Hybrid Nanocellulose-Copper (II) Oxide as Engine Oil Additives for Tribological Behavior Improvement

Abstract

1. Introduction

2. Methodology

2.1. Nanoparticle Preparation and Characterization

2.2. Nanolubricant Preparation and Its Stability

2.3. Kinematic Viscosity and Viscosity Index (VI)

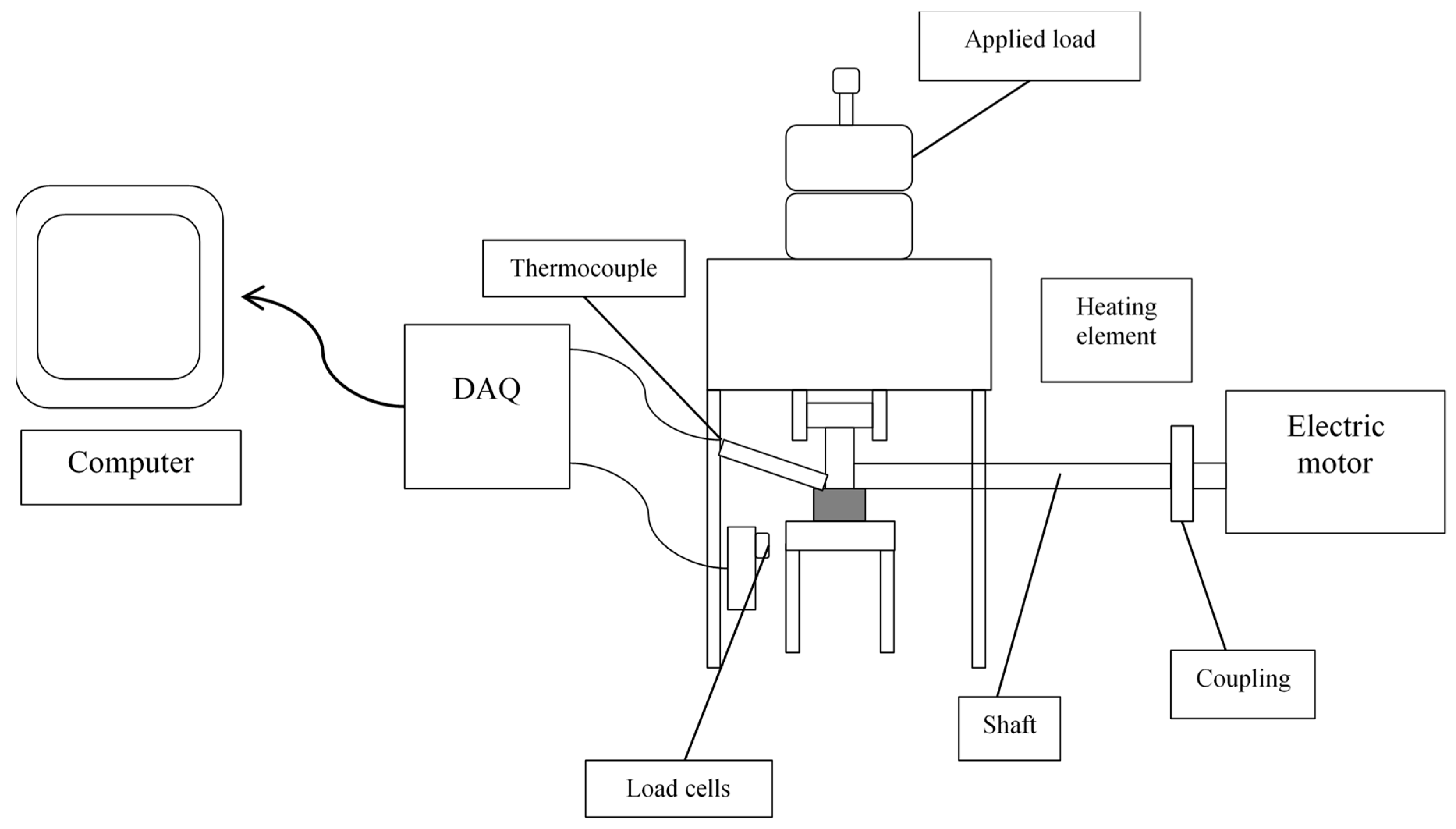

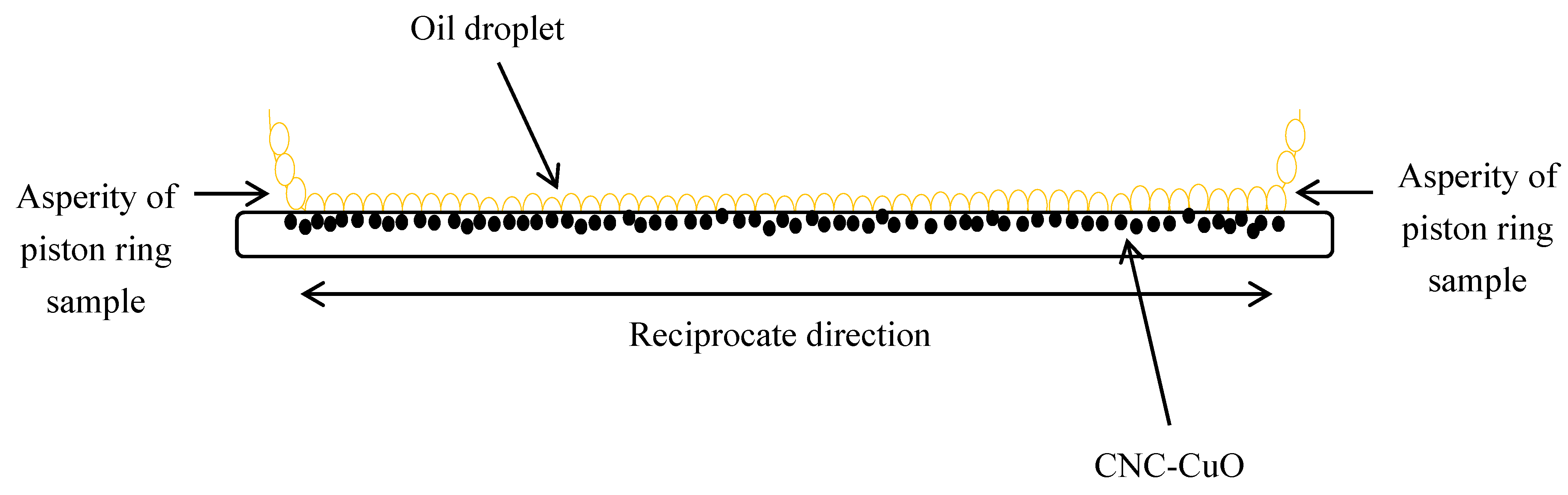

2.4. Tribological Testing

3. Results and Discussion

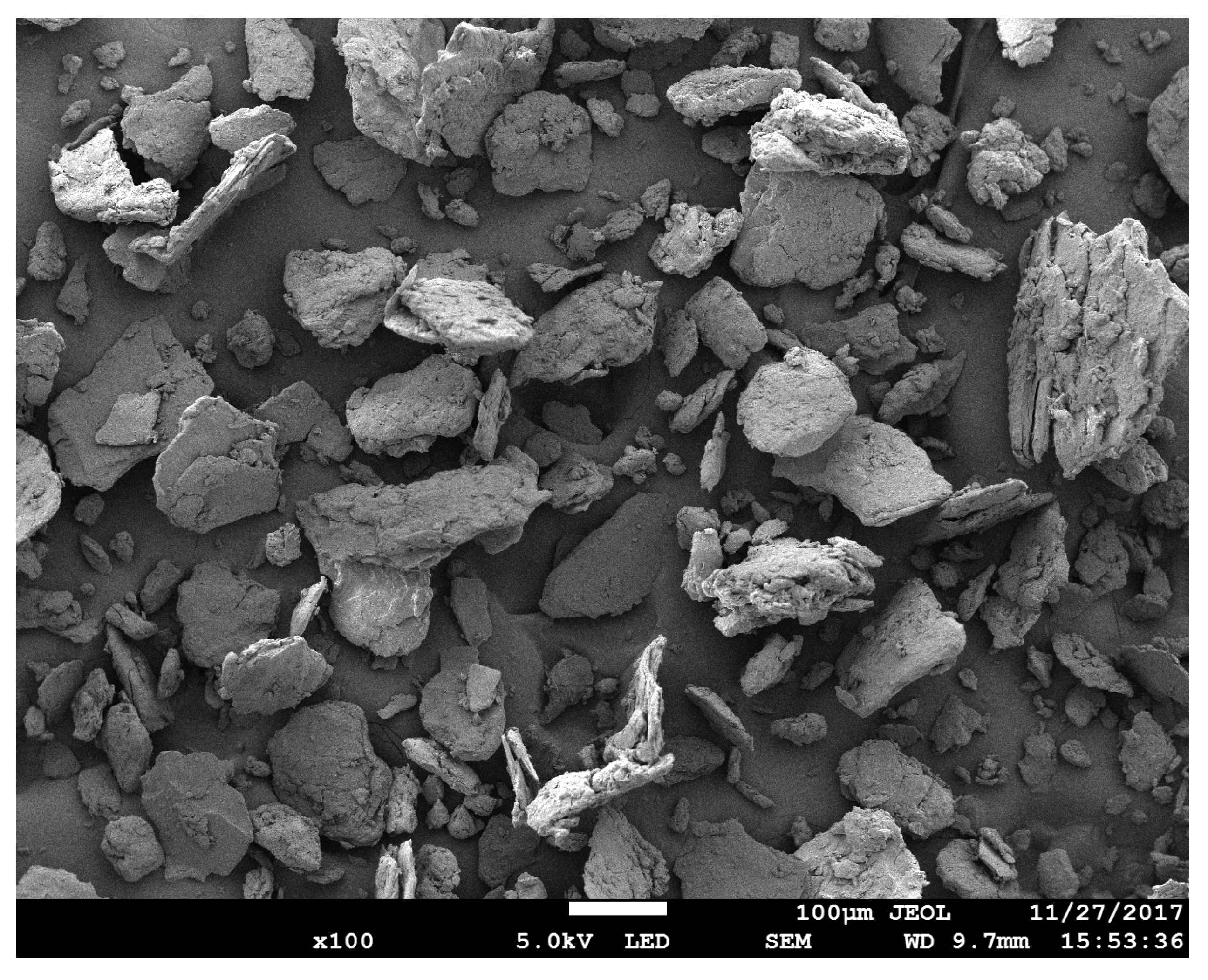

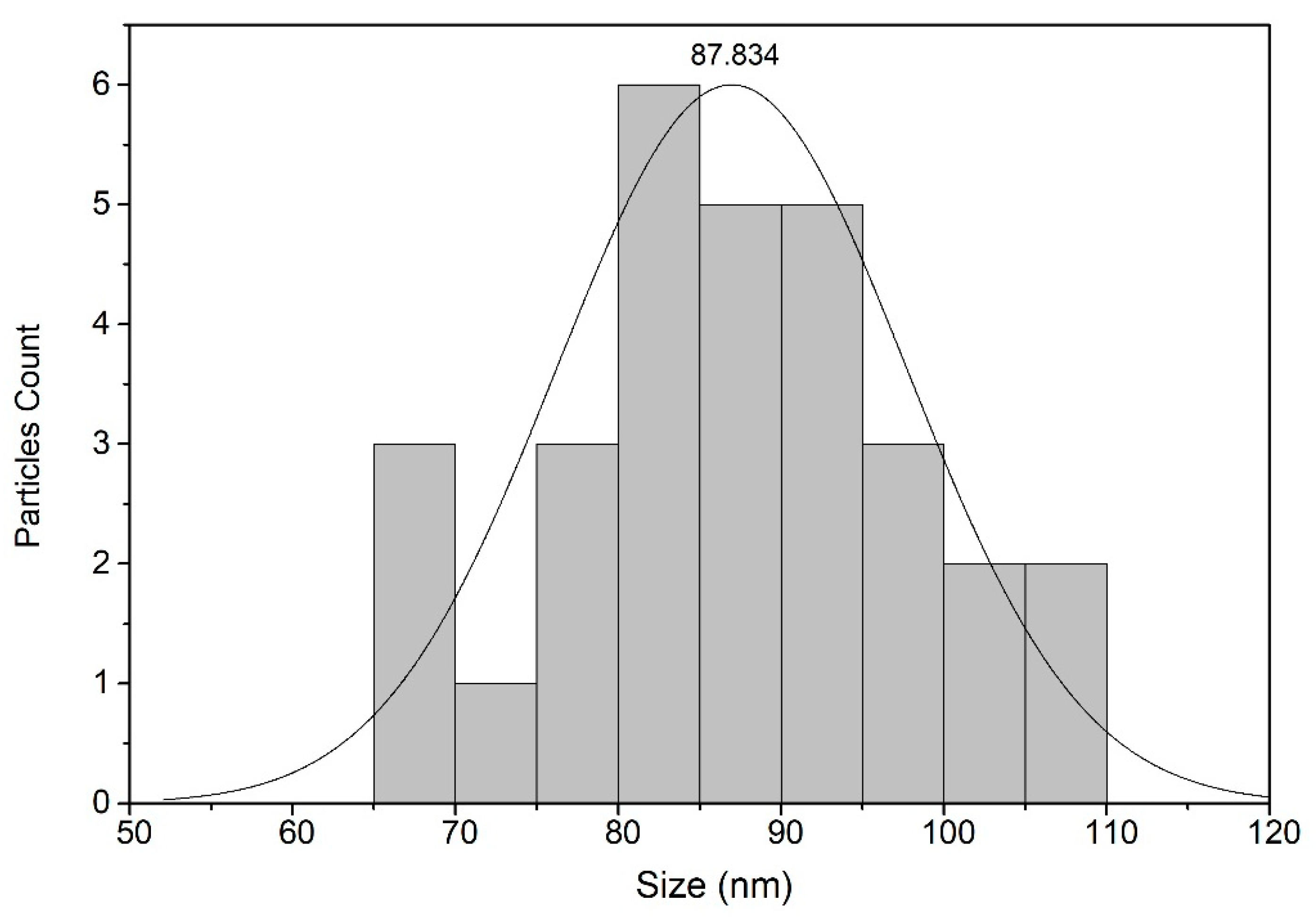

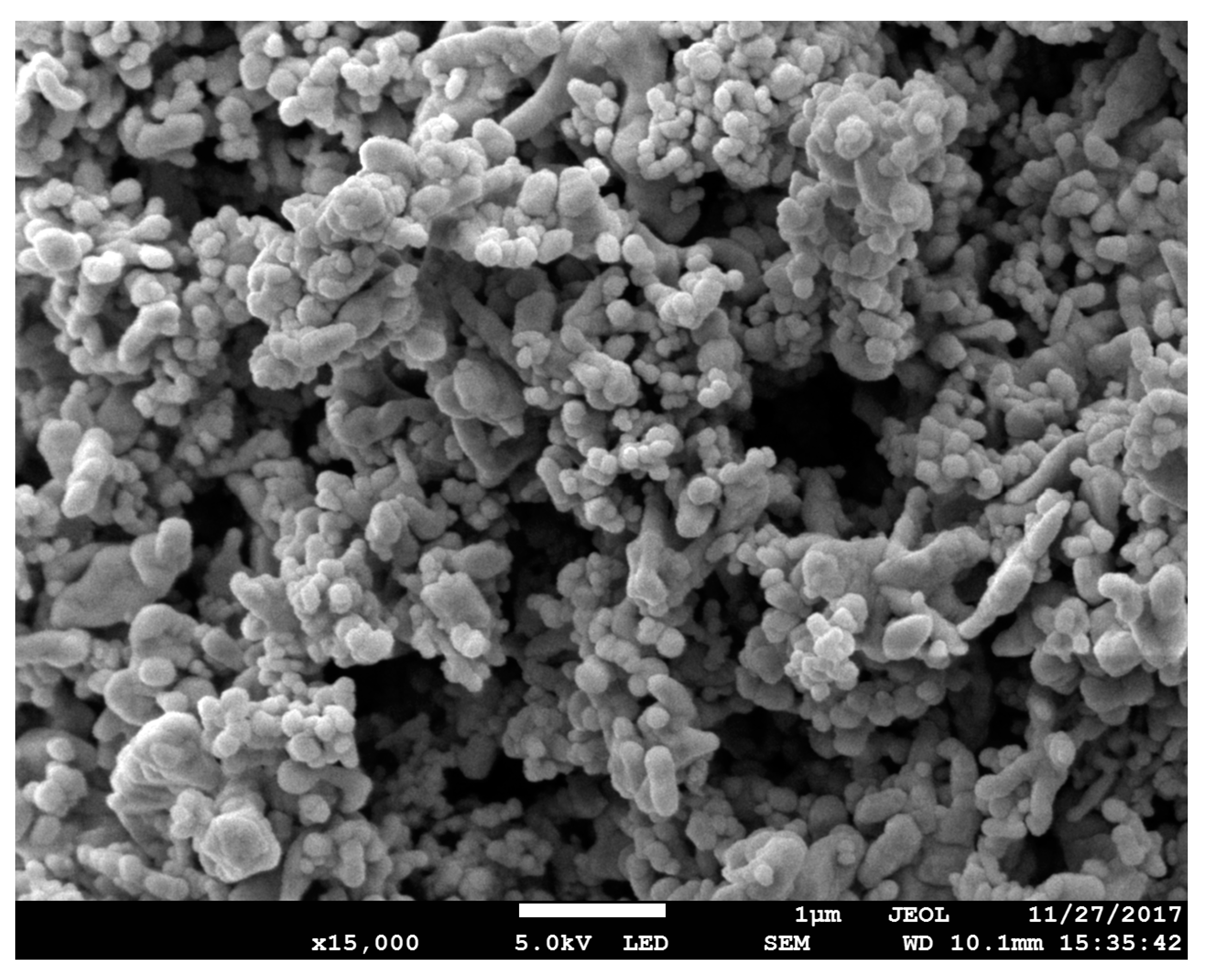

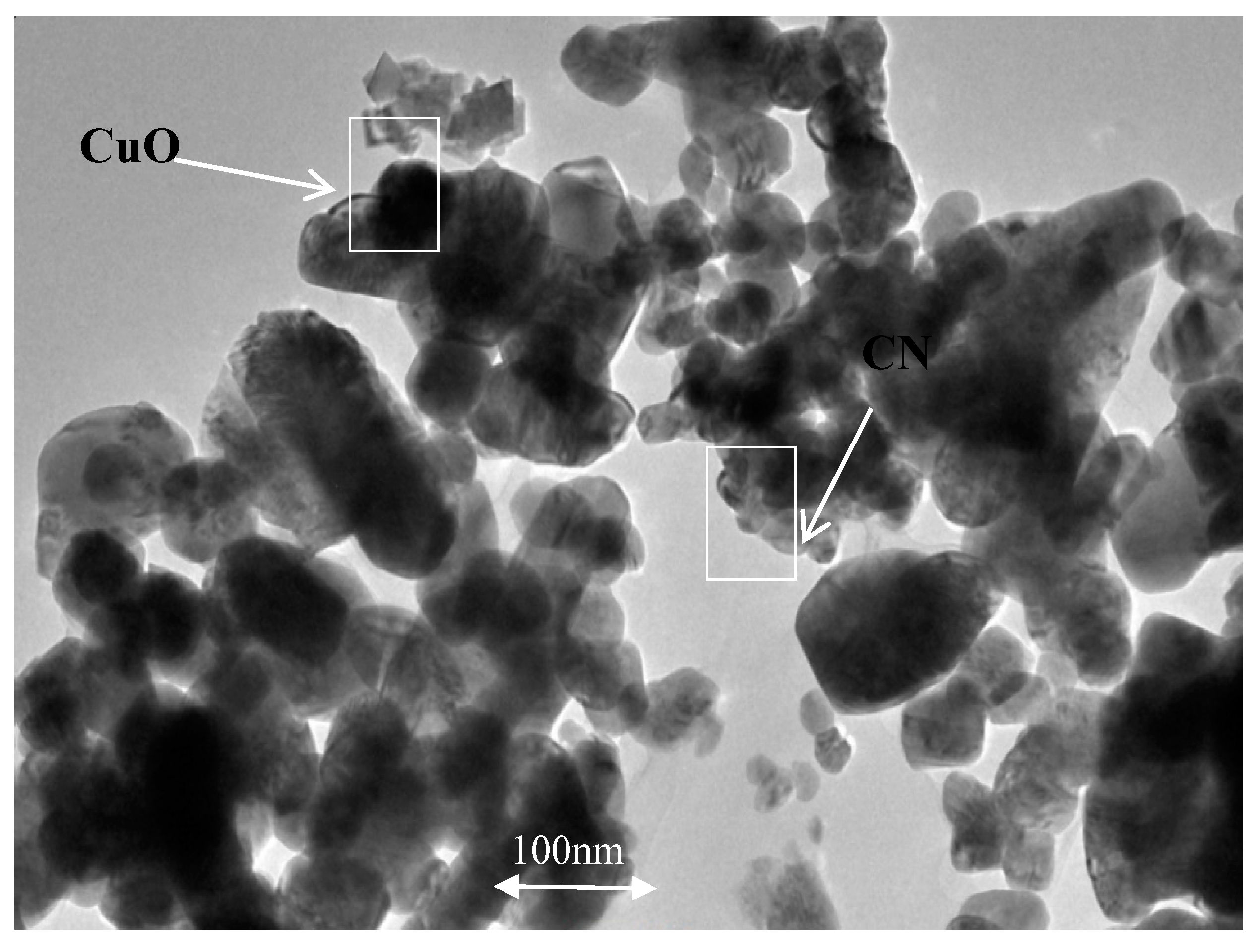

