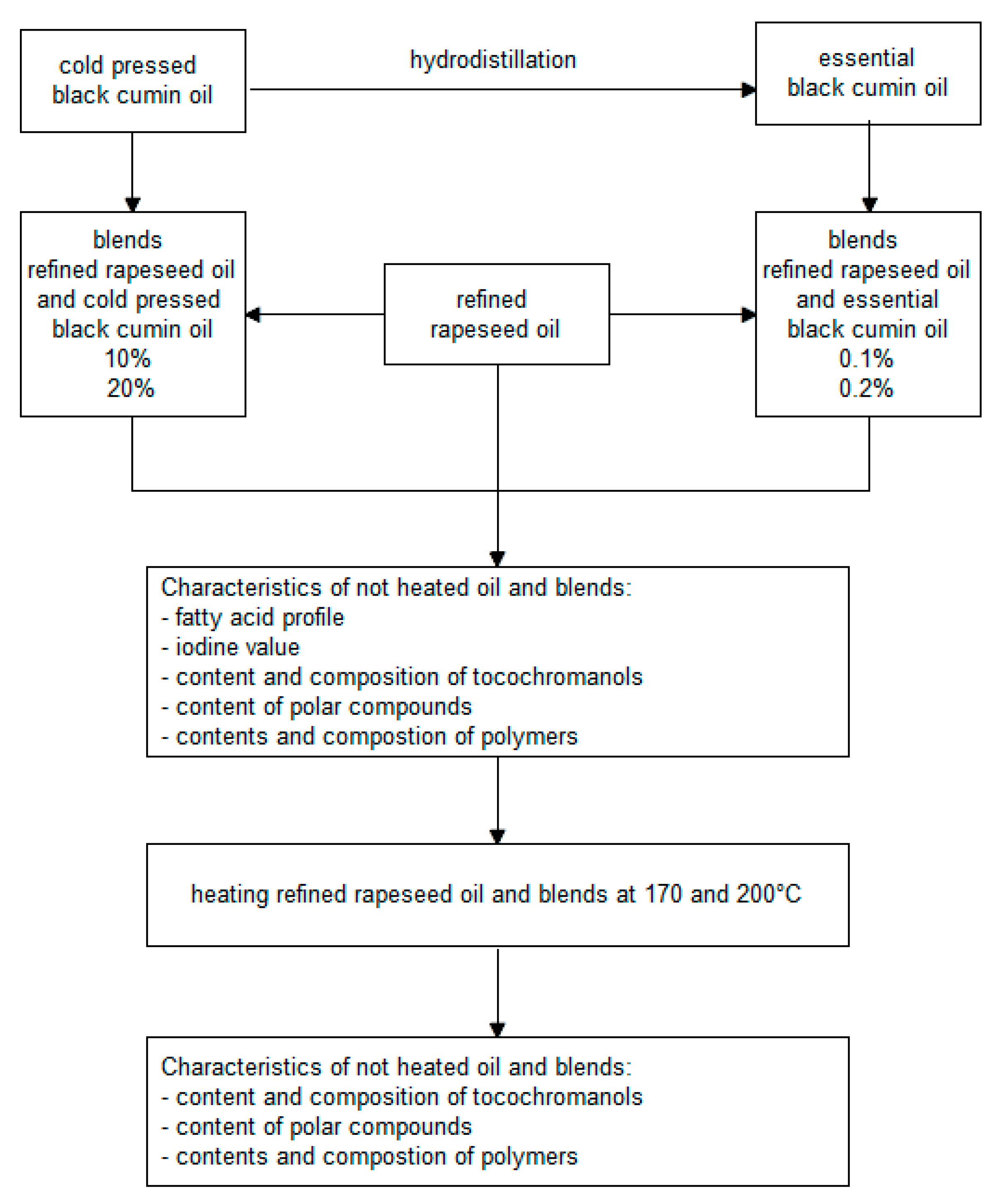

4. Materials and Methods

4.1. Research Material

4.2. Preparation and Composition Analysis of Black Cumin Essential Oil

4.3. Preparation of Fortified Oils

4.4. Heating Procedure

4.5. Fatty Acid Composition

4.6. Iodine Value Calculation

4.7. Tocochromanols Analysis

4.8. Total Polar Compounds (TPC) Analysis

4.9. Triacylglycerols (TAG) Polymers Analysis

4.10. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Perez-Herrera, A.; Rangel-Zuñiga, O.A.; Delgado-Lista, J.; Marin, C.; Perez-Martinez, P.; Tasset, I.; Tunez, I.; Quintana-Navarro, G.M.; Lopez-Segura, F.; De Castro, M.D.L.; et al. The antioxidants in oils heated at frying temperature, whether natural or added, could protect against postprandial oxidative stress in obese people. Food Chem. 2013, 138, 2250–2259. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, H.; Ghorbani, M.; Meshginfar, N.; Mahoonak, A.S. A Review on Frying: Procedure, Fat, Deterioration Progress and Health Hazards. JAOCS J. Am. Oil Chem. Soc. 2016, 93, 445–466. [Google Scholar] [CrossRef]

- Cao, W.; Wang, X.; Zhang, W.; Wang, X. Toxic effects of triacylglycerol polymer on macrophages in vitro. Eur. J. Lipid Sci. Technol. 2013, 115, 756–763. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Sun, D.; Li, J.; Wang, Y.; Cao, P.; Liu, Y. Effects of polar compounds generated from the deep-frying process of palm oil on lipid metabolism and glucose tolerance in kunming mice. J. Agric. Food Chem. 2017, 65, 208–215. [Google Scholar] [CrossRef] [PubMed]

- López-Varela, S.; Sánchez-Muniz, F.J.; Cuesta, C. Decreased food efficiency ratio, growth retardation and changes in liver fatty acid composition in rats consuming thermally oxidized and polymerized sunflower oil used for frying. Food Chem. Toxicol. 1995, 33, 181–189. [Google Scholar] [CrossRef]

- Sánchez-Muniz, F.J.; López-Varela, S.; Garrido-Polonio, M.C.; Cuesta, C. Dietary effects on growth, liver peroxides, and serum and lipoprotein lipids in rats fed a thermoxidised and polymerised sunflower oil. J. Sci. Food Agric. 1998, 76, 364–372. [Google Scholar] [CrossRef]

