Nano-Encapsulated Essential Oils as a Preservation Strategy for Meat and Meat Products Storage

Abstract

1. Introduction

2. Mechanism of Deterioration in Meat

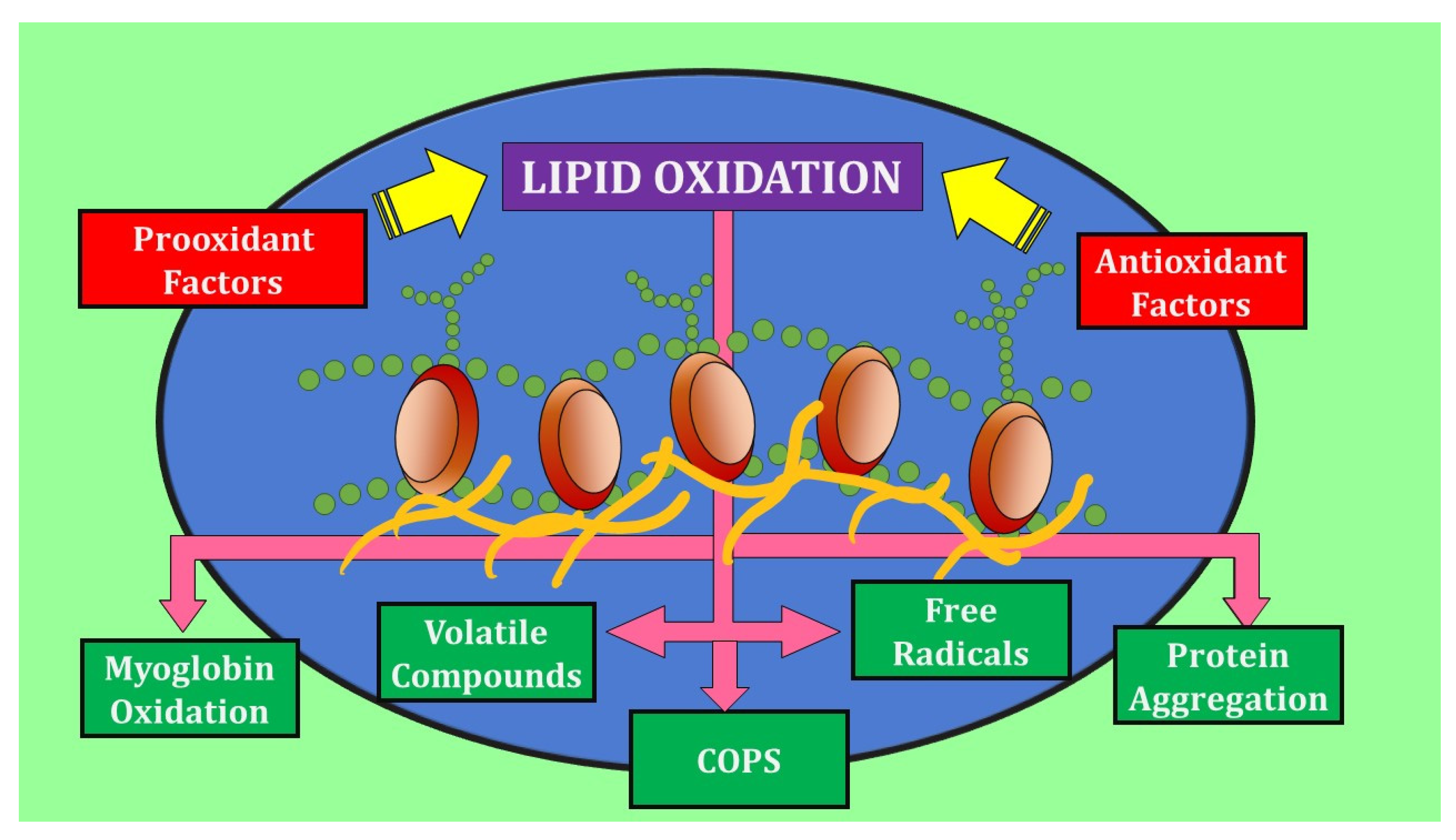

2.1. Lipid Oxidation in Meat

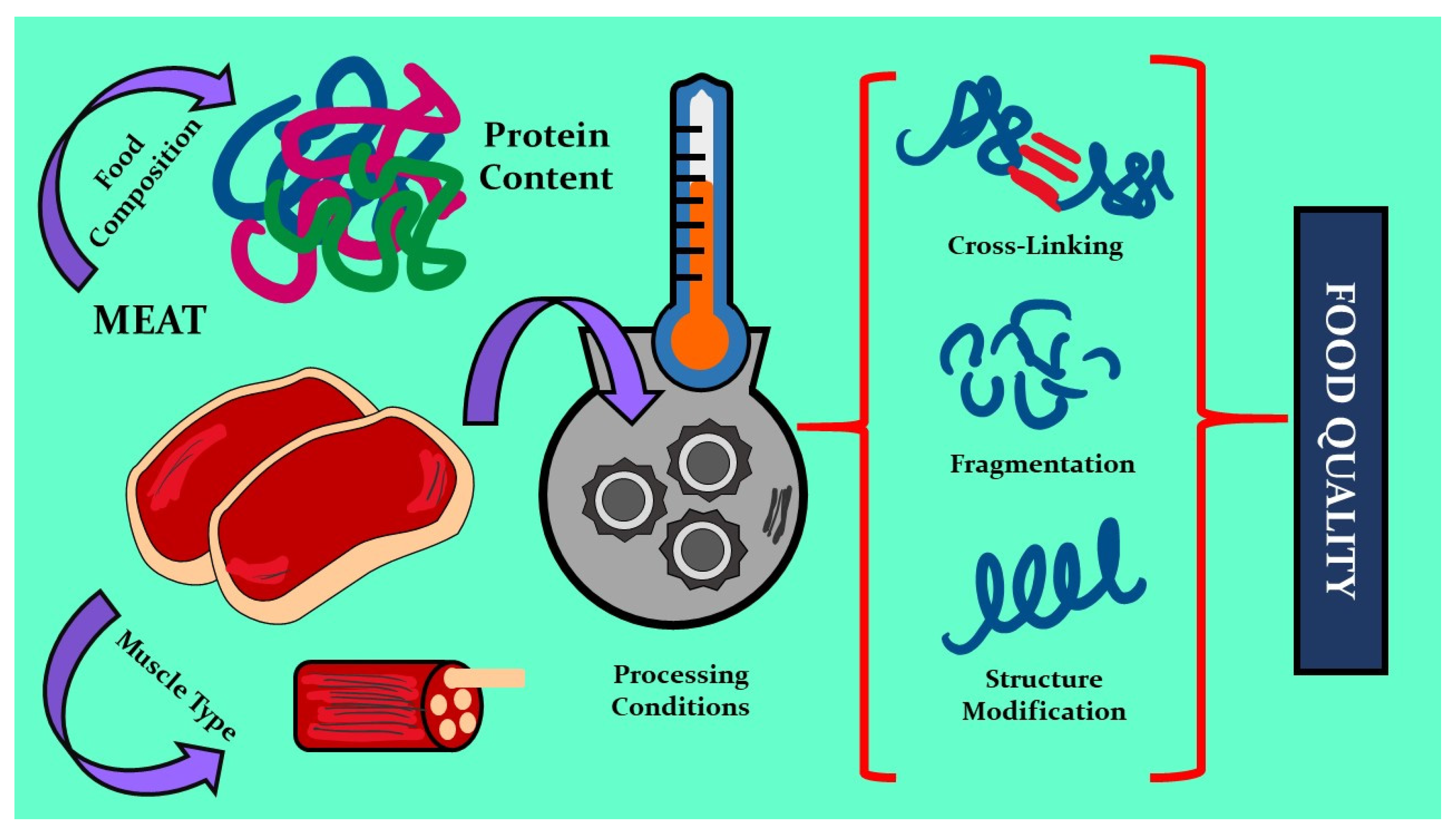

2.2. Protein Oxidation in Meat

2.3. Meat Spoilage Due to Microorganisms

3. Use of Preservative Compounds with Meat and Meat Products

3.1. Synthetic Preservatives

3.2. Preservatives of Natural Origin

3.3. Antioxidants

3.4. Antimicrobials

4. Essential Oils

4.1. Antioxidant Capacity

4.2. Antimicrobial Activity

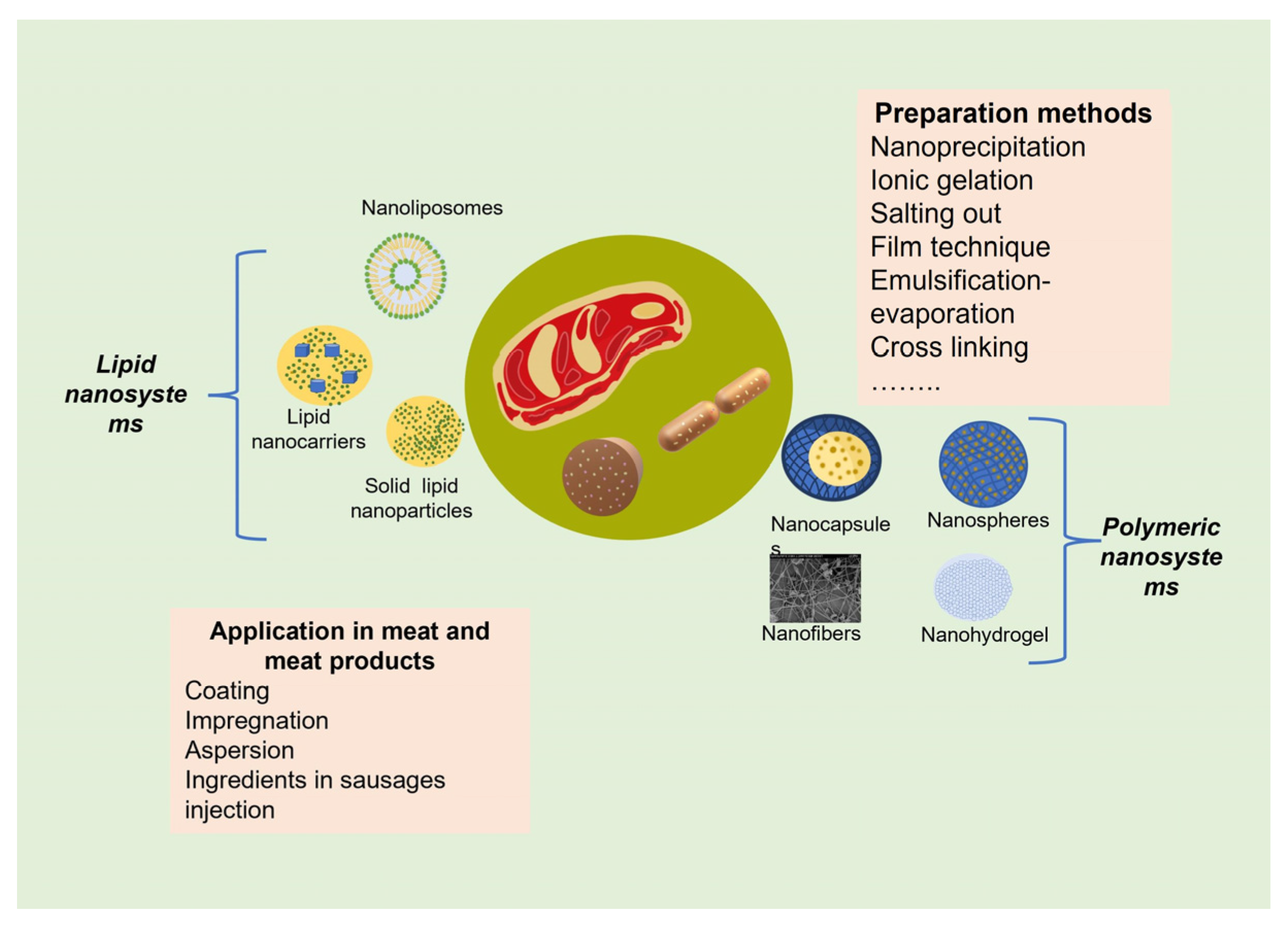

5. Nanosystems for Encapsulation of Essential Oils

5.1. Organic Nanosystems

5.1.1. Nanoemulsions

5.1.2. Nanoliposomes

5.1.3. SLN and NLC

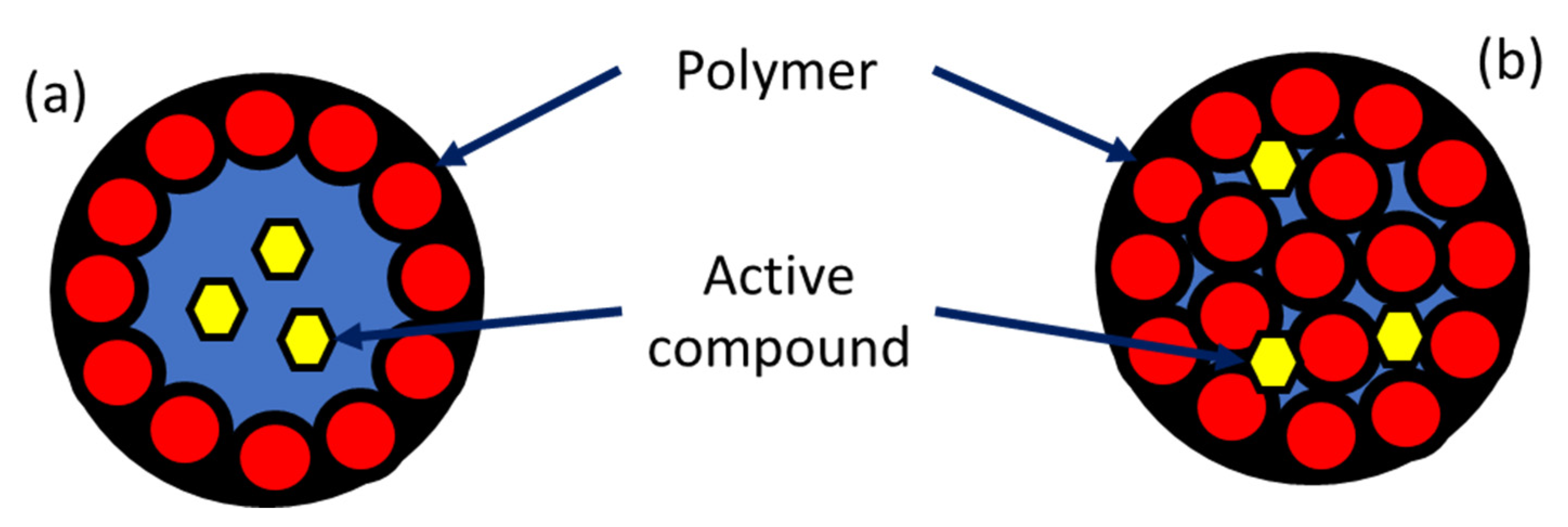

5.1.4. Polymeric Nanoparticles

5.1.5. Nanofibers

5.1.6. Nanocrystals

5.1.7. Nanogels

5.1.8. Inclusion Complexes

6. Applications of Nanosystems in Meat Preservation

7. Conclusions

8. Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, G.H.; Xu, X.L.; Liu, Y. Preservation Technologies for Fresh Meat—A Review. Meat Sci. 2010, 86, 119–128. [Google Scholar] [CrossRef] [PubMed]

