Selection of Enzymatic Treatments for Upcycling Lentil Hulls into Ingredients Rich in Oligosaccharides and Free Phenolics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Enzymatic Treatments

2.3. Comparison of Microwave, Enzymatic and Sequential Microwave–Enzymatic Treatments of Lentil Hull

2.4. Determination of Total Dietary Fiber (TDF), Insoluble Dietary Fiber (IDF) and Soluble Dietary Fiber (SDF) Fractions

2.5. Determination of Total Protein and Starch

2.6. Determination of Anti-Nutrients

2.7. Extraction of Free and Insoluble Phenolic Compounds

2.8. Determination of Total Free and Insoluble Phenolic Content

2.9. Analysis of Phenolic Profile by HPLC-DAD-ESI-MS2

2.10. Oxygen Radical Absorption Capacity (ORAC) Assay

2.11. ABTS (2,2′-Azinobis 3-ethylbenzothiazoline-6-sulfonic acid) Radical Scavenging Assay

2.12. Statistical Analysis

3. Results

3.1. Red Lentil Hulls Are a Source of Dietary Fiber and Polyphenols, Containing Considerable Amounts of Protein and Trypsin Inhibitors and Minor Amounts of Starch and Phytic Acid

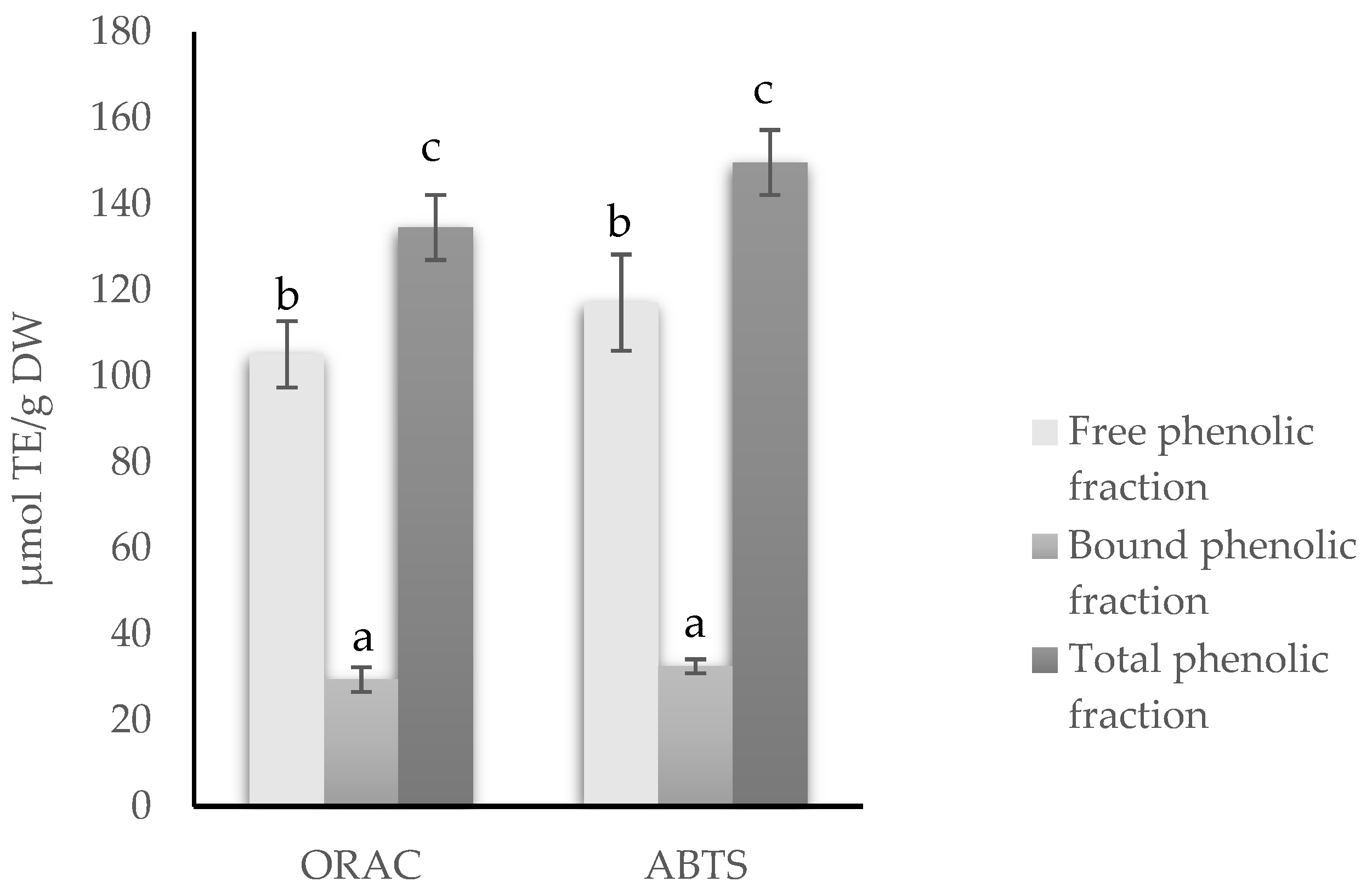

3.2. Free Phenolic Compounds in Lentil Hulls Are Major Contributors to the Antioxidant Activity of Lentil Hulls

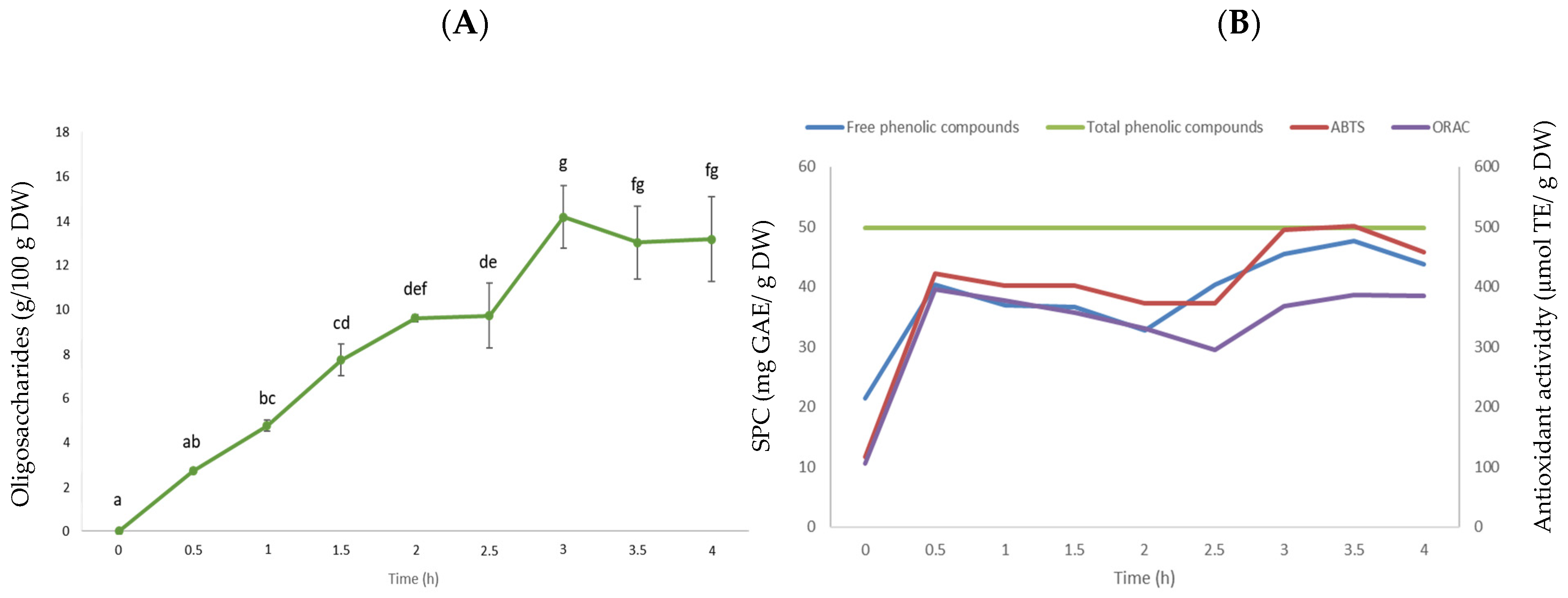

3.3. Pectinex® Ultra Tropical Released High Amounts of Oligosaccharides and Phenolics from Lentil Hull Food Matrix

3.4. Pectinex Treatment of Lentil Hull Increased the Bioactive Compounds and Antioxidant Activity to a Greater Extent than Microwaves or Their Combined Treatment

