Characterising a Custom-Built Radio Frequency PECVD Reactor to Vary the Mechanical Properties of TMDSO Films

Abstract

:1. Introduction

2. Results and Discussion

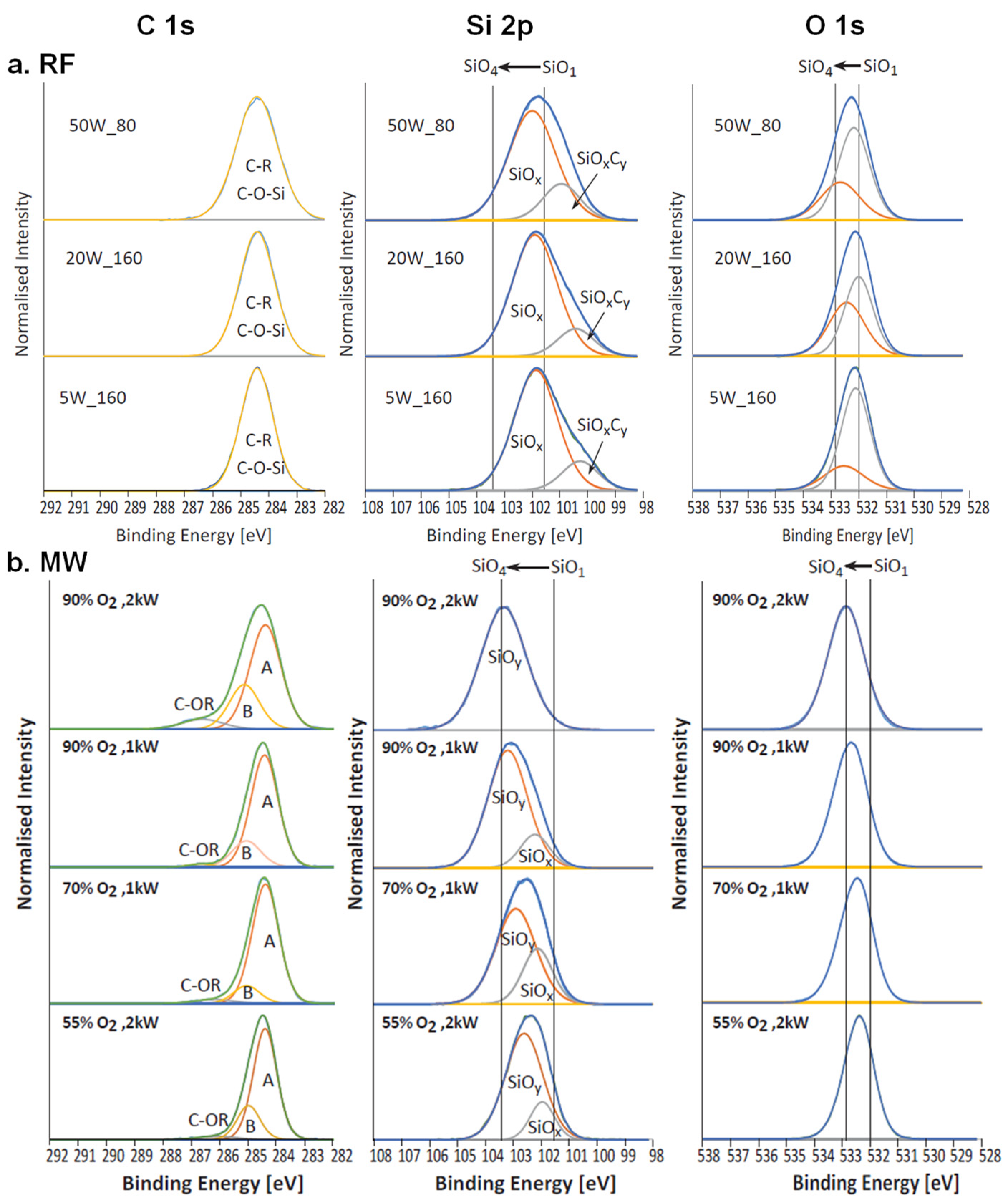

2.1. Thickness and Chemistry of TMDSO Films

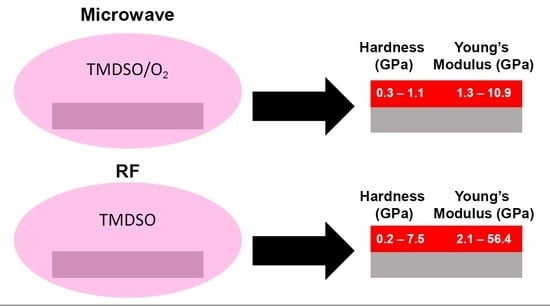

2.2. Mechanical Properties of TMDSO Films

3. Materials and Methods

3.1. Materials

3.2. Substrate Preparation

3.3. MW TMDSO Films

3.4. RF TMDSO Films

3.5. Spectroscopic Ellipsometry

3.6. XPS

3.7. AFM

3.8. Nano-Indentation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hegemann, D.; Brunner, H.; Oehr, C. Evaluation of deposition conditions to design plasma coatings like SiOx and a-C:H on polymers. Surf. Coat. Technol. 2003, 174–175, 253–260. [Google Scholar] [CrossRef]

- Hegemann, D.; Oehr, C.; Fischer, A. Design of functional coatings. J. Vac. Sci. Technol. A 2005, 23, 5–11. [Google Scholar] [CrossRef]

- Bahroun, K.; Behm, H.; Mitschker, F.; Awakowicz, P.; Dahlmann, R.; Hopmann, C. Influence of layer type and order on barrier properties of multilayer PECVD barrier coatings. J. Phys. D Appl. Phys. 2013, 47, 015201. [Google Scholar] [CrossRef]

- Hall, C.J.; Murphy, P.J.; Griesser, H.J. Influence of Tetramethyldisiloxane-Oxygen Mixtures on the Physical Properties of Microwave PECVD Coatings and Subsequent Post-Plasma Reactions. Plasma Process. Polym. 2015, 12, 555–563. [Google Scholar] [CrossRef]

- Hall, C.J.; Murphy, P.J.; Griesser, H.J. Direct Imaging of Mechanical and Chemical Gradients Across the Thickness of Graded Organosilicone Microwave PECVD Coatings. ACS Appl. Mater. Interfaces 2014, 6, 1279–1287. [Google Scholar] [CrossRef] [PubMed]