- McMillin, K.W. Advancements in Meat Packaging. Meat Sci. 2017, 132, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Śmiecińska, K.; Daszkiewicz, T. Lipid Oxidation and Color Changes in Beef Stored under Different Modified Atmospheres. J. Food Process. Preserv. 2021, 45, e15263. [Google Scholar] [CrossRef]

- Kumar, Y.; Yadav, D.N.; Ahmad, T.; Narsaiah, K. Recent Trends in the Use of Natural Antioxidants for Meat and Meat Products. Compr. Rev. Food Sci. Food Saf. 2015, 14, 796–812. [Google Scholar] [CrossRef]

- Oswell, N.J.; Thippareddi, H.; Pegg, R.B. Practical Use of Natural Antioxidants in Meat Products in the U.S.: A Review. Meat Sci. 2018, 145, 469–479. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef]

- Jayasena, D.D.; Jo, C. Potential Application of Essential Oils as Natural Antioxidants in Meat and Meat Products: A Review. Food Rev. Int. 2014, 30, 71–90. [Google Scholar] [CrossRef]

- El-Saber Batiha, G.; Hussein, D.E.; Algammal, A.M.; George, T.T.; Jeandet, P.; Al-Snafi, A.E.; Tiwari, A.; Pagnossa, J.P.; Lima, C.M.; Thorat, N.D.; et al. Application of Natural Antimicrobials in Food Preservation: Recent Views. Food Control 2021, 126, 108066. [Google Scholar] [CrossRef]