- Johnson, O.C.; Kummerow, F.A. Chemical changes which take place in an edible oil during thermal oxidation. J. Am. Oil Chem. Soc. 1957, 34, 407–409. [Google Scholar] [CrossRef]

- Santos, J.C.O.; Santos, I.M.G.; Souza, A.G. Effect of heating and cooling on rheological parameters of edible vegetable oils. J. Food Eng. 2005, 67, 401–405. [Google Scholar] [CrossRef]

- Dobarganes, C.; Márquez-Ruiz, G.; Velasco, J. Interactions between fat and food during deep-frying. Eur. J. Lipid Sci. Technol. 2000, 102, 521–528. [Google Scholar] [CrossRef]

- Cahill, L.E.; Pan, A.; Chiuve, S.E.; Sun, Q.; Willett, W.C.; Hu, F.B.; Rimm, E.B. Fried-food consumption and risk of type 2 diabetes and coronary artery disease: A prospective study in 2 cohorts of US women and men. Am. J. Clin. Nutr. 2014, 100, 667–675. [Google Scholar] [CrossRef]

- Sayon-Orea, C.; Bes-Rastrollo, M.; Basterra-Gortari, F.J.; Beunza, J.J.; Guallar-Castillon, P.; de la Fuente-Arrillaga, C.; Martinez-Gonzalez, M.A. Consumption of fried foods and weight gain in a Mediterranean cohort: The SUN project. Nutr. Metab. Cardiovasc. Dis. 2013, 23, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Sayon-Orea, C.; Martinez-Gonzalez, M.A.; Gea, A.; Flores-Gomez, E.; Basterra-Gortari, F.J.; Bes-Rastrollo, M. Consumption of fried foods and risk of metabolic syndrome: The SUN cohort study. Clin. Nutr. 2014, 33, 545–549. [Google Scholar] [CrossRef] [PubMed]

- Gadiraju, T.V.; Patel, Y.; Gaziano, J.M.; Djoussé, L. Fried food consumption and cardiovascular health: A review of current evidence. Nutrients 2015, 7, 8424–8430. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Chen, X.; Wang, Q.; Meng, Y.; Wang, D.; Wang, X. Influence of the essential oil of Mentha spicata cv. Henanshixiang on sunflower oil during the deep-frying of Chinese Maye. LWT 2020, 122, 109020. [Google Scholar] [CrossRef]

