Development of the Method for Determination of Volatile Sulfur Compounds (VSCs) in Fruit Brandy with the Use of HS–SPME/GC–MS

Abstract

1. Introduction

2. Results

2.1. Optimization of Solid-Phase Microextraction (SPME) Parameters

2.1.1. Selection of Fiber Coating

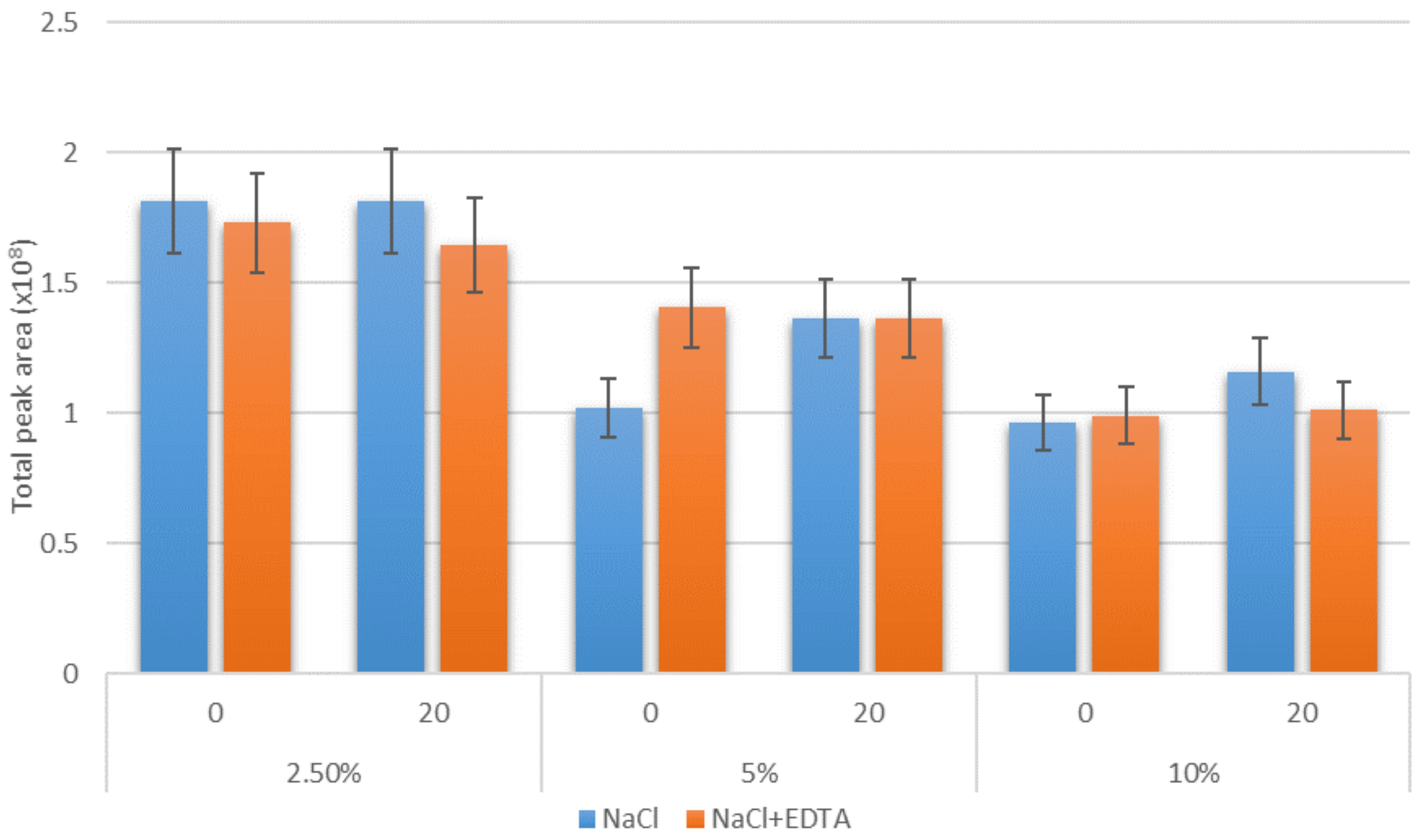

2.1.2. Effect of Ethanol and Sodium Chloride Concentration

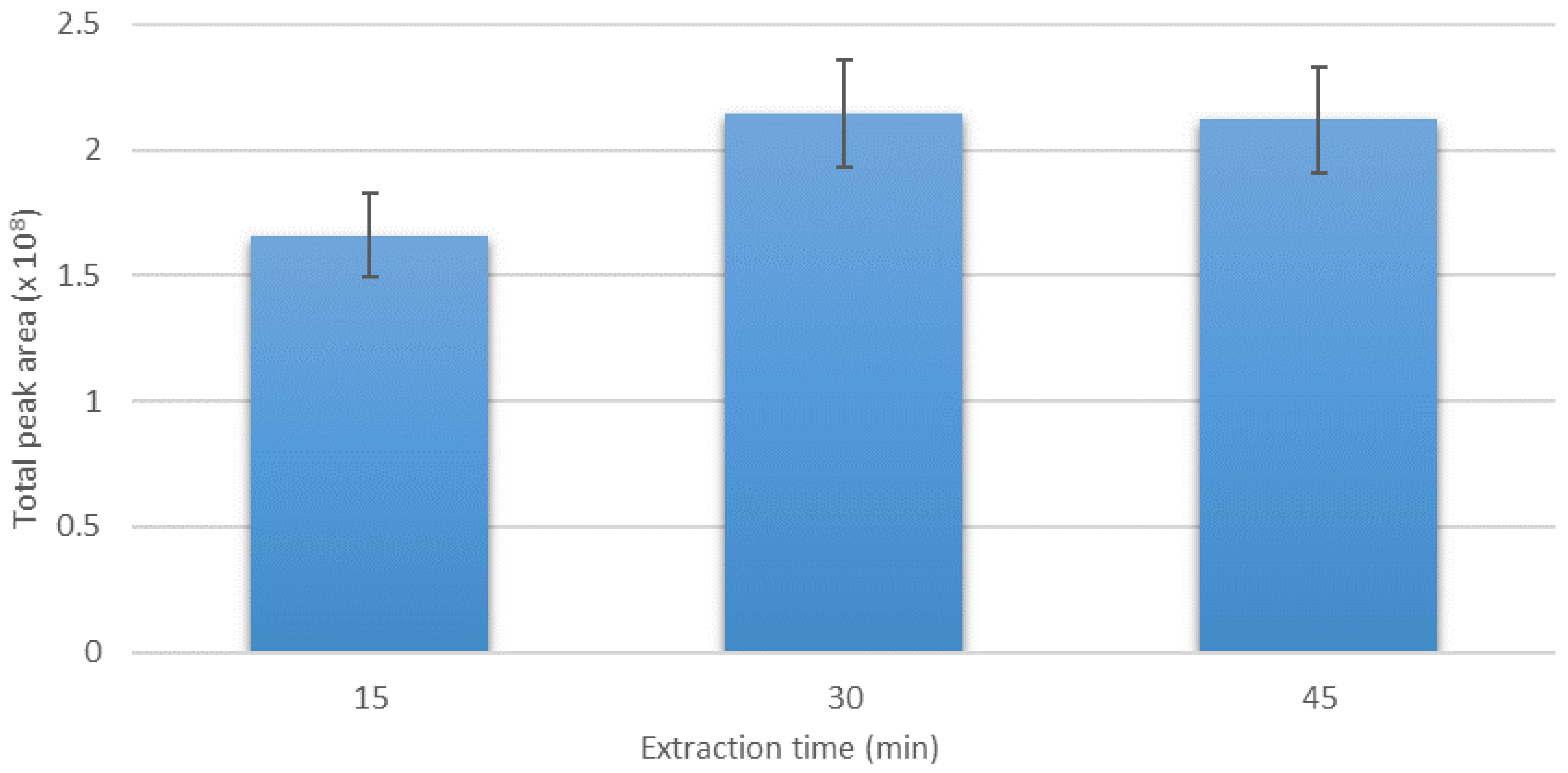

2.1.3. Effect of Extraction Time and Temperature

2.2. Method Validation

2.3. Analysis of Real Samples

3. Materials and Methods

3.1. Chemicals

3.2. SPME Equipment and HS–SPME Optimization

3.3. Sample Preparation

3.4. Gas Chromatography–Mass Spectrometry (GC–MS) Analysis

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- McGorrin, R.J.; Hall, W. The Significance of Volatile Sulfur Compounds in Food Flavors: An Overview. In Volatile Sulfur Compounds in Food; Oxford University Press: Oxford, UK, 2011; Volume 1068, pp. 3–31. [Google Scholar]

- Fedrizzi, B.; Magno, F.; Badocco, D.; Nicolini, G.; Versini, G. Aging Effects and Grape Variety Dependence on the Content of Sulfur Volatiles in Wine. J. Agric. Food Chem. 2007, 55, 10880–10887. [Google Scholar] [CrossRef]

- Mestres, M.; Busto, O.; Guasch, J. Analysis of organic sulfur compounds in wine aroma. J. Chromatogr. A 2000, 881, 569–581. [Google Scholar] [CrossRef]

