Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt

Abstract

1. Introduction

2. Results

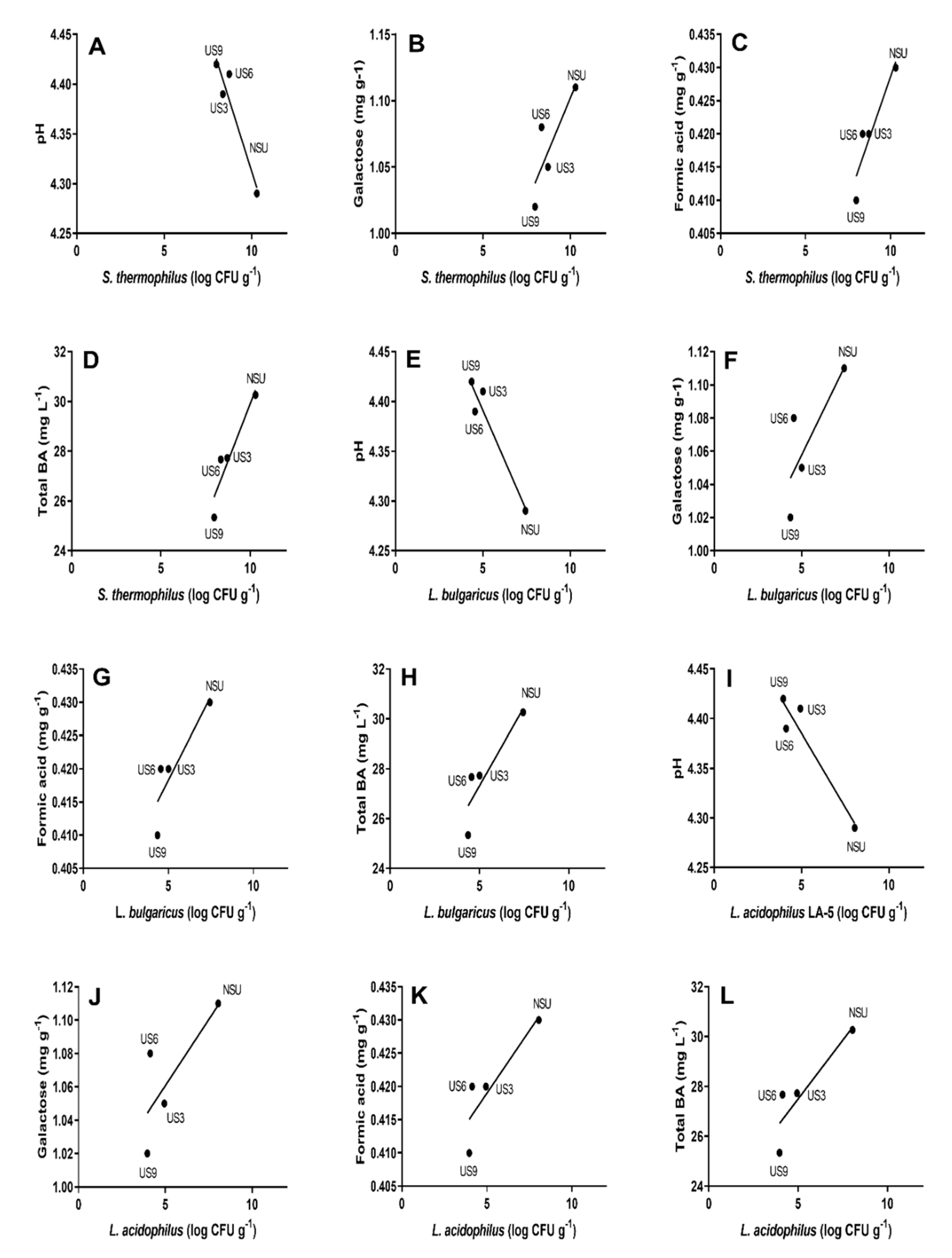

2.1. Microbial Growth Evaluation of Freshly Prepared Goat Milk Yogurts

2.2. Chemical Composition of Freshly Prepared Goat Milk Yogurt

2.3. Monosaccharides, Disaccharides, and Organic Acids Content in Goat Milk Yogurt during Storage

2.4. Evaluation of pH Values of Goat Milk Yogurt Samples during Storage

2.5. Biogenic Amine Content during Goat Milk Yogurt Sample Storage

2.6. Textural Properties during Goat Milk Yogurt Storage

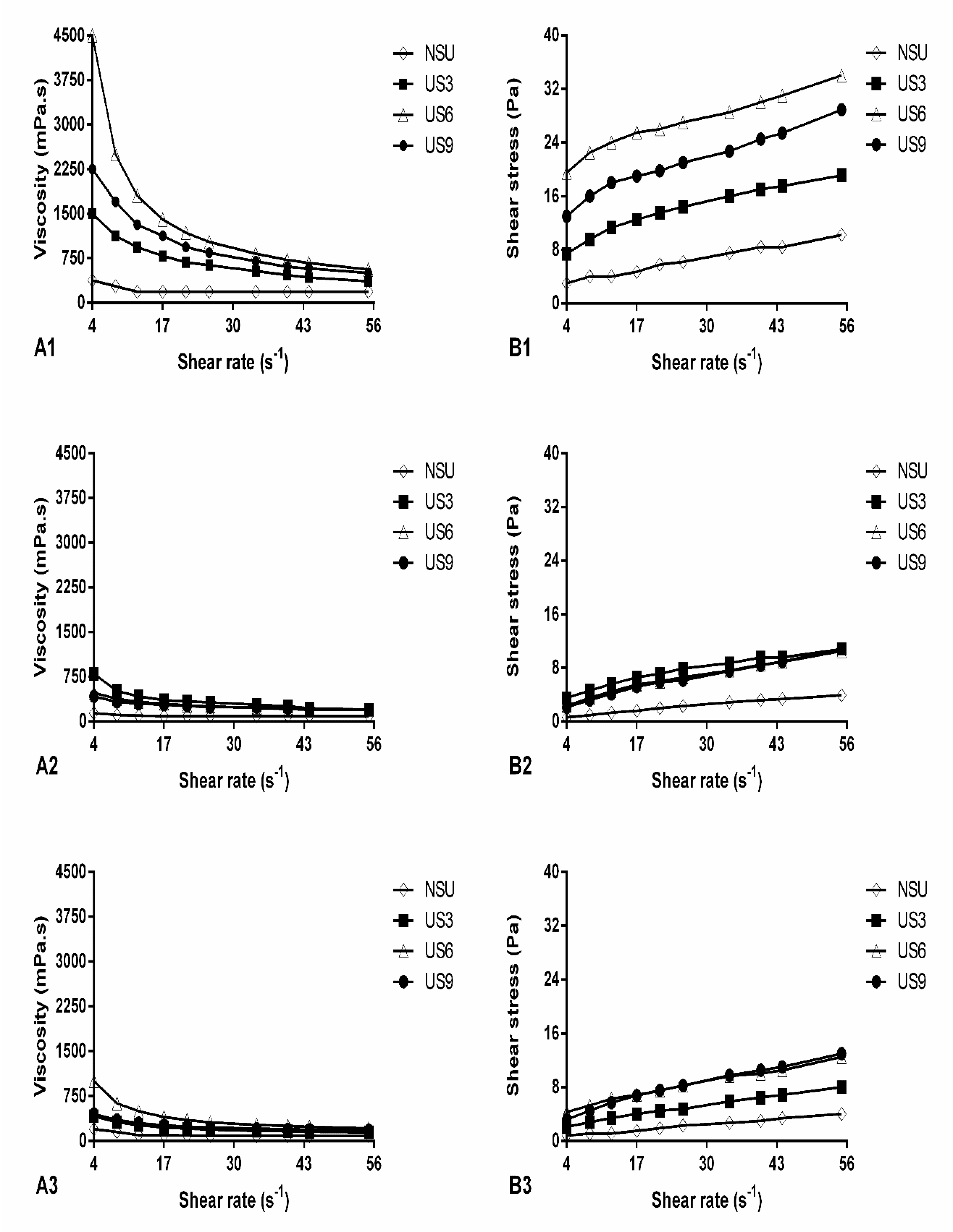

2.7. Rheological Behavior and Apparent Viscosity during Goat Milk Yogurt Samples Storage

3. Discussion

4. Materials and Methods

4.1. Reagents and Chemicals

4.2. Preparation of Goat Milk Yogurt Samples

4.3. Ultrasound (US) Treatments

4.4. Microbial Analysis

4.5. Chemical Characterization of Goat Milk Yogurt

4.5.1. Chemical Composition

4.5.2. Monosaccharides, Disaccharides, and Organic Acids Quantification by HPLC-DAD-RID

4.5.3. Biogenic Amine Quantification by RP-HPLC-DAD

4.6. Physical Characterization of Goat Milk Yogurt

4.6.1. pH Determination

4.6.2. Textural Properties of Goat Milk Yogurt

4.6.3. Rheological Behavior and Apparent Viscosity of Goat Milk Yogurt

4.7. Internal Validation of Predictive Models