- Kmiecik, D.; Gramza-Michałowska, A.; Korczak, J. Anti-polymerization activity of tea and fruits extracts during rapeseed oil heating. Food Chem. 2018, 239, 858–864. [Google Scholar] [CrossRef]

- Kostadinović Veličkovska, S.; Brühl, L.; Mitrev, S.; Mirhosseini, H.; Matthäus, B. Quality evaluation of cold-pressed edible oils from Macedonia. Eur. J. Lipid Sci. Technol. 2015, 117, 2023–2035. [Google Scholar] [CrossRef] [Green Version]

- Bozdoğan Konuşkan, D. Minor bioactive lipids in cold pressed oils. In Cold Pressed Oils; Academic Press: Cambridge, MA, USA, 2020; pp. 7–14. ISBN 9780128181881. [Google Scholar]

- Durazzo, A.; Fawzy Ramadan, M.; Lucarini, M. Editorial: Cold Pressed Oils: A Green Source of Specialty Oils. Front. Nutr. 2022, 8, 2021–2022. [Google Scholar] [CrossRef]

- Ketenoglu, O.; Kiralan, S.S.; Kiralan, M.; Ozkan, G.; Ramadan, M.F. Cold pressed black cumin (Nigella sativa L.) seed oil. In Cold Pressed Oils; Academic Press: Cambridge, MA, USA, 2020; pp. 53–64. ISBN 9780128181881. [Google Scholar]

- Mazaheri, Y.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. A comprehensive review of the physicochemical, quality and nutritional properties of Nigella sativa oil. Food Rev. Int. 2019, 35, 342–362. [Google Scholar] [CrossRef]

- Kazemi, M. Phytochemical Composition, Antioxidant, Anti-inflammatory and Antimicrobial Activity of Nigella sativa L. Essential Oil. J. Essent. Oil-Bear. Plants 2014, 17, 1002–1011. [Google Scholar] [CrossRef]

- Lutterodt, H.; Luther, M.; Slavin, M.; Yin, J.; Parry, J.; Gao, J.; Lucy, L. Fatty acid profile, thymoquinone content, oxidative stability, and antioxidant properties of cold-pressed black cumin seed oils. LWT—Food Sci. Technol. 2010, 43, 1409–1413. [Google Scholar] [CrossRef]

- Erkan, N.; Ayranci, G.; Ayranci, E. Antioxidant activities of rosemary (Rosmarinus Officinalis L.) extract, blackseed (Nigella sativa L.) essential oil, carnosic acid, rosmarinic acid and sesamol. Food Chem. 2008, 110, 76–82. [Google Scholar] [CrossRef] [PubMed]

- Kokoska, L.; Havlik, J.; Valterova, I.; Sovova, H.; Sajfrtova, M.; Jankovska, I. Comparison of chemical composition and antibacterial activity of Nigella sativa seed essential oils obtained by different extraction methods. J. Food Prot. 2008, 71, 2475–2480. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burits, M.; Bucar, F. Antioxidant activity of Nigella sativa essential oil. Phyther. Res. 2000, 14, 323–328. [Google Scholar] [CrossRef]

- Jrah Harzallah, H.; Kouidhi, B.; Flamini, G.; Bakhrouf, A.; Mahjoub, T. Chemical composition, antimicrobial potential against cariogenic bacteria and cytotoxic activity of Tunisian Nigella sativa essential oil and thymoquinone. Food Chem. 2011, 129, 1469–1474. [Google Scholar] [CrossRef]

- Khalid, A.K.; Shedeed, M.R. Yield and Chemical Composition of Nigella sativa L. Essential Oil Produced under Kinetin Treatments. J. Essent. Oil-Bear. Plants 2016, 19, 1740–1746. [Google Scholar] [CrossRef]

- Konuskan, D.B.; Arslan, M.; Oksuz, A. Physicochemical properties of cold pressed sunflower, peanut, rapeseed, mustard and olive oils grown in the Eastern Mediterranean region. Saudi J. Biol. Sci. 2019, 26, 340–344. [Google Scholar] [CrossRef]

- Kiralan, M.; Özkan, G.; Bayrak, A.; Ramadan, M.F. Physicochemical properties and stability of black cumin (Nigella sativa) seed oil as affected by different extraction methods. Ind. Crops Prod. 2014, 57, 52–58. [Google Scholar] [CrossRef]

- Ramadan, M.F. Healthy blends of high linoleic sunflower oil with selected cold pressed oils: Functionality, stability and antioxidative characteristics. Ind. Crops Prod. 2013, 43, 65–72. [Google Scholar] [CrossRef]