3.5. Pectinex Treatment of Lentil Hull Increased the Content of Extractable Flavan-3-ols to a Greater Extent than Microwaves or Their Combined Treatment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Romano, A.; Gallo, V.; Ferranti, P.; Masi, P. Lentil flour: Nutritional and technological properties, in vitro digestibility and perspectives for use in the food industry. Curr. Opin. Food Sci. 2021, 40, 157–167. [Google Scholar] [CrossRef]

- Zhong, L.; Fang, Z.; Wahlqvist, M.L.; Wu, G.; Hodgson, J.M.; Johnson, S.K. Seed coats of pulses as a food ingredient: Characterization, processing, and applications. Trends Food Sci. Technol. 2018, 80, 35–42. [Google Scholar] [CrossRef]

- Tiwari, U.; Cummins, E. Chapter 7—Legume fiber characterization, functionality, and process effects. In Pulse Foods, 2nd ed.; Tiwari, B.K., Gowen, A., McKenna, B., Eds.; Academic Press: London, UK, 2021; pp. 147–175. [Google Scholar] [CrossRef]

- Sun, Y.; Deng, Z.; Liu, R.; Zhang, H.; Zhu, H.; Jiang, L.; Tsao, R. A comprehensive profiling of free, conjugated and bound phenolics and lipophilic antioxidants in red and green lentil processing by-products. Food Chem. 2020, 325, 126925. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Sun, L.; Miao, M.; Zhang, G. Plant-sourced intrinsic dietary fiber: Physical structure and health function. Trends Food Sci. Technol. 2021, 118, 341–355. [Google Scholar] [CrossRef]

- Yeo, J.; Shahidi, F. Identification and quantification of soluble and insoluble-bound phenolics in lentil hulls using HPLC-ESI-MS/MS and their antioxidant potential. Food Chem. 2020, 315, 126202. [Google Scholar] [CrossRef]

- Peng, L.; Guo, F.; Pei, M.; Tsao, R.; Wang, X.; Jiang, L.; Sun, Y.; Xiong, H. Anti-inflammatory effect of lentil hull (Lens culinaris) extract via MAPK/NF-κB signaling pathways and effects of digestive products on intestinal barrier and inflammation in Caco-2 and Raw264.7 co-culture. J. Funct. Foods 2022, 92, 105044. [Google Scholar] [CrossRef]

- Elessawy, F.M.; Vandenberg, A.; El-Aneed, A.; Purves, R.W. An Untargeted Metabolomics Approach for Correlating Pulse Crop Seed Coat Polyphenol Profiles with Antioxidant Capacity and Iron Chelation Ability. Molecules 2021, 26, 3833. [Google Scholar] [CrossRef]

- Yeo, J.; Tsao, R.; Sun, Y.; Shahidi, F. Liberation of insoluble-bound phenolics from lentil hull matrices as affected by Rhizopus oryzae fermentation: Alteration in phenolic profiles and their inhibitory capacities against low-density lipoprotein (LDL) and DNA oxidation. Food Chem. 2021, 363, 130275. [Google Scholar] [CrossRef]

- Rastall, R.A.; Diez-Municio, M.; Forssten, S.D.; Hamaker, B.; Meynier, A.; Moreno, F.J.; Respondek, F.; Stah, B.; Venema, K.; Wiese, M. Structure and function of non-digestible carbohydrates in the gut microbiome. Benef Microbes 2022, 13, 95–168. [Google Scholar] [CrossRef]

- Bautista-Expósito, S.; Tomé-Sánchez, I.; Martín-Diana, A.B.; Frias, J.; Peñas, E.; Rico, D.; Casas, M.J.G.; Martínez-Villaluenga, C. Enzyme Selection and Hydrolysis under Optimal Conditions Improved Phenolic Acid Solubility, and Antioxidant and Anti-Inflammatory Activities of Wheat Bran. Antioxidants 2020, 9, 984. [Google Scholar] [CrossRef]

- Jiménez-Pulido, I.J.; Rico, D.; Martinez-Villaluenga, C.; Pérez-Jiménez, J.; Luis, D.D.; Martín-Diana, A.B. Sprouting and Hydrolysis as Biotechnological Tools for Development of Nutraceutical Ingredients from Oat Grain and Hull. Foods 2022, 11, 2769. [Google Scholar] [CrossRef]