4.8. Statistical Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Getaneh, G.; Mebrat, A.; Wubie, A.; Kendie, H. Review on goat milk composition and its nutritive value. J. Nutr. Health Sci. 2016, 3, 1–10. [Google Scholar] [CrossRef]

- Pastuszka, R.; Barłowska, J.; Litwińczuk, Z. Nutritional value and health-promoting properties of goat milk. Med. Weter 2015, 71, 480–485. [Google Scholar]

- Turknem, N. The nutritional value and health benefits of goat milk components. In Nutrients in Dairy and Their Implications on Health and Disease, 1st ed.; Watson, R.R., Collier, R.J., Preedy, V.R., Eds.; Elsevier: London, UK, 2017; Volume 1, pp. 441–449. [Google Scholar] [CrossRef]

- Costa, M.; Frasao, B.; Silva, A.C.; Freitas, M.; Franco, R.M.; Conte-Junior, C. Cupuassu (Theobroma grandiflorum) pulp, probiotic, and prebiotic: Influence on color, apparent viscosity, and texture of goat milk yogurts. J. Dairy Sci. 2015, 98, 5995–6003. [Google Scholar] [CrossRef]

- Costa, M.; Balthazar, C.F.; Franco, R.M.; Mársico, E.T.; Cruz, A.G.; Conte-Junior, C. Changes on expected taste perception of probiotic and conventional yogurts made from goat milk after rapidly repeated exposure. J. Dairy Sci. 2014, 97, 2610–2618. [Google Scholar] [CrossRef]

- Eissa, E.A.; Ahmed, I.M.; Yagoub, A.E.A.; Babiker, E.E. Physicochemical, microbiological and sensory characteristics of yoghurt produced from goat milk. Live Stock. Res. Rural Dev. 2010, 22, 247–253. [Google Scholar]