- Hall, C.J.; Ponnusamy, T.; Murphy, P.J.; Lindberg, M.; Antzutkin, O.N.; Griesser, H.J. A Solid-State Nuclear Magnetic Resonance Study of Post-Plasma Reactions in Organosilicone Microwave Plasma-Enhanced Chemical Vapor Deposition (PECVD) Coatings. ACS Appl. Mater. Interfaces 2014, 6, 8353–8362. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Yu, Q. Deposition of silicon oxide hard coatings by low-temperature radio-frequency plasmas. J. Appl. Polym. Sci. 2010, 116, 245–251. [Google Scholar] [CrossRef]

- Benitez, F.; Martinez, E.; Esteve, J. Improvement of hardness in plasma polymerized hexamethyldisiloxane coatings by silica-like surface modification. Thin Solid Films 2000, 377–378, 109–114. [Google Scholar] [CrossRef]

- Trunec, D.; Zajíčková, L.; Buršíková, V.; Studnička, F.; Sťahel, P.; Prysiazhnyi, V.; Peřina, V.; Houdková, J.; Navrátil, Z.; Franta, D. Deposition of hard thin films from HMDSO in atmospheric pressure dielectric barrier discharge. J. Phys. D Appl. Phys. 2010, 43, 225403. [Google Scholar] [CrossRef]

- Bousquet, A.; Bursikova, V.; Goullet, A.; Djouadi, A.; Zajickova, L.; Granier, A. Comparison of structure and mechanical properties of SiO2-like films deposited in O2/HMDSO pulsed and continuous plasmas. Surf. Coat. Technol. 2006, 200, 6517–6521. [Google Scholar] [CrossRef]

- Batory, D.; Jedrzejczak, A.; Szymanski, W.; Niedzielski, P.; Fijalkowski, M.; Louda, P.; Kotela, I.; Hromadka, M.; Musil, J. Mechanical characterization of a-C:H:SiOx coatings synthesized using radio-frequency plasma-assisted chemical vapor deposition method. Thin Solid Films 2015, 590, 299–305. [Google Scholar] [CrossRef]