- Schwartz, H.; Ollilainen, V.; Piironen, V.; Lampi, A.M. Tocopherol, tocotrienol and plant sterol contents of vegetable oils and industrial fats. J. Food Compos. Anal. 2008, 21, 152–161. [Google Scholar] [CrossRef]

- Kasprzak, M.; Rudzińska, M.; Przybylski, R.; Kmiecik, D.; Siger, A.; Olejnik, A. The degradation of bioactive compounds and formation of their oxidation derivatives in refined rapeseed oil during heating in model system. LWT 2020, 123, 109078. [Google Scholar] [CrossRef]

- Saoudi, S.; Chammem, N.; Sifaoui, I.; Bouassida-Beji, M.; Jiménez, I.A.; Bazzocchi, I.L.; Silva, S.D.; Hamdi, M.; Bronze, M.R. Influence of Tunisian aromatic plants on the prevention of oxidation in soybean oil under heating and frying conditions. Food Chem. 2016, 212, 503–511. [Google Scholar] [CrossRef] [PubMed]

- Matthäus, B. Utilization of high-oleic rapeseed oil for deep-fat frying of French fries compared to other commonly used edible oils. Eur. J. Lipid Sci. Technol. 2006, 108, 200–211. [Google Scholar] [CrossRef]

- Aladedunye, F.; Przybylski, R. Frying stability of high oleic sunflower oils as affected by composition of tocopherol isomers and linoleic acid content. Food Chem. 2013, 141, 2373–2378. [Google Scholar] [CrossRef] [PubMed]

- Warner, K.; Moser, J. Frying stability of purified mid-oleic sunflower oil triacylglycerols with added pure tocopherols and tocopherol mixtures. JAOCS J. Am. Oil Chem. Soc. 2009, 86, 1199–1207. [Google Scholar] [CrossRef]

- Boukandoul, S.; Santos, C.S.P.; Casal, S.; Zaidi, F. Oxidation delay of sunflower oil under frying by moringa oil addition: More than just a blend. J. Sci. Food Agric. 2019, 99, 5483–5490. [Google Scholar] [CrossRef]

- Kiralan, M.; Ulaş, M.; Özaydin, A.; Özdemır, N.; Özkan, G.; Bayrak, A.; Ramadan, M.F. Blends of Cold Pressed Black Cumin Oil and Sunflower Oil with Improved Stability: A Study Based on Changes in the Levels of Volatiles, Tocopherols and Thymoquinone during Accelerated Oxidation Conditions. J. Food Biochem. 2017, 41, e12272. [Google Scholar] [CrossRef]

- Erkan, N.; Ayranci, G.; Ayranci, E. Lipid oxidation inhibiting capacities of black seed essential oil and rosemary extract. Eur. J. Lipid Sci. Technol. 2012, 114, 175–184. [Google Scholar] [CrossRef]

- Chandran, J.; Nayana, N.; Roshini, N.; Nisha, P. Oxidative stability, thermal stability and acceptability of coconut oil flavored with essential oils from black pepper and ginger. J. Food Sci. Technol. 2017, 54, 144–152. [Google Scholar] [CrossRef] [Green Version]

- Olmedo, R.H.; Asensio, C.M.; Grosso, N.R. Thermal stability and antioxidant activity of essential oils from aromatic plants farmed in Argentina. Ind. Crops Prod. 2015, 69, 21–28. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Li, S.; Xu, Y.; Wang, X.; Wang, C. Carvacrol methyl ether, a compound from the essential oil of Gardenia jasminoides fruits, exhibits antioxidant effects in the deep-frying of Chinese Youmotou using sunflower oil. LWT 2020, 128, 109502. [Google Scholar] [CrossRef]

- Wang, D.; Dong, Y.; Wang, Q.; Wang, X.; Fan, W. Limonene, the compound in essential oil of nutmeg displayed antioxidant effect in sunflower oil during the deep-frying of Chinese Maye. Food Sci. Nutr. 2020, 8, 511–520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, G.; Han, S.; Zhang, Y.; Liu, T.T.; Karrar, E.; Jin, Q.; Zhang, H.; Wang, X. Effect of phenolic extracts from Camellia oleifera seed cake on the formation of polar compounds, core aldehydes, and monoepoxy oleic acids during deep-fat frying. Food Chem. 2022, 372, 131143. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, G.; Squeo, G.; Estivi, L.; Quezada Berru, S.; Buleje, D.; Caponio, F.; Brandolini, A.; Hidalgo, A. Changes in stability, tocopherols, fatty acids and antioxidant capacity of sacha inchi (Plukenetia volubilis) oil during French fries deep-frying. Food Chem. 2021, 340, 127942. [Google Scholar] [CrossRef] [PubMed]