- Gursel, A.; Gursoy, A.; Anli, E.A.K.; Budak, S.O.; Aydemir, S.; Durlu-Ozkaya, F. Role of milk protein-based products in some quality attributes of goat milk yogurt. J. Dairy Sci. 2016, 99, 2694–2703. [Google Scholar] [CrossRef] [PubMed]

- Loveday, S.M.; Sarkar, A.; Singh, H. Innovative yoghurts: Novel processing technologies for improving acid milk gel texture. Trends Food Sci. Technol. 2013, 33, 5–20. [Google Scholar] [CrossRef]

- Delgado, K.F.; Frasao, B.S.; Costa, M.P.; Conte-Junior, C. Different alternatives to improve rheological and textural characteristics of fermented goat products-A Review. Rheol. Open Access 2017, 1, 1–6. [Google Scholar]

- Ozawa, T.; Mukuda, K.; Fujita, M.; Nishitani, J. Goat milk acceptance and promotion methods in Japan: The questionnaire survey to middle class households. Anim. Sci. J. 2009, 80, 212–219. [Google Scholar] [CrossRef] [PubMed]

- Chandrapala, J.; Oliver, C.; Kentish, S.; Ashokkumar, M. Ultrasonics in food processing-food quality assurance and food safety. Trends Food Sci. Technol. 2012, 26, 88–98. [Google Scholar] [CrossRef]

- Nguyen, N.H.A.; Anema, S.G. Effect of ultrasonication on the properties of skim milk used in the formation of acid gels. Innov. Food Sci. Emerg. Technol. 2010, 11, 616–622. [Google Scholar] [CrossRef]

- Nguyen, T.M.P.; Lee, Y.K.; Zhou, W. Stimulating fermentative activities of bifidobacteria in milk by high intensity ultrasound. Int. Dairy J. 2009, 19, 410–416. [Google Scholar] [CrossRef]

- Nöbel, S.; Ross, N.-L.; Protte, K.; Körzendörfer, A.; Hitzmann, B.; Hinrichs, J. Microgel particle formation in yogurt as influenced by sonication during fermentation. J. Food Eng. 2016, 180, 29–38. [Google Scholar] [CrossRef]

- Riener, J.; Noci, F.; Cronin, D.A.; Morgan, D.J.; Lyng, J.G. The effect of thermosonication of milk on selected physicochemical and microstructural properties of yoghurt gels during fermentation. Food Chem. 2009, 114, 905–911. [Google Scholar] [CrossRef]

- Riener, J.; Noci, F.; Cronin, D.A.; Morgan, D.J.; Lyng, J.G. A comparison of selected quality characteristics of yoghurts prepared from thermosonicated and conventionally heated milks. Food Chem. 2010, 119, 1108–1113. [Google Scholar] [CrossRef]

- Sfakianakis, P.; Tzia, C. Conventional and Innovative Processing of Milk for Yogurt Manufacture; Development of Texture and Flavor: A Review. Foods 2014, 3, 176–193. [Google Scholar] [CrossRef] [PubMed]

- Wójciak, K.M.; Stasiak, D.M.; Stadnik, J.; Ferysiuk, K.; Kononiuk, A. The influence of sonication time on the biogenic amines formation as a critical point in uncured dry-fermented beef manufacturing. Int. J. Food Sci. 2019, 54, 75–83. [Google Scholar] [CrossRef]

- Linares, D.M.; del Río, B.; Ladero, V.; Martínez, N.; Fernández, M.; Martín, M.C.; Martín, M.A. Factors influencing biogenic amines accumulation in dairy products. Front. Microbiol. 2012, 3, 1–10. [Google Scholar] [CrossRef]

- Benkerroum, N. Biogenic Amines in Dairy Products: Origin, Incidence, and Control Means. Compr. Rev. Food Sci. Food Saf. 2016, 15, 801–826. [Google Scholar] [CrossRef]

- Costa, M.P.; Balthazar, C.F.; Rodrigues, B.L.; Lázaro, C.A.; Silva, A.C.O.; Gomes, A.C.; Conte-Junior, C.A. Probiotic fermented cow’s and goat’s milks: Determination of biogenic amines and sensory acceptance. Food Sci. Nutr. 2015, 3, 172–178. [Google Scholar] [CrossRef]

- Vieira, C.P.; Costa, M.P.; Frasao, B.S.; Silva, V.L.; Moreira, R.V.B.P.; Nunes, Y.E.O.; Conte-Junior, C.A. Nondestructive prediction of the overall quality of cow milk yogurt by correlating a biogenic amine index with traditional quality parameters using validated nonlinear models. J. Food Comp. Anal. 2019, 84, 103328. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, B.; Kumar, R.; Kumar, S.; Khatkar, S.K.; Kanawjia, S.K. Nutritional features of goat milk—A review. Indian J. Dairy Sci. 2012, 65, 266–273. [Google Scholar] [CrossRef]

- McCabe-Sellers, B.J.; Staggs, C.G.; Bogle, M.L. Tyramine in foods and monoamine oxidase inhibitor drugs: A crossroad where medicine, nutrition, pharmacy, and food industry converge. J. Food Compos. Anal. 2006, 19, S58–S65. [Google Scholar] [CrossRef]

- Tadjine, D. Milk heat treatment affects microbial characteristics of cows’ and goats’ “Jben” traditional fresh cheeses. Food Sci. Technol. 2020, 1–8. [Google Scholar] [CrossRef]

