Evaluating the Functional Characteristics of Certain Insect Flours (Non-Defatted/Defatted Flour) and Their Protein Preparations

Abstract

1. Introduction

2. Results and Discussion

2.1. Nutritive Value

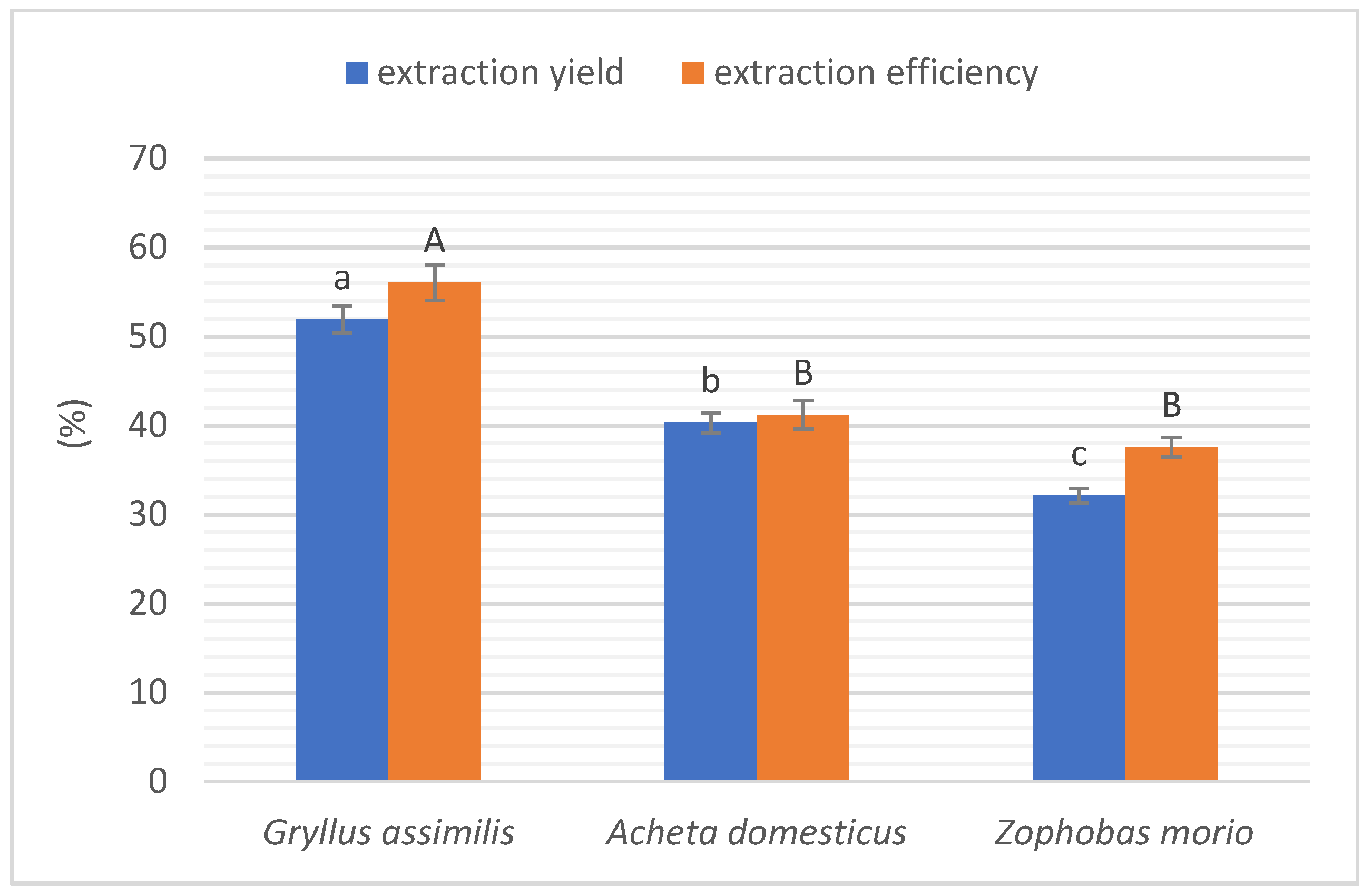

2.2. Extraction Yield and Efficiency

2.3. Functional Properties

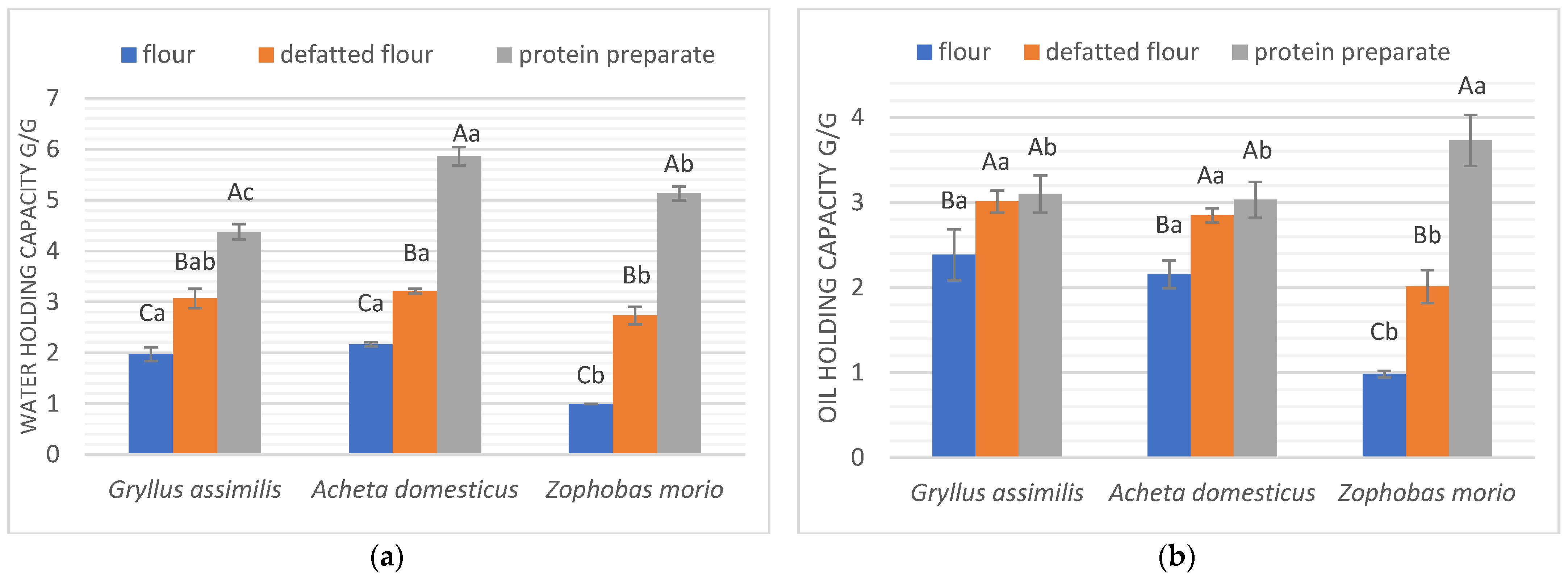

2.3.1. Water and Oil Holding Capacity

2.3.2. Foaming Properties

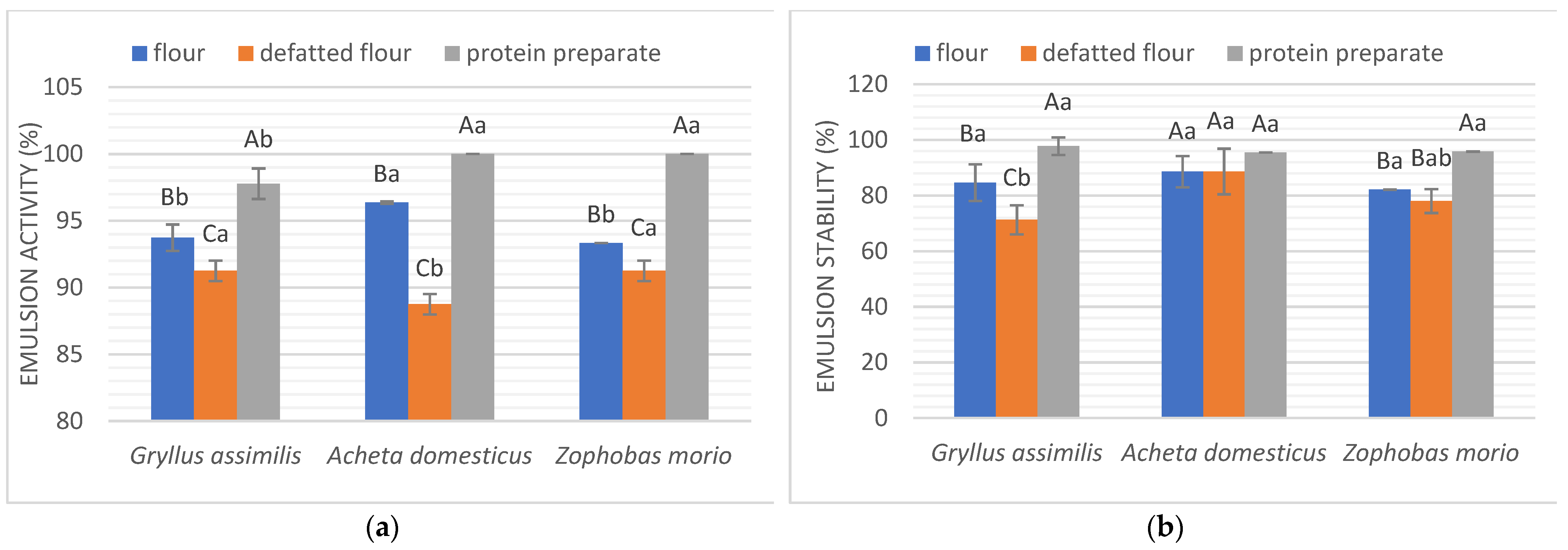

2.3.3. Emulsifying Properties

2.4. The Sensory Analysis

3. Materials and Methods

3.1. Raw Materials

3.2. Obtaining the Protein Preparation

3.3. Defatting of Flour

3.4. Nutritive Value

3.5. Calculation of Extraction Yield and Efficiency

3.6. Functional Properties

3.6.1. Water Holding Capacity

3.6.2. Oil Holding Capacity

3.6.3. Foaming Properties

3.6.4. Emulsifying Properties

3.7. The Sensory Evaluation

3.8. Statistical Analysis