- Perinelli, D.R.; Palmieri, G.F.; Cespi, M.; Bonacucina, G.; Montesano, D.; Petrelli, R. Molecules Encapsulation of Flavours and Fragrances into Polymeric Capsules and Cyclodextrins Inclusion Complexes: An Update. Molecules 2020, 25, 5878. [Google Scholar] [CrossRef]

- Sahani, S.; Sharma, Y.C. Advancements in Applications of Nanotechnology in Global Food Industry. Food Chem. 2021, 342. [Google Scholar] [CrossRef]

- Carrillo-Inungaray, M.L.; Trejo-Ramirez, J.A.; Reyes-Munguia, A.; Carranza-Alvarez, C. Use of Nanoparticles in the Food Industry: Advances and Perspectives. Impact of Nanoscience in the Food Industry; Academic Press: Cambridge, MA, USA, 2018; pp. 419–444. [Google Scholar] [CrossRef]

- He, X.; Deng, H.; Hwang, H.-M. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Coombs, C.E.O.; Holman, B.W.B.; Friend, M.A.; Hopkins, D.L. Long-Term Red Meat Preservation Using Chilled and Frozen Storage Combinations: A Review. Meat Sci. 2017, 125, 84–94. [Google Scholar] [CrossRef] [PubMed]

- Osaili, T.M.; Hasan, F.; Al-Nabulsi, A.A.; Dhanasekaran, D.K.; Obaid, R.S.; Hashim, M.S.; Radwan, H.M.; Cheikh Ismail, L.; Hasan, H.; Faris, M.A.I.E.; et al. Effect of Essential Oils and Vacuum Packaging on Spoilage-Causing Microorganisms of Marinated Camel Meat during Storage. Foods 2021, 10, 2980. [Google Scholar] [CrossRef] [PubMed]