- Campillo, N.; Pe, R.; López-garcía, I.; Hernández-córdoba, M. Headspace solid-phase microextraction for the determination of volatile organic sulphur and selenium compounds in beers, wines and spirits using gas chromatography and atomic emission detection. J. Chromatogr. A 2009, 1216, 6735–6740. [Google Scholar] [CrossRef] [PubMed]

- Swan, H.B. Determination of Existing and Potential Dimethyl Sulphide in Red Wines by Gas Chromatography Atomic Emission Spectroscopy. J. Food Compos. Anal. 2000, 13, 207–217. [Google Scholar] [CrossRef]

- Śliwińska, M.; Wiśniewska, P.; Dymerski, T.; Wardencki, W.; Namieśnik, J. The flavour of fruit spirits and fruit liqueurs: A review. Flavour Frag. J. 2015, 30, 197–207. [Google Scholar] [CrossRef]

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Grape brandy production, composition and sensory evaluation. J. Sci. Food Agric. 2014, 94, 404–414. [Google Scholar] [CrossRef]

- López, F.; Rodríguez-Bencomo, J.J.; Orriols, I.; Pérez-Correa, J.R. Fruit Brandies. In Science and Technology of Fruit Wine Production; Kosseva, M.R., Joshi, V.K., Panesar, P.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 531–556. [Google Scholar]

