Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg

Abstract

1. Introduction

2. Results and Discussion

2.1. Effect of Grinding Process and Storage Time on Antioxidant Properties of Ginger Rhizome and Nutmeg

2.2. Model Fitting and Data Analysis Using Response Surface Methodology

2.3. Analysis of Response Surfaces

2.4. Verification of the Optimal Extraction Models

2.5. Composition of Phenolic Acids in Ginger Rhizome and Nutmeg Extracts Obtained Using Optimal Grinding Parameters and Storage Time

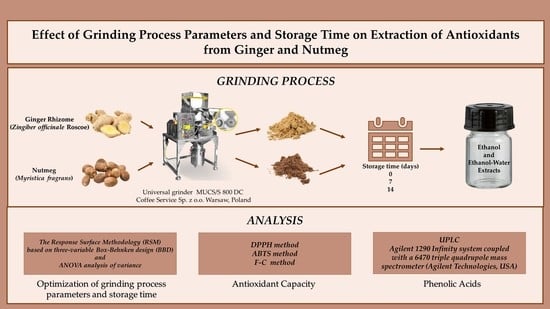

3. Materials and Methods

3.1. Materials

3.2. Grinding Process and Storage Conditions

3.3. Preparation of Ethanol and Ethanol-Water Extracts

3.4. Antioxidant Properties Determination

3.5. Experimental Design and Mathematical Model

3.6. Determination of Phenolic Acids

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saul, H.; Madella, M.; Fisher, A.; Glykou, A.; Hartz, S.; Craig, O.E. Phytoliths in pottery reveal the use of spice in European prehistoric cuisine. PLoS ONE 2013, 8, e70583. [Google Scholar] [CrossRef]

- Van der Veen, M.; Morales, J. The Roman and Islamic spice trade: New archaeological evidence. J. Ethnopharmacol. 2015, 167, 54–63. [Google Scholar] [CrossRef]

- Sachan, A.K.; Kumar, S.; Kumari, K.; Singh, D. Medicinal uses of spices used in our traditional culture: World wide. J. Med. Plants Stud. 2018, 6, 116–122. [Google Scholar]

- Tapsel, L.C.; Hemphill, I.; Cobiac, L.; Patch, C.S.; Sullivan, D.R.; Fenech, M.; Roodenrys, S.; Keogh, J.B.; Clifton, P.M.; Williams, P.G.; et al. Health benefits of herbs and spices: The past, the present, the future. Med. J. Aust. 2016, 185, 4–24. [Google Scholar] [CrossRef]

- Natheer, S.E. Antimicrobial and biochemical analysis of some spices extract against food spoilage pathogens. J. Food Saf. 2010, 12, 71–75. [Google Scholar]

- Mishra, R.K.; Kumar, A.; Kumar, A. Pharmacological activity of Zingiber officinale. Int. J. Pharm. Chem. Sci. 2012, 1, 1073–1078. [Google Scholar]

- Li, H.; Liu, Y.; Luo, D.; Ma, Y.; Zhang, J.; Li, M.; Yao, L.; Shi, X.; Liu, X.; Yang, K. Ginger for health care: An overview of systematic reviews. Complement. Ther. Med. 2019, 45, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, K. Ginger rhizomes (Zingiber officinale): A spice with multiple healthy beneficial potentials. PharmaNutrition 2017, 5, 18–28. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, Y. Comparative antibacterial activities of extracts of dried ginger and processed ginger. Pharmacog. J. 2010, 2, 41–44. [Google Scholar] [CrossRef]

- Malu, S.P.; Obochi, G.O.; Tawo, E.N.; Nyong, B.E. Antibacterial activity and medicinal properties of ginger (Zingiber officinale). Glob. J. Pure Appl. Math. 2009, 15, 365–368. [Google Scholar] [CrossRef][Green Version]

- Ghafoor, K.; Al Juhaimi, F.; Özcan, M.M.; Uslu, N.; Babiker, E.E.; Mohamed Ahmed, I.A. Total phenolics, total carotenoids, individual phenolics and antioxidant activity of ginger (Zingiber officinale) rhizome as affected by drying methods. LWT-Food Sci. Technol. 2020, 126, 109354. [Google Scholar] [CrossRef]

- Jelled, A.; Fernandes, Â.; Barros, L.; Chahdoura, H.; Achour, L.; Ferreira, I.C.F.R.; Cheikh, H.B. Chemical and antioxidant parameters of dried forms of ginger rhizomes. Ind. Crops Prod. 2015, 77, 30–35. [Google Scholar] [CrossRef]

- Idris, N.A.; Yasin, H.M.; Usman, A. Voltammetric and spectroscopic determination of polyphenols and antioxidants in ginger (Zingiber officinale Roscoe). Heliyon 2019, 5, e01717. [Google Scholar] [CrossRef]

- Akbar, S. Myristica fragrans Houtt. (Myristicaceae). In Handbook of 200 Medicinal Plants; Springer: Cham, Switzerland, 2020; pp. 1239–1249. [Google Scholar] [CrossRef]

- Agbogidi, O.M.; Azagbaekwe, O.P. Health and nutritional benefits of nutmeg (Mystica fragrans Houtt.). Sci. Agric. 2013, 1, 40–44. [Google Scholar]

- Tajuddin; Ahmad, S.; Latif, A.; Qasmi, I.A.; Amin, K.M.Y. An experimental study of sexual function improving effect of Myristica fragrans Houtt. (nutmeg). BMC Complement. Med. Ther. 2005, 5, 16. [Google Scholar] [CrossRef]