- Baratella, D.; Bonaiuto, E.; Magro, M.; Roger, J.A.; Kanamori, Y.; Lima, G.P.P.; Agostinelli, E.; Vianello, F. Endogenous and food-derived polyamines: Determination by electrochemical sensing. Amino Acids 2018, 50, 1187–1203. [Google Scholar] [CrossRef]

- Büyükuslu, N. Dietary polyamines and diseases: Reducing polyamine intake can be beneficial in cancer treatment. J. Nutr. 2015, 2, 27–38. [Google Scholar] [CrossRef][Green Version]

- Saikali, J.; Picard, C.; Freitas, M.; Holt, P. Fermented milks, probiotic cultures, and colon cancer. Nutr. Cancer 2004, 49, 14–24. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, K.; Song, M.; Ogino, S.; Fuchs, C.S.; Chan, A.T.; Giovannucci, E.L.; Cao, Y.; Zhang, X. Yogurt consumption and risk of conventional and serrated precursors of colorectal cancer. Gut 2020, 69, 970–972. [Google Scholar] [CrossRef]

- Matsumoto, M.; Benno, Y. Consumption of Bifidobacterium lactis LKM512 yogurt reduces gut mutagenicity by increasing gut polyamine contents in healthy adult subjects. Mutat. Res. 2004, 568, 147–153. [Google Scholar] [CrossRef]

- Matsumoto, M.; Ohishi, H.; Benno, Y. Impact of LKM512 yogurt on improvement of intestinal environment of the elderly. FEMS Immunol. Med. Microbiol. 2001, 31, 181–186. [Google Scholar] [CrossRef]

- Kesse, E.; Bertrais, S.; Astorg, P.; Jaouen, A.; Arnaultu, N.; Galan, P.; Hercberg, S. Dairy products, calcium and phosphorus intake, and the risk of prostate cancer: Results of the French prospective SU.VI.MAX (Supple’mentation en Vitamines et Mine’raux Antioxydants) study. Brit. J. Nutr. 2006, 95, 539–545. [Google Scholar] [CrossRef]

- López-Plaza, B.; Bermejo, L.M.; Santurino, C.; Cavero-Redondo, I.; Álvarez-Bueno, C.; Gómez-Candela, C. Milk and dairy product consumption and prostate cancer risk and mortality: An overview of systematic reviews and meta-analyses. Adv. Nutr. 2019, 10, S212–S223. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.C.; Chow, W.-H.; Boffetta, P.; Moore, L.; Zaridze, D.; Moukeria, A.; Janout, V.; Kollarova, H.; Bencko, V.; Navratilova, M.; et al. Dietary risk factors for kidney cancer in eastern and central Europe. Am. J. Epidemiol. 2007, 166, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Vieira, C.P.; Costa, M.P.; Silva, V.L.; Frasao, B.S.; Aquino, L.F.C.; Nunes, Y.E.O.; Conte-Junior, C.A. Development and validation of RP-HPLC-DAD method for biogenic amines determination in probiotic yogurts. Arab. J. Chem. 2020, 13, 1582–1597. [Google Scholar] [CrossRef]

- Benamouzig, R.; Mahé, S.; Luengo, C.; Rautureau, J.; Tomé, D. Fast and postprandial polyamine concentrations in the human digestive lumen. Am. J. Clin. Nutr. 1997, 65, 766–770. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Feng, Z.; Chen, N. Spermidine as a target for cancer therapy. Pharm. Res. 2020, 159, 104943. [Google Scholar] [CrossRef]

- Jalilzadeh, A.; Hesari, J.; Peighambardoust, S.H.; Javidipour, I. The effect of ultrasound treatment on microbial and physicochemical properties of Iranian ultrafiltered feta-type cheese. J. Dairy Sci. 2018, 101, 5809–5820. [Google Scholar] [CrossRef] [PubMed]

- Bonczar, G.; Filipczak-Fiutak, M.; Pluta-Kubica, A.; Duda, I.; Walczycka, M.; Staruch, L. The range of protein hydrolysis and biogenic amines content in selected acid-and rennet-curd cheeses. Chem. Pap. 2018, 72, 2599–2606. [Google Scholar] [CrossRef]

- Karlović, S. Reducing fat globules particle-size in goat milk: Ultrasound and high hydrostatic pressures approach. Chem. Biochem. Eng. Q. 2015, 28, 499–507. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, S.; Uluko, H.; Liu, L.; Lu, J.; Xue, H.; Kong, F.; Lv, J. Effect of ultrasound pretreatment on rennet-induced coagulation properties of goat’s milk. Food Chem. 2014, 165, 167–174. [Google Scholar] [CrossRef]

- Codex Alimentarius. Codex Standard for Fermented Milks. Codex Standard 243-2003 in Codex Alimentarius: Milk and Milk Products, 2nd ed.; Codex Alimentarius Commission: Brussels, Belgium, 2010; pp. 1–11. [Google Scholar]

- Bedani, R.; Rossi, E.A.; Saad, S.M.I. Impact of inulin and okara on Lactobacillus acidophilus LA-5 and Bifidobacterium animalis BB-12 viability in a fermented soy product and probiotic survival under in vitro simulated gastrointestinal conditions. Food Microbiol. 2013, 34, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Kumon, R.E.; Deng, C.X. Mechanisms of microbubble-facilitated sonoporation for drug and gene delivery. Ther. Deliv. 2015, 5, 467–486. [Google Scholar] [CrossRef] [PubMed]

- Ojha, K.S.; Mason, T.J.; O’Donnell, C.P.; Kerry, J.P.; Tiwari, B.K. Ultrasound technology for food fermentation applications. Ultrason. Sonochem. 2017, 34, 410–417. [Google Scholar] [CrossRef]