- Radenkovs, V.; Juhnevica-Radenkova, K.; Górnaś, P.; Seglina, D. Non-waste technology through the enzymatic hydrolysis of agro-industrial by-products. Trends Food Sci. Technol. 2018, 77, 64–76. [Google Scholar] [CrossRef]

- Martín-Diana, A.B.; Tomé-Sánchez, I.; García-Casas, M.J.; Martínez-Villaluenga, C.; Frías, J.; Rico, D. A Novel Strategy to Produce a Soluble and Bioactive Wheat Bran Ingredient Rich in Ferulic Acid. Antioxidants 2021, 10, 969. [Google Scholar] [CrossRef] [PubMed]

- İşçimen, E.M.; Hayta, M. Microwave-assisted aqueous two-phase system based extraction of phenolics from pulses: Antioxidant properties, characterization and encapsulation. Ind. Crops Prod. 2021, 173, 114144. [Google Scholar] [CrossRef]

- Singla, M.; Singh, A.; Sit, N. Effect of microwave and enzymatic pretreatment and type of solvent on kinetics of ultrasound assisted extraction of bioactive compounds from ripe papaya peel. J. Food Process Eng. 2022, e14119. [Google Scholar] [CrossRef]

- Peng, G.; Gan, J.; Dong, R.; Chen, Y.; Xie, J.; Huang, Z.; Gu, Y.; Huang, D.; Yu, Q. Combined microwave and enzymatic treatment improve the release of insoluble bound phenolic compounds from the grapefruit peel insoluble dietary fiber. LWT 2021, 149, 111905. [Google Scholar] [CrossRef]

- Bautista-Expósito, S.; Vandenberg, A.; Peñas, E.; Frias, J.; Martínez-Villaluenga, C. Lentil and Fava Bean With Contrasting Germination Kinetics: A Focus on Digestion of Proteins and Bioactivity of Resistant Peptides. Front. Plant Sci. 2021, 12, 754287. [Google Scholar] [CrossRef] [PubMed]

- Dinelli, G.; Segura-Carretero, A.; Di Silvestro, R.; Marotti, I.; Arráez-Román, D.; Benedettelli, S.; Ghiselli, L.; Fernadez-Gutierrez, A. Profiles of phenolic compounds in modern and old common wheat varieties determined by liquid chromatography coupled with time-of-flight mass spectrometry. J. Chromatogr. A 2011, 1218, 7670–7681. [Google Scholar] [CrossRef] [PubMed]

- Tomé-Sánchez, I.; Martín-Diana, A.B.; Peñas, E.; Frias, J.; Rico, D.; Jiménez-Pulido, I.; Martínez-Villaluenga, C. Bioprocessed Wheat Ingredients: Characterization, Bioaccessibility of Phenolic Compounds, and Bioactivity During in vitro Digestion. Front. Plant Sci. 2021, 12, 790898. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Expósito, S.; Peñas, E.; Dueñas, M.; Silván, J.M.; Frias, J.; Martínez-Villaluenga, C. Individual contributions of Savinase and Lactobacillus plantarum to lentil functionalization during alkaline pH-controlled fermentation. Food Chem. 2018, 257, 341–349. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Kaya, E.; Tuncel, N.B.; Yılmaz Tuncel, N. The effect of ultrasound on some properties of pulse hulls. J. Food Sci. Technol. 2017, 54, 2779–2788. [Google Scholar] [CrossRef]

- Hou, D.; Feng, Q.; Tang, J.; Shen, Q.; Zhou, S. An update on nutritional profile, phytochemical compounds, health benefits, and potential applications in the food industry of pulses seed coats: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2022, 1–23. [Google Scholar] [CrossRef]

- Tripathi, A.; Iswarya, V.; Singh, N.; Rawson, A. Chapter 4—Chemistry of pulses—Micronutrients. In Pulse Foods, 2nd ed.; Tiwari, B.K., Gowen, A., McKenna, B., Eds.; Academic Press: London UK, 2021; pp. 61–86. [Google Scholar] [CrossRef]

- Sreerama, Y.N.; Neelam, D.A.; Sashikala, V.B.; Pratape, V.M. Distribution of Nutrients and Antinutrients in Milled Fractions of Chickpea and Horse Gram: Seed Coat Phenolics and Their Distinct Modes of Enzyme Inhibition. J. Agric. Food Chem. 2010, 58, 4322–4330. [Google Scholar] [CrossRef]