- Ehrenpreis, J.E.; DesLauriers, C.; Lank, P.; Armstrong, P.K.; Leikin, J.B. Nutmeg poisonings: A retrospective review of 10 years experience from the Illinois Poison Center, 2001–2011. J. Med. Toxicol. 2014, 10, 148–151. [Google Scholar] [CrossRef]

- Stein, U.; Greyer, H.; Hentschel, H. Nutmeg (myristicin) poisoning—Report on a fatal case and a series of cases recorded by a poison information centre. Forensic Sci. Int. 2001, 118, 87–90. [Google Scholar] [CrossRef]

- Sangalli, B.C.; Chiang, W. Toxicology of nutmeg abuse. J. Toxicol. Clin. Toxicol. 2000, 38, 671–678. [Google Scholar] [CrossRef]

- Beckerman, B.; Persaud, H. Nutmeg overdose: Spice not so nice. Complement. Ther. Med. 2019, 46, 44–46. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Fazilah, A.; Effarizah, M.E. Toxicity of nutmeg (Myristicin): A Review. Int. J. Adv. Sci. Eng. Inf. Technol. 2015, 5, 61–64. [Google Scholar] [CrossRef]

- Takikawa, A.; Abe, K.; Yamamoto, M.; Ishimaru, S.; Yasui, M.; Okubo, Y.; Yokoigawa, K. Antimicrobial activity of nutmeg against Escherichia coli O157. J. Biosci. Bioeng. 2002, 94, 315–320. [Google Scholar] [CrossRef]

- Narasimhan, B.; Dhake, A.S. Antibacterial principles from Myristica fragrans seeds. J. Med. Food 2006, 9, 395–399. [Google Scholar] [CrossRef]

- Gao, W.; Chen, F.; Wang, X.; Meng, Q. Recent advances in processing food powders by using superfine grinding techniques: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2222–2255. [Google Scholar] [CrossRef]

- Archana; Aman, A.K.; Singh, R.K.; Kr, N.; Jabeen, A. Effect of superfine grinding on structural, morphological and antioxidant properties of ginger (Zingiberofficinale) nano crystalline food powder. Mater. Today Proc. 2021, 43, 3397–3403. [Google Scholar] [CrossRef]

- McKee, L.H.; Thompson, L.D.; Harden, M.L. Effect of three grinding methods on some properties of nutmeg. LWT Food Sci. Technol. 1993, 26, 121–125. [Google Scholar] [CrossRef]

- Formoso, P.; Tundis, R.; Pellegrino, M.C.; Leporini, M.; Sicari, V.; Romeo, R.; Gervasi, L.; Corrente, G.A.; Beneduci, A.; Loizzo, M.R. Preparation, characterization, and bioactivity of Zingiber officinale Roscoe powder-based Pickering emulsions. J. Sci. Food Agric. 2022, 102, 6566–6577. [Google Scholar] [CrossRef]

- Özcan, M.M. The effect of ginger (Zingiber officinale) powders at different concentrations on bioactive compounds, antioxidant activity, phenolic constituents, nutrients and sensory characteristics of wheat bread. Int. J. Gastron. Food Sci. 2022, 28, 100532. [Google Scholar] [CrossRef]

- Mancini, S.; Paci, G.; Dal Bosco, A.; Mattioli, S.; Preziuso, G. Effect of ginger powder addition on quality, fatty acids profile, lipid oxidation and antioxidant capacity of cooked pork burgers. Eur. Food Res. Technol. 2019, 245, 1377–1386. [Google Scholar] [CrossRef]

- Barnwal, P.; Mohite, A.; Singh, K.K.; Kumar, P.; Zachariah, T.J.; Saxena, S.N. Effect of cryogenic and ambient grinding on grinding characteristics of cinnamon and turmeric. Int. J. Seed Spices 2014, 4, 26–31. [Google Scholar]

- Makanjuola, S.A. Influence of particle size and extraction solvent on antioxidant properties of extracts of tea, ginger, and tea–ginger blend. Food Sci. Nutr. 2017, 5, 1179–1185. [Google Scholar] [CrossRef]

- De Luna, S.L.R.; Ramirez-Garza, R.E.; Serna Saldivar, S.O. Environmentally friendly methods for flavonoid extraction from plant material: Impact of their operating conditions on yield and antioxidant properties. Sci. World J. 2020, 2020, 6792069. [Google Scholar] [CrossRef]

- Yeretzian, C.; Pascual, E.C.; Goodman, B.A. Effect of roasting conditions and grinding on free radical contents of coffee beans stored in air. Food Chem. 2012, 131, 811–816. [Google Scholar] [CrossRef]

- Ghasemzadeh, A.; Jaafar, H.Z.; Rahmat, A. Changes in antioxidant and antibacterial activities as well as phytochemical constituents associated with ginger storage and polyphenol oxidase activity. BMC Complement. Altern. Med. 2016, 16, 382. [Google Scholar] [CrossRef]

- Maizura, M.; Aminah, A.; Wan Aida, W.M. Total phenolic content and antioxidant activity of kesum (Polygonum minus), ginger (Zingiber officinale) and turmeric (Curcuma longa) extract. Int. Food Res. J. 2011, 18, 526–531. [Google Scholar]

- Baker, I.; Chohan, M.; Opara, E.I. Impact of cooking and digestion, in vitro, on the antioxidant capacity and anti-inflammatory activity of cinnamon, clove and nutmeg. Plant Foods Hum. Nutr. 2013, 68, 364–369. [Google Scholar] [CrossRef]

