Physicochemical Properties and Bioactivity of a New Guar Gum-Based Film Incorporated with Citral to Brown Planthopper, Nilaparvata lugens (Stål) (Hemiptera: Delphacidae)

Abstract

1. Introduction

2. Results

2.1. Bioactivity of Film-forming Emulsion to BPH

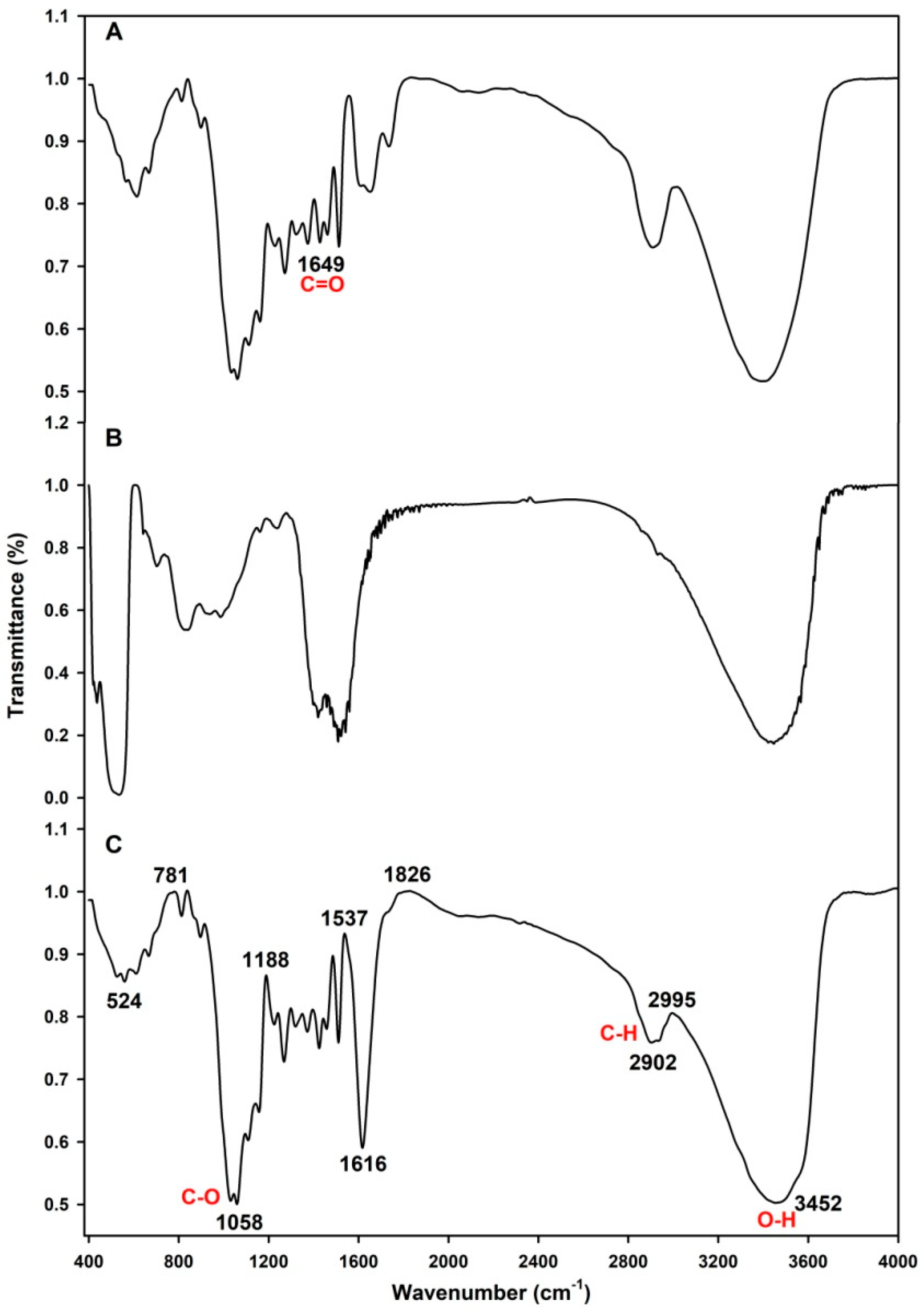

2.2. FTIR Spectroscopy Analysis

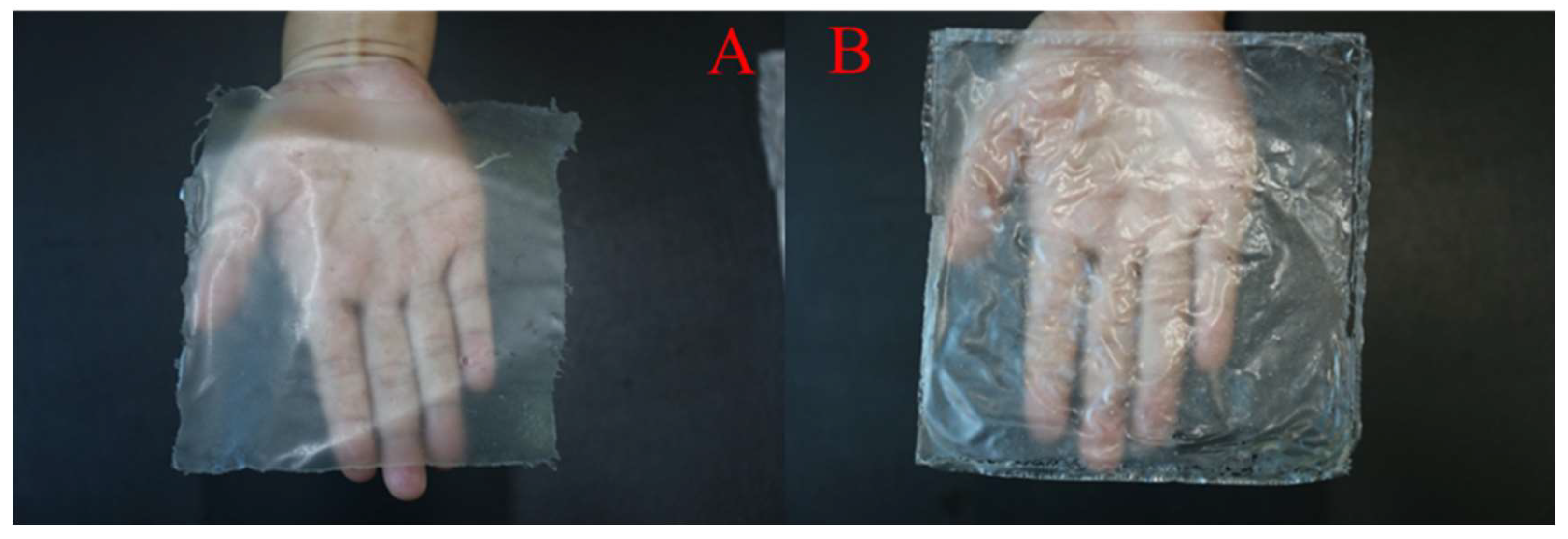

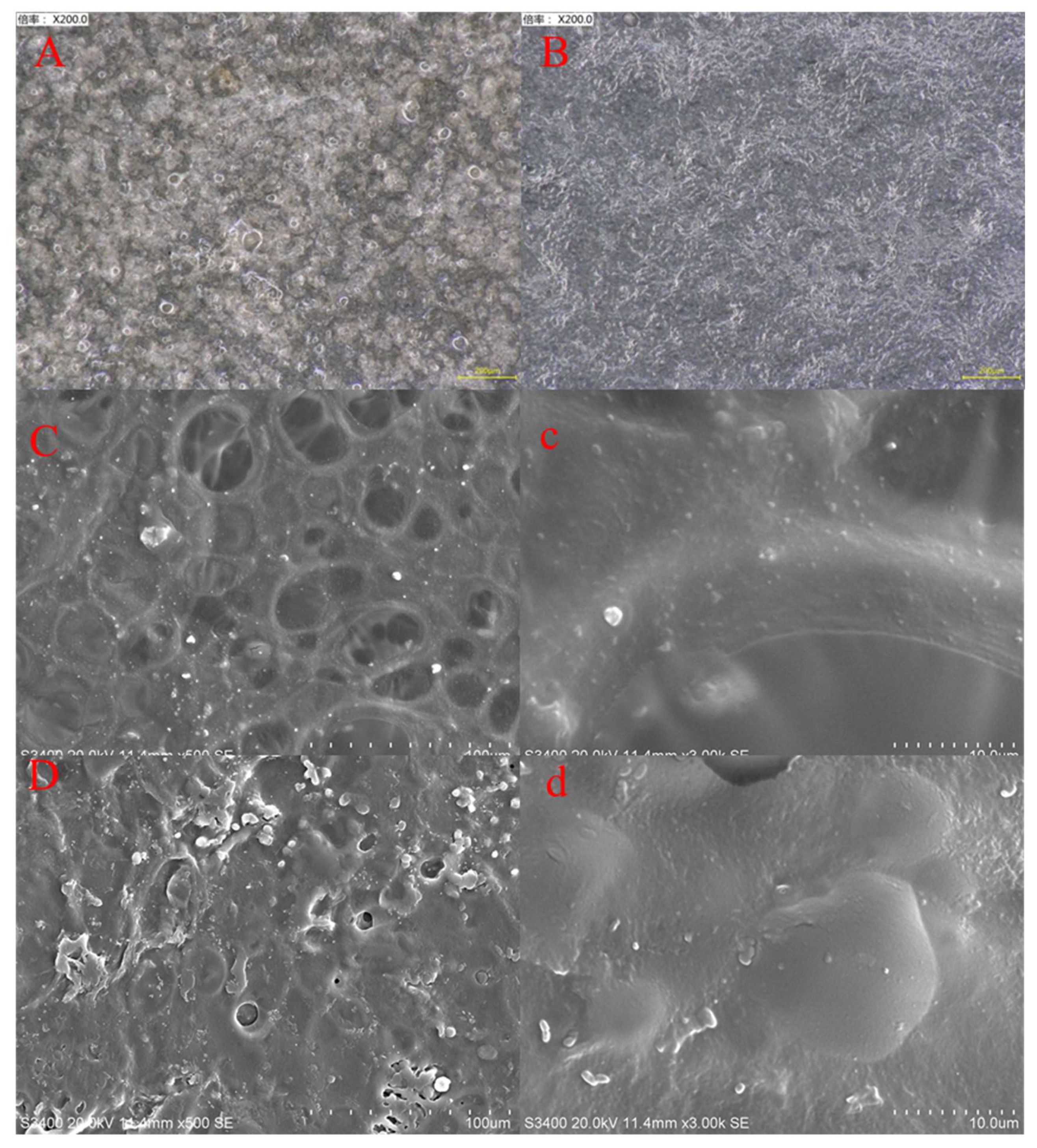

