Electroplating Cobalt Films on Silicon Nanostructures for Sensing Molecules

Abstract

1. Introduction

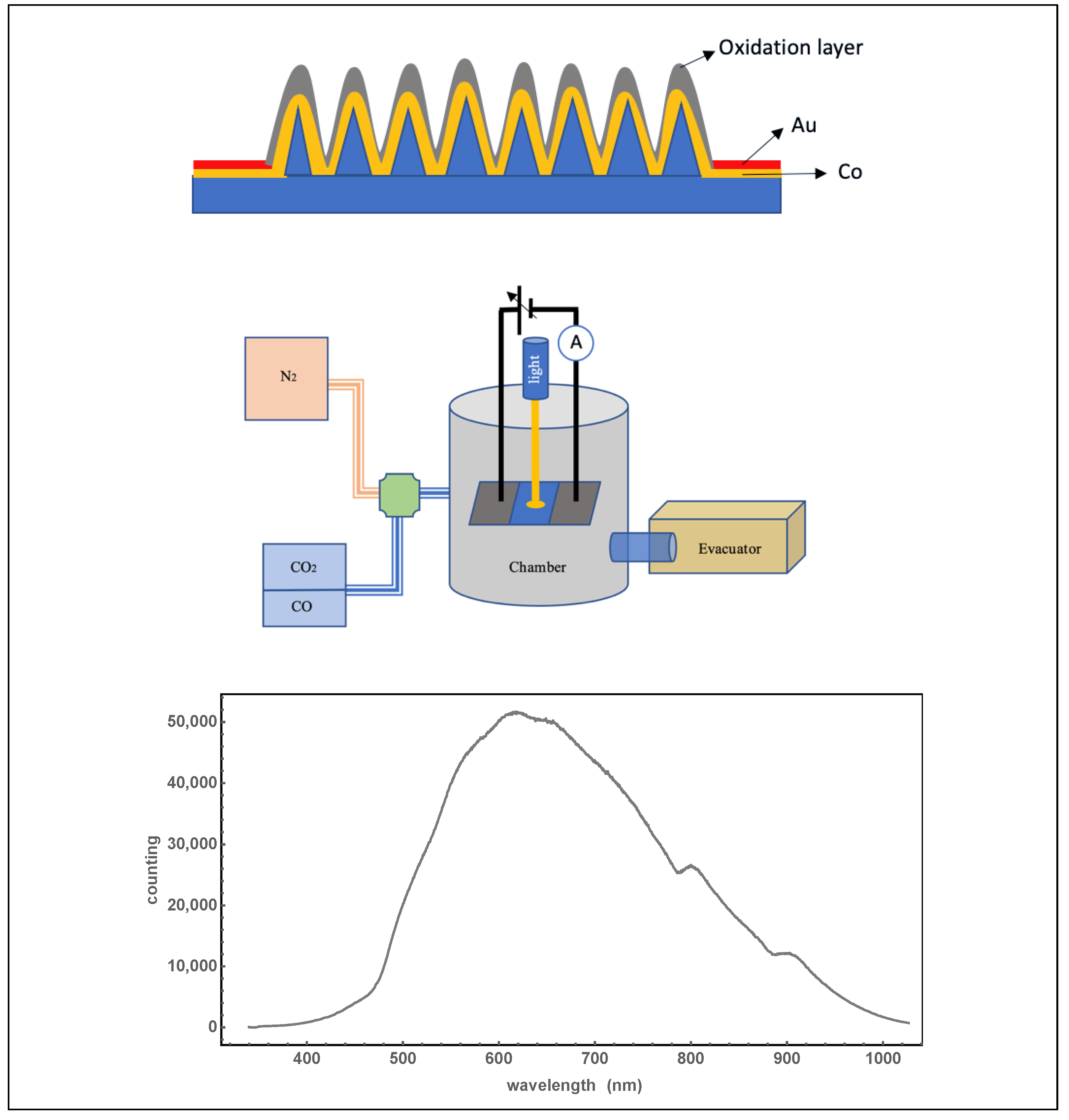

2. Methodology

3. Results and Discussion

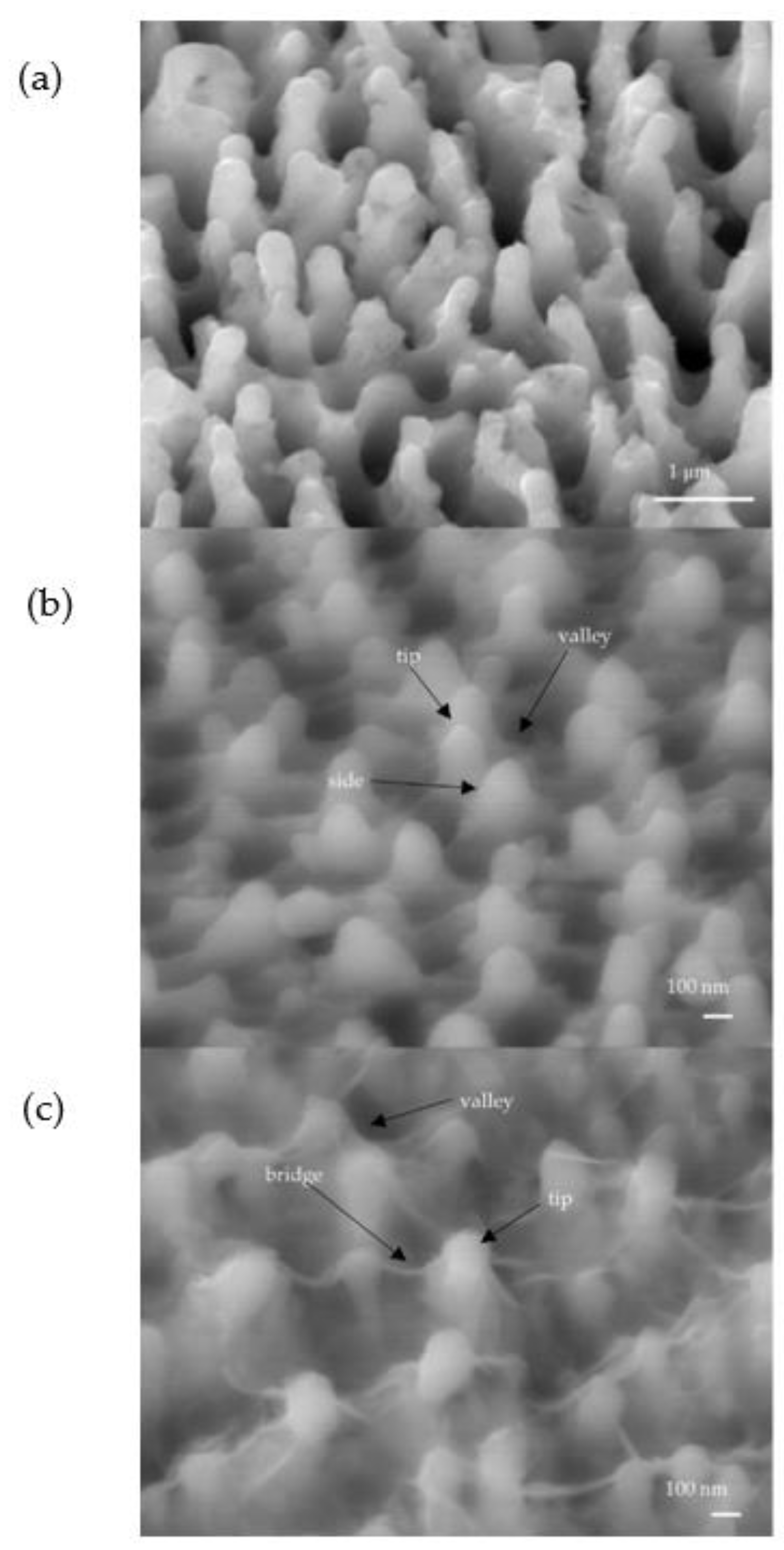

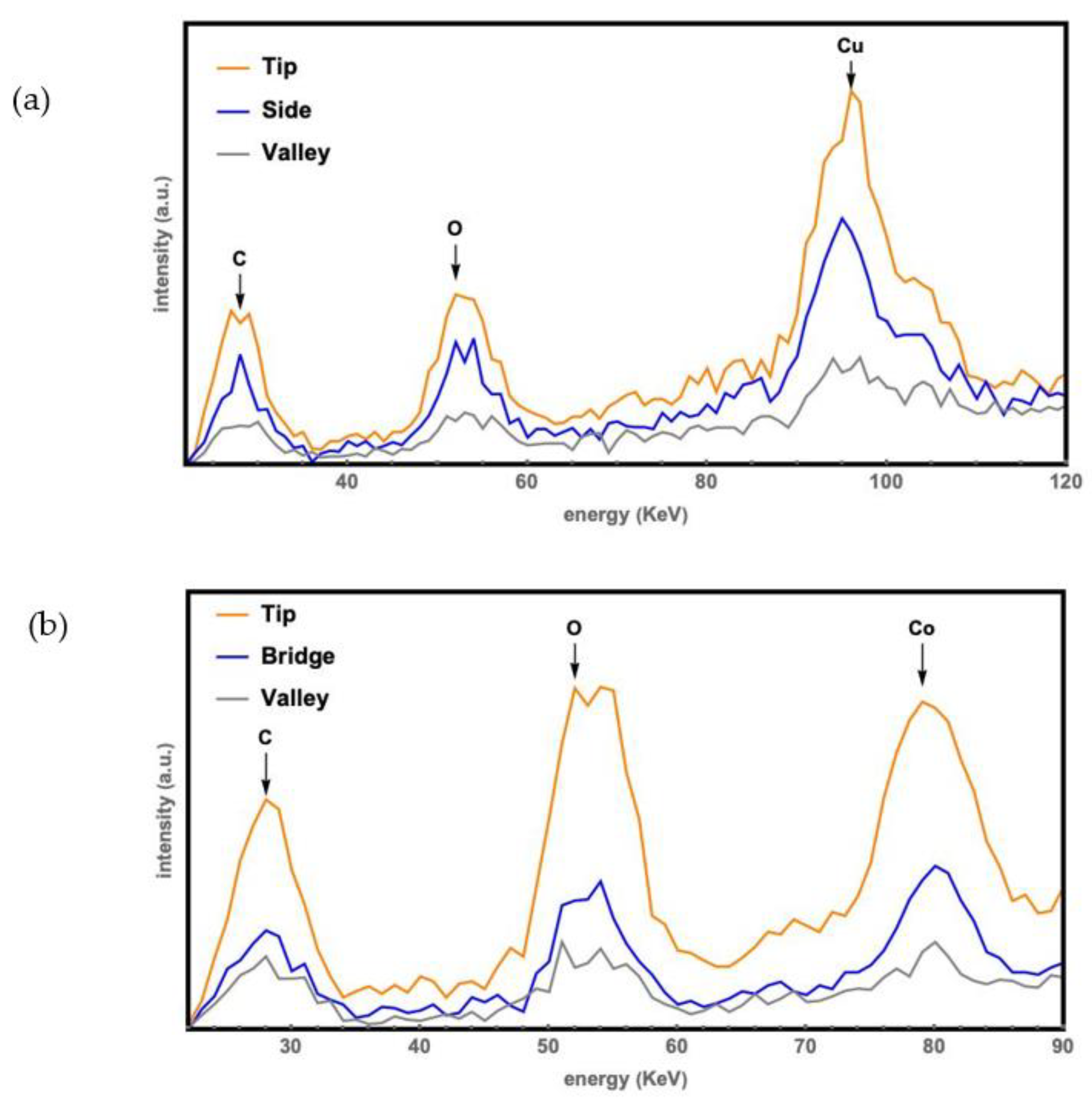

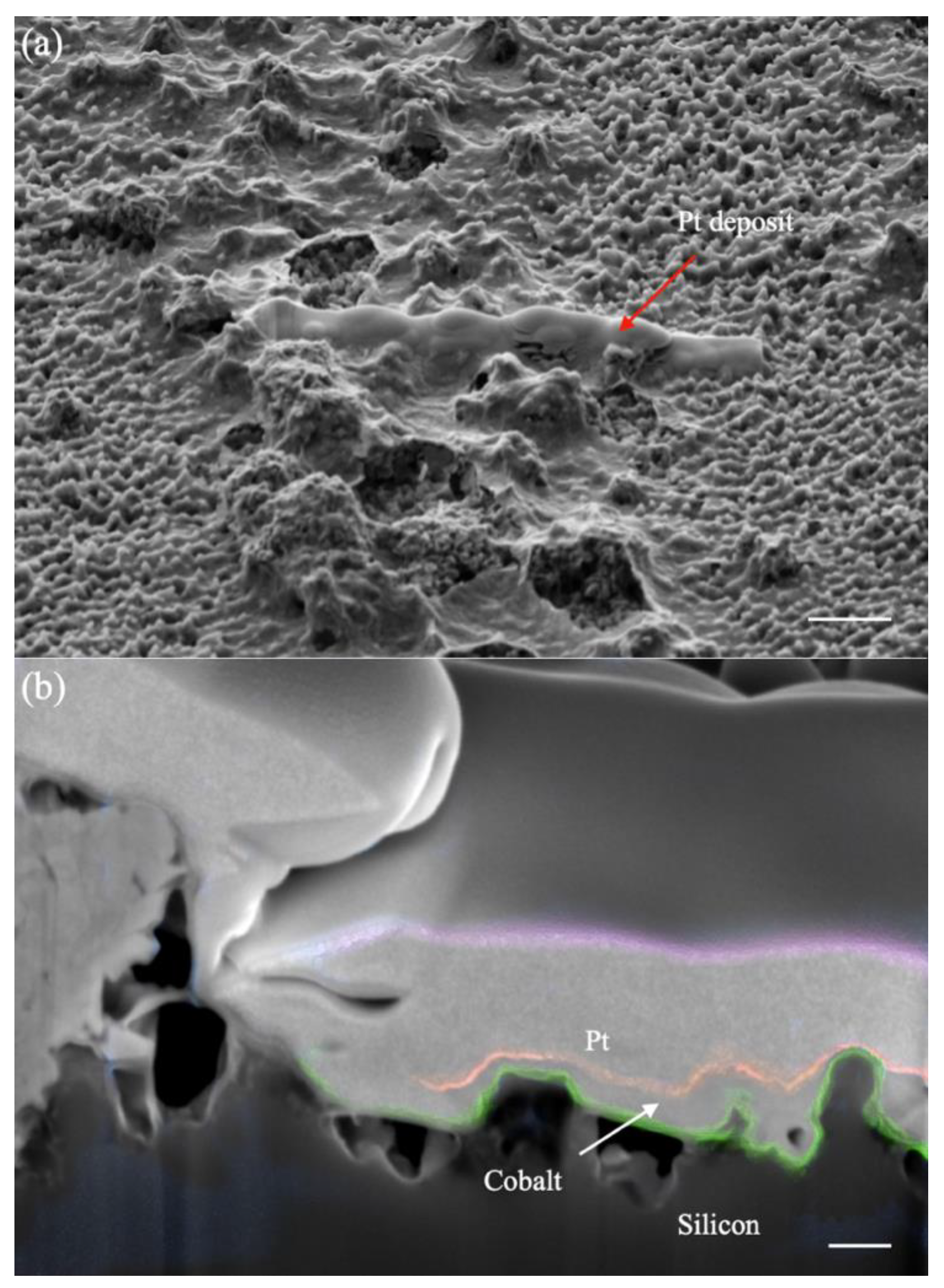

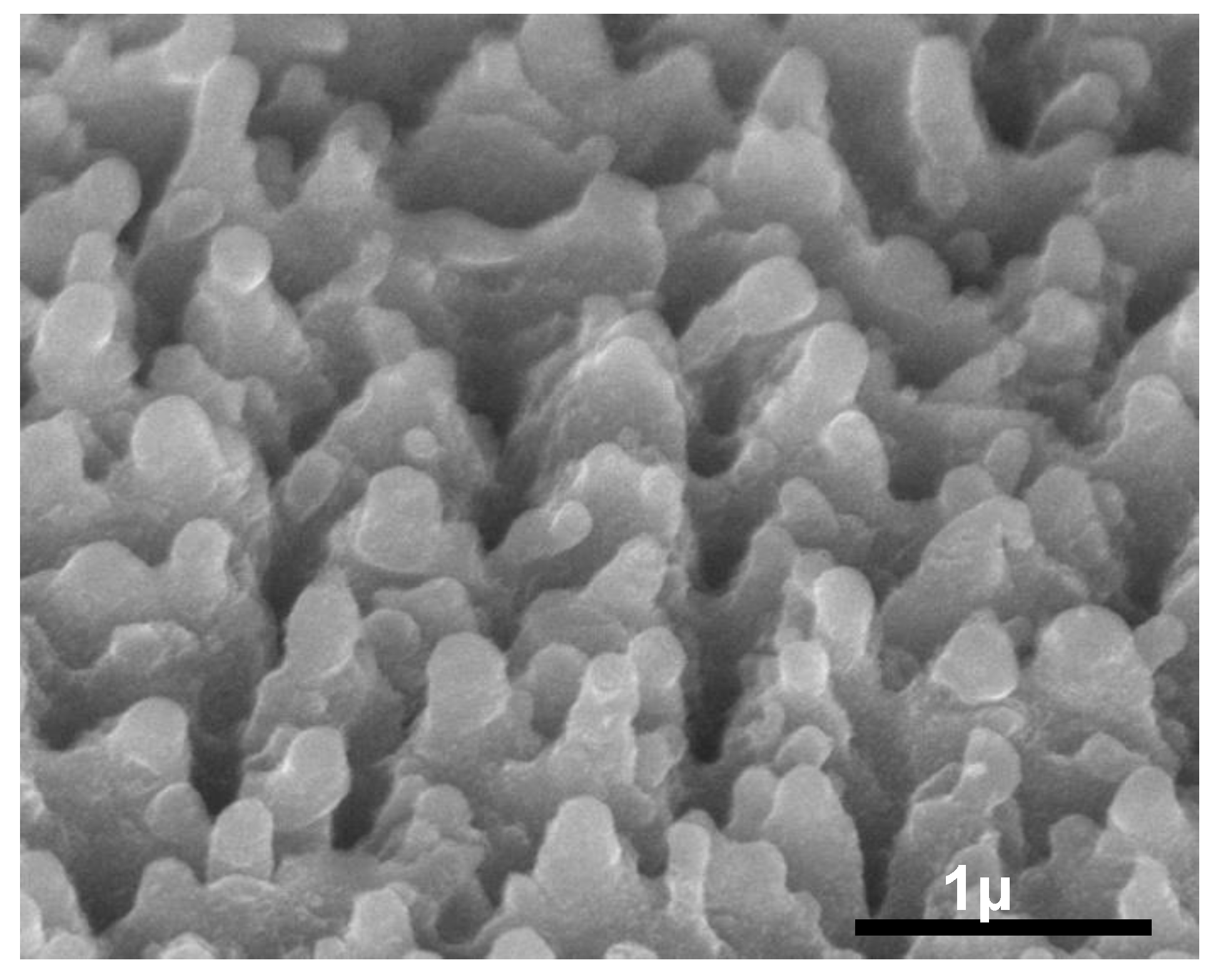

3.1. Sample Preparation

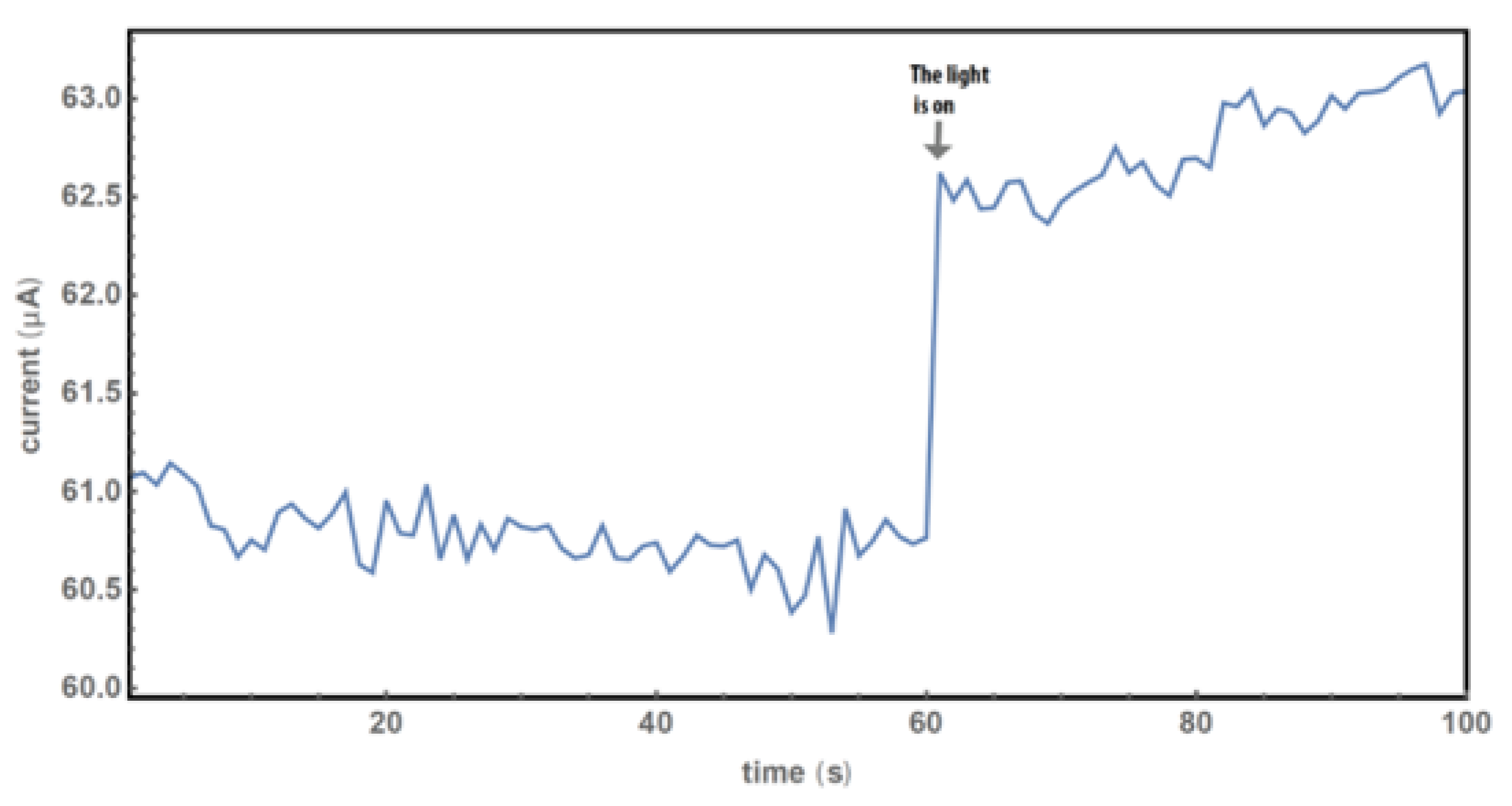