- Al Jumayi, H.A.; Allam, A.Y.; El-Beltagy, A.E.-D.; Algarni, E.H.; Mahmoud, S.F.; El Halim Kandil, A.A. Bioactive compound, antioxidant, and radical scavenging activity of some plant aqueous extracts for enhancing shelf life of cold-stored rabbit meat. Antioxidants 2022, 11, 1056. [Google Scholar] [CrossRef]

- Gupta, A.D.; Bansal, V.K.; Babu, V.; Maithil, N. Chemistry, antioxidant and, antimicrobial potential of nutmeg (Myristica fragrans Houtt). J. Genet. Eng. Biotechnol. 2013, 11, 25–31. [Google Scholar] [CrossRef]

- Su, L.; Yin, J.; Charles, D.; Zhou, K.; Moore, J.; Yu, L. Total phenolic contents, chelating capacities, and radical-scavenging properties of black peppercorn, nutmeg, rosehip, cinnamon and oregano leaf. Food Chem. 2007, 100, 990–997. [Google Scholar] [CrossRef]

- Ghasemzadeh, A.; Jaafar, H.Z.E.; Rahmat, A. Antioxidant activities, total phenolics and flavonoids content in two varieties of Malaysia young ginger (Zingiber officinale Roscoe). Molecules 2010, 15, 4324–4333. [Google Scholar] [CrossRef]

- Apak, R.; Özyürek, M.; Güçlü, K.; Çapanoğlu, E. Antioxidant activity/capacity measurement. 2. Hydrogen atom transfer (HAT)-based, mixed-mode (electron transfer (ET)/HAT), and lipid peroxidation assays. J. Agric. Food Chem. 2016, 64, 1028–1045. [Google Scholar] [CrossRef]

- Szydłowska-Czerniak, A.; Poliński, S.; Momot, M. Optimization of ingredients for biscuits enriched with rapeseed press cake—Changes in their antioxidant and sensory properties. Appl. Sci. 2021, 11, 1558. [Google Scholar] [CrossRef]

- Tohma, H.; Gülçin, İ.; Bursal, E.; Gören, A.C.; Alwasel, S.H.; Köksal, E. Antioxidant activity and phenolic compounds of ginger (Zingiber officinale Rosc.) determined by HPLC-MS/MS. J. Food Meas. Charact. 2017, 11, 556–566. [Google Scholar] [CrossRef]

- Muzolf-Panek, M.; Stuper-Szablewska, K. Comprehensive study on the antioxidant capacity and phenolic profiles of black seed and other spices and herbs: Effect of solvent and time of extraction. J. Food Meas. Charact. 2021, 15, 4561–4574. [Google Scholar] [CrossRef]

- Poliński, S.; Topka, P.; Tańska, M.; Kowalska, S.; Czaplicki, S.; Szydłowska-Czerniak, A. Impact of bioactive compounds of plant leaf powders in white chocolate production: Changes in antioxidant properties during the technological processes. Antioxidants 2022, 11, 752. [Google Scholar] [CrossRef]

| Exp. | Independent Variables | Dependent Variables | |||||||

|---|---|---|---|---|---|---|---|---|---|

| X1 (mm) | X2 (Hz) | X3 (Days) | DPPH Method (mmol TE/100 g) | ABTS Method (mmol TE/100 g) | F–C Method (mg GA/100 g) | ||||

| Experimental | Predicted | Experimental | Predicted | Experimental | Predicted | ||||

| Extraction with Ethanol | |||||||||

| 1 | 2.0 (1) | 40 (0) | 0 (−1) | 22.5 ± 0.1 a | 22.3 | 95.3 ± 1.9 a | 92.4 | 153.9 ± 3.2 b,c | 149.6 |

| 2 | 2.0 (1) | 40 (0) | 14 (1) | 29.6 ± 0.3 c | 29.4 | 157.3 ± 2.8 b | 154.4 | 151.5 ± 2.4 a,b | 147.2 |

| 3 | 2.0 (1) | 50 (1) | 7 (0) | 42.2 ± 0.9 f | 42.5 | 229.1 ± 0.9 g | 232.0 | 162.7 ± 1.6 c,d | 167.0 |

| 4 | 2.0 (1) | 30 (−1) | 7 (0) | 38.5 ± 0.2 e | 38.8 | 198.2 ± 0.9 d,e | 201.1 | 202.7 ± 1.9 f | 207.0 |

| 5 | 1.4 (0) | 50 (1) | 0 (−1) | 23.1 ± 0.5 a | 23.1 | 96.9 ± 2.3 a | 96.9 | 278.5 ± 1.5 g | 278.5 |

| 6 | 1.4 (0) | 50 (1) | 14 (1) | 37.6 ± 0.6 e | 37.6 | 184.0 ± 4.0 c | 184.0 | 178.5 ± 2.6 e | 178.5 |

| 7 | 1.4 (0) | 30 (−1) | 0 (−1) | 26.9 ± 0.3 b | 26.9 | 196.0 ± 2.0 d | 196.0 | 165.3 ± 2.8 d | 165.3 |

| 8 | 1.4 (0) | 30 (−1) | 14 (1) | 33.1 ± 0.3 d | 33.1 | 262.0 ± 2.0 h | 262.0 | 152.9 ± 2.6 a,b | 152.9 |