- Regulation (EU) 2019/787 of the European Parliament and of the Council of 17 April 2019 on the definition, description, presentation and labelling of spirit drinks, the use of the names of spirit drinks in the presentation and labelling of other foodstuffs, the protection of geographical indications for spirit drinks, the use of ethyl alcohol and distillates of agricultural origin in alcoholic beverages, and repealing Regulation (EC) No 110/2008. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2019.130.01.0001.01.ENG (accessed on 8 March 2020).

- Ledauphin, J.; Basset, B.; Cohen, S.; Payot, T.; Barillier, D. Identification of trace volatile compounds in freshly distilled Calvados and Cognac: Carbonyl and sulphur compounds. J. Food Compos. Anal. 2006, 19, 28–40. [Google Scholar] [CrossRef]

- Mestres, M.; Busto, O.; Guasch, J. Chromatographic analysis of volatile sulphur compounds in wines using the static headspace technique with flame photometric detection. J. Chromatogr. A 1997, 773, 261–269. [Google Scholar] [CrossRef]

- Le Pape, M.-A.; Grua-Priol, J.; Prost, C.; Demaimay, M. Optimization of Dynamic Headspace Extraction of the Edible Red Algae Palmaria palmata and Identification of the Volatile Components. J. Agric. Food Chem. 2004, 52, 550–556. [Google Scholar] [CrossRef]