- Zajíčková, L.; Buršíková, V.; Franta, D.; Bousquet, A.; Granier, A.; Goullet, A.; Buršík, J. Comparative Study of Films Deposited from HMDSO/O2 in Continuous Wave and Pulsed rf Discharges. Plasma Process. Polym. 2007, 4, S287–S293. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Lai, Y.-C.; Chen, J.-H.; Wu, C.-Y. Cold atmospheric pressure plasma-polymerized organosilicon oxide films for enhancing scratch resistance of flexible carbon fiber-reinforced polymer composites. Thin Solid Films 2019, 686, 137420. [Google Scholar] [CrossRef]

- Zhou, M.-L.; Fu, Y.-B.; Chen, Q.; Ge, Y.-J. Deposition of SiOx barrier films by O2 /TMDSO RF-PECVD. Chin. Phys. 2007, 16, 1101–1104. [Google Scholar] [CrossRef]

- Mackova, A.; Perina, V.; Stryhal, Z.; Pavlik, J.; Svec, M.; Quédé, A.; Supiot, P.; Borvon, G.; Granier, A.; Raynaud, P. The combined study of the organosilicon films by RBS, ERDA and AFM analytical methods obtained from PECVD and PACVD. Surf. Sci. 2004, 566–568, 1143–1146. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Drzal, L.T. The role of the fiber-matrix interphase on composite properties. Vacuum 1990, 41, 1615–1618. [Google Scholar] [CrossRef]

- Metcalfe, A.G. Introduction and review. In Interfaces in Metal Matrix Composites: Composite Materials, Vol. 1; Metcalfe, A.G., Ed.; Elsevier Science & Technology: Saint Louis, MO, USA, 1974; pp. 2–32. [Google Scholar]

- Cech, V.; Babik, A.; Knob, A.; Palesch, E. Plasma polymers used for controlled interphases in polymer composites. In Proceedings of the 13th International Conference on Plasma Surface Engineering, Garmisch-Partenkirchen, Germany, 10–14 September 2012; pp. 51–55. [Google Scholar]

- Kim, J.-K.; Mai, Y.-W. High strength, high fracture toughness fibre composites with interface control—A review. Compos. Sci. Technol. 1991, 41, 333–378. [Google Scholar] [CrossRef]

- Dilsiz, N.; Erinç, N.K.; Bayramli, E.; Akovali, G. Surface energy and mechanical properties of plasma-modified carbon fibers. Carbon 1995, 33, 853–858. [Google Scholar] [CrossRef]

- Li, R.; Ye, L.; Mai, Y.-W. Application of plasma technologies in fibre-reinforced polymer composites: A review of recent developments. Compos. Part A Appl. Sci. Manuf. 1997, 28, 73–86. [Google Scholar] [CrossRef]

- Sugihara, H.; Jones, F.R. Promoting the adhesion of high-performance polymer fibers using functional plasma polymer coatings. Polym. Compos. 2009, 30, 318–327. [Google Scholar] [CrossRef]

- Jones, F.R. A Review of Interphase Formation and Design in Fibre-Reinforced Composites. J. Adhes. Sci. Technol. 2010, 24, 171–202. [Google Scholar] [CrossRef]

- Ligot, S.; Bousser, E.; Cossement, D.; Klemberg-Sapieha, J.; Viville, P.; Dubois, P.; Snyders, R. Correlation Between Mechanical Properties and Cross-Linking Degree of Ethyl Lactate Plasma Polymer Films. Plasma Process. Polym. 2015, 12, 508–518. [Google Scholar] [CrossRef]

- Cech, V.; Vanek, J.; Goruppa, A.A.; Jones, F.R. RF-power-controlled young’s modulus of plasma-polymerized organosilicon films. J. Mater. Res. 2005, 40, 5099–5102. [Google Scholar] [CrossRef]

- Radjef, R.; Jarvis, K.; Fox, B.L.; McArthur, S.L. Design and characterization of a plasma chamber for improved radial and axial film uniformity. Plasma Process. Polym. 2020, 17, 2000017. [Google Scholar] [CrossRef]