| 9 | 1.4 (0) | 40 (0) | 7 (0) | 31.9 ± 0.6 d | 28.8 | 209.5 ± 1.6 f | 197.9 | 355.9 ± 4.8 h,i | 355.8 |

| 10 | 1.0 (−1) | 40 (0) | 0 (−1) | 86.4 ± 0.7 g | 86.7 | 378.0 ± 8.0 j | 380.9 | 383.3 ± 4.1 j | 387.6 |

| 11 | 1.0 (−1) | 40 (0) | 14 (1) | 95.0 ± 1.2 h | 95.3 | 308.0 ± 5.0 i | 310.9 | 464.1 ± 4.0 l | 468.4 |

| 12 | 1.0 (−1) | 50 (1) | 7 (0) | 99.0 ± 1.2 i | 98.8 | 430.0 ± 5.0 k | 427.1 | 507.4 ± 11.5 m | 503.1 |

| 13 | 1.0 (−1) | 30 (−1) | 7 (0) | 113.0 ± 2.0 j | 112.8 | 454.0 ± 9.0 l | 451.1 | 434.5 ± 2.7 k | 430.2 |

| 14 | 1.4 (0) | 40 (0) | 7 (0) | 29.4 ± 0.5 c | 28.8 | 206.1 ± 1.9 e,f | 197.9 | 348.0 ± 3.2 h | 355.8 |

| 15 | 1.4 (0) | 40 (0) | 7 (0) | 25.2 ± 0.2 b | 28.8 | 178.0 ± 4.0 c | 197.9 | 363.4 ± 4.4 i | 355.8 |

| Extraction with Ethanol-Water | |||||||||

| 1 | 2.0 (1) | 40 (0) | 0 (−1) | 52.9 ± 1.3 c | 45.6 | 99.3 ± 1.0 b | 79.3 | 146.5 ± 2.0 b | 131.0 |

| 2 | 2.0 (1) | 40 (0) | 14 (1) | 67.1 ± 0.9 d | 59.8 | 108.6 ± 1.7 b | 88.6 | 158.6 ± 2.9 c | 143.1 |

| 3 | 2.0 (1) | 50 (1) | 7 (0) | 43.6 ± 0.9 b | 50.9 | 127.0 ± 2.8 c | 147.0 | 228.0 ± 2.4 g | 243.6 |

| 4 | 2.0 (1) | 30 (−1) | 7 (0) | 26.4 ± 0.6 a | 33.7 | 101.9 ± 2.5 b | 121.9 | 211.6 ± 1.8 f | 227.2 |

| 5 | 1.4 (0) | 50 (1) | 0 (−1) | 85.9 ± 1.8 f | 85.9 | 171.0 ± 4.1 e | 171.0 | 199.8 ± 2.8 e | 199.8 |

| 6 | 1.4 (0) | 50 (1) | 14 (1) | 189.9 ± 2.6 m | 189.9 | 284.8 ± 2.7 f | 284.8 | 181.1 ± 3.0 d | 181.1 |

| 7 | 1.4 (0) | 30 (−1) | 0 (−1) | 54.0 ± 0.2 c | 54.0 | 80.4 ± 1.3 a | 80.4 | 81.0 ± 1.2 a | 81.0 |

| 8 | 1.4 (0) | 30 (−1) | 14 (1) | 112.6 ± 4.7 h | 112.6 | 125.3 ± 2.3 c | 125.3 | 185.1 ± 2.2 d | 185.1 |

| 9 | 1.4 (0) | 40 (0) | 7 (0) | 120.4 ± 0.9 i | 122.4 | 145.7 ± 1.8 d | 130.4 | 215.1 ± 1.6 f | 225.8 |

| 10 | 1.0 (−1) | 40 (0) | 0 (−1) | 171.2 ± 3.7 l | 178.5 | 321.3 ± 6.6 g | 341.3 | 332.6 ± 2.8 i | 348.2 |

| 11 | 1.0 (−1) | 40 (0) | 14 (1) | 78.7 ± 0.9 e | 86.0 | 367.0 ± 5.6 h | 387.0 | 189.0 ± 1.3 d | 204.6 |

| 12 | 1.0 (−1) | 50 (1) | 7 (0) | 166.0 ± 0.7 k | 158.7 | 429.3 ± 7.7 i | 409.3 | 390.2 ± 8.1 j | 374.7 |

| 13 | 1.0 (−1) | 30 (−1) | 7 (0) | 92.6 ± 1.8 g | 85.3 | 440.0 ± 9.2 j | 420.0 | 390.3 ± 8.7 j | 374.8 |

| 14 | 1.4 (0) | 40 (0) | 7 (0) | 118.8 ± 1.8 i | 122.4 | 120.9 ± 2.2 c | 130.4 | 210.2 ± 4.0 f | 225.8 |

| 15 | 1.4 (0) | 40 (0) | 7 (0) | 128.0 ± 2.1 j | 122.4 | 124.5 ± 3.0 c | 130.4 | 252.2 ± 4.4 h | 225.8 |

| Exp. | Independent Variables | Dependent Variables | |||||||

|---|---|---|---|---|---|---|---|---|---|

| X1 (mm) | X2 (Hz) | X3 (Days) | DPPH Method (mmol TE/100 g) | ABTS Method (mmol TE/100 g) | F–C Method (mg GA/100 g) | ||||

| Experimental | Predicted | Experimental | Predicted | Experimental | Predicted | ||||

| Extraction with Ethanol | |||||||||

| 1 | 2.0 (1) | 40 (0) | 0 (−1) | 29.8 ± 0.6 a | 7.4 | 71.9 ± 1.2 a | 66.7 | 125.9 ± 2.4 a | 163.8 |