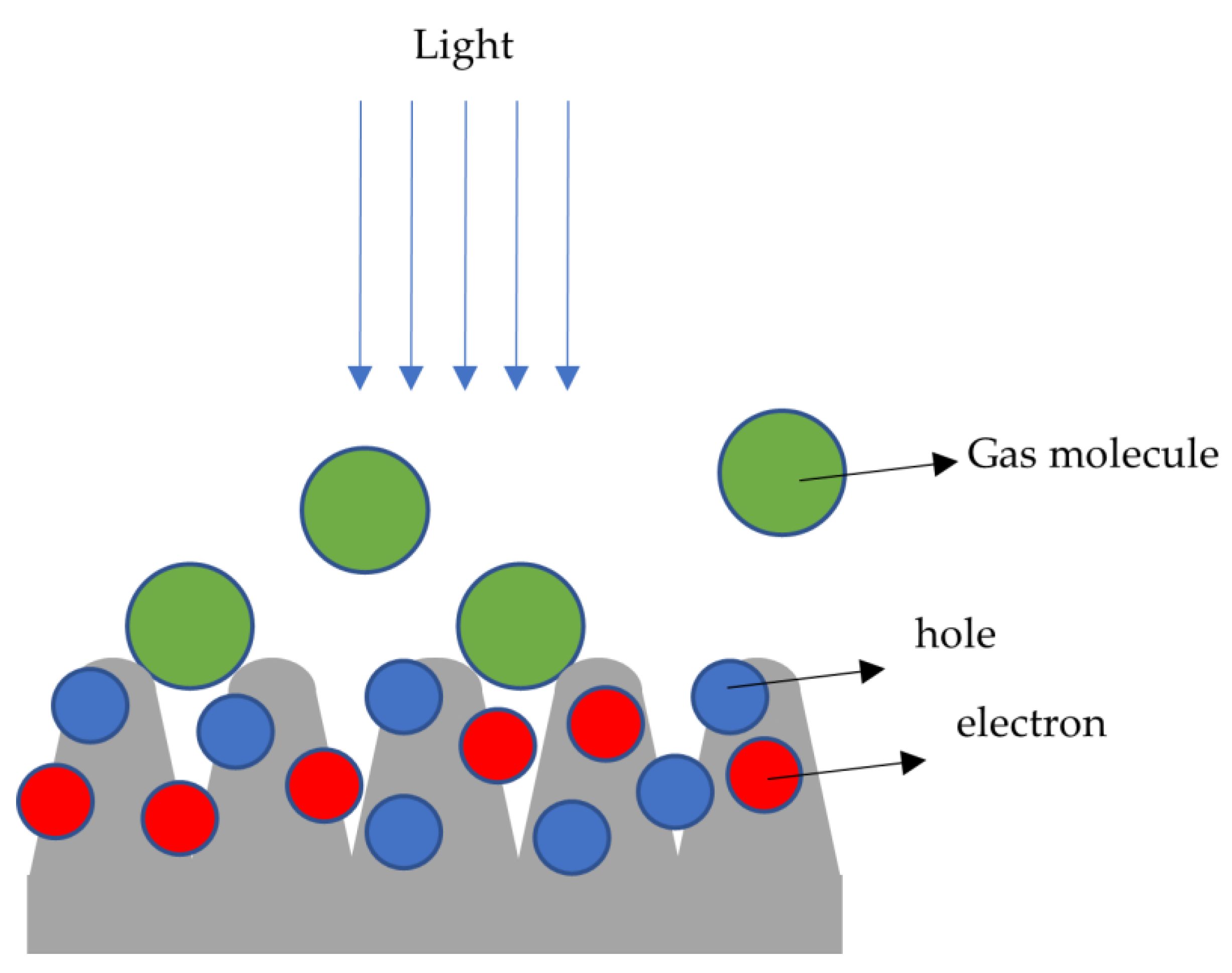

3.2. Interactions between Molecules and the Electroplated Cobalt under Illumination

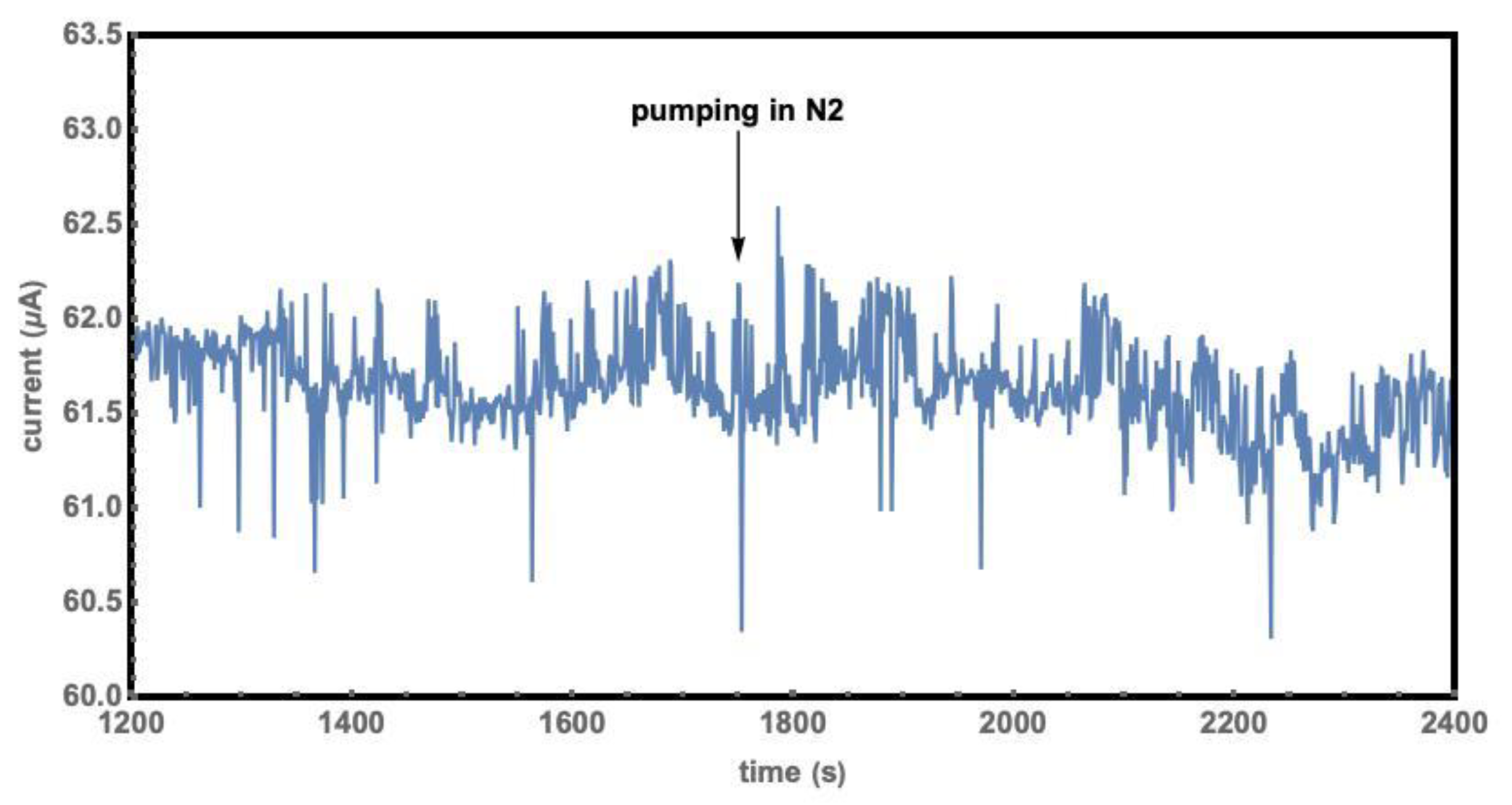

3.3. Test for Intereactions between Molecults and the CoO Surface

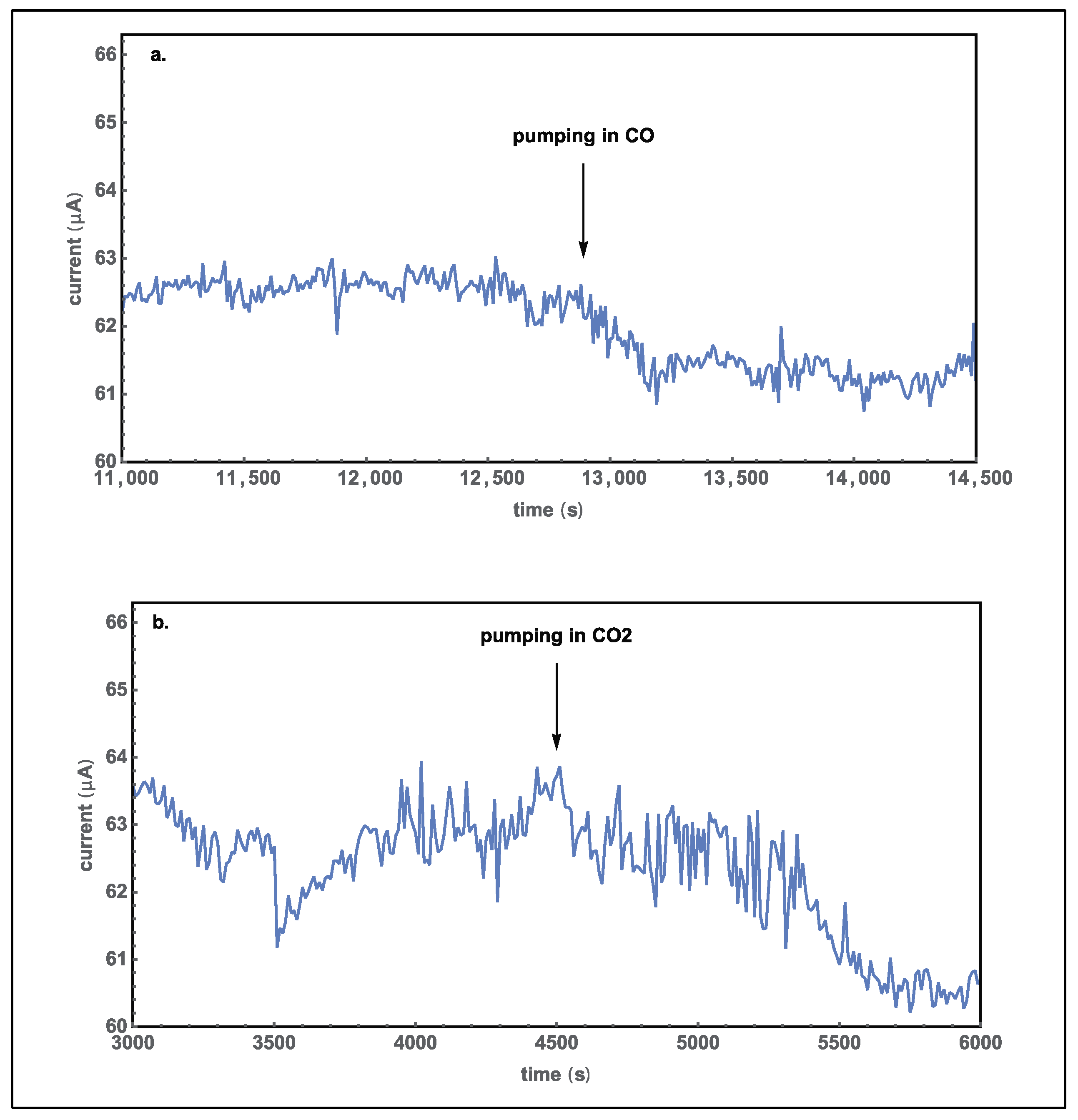

3.4. The Mechanism of the Interaction between Molecules with the Electroplated Cobalt Surface

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Huo, H.; Shen, M. Platinum