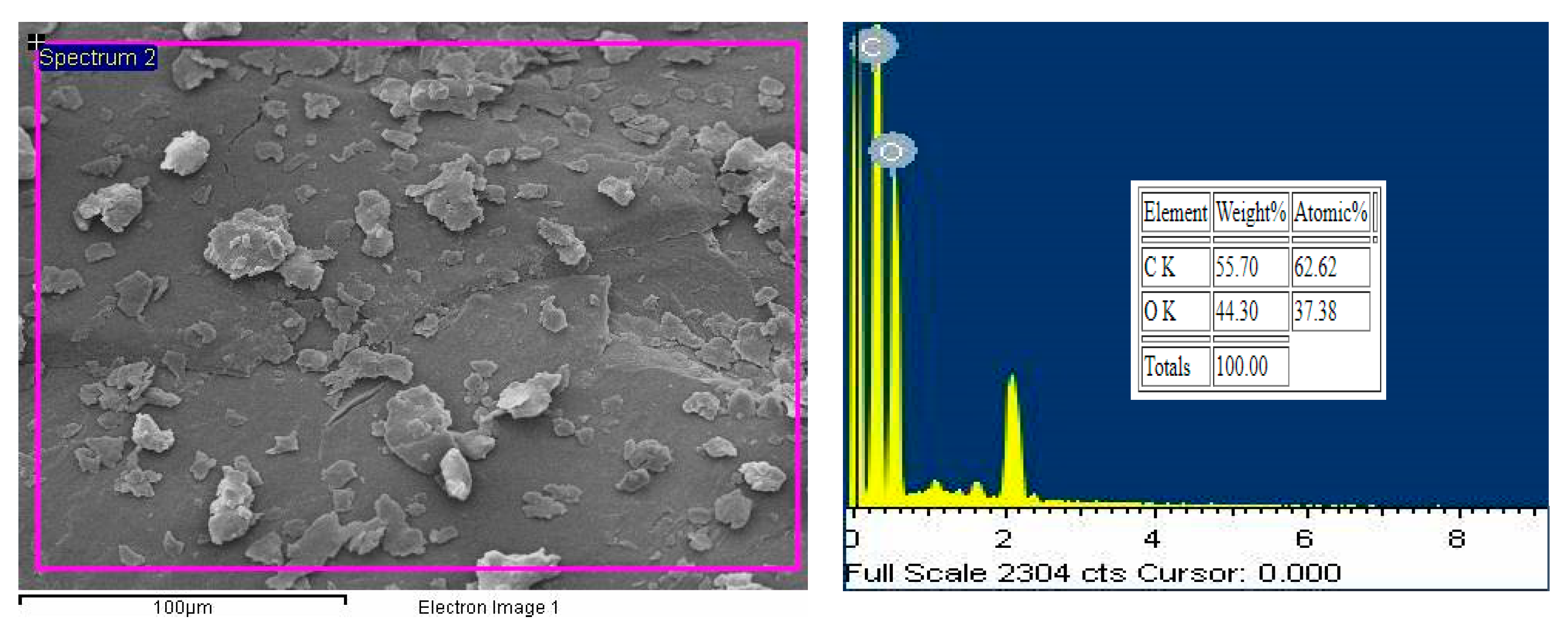

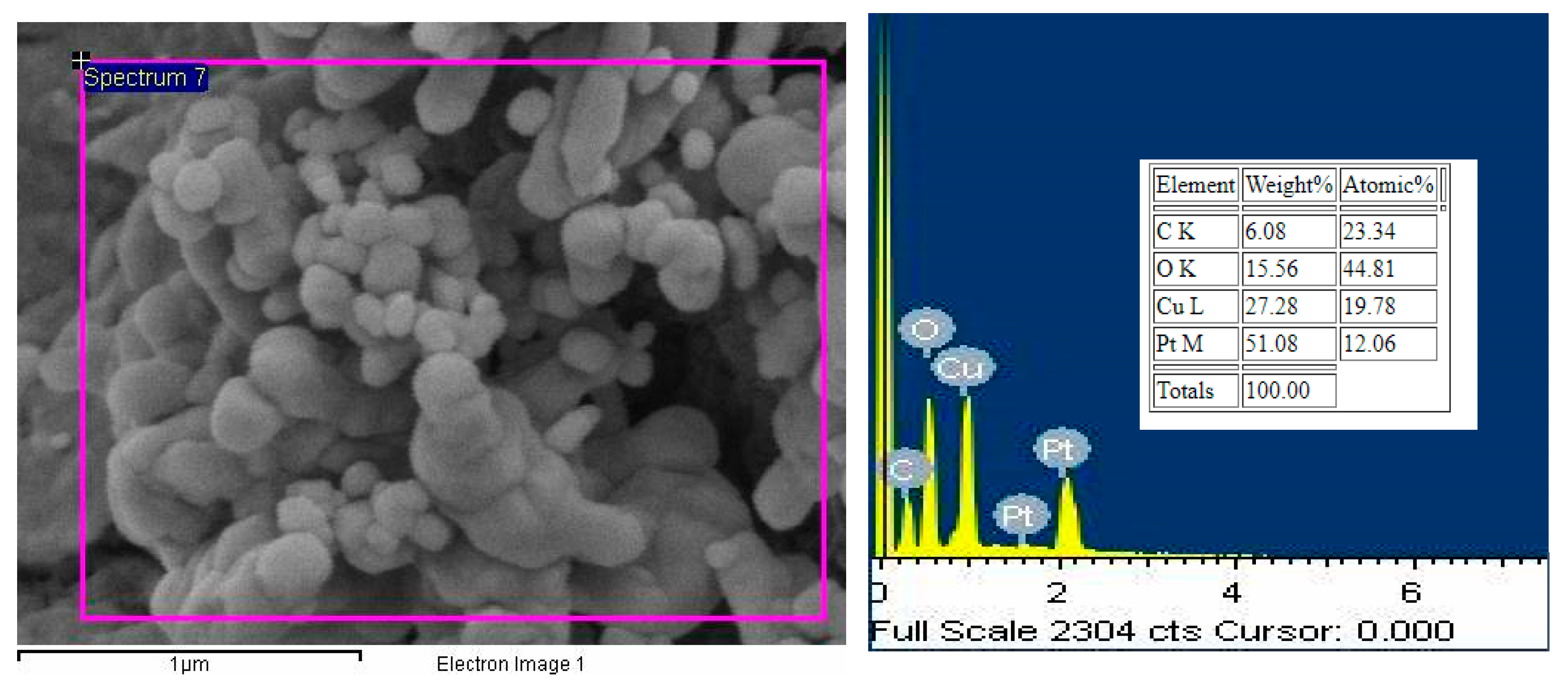

3.1. Nanoparticle Characterization

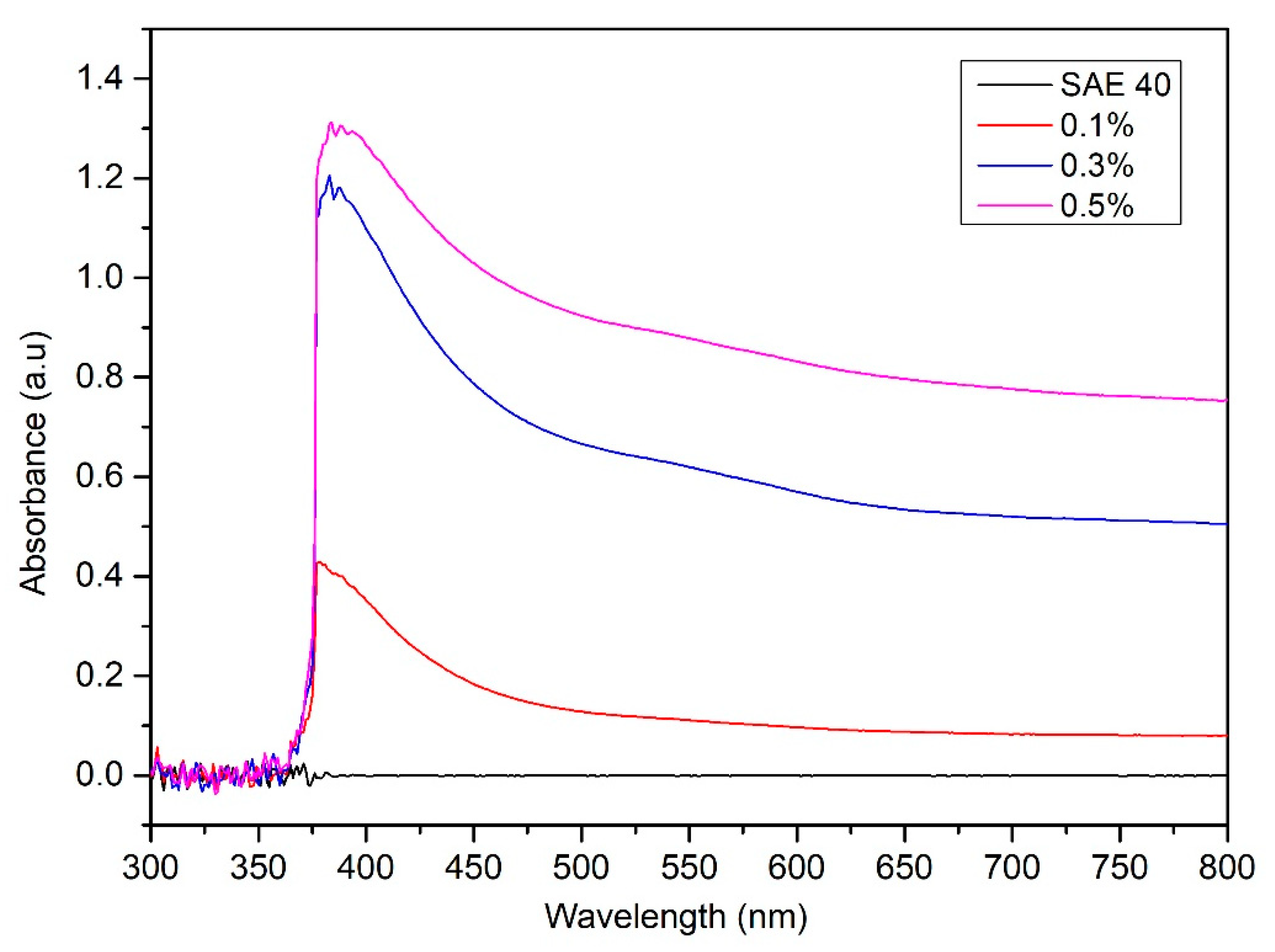

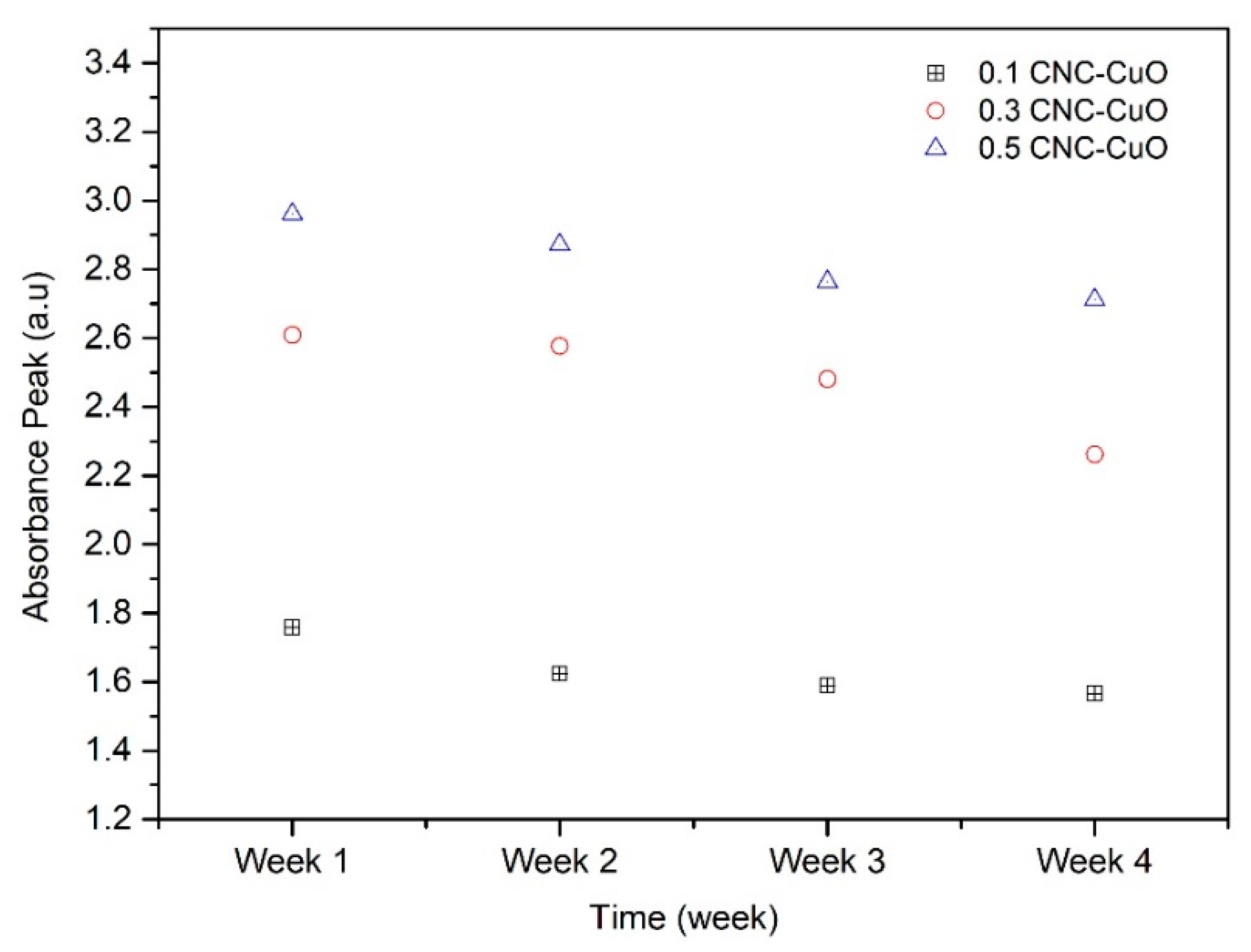

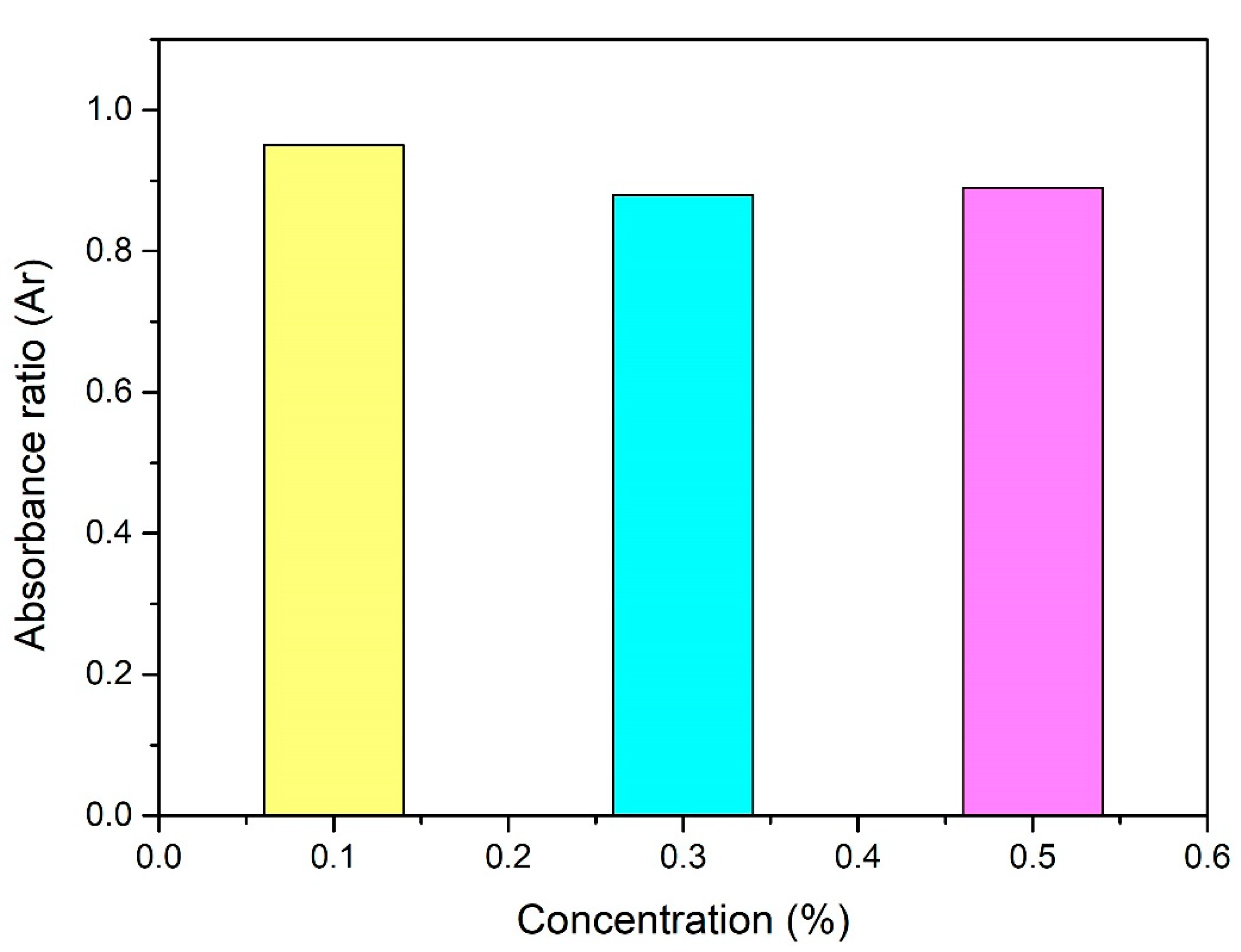

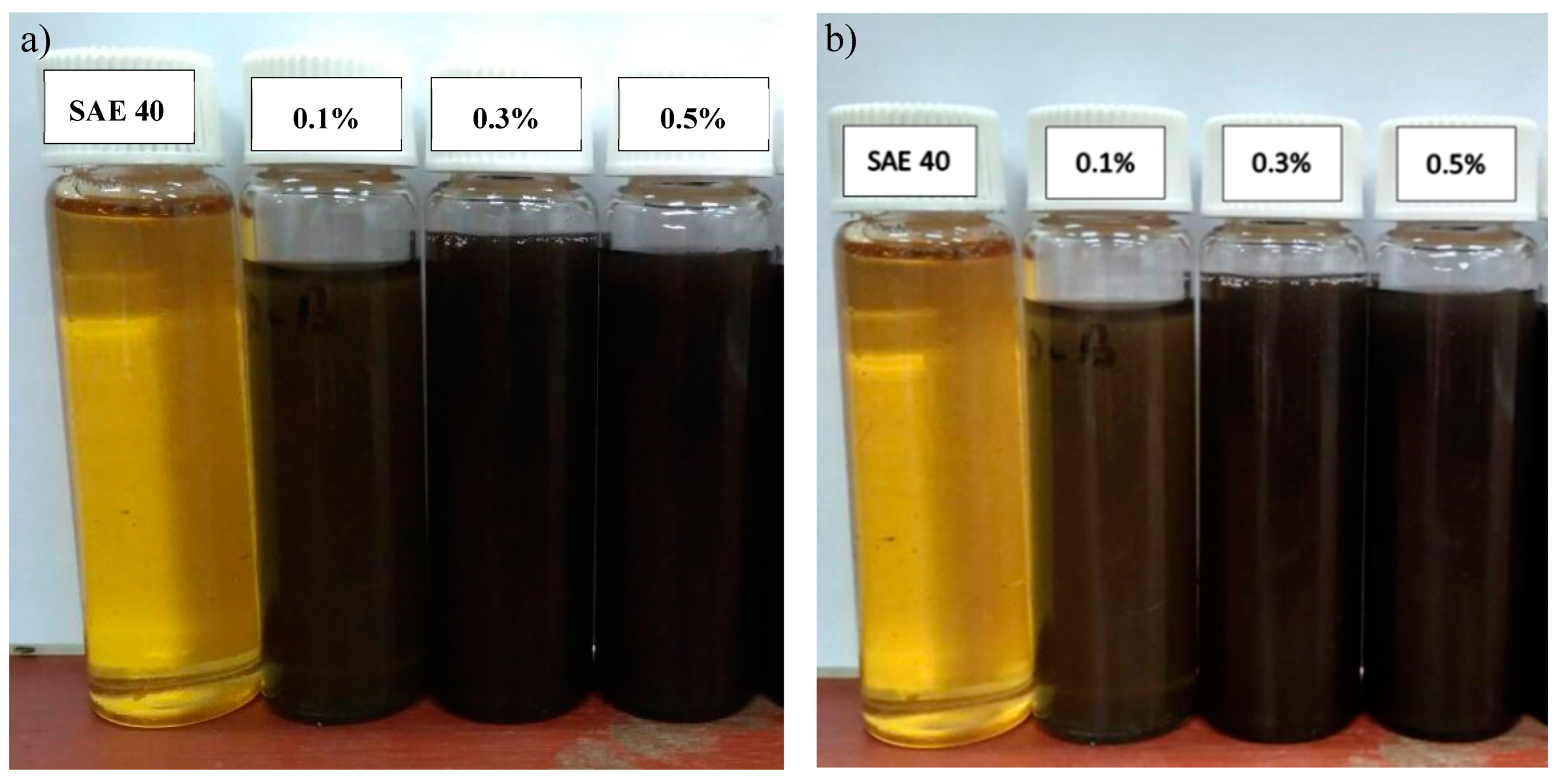