| 2 | 2.0 (1) | 40 (0) | 14 (1) | 42.1 ± 1.1 c | 19.7 | 163.0 ± 4.0 c | 157.8 | 191.1 ± 3.7 c | 229.0 |

| 3 | 2.0 (1) | 50 (1) | 7 (0) | 60.7 ± 0.7 e | 83.1 | 206.0 ± 3.0 d | 211.2 | 246.3 ± 2.4 e | 208.4 |

| 4 | 2.0 (1) | 30 (−1) | 7 (0) | 31.1 ± 0.6 a | 53.5 | 62.3 ± 1.5 a | 67.5 | 187.1 ± 3.2 c | 149.2 |

| 5 | 1.4 (0) | 50 (1) | 0 (−1) | 35.3 ± 0.4 b | 35.3 | 143.7 ± 1.1 b | 143.7 | 243.1 ± 3.0 e | 243.1 |

| 6 | 1.4 (0) | 50 (1) | 14 (1) | 41.2 ± 0.7 c | 41.2 | 327.0 ± 6.0 f | 327.0 | 320.5 ± 3.0 g | 320.5 |

| 7 | 1.4 (0) | 30 (−1) | 0 (−1) | 53.7 ± 0.9 d | 53.7 | 154.0 ± 3.0 b,c | 154.0 | 144.6 ± 2.8 b | 144.6 |

| 8 | 1.4 (0) | 30 (−1) | 14 (1) | 77.6 ± 0.7 f | 77.6 | 223.0 ± 3.0 e | 223.0 | 232.7 ± 1.5 d | 232.7 |

| 9 | 1.4 (0) | 40 (0) | 7 (0) | 173.4 ± 1.4 i | 174.3 | 446.9 ± 10.2 i | 449.2 | 445.7 ± 2.9 i | 487.9 |

| 10 | 1.0 (−1) | 40 (0) | 0 (−1) | 52.4 ± 0.6 d | 74.8 | 430.0 ± 10.0 h | 435.2 | 495.5 ± 6.6 j | 457.6 |

| 11 | 1.0 (−1) | 40 (0) | 14 (1) | 140.5 ± 1.2 g | 162.9 | 506.0 ± 6.0 k | 511.2 | 315.9 ± 3.7 g | 278.0 |

| 12 | 1.0 (−1) | 50 (1) | 7 (0) | 162.2 ± 2.6 h | 139.8 | 634.0 ± 14.0 l | 628.8 | 362.8 ± 5.7 h | 400.7 |

| 13 | 1.0 (−1) | 30 (−1) | 7 (0) | 230.0 ± 5.0 k | 207.6 | 377.0 ± 7.0 g | 371.8 | 261.7 ± 4.7 f | 299.6 |

| 14 | 1.4 (0) | 40 (0) | 7 (0) | 189.5 ± 1.9 j | 174.3 | 437.0 ± 9.0 h,i | 449.2 | 506.8 ± 7.0 k | 487.9 |

| 15 | 1.4 (0) | 40 (0) | 7 (0) | 159.9 ± 1.4 h | 174.3 | 463.8 ± 2.4 j | 449.2 | 511.1 ± 9.7 k | 487.9 |

| Extraction with Ethanol-Water | |||||||||

| 1 | 2.0 (1) | 40 (0) | 0 (−1) | 28.3 ± 0.9 a | 21.5 | 165.5 ± 3.8 b | 140.5 | 169.2 ± 3.3 b | 186.7 |

| 2 | 2.0 (1) | 40 (0) | 14 (1) | 41.8 ± 2.0 b | 35.0 | 170.3 ± 3.1 b | 145.3 | 198.6 ± 2.3 c | 216.1 |

| 3 | 2.0 (1) | 50 (1) | 7 (0) | 39.1 ± 0.6 b | 45.9 | 191.8 ± 4.2 c | 216.8 | 279.9 ± 4.4 e | 262.4 |

| 4 | 2.0 (1) | 30 (−1) | 7 (0) | 33.4 ± 0.4 a,b | 40.2 | 147.5 ± 3.4 a | 172.5 | 233.3 ± 4.6 d | 215.8 |

| 5 | 1.4 (0) | 50 (1) | 0 (−1) | 64.0 ± 0.7 d | 64.0 | 261.1 ± 5.8 e | 261.1 | 348.5 ± 2.8 g | 348.5 |

| 6 | 1.4 (0) | 50 (1) | 14 (1) | 89.4 ± 1.4 e | 89.4 | 345.9 ± 7.9 f | 345.9 | 281.2 ± 4.9 e | 281.2 |

| 7 | 1.4 (0) | 30 (−1) | 0 (−1) | 36.1 ± 0.3 a,b | 36.1 | 204.5 ± 4.4 c | 204.5 | 232.7 ± 5.1 d | 232.7 |

| 8 | 1.4 (0) | 30 (−1) | 14 (1) | 53.1 ± 0.6 c | 53.1 | 238.1 ± 4.4 d | 238.1 | 148.2 ± 1.3 a | 148.2 |

| 9 | 1.4 (0) | 40 (0) | 7 (0) | 143.5 ± 1.7 h | 149.9 | 458.5 ± 10.9 g | 460.8 | 443.7 ± 5.0 i | 427.5 |

| 10 | 1.0 (−1) | 40 (0) | 0 (−1) | 108.7 ± 4.7 f | 115.5 | 354.2 ± 5.0 f | 379.2 | 459.6 ± 6.6 j | 442.1 |