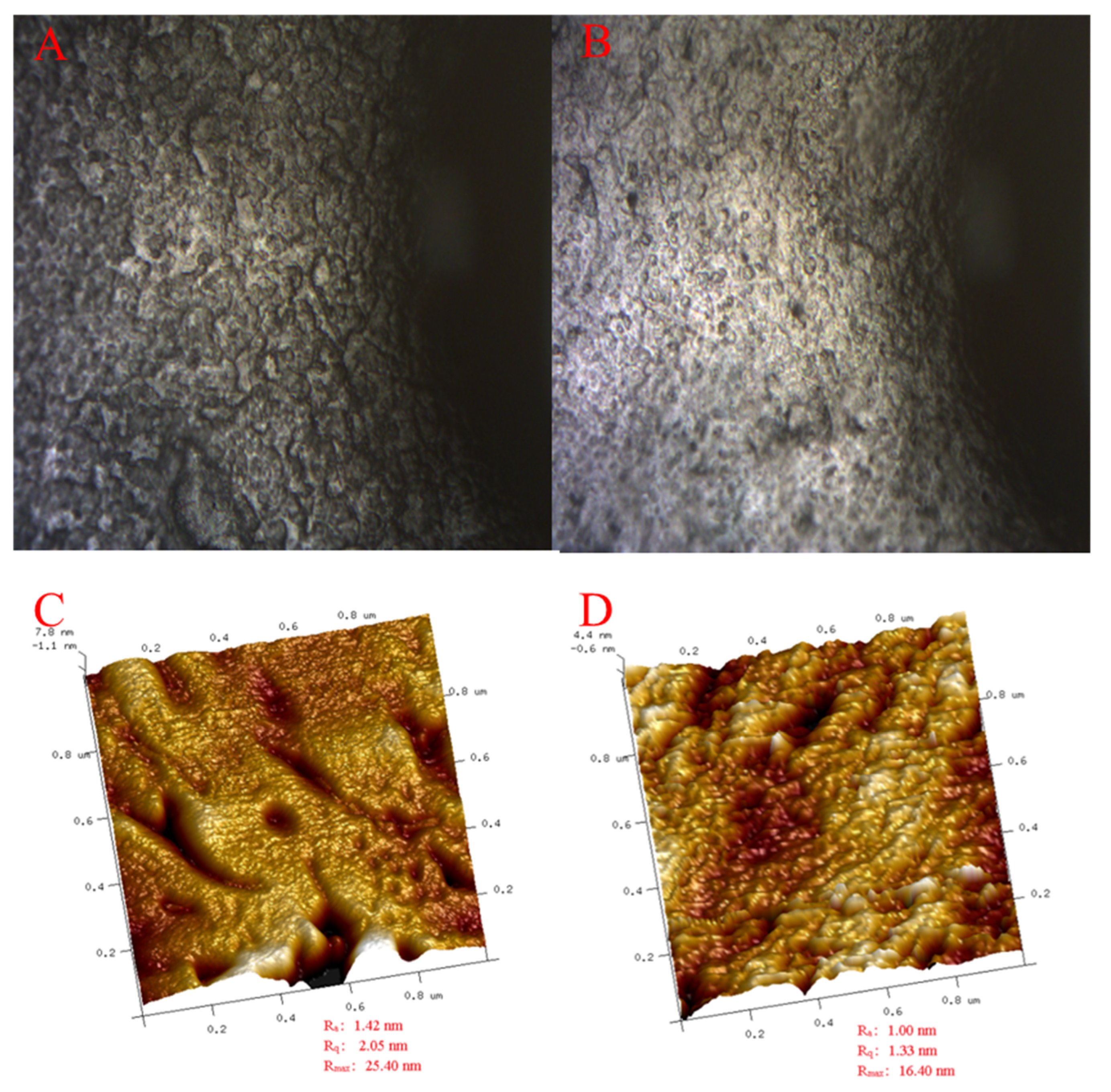

2.3. Microstructure of the Films

2.4. Physicochemical Properties of the Films

3. Discussion

4. Materials and Methods

4.1. Chemicals

4.2. Rice and Insects

4.3. Preparation of Film-Forming Emulsion

4.4. Bioactivity Test of Film-Forming Emulsion

4.4.1. Toxicity Bioassay

4.4.2. Mortality Test

4.5. Fourier-Transform Infrared (FTIR) Spectroscopy

4.6. Preparation of Films

4.7. Microstructure of the Films

4.8. Physicochemical Properties of the Films

4.9. Statistical Analysis

5. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Brar, D.S.; Virk, P.S.; Jena, K.K.; Khush, G.S. Breeding for Resistance to Planthoppers in Rice. Planthopper: New Threats to the Sustainability of Intensive Rice Production Systems in Asia. Available online: http://ageconsearch.umn.edu/record/164471/files/Planthoppers (accessed on 1 April 2017).