- Myszka, K.; Schmidt, M.T.; Majcher, M.; Juzwa, W.; Czaczyk, K. β-Caryophyllene-rich pepper essential oils suppress spoilage activity of Pseudomonas fluorescens KM06 in fresh-cut lettuce. LWT—Food Sci. Technol. 2017, 83, 118–126. [Google Scholar] [CrossRef]

- AOCS. AOCS Official Method Ce 1h-05. Determination of cis-, trans-, Saturated, Monounsaturated and Polyunsaturated Fatty Acids in Vegetable or Non-ruminant Animal Oils and Fats by Capillary GLC. In Official Methods and Recommended Practices of the American Oil Chemists’ Society; American Oil Chemists’ Society: Champaign, IL, USA, 2005. [Google Scholar]

- AOCS. AOCS Official Method Cd 1c-85. Calculated iodine value. In Official Methods and Recommended Practices of the American Oil Chemists’ Society; American Oil Chemists’ Society: Champaign, IL, USA, 2009. [Google Scholar]

- Siger, A.; Michalak, M.; Rudzińska, M. Canolol, tocopherols, plastochromanol-8, and phytosterols content in residual oil extracted from rapeseed expeller cake obtained from roasted seed. Eur. J. Lipid Sci. Technol. 2016, 118, 1358–1367. [Google Scholar] [CrossRef]

- AOCS. AOCS Official Method 982.27. Polar components in frying fats. In Official Methods and Recommended Practices of the American Oil Chemists’ Society; American Oil Chemists’ Society: Champaign, IL, USA, 1984. [Google Scholar]

| No. | Compounds | Concentration (%) | Retention Time (min) | RI |

|---|---|---|---|---|

| 1 | α-thujene | 15.32 | 7.811 | 933 |

| 2 | α-pinene | 3.94 | 7.99 | 943 |

| 3 | sabinene | 1.60 | 8.729 | 980 |

| 4 | β-pinene | 3.43 | 8.866 | 987 |

| 5 | 3-Carene | 0.81 | 9.561 | 1024 |

| 6 | p-cymene | 33.51 | 9.709 | 1033 |

| 7 | limonene | 4.08 | 9.799 | 1038 |

| 8 | γ-terpinene | 4.37 | 10.317 | 1066 |

| 9 | cis-4-methoxythujane | 0.97 | 11.011 | 1102 |

| 10 | trans-4-methoxythujane | 4.76 | 11.429 | 1128 |

| 11 | terpinen-4-ol | 0.39 | 12.563 | 1192 |

| 12 | β-cyclocitral | 0.73 | 12.863 | 1210 |

| 13 | thymoquinone | 23.55 | 13.646 | 1260 |

| 14 | α-longipinene | 0.60 | 15.405 | 1373 |

| 15 | longifolene | 1.93 | 16.363 | - |

| RwA | 10% CP | 20% CP | 0.1% ES | 0.2% ES | |

|---|---|---|---|---|---|

| [%] | |||||

| 16:0 | 4.52 ± 0.08 c | 5.44 ± 0.16 b | 6.04 ± 0.14 a | 4.63 ± 0.00 c | 4.60 ± 0.13 c |

| 16:1 | 0.17 ± 0.01 a | 0.18 ± 0.01 a | 0.18 ± 0.00 a | 0.18 ± 0.01 a | 0.18 ± 0.01 a |

| 18:0 | 1.74 ± 0.03 c | 1.83 ± 0.00 b | 1.96 ± 0.00 a | 1.71 ± 0.01 c | 1.72 ± 0.00 c |

| 18:1 | 65.60 ± 0.14 a | 61.6 ± 0.06 b | 57.69 ± 0.28 c | 65.22 ± 0.03 a | 65.18 ± 0.02 a |

| 18:2 | 18.46 ± 0.06 a | 22.04 ± 0.06 b | 25.91 ± 0.27 c | 18.49 ± 0.01 a | 18.52 ± 0.06 a |