- Gholamhosseinpour, A.; Hashemi, S.M.B. Ultrasound pretreatment of fermented milk containing probiotic Lactobacillus plantarum AF1: Carbohydrate metabolism and antioxidant activity. J. Food Process. Eng. 2019, 42, e12930. [Google Scholar] [CrossRef]

- Gursoy, O.; Yilmaz, Y.; Gokce, O.; Ertan, K. Effect of ultrasound power on physicochemical and rheological properties of yoghurt drink produced with thermosonicated milk. Emir. J. Food Agric. 2016, 28, 235–241. [Google Scholar] [CrossRef]

- Barukčić, I.; Jakopović, K.L.; Herceg, Z.; Karlović, S.; Božanić, R. Influence of high intensity ultrasound on microbial reduction, physicochemical characteristics and fermentation of sweet whey. Innov. Food Sci. Emerg. Technol. 2015, 27, 94–101. [Google Scholar] [CrossRef]

- Cameron, M.; McMaster, L.D.; Britz, T.J. Electron microscopic analysis of dairy microbes inactivated by ultrasound. Ultrason. Sonochem. 2008, 15, 960–964. [Google Scholar] [CrossRef]

- Abesinghe, A.M.N.L.; Islam, N.; Vidanarachchi, J.K.; Prakash, S.; Silva, K.F.S.T.; Karim, M.A. Effects of ultrasound on the fermentation profile of fermented milk products incorporated with lactic acid bacteria. Int. Dairy J. 2019, 90, 1–14. [Google Scholar] [CrossRef]

- Vianna, F.S.; Canto, A.C.V.d.C.S.; Costa-Lima, B.; Salim, A.P.; Balthazar, C.F.; Costa, M.P.; Panzenhagen, P.; Rachid, R.; Franco, R.M.; Conte-Junior, C.A. Milk from different species on physicochemical and microstructural yoghurt properties. Cienc. Rural 2019, 49, 1–15. [Google Scholar] [CrossRef]

- Costa, M.P.; Conte-Junior, C.A. Chromatographic methods for the determination of carbohydrates and organic acids in foods of animal origin. Compr. Rev. Food Sci. Food Saf. 2015, 14, 586–600. [Google Scholar] [CrossRef]

- Costa, M.P.; Frasao, B.S.; Lima, B.R.C.C.; Rodrigues, B.L.; Conte-Junior, C.A. Simultaneous analysis of carbohydrates and organic acids by HPLC-DAD-RI for monitoring goat’s milk yogurts fermentation. Talanta 2016, 152, 162–170. [Google Scholar] [CrossRef] [PubMed]

- Mba, A.U.; Boyo, B.S.; Oyenuga, V.A. Studies on the milk composition of West African dwarf, Red Sokoto and Saanen goats at different stages of lactation. J. Dairy Res. 1975, 42, 217–226. [Google Scholar] [CrossRef]

- Bagnicka, E.; Łukaszewicz, M.; Ådnøy, T. Genetic parameters of somatic cell score and lactose content in goat’s milk. J. Anim. Feed Sci. 2016, 25, 210–215. [Google Scholar] [CrossRef]

- Mousavi, M.; Heshmati, A.; Daraei, G.A.; Vahidinia, A.; Taheri, M. Texture and sensory characterization of functional yogurt supplemented with flaxseed during cold storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef]

- Nishimura, J.; Makino, S.; Kimura, K.; Isogai, E.; Saito, T. Influence of different sterilization conditions on the growth and exopolysaccharide of Streptococcus thermophilus and co-cultivation with Lactobacillus delbrueckii subsp. bulgaricus OLL1073R-1. Adv. Microbiol. 2015, 5, 760–767. [Google Scholar] [CrossRef][Green Version]

- Nguyen, T.M.P.; Lee, Y.K.; Zhou, W. Effect of high intensity ultrasound on carbohydrate metabolism of bifidobacteria in milk fermentation. Food Chem. 2012, 130, 866–874. [Google Scholar] [CrossRef]

- Kailasapathy, K.; Harmstorf, I.; Phillips, M. Survival of Lactobacillus acidophilus and Bifidobacterium animalis ssp. lactis in stirred fruit yogurts. Lwt-Food Sci. Technol. 2008, 41, 1317–1322. [Google Scholar] [CrossRef]

- Pintado, A.I.E.; Pinho, O.; Ferreira, I.M.P.L.V.O.; Pintado, M.M.E.; Gomes, A.M.P.; Malcata, F.X. Microbiological, biochemical and biogenic amine profiles of Terrincho cheese manufactured in several dairy farms. Int. Dairy J. 2008, 18, 631–640. [Google Scholar] [CrossRef]

- Kuley, E.; Balıkcı, E.; Özoğul, İ.; Gökdogan, S.; Özoğul, F. Stimulation of cadaverine production by foodborne pathogens in the presence of Lactobacillus, Lactococcus, and Streptococcus spp. J. Food Sci. 2012, 77, M650–M658. [Google Scholar] [CrossRef]

- EFSA Panel on Biological Hazards (BIOHAZ). Scientific opinion on risk based control of biogenic amine formation in fermented foods. Efsa J. 2011, 9, 93. [Google Scholar] [CrossRef]

- Fisberg, M.; Machado, R. History of yogurt and current patterns of consumption. Nutr. Rev. 2015, 73, 4–7. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#home (accessed on 29 June 2020).

- FAS-USDA. Available online: https://www.fas.usda.gov/data (accessed on 29 June 2020).