3.2. Suspension Stability of CNC-CuO in SAE 40

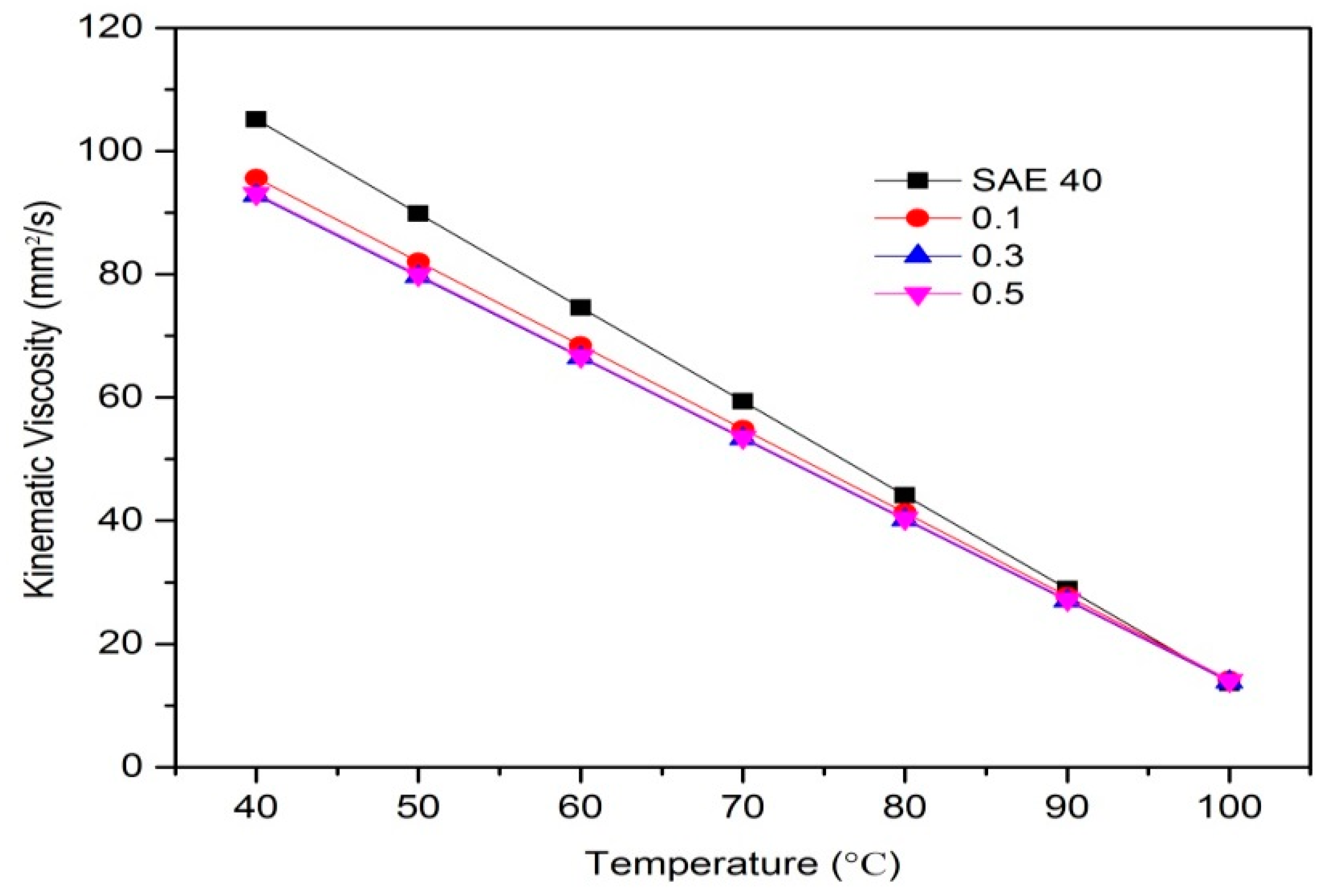

3.3. Effect of CNC-CuO on the Lubricant Viscosity

3.4. Tribological Performance of CNC-CuO Nano Lubricant

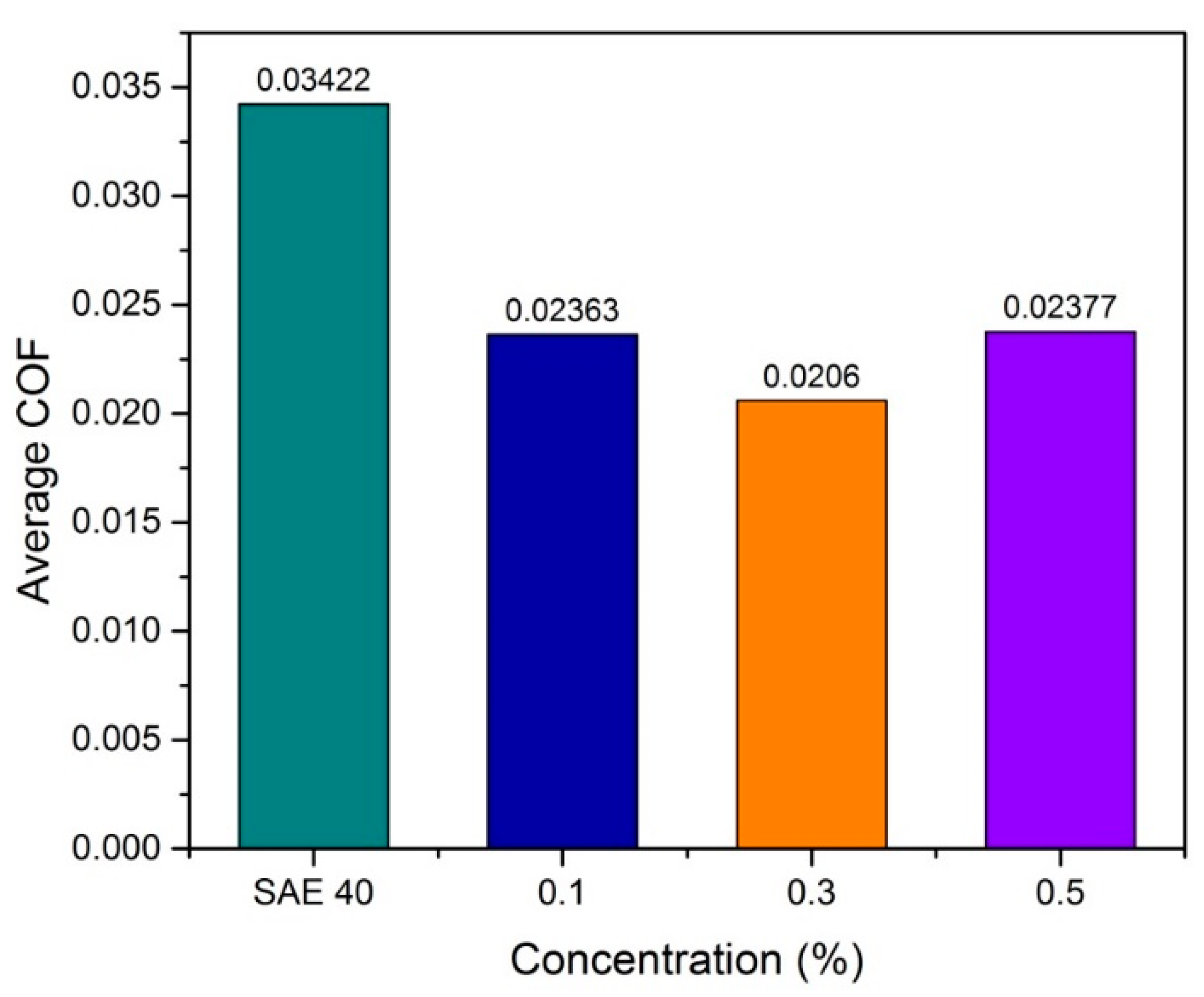

3.4.1. Friction and Wear Behaviour at High Low-Speed Load and High-Speed, Low Load