- Guyon, C.; Meynier, A.; de Lamballerie, M. Protein and Lipid Oxidation in Meat: A Review with Emphasis on High-Pressure Treatments. Trends Food Sci. Technol. 2016, 50, 131–143. [Google Scholar] [CrossRef]

- Wahyuni, H.C.; Vanany, I.; Ciptomulyono, U. Cold Chain Management in Meat Storage, Distribution and Retail: A Review. IOP Conf. Ser. Earth Environ. Sci 2017, 85, 12022. [Google Scholar] [CrossRef]

- Amaral, A.B.; da Silva, M.V.; Lannes, S.C.D.S. Lipid Oxidation in Meat: Mechanisms and Protective Factors—A Review. Food Sci. Technol. 2018, 38, 1–15. [Google Scholar] [CrossRef]

- Mozuraityte, R.; Kristinova, V.; Rustad, T. Oxidation of Food Components. In Encyclopedia of Food and Health; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 186–190. ISBN 9780123849533. [Google Scholar]

- Abeyrathne, E.D.N.S.; Nam, K.; Ahn, D.U. Analytical Methods for Lipid Oxidation and Antioxidant Capacity in Food Systems. Antioxidants 2021, 10, 1587. [Google Scholar] [CrossRef]

- Irwin, J.W.; Hedges, N. Measuring Lipid Oxidation. In Understanding and Measuring the Shelf-Life of Food; Steele, R., Ed.; Woodhead Publishing: Cambridge, UK, 2004; pp. 289–316. ISBN 978-1-85573-732-7. [Google Scholar]

- Cai, M.; Zhang, G.; Wang, J.; Li, C.; Cui, H.; Lin, L. Application of Glycyrrhiza Polysaccharide Nanofibers Loaded with Tea Tree Essential Oil/ Gliadin Nanoparticles in Meat Preservation. Food Biosci. 2021, 43, 101270. [Google Scholar] [CrossRef]

- Fuentes, V.; Ventanas, J.; Morcuende, D.; Estévez, M.; Ventanas, S. Lipid and Protein Oxidation and Sensory Properties of Vacuum-Packaged Dry-Cured Ham Subjected to High Hydrostatic Pressure. Meat Sci. 2010, 85, 506–514. [Google Scholar] [CrossRef]

- Estévez, M. Protein Carbonyls in Meat Systems: A Review. Meat Sci. 2011, 89, 259–279. [Google Scholar] [CrossRef]

- Soladoye, O.P.; Juárez, M.L.; Aalhus, J.L.; Shand, P.; Estévez, M. Protein Oxidation in Processed Meat: Mechanisms and Potential Implications on Human Health. Compr. Rev. Food Sci. Food Saf. 2015, 14, 106–122. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Munekata, P.E.S.; Zhang, W.; Garcia-Oliveira, P.; Carpena, M.; Prieto, M.A.; Bohrer, B.; Lorenzo, J.M. Protein Oxidation in Muscle Foods: A Comprehensive Review. Antioxidants 2022, 11, 60. [Google Scholar] [CrossRef] [PubMed]

- Grón, I.U. Antioxidants. In Ingredients in Meat Products; Tarté, R., Ed.; Springer: New York, NY, USA, 2009; pp. 291–300. [Google Scholar] [CrossRef]

- Eshamah, H.L.; Naas, H.T.; Garbaj, A.M.; Azwai, S.M.; Gammoudi, F.T.; Barbieri, I.; Eldaghayes, I.M. Extent of Pathogenic and Spoilage Microorganisms in Whole Muscle Meat, Meat Products and Seafood Sold in Libyan Market. Open Vet. J. 2020, 10, 276–288. [Google Scholar] [CrossRef] [PubMed]

- Hee Yu, H.; Chin, Y.-W.; Paik, H.-D.; Prieto Benavides, N.; Manuel Lorenzo Rodriguez, J. Application of Natural Preservatives for Meat and Meat Products against Food-Borne Pathogens and Spoilage Bacteria: A Review. Foods 2021, 10, 2418. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Ochoa, L.; Aguirre-Prieto, Y.B.; Nevárez-Moorillón, G.V.; Gutierrez-Mendez, N.; Salas-Muñoz, E. Use of Essential Oils and Extracts from Spices in Meat Protection. J. Food Sci. Technol. 2014, 51, 957–963. [Google Scholar] [CrossRef][Green Version]

- Simpson, C.A.; Sofos, J.N. Antimicrobial Ingredients. Ingredients Meat Prod. Prop. Funct. Appl. 2009, 301–377. [Google Scholar] [CrossRef]

- James, S.J.; James, C. Meat Refrigeration; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9781855734425. [Google Scholar]

- Cunha, L.C.M.; Monteiro, M.L.G.; Lorenzo, J.M.; Munekata, P.E.S.; Muchenje, V.; de Carvalho, F.A.L.; Conte-Junior, C.A. Natural Antioxidants in Processing and Storage Stability of Sheep and Goat Meat Products. Food Res. Int. 2018, 111, 379–390. [Google Scholar] [CrossRef]

- U.S Food & Drug Administration Food Additive Status List. Available online: https://www.fda.gov/food/food-additives-petitions/food-additive-status-list (accessed on 19 January 2022).

- Pateiro, M.; Barba, F.J.; Domínguez, R.; Sant’Ana, A.S.; Mousavi Khaneghah, A.; Gavahian, M.; Gómez, B.; Lorenzo, J.M. Essential Oils as Natural Additives to Prevent Oxidation Reactions in Meat and Meat Products: A Review. Food Res. Int. 2018, 113, 156–166. [Google Scholar] [CrossRef]

- Horbańczuk, O.K.; Jóźwik, A.; Wyrwisz, J.; Marchewka, J.; Atanasov, A.G.; Wierzbicka, A. The Activity of Chosen Antioxidant Enzymes in Ostrich Meat in Relation to the Type of Packaging and Storage Time in Refrigeration. Biomolecules 2021, 11, 1338. [Google Scholar] [CrossRef]

- Mukurumbira, A.R.; Shellie, R.A.; Keast, R.; Palombo, E.A.; Jadhav, S.R. Encapsulation of Essential Oils and Their Application in Antimicrobial Active Packaging. Food Control 2022, 136, 108883. [Google Scholar] [CrossRef]