- Du, X.; Finn, C.E.; Qian, M.C. Volatile composition and odour-activity value of thornless ‘Black Diamond’ and ‘Marion’ blackberries. Food Chem. 2010, 119, 1127–1134. [Google Scholar] [CrossRef]

- Ashmore, L.; Craske, J.D.; Srzednicki, G. Optimisation of ambient temperature vacuum distillation technique for the characterisation of volatile compounds in mushrooms. Int. Food Res. J. 2013, 20, 1211–1214. [Google Scholar]

- Pozo-Bayón, M.A.; Guichard, E.; Cayot, N. Feasibility and application of solvent assisted flavour evaporation and standard addition method to quantify the aroma compounds in flavoured baked matrices. Food Chem. 2006, 99, 416–423. [Google Scholar] [CrossRef]

- Da Porto, C.; Decorti, D. Countercurrent supercritical fluid extraction of grape-spirit. J. Supercriti. Fluids 2010, 55, 128–131. [Google Scholar] [CrossRef]

- Kremr, D.; Bajerová, P.; Bajer, T.; Eisner, A.; Adam, M.; Ventura, K. Using headspace solid-phase microextraction for comparison of volatile sulphur compounds of fresh plants belonging to families Alliaceae and Brassicaceae. J. Food Sci. Technol. 2015, 52, 5727–5735. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, W.; Li, S.; Zhang, A.; Zhang, Y.; Liu, S. Characterization of the Key Aroma Compounds in Proso Millet Wine Using Headspace Solid-Phase Microextraction and Gas Chromatography-Mass Spectrometry. Molecules 2018, 23, 462. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, A.T.; Jonsson, S. Trace determination of volatile sulfur compounds by solid-phase microextraction and GC-MS. Analyst 2002, 127, 1045–1049. [Google Scholar] [CrossRef]

- Kataoka, H.; Lord, H.L.; Pawliszyn, J. Applications of solid-phase microextraction in food analysis. J. Chromatogr. A 2000, 880, 35–62. [Google Scholar] [CrossRef]

- Hill, P.G.; Smith, R.M. Determination of sulphur compounds in beer using headspace solid-phase microextraction and gas chromatographic analysis with pulsed flame photometric detection. J. Chromatogr. A 2000, 872, 203–213. [Google Scholar] [CrossRef]

- Davis, P.M.; Qian, M.C. Effect of Ethanol on the Adsorption of Volatile Sulfur Compounds on Solid Phase Micro-Extraction Fiber Coatings and the Implication for Analysis in Wine. Molecules 2019, 24, 3392. [Google Scholar] [CrossRef]

- Urruty, L.; Montury, M. Influence of Ethanol on Pesticide Extraction in Aqueous Solutions by Solid-Phase Microextraction. J. Agric. Food Chem. 1996, 44, 3871–3877. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Tonidandel, L.; Moser, S.; Román Villegas, T.; Larcher, R. Rapid Analysis of 27 Volatile Sulfur Compounds in Wine by Headspace Solid-Phase Microextraction Gas Chromatography Tandem Mass Spectrometry. Food Analyt. Methods 2017, 10, 3706–3715. [Google Scholar] [CrossRef]

- Ledauphin, J.; Guichard, H.; Saint-Clair, J.-F.; Picoche, B.; Barillier, D. Chemical and Sensorial Aroma Characterization of Freshly Distilled Calvados. 2. Identification of Volatile Compounds and Key Odorants. J. Agric. Food Chem. 2003, 51, 433–442. [Google Scholar] [CrossRef] [PubMed]

- Fedrizzi, B.; Magno, F.; Moser, S.; Nicolini, G.; Versini, G. Concurrent quantification of light and heavy sulphur volatiles in wine by headspace solid-phase microextraction coupled with gas chromatography/mass spectrometry. Rapid Commun. Mass Spectrometry 2007, 21, 707–714. [Google Scholar] [CrossRef] [PubMed]