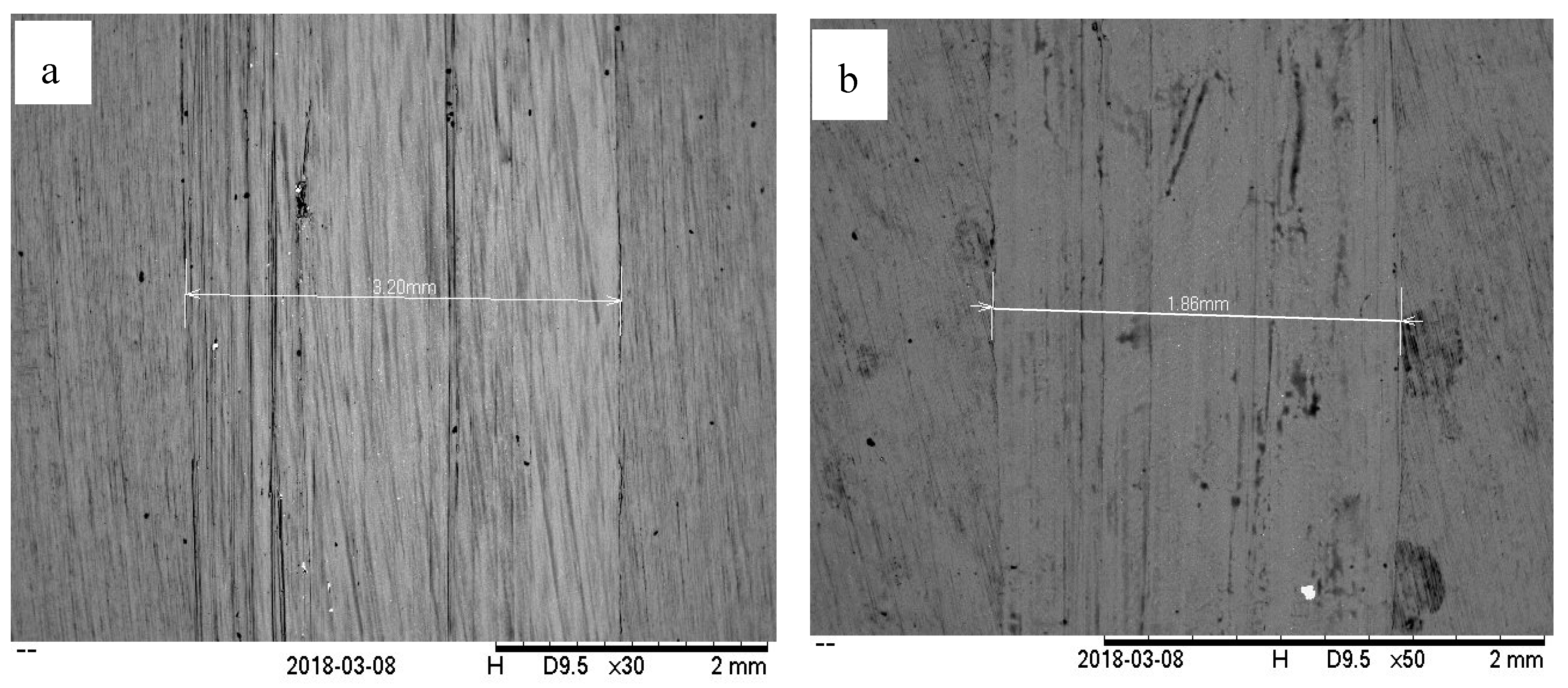

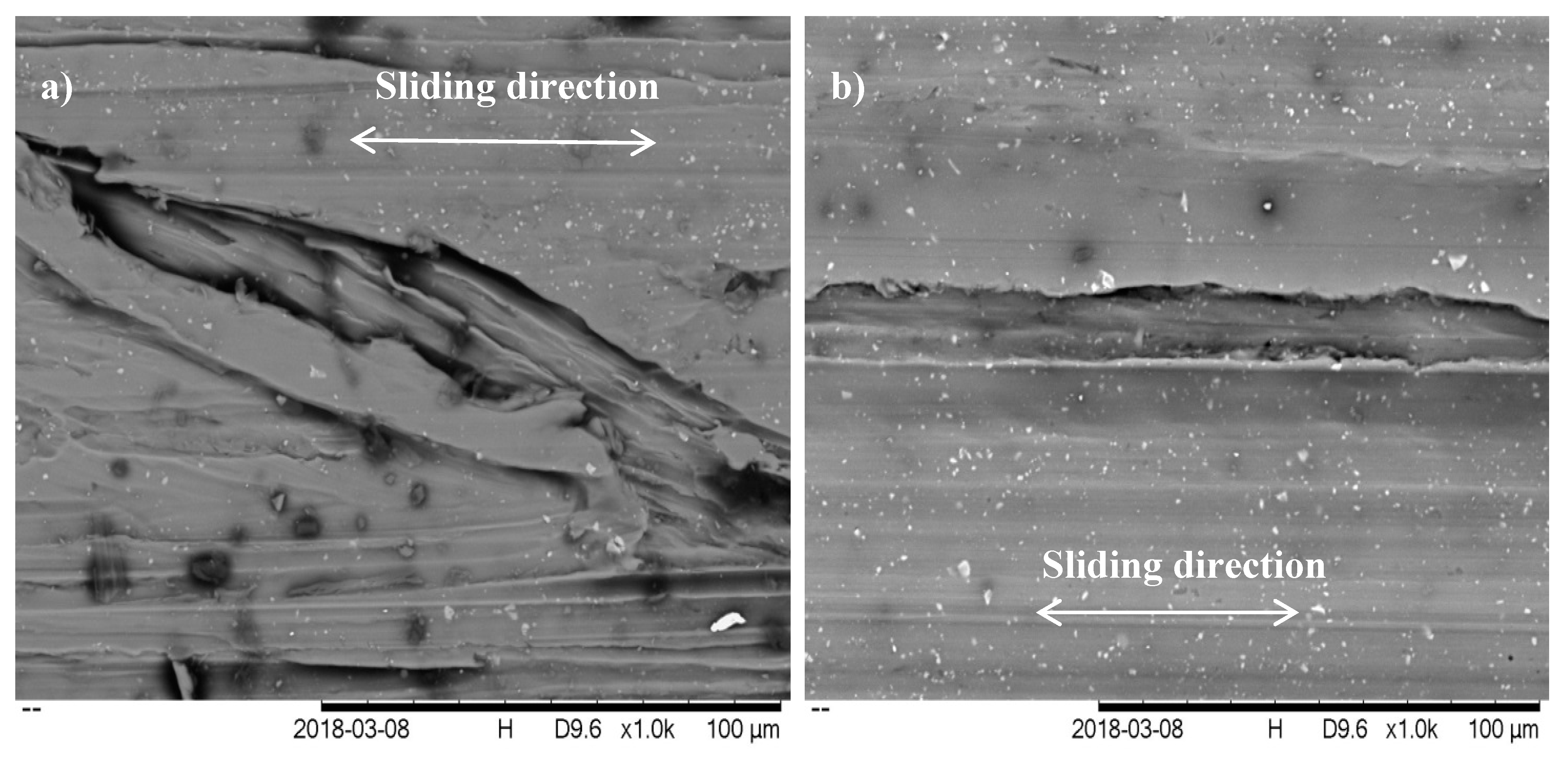

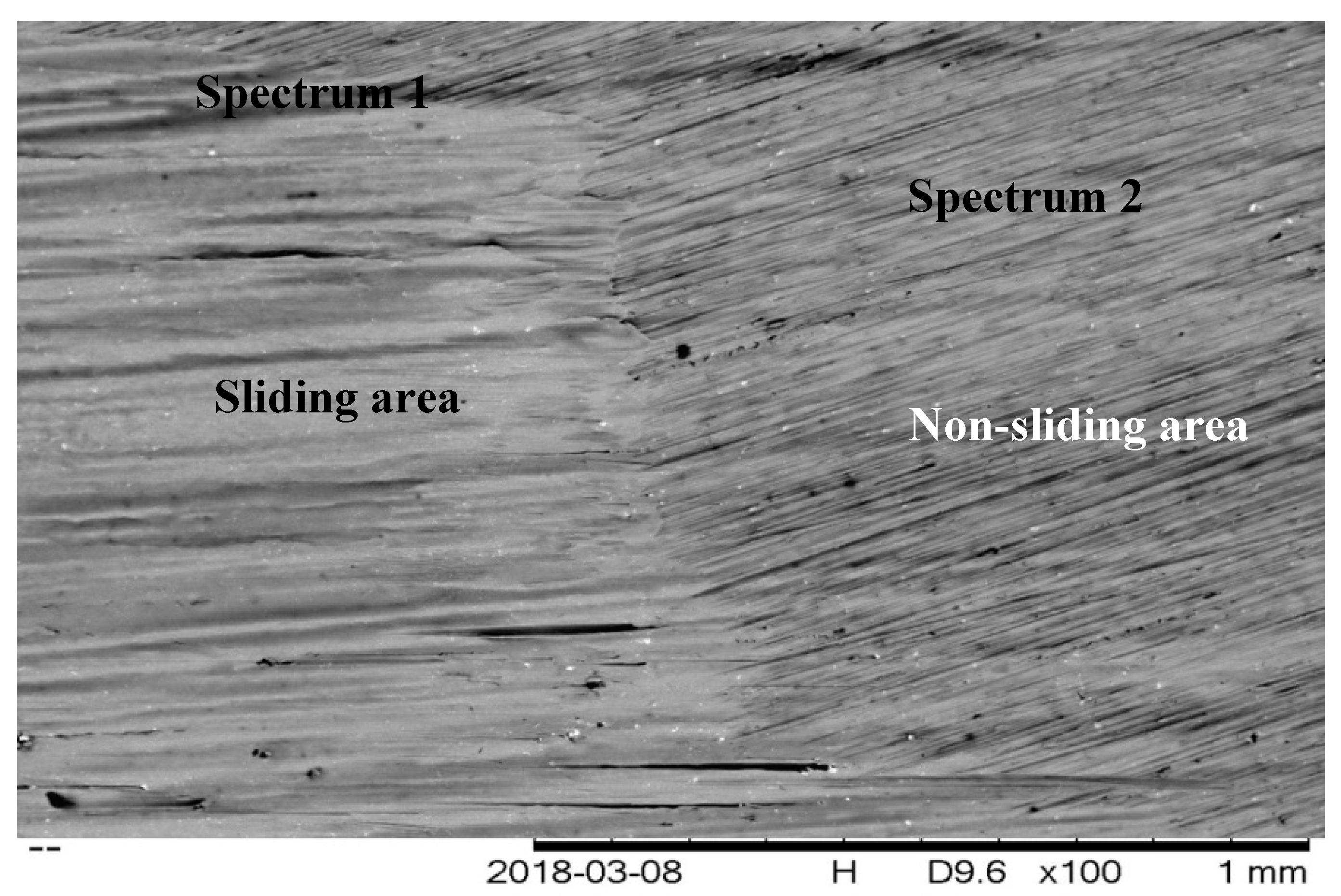

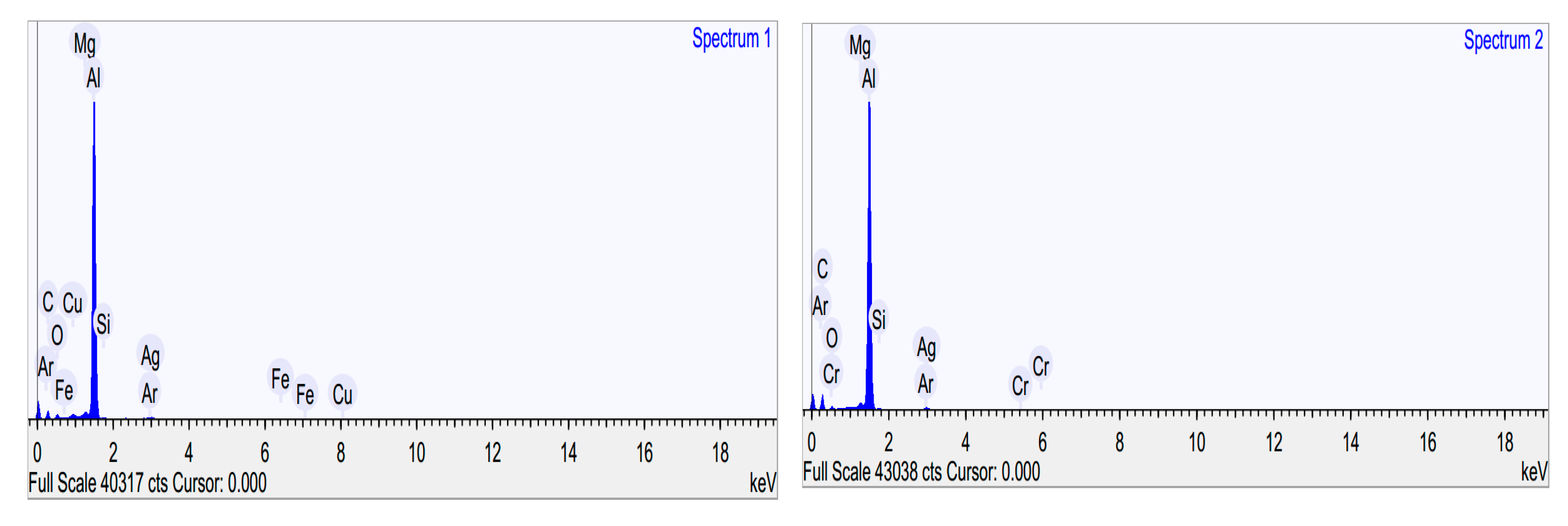

3.4.2. Wear Mechanism

4. Conclusions

- The average CNC-CuO nanoparticle size is 82.6 nm. The