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Jeong, M.S.; Lee, S.D.; Cho, S.J. Effect of three defatting solvents on the techno-functional properties of an edible insect (Gryllus bimaculatus) protein concentrate. Molecules 2021, 26, 5307. [Google Scholar] [CrossRef] [PubMed]

- Gravel, A.; Marciniak, A.; Couture, M.; Doyen, A. Effects of Hexane on Protein Profile, Solubility and Foaming Properties of Defatted Proteins Extracted from Tenebrio molitor Larvae. Molecules 2021, 26, 351. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.S.G.; van den Berg, E.; Stieger, M. The influence of product preparation, familiarity and individual traits on the consumer acceptance of insects as food. Food Qual. Prefer. 2016, 52, 222–231. [Google Scholar] [CrossRef]

- Gere, A.; Székely, G.; Kovács, S.; Kókai, Z.; Sipos, L. Readiness to adopt insects in Hungary: A case study. Food Qual. Prefer. 2017, 59, 81–86. [Google Scholar] [CrossRef]

- Verbeke, W. Profiling consumers who are ready to adopt insects as a meat substitute in a Western society. Food Qual. Prefer. 2015, 39, 147–155. [Google Scholar] [CrossRef]

- Zielińska, E.; Baraniak, B.; Karaś, M. Antioxidant and anti-inflammatory activities of hydrolysates and peptide fractions obtained by enzymatic hydrolysis of selected heat-treated edible insects. Nutrients 2017, 9, 970. [Google Scholar] [CrossRef]

- Zielińska, E.; Karaś, M.; Jakubczyk, A.; Zieliński, D.; Baraniak, B. Edible Insects as Source of Proteins. In Bioactive Molecules in Food; Springer: Cham, Switzerland, 2019; pp. 389–441. ISBN 9783319545288. [Google Scholar]

- Van Huis, A.; Van Itterbeeck, J.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insects. Future Prospects for Food and Feed Security; Food and Agriculture Organization of the United Nations: New York, NY, USA, 2013; Volume 171, ISBN 9789251075951. [Google Scholar]

- Stone, A.K.; Tanaka, T.; Nickerson, M.T. Protein quality and physicochemical properties of commercial cricket and mealworm powders. J. Food Sci. Technol. 2019, 56, 3355–3363. [Google Scholar] [CrossRef]