- Ornaghi, M.G.; Guerrero, A.; Vital, A.C.P.; de Souza, K.A.; Passetti, R.A.C.; Mottin, C.; de Araújo Castilho, R.; Sañudo, C.; do Prado, I.N. Improvements in the Quality of Meat from Beef Cattle Fed Natural Additives. Meat Sci. 2020, 163, 108059. [Google Scholar] [CrossRef] [PubMed]

- Ripolles-Avila, C.; García-Hernández, N.; Cervantes-Huamán, B.H.; Mazaheri, T.; Rodríguez-Jerez, J.J. Quantitative and Compositional Study of Monospecies Biofilms of Spoilage Microorganisms in the Meat Industry and Their Interaction in the Development of Multispecies Biofilms. Microorganisms 2019, 7, 655. [Google Scholar] [CrossRef] [PubMed]

- Chemat, F.; Abert Vian, M.; Fabiano-Tixier, A.S.; Nutrizio, M.; Režek Jambrak, A.; Munekata, P.E.S.; Lorenzo, J.M.; Barba, F.J.; Binello, A.; Cravotto, G. A Review of Sustainable and Intensified Techniques for Extraction of Food and Natural Products. Green Chem. 2020, 22, 2325–2353. [Google Scholar] [CrossRef]

- Lauková, A. Using Natural and Novel Antimicrobials to Improve the Safety and Shelf-Life Stability of Processed Meat Products. In Processed Meats: Improving Safety, Nutrition and Quality; Elsevier Ltd.: Amsterdam, The Netherlands, 2011; pp. 299–330. ISBN 9781845694661. [Google Scholar]

- Pateiro, M.; Munekata, P.E.S.; Sant’ana, A.S.; Domínguez, R.; Rodríguez-Lázaro, D.; Lorenzo, J.M. Application of Essential Oils as Antimicrobial Agents against Spoilage and Pathogenic Microorganisms in Meat Products. Int. J. Food Microbiol. 2021, 337, 108966. [Google Scholar] [CrossRef]

- Ju, J.; Xie, Y.; Yu, H.; Guo, Y.; Cheng, Y.; Qian, H.; Yao, W. Synergistic Interactions of Plant Essential Oils with Antimicrobial Agents: A New Antimicrobial Therapy. Crit. Rev. Food Sci. Nutr. 2020, 62, 1740–1751. [Google Scholar] [CrossRef] [PubMed]

- Dutra Da Silva, B.; Campos Bernardes, P.; Fontes Pinheiro, P.; Fantuzzi, E.; Roberto, C.D. Chemical Composition, Extraction Sources and Action Mechanisms of Essential Oils: Natural Preservative and Limitations of Use in Meat Products. Meat Sci. 2021, 176, 108463. [Google Scholar] [CrossRef] [PubMed]

- Hayes, J.; Brunton, N. The Use of Nutraceuticals in Processed Meat Products and Their Effects on Product Quality, Safety and Acceptability. In Processed Meats: Improving Safety, Nutrition and Quality; Elsevier Ltd.: Amsterdam, The Netherlands, 2011; pp. 372–402. ISBN 9781845694661. [Google Scholar]

- Dutra Da Silva, B.; do Rosário, D.K.A.; Weitz, D.A.; Conte-Junior, C.A. Essential Oil Nanoemulsions: Properties, Development, and Application in Meat and Meat Products. Trends Food Sci. Technol. 2022, 121, 1–13. [Google Scholar] [CrossRef]

- Sabliov, C.M.; Chen, H.; Yada, R.Y. (Eds.) Nanotechnology and Functional Foods: Effective Delivery of Bioactive Ingredients; Wiley & Sons, Ltd.: Chichester, UK, 2015; pp. 1–388. [Google Scholar] [CrossRef]

- Romero, G.; Moya, S.E. Synthesis of Organic Nanoparticles. Front. Nanosci. 2012, 4, 115–141. [Google Scholar] [CrossRef]

- González-Reza, R.M.; Zambrano-Zaragoza, M.L.; Hernández-Sánchez, H. Polymeric Nanoparticles in Foods. In Nanotechnology in the Life Sciences; Springer Science and Business Media B.V.: New York, NY, USA, 2019; pp. 217–233. [Google Scholar]

- Haider, A.; Haider, S.; Kang, I.K. A Comprehensive Review Summarizing the Effect of Electrospinning Parameters and Potential Applications of Nanofibers in Biomedical and Biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Soleimanian, Y.; Goli, S.A.H.; Shirvani, A.; Elmizadeh, A.; Marangoni, A.G. Wax-Based Delivery Systems: Preparation, Characterization, and Food Applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2994–3030. [Google Scholar] [CrossRef]

- Crucho, C.I.C.C.; Barros, M.T. Polymeric Nanoparticles: A Study on the Preparation Variables and Characterization Methods. Mater. Sci. Eng. C 2017, 80, 771–784. [Google Scholar] [CrossRef] [PubMed]

- The European Commmision EUR-Lex-32011H0696-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32011H0696 (accessed on 19 January 2022).

- Ranjan, S.; Dasgupta, N.; Lichtfouse, E. Sustainable Agriculture Reviews 20 Nanoscience in Food and Agriculture 1; Sustainable Agriculture Reviews; Ranjan, S., Dasgupta, N., Lichtfouse, E., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 20, ISBN 9783319393056. [Google Scholar]

- Martínez Rivas, C.J.; Tarhini, M.; Badri, W.; Miladi, K.; Greige-Gerges, H.; Nazari, Q.A.; Galindo Rodríguez, S.A.; Román, R.Á.; Fessi, H.; Elaissari, A. Nanoprecipitation Process: From Encapsulation to Drug Delivery. Int. J. Pharm. 2017, 532, 66–81. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ghazanfari, S.; Davood Sharifi, S. Comparative Effects of Dietary Organic, Inorganic, and Nano-Selenium Complexes and Rosemary Essential Oil on Performance, Meat Quality and Selenium Deposition in Muscles of Broiler Chickens. Livest. Sci. 2019, 226, 21–30. [Google Scholar] [CrossRef]