- Fedrizzi, B.; Versini, G.; Lavagnini, I.; Nicolini, G.; Magno, F. Gas chromatography–mass spectrometry determination of 3-mercaptohexan-1-ol and 3-mercaptohexyl acetate in wine. Analyt. Chim. Acta 2007, 596, 291–297. [Google Scholar] [CrossRef] [PubMed]

- Câmara, J.S.; Alves, M.A.; Marques, J.C. Development of headspace solid-phase microextraction-gas chromatography–mass spectrometry methodology for analysis of terpenoids in Madeira wines. Analyt. Chim. Acta 2006, 555, 191–200. [Google Scholar] [CrossRef]

- Tikunov, Y.; Lommen, A.; de Vos, C.H.R.; Verhoeven, H.A.; Bino, R.J.; Hall, R.D.; Bovy, A.G. A Novel Approach for Nontargeted Data Analysis for Metabolomics. Large-Scale Profiling of Tomato Fruit Volatiles. Plant Physiol. 2005, 139, 1125–1137. [Google Scholar] [CrossRef]

- Locatelli, D.A.; Altamirano, J.C.; Luco, J.M.; Norlin, R.; Camargo, A.B. Solid phase microextraction coupled to liquid chromatography. Analysis of organosulphur compounds avoiding artifacts formation. Food Chem. 2014, 157, 199–204. [Google Scholar] [CrossRef]

- Block, E. Flavor artifacts. J. Agric. Food Chem. 1993, 41, 692. [Google Scholar] [CrossRef]

- Block, E.; Calvey, E.M. Facts and Artifacts in Allium Chemistry. In Sulfur Compounds in Foods; American Chemical Society: Washington, DC, USA, 1994; pp. 63–79. [Google Scholar]

- Block, E. Challenges and Artifact Concerns in Analysis of Volatile Sulfur Compounds. In Volatile Sulfur Compounds in Food; Oxford University Press: Oxford, UK, 2011; pp. 35–63. [Google Scholar]

- Siebert, T.E.; Solomon, M.R.; Pollnitz, A.P.; Jeffery, D.W. Selective Determination of Volatile Sulfur Compounds in Wine by Gas Chromatography with Sulfur Chemiluminescence Detection. J. Agric. Food Chem. 2010, 58, 9454–9462. [Google Scholar] [CrossRef]

- López, R.; Lapeña, A.C.; Cacho, J.; Ferreira, V. Quantitative determination of wine highly volatile sulfur compounds by using automated headspace solid-phase microextraction and gas chromatography-pulsed flame photometric detection. J. Chromatogr. A 2007, 1143, 8–15. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds used in the analyses are available from the authors. |

| Compound | Ethanol | 2.5% | 5% | 10% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NaCl | 0 | 10 | 20 | 30 | 0 | 10 | 20 | 30 | 0 | 10 | 20 | 30 | |

| Ethanethiol | 12.3 | 14.5 | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Dimethyl-sulfide | 25.7 | 28.7 | 100.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| 1-Propanethiol | 65.2 | 43.1 | 100.0 | 59.5 | 17.7 | 22.6 | 13.9 | 10.9 | 10.4 | 5.7 | 6.3 | 3.8 | |

| Thiophene | 71.8 | 55.6 | 100.0 | 64.7 | 18.0 | 42.8 | 35.4 | 28.8 | 13.4 | 22.0 | 27.7 | 14.3 | |

| Diethyl-sulfide | 58.9 | 48.0 | 100.0 | 76.0 | 14.2 | 38.2 | 50.5 | 26.5 | 19.1 | 19.4 | 16.6 | 11.9 | |

| 1-Butanethiol | 80.2 | 53.5 | 100.0 | 74.8 | 22.0 | 32.2 | 48.5 | 25.4 | 30.6 | 19.4 | 22.3 | 11.7 | |

| Dimethyl-disulfide | 56.0 | 50.1 | 100.0 | 81.5 | 15.4 | 37.0 | 69.8 | 46.7 | 18.7 | 52.5 | 18.5 | 16.4 | |