- Mishyna, M.; Martinez, J.J.I.; Chen, J.; Benjamin, O. Extraction, characterization and functional properties of soluble proteins from edible grasshopper (Schistocerca gregaria) and honey bee (Apis mellifera). Food Res. Int. 2019, 116, 697–706. [Google Scholar] [CrossRef]

- Zielińska, E.; Karaś, M.; Baraniak, B. Comparison of functional properties of edible insects and protein preparations thereof. LWT—Food Sci. Technol. 2018, 91, 168–174. [Google Scholar] [CrossRef]

- Bußler, S.; Rumpold, B.A.; Jander, E.; Rawel, H.M.; Schlüter, O.K. Recovery and techno-functionality of flours and proteins from two edible insect species: Meal worm (Tenebrio molitor) and black soldier fly (Hermetia illucens) larvae. Heliyon 2016, 2, e00218. [Google Scholar] [CrossRef]

- Jongema, Y. World List of Edible Insects. Available online: https://www.wur.nl/en/research-results/chair-groups/plant-sciences/laboratory-of-entomology/edible-insects/worldwide-species-list.htm (accessed on 20 August 2022).

- Skotnicka, M.; Karwowska, K.; Kłobukowski, F.; Borkowska, A.; Pieszko, M. Possibilities of the Development of Edible Insect-Based Foods in Europe. Foods 2021, 10, 766. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, C.; Shi, J.; Giusto, A.; Siegrist, M. The psychology of eating insects: A cross-cultural comparison between Germany and China. Food Qual. Prefer. 2015, 44, 148–156. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Gumienna, M.; Rybicka, I.; Górna, B.; Sarbak, P.; Dziedzic, K.; Kmiecik, D. Nutritional Value and Biological Activity of Gluten-Free Bread Enriched with Cricket Powder. Molecules 2021, 26, 1184. [Google Scholar] [CrossRef]

- Villaseñor, V.M.; Enriquez-Vara, J.N.; Urías-Silva, J.E.; Mojica, L. Edible Insects: Techno-functional Properties Food and Feed Applications and Biological Potential. Food Rev. Int. 2021, 37, 1–27. [Google Scholar] [CrossRef]

- Son, Y.J.; Choi, S.Y.; Hwang, I.K.; Nho, C.W.; Kim, S.H. Could Defatted Mealworm (Tenebrio molitor) and Mealworm Oil Be Used as Food Ingredients? Foods 2020, 9, 40. [Google Scholar] [CrossRef]

- Gravel, A.; Doyen, A. The use of edible insect proteins in food: Challenges and issues related to their functional properties. Innov. Food Sci. Emerg. Technol. 2020, 59, 102272. [Google Scholar] [CrossRef]

- Purschke, B.; Meinlschmidt, P.; Horn, C.; Rieder, O.; Jäger, H. Improvement of techno-functional properties of edible insect protein from migratory locust by enzymatic hydrolysis. Eur. Food Res. Technol. 2018, 244, 999–1013. [Google Scholar] [CrossRef]

- Omotoso, O.T. Nutritional quality, functional properties and anti-nutrient compositions of the larva of Cirina forda (Westwood) (Lepidoptera: Saturniidae). J. Zhejiang Univ. Sci. B. 2006, 7, 51–55. [Google Scholar] [CrossRef]

- EFSA Scientific Committee Risk profile related to production and consumption of insects as food and feed. EFSA J. 2015, 13, 4257. [CrossRef]

- Chatsuwan, N.; Nalinanon, S.; Puechkamut, Y.; Lamsal, B.P.; Pinsirodom, P. Characteristics, Functional Properties, and Antioxidant Activities of Water-Soluble Proteins Extracted from Grasshoppers, Patanga succincta and Chondracris roseapbrunner. J. Chem. 2018, 2018, 6528312. [Google Scholar] [CrossRef]

- Clarkson, C.; Mirosa, M.; Birch, J. Potential of extracted Locusta migratoria protein fractions as value-added ingredients. Insects 2018, 9, 20. [Google Scholar] [CrossRef]

- Mishyna, M.; Keppler, J.K.; Chen, J. Techno-functional properties of edible insect proteins and effects of processing. Curr. Opin. Colloid Interface Sci. 2021, 56, 101508. [Google Scholar] [CrossRef]

- Omotoso, O.T. An evaluation of the nutrients and some anti-nutrients in Silkworm, Bombyxmori L. (Bombycidae: Lepidoptera). Jordan J. Biol. Sci. 2015, 8, 45–50. [Google Scholar] [CrossRef]