- Belluco, S.; Gallocchio, F.; Losasso, C.; Ricci, A. State of Art of Nanotechnology Applications in the Meat Chain: A Qualitative Synthesis. Crit. Rev. Food Sci. Nutr. 2018, 58, 1084–1096. [Google Scholar] [CrossRef] [PubMed]

- Moradi, M.; Razavi, R.; Khalid Omer, A.; Farhangfar, A.; Mcclements, D.J. Interactions between Nanoparticle-Based Food Additives and Other Food Ingredients: A Review of Current Knowledge. Trends Food Sci. Technol. 2022, 120, 75–87. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, A.; Wang, W.; Ye, R.; Liu, Y.; Xiao, J.; Wang, K. Characterisation of Microemulsion Nanofilms Based on Tilapia Fish Skin Gelatine and ZnO Nanoparticles Incorporated with Ginger Essential Oil: Meat Packaging Application. Int. J. Food Sci. Technol. 2017, 52, 1670–1679. [Google Scholar] [CrossRef]

- Sani, I.K.; Geshlaghi, S.P.; Pirsa, S.; Asdagh, A. Composite Film Based on Potato Starch/Apple Peel Pectin/ZrO2 Nanoparticles/ Microencapsulated Zataria Multiflora Essential Oil; Investigation of Physicochemical Properties and Use in Quail Meat Packaging. Food Hydrocoll. 2021, 117, 106719. [Google Scholar] [CrossRef]

- Ahmed, J.; Arfat, Y.A.; Bher, A.; Mulla, M.; Jacob, H.; Auras, R. Active Chicken Meat Packaging Based on Polylactide Films and Bimetallic Ag–Cu Nanoparticles and Essential Oil. J. Food Sci. 2018, 83, 1299–1310. [Google Scholar] [CrossRef]

- Sharma, S.; Mulrey, L.; Byrne, M.; Jaiswal, A.K.; Jaiswal, S. Encapsulation of Essential Oils in Nanocarriers for Active Food Packaging. Foods 2022, 11, 2337. [Google Scholar] [CrossRef]

- Zambrano-Zaragoza, M.L.; Quintanar-Guerrero, D.; Mendoza-Muñoz, N.; Leyva-Gómez, G. Nanoemulsions and Nanosized Ingredients for Food Formulations. In Handbook of Food Nanotechnology; Jafari, S.M., Ed.; Academic Press, Elsevier: Chennai, India, 2020; pp. 207–256. [Google Scholar]

- Hojati, N.; Amiri, S.; Radi, M. Effect of Cinnamaldehyde Nanoemulsion on the Microbiological Property of Sausage. J. Food Meas. Charact. 2022, 16, 2478–2485. [Google Scholar] [CrossRef]

- Amiri, E.; Aminzare, M.; Azar, H.H.; Mehrasbi, M.R. Combined Antioxidant and Sensory Effects of Corn Starch Films with Nanoemulsion of Zataria Multiflora Essential Oil Fortified with Cinnamaldehyde on Fresh Ground Beef Patties. Meat Sci. 2019, 153, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Chavoshi, F.; Didar, Z.; Vazifedoost, M.; Shahidi Noghabi, M.; Zendehdel, A. P Syllium Seed Gum Films Loading Oliveria Decumbens Essential Oil Encapsulated in Nanoliposomes: Preparation and Characterization. J. Food Meas. Charact. 2022, 16, 4318–4330. [Google Scholar] [CrossRef]

- Homayounpour, P.; Alizadeh Sani, M.; Shariatifar, N. Application of Nano-Encapsulated Allium Sativum L. Essential Oil to Increase the Shelf Life of Hamburger at Refrigerated Temperature with Analysis of Microbial and Physical Properties. J. Food Process. Preserv. 2021, 45, e15907. [Google Scholar] [CrossRef]

- Taha, M.; EL-Dannasoury, M.; Mahmoud, S.; Moghazy, M. Application of Normal Essential Oil and Loaded-Solid Lipid Nanoparticles as Antioxidant. Al-Azhar J. Agric. Res. 2019, 44, 180–186. [Google Scholar] [CrossRef]

- Sepahvand, S.; Amiri, S.; Radi, M.; Amiri, M.J. Effect of Thymol and Nanostructured Lipid Carriers (NLCs) Incorporated with Thymol as Antimicrobial Agents in Sausage. Sustainability 2022, 14, 1973. [Google Scholar] [CrossRef]

- Rao, J.P.; Geckeler, K.E. Polymer Nanoparticles: Preparation Techniques and Size-Control Parameters. Prog. Polym. Sci. 2011, 36, 887–913. [Google Scholar] [CrossRef]

- Zambrano-zaragoza, M.L.; González-Reza, R.; Mendoza-Muñoz, N.; Miranda-Linares, V.; Bernal-Couoh, T.F.; Mendoza-Elvira, S.; Quintanar-Guerrero, D. Nanosystems in Edible Coatings: A Novel Strategy for Food Preservation. Int. J. Mol. Sci. 2018, 19, 705. [Google Scholar] [CrossRef]

- Boskovic, M.; Glisic, M.; Djordjevic, J.; Vranesevic, J.; Djordjevic, V.; Baltic, M.Z. Preservation of Meat and Meat Products Using Nanoencapsulated Thyme and Oregano Essential Oils. IOP Conf. Ser. Earth Environ. Sci. 2019, 333, 012038. [Google Scholar] [CrossRef]

- Arana-Sánchez, A.; Estarrón-Espinosa, M.; Obledo-Vázquez, E.N.; Padilla-Camberos, E.; Silva-Vázquez, R.; Lugo-Cervantes, E. Antimicrobial and Antioxidant Activities of Mexican Oregano Essential Oils (Lippia graveolens H. B. K.) with Different Composition When Microencapsulated in Beta-Cyclodextrin. Lett. Appl. Microbiol. 2010, 50, 585–590. [Google Scholar] [CrossRef]

- Arkoun, M.; Daigle, F.; Holley, R.A.; Heuzey, M.C.; Ajji, A. Chitosan-Based Nanofibers as Bioactive Meat Packaging Materials. Packag. Technol. Sci. 2018, 31, 185–195. [Google Scholar] [CrossRef]

- Badawy, M.E.I.; Lotfy, T.M.R.; Shawir, S.M.S. Facile Synthesis and Characterizations of Antibacterial and Antioxidant of Chitosan Monoterpene Nanoparticles and Their Applications in Preserving Minced Meat. Int. J. Biol. Macromol. 2020, 156, 127–136. [Google Scholar] [CrossRef] [PubMed]