| 11 | 1.0 (−1) | 40 (0) | 14 (1) | 154.1 ± 3.0 i | 160.9 | 620.1 ± 12.1 j | 645.1 | 272.7 ± 2.6 e | 255.2 |

| 12 | 1.0 (−1) | 50 (1) | 7 (0) | 186.9 ± 1.9 j | 180.1 | 657.4 ± 0.7 k | 632.4 | 312.9 ± 7.6 f | 330.4 |

| 13 | 1.0 (−1) | 30 (−1) | 7 (0) | 132.9 ± 4.1 g | 126.1 | 520.2 ± 19.4 i | 495.2 | 424.8 ± 8.6 h | 442.3 |

| 14 | 1.4 (0) | 40 (0) | 7 (0) | 163.8 ± 5.3 i | 149.9 | 481.6 ± 3.0 h | 460.8 | 419.1 ± 7.1 h | 427.5 |

| 15 | 1.4 (0) | 40 (0) | 7 (0) | 142.4 ± 2.5 g,h | 149.9 | 442.3 ± 8.4 g | 460.8 | 419.6 ± 4.4 h | 427.5 |

| Term | Coefficient | |||||

|---|---|---|---|---|---|---|

| DPPH Method (mmol TE/100 g) | ABTS Method (mmol TE/100 g) | F–C Method (mg GA/100 g) | DPPH Method (mmol TE/100 g) | ABTS Method (mmol TE/100 g) | F–C Method (mg GA/100 g) | |

| Ginger Rhizome Ethanol Extract | Ginger Rhizome Ethanol-Water Extract | |||||

| β0 | 839.4 * | 1372.3 | −52.4 | 351.5 | 4752.7 ** | 2748.2 |

| β1 | −831.1 * | −223.9 | −1164.1 | −666.8 | −5288.8 ** | −3247.7 |

| β2 | −11.3 | −0.44 | 43.5 * | 12.7 | −88.9 * | −32.7 |

| β3 | 0.06 | −58.1 | 114.6 ** | −98.6 ** | −30.5 | −54.5 |

| β11 | 243.8 * | −58.1 | 384.0 | 215.4 | 1651.7 * | 999.2 |

| β22 | 0.08 * | 0.40 * | −0.62 ** | −0.11 * | 0.43 * | 0.17 |

| β33 | −0.14 | −1.1 * | −2.1 ** | −0.02 | −0.16 | −1.7 * |

| β12 | 5.4 | −51.3 | 20.4 | −0.51 | 77.7 * | 32.6 |

| β13 | 2.0 | 93.1 | −98.6 * | 124.7 ** | 40.4 | 121.9 |

| β23 | 0.03 | 0.08 | −0.31 * | 0.16 * | 0.25 | −0.44 |

| β112 | −1.5 | 18.0 | −8.7 | −0.77 | −25.3 * | −10.6 |

| β113 | −0.70 | −27.9 | 30.9 * | −39.0 ** | −14.4 | −36.9 |

| Nutmeg Ethanol Extract | Nutmeg Ethanol−Water Extract | |||||

| β0 | −314.9 | −3969.4 ** | −1468.2 | −702.7 | −1449.1 | 2880.1 * |

| β1 | 81.9 | 3555.8 * | −568.9 | 183.9 | 673.6 | −4654.7 * |

| β2 | 18.6 | 168.4 ** | 111.9 | 35.7 | 76.3 * | −31.1 |

| β3 | 65.1 * | −0.46 | −93.1 | 26.0 | 126.9 * | −15.5 |

| β11 | −114.7 | −1232.6 * | 119.6 | −60.4 | −242.2 | 1360.8 * |

| β22 | −0.34 * | −1.1 ** | −1.4 * | −0.37 * | −0.73 * | −1.7 * |

| β33 | −1.8 ** | −2.7 ** | −2.4 * | −1.1 * | −2.6 ** | −2.2 ** |

| β12 | 5.8 | −108.7 * | 3.4 | −4.0 | −15.8 | 116.0 * |

| β13 | −43.7 | 40.5 | 164.3 | −12.5 | −110.0 | 37.3 |

| β23 | −0.06 | 0.41 | −0.04 | 0.03 | 0.18 | 0.06 |

| β112 | −0.30 | 34.3 * | −1.8 | 0.54 | 3.7 | −36.0 * |

| β113 | 12.8 | −13.1 | −48.9 | 3.4 | 30.4 | −7.3 |

| Model Parameters | df | SS | MS | F Value | SS | MS | F Value |

|---|---|---|---|---|---|---|---|

| Ginger Rhizome Ethanol Extract | Ginger Rhizome Ethanol-Water Extract | ||||||

| DPPH Method | |||||||

| Regression | 11 | 15,804.6 | 1436.8 | 125.3 * | 31,255.0 | 2841.4 | 117.6 * |

| Residual | 3 | 23.4 | 7.8 | 479.0 | 159.7 | ||

| Lack-of-fit | 1 | 0.5 | 0.5 | 0.044 | 430.7 | 430.7 | 17.8 |

| Pure error | 2 | 22.9 | 11.5 | 48.3 | 24.2 | ||

| Total | 14 | 15,828.0 | 31,734.0 | ||||

| R2, Adjusted R2 | 0.9983, 0.9923 | 0.9859, 0.9341 | |||||

| ABTS Method | |||||||

| Regression | 11 | 176,690.3 | 16,062.8 | 53.7 * | 242,400.4 | 22,036.4 | 122.7 * |