- Silva, V.L.M.; Costa, M.P.; Vieira, C.P.; Conte-Junior, C.A. Short communication: Biogenic amine formation during fermentation in functional sheep milk yogurts. J. Dairy Sci. 2019, 102, 8704–8709. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.W.; Oglesby, J.; Hayek, S.A.; Aljaloud, S.O.; Gyawali, R.; Ibrahim, S.A. Impact of different gums on textural and microbial properties of goat milk yogurts during refrigerated storage. Foods 2019, 8, 169. [Google Scholar] [CrossRef]

- Miocinovic, J.; Miloradovic, Z.; Josipovic, M.; Nedeljkovic, A.; Radovanovic, M.; Pudja, P. Rheological and textural properties of goat and cow milk set type yoghurts. Int. Dairy J. 2016, 58, 43–45. [Google Scholar] [CrossRef]

- Körzendörfer, A.; Nöbel, S.; Hinrichs, J. Particle formation induced by sonication during yogurt fermentation—Impact of exopolysaccharide-producing starter cultures on physical properties. Food Res. Int. 2017, 97, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Körzendörfer, A.; Schäfer, J.; Hinrichs, J.; Nöbel, S. Power ultrasound as a tool to improve the processability of protein-enriched fermented milk gels for Greek yogurt manufacture. J. Dairy Sci. 2019, 102, 7826–7837. [Google Scholar] [CrossRef] [PubMed]

- Kamble, K.D.; Kokate, P.S. Production and keeping quality of yogurt from buffalo and cow milk—A traditional milk product of high health value. Indian J. Tradit. Know. 2015, 14, 279–284. [Google Scholar] [CrossRef]

- Gandhi, A.; Shah, N.P. Cell growth and proteolytic activity of Lactobacillus acidophilus, Lactobacillus helveticus, Lactobacillus delbrueckii ssp. bulgaricus, and Streptococcus thermophilus in milk as affected by supplementation with peptide fractions. Int. J. Food Sci. Nutr. 2014, 65, 937–941. [Google Scholar] [CrossRef]

- Li, J.; Guo, M. Effects of polymerized whey proteins on consistency and water-holding properties of goat’s milk yogurt. Food Chem. Toxicol. 2006, 71, C34–C38. [Google Scholar] [CrossRef]

- Behnia, A.; Karazhiyan, H.; Niazmand, R.; Nafchi, A.R.M. Rheological properties of low fat yogurt containing cress seed gum. Agric. Sci. 2013, 4, 29–32. [Google Scholar] [CrossRef]

- Wu, H.; Hulbert, G.J.; Mount, J.R. Effects of ultrasound on milk homogenization and fermentation with yogurt starter. Innov. Food Sci. Emerg. Technol. 2000, 1, 211–218. [Google Scholar] [CrossRef]

- Ramírez-Sucre, M.O.; Vélez-Ruiz, J.F. Physicochemical, rheological and stability characterization of a caramel flavored yogurt. LWT-Food Sci. Technol. 2013, 51, 233–241. [Google Scholar] [CrossRef]

- Keogh, M.K.; O’Kennedy, B.T. Rheology of stirred yogurt as affected by added milk fat, protein and hydrocolloids. J. Food Sci. 1998, 63, 108–112. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B.; Saravacos, G.D. Rheological properties of fluid fruit and vegetable puree products: Compilation of literature data. Int. J. Food Prop. 2007, 4, 179–200. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis, 19th ed.; AOAC Int.: Arlington, VA, USA, 2012. [Google Scholar]

- Lee, W.J.; Lucey, J.A. Formation and physical properties of yogurt. Asian Austral. J. Anim. 2010, 23, 1127–1136. [Google Scholar] [CrossRef]

- Steyerberg, E.W.; Harrell, F.E., Jr.; Borsboom, G.J.; Eijkemans, M.J.C.; Vergouwe, Y.; Habbema, J.D.F. Internal validation of predictive models: Efficiency of some procedures for logistic regression analysis. J. Clin. Epidemiol. 2001, 54, 774–781. [Google Scholar] [CrossRef]

- Harrell, F.E.; Lee, K.L.; Mark, D.B. Tutorial in biostatistics multivariable prognostic models: Issues in developing models, evaluating assumptions and adequacy, and measuring and reducing errors. Stat. Med. 1996, 15, 361–387. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Parameter 1 | Treatment 2 | |||

|---|---|---|---|---|

| NSU | US3 | US6 | US9 | |

| Lactobacillus bulgaricus | 7.44 ± 0.15 c | 5.01 ± 0.24 b | 4.56 ± 0.32 a | 4.36 ± 0.19 a |

| Streptococcus thermophilus | 10.30 ± 0.34 c | 8.72 ± 0.15 b | 8.36 ± 0.34 ab | 7.98 ± 0.38 a |

| Lactobacillus acidophilus LA-5 | 8.05 ± 0.03 c | 4.94 ± 0.33 b | 4.13 ± 0.56 a | 3.96 ± 0.17 a |