peak absorbance for 0.1 concentration is 419 while for 0.3 and 0.5, is 415 nm.

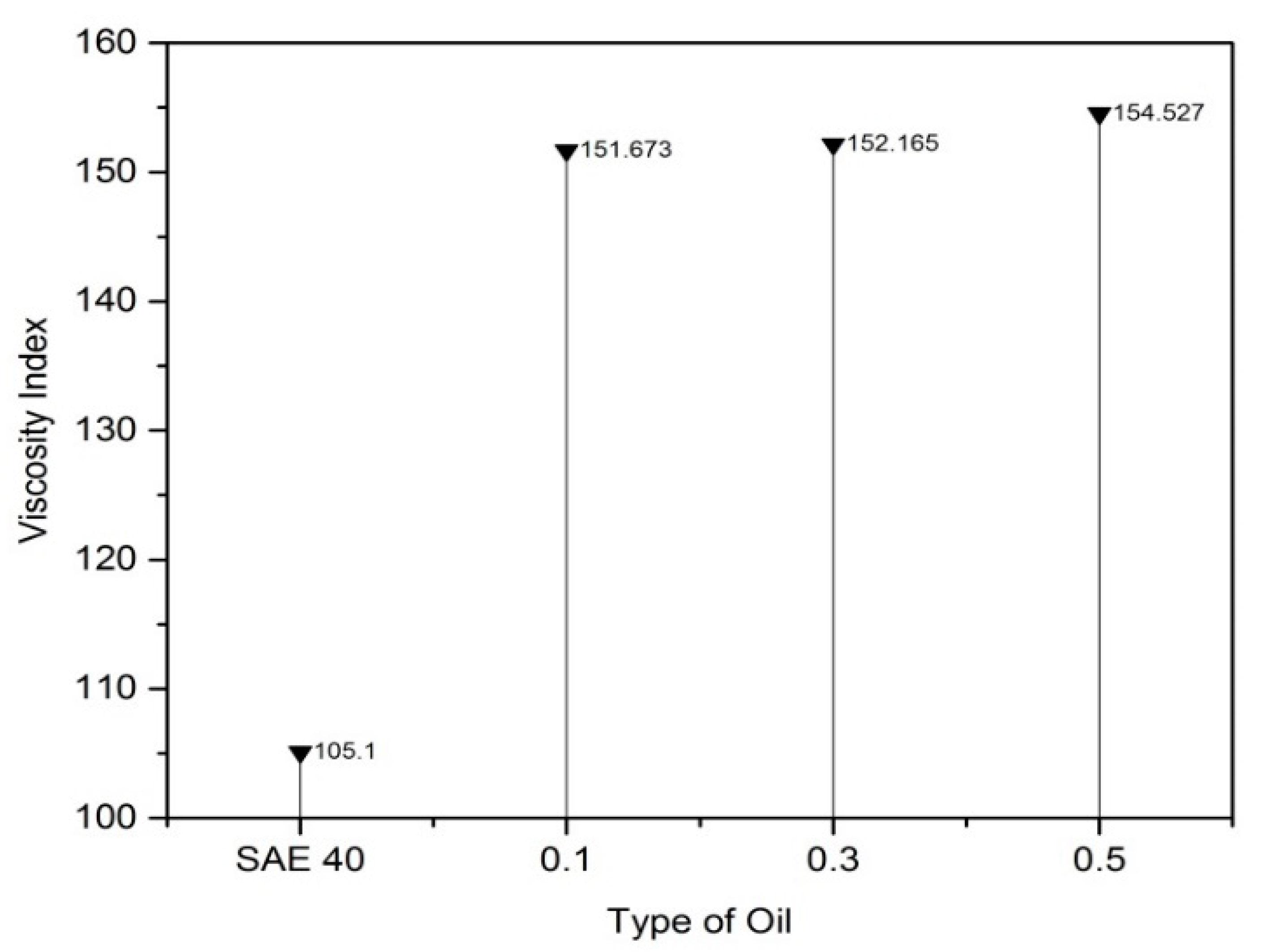

- SAE 40 shows higher kinematic viscosity values at 40 °C than all another lubricants that contain CNC-CuO nanoparticles while between the concentration of the CNC-CuO nanoparticle, 0.1 shows a slightly higher kinematic viscosity while 0.3 and 0.5 do not show many differences. As the temperature of the viscosity approaches 100 °C, the nano lubricant kinematic viscosity value was close to the base oil (SAE 40). As for VI, as the concentration increases, VI increases.