- Wani, I.A.; Sogi, D.S.; Wani, A.A.; Gill, B.S. Physico-chemical and functional properties of flours from Indian kidney bean (Phaseolus vulgaris L.) cultivars. LWT—Food Sci. Technol. 2013, 53, 278–284. [Google Scholar] [CrossRef]

- Barać, M.B.; Pešić, M.B.; Stanojević, S.P.; Kostić, A.Ž.; Čabrilo, S.B. Techno-functional properties of pea (Pisum sativum) protein isolates—A review. Acta Period. Technol. 2015, 46, 1–18. [Google Scholar] [CrossRef]

- Kinsella, J.E. Functional properties of proteins: Possible relationships between structure and function in foams. Food Chem. 1981, 7, 273–288. [Google Scholar] [CrossRef]

- Rumpold, B.A.; Schlüter, O.K. Nutritional composition and safety aspects of edible insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Jeong, C.H.; Han, S.G.; Kim, Y.B.; Paik, H.D.; Choi, Y.S. Technical Functional Properties of Water- and Salt-soluble Proteins Extracted from Edible Insects. Food Sci. Anim. Resour. 2019, 39, 643–654. [Google Scholar] [CrossRef]

- Cilia, M.; Fish, T.; Yang, X.; Mclaughlin, M.; Thannhauser, T.W.; Gray, S. A Comparison of Protein Extraction Methods Suitable for Gel-Based Proteomic Studies of Aphid Proteins. J. Biomol. Tech. 2009, 20, 201. [Google Scholar]

- Girón-Calle, J.; Alaiz, M.; Vioque, J. Effect of chickpea protein hydrolysates on cell proliferation and in vitro bioavailability. Food Res. Int. 2010, 43, 1365–1370. [Google Scholar] [CrossRef]

- AOAC Official Methods of Analysis; AOAC International: Rockville, MD, USA, 2010; pp. 2–4.

- European Union. Regulation (eu) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Off. J. Eur. Union 2011, 18–63.

- Diniz, F.M.; Martin, A.M. Effects of the Extent of Enzymatic Hydrolysis on Functional Properties of Shark Protein Hydrolysate. LWT-Food Sci. Technol. 1997, 30, 266–272. [Google Scholar] [CrossRef]

- Haque, Z.U.; Mozaffar, Z. Casein hydrolysate. II. Functional properties of peptides. Food Hydrocoll. 1992, 5, 559–571. [Google Scholar] [CrossRef]

- Guo, F.; Xiong, Y.L.; Qin, F.; Jian, H.; Huang, X.; Chen, J. Surface Properties of Heat-Induced Soluble Soy Protein Aggregates of Different Molecular Masses. J. Food Sci. 2015, 80, C279–C287. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Q.; Ma, T.; Ren, J. Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res. Int. 2009, 42, 343–348. [Google Scholar] [CrossRef]

| Species | Form | Protein (%) | Fat (%) | Ash (%) | Carbohydrates (%) | Moisture (%) | Energy Value 100 g | |

|---|---|---|---|---|---|---|---|---|

| kcal | kJ | |||||||

| Gryllus assimilis | flour | 59.24 ± 0.41 e | 26.25 ± 0.45 b | 4.05 ± 0.16 b | 3.32 ± 0.36 f | 7.14 ± 0.21 c | 487 ± 7.1 b | 2035 ± 21 b |

| defatted flour | 76.02 ± 0.53 a | 3.66 ± 0.52 g | 4.93 ± 0.17 a | 8.11 ± 0.45 c | 7.27 ± 0.48 c | 370 ± 5.8 e | 1566 ± 12 f | |

| protein preparation | 64.00 ± 0.45 d | 12.98 ± 0.86 e | 3.88 ± 0.24 b | 10.57 ± 0.33 a | 7.15 ± 0.69 c | 421 ± 4.7 d | 1772 ± 13 d | |

| Acheta domesticus | flour | 64.93 ± 0.45 d | 18.54 ± 0.34 d | 5.1 ± 0.13 a | 4.94 ± 0.21 e | 7.29 ± 0.31 c | 446 ± 3.4 c | 1874 ± 14 c |