- Jarvis, K.; McArthur, S. Exploiting reactor geometry to manipulate the properties of plasma polymerized acrylic acid films. Materials 2019, 12, 2597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Y.-S.; Lai, Y.-C.; Chen, J.-H. Scratch Resistance of Flexible Carbon Fiber-Reinforced Polymer Composites Improved by Atmospheric Pressure Plasma Polymerized-Organosilicon Oxide Films. Polym. Compos. 2019, 40, E1893–E1902. [Google Scholar] [CrossRef]

- Radjef, R.; Jarvis, K.L.; Fox, B.L.; McArthur, S.L. Comparing the properties of commercially treated and air plasma treated carbon fibers. Surf. Coat. Technol. 2021, 408, 126751. [Google Scholar] [CrossRef]

- Kettle, A.P.; Jones, F.R.; Alexander, M.R.; Short, R.D.; Stollenwerk, M.; Zabold, J.; Michaeli, W.; Wu, W.; Jacobs, E.; Verpoest, I. Experimental evaluation of the interphase region in carbon fibre composites with plasma polymerised coatings. Compos. Part A Appl. Sci. Manuf. 1998, 29, 241–250. [Google Scholar] [CrossRef]

- Abbas, A.; Vivien, C.; Bocquet, B.; Guillochon, D.; Supiot, P. Preparation and multi-characterization of plasma polymerized allylamine films. Plasma Process. Polym. 2009, 6, 593–604. [Google Scholar] [CrossRef]

- Yasuda, H. Glow discharge polymerization. J. Polym. Sci. Macromol. Rev. 1981, 16, 199–293. [Google Scholar] [CrossRef]

- Akhavan, B.; Jarvis, K.; Majewski, P. Evolution of Hydrophobicity in Plasma Polymerised 1,7-Octadiene Films. Plasma Process. Polym. 2013, 10, 1018–1029. [Google Scholar] [CrossRef]

- Alexander, M.R.; Jones, F.R.; Short, R.D. Radio-Frequency Hexamethyldisiloxane Plasma Deposition: A Comparison of Plasma- and Deposit-Chemistry. Plasmas Polym. 1997, 2, 277–300. [Google Scholar] [CrossRef]

- Alexander, M.R.; Short, R.D.; Jones, F.R.; Michaeli, W.; Blomfield, C.J. A study of HMDSO/O2 plasma deposits using a high-sensitivity and -energy resolution XPS instrument: Curve fitting of the Si 2p core level. Appl. Surf. Sci. 1999, 137, 179–183. [Google Scholar] [CrossRef]

- O’Hare, L.-A.; Parbhoo, B.; Leadley, S.R. Development of a methodology for XPS curve-fitting of the Si 2p core level of siloxane materials. Surf. Interface Anal. 2004, 36, 1427–1434. [Google Scholar] [CrossRef]

- Ghali, N.; Vivien, C.; Mutel, B.; Rives, A. Multilayer coating by plasma polymerization of TMDSO deposited on carbon steel: Synthesis and characterization. Surf. Coat. Technol. 2014, 259, 504–516. [Google Scholar] [CrossRef]

- Zheng, L.; Schmid, A.W.; Lambropoulos, J.C. Surface effects on Young’s modulus and hardness of fused silica by nanoindentation study. J. Mater. Res. 2007, 42, 191–198. [Google Scholar] [CrossRef]

- Nwankire, C.E.; Favaro, G.; Duong, Q.-H.; Dowling, D.P. Enhancing the Mechanical Properties of Superhydrophobic Atmospheric Pressure Plasma Deposited Siloxane Coatings. Plasma Process. Polym. 2011, 8, 305–315. [Google Scholar] [CrossRef] [Green Version]

- Benítez, F.; Martínez, E.; Galán, M.; Serrat, J.; Esteve, J. Mechanical properties of plasma deposited polymer coatings. Surf. Coat. Technol. 2000, 125, 383–387. [Google Scholar] [CrossRef]

- Beake, B.D.; Leggett, G.J.; Alexander, M.R. Characterisation of the mechanical properties of plasma-polymerised coatings by nanoindentation and nanotribology. J. Mater. Sci. 2002, 37, 4919–4927. [Google Scholar] [CrossRef]