| Ethyl-thioacetate | 49.9 | 50.8 | 100.0 | 91.3 | 15.0 | 32.7 | 51.6 | 53.9 | 15.2 | 28.6 | 30.7 | 38.4 | |

| 1-Pentanethiol | 85.2 | 68.3 | 100.0 | 71.1 | 39.0 | 34.5 | 48.9 | 40.9 | 38.9 | 38.4 | 43.9 | 25.3 | |

| Dipropyl-sulfide | 89.8 | 78.3 | 100.0 | 80.5 | 43.5 | 53.6 | 61.0 | 51.0 | 38.3 | 49.5 | 50.8 | 33.4 | |

| Diethyl-disulfide | 80.5 | 74.8 | 100.0 | 80.3 | 39.5 | 53.5 | 64.8 | 54.4 | 33.4 | 48.3 | 49.3 | 35.8 | |

| Thiophenol | 100.0 | 2.1 | 2.2 | 2.8 | 52.0 | 1.0 | 1.2 | 1.6 | 31.5 | 1.1 | 0.5 | 0.9 | |

| 2-Methyltetrahydrothiophene-3-one | 86.9 | 50.9 | 88.6 | 100.0 | 30.3 | 28.9 | 47.7 | 50.6 | 16.9 | 27.0 | 39.1 | 39.3 | |

| 3-Thiophenecarboxaldehyde | 32.1 | 48.1 | 100.0 | 96.6 | 12.6 | 33.1 | 74.3 | 82.1 | 9.9 | 28.6 | 38.2 | 51.1 | |

| 2-Thiophenecarboxaldehyde | 47.1 | 55.0 | 90.8 | 100.0 | 23.6 | 40.1 | 69.8 | 89.0 | 19.6 | 32.9 | 37.7 | 55.5 | |

| Ethyl-3-(methylthio)propionate | 24.6 | 40.7 | 80.2 | 100.0 | 13.1 | 29.0 | 59.6 | 69.9 | 9.5 | 27.8 | 33.4 | 50.5 | |

| Dibutyl-sulfide | 100.0 | 83.5 | 96.4 | 82.7 | 65.2 | 70.1 | 75.2 | 69.1 | 68.3 | 70.9 | 77.8 | 49.4 | |

| Dipropyl-disulfide | 100.0 | 86.4 | 99.3 | 85.2 | 65.2 | 72.3 | 79.0 | 70.9 | 66.9 | 73.0 | 79.0 | 50.2 | |

| Benzothiazole | 36.7 | 51.5 | 86.9 | 100.0 | 18.5 | 53.5 | 64.5 | 87.2 | 7.2 | 19.3 | 29.1 | 34.3 | |