| Ash | 0.70 ± 0.14 a | 0.80 ± 0.08 a | 0.77 ± 0.10 a | 0.72 ± 0.10 a |

| Fat | 3.33 ± 0.15 a | 3.30 ± 0.26 a | 3.47 ± 0.15 a | 3.30 ± 0.17 a |

| Moisture | 87.33 ± 0.74 a | 87.61 ± 3.23 a | 87.80 ± 0.44 a | 87.80 ± 0.01 a |

| Protein | 0.70 ± 0.11 a | 0.61 ± 0.08 a | 0.61 ± 0.16 a | 0.64 ± 0.1 2a |

| Parameter 1 | Treatment 2 | Storage Time (Day) | ||

|---|---|---|---|---|

| 1 | 14 | 28 | ||

| Lactose | NSU | 50.40 ± 1.59 ab,B | 48.05 ± 2.10 a,A | 48.60 ± 2.06 AB |

| US3 | 49.92 ± 2.54 a | 49.44 ± 2.71 ab | 49.47 ± 2.19 | |

| US6 | 51.84 ± 1.02 ab,B | 49.60 ± 2.50 ab,A | 51.01 ± 0.74 AB | |

| US9 | 52.62 ± 1.67 b | 51.91 ± 2.49 b | 51.25 ± 3.72 | |

| Glucose | NSU | 0.10 ± 0.02 ab | 0.10 ± 0.01 a | 0.09 ± 0.01 a |

| US3 | 0.12 ± 0.03 bc,A | 0.15 ± 0.02 b,AB | 0.16 ± 0.02 c,B | |

| US6 | 0.14 ± 0.03 c | 0.16 ± 0.04 b | 0.14 ± 0.01 b | |

| US9 | 0.08 ± 0.01 a | 0.08 ± 0.00 a | 0.08 ± 0.00 a | |

| Galactose | NSU | 1.11 ± 0.08 | 1.12 ± 0.06 b | 1.11 ± 0.09 b |

| US3 | 1.05 ± 0.06 | 1.10 ± 0.06 ab | 1.08 ± 0.05 b | |

| US6 | 1.08 ± 0.03 | 1.07 ± 0.05 ab | 1.11 ± 0.01 b | |

| US9 | 1.02 ± 0.12 | 1.01 ± 0.10 a | 0.99 ± 0.07 a | |

| Citric acid | NSU | 0.13 ± 0.01 b,B | 0.11 ± 0.01 ab,A | 0.12 ± 0.01 b,B |

| US3 | 0.11 ± 0.01 a | 0.10 ± 0.01 a | 0.11 ± 0.01 a | |

| US6 | 0.13 ± 0.01 b | 0.11 ± 0.03 ab | 0.13 ± 0.00 b | |

| US9 | 0.13 ± 0.01 b | 0.13 ± 0.00 b | 0.13 ± 0.01 b | |

| Lactic acid | NSU | 1.37 ± 0.08 ab | 1.37 ± 0.07 | 1.33 ± 0.14 |

| US3 | 1.26 ± 0.04 a | 1.30 ± 0.04 | 1.26 ± 0.04 | |

| US6 | 1.39 ± 0.15 ab | 1.28 ± 0.12 | 1.32 ± 0.02 | |

| US9 | 1.46 ± 0.19 b | 1.37 ± 0.14 | 1.32 ± 0.11 | |

| Formic acid | NSU | 0.43 ± 0.01 b | 0.42 ± 0.01 c | 0.43 ± 0.01 b |

| US3 | 0.42 ± 0.00 ab,AB | 0.41 ± 0.01 bc,A | 0.42 ± 0.01 ab,B | |

| US6 | 0.42 ± 0.00 ab | 0.41 ± 0.01 ab | 0.39 ± 0.05 a | |

| US9 | 0.41 ± 0.01 a,B | 0.40 ± 0.01 a,A | 0.42 ± 0.00 ab,B | |

| Biogenic Amines (mg L−1) | Treatment | Storage Time (day) | ||

|---|---|---|---|---|

| 1 | 14 | 28 | ||

| Cadaverine | NSU | 2.80 ± 0.44 a,A | 2.80 ± 0.44 a,A | 3.90 ± 0.72 ab,B |

| US3 | 2.61 ± 0.53 a,A | 2.69 ± 0.57 a,A | 2.93 ± 0.72 a,A | |

| US6 | 3.80 ± 0.92 b,A | 4.54 ± 0.90 b,AB | 5.47 ± 1.42 c,B | |

| US9 | 3.01 ± 0.85 ab,A | 5.49 ± 1.27 b,B | 5.21 ± 1.22 bc,B | |

| Putrescine | NSU | 2.56 ± 0.76 a,A | 3.83 ± 0.67 b,B | 4.12 ± 0.96 a,B |

| US3 | 2.80 ± 0.47 a,A | 2.91 ± 0.68 a,A | 3.16 ± 0.87 a,A | |

| US6 | 2.79 ± 0.51 a,A | 2.88 ± 0.54 a,A | 3.34 ± 0.93 a,A | |

| US9 | 2.61 ± 0.71 a,A | 2.77 ± 0.59 a,A | 3.16 ± 0.54 a,A | |

| Spermidine | NSU | 2.34 ± 0.64 b,A | 4.53 ± 1.12 b,B | 5.87 ± 1.19 c,C |

| US3 | 2.32 ± 0.66 b,A | 2.24 ± 0.55 a,A | 5.04 ± 0.84 bc,B | |

| US6 | 1.54 ± 0.36 a,A | 1.88 ± 0.47 a,A | 4.21 ± 0.90 ab,B | |

| US9 | 1.29 ± 0.36 a,A | 1.55 ± 0.42 a,A | 3.39 ± 0.91 a,B | |

| Spermine | NSU | 1.95 ± 0.33 a,A | 3.00 ± 0.75 c,B | 3.23 ± 0.97 b,B |

| US3 | 1.69 ± 0.20 a,A | 2.48 ± 0.65 bc,B | 2.95 ± 0.52 b,B | |

| US6 | 1.78 ± 0.21 a,A | 1.52 ± 0.09 a,A | 2.49 ± 0.70 ab,B | |

| US9 | 1.85 ± 0.29 a,A | 1.82 ± 0.40 ab,A | 1.93 ± 0.30 a,A | |