| Residual | 3 | 665.7 | 221.9 | 3559.1 | 1186.4 | ||

| Lack-of-fit | 1 | 67.9 | 67.9 | 0.23 | 3200.0 | 3200.0 | 17.8 |

| Pure error | 2 | 597.8 | 298.9 | 359.1 | 179.6 | ||

| Total | 14 | 177,356.0 | 245,959.5 | ||||

| R2, Adjusted R2 | 0.9960, 0.9814 | 0.9845, 0.9274 | |||||

| F–C Method | |||||||

| Regression | 11 | 235,560.5 | 21,414.6 | 361.1 ** | 106,111.1 | 9646.5 | 18.3 |

| Residual | 3 | 267.4 | 89.1 | 2989.2 | 996.4 | ||

| Lack-of-fit | 1 | 148.8 | 148.8 | 2.5 | 1934.4 | 1934.4 | 3.7 |

| Pure error | 2 | 118.6 | 59.3 | 1054.8 | 527.4 | ||

| Total | 14 | 235,827.9 | 109,100.3 | ||||

| R2, Adjusted R2 | 0.9988, 0.9945 | 0.9713, 0.8661 | |||||

| Nutmeg Ethanol Extract | Nutmeg Ethanol-Water Extract | ||||||

| DPPH Method | |||||||

| Regression | 11 | 63,367.1 | 5760.6 | 26.2 | 42,957.5 | 3905.2 | 26.9 |

| Residual | 3 | 4462.3 | 1487.4 | 663.1 | 221.0 | ||

| Lack-of-fit | 1 | 4023.1 | 4023.1 | 18.3 | 372.7 | 372.7 | 2.6 |

| Pure error | 2 | 439.2 | 219.6 | 290.4 | 145.2 | ||

| Total | 14 | 67,829.4 | 43,620.6 | ||||

| R2, Adjusted R2 | 0.9329, 0.6868 | 0.9847, 0.9286 | |||||

| ABTS Method | |||||||

| Regression | 11 | 44,2194.8 | 40,199.5 | 218.9 ** | 409,498.0 | 37227.1 | 95.4 * |

| Residual | 3 | 583.6 | 194.5 | 5770.2 | 1923.4 | ||

| Lack-of-fit | 1 | 216.3 | 216.3 | 1.2 | 4990.0 | 4990.0 | 12.8 |

| Pure error | 2 | 367.3 | 183.7 | 780.2 | 390.1 | ||

| Total | 14 | 44,2778.4 | 415,268.2 | ||||

| R2, Adjusted R2 | 0.9987, 0.9937 | 0.9859, 0.9340 | |||||

| F–C Method | |||||||

| Regression | 11 | 236,564.6 | 21,505.9 | 16.1 | 149,008.4 | 13,546.2 | 68.5 * |

| Residual | 3 | 14,175.2 | 4725.1 | 2845.4 | 948.5 | ||

| Lack-of-fit | 1 | 11,498.9 | 11498.9 | 8.6 | 2450.0 | 2450.0 | 12.4 |

| Pure error | 2 | 2676.3 | 1338.2 | 395.4 | 197.7 | ||

| Total | 14 | 250,739.8 | 151,853.8 | ||||

| R2, Adjusted R2 | 0.9414, 0.7267 | 0.9813, 0.9128 | |||||

| Response Variable | Optimum Conditions | Predicted Values | Experimental Values | ||

|---|---|---|---|---|---|

| X1 [mm] | X2 [Hz] | X3 [Days] | |||

| Ginger Rhizome Ethanol Extract | |||||

| DPPH (mmol TE/100 g) | 2.0 | 43 | 9 | 30.0 | 34.5 ± 0.1 |

| ABTS (mmol TE/100 g) | 179.5 | 176.2 ± 2.5 | |||

| TPC (mg GA/100 g) | 222.6 | 216.0 ± 9.3 | |||

| Ginger Rhizome Ethanol-Water Extract | |||||

| DPPH (mmol TE/100 g) | 1.0 | 50 | 1 | 189.9 | 180.8 ± 4.3 |

| ABTS (mmol TE/100 g) | 365.5 | 361.4 ± 2.6 | |||

| TPC (mg GA/100 g) | 399.8 | 392.3 ± 8.6 | |||

| Nutmeg Ethanol Extract | |||||

| DPPH (mmol TE/100 g) | 1.0 | 41 | 7 | 204.4 | 209.8 ± 0.3 |

| ABTS (mmol TE/100 g) | 620.3 | 619.55 ± 2.8 | |||

| TPC (mg GA/100 g) | 486.1 | 482.9 ± 3.9 | |||

| Nutmeg Ethanol-Water Extract | |||||

| DPPH (mmol TE/100 g) | 1.0 | 40 | 7 | 188.3 | 185.3 ± 0.2 |

| ABTS (mmol TE/100 g) | 630.6 | 659.4 ± 2.3 | |||

| TPC (mg GA/100 g) | 459.5 | 453.2 ± 7.4 | |||

| Phenolic Compounds (μg/100 mL) | Ginger Rhizome Extract | Nutmeg Extract | ||

|---|---|---|---|---|

| Ethanol | Ethanol-Water | Ethanol | Ethanol-Water | |

| Caffeic acid | 6.71 ± 0.45 | <LOD | <LOD | <LOD |

| Ellagic acid | 62.58 ± 3.09 a | 26.90 ± 0.38 b | <LOD | <LOD |

| Ferulic acid | 59.99 ± 1.30 a | 49.45 ± 1.28 b | 34.64 ± 2.05 c | 22.47 ± 0.16 d |