- Galgano, F.; Tolve, R.; Scarpa, T.; Caruso, M.C.; Lucini, L.; Senizza, B.; Condelli, N. Extraction Kinetics of Total Polyphenols, Flavonoids, and Condensed Tannins of Lentil Seed Coat: Comparison of Solvent and Extraction Methods. Foods 2021, 10, 1810. [Google Scholar] [CrossRef]

- Jagelaviciute, J.; Basinskiene, L.; Cizeikiene, D.; Syrpas, M. Technological Properties and Composition of Enzymatically Modified Cranberry Pomace. Foods 2022, 11, 2321. [Google Scholar] [CrossRef]

- Paranavitana, L.; Oh, W.Y.; Yeo, J.; Shahidi, F. Determination of soluble and insoluble-bound phenolic compounds in dehulled, whole, and hulls of green and black lentils using electrospray ionization (ESI)-MS/MS and their inhibition in DNA strand scission. Food Chem. 2021, 361, 130083. [Google Scholar] [CrossRef]

- Verstraeten, S.V.; Keen, C.L.; Schmitz, H.H.; Fraga, C.G.; Oteiza, P.I. Flavan-3-ols and procyanidins protect liposomes against lipid oxidation and disruption of the bilayer structure. Free Radic. Biol. Med. 2003, 34, 84–92. [Google Scholar] [CrossRef]

- Escarnot, E.; Aguedo, M.; Paquot, M. Enzymatic hydrolysis of arabinoxylans from spelt bran and hull. J. Cereal Sci. 2012, 55, 243–253. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Rinken, T. Immobilization of Pectinolytic Enzymes on Nylon 6/6 Carriers. Appl. Sci. 2021, 11, 4591. [Google Scholar] [CrossRef]

- Babbar, N.; Dejonghe, W.; Gatti, M.; Sforza, S.; Elst, K. Pectic oligosaccharides from agricultural by-products: Production, characterization and health benefits. Crit. Rev. Biotechnol. 2016, 36, 594–606. [Google Scholar] [CrossRef]

- Nomura, K.; Sakai, M.; Ohboshi, H.; Nakamura, A. Extraction of a water-soluble polysaccharide fraction from lentils and its potential application in acidified protein dispersions. Food Hydrocoll. 2021, 117, 106740. [Google Scholar] [CrossRef]

- Agrawal, R.M.; Miller, M.J.; Singh, V.; Stein, H.H.; Takhar, P.S. Enzymatic hydrolysis and fermentation of soy flour to produce ethanol and soy protein concentrate with increased polyphenols. J. Am. Oil Chem. Soc. 2022, 99, 379–391. [Google Scholar] [CrossRef]

- Peng, D.; Zhao-Peng, S.; Jing-liang, Z.; Guo-Xia, L.; Guo-Shao, W.; Xiao-Lu, J. Study on preparation of pectic oligosaccharides from blackberry by enzymatic hydrolysis and its antioxidant activities. Sci. Technol. Food Ind. 2016, 76–79. [Google Scholar]

- de Camargo, A.C.; Regitano-d’Arce, M.A.; Biasoto, A.C.; Shahidi, F. Enzyme-assisted extraction of phenolics from winemaking by-products: Antioxidant potential and inhibition of alpha-glucosidase and lipase activities. Food Chem. 2016, 212, 395–402. [Google Scholar] [CrossRef]

- Gómez-García, R.; Martínez-Ávila, G.C.G.; Aguilar, C.N. Enzyme-assisted extraction of antioxidative phenolics from grape (Vitis vinifera L.) residues. 3 Biotech 2012, 2, 297–300. [Google Scholar] [CrossRef]

- Motikar, P.D.; More, P.R.; Arya, S.S. A novel, green environment-friendly cloud point extraction of polyphenols from pomegranate peels: A comparative assessment with ultrasound and microwave-assisted extraction. Sep. Sci. Technol. 2021, 56, 1014–1025. [Google Scholar] [CrossRef]

- Périno, S.; Pierson, J.T.; Ruiz, K.; Cravotto, G.; Chemat, F. Laboratory to pilot scale: Microwave extraction for polyphenols lettuce. Food Chem. 2016, 204, 108–114. [Google Scholar] [CrossRef]