| 20:0 | 0.66 ± 0.01 a | 0.68 ± 0.02 b | 0.63 ± 0.01 b | 0.75 ± 0.00 a | 0.74 ± 0.00 a |

| 18:3 | 8.39 ± 0.03 a | 7.80 ± 0.13 b | 7.18 ± 0.12 c | 8.53 ± 0.01 a | 8.57 ± 0.05 a |

| 22:0 | 0.29 ± 0.01 a | 0.26 ± 0.02 ab | 0.24 ± 0.01 b | 0.30 ± 0.00 a | 0.30 ± 0.01 a |

| 22:1 | 0.17 ± 0.01 b | 0.18 ± 0.00 ab | 0.16 ± 0.00 b | 0.20 ± 0.00 a | 0.20 ± 0.00 a |

| SFA | 7.22 ± 0.03 c | 8.21 ± 0.12 b | 8.87 ± 0.12 a | 7.39 ± 0.01 c | 7.36 ± 0.13 c |

| MUFA | 65.94 ± 0.12 a | 61.96 ± 0.07 b | 58.03 ± 0.27 c | 65.6 ± 0.01 a | 65.55 ± 0.01 a |

| PUFA | 26.84 ± 0.09 c | 29.70 ± 0.18 b | 33.20 ± 0.15 a | 27.02 ± 0 c | 27.17 ± 0.11 c |

| Iodine value | 110.61 ± 0.08 c | 111.84 ± 0.37 b | 113.57 ± 0.07 a | 110.75 ± 0.00 c | 110.86 ± 0.25 c |

| RwA | 10% CP | 20% CP | 0.1% ES | 0.2% ES | |

|---|---|---|---|---|---|

| [mg/100 g] | |||||

| α-tocopherol | 28.71 ± 0.45 a | 25.82 ± 0.36 ab | 23.78 ± 0.60 b | 28.69 ± 1.24 a | 29.26 ± 0.75 b |

| β-tocopherol | 0.12 ± 0.03 a | 0.05 ± 0.01 a | 0.05 ± 0.01 a | 0.13 ± 0.03 a | 0.15 ± 0.03 a |

| γ-tocopherol | 32.39 ± 0.85 ba | 30.08 ± 0.51 b | 27.67 ± 0.63 c | 32.21 ± 0.27 ba | 33.65 ± 0.81 a |

| δ-tocopherol | 0.73 ± 0.05 a | 0.56 ± 0.01 bc | 0.54 ± 0.04 c | 0.65 ± 0.02 ab | 0.67 ± 0.04 ab |

| α-tocotrienol | nd | 0.55 ± 0.05 b | 1.12 ± 0.08 a | nd | nd |

| β-tocotrienol | nd | 0.78 ± 0.05 b | 2.72 ± 0.11 a | nd | nd |

| PC-8 | 4.55 ± 0.43 a | 4.22 ± 0.06 a | 3.81 ± 0.23 a | 4.53 ± 0.23 a | 4.62 ± 0.06 a |

| Total tocochromanols | 66.49 ± 1.70 a | 62.06 ± 0.95 b | 59.65 ± 1.17 b | 66.21 ± 1.64 a | 68.35 ± 1.63 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedko, M.; Kmiecik, D.; Siger, A.; Majcher, M. The Stability of Refined Rapeseed Oil Fortified by Cold-Pressed and Essential Black Cumin Oils under a Heating Treatment. Molecules 2022, 27, 2461. https://doi.org/10.3390/molecules27082461

Fedko M, Kmiecik D, Siger A, Majcher M. The Stability of Refined Rapeseed Oil Fortified by Cold-Pressed and Essential Black Cumin Oils under a Heating Treatment. Molecules. 2022; 27(8):2461. https://doi.org/10.3390/molecules27082461

Chicago/Turabian StyleFedko, Monika, Dominik Kmiecik, Aleksander Siger, and Małgorzata Majcher. 2022. "The Stability of Refined Rapeseed Oil Fortified by Cold-Pressed and Essential Black Cumin Oils under a Heating Treatment" Molecules 27, no. 8: 2461. https://doi.org/10.3390/molecules27082461

APA StyleFedko, M., Kmiecik, D., Siger, A., & Majcher, M. (2022). The Stability of Refined Rapeseed Oil Fortified by Cold-Pressed and Essential Black Cumin Oils under a Heating Treatment. Molecules, 27(8), 2461. https://doi.org/10.3390/molecules27082461