| defatted flour | 75.35 ± 0.53 a | 3.43 ± 0.81 g | 4.8 ± 0.24 a | 9.44 ± 0.55 ab | 6.99 ± 0.02 c | 370 ± 8.2 e | 1568 ± 14 f | |

| protein preparation | 66.34 ± 0.46 c | 14.12 ± 1.12 e | 3.73 ± 0.07 b | 9.31 ± 0.54 bc | 6.5 ± 0.05 c | 430 ± 9.9 cd | 1809 ± 17 d | |

| Zophobas morio | flour | 49.06 ± 0.34 g | 41.9 ± 1.53 a | 2.32 ± 0.12 c | 3.83 ± 0.33 ef | 3.83 ± 0.22 d | 585 ± 9.7 a | 2433 ± 16 a |

| defatted flour | 70.51 ± 0.49 b | 6.51 ± 0.67 f | 3.65 ± 0.35 b | 10.57 ± 0.63 a | 8.77 ± 0.86 b | 383 ± 5.6 e | 1619 ± 11 e | |

| protein preparation | 57.35 ± 0.4 f | 23.22 ± 1.24 c | 2.10 ± 0.11 c | 6.14 ± 0.17 d | 11.19 ± 0.17 a | 447 ± 9.5 c | 1870 ± 13 c | |

| Species | Form | The Studied Characteristics | Overall Score of the Product | |||

|---|---|---|---|---|---|---|

| Color | Smell | Consistency | Overall Acceptability | |||

| Weighting Factor | ||||||

| 0.2 | 0.3 | 0.3 | 0.2 | |||

| Gryllus assimilis | flour | 4.13 ± 0.72 a | 3.38 ± 0.62 a | 4.0 ± 0.52 ab | 3.75 ± 0.68 a | 3.79 ± 0.49 ab |

| defatted flour | 3.81 ± 0.75 a | 4.0 ± 0.89 a | 4.38 ± 0.62 a | 4.44 ± 0.73 a | 4.16 ± 0.51 ab | |

| protein preparation | 4.31 ± 0.48 a | 3.25 ± 0.77 a | 3.81 ± 0.75 ab | 4.13 ± 0.5 a | 3.81 ± 0.32 ab | |

| Acheta domesticus | flour | 4.0 ± 0.89 a | 4.38 ± 0.62 a | 3.94 ± 0.68 ab | 3.88 ± 0.5 a | 4.07 ± 0.35 ab |

| defatted flour | 4.5 ± 0.52 a | 4.31 ± 0.87 a | 4.63 ± 0.5 a | 4.44 ± 0.63 a | 4.47 ± 0.47 a | |

| protein preparation | 4.63 ± 0.5 a | 3.31 ± 0.95 a | 3.63 ± 0.72 ab | 4.06 ± 0.68 a | 3.82 ± 0.37 ab | |

| Zophobas morio | flour | 3.13 ± 1.02 a | 3.63 ± 0.72 a | 2.25 ± 0.68 b | 2.69 ± 0.7 a | 2.93 ± 0.59 b |

| defatted flour | 4.19 ± 0.83 a | 3.81 ± 0.75 a | 4.38 ± 0.72 a | 4.25 ± 0.68 a | 4.14 ± 0.47 ab | |

| protein preparation | 4.06 ± 0.68 a | 3.31 ± 0.6 a | 3.88 ± 0.81 ab | 3.94 ± 0.68 a | 3.76 ± 0.35 ab | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zielińska, E. Evaluating the Functional Characteristics of Certain Insect Flours (Non-Defatted/Defatted Flour) and Their Protein Preparations. Molecules 2022, 27, 6339. https://doi.org/10.3390/molecules27196339

Zielińska E. Evaluating the Functional Characteristics of Certain Insect Flours (Non-Defatted/Defatted Flour) and Their Protein Preparations. Molecules. 2022; 27(19):6339. https://doi.org/10.3390/molecules27196339

Chicago/Turabian StyleZielińska, Ewelina. 2022. "Evaluating the Functional Characteristics of Certain Insect Flours (Non-Defatted/Defatted Flour) and Their Protein Preparations" Molecules 27, no. 19: 6339. https://doi.org/10.3390/molecules27196339

APA StyleZielińska, E. (2022). Evaluating the Functional Characteristics of Certain Insect Flours (Non-Defatted/Defatted Flour) and Their Protein Preparations. Molecules, 27(19), 6339. https://doi.org/10.3390/molecules27196339