- Alexander, M.R.; Duc, T.M. The chemistry of deposits formed from acrylic acid plasmas. J. Mater. Chem. 1998, 8, 937–943. [Google Scholar] [CrossRef]

- Cools, P.; Declercq, H.; De Geyter, N.; Morent, R. A stability study of plasma polymerized acrylic acid films. Appl. Surf. Sci. 2018, 432, 214–223. [Google Scholar] [CrossRef]

- Jiang, W.-G.; Su, J.-J.; Feng, X.-Q. Effect of surface roughness on nanoindentation test of thin films. Eng. Fract. Mech. 2008, 75, 4965–4972. [Google Scholar] [CrossRef]

- Derjaguin, B.V.; Muller, V.M.; Toporov, Y.P. Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 1975, 53, 314–326. [Google Scholar] [CrossRef]

- Pittenger, B.; Erina, N.; Su, C. Application Note #128: Quantitative Mechanical Property Mapping at the Nanoscale with PeakForce QNM; Bruker Nano Surfaces Division: Tucson, AZ, USA, 2012. [Google Scholar]

- Trivedi, R.; Hoferek, L.; Cech, V. Depth profile of mechanical properties of plasma-polymerized tetravinylsilane films evaluated by cyclic nanoindentation. Surf. Coat. Technol. 2011, 205, S470–S474. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C.; Brotzen, F.R. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Wang, M.; Liechti, K.M.; White, J.M.; Winter, R.M. Nanoindentation of polymeric thin films with an interfacial force microscope. J. Mech. Phys. Solids 2004, 52, 2329–2354. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M. Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J. Mater. Res. 1999, 14, 292–301. [Google Scholar] [CrossRef]

- Geng, K.; Yang, F.; Druffel, T.; Grulke, E.A. Nanoindentation behavior of ultrathin polymeric films. Polymer 2005, 46, 11768–11772. [Google Scholar] [CrossRef]