- Gagaoua, M.; Bhattacharya, T.; Lamri, M.; Oz, F.; Dib, A.L.; Oz, E.; Uysal-Unalan, I.; Tomasevic, I. Green Coating Polymers in Meat Preservation. Coatings 2021, 11, 1379. [Google Scholar] [CrossRef]

- Criado, P.; Fraschini, C.; Salmieri, S.; Lacroix, M. Cellulose Nanocrystals (CNCs) Loaded Alginate Films against Lipid Oxidation of Chicken Breast. Food Res. Int. 2020, 132, 109110. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.P.; Fabi, J.P. Food Biopolymers-Derived Nanogels for Encapsulation and Delivery of Biologically Active Compounds: A Perspective Review. Food Hydrocoll. Heal. 2022, 2, 100079. [Google Scholar] [CrossRef]

- Muthukrishnan, L. Nanonutraceuticals—Challenges and Novel Nano-Based Carriers for Effective Delivery and Enhanced Bioavailability. Food Bioprocess Technol. 2022, 15, 2155–2184. [Google Scholar] [CrossRef]

- Hadian, M.; Rajaei, A.; Mohsenifar, A.; Tabatabaei, M. Encapsulation of Rosmarinus Officinalis Essential Oils in Chitosan-Benzoic Acid Nanogel with Enhanced Antibacterial Activity in Beef Cutlet against Salmonella Typhimurium during Refrigerated Storage. LWT 2017, 84, 394–401. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Cui, H.; Lin, L. Encapsulation Strategies to Enhance the Antibacterial Properties of Essential Oils in Food System. Food Control 2021, 123, 107856. [Google Scholar] [CrossRef]

- Rezaei, A.; Fathi, M.; Jafari, S.M. Nanoencapsulation of Hydrophobic and Low-Soluble Food Bioactive Compounds within Different Nanocarriers. Food Hydrocoll. 2019, 88, 146–162. [Google Scholar] [CrossRef]

- Wang, C.; Wu, L.; Zhang, Y.; Xu, M.; Saldaña, M.D.A.; Fan, X.; Sun, W. A Water-Absorbent Mat Incorporating β-Cyclodextrin/Eugenol Inclusion Complex for Preservation of Cold Fresh Mutton. Food Biophys. 2022, 17, 437–447. [Google Scholar] [CrossRef]

- Cui, H.; Lu, J.; Li, C.; Lin, L. Fabrication of Phospholipid Nanofibers Containing Eugenol@cationic Starch Nanoparticles against Bacillus Cereus in Beef. LWT 2021, 144, 111262. [Google Scholar] [CrossRef]

- Surendhiran, D.; Cui, H.; Lin, L. Encapsulation of Phlorotannin in Alginate/PEO Blended Nanofibers to Preserve Chicken Meat from Salmonella Contaminations. Food Packag. Shelf Life 2019, 21, 100346. [Google Scholar] [CrossRef]

- Sarikurkcu, C.; Zengin, G.; Oskay, M.; Uysal, S.; Ceylan, R.; Aktumsek, A. Composition, Antioxidant, Antimicrobial and Enzyme Inhibition Activities of Two Origanum Vulgare Subspecies (Subsp. vulgare and Subsp. hirtum) Essential Oils. Ind. Crop. Prod. 2015, 70, 178–184. [Google Scholar] [CrossRef]

- Viacava, G.E.; Ayala-Zavala, J.F.; González-Aguilar, G.A.; Ansorena, M.R. Effect of Free and Microencapsulated Thyme Essential Oil on Quality Attributes of Minimally Processed Lettuce. Postharvest Biol. Technol. 2018, 145, 125–133. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L. Fabrication and Characterization of Chitosan Nanoemulsions Loading Thymol or Thyme Essential Oil for the Preservation of Refrigerated Pork. Int. J. Biol. Macromol. 2020, 162, 1509–1515. [Google Scholar] [CrossRef] [PubMed]

- Snoussi, A.; Chouaibi, M.; Ben Haj Koubaier, H.; Bouzouita, N. Encapsulation of Tunisian Thyme Essential Oil in O/W Nanoemulsions: Application for Meat Preservation. Meat Sci. 2022, 188, 108785. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, T.; Liu, L.; Liu, Y.; Wu, X. Impacts of Chitosan Nanoemulsions with Thymol or Thyme Essential Oil on Volatile Compounds and Microbial Diversity of Refrigerated Pork Meat. Meat Sci. 2022, 185, 108706. [Google Scholar] [CrossRef]

- Lin, L.; Zhu, Y.; Cui, H. Electrospun Thyme Essential Oil/Gelatin Nanofibers for Active Packaging against Campylobacter Jejuni in Chicken. LWT 2018, 97, 711–718. [Google Scholar] [CrossRef]

- Ghaderi-Ghahfarokhi, M.; Barzegar, M.; Sahari, M.A.; Azizi, M.H. Nanoencapsulation Approach to Improve Antimicrobial and Antioxidant Activity of Thyme Essential Oil in Beef Burgers During Refrigerated Storage. Food Bioprocess Technol. 2016, 9, 1187–1201. [Google Scholar] [CrossRef]

- Ahmadabadi, L.R.; Hosseini, S.E.; Seyedein Ardebili, S.M.; Mousavi Khaneghah, A. Application of Clove Essential Oil-Loaded Nanoemulsions in Coating of Chicken Fillets. J. Food Meas. Charact. 2022, 16, 819–828. [Google Scholar] [CrossRef]

- Hemmatkhah, F.; Zeynali, F.; Almasi, H. Encapsulated Cumin Seed Essential Oil-Loaded Active Papers: Characterization and Evaluation of the Effect on Quality Attributes of Beef Hamburger. Food Bioprocess Technol. 2020, 13, 533–547. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Liu, T.; Liu, Y.; Wu, X.; Liu, L. Mandarin (Citrus reticulata L.) Essential Oil Incorporated into Chitosan Nanoparticles: Characterization, Anti-Biofilm Properties and Application in Pork Preservation. Int. J. Biol. Macromol. 2021, 185, 620–628. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, X.; Kang, H.; Peng, X. Antimicrobial and Antioxidant Effects of Edible Nanoemulsion Coating Based on Chitosan and Schizonepeta Tenuifolia Essential Oil in Fresh Pork. J. Food Process. Preserv. 2021, 45, e15909. [Google Scholar] [CrossRef]