- Reissig, W.H.; Heinrichs, E.A.; Valencia, S.L. Effects of insecticides on Nilaparvata lugens, and its predators: Spiders, Microvelia atrolineata and Cyrtorhinus lividipennis. Env. Entomol. 1982, 11, 193–199. [Google Scholar] [CrossRef]

- Zhang, X.L.; Liu, X.Y.; Zhu, F.X.; Li, J.H.; You, H.; Lu, P. Field evolution of insecticide resistance in the brown planthopper (Nilaparvata lugens Stål) in China. Crop Prot. 2014, 58, 61–66. [Google Scholar] [CrossRef]

- Liao, X.; Peng, F.X.; Pei, P.G.; Hu, W.; Li, J.H. The Current Susceptibilities of Brown Planthopper Nilaparvata Lugens to Triflumezopyrim and other Frequently Used Insecticides in China. Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1111/1744-7917.12764 (accessed on 26 April 2020).

- Londingkene, J.A.; Trisyono, Y.A.; Witjaksono, G.; Martono, E. Resistance to imidacloprid and effect of three synergists on the resistance level of brown planthopper. In AIP Conference Proceedings; AIP Publishing (American Institute of Physics): College Park, MD, USA, 2016; Volume 1755, pp. 140008-1–140008-4. [Google Scholar] [CrossRef]

- Jeong, I.H.; Jeon, S.W.; Lee, S.K.; Park, B.; Park, S.K.; Lee, S.B.; Choi, N.J.; Lee, S.W.; Lee, S.H.; Kwon, D.H. Insecticide cross-resistanceand developmental characteristics on the two rice varieties, ‘chinnong’ and ‘chuchung’, of the imidacloprid-resistant brown planthopper. Korean J. Pestic. Sci. 2017, 21, 381–388. [Google Scholar] [CrossRef]

- Matsumura, M.; Sanada-Morimura, S.; Otuka, A.; Sonoda, S.; Thanh, D.V.; Chien, H.V.; Tuong, P.V.; Loc, P.M.; Liu, Z.W.; Zhu, Z.R.; et al. Insecticide susceptibilities of the two rice planthoppers Nilaparvata lugens and Sogatella furcifera in East Asia, the Red River Delta, and the Mekong Delta. Pest Manag. 2018, 74, 456–464. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Xie, P.; Dong, C.H.; Han, Y.Q.; Tang, T.; Liu, Y.; Zhong, J.; Bai, L.Y.; Zhou, X.M. Cross-resistance and baseline susceptibility of brown planthopper nilaparvata lugens (hemiptera: Delphacidae) from China to Cycloxaprid. J. Econ. Entomol. 2018, 11, 2359–2363. [Google Scholar] [CrossRef] [PubMed]

- APRD. Arthropod Pesticide Resistance Database. 2019. Available online: https://www.pesticideresistance.org/search.php (accessed on 8 December 2019).

- Aider, M. Chitosan application for active bio-based films production andpotential in the food industry: Review. Lwt-Food Sci. Technol. 2010, 43, 837–852. [Google Scholar] [CrossRef]

- Peng, L.; Trumble, J.T.; Munyaneza, J.E.; Liu, T.X. Repellency of a kaolin particle film to potato psyllid, bactericera cockerelli (hemiptera: Psyllidae), on tomato under laboratory and field conditions. Pest Manag. Sci. 2011, 67, 815–824. [Google Scholar] [CrossRef]

- Giteru, S.G.; Coorey, R.; Bertolatti, D.; Watkin, E.; Stuart, J.S.; Fang, Z.X. Physicochemical and antimicrobial properties of citral and quercetin incorporated kafirin-based bioactive films. Food Chem. 2015, 168, 341–347. [Google Scholar] [CrossRef]

- Sahraee, S.; Milani, J.M.; Ghanbarzadeh, B.; Hamishehkar, H. Physicochemical and antifungal properties of bio-nanocomposite film based on gelatin-chitin nanoparticles. Int. J. Biol. Macromol. 2017, 97, 373–381. [Google Scholar] [CrossRef]

- Dutta, P.K.; Tripathi, S.; Mehrotra, G.K.; Dutta, J. Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 2009, 114, 1173–1182. [Google Scholar] [CrossRef]

- Aydinli, M.; Tutas, M. Water sorption and water vapour permeability propertiesof polysaccharide (locust bean gum) based edible films. Lwt-Food Sci. Technol. 2000, 33, 63–67. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Souza, B.W.S.; Simões, J.; Teixeira, J.A.; Domingues, M.R.M.; Coimbra, M.A.; Vicente, A.A. Structural and thermal characterization of galactomannans from non-conventional sources. Carbohydr. Polym. 2011, 83, 179–185. [Google Scholar] [CrossRef]

- Antoniou, J.; Liu, F.; Majeed, H.; Zhong, F. Characterization of tara gum edible films incorporated with bulk chitosan and chitosan nanoparticles: A comparative study. Food Hydrocoll. 2015, 44, 309–319. [Google Scholar] [CrossRef]

- Albuquerque, P.B.; Cerqueira, M.A.; Vicente, A.A.; Teixeira, J.A.; Carneiro-da-Cunha, M.G. Immobilization of bioactive compounds in Cassia grandis galactomannan-based films: Influence on physicochemical properties. Int. J. Biol. Macromol. 2017, 96, 727–735. [Google Scholar] [CrossRef] [PubMed]