| Compound | Temperature (°C) | ||||

|---|---|---|---|---|---|

| 20 | 35 | 50 | 65 | 75 | |

| Ethanethiol | 100.0 | 32.2 | 14.4 | 0.0 | 0.0 |

| Dimethyl-sulfide | 100.0 | 42.0 | 29.9 | 0.0 | 0.0 |

| 1-Propanethiol | 100.0 | 41.3 | 37.7 | 5.8 | 2.6 |

| Thiophene | 100.0 | 83.7 | 59.5 | 11.6 | 6.6 |

| Diethyl-sulfide | 100.0 | 75.3 | 47.9 | 10.4 | 6.9 |

| 1-Butanethiol | 100.0 | 79.3 | 47.7 | 14.6 | 6.3 |

| Dimethyl-disulfide | 100.0 | 88.6 | 57.4 | 18.5 | 5.7 |

| Ethyl-thioacetate | 100.0 | 89.9 | 69.5 | 31.1 | 16.1 |

| 1-Pentanethiol | 100.0 | 88.2 | 58.6 | 18.8 | 8.7 |

| Dipropyl-sulfide | 100.0 | 99.0 | 77.5 | 30.8 | 14.6 |

| Diethyl-disulfide | 97.2 | 100.0 | 80.8 | 36.9 | 18.3 |

| Thiophenol | 80.3 | 100.0 | 85.3 | 48.9 | 34.3 |

| 2-Methyltetrahydrothiophene-3-one | 63.2 | 100.0 | 89.7 | 58.9 | 31.7 |

| 3-Thiophenecarboxaldehyde | 30.7 | 64.1 | 100.0 | 69.6 | 54.7 |

| 2-Thiophenecarboxaldehyde | 28.2 | 64.3 | 100.0 | 78.9 | 59.9 |

| Ethyl-3-(methylthio)propionate | 20.2 | 57.5 | 100.0 | 54.0 | 42.5 |

| Dibutyl-sulfide | 87.9 | 97.0 | 100.0 | 66.3 | 41.6 |

| Dipropyl-disulfide | 86.3 | 97.2 | 100.0 | 69.8 | 44.1 |

| Benzothiazole | 20.6 | 37.5 | 69.6 | 100.0 | 86.9 |

| Compound | R2 | LOQ (µg/L) | LOD (µg/L) | Range of assayed concentration (µg/L) | Linearity (µg/L) | Recovery (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | ||||

| Ethanethiol | 0.9950 | 0.569 | 0.171 | 0.04 | 40.77 | 0.64 | 10.19 | 89.91 | 113.03 |

| Dimethyl-sulfide | 0.9904 | 0.208 | 0.063 | 0.04 | 37.84 | 0.59 | 9.46 | 78.02 | 107.77 |

| 1-Propanethiol | 0.9894 | 0.611 | 0.183 | 0.06 | 60.97 | 0.95 | 15.25 | 75.71 | 176.99 |

| Diethyl-sulfide | 0.9972 | 0.081 | 0.024 | 0.07 | 69.23 | 0.08 | 34.62 | 96.66 | 109.41 |

| 1-Butanethiol | 0.9319 | 0.011 | 0.003 | 0.07 | 67.27 | 0.53 | 16.82 | 87.24 | 133.87 |

| Dimethyl-disulfide | 0.9947 | 0.009 | 0.003 | 0.09 | 94.60 | 0.09 | 94.70 | 96.48 | 109.44 |

| Ethyl thioacetate | 0.9924 | 0.002 | 0.001 | 0.08 | 86.65 | 0.08 | 43.32 | 93.99 | 106.68 |

| 1-Pentanethiol | 0.9640 | 0.014 | 0.004 | 0.07 | 70.93 | 0.14 | 8.87 | 86.11 | 129.13 |

| Dipropyl-sulfide | 0.9954 | 0.146 | 0.044 | 0.07 | 72.95 | 0.15 | 36.48 | 97.68 | 105.53 |

| Diethyl-disulfide | 0.9932 | 0.116 | 0.035 | 0.09 | 89.56 | 0.12 | 11.19 | 89.01 | 105.88 |

| Thiophenol | 0.9969 | 0.048 | 0.015 | 0.09 | 94.41 | 0.09 | 23.60 | 102.08 | 122.60 |

| 2-Methyltetrahydrothiophene-3-one | 0.9991 | 0.045 | 0.014 | 0.11 | 108.57 | 0.11 | 108.57 | 92.48 | 108.62 |

| 3-Thiophenecarboxaldehyde | 0.9984 | 0.053 | 0.016 | 0.11 | 114.68 | 0.11 | 57.34 | 90.37 | 110.20 |

| 2-Thiophenecarboxaldehyde | 0.9983 | 0.208 | 0.063 | 0.11 | 111.71 | 0.21 | 55.85 | 92.89 | 106.75 |

| Ethyl 3-(methylthio)propionate | 0.9943 | 0.187 | 0.056 | 0.09 | 95.86 | 0.09 | 47.93 | 99.94 | 109.93 |

| Dibutyl-sulfide | 0.9957 | 0.103 | 0.031 | 0.07 | 75.60 | 0.10 | 37.80 | 92.89 | 112.25 |