- Fallah, A.A.; Sarmast, E.; Habibian Dehkordi, S.; Isvand, A.; Dini, H.; Jafari, T.; Soleimani, M.; Mousavi Khaneghah, A. Low-Dose Gamma Irradiation and Pectin Biodegradable Nanocomposite Coating Containing Curcumin Nanoparticles and Ajowan (Carum copticum) Essential Oil Nanoemulsion for Storage of Chilled Lamb Loins. Meat Sci. 2022, 184, 108700. [Google Scholar] [CrossRef] [PubMed]

- Karimi-Dehkordi, M.; Ghaffarnezhad, M.; Mohammadi, F.; Ghirati, M.; Rezaeifar, M.; Rajabi, N.; Alizadeh, O. Whey Protein Coating Incorporated with Essential Oil, Bioactive Peptides and Nanoparticle Extends Shelf-Life of Chicken Breast Slices. J. Food Meas. Charact. 2021, 15, 5266–5276. [Google Scholar] [CrossRef]

| Abbreviation | Meaning |

|---|---|

| BHA | Butylated hydroxyanisole |

| BHT | Butylated hydroxytoluene |

| EDTA | Ethylenediaminetetraacetic acid |

| Eos | Essential oils |

| FDA | U.S. Food and Drug Administration |

| GPx | Glutathione peroxidase |

| GRAS | Generally recognized as safe |

| MDA | Malonaldehyde |

| NLC | Nanostructured lipid carriers |

| PG | Propyl gallate |

| ROS | Reactive oxygen species |

| SLN | Solid lipid nanoparticles |

| SOD | Superoxide dismutase |

| TBARS | Thiobarbituric acid reactive substances |

| TBHQ | Tert-butyl hydroquinone |

| Nanostructure | Polymer Layer | Average Size Distribution (nm) | Product Sample | Results * | Reference |

|---|---|---|---|---|---|

| Nanoparticles | Chitosan | Not reported | Fresh pork | After 12 days of storage (4 °C) ≥20% TBARS ≥20% Pseudomonas | [89] |

| Nanofibers | β-cyclodextrin-ε-polylysine nanoparticles and gelatin nanofiber | 206.2 | Fresh chicken | After 6 days of storage (4 °C) 4% aerobic bacteria count ≥ 20% TBARS | [90] |

| Nanoparticles | Chitosan | 121.03 | Beef patties | After 8 days of storage (4 °C) ≥40% enterobacteriaceae ≥25% mesophilic ≥68% Staphylococcus aureus ≥67% yeast and mold ≥84% TBARS | [91] |

| Nanostructures | Polymer | Essential Oil | Active Compound | Particle Size (nm) | Product Sample | Results * | Ref. |

| Nanoparticle | Chitosan | Mandarin (Citrus reticulata) | (−) limonene (78.89%) and γ-terpinene (14.56%) | 161.9 | Fresh pork fillets | After 6 days of storage (4 °C) ≥25% TVC bacteria | [94] |

| Nanoemulsion | Chitosan | (Schizonepeta tenuifolia) | Not reported | 92.3 | Fresh pork slices | After 16 days of storage (4 °C) 1.94 Pseudomonas spp. log cycles 1.87 Enterobacteriaceae log cycles, 50% TBARS | [95] |

| Nanoparticles Nanoemulsion | Pectin | Curcuma (Curcuma longa) & Ajowan (Carum copticum) | 7-bis(4-hydroxy-3-methoxy-phenyl)-1,6-heptadiene-3,5-dione Thymol (59.8%) and γ-terpinene (18.9%) | 10 nm curcuma nanoparticle (CNP) 90.23 nm | Lamb loins | 25 days of storage (4 °C) Total mesophilic bacteria: ≥25% CNP, ANE ≥35% mixture (CNP & ANE) Total psychotropic bacteria: ≥30% CNP, ANE ≥40% mixture (CNP & ANE) Enterobacteriaceae: ≥35% CNP, ANE ≥50% mixture (CNP & ANE) TBARS: ≥37% CNP, ANE ≥60% mixture (CNP & ANE) | [96] |

| Nanoparticles | Whey protein | Aloysia citrodora (geranial 28.32%, limonene 12.59% and arcurcumene 8.63%) | Not reported | Chicken breast slices | After 12 days of storage (4 °C) ≥45% TBAR; ≥20% Mesophilic bacteria; ≥15% Psychotropic bacteria ≥13% Pseudomonas ssp. | [97] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ojeda-Piedra, S.A.; Zambrano-Zaragoza, M.L.; González-Reza, R.M.; García-Betanzos, C.I.; Real-Sandoval, S.A.; Quintanar-Guerrero, D. Nano-Encapsulated Essential Oils as a Preservation Strategy for Meat and Meat Products Storage. Molecules 2022, 27, 8187. https://doi.org/10.3390/molecules27238187

Ojeda-Piedra SA, Zambrano-Zaragoza ML, González-Reza RM, García-Betanzos CI, Real-Sandoval SA, Quintanar-Guerrero D. Nano-Encapsulated Essential Oils as a Preservation Strategy for Meat and Meat Products Storage. Molecules. 2022; 27(23):8187. https://doi.org/10.3390/molecules27238187

Chicago/Turabian StyleOjeda-Piedra, Sergio A., María L. Zambrano-Zaragoza, Ricardo M. González-Reza, Claudia I. García-Betanzos, Samantha A. Real-Sandoval, and David Quintanar-Guerrero. 2022. "Nano-Encapsulated Essential Oils as a Preservation Strategy for Meat and Meat Products Storage" Molecules 27, no. 23: 8187. https://doi.org/10.3390/molecules27238187

APA StyleOjeda-Piedra, S. A., Zambrano-Zaragoza, M. L., González-Reza, R. M., García-Betanzos, C. I., Real-Sandoval, S. A., & Quintanar-Guerrero, D. (2022). Nano-Encapsulated Essential Oils as a Preservation Strategy for Meat and Meat Products Storage. Molecules, 27(23), 8187. https://doi.org/10.3390/molecules27238187