- Spadoni Andreani, E.; Karboune, S. Comparison of enzymatic and microwave-assisted alkaline extraction approaches for the generation of oligosaccharides from American Cranberry (Vaccinium macrocarpon) Pomace. J. Food Sci. 2020, 85, 2443–2451. [Google Scholar] [CrossRef]

- Rehinan, Z.-U.; Rashid, M.; Shah, W.H. Insoluble dietary fibre components of food legumes as affected by soaking and cooking processes. Food Chem. 2004, 85, 245–249. [Google Scholar] [CrossRef]

- Liu, Y.; Ragaee, S.; Marcone, M.F.; Abdel-Aal, E.-S.M. Composition of Phenolic Acids and Antioxidant Properties of Selected Pulses Cooked with Different Heating Conditions. Foods 2020, 9, 908. [Google Scholar] [CrossRef]

- Sharma, M.; Dash, K.K. Microwave and ultrasound assisted extraction of phytocompounds from black jamun pulp: Kinetic and thermodynamics characteristics. Innov. Food Sci. Emerg. Technol. 2022, 75, 102913. [Google Scholar] [CrossRef]

- Oszmiański, J.; Wojdyło, A.; Kolniak, J. Effect of pectinase treatment on extraction of antioxidant phenols from pomace, for the production of puree-enriched cloudy apple juices. Food Chem. 2011, 127, 623–631. [Google Scholar] [CrossRef]

- Valencia-Hernandez, L.J.; Wong-Paz, J.E.; Ascacio-Valdés, J.A.; Chávez-González, M.L.; Contreras-Esquivel, J.C.; Aguilar, C.N. Procyanidins: From Agro-Industrial Waste to Food as Bioactive Molecules. Foods 2021, 10, 3152. [Google Scholar] [CrossRef]

- Peng, M.; Jiang, C.; Jing, H.; Du, X.; Fan, X.; Zhang, Y.; Wang, H. Comparison of different extraction methods on yield, purity, antioxidant, and antibacterial activities of proanthocyanidins from chokeberry (Aronia melanocarpa). J. Food Meas. Charact. 2022, 16, 2049–2059. [Google Scholar] [CrossRef]

- Renard, C.M.; Baron, A.; Guyot, S.; Drilleau, J.-F. Interactions between apple cell walls and native apple polyphenols: Quantification and some consequences. Int. J. Biol. Macromol. 2001, 29, 115–125. [Google Scholar] [CrossRef]

- Oszmiański, J.; Wojdylo, A.; Kolniak, J. Effect of Enzymatic Mash Treatment and Storage on Phenolic Composition, Antioxidant Activity, and Turbidity of Cloudy Apple Juice. J. Agric. Food Chem. 2009, 57, 7078–7085. [Google Scholar] [CrossRef]

- Lima, M.d.S.; da Conceição Prudêncio Dutra, M.; Toaldo, I.M.; Corrêa, L.C.; Pereira, G.E.; de Oliveira, D.; Bordignon-Luiz, M.T.; Ninow, J.L. Phenolic compounds, organic acids and antioxidant activity of grape juices produced in industrial scale by different processes of maceration. Food Chem. 2015, 188, 384–392. [Google Scholar] [CrossRef]

- Fernandes, P.A.R.; Le Bourvellec, C.; Renard, C.M.G.C.; Nunes, F.M.; Bastos, R.; Coelho, E.; Wessel, D.F.; Coimbra, M.A.; Cardoso, S.M. Revisiting the chemistry of apple pomace polyphenols. Food Chem. 2019, 294, 9–18. [Google Scholar] [CrossRef]

- Dueñas, M.; Sun, B.; Hernández, T.; Estrella, I.; Spranger, M.I. Proanthocyanidin composition in the seed coat of lentils (Lens culinaris L.). J. Agric. Food Chem. 2003, 51, 7999–8004. [Google Scholar] [CrossRef]