| Dipropyl-disulfide | 0.9957 | 0.132 | 0.040 | 0.08 | 81.55 | 0.13 | 10.19 | 94.36 | 110.31 |

| Benzothiazole | 0.9945 | 0.208 | 0.062 | 0.10 | 107.10 | 0.21 | 53.55 | 112.95 | 125.63 |

| Compound | Molecular Formula | Retention Time | Pear Brandy | Plum Brandy | Apple Brandy |

|---|---|---|---|---|---|

| Ethanethiol | C2H6S | 1.56 | <LOD | <LOD | <LOD |

| Dimethyl-sulfide | C2H6S | 1.626 | <LOD | <LOD | <LOD |

| 1-Propanethiol | C3H8S | 2.177 | <LOD | <LOD | <LOD |

| Diethyl-sulfide | C4H10S | 3.555 | <LOD | <LOD | <LOD |

| 1-Butanethiol | C4H10S | 3.815 | 1.17±0.06 | <LOD | <LOD |

| Dimethyl-disulfide | C2H6S2 | 4.521 | <LOD | 0.14 ± 0.03 | 0.11 ± 0.03 |

| Ethyl thioacetate | C4H8OS | 5.57 | <LOD | <LOD | <LOD |

| 1-Pentanethiol | C5H12S | 7.568 | <LOD | <LOD | <LOD |

| Dipropyl sulfide | C6H14S | 9.895 | <LOQ | <LOD | <LOD |

| Diethyl disulfide | C4H10S2 | 10.478 | <LOD | <LOQ | <LOD |

| Thiophenol | C6H6S | 11.292 | <LOQ | <LOQ | <LOQ |

| 2-Methyltetrahydrothiophene-3-one | C5H8OS | 11.539 | <LOD | <LOD | 81.76 ± 1.06 |

| 3-Thiophenecarboxaldehyde | C5H4OS | 11.578 | <LOD | <LOD | <LOD |

| 2-Thiophenecarboxaldehyde | C5H4OS | 11.785 | 3.39 ± 0.17 | <LOD | <LOD |

| Ethyl 3-(methylthio)propionate | C6H12O2S | 13.941 | <LOD | <LOD | <LOQ |

| Dibutyl sulfide | C8H18S | 14.007 | <LOQ | <LOD | <LOD |

| Dipropyl disulfide | C6H14S2 | 14.254 | <LOQ | <LOQ | <LOD |

| Benzothiazole | C7H5NS | 15.839 | <LOD | <LOD | <LOD |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dziekońska-Kubczak, U.; Pielech-Przybylska, K.; Patelski, P.; Balcerek, M. Development of the Method for Determination of Volatile Sulfur Compounds (VSCs) in Fruit Brandy with the Use of HS–SPME/GC–MS. Molecules 2020, 25, 1232. https://doi.org/10.3390/molecules25051232

Dziekońska-Kubczak U, Pielech-Przybylska K, Patelski P, Balcerek M. Development of the Method for Determination of Volatile Sulfur Compounds (VSCs) in Fruit Brandy with the Use of HS–SPME/GC–MS. Molecules. 2020; 25(5):1232. https://doi.org/10.3390/molecules25051232

Chicago/Turabian StyleDziekońska-Kubczak, Urszula, Katarzyna Pielech-Przybylska, Piotr Patelski, and Maria Balcerek. 2020. "Development of the Method for Determination of Volatile Sulfur Compounds (VSCs) in Fruit Brandy with the Use of HS–SPME/GC–MS" Molecules 25, no. 5: 1232. https://doi.org/10.3390/molecules25051232

APA StyleDziekońska-Kubczak, U., Pielech-Przybylska, K., Patelski, P., & Balcerek, M. (2020). Development of the Method for Determination of Volatile Sulfur Compounds (VSCs) in Fruit Brandy with the Use of HS–SPME/GC–MS. Molecules, 25(5), 1232. https://doi.org/10.3390/molecules25051232