| Power (W)—E1 | 5 | 20 | 50 |

| Power (W)—E2 | 13 | 30 | 60 |

| Elecrode spacing (mm) | 160 | 160 | 80 |

| Sample Position | Film thickness (nm) | ||

| 0°(Facing E1) | 236 ± 2 | 253 ± 1 | 127 ± 6 |

| 90°(Facing up) | 213 ± 9 | 244 ± 2 | 171 ± 1 |

| −90°(Facing down) | 221 ± 6 | 237 ± 2 | 177 ± 1 |

| 180°(Facing E2) | 204 ± 1 | 228 ± 1 | 141 ± 1 |

| E1 | Sample | XPS Atomic Concentration (%) | ||||

|---|---|---|---|---|---|---|

| Power (W) | Position | C | O | Si | O/C | O/Si |

| 5 | 0° | 51.9 ± 0.2 | 21.3 ± 0.2 | 26.8 ± 0.1 | 0.41 | 0.79 |

| 90° | 52.1 ± 0.1 | 21.2 ± 0.1 | 26.6 ± 0.1 | 0.41 | 0.80 | |

| −90° | 52.1 ± 0.3 | 21.2 ± 0.1 | 26.6 ± 0.2 | 0.41 | 0.80 | |

| 180° | 52.2 ± 0.1 | 21.0 ± 0.1 | 26.8 ± 0.1 | 0.4 | 0.78 | |

| 20 | 0° | 49.8 ± 0.2 | 23.4 ± 0.1 | 26.8 ± 0.3 | 0.47 | 0.87 |

| 90° | 50.8 ± 0.2 | 22.6 ± 0.2 | 26.6 ± 0.1 | 0.45 | 0.85 | |

| −90° | 50.7 ± 0.1 | 22.7 ± 0.1 | 26.6 ± 0.1 | 0.45 | 0.85 | |

| 180° | 50.9 ± 0.4 | 22.4 ± 0.1 | 26.7 ± 0.3 | 0.44 | 0.84 | |

| 50 | 0° | 51.9 ± 0.2 | 22.5 ± 0.1 | 25.7 ± 0.2 | 0.43 | 0.87 |

| 90° | 49.4 ± 0.6 | 23.7 ± 0.3 | 26.8 ± 0.2 | 0.48 | 0.88 | |

| −90° | 49.0 ± 0.2 | 24.1 ± 0.4 | 27.0 ± 0.2 | 0.49 | 0.89 | |

| 180° | 49.7 ± 0.2 | 23.8 ± 0.3 | 26.5 ± 0.1 | 0.48 | 0.90 | |

| Power | O2 | Deposition | Film Thickness | XPS Atomic Concentration (%) | ||

|---|---|---|---|---|---|---|

| (kW) | (%) | Time (S) | (nm) | C | O | Si |

| 1 | 70 | 6 | 414 ± 2 | 33 ± 1.0 | 42 ± 0.1 | 25 ± 0.1 |

| 1 | 90 | 30 | 529 ± 7 | 22 ± 0.6 | 51 ± 0.6 | 27 ± 1.0 |

| 2 | 55 | 25 | 343 ± 6 | 39 ± 0.1 | 36 ± 0.1 | 25 ± 0.1 |

| 2 | 90 | 20 | 393 ± 5 | 16 ± 0.4 | 57 ± 0.3 | 27 ± 0.2 |

| RF | Sample | MW Power | O2 | Young’s Modulus | Hardness | Rq-AFM | DMT-Modulus |

|---|---|---|---|---|---|---|---|

| Power (W) | Position | (kW) | (%) | (GPa) | (GPa) | (nm) | (GPa) |

| 5 | 0° | - | - | 2.1 | 0.2 | 2.1 ± 0.1 | 2.8 ± 0.8 |

| 90° | - | - | 2.2 | 0.2 | 2.2 ± 0.2 | 2.1 ± 0.5 | |

| 20 | 0° | - | - | 5.6 ± 0.7 | 0.96 ± 0.09 | 2.5 ± 0.6 | 10.1 ± 3.0 |

| 90° | - | - | 4.2 ± 0.6 | 0.73 ± 0.1 | 2.6 ± 0.1 | 7.0 ± 2.3 | |

| 50 | 0° | - | - | 56.4 ± 1.01 | 7.46 ± 1.01 | 1.6 ± 0.2 | 26.2 ± 7.4 |

| 90° | - | - | 34.7 ± 4.8 | 4.77 ± 0.8 | 1.4 ± 0.2 | 40.3 ± 18.3 | |

| - | - | 1 | 70 | 1.31 ± 0.08 | 0.25 ± 0.03 | 0.4 ± 0.1 | 0.75 ± 0.04 |

| - | - | 1 | 90 | 6.38 ± 0.52 | 1.05 ± 0.13 | 0.7 ± 0.3 | 8.6 ± 0.9 |

| - | - | 2 | 55 | 1.31 ± 0.18 | 0.26 ± 0.05 | 0.6 ± 0.1 | 0.28 ± 0.01 |

| - | - | 2 | 90 | 10.87 ± 2.13 | 0.93 ± 0.24 | 9.6 ± 1.7 | 5.9 ± 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radjef, R.; Jarvis, K.L.; Hall, C.; Ang, A.; Fox, B.L.; McArthur, S.L. Characterising a Custom-Built Radio Frequency PECVD Reactor to Vary the Mechanical Properties of TMDSO Films. Molecules 2021, 26, 5621. https://doi.org/10.3390/molecules26185621

Radjef R, Jarvis KL, Hall C, Ang A, Fox BL, McArthur SL. Characterising a Custom-Built Radio Frequency PECVD Reactor to Vary the Mechanical Properties of TMDSO Films. Molecules. 2021; 26(18):5621. https://doi.org/10.3390/molecules26185621

Chicago/Turabian StyleRadjef, Racim, Karyn L. Jarvis, Colin Hall, Andrew Ang, Bronwyn L. Fox, and Sally L. McArthur. 2021. "Characterising a Custom-Built Radio Frequency PECVD Reactor to Vary the Mechanical Properties of TMDSO Films" Molecules 26, no. 18: 5621. https://doi.org/10.3390/molecules26185621

APA StyleRadjef, R., Jarvis, K. L., Hall, C., Ang, A., Fox, B. L., & McArthur, S. L. (2021). Characterising a Custom-Built Radio Frequency PECVD Reactor to Vary the Mechanical Properties of TMDSO Films. Molecules, 26(18), 5621. https://doi.org/10.3390/molecules26185621