- Lv, R.; Kong, Q.; Mou, H.; Fu, X. Effect of guar gum on stability and physical properties of orange juice. Int. J. Biol. Macromol. 2017, 98, 565–574. [Google Scholar] [CrossRef]

- Prajapati, V.D.; Jani, G.K.; Moradiya, N.G.; Randeria, N.P.; Nagar, B.J.; Naikwadi, N.N.; Variya, B.C. Galactomannan: A versatile biodegradable seed polysaccharide. Int. J. Biol. Macromol. 2013, 60, 83–92. [Google Scholar] [CrossRef]

- Vilas, D.C.; Kunal, P.; Preetam, S. Characterization of tri-phasic edible films from chitosan, guar gum, and whey protein isolate loaded with plant-based antimicrobial compounds. Polym. -Plast. Technol. Eng. 2019, 58, 255–269. [Google Scholar] [CrossRef]

- Saberi, B.; Vuong, Q.V.; Chockchaisawasdee, S.; Golding, J.B.; Scarlett, C.J.; Stathopoulos, C.E. Physical, barrier, and antioxidant properties of pea starch-guar gum biocomposite edible films by incorporation of natural plant extracts. Food Bioprocess Technol. 2017, 10, 2240–2250. [Google Scholar] [CrossRef]

- Saberi, B.; Chockchaisawasdee, S.; Golding, J.B.; Scarlett, C.J.; Stathopoulos, C.E. Characterization of pea starch-guar gum biocomposite edible films enriched by natural antimicrobial agents for active food packaging. Food Bioprod. Process. 2017, 105, 51–63. [Google Scholar] [CrossRef]

- Dhumal, C.V.; Pal, K.; Sarkar, P. Synthesis, characterization, and antimicrobial efficacy of composite films from guar gum/sago starch/whey protein isolate loaded with carvacrol, citral and carvacrol-citral mixture. J. Mater. Sci. Mater. Med. 2019, 30, 117. [Google Scholar] [CrossRef]

- Dhumal, C.V.; Ahmed, J.; Bandara, N.; Sarkar, P. Improvement of antimicrobial activity of sago starch/guar gum bi-phasic edible films by incorporating carvacrol and citral. Food Packag. Shelf Life 2019, 21, 100380. [Google Scholar] [CrossRef]

- Seydim, A.C.; Sarikus, G. Antimicrobial activity of whey protein based edible films incorporated with oregano, rosemary and garlic essential oils. Food Res. Int. 2006, 39, 639–644. [Google Scholar] [CrossRef]

- Ojagh, S.M.; Rezaei, M.; Razavi, S.H.; Hosseini, S.M.H. Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem. 2010, 122, 161–166. [Google Scholar] [CrossRef]

- Seow, Y.X.; Yeo, C.R.; Chung, H.L.; Yuk, H.G. Plant essential oils as active antimicrobial agents. Crit. Rev. Food Sci. Nutr. 2014, 54, 625–644. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Song, K.; Zhang, X.; Sun, Y.; Sui, Y.; Chen, Y.; Jia, Z.; Sun, H.; Sun, Z.; Xia, X. Antimicrobial activity and possible mechanism of action of citral against Cronobacter sakazakii. Plos One 2016, 11, e0159006. [Google Scholar] [CrossRef] [PubMed]

- Si, W.; Ni, X.; Gong, J.; Yu, H.; Tsao, R.; Han, Y. Antimicrobial activity of essential oils and structurally related synthetic food additives towards Clostridium perfringens. J. Appl. Microbiol. 2009, 106, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Amna, A.S.; Suzan, A.K. Chemical and antimicrobial studies of monoterpene: Citral. Pestic. Biochem. Physiol. 2010, 98, 89–93. [Google Scholar] [CrossRef]

- Hierro, I.; Valero, A.; Pérez, P.; González, P.; Cabo, M.M.; MontillacM, M.P.; Navarro, C. Action of different monoterpenic compounds against Anisakis simplex s.l. L3 larvae. Phytomedicine 2004, 11, 77–82. [Google Scholar] [CrossRef]

- Oyedele, A.O.; Gbolade, A.A.; Sosan, M.B.; Adewoyin, F.B.; Soyelu, O.L.; Orafidiya, O.O. Formulation of an effective mosquito-repellent topical product from lemongrass oil. Phytomedicine 2002, 9, 259–262. [Google Scholar] [CrossRef]

- Hao, H.; Wei, J.; Dai, J.; Du, J. Host-seeking and blood- feeding behavior of Aedes albopictus (Diptera: Culicidae) exposed to vapors of geraniol, citral, citronellal, eugenol, or anisaldehyde. J. Med Entomol. 2008, 45, 533–539. [Google Scholar] [CrossRef]

- Tak, J.H.; Isman, M.B. Metabolism of citral, the major constituent of lemongrass oil, in the cabbage looper, trichoplusia ni, and effects of enzyme inhibitors on toxicity and metabolism. Pestic. Biochem. Physiol. 2016, 133, 20–25. [Google Scholar] [CrossRef] [PubMed]

- Silva-Angulo, A.B.; Zanini, S.F.; Rosenthal, A.; Rodrigo, D.; Klein, G.; Martinez, A. Comparative study of the effects of citral on the growth and injury of Listeria innocua and Listeria monocytogenes cells. PLoS ONE 2015, 10, e0114026. [Google Scholar] [CrossRef] [PubMed]