| Gallic acid | 53.60 ± 1.86 a | 43.08 ± 4.43 b | <LOD | <LOD |

| p-Coumaric acid | 23.10 ± 1.15 b | 35.99 ± 0.14 a | 19.36 ± 0.63 c | 12.94 ± 0.15 d |

| p-OH-Benzoic acid | 65.08 ± 2.75 a | 39.91 ± 0.13 b | 38.21 ± 0.89 b | 12.38 ± 0.40 c |

| Protocatechuic acid | 19.70 ± 1.93 d | 26.44 ± 0.72 c | 100.87 ± 1.40 a | 75.91 ± 0.55 b |

| Salicylic acid | 26.83 ± 2.67 b | 35.29 ± 2.01 a | 12.58 ± 1.43 c | 11.11 ± 0.75 c |

| Sinapic acid | 13.66 ± 1.45 b,c | 12.58 ± 0.92 c | 25.14 ± 1.74 a | 15.24 ± 0.16 b |

| Syringic acid | 13.98 ± 1.58 b | 11.72 ± 0.18 c | 18.12 ± 0.73 a | 11.55 ± 0.39 c |

| Vanillic acid | 115.19 ± 5.18 a | 83.43 ± 0.70 b | 51.60 ± 0.19 c | 38.26 ± 0.71 d |

| Phenolic Compounds | [M-H]- (m/z) | Product Ion (m/z) | Dwell | Fragmentor (V) | Collision Energy (V) | Cell Accelerator (V) |

|---|---|---|---|---|---|---|

| 3,5-Dichloro-2-OH-benzoic acid | 207 | 163 | 40 | 104 | 16 | 7 |

| Caffeic acid | 179 | 135.1 | 40 | 104 | 16 | 7 |

| Chlorogenic acid | 353.1 | 191.1 | 40 | 104 | 12 | 7 |

| Ellagic acid | 301 | 300.1 | 40 | 168 | 36 | 7 |

| Ferulic acid | 193.1 | 134.1 | 40 | 104 | 16 | 7 |

| Gallic acid | 169 | 125.1 | 40 | 104 | 12 | 7 |

| p-Coumaric acid | 163 | 119.1 | 40 | 72 | 16 | 7 |

| Protocatechuic acid | 153.1 | 109.1 | 40 | 104 | 12 | 7 |

| p-OH-Benzoic acid | 137 | 93.1 | 40 | 72 | 16 | 7 |

| Salicylic acid | 137.1 | 93.1 | 40 | 72 | 16 | 7 |

| Sinapic acid | 223.1 | 208.1 | 40 | 104 | 12 | 7 |

| Syringic acid | 197 | 182.1 | 40 | 104 | 12 | 7 |

| Vanillic acid | 167 | 152.1 | 40 | 72 | 12 | 7 |

| Phenolic Compounds | Equation of Linear Regression | R2 | LOD | LOQ |

|---|---|---|---|---|

| 3,5-Dichloro-2-OH-benzoic acid | y = 3061x + 40,191 | 0.959 | 0.118 | 0.392 |

| Caffeic acid | y = 15,829x + 56,299 | 0.995 | 0.038 | 0.127 |

| Chlorogenic acid | y = 12,320x + 25492 | 0.998 | 0.171 | 0.570 |

| Ellagic acid | y = 1143x + 2849 | 0.995 | 0.215 | 0.717 |

| Ferulic acid | y = 2442x + 2696 | 0.999 | 0.159 | 0.528 |

| Gallic acid | y = 6702x + 61,152 | 0.978 | 0.549 | 1.830 |

| p-Coumaric acid | y = 11,203x + 86,477 | 0.983 | 0.138 | 0.460 |

| Protocatechuic acid | y = 17,995x + 92,122 | 0.992 | 0.416 | 1.388 |

| p-OH-Benzoic acid | y = 16,541x + 145,092 | 0.976 | 0.302 | 1.007 |

| Salicylic acid | y = 32,481x + 226,324 | 0.986 | 0.002 | 0.006 |

| Sinapic acid | y = 3165x + 2785 | 0.999 | 0.373 | 1.245 |

| Syringic acid | y = 1590x − 5036 | 0.995 | 0.038 | 0.126 |

| Vanillic acid | y = 826x − 1108 | 1.000 | 0.065 | 0.218 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poliński, S.; Topka, P.; Tańska, M.; Kowalska, S.; Czaplicki, S.; Szydłowska-Czerniak, A. Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg. Molecules 2022, 27, 7395. https://doi.org/10.3390/molecules27217395

Poliński S, Topka P, Tańska M, Kowalska S, Czaplicki S, Szydłowska-Czerniak A. Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg. Molecules. 2022; 27(21):7395. https://doi.org/10.3390/molecules27217395

Chicago/Turabian StylePoliński, Szymon, Patrycja Topka, Małgorzata Tańska, Sylwia Kowalska, Sylwester Czaplicki, and Aleksandra Szydłowska-Czerniak. 2022. "Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg" Molecules 27, no. 21: 7395. https://doi.org/10.3390/molecules27217395

APA StylePoliński, S., Topka, P., Tańska, M., Kowalska, S., Czaplicki, S., & Szydłowska-Czerniak, A. (2022). Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg. Molecules, 27(21), 7395. https://doi.org/10.3390/molecules27217395