| Tyramine | NSU | 16.50 ± 4.76 a,A | 18.35 ± 1.12 b,A | 19.34 ± 1.12 b,A |

| US3 | 14.33 ± 2.24 a,A | 17.30 ± 0.93 ab,B | 18.20 ± 1.67 ab,B | |

| US6 | 16.00 ± 1.13 a,A | 16.24 ± 1.16 a,AB | 17.76 ± 1.65 ab,B | |

| US9 | 14.93 ± 1.36 a,A | 15.96 ± 2.74 a,A | 16.58 ± 0.99 a,A | |

| Total concentration | NSU | 30.26 ± 1.64 a,A | 32.79 ± 2.80 a,A | 32.06 ± 6.10 a,A |

| US3 | 27.73 ± 1.51 b,A | 27.87 ± 2.03 b,A | 28.05 ± 1.89 a,A | |

| US6 | 27.67 ± 1.74 b,A | 27.05 ± 2.26 b,A | 31.51 ± 3.93 a,B | |

| US9 | 25.34 ± 1.27 c,A | 27.58 ± 1.85 b,B | 28.61 ± 1.70 a,B | |

| Parameter 1 | Treatment 2 | Storage Time (Day) | ||

|---|---|---|---|---|

| 1 | 14 | 28 | ||

| F (g) | NSU | 34.16 ± 0.41 a,B | 33.55 ± 0.26 c,A | 33.89 ± 0.27 a,AB |

| US3 | 33.56 ± 2.07 a,B | 27.26 ± 1.76 a,A | 32.22 ± 3.10 a,B | |

| US6 | 36.59 ± 0.78 b,C | 25.79 ± 1.61 a,A | 31.45 ± 2.94 a,B | |

| US9 | 34.70 ± 2.17 ab,B | 30.45 ± 4.20 b,A | 31.86 ± 2.27 a,AB | |

| Cn (g s) | NSU | 360.25 ± 6.64 ab,A | 365.24 ± 4.46 c,A | 365.81 ± 3.49 a,A |

| US3 | 347.71 ± 16.48 a,B | 272.51 ± 23.98 ab,A | 339.85 ± 44.41 a,B | |

| US6 | 384.48 ± 8.92 b,C | 254.59 ± 22.79 a,A | 321.80 ± 46.89 a,B | |

| US9 | 356.80 ± 37.02 a,A | 309.66 ± 47.94 b,A | 322.20 ± 33.28 a,A | |

| Ch (g) | NSU | −5.07 ± 0.43 b,A | −3.21 ± 0.30 d,B | −5.03 ± 0.21 b,A |

| US3 | −4.90 ± 0.39 b,B | −7.27 ± 0.65 b,A | −4.99 ± 0.66 b,B | |

| US6 | −6.29 ± 0.78 a,B | −8.45 ± 0.75 a,A | −6.10 ± 0.66 a,B | |

| US9 | −5.89 ± 0.72 a,A | −5.04 ± 119 c,A | −5.43 ± 0.76 ab,A | |

| K (Pa sn) | NSU | 1.81 ± 0.56 a,B | 0.04 ± 0.03 a,A | 0.08 ± 0.01 a,A |

| US3 | 3.73 ± 1.11 a,B | 0.84 ± 0.46 b,A | 0.44 ± 0.04 a,A | |

| US6 | 13.90 ± 3.51 b,B | 2.26 ± 0.52 b,A | 1.13 ± 0.16 b,A | |

| US9 | 5.54 ± 0.80 a,B | 0.65 ± 0.18 ab,A | 0.48 ± 0.02 a,A | |

| n | NSU | 0.48 ± 0.01 b,A | 0.44 ± 0.06 a,A | 0.75 ± 0.17 a,B |

| US3 | 0.43 ± 0.07 b,A | 0.67 ± 0.05 b,B | 0.62 ± 0.14 a,AB | |

| US6 | 0.17 ± 0.03 a,A | 0.40 ± 0.08 a,B | 0.61 ± 0.03 a,C | |

| US9 | 0.40 ± 0.03 b,A | 0.70 ± 0.01 b,B | 0.67 ± 0.09 a,B | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado, K.; Vieira, C.; Dammak, I.; Frasão, B.; Brígida, A.; Costa, M.; Conte-Junior, C. Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt. Molecules 2020, 25, 4638. https://doi.org/10.3390/molecules25204638

Delgado K, Vieira C, Dammak I, Frasão B, Brígida A, Costa M, Conte-Junior C. Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt. Molecules. 2020; 25(20):4638. https://doi.org/10.3390/molecules25204638

Chicago/Turabian StyleDelgado, Karina, Carla Vieira, Ilyes Dammak, Beatriz Frasão, Ana Brígida, Marion Costa, and Carlos Conte-Junior. 2020. "Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt" Molecules 25, no. 20: 4638. https://doi.org/10.3390/molecules25204638

APA StyleDelgado, K., Vieira, C., Dammak, I., Frasão, B., Brígida, A., Costa, M., & Conte-Junior, C. (2020). Different Ultrasound Exposure Times Influence the Physicochemical and Microbial Quality Properties in Probiotic Goat Milk Yogurt. Molecules, 25(20), 4638. https://doi.org/10.3390/molecules25204638