nanostructures formed by femtosecond laser irradiation in water. J. Appl. Phys. 2012, 112, 104314. [Google Scholar] [CrossRef]

- Kan, Z.; Zhang, Q.; Ren, H.; Shen, M. Femtosecond laser induced formation of graphene nanostructures in water and their field emission properties. Mater. Res. Express. 2019, 6, 085016. [Google Scholar] [CrossRef]

- Kan, Z.; Zhu, Q.; Ren, H.; Shen, M. Femtosecond Laser-Induced Thermal Transport in Silicon with Liquid Cooling Bath. Materials 2019, 12, 2043. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Carey, J.E.; Crouch, C.H.; Kandyla, M.; Stone, H.A.; Mazur, E. High-density regular arrays of nanometer-scale rods formed on silicon surfaces via femtosecond laser irradiation in water. Nano Lett. 2008, 8, 2087–2091. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Crouch, C.H.; Carey, J.E.; Mazur, E. Femtosecond laser-induced formation of submicrometer spikes on silicon in water. Appl. Phys. Lett. 2004, 85, 5694–5696. [Google Scholar] [CrossRef]

- Huo, H.; Wang, C.; Ren, H.; Johnson, M.; Shen, M. Surface enhanced Raman scattering sensing with nanostructures fabricated by soft nanolithography. J. Macromol. Sci. 2009, 46, 1182–1184. [Google Scholar] [CrossRef]

- Huo, H.; Wang, C.; Yan, F.; Ren, H.; Shen, M. Room temperature SnO2 thin film gas sensor fabricated on Si nanospikes. J. Nanosci. Nanotechnol 2009, 9, 4817–4819. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Ren, H.; Zeng, M.; Zhu, Q.; Zhang, Q.; Kan, Z.; Wang, Z.; Shen, M. Acharige MJT, Ruths M. Low-cost visible-light photosynthesis of water and adsorbed carbon dioxide into long-chain hydrocarbons. Chem. Phys. Lett. 2020, 739, 136985. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, C.; Ren, H.; Zeng, M.; Kan, Z.; Wang, Z.; Shen, M. Conversion of water and carbon dioxide into methanol with solar energy on Au/Co nanostructured surfaces. MRX 2020, 7, 035014. [Google Scholar] [CrossRef]

- Huo, H.; Ren, H.; Wang, C.; Shen, M. Enhancing sensitivity of semiconductor-based gas sensors on nanostructured surfaces. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2011, San Diego, CA, USA, 18 April 2011; p. 79815T. [Google Scholar]