- Giteru, S.G.; Oey, I.; Ali, M.A.; Johnson, S.K.; Fang, Z. Effect of kafirin-based films incorporating citral and quercetin on storage of fresh chicken fillets. Food Control 2017, 80, 37–44. [Google Scholar] [CrossRef]

- Li, R.Y.; Wu, X.M.; Yin, X.H.; Long, Y.H.; Li, M. Naturally produced citral can significantly inhibit normal physiology and induce cytotoxicity on magnaporthe grisea. Pestic Biochem Physiol 2014, 118, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.X.; Zheng, X.S.; Yang, Y.J.; Tian, J.C.; Lu, Y.H.; Tan, H.K.; Heong, K.L.; Lu, Z.X. Methyl eugenol bioactivities as a new potential botanical insecticide against major insect pests and their natural enemies on rice (Oriza sativa). Crop Prot. 2015, 72, 144–149. [Google Scholar] [CrossRef]

- Dai, Z.Y.; Tan, J.; Zhou, C.; Yang, X.F.; Yang, F.; & Zhang, S.J.; Sun, S.C.; Miao, X.X.; Shi, Z.Y. The osmir396-osgrf8-osf3h-flavonoid pathway mediates resistance to the brown planthopper in rice (oryza sativa). Plant Biotechnol 2019, 17, 1657–1669. [Google Scholar] [CrossRef]

- Li, RY.; Li, M.; Wu, XM.; Hu, AL.; Yang, F.; Xu, XL.; Han, JB.; Hu, XF.; Yin, XH. Dynamic changes of resistance to conventional insecticides in the brownplanthopper, Nilaparvata lugens (Hemiptera: Delphacidae) in the main rice growing regions in Guizhou Province, southwestern China. Acta Entomol. Sin. 2016, 59, 1232–1237. [Google Scholar] [CrossRef]

- Puterka, G.J.; Michael, G.D.; Sekutowski, D.G.; Unruh, T.R.; Jones, S.K. Progress toward liquid formulations of particle films for insect and disease control in pear. Env. Entomol. 2000, 29, 329–339. [Google Scholar] [CrossRef]

- Glenn, D.M.; Puterka, G.J.; Vanderzwet, T.; Byers, R.E.; Feldman, C. Hydrophobic particle films: A new paradigm for suppression of arthropod pests and plant diseases. J Econ Entomol 1999, 92, 759–771. [Google Scholar] [CrossRef]

- Tak, J.H.; Jovel, E.; Isman, M.B. Contact, fumigant, and cytotoxic activities of thyme and lemongrass essential oils against larvae and an ovarian cell line of the cabbage looper, trichoplusia ni. J. Pest Sci. 2016, 89, 183–193. [Google Scholar] [CrossRef]

- Tak, J.H.; Jovel, E.; Isman, M.B. Effects of rosemary, thyme and lemongrass oils and their major constituents on detoxifying enzyme activity and insecticidal activity in trichoplusia ni. Pestic. Biochem. Physiol. 2017, 140, 9–16. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, F.; Fan, R.; Gao, Y. Physicochemical stability of citral emulsions stabilized by milk proteins (lactoferrin, α-lactalbumin, β-lactoglobulin) and beet pectin. Colloids Surf. A: Phys. Eng. Asp. 2015, 487, 104–112. [Google Scholar] [CrossRef]

- Tian, H.X.; Li, D.; Xu, T.; Hu, J.; Zhao, B. Citral stabilization and characterization of nanoemulsions stabilized by a mixture of gelatin and tween 20 in an acidic system. J. Sci. Food Agric. 2017, 97, 2991–2998. [Google Scholar] [CrossRef] [PubMed]

- Nash, J.J.; Erk, K.A. Stability and interfacial viscoelasticity of oil-water nanoemulsions stabilized by soy lecithin and tween 20 for the encapsulation of bioactive carvacrol. Colloids Surf. A: Phys. Eng. Asp. 2017, 517, 1–11. [Google Scholar] [CrossRef]

- Kaith, B.S.; Sharma, R.; Kalia, S.; Bhatti, M.S. Response surface methodology and optimized synthesis of guar gum-based hydrogels with enhanced swelling capacity. RSC Adv. 2014, 4, 40339–40344. [Google Scholar] [CrossRef]

- Haiyee, Z.A.; Saim, N.; Said, M.; Illias, R.M.; Mustapha, W.A.W.; Hassan, O. Characterization of cyclodextrin complexes with turmeric oleoresin. Food Chem. 2009, 114, 459–465. [Google Scholar] [CrossRef]

- Ortiz-Tafoya, M.C.; Tecante, A. Physicochemical characterization of sodium stearoyl lactylate (SSL), polyoxyethylene sorbitan monolaurate (Tween 20) and κ-carrageenan. Data Brief 2018, 19, 642–650. [Google Scholar] [CrossRef]

- Kim, J.M.; Marshall, M.R.; Cornell, J.A.; Iii, J.F.P.; Wei, C.I. Antibacterial activity of carvacrol, citral, and geraniol against Salmonella typhimurium in culture medium and on fish cubes. J. Food Sci. 1995, 60, 1364–1368. [Google Scholar] [CrossRef]

- Hashemi Gahruie, H.; Ziaee, E.; Eskandari, M.H.; Hosseini, S.M.H. Characterization of basil seed gum-based edible films incorporated with Zataria multiflora essential oil nanoemulsion. Carbohydr. Polym. 2017, 166, 93–103. [Google Scholar] [CrossRef]