- Aguilera, Y.; DUENas, M.; Estrella, I.; Hernandez, T.; Benitez, V.; Esteban, R.M.; Martin-Cabrejas, M.A. Evaluation of phenolic profile and antioxidant properties of Pardina lentil as affected by industrial dehydration. J. Agric. Food Chem. 2010, 58, 10101–10108. [Google Scholar] [CrossRef]

| Nutritional Parameters | Units | Mean ± SD 1 |

|---|---|---|

| TDF | g/100 g | 78.43 ± 2.13 |

| IDF | g/100 g | 69.32 ± 2.67 |

| HMW-SDF | g/100 g | 9.11 ± 0.55 |

| Oligosaccharides | g/100 g | ND |

| Protein | g/100 g | 9.12 ± 0.01 |

| Starch | g/100 g | 0.13 ± 0.01 |

| Phytic acid | g/100 g | 0.06 ± 0.00 |

| Trypsin inhibitory activity | TIU/mg | 18.26 ± 1.50 |

| Total phenolic compounds | mg GAE/g | 49.76 ± 4.74 |

| Free phenolic compounds | mg GAE/g | 21.44 ± 0.82 |

| Bound phenolic compound | mg GAE/g | 27.45 ± 2.62 |

| Total Condensed tannins | mg CAE/g | 15.83 ± 1.32 |

| Enzymes | OS (g/100 g DW) | SPC (mg GAE/g DW) | SPC Ratio (%) | ORAC (µmol TE/g DW) | ABTS (µmol TE/g DW) |

|---|---|---|---|---|---|

| Control | ND | 21.45 ± 2.62 | - | 105.11 ± 7.72 | 117.12 ± 11.17 |

| Ultraflo® XL | 3.12 ± 0.15 a,*** | 41.04 ± 1.25 ab,* | 71.39 ± 4.57 ab | 451.40 ± 10.85 b,* | 402.01 ± 37.07 b,* |

| Ultraflo® Max | 1.89 ± 0.01 a | 38.29 ± 1.44 ab,* | 61.35 ± 5.24 ab | 399.93 ± 19.40 a,* | 390.82 ± 18.95 a,* |

| Ultimase® BWL 40 | 1.55 ± 0.17 a | 40.70 ± 0.37 ab,* | 70.14 ± 1.34 ab | 445.01 ± 9.79 b,* | 417.31 ± 43.18 b,* |

| Viscozyme® L | 7.54 ± 0.03 b,* | 41.44 ± 0.62 bc,* | 72.83 ± 2.27 bc | 421.06 ± 14.56 b,* | 421.55 ± 34.28 b,* |

| Celluclast® 1.5L | 3.57 ± 0.04 a,** | 39.81 ± 0.97 ab,* | 66.92 ± 3.55 ab | 408.08 ± 11.60 a,* | 384.80 ± 32.34 a,* |

| Pectinex® Ultra Tropical | 14.17 ± 1.41 c,* | 45.51 ± 4.44 c,* | 98.59 ± 0.96 c | 442.04 ± 15.44 b,* | 424.06 ± 29.11 b,* |

| Shearzyme® Plus 2X | 9.79 ± 0.66 b,* | 36.18 ± 0.21 a,* | 53.67 ± 0.75 a | 342.17 ± 34.09 a,* | 359.95 ± 17.17 a,* |

| Treatment | Oligosaccharides (g/100 g DW) | SPC (mg GAE/g DW) | Water-Soluble Fraction Yield (g/100 g DW) | ORAC (µmol TE/g DW) | ABTS (µmol TE/g DW) |

|---|---|---|---|---|---|

| Control | ND | 21.45 ± 2.62 a | 9.58 ± 0.47 a | 105.11 ± 7.72 a | 117.12 ± 11.17 a |

| MW | 4.65 ± 0.23 a | 36.28 ± 0.60 b | 12.59 ± 0.93 b | 245.60 ± 5.65 b | 236.97 ± 19.27 b |

| EH-P | 14.17 ± 1.41 c | 45.51 ± 4.44 d | 24.92 ± 0.25 c | 442.04 ± 15.44 d | 424.06 ± 29.11 d |

| MW + EH-P | 12.12 ± 0.81 b | 41.45 ± 0.96 c | 34.27 ± 0.67 d | 403.98 ± 20.33 c | 376.98 ± 15.63 c |

| Compound | Control | MW | EH-P | MW + EH-P |

|---|---|---|---|---|

| Phenolic acid | ||||

| Gallic acid | 373.93 ± 30.88 a | 464.02 ± 10.39 a | 403.44 ± 37.10 a | 507.18 ± 49.37 a |

| trans-p-coumaric acid derivative I | 7.45 ± 0.96 b | 7.17 ± 0.80 b | 20.98 ± 2.03 c | t a |

| trans-p-coumaric acid derivative II | 17.53 ± 0.96 c | 15.06 ± 1.86 c | 7.84 ± 0.92 b | t a |