- Huo, H.; Yan, F.; Wang, C.; Ren, H.; Shen, M. Low-cost self-cleaning room temperature SnO2 thin film gas sensor on polymer nanostructures. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2010, San Diego, CA, USA, 31 March 2010; p. 76474R. [Google Scholar]

- Ren, H.; Huo, H.; Shen, M.; Ruths, M.; Sun, H. Femtosecond laser irradiation enhanced room temperature tin oxide nanostructure gas sensor. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2013, San Diego, CA, USA, 19 April 2013; p. 86923S. [Google Scholar]

- Ren, H.; Huo, H.; Wang, P.; Wang, C.; Liu, S.; Shen, M.; Sun, H.; Ruths, M. The electric field effect on the sensitivity of tin oxide gas sensors on nanostructured substrates at low temperature. Int. J. Smart Nano Mater. 2014, 5, 257–269. [Google Scholar] [CrossRef][Green Version]

- Ren, H.; Wang, P.; Huo, H.; Shen, M.; Ruths, M.; Sun, H. Effects of surface electric field on SnO2 room temperature gas sensors fabricated on nanospike substrates. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2012, San Diego, CA, USA, 6 April 2012; p. 83454T. [Google Scholar]

- Wang, P.; Ren, H.; Huo, H.; Shen, M.; Sun, H.; Ruths, M. Failure study of SnO2 room temperature gas sensors fabricated on nanospike substrates. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; SPIE: San Diego, CA, USA, 6 April 2012; Volume 8345, pp. 1159–1165. [Google Scholar]

- Wang, N.; Hang, T.; Shanmugam, S.; Li, M. Preparation and characterization of nickel–cobalt alloy nanostructures array fabricated by electrodeposition. CrystEngComm 2014, 16, 6937–6943. [Google Scholar] [CrossRef]

- Wang, X.; Ma, X.; Church, J.; Jung, S.; Son, Y.; Lee, W.H.; Cho, H.J. ZnO nanoflakes as a template for in-situ electrodeposition of nanostructured cobalt electrodes as amperometric phosphate sensors. Mater. Lett. 2017, 192, 107–110. [Google Scholar] [CrossRef]

- Khelladi, M.R.; Mentar, L.; Azizi, A.; Kadirgan, F.; Schmerber, G.; Dinia, A. Nucleation, growth and properties of Co nanostructures electrodeposited on n-Si (1 1 1). Appl. Surf. Sci. 2012, 258, 3907–3912. [Google Scholar] [CrossRef]

- Voigtländer, B. Lock-In Technique. In Scanning Probe Microscopy; Springer: Berlin/Heidelberg, Germany, 2015; pp. 101–105. [Google Scholar]

- Lancelot, C.; Ordomsky, V.V.; Stéphan, O.; Sadeqzadeh, M.; Karaca, H.l.; Lacroix, M.; Curulla-Ferré, D.; Luck, F.; Fongarland, P.; Griboval-Constant, A. Direct evidence of surface oxidation of cobalt nanoparticles in alumina-supported catalysts for Fischer–Tropsch synthesis. ACS Catal. 2014, 4, 4510–4515. [Google Scholar] [CrossRef]

- Peter, Y.; Cardona, M. Fundamentals of Semiconductors: Physics and Materials Properties; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; pp. 203–241. [Google Scholar]

- Yang, M.; Wang, D.; Peng, L.; Zhao, Q.; Lin, Y.; Wei, X. Surface photocurrent gas sensor with properties dependent on Ru (dcbpy) 2 (NCS) 2-sensitized ZnO nanoparticles. Sens. Actuators B Chem. 2006, 117, 80–85. [Google Scholar] [CrossRef]

- Zhai, J.; Wang, D.; Peng, L.; Lin, Y.; Li, X.; Xie, T. Visible-light-induced photoelectric gas sensing to formaldehyde based on CdS nanoparticles/ZnO heterostructures. Sens. Actuators B Chem. 2010, 147, 234–240. [Google Scholar] [CrossRef]

- Fabbri, B.; Gaiardo, A.; Guidi, V.; Malagù C Giberti, A. Photo-activation of cadmium sulfide films for gas sensing. Procedia Eng. 2014, 87, 140–143. [Google Scholar] [CrossRef]

| Current Density | Oxidation Time | Bridge Number | |

|---|---|---|---|

| 1st | 0.5μA/cm2 | 24 Hours | 26 |

| 2nd | 0.5μA/cm2 | 3 Hours | 6 |

| 3rd | 0.5μA/cm2 | 0.5 Hour | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Kan, Z.; Wang, Z.; Huo, H.; Shen, M. Electroplating Cobalt Films on Silicon Nanostructures for Sensing Molecules. Molecules 2022, 27, 8440. https://doi.org/10.3390/molecules27238440

Chen C, Kan Z, Wang Z, Huo H, Shen M. Electroplating Cobalt Films on Silicon Nanostructures for Sensing Molecules. Molecules. 2022; 27(23):8440. https://doi.org/10.3390/molecules27238440

Chicago/Turabian StyleChen, Chihyang, Zhe Kan, Zibo Wang, Haibin Huo, and Mengyan Shen. 2022. "Electroplating Cobalt Films on Silicon Nanostructures for Sensing Molecules" Molecules 27, no. 23: 8440. https://doi.org/10.3390/molecules27238440

APA StyleChen, C., Kan, Z., Wang, Z., Huo, H., & Shen, M. (2022). Electroplating Cobalt Films on Silicon Nanostructures for Sensing Molecules. Molecules, 27(23), 8440. https://doi.org/10.3390/molecules27238440