- Li, J.; Ye, F.; Lei, L.; Zhao, G. Combined effects of octenylsuccination and oregano essential oil on sweet potato starch films with an emphasis on water resistance. Int. J. Biol. Macromol. 2018, 115, 547–553. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Aliheidari, N.; Fahmi, R.; Shojaee-Aliabadi, S.; Keshavarz, B.; Cran, M.J.; Khaksar, R. Physical, mechanical and barrier properties of corn starch films incorporated with plant essential oils. Carbohydr. Polym. 2013, 98, 1117–1126. [Google Scholar] [CrossRef] [PubMed]

- Atef, M.; Rezaei, M.; Behrooz, R. Characterization of physical, mechanical, and antibacterial properties of agar-cellulose bionanocomposite films incorporated with savory essential oil. Food Hydrocoll 2015, 45, 150–157. [Google Scholar] [CrossRef]

- Yoo, S.; Krochta, J.M. Whey protein–polysaccharide blended edible film formation and barrier, tensile, thermal and transparency properties. J. Sci. Food Agric. 2011, 91, 2628–2636. [Google Scholar] [CrossRef] [PubMed]

- Kristo, E.; Koutsoumanis, K.P.; Biliaderis, C.G. Thermal mechanical and water vapor barrier properties of sodium caseinate films containing antimicrobials and their inhibitory action on Listeria monocytogene. Food Hydrocoll. 2008, 22, 373–386. [Google Scholar] [CrossRef]

- Flores, S.; Conte, A.; Campos, C.; Gerschenson, L.; Nobile, M.D. Mass transport properties of tapioca-based active edible films. J. Food Eng. 2007, 81, 580–586. [Google Scholar] [CrossRef]

- Ionescu, D.; Popescu, A.; Dra˘gusin, M.; Dima, M.; Iftime, A.; Ganea, C. Modulation by quercetin of the effect of certain Hofmeister anions on artificial lipid bilayers. Rom. J. Biophys. 2007, 17, 85–95. [Google Scholar]

- Acevedo-Fani, A.; Salvia-Trujillo, L.; Rojas-Graü, M.A.; Olga, M.B. Edible films from essential-oil-loaded nanoemulsions: Physicochemical characterization and antimicrobial properties. Food Hydrocoll. 2015, 47, 168–177. [Google Scholar] [CrossRef]

- Norajit, K.; Kim, K.M.; Ryu, G.H. Comparative studies on the characterization and antioxidant properties of biodegradable alginate films containing ginseng extract. J. Food Eng. 2010, 98, 377–384. [Google Scholar] [CrossRef]

- Shojaee-Aliabadi, S.; Hosseini, H.; Mohammadifar, M.A.; Mohammed, A.; Ghasemlou, M.; Hosseini, S.M.; Khaksar, R. Characterization of k-carrageenan films incorporated plant essential oils with improved antimicrobial activity. Carbohydr. Polym. 2014, 101, 582–591. [Google Scholar] [CrossRef]

- Sanchez-Gonzalez, L.; Chiralt, A.; Gonzalez-Martínez, C.; & Chafer, M. Effect of essential oils on properties of film forming emulsions and films based on hydroxypropylmethylcellulose and chitosan. J. Food Eng. 2011, 105, 246–253. [Google Scholar] [CrossRef]

- Amalin, D.M.; Averion, L.; Bihis, D.; Legaspi, C.J.; David, E.F. Effectiveness of kaolin clay particle film in managing Helopeltis collaris (hemiptera: Miridae), a major pest of cacao in the philippines. Fla. Entomol. Int. J. Am. 2015, 98, 354–355. [Google Scholar] [CrossRef]

- EC (European Commission). Regulation (EC) No. 1107/2009 of the European parliament and the Council of 21 October 2009 Concerning the Placing of Plant Protection Products on the Market and Repealing Council Directives 79/117/EEC and 91/414/EEC. Available online: https://europa.eu/search/index.do?queryText=Regulation+(EC)+No.+1107%2F2009&query_source=europa&more_options_date=*&more_options_date_from=&more_options_date_to=&more_options_language=en&more_options_f_formats=*&swlang=en (accessed on 21 October 2019).

- Chandler, D.; Bailey, A.S.; Tatchell, G.M.; Davidson, G.; Greaves, J.; Grant, W.P. The development, regulation and use of biopesticides for integrated pest management. Philos. Trans. R. Soc. B: Biol. Sci. 2011, 366, 1987–1998. [Google Scholar] [CrossRef] [PubMed]

- Villaverde, J.J.; Sevilla-Morán, B.; Sandín-España, P.; López-Goti, C.; Alonso-Prados, J.L. Challenges of biopesticides under the European regulation (EC) No. 1107/2009. 2014, 43, 437–482. In Studies in Natural Products Chemistry; Elsevier Press: Amsterdam, The Netherlands, 2014; ISBN 978-0-444-63430-6. [Google Scholar] [CrossRef]

- Saurabh, C.K.; Gupta, S.; Variyar, P.S.; Sharma, A. Effect of addition of nanoclay, beeswax, tween-80 and glycerol on physicochemical properties of guar gum films. Ind. Crop. Prod. 2016, 89, 109–118. [Google Scholar] [CrossRef]