| Prodelphinidin | ||||

| Dimer prodelphinidin I | 446.10 ± 14.92 a | 517.98 ± 40.45 a | 536.34 ± 15.70 a | 550.42 ± 26.96 a |

| Dimer prodelphinidin II | 85.48 ± 1.69 a | 156.01 ± 68.59 ab | 391.85 ± 9.99 c | 243.11 ± 6.65 b |

| Dimer prodelphinidin III | 51.04 ± 1.13 a | 99.98 ± 14.93 b | 115.01 ± 8.83 b | 116.78 ± 5.46 b |

| Trimer prodelphinidin | 389.8 ± 34.42 a | 525.96 ± 54.47 b | 660.25 ± 15.02 c | 550.87 ± 5.96 bc |

| Procyanidin | ||||

| Galloylated dimer I | 532.8 ± 49.12 a | 546.38 ± 10.02 a | 955.32 ± 32.57 c | 764.40 ± 43.70 b |

| Galloylated dimer II | 100.17 ± 20.93 a | 111.31 ± 30.51 a | 205.57 ± 11.87 b | 159.77 ± 7.20 ab |

| Dimer procyanidin I | 111.70 ± 21.67 a | 146.26 ± 15.28 a | 263.10 ± 2.12 c | 202.29 ± 16.23 b |

| Dimer procyanidin II | 481.45 ± 1.24 a | 648.39 ± 51.75 b | 760.26 ± 11.67 b | 872.67 ± 4.31 c |

| Trimer procyanidin | 452.84 ± 53.58 a | 594.95 ± 53.99 b | 974.60 ± 3.86 c | 912.56 ± 1.74 c |

| Flavonoid | ||||

| (+)-catechin O-hexoside | 762.7 ± 0.12 a | 799.62 ± 74.90 a | 965.40 ± 1.00 b | 957.21 ± 16.46 b |

| (+)-catechin | 164.78 ± 16.53 a | 553.83 ± 12.19 c | 426.83 ± 22.79 b | 416.01 ± 11.33 b |

| (-)-epicatechin | 158.28 ± 11.44 a | 179.61 ± 7.32 a | 211.64 ± 21.23 a | 165.27 ± 23.58 a |

| Quercetin rutinoside hexoside | 9.54 ± 0.35 c | 9.02 ± 0.41 c | 4.89 ± 0.05 a | 7.14 ± 0.63 b |

| Kaempferol dirutinoside | 59.62 ± 2.73 b | 59.16 ± 3.57 b | 20.74 ± 0.11 a | 25.88 ± 1.55 a |

| Kaempferol rutinoside hexoside | 58.54 ± 2.36 b | 54.55 ± 0.20 b | 29.41 ± 0.48 a | 32.27 ± 1.16 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bautista-Expósito, S.; Vandenberg, A.; Dueñas, M.; Peñas, E.; Frias, J.; Martínez-Villaluenga, C. Selection of Enzymatic Treatments for Upcycling Lentil Hulls into Ingredients Rich in Oligosaccharides and Free Phenolics. Molecules 2022, 27, 8458. https://doi.org/10.3390/molecules27238458

Bautista-Expósito S, Vandenberg A, Dueñas M, Peñas E, Frias J, Martínez-Villaluenga C. Selection of Enzymatic Treatments for Upcycling Lentil Hulls into Ingredients Rich in Oligosaccharides and Free Phenolics. Molecules. 2022; 27(23):8458. https://doi.org/10.3390/molecules27238458

Chicago/Turabian StyleBautista-Expósito, Sara, Albert Vandenberg, Montserrat Dueñas, Elena Peñas, Juana Frias, and Cristina Martínez-Villaluenga. 2022. "Selection of Enzymatic Treatments for Upcycling Lentil Hulls into Ingredients Rich in Oligosaccharides and Free Phenolics" Molecules 27, no. 23: 8458. https://doi.org/10.3390/molecules27238458

APA StyleBautista-Expósito, S., Vandenberg, A., Dueñas, M., Peñas, E., Frias, J., & Martínez-Villaluenga, C. (2022). Selection of Enzymatic Treatments for Upcycling Lentil Hulls into Ingredients Rich in Oligosaccharides and Free Phenolics. Molecules, 27(23), 8458. https://doi.org/10.3390/molecules27238458