- Zhuang, Y.L.; Shen, J.L. A method for monitoring of resistance to buprofezin in brown planthopper. J. Nanjing Agric. Univ. 2000, 23, 114–117. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Zhu, Y.C.; Ma, C.; Huang, Y.; Shen, J. Susceptibility to neonicotinoids and risk of resistance development in the brown planthopper, Nilaparvata lugens (Stål) (Homoptera: Delphacidae). Pest Manag.Sci. 2008, 64, 1278–1284. [Google Scholar] [CrossRef]

- Yin, J.L.; Xu, H.W.; Wu, J.C.; Huan, J.; Hu, J.H.; Yang, G.Q. Cultivar and insecticide applications affect the physiological development of the brown planthopper, Nilaparvata lugens (Stal) (Hemiptera: Delphacidae). Env. Entomol. 2008, 37, 206–212. [Google Scholar] [CrossRef][Green Version]

- Mei, Y.; Zhao, Y. Barrier and mechanical properties of milk protein-based edible films containing nutraceuticals. J. Agric. Food Chem. 2003, 51, 1914–1918. [Google Scholar] [CrossRef]

- Kavoosi, G.; Dadfar, S.M.M.; Purfard, A.M. Mechanical, physical, antioxidant, and antimicrobial properties of gelatin films incorporated with thymol for potential use as nano wound dressing. J. Food Sci. 2013, 78, 244–250. [Google Scholar] [CrossRef]

- Ayranci, E.; Tunc, S. A method for the measurement of the oxygen permeability and the development of edible films to reduce the rate of oxidative reactions in fresh foods. Food Chem. 2003, 80, 423–431. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds GC film-forming emulsion and GG film-forming emulsion are available from the authors. |

| Ratio of Citral and Guar Gum | Total Number of Nymphs Treated | Toxicity Regression Equations (Y) | Correlation Coefficient (r) | LC50 (95% Confidence Interval) (mg/mL) | Chi-Square Value |

|---|---|---|---|---|---|

| 3:1 | 225 | y = 4.262 + 0.981x | 0.980 | 5.65 (2.58−12.39) | 0.8397 |

| 2:1 | 225 | y = 4.262 + 0.867x | 0.992 | 7.11 (2.48−20.40) | 0.2124 |

| 1:1 | 225 | y = 4.475 + 0.828x | 0.976 | 4.30 (1.64−11.31) | 0.6948 |

| 1:2 | 225 | y = 3.782 + 1.334x | 0.998 | 8.19 (2.98−22.47) | 0.0514 |

| 1:3 | 225 | y = 4.014 + 0.830x | 0.976 | 15.43 (3.12−76.21) | 0.6044 |

| citral | 225 | y = 3.769 + 0.748x | 0.978 | 44.38 (2.06−954.28) | 0.3503 |

| GG | 225 | y = 3.483 + 0.705x | 0.957 | 141.51 (3.72−5387.85) | 0.6624 |

| Film Type | Mechanical Properties | Physical Properties | |||

|---|---|---|---|---|---|

| Thickness (mm) | TS (N/mm2) | EAB (%) | SOW (%) | OP (×10−9cm3/m2·d·Pa) | |

| GG film | 39.10 ± 2.80 a | 41.89 ± 1.96 a | 1.82 ± 0.38 a | 30.30 ± 0.26 a | 8.26 ± 0.38 a |

| GC film | 41.70 ± 2.30 a | 38.30 ± 1.40 a | 2.03 ± 0.49 a | 15.00 ± 0.23 b | 2.37 ± 0.21 b |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Guo, C.; Li, M.; Li, R.; Wu, X.; Hu, A.; Hu, X.; Mo, F.; Wu, S. Physicochemical Properties and Bioactivity of a New Guar Gum-Based Film Incorporated with Citral to Brown Planthopper, Nilaparvata lugens (Stål) (Hemiptera: Delphacidae). Molecules 2020, 25, 2044. https://doi.org/10.3390/molecules25092044

Gao X, Guo C, Li M, Li R, Wu X, Hu A, Hu X, Mo F, Wu S. Physicochemical Properties and Bioactivity of a New Guar Gum-Based Film Incorporated with Citral to Brown Planthopper, Nilaparvata lugens (Stål) (Hemiptera: Delphacidae). Molecules. 2020; 25(9):2044. https://doi.org/10.3390/molecules25092044

Chicago/Turabian StyleGao, Xiubing, Can Guo, Ming Li, Rongyu Li, Xiaomao Wu, Anlong Hu, Xianfeng Hu, Feixu Mo, and Shuai Wu. 2020. "Physicochemical Properties and Bioactivity of a New Guar Gum-Based Film Incorporated with Citral to Brown Planthopper, Nilaparvata lugens (Stål) (Hemiptera: Delphacidae)" Molecules 25, no. 9: 2044. https://doi.org/10.3390/molecules25092044

APA StyleGao, X., Guo, C., Li, M., Li, R., Wu, X., Hu, A., Hu, X., Mo, F., & Wu, S. (2020). Physicochemical Properties and Bioactivity of a New Guar Gum-Based Film Incorporated with Citral to Brown Planthopper, Nilaparvata lugens (Stål) (Hemiptera: Delphacidae). Molecules, 25(9), 2044. https://doi.org/10.3390/molecules25092044