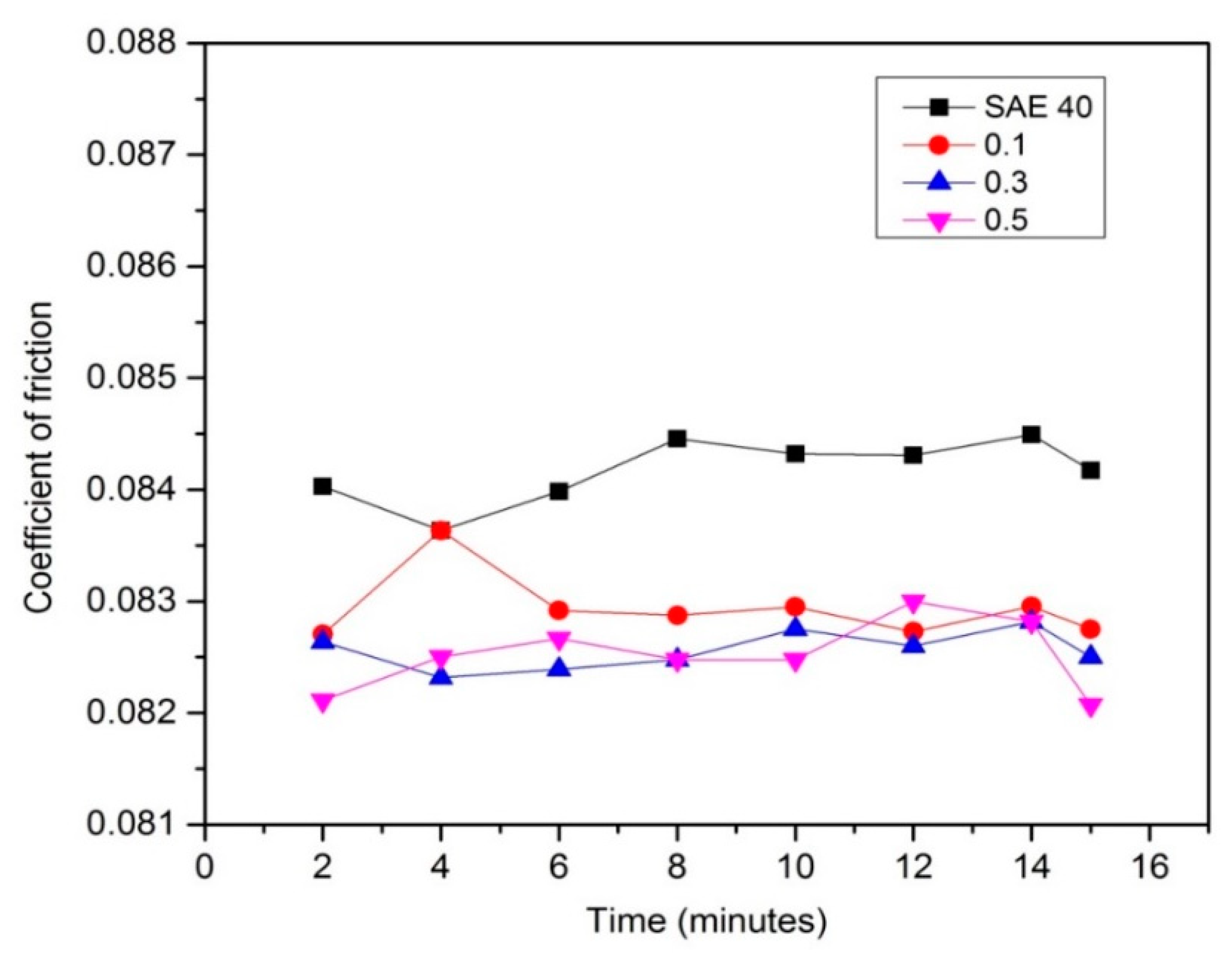

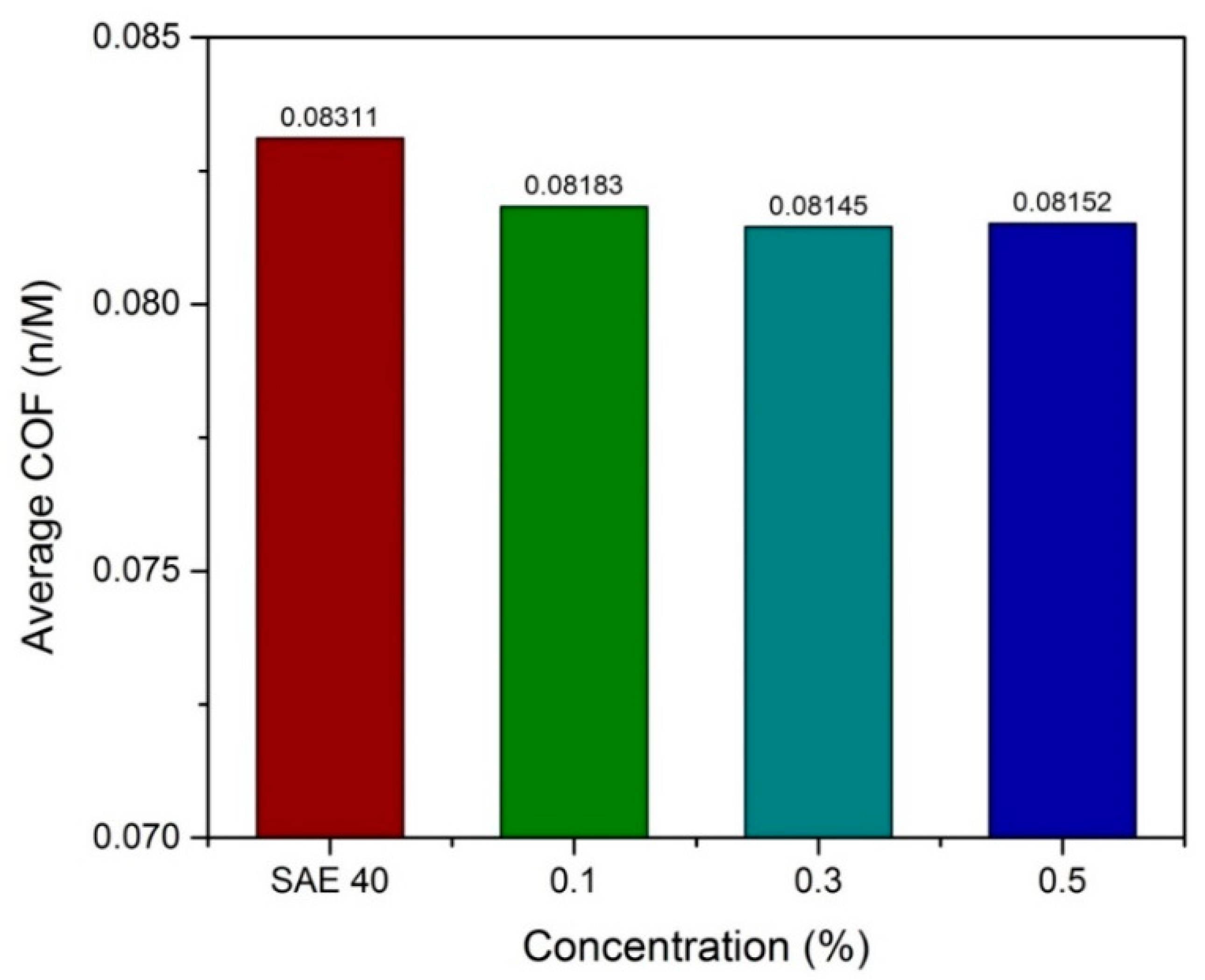

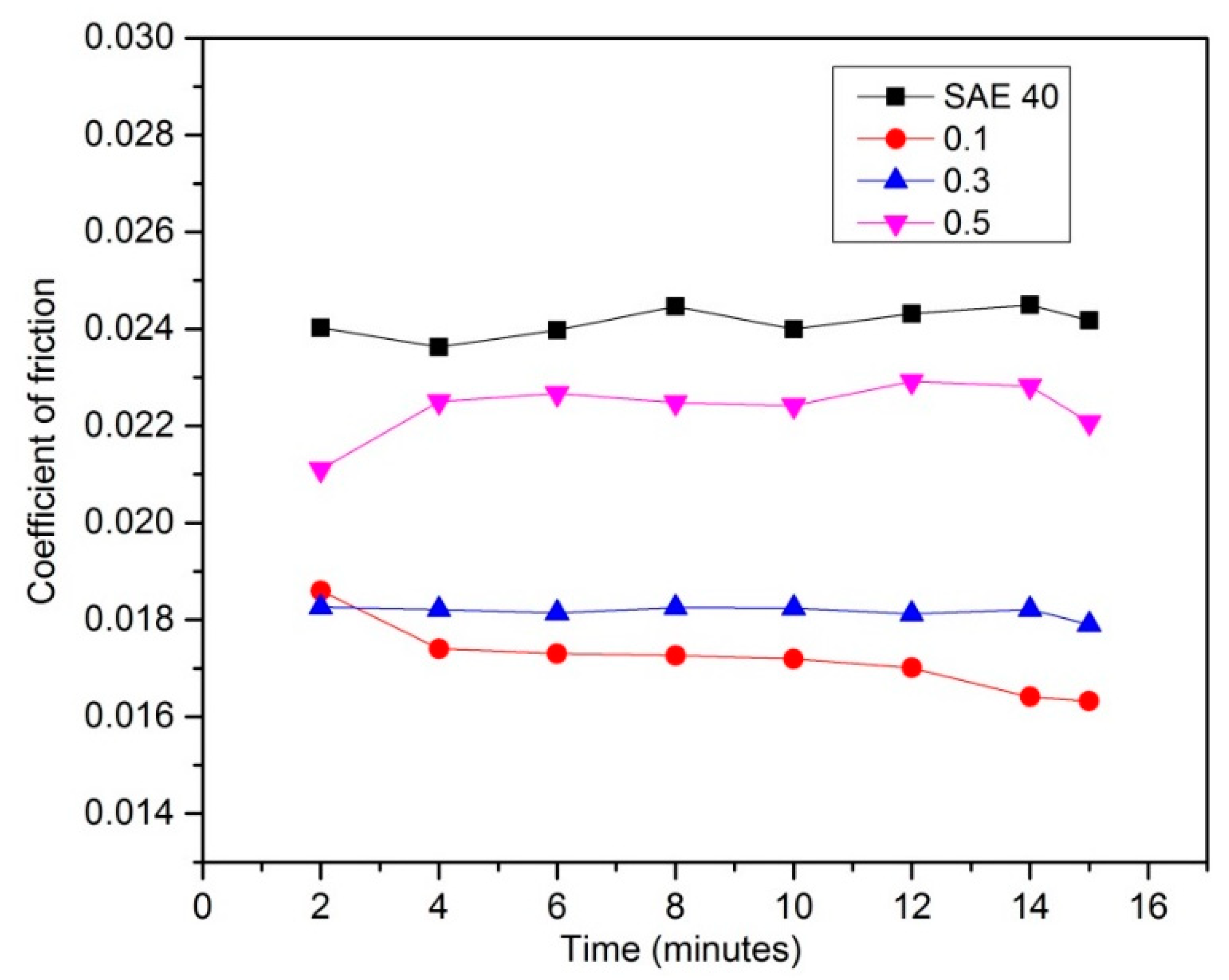

- At low speed and high load, SAE 40 clearly shows the highest friction compared to a lubricant that contains CNC-CuO nanoparticle. At the initial stage, 0.1, 0.3 and 0.5 show almost the same COF while SAE 40 shows the highest friction. At low speed and high load, the temperature of the friction region is 40 °C, which results in a decrease in the viscosities of the SAE 40 and CNC-CuO nanolubricants. The average COF result also shows that SAE 40 is the highest, while at different concentrations of CNC-CuO, it did not show many differences. At high speed and low load, the result clearly shows that SAE 40 produces the highest friction during sliding contact while as the concentration of CNC-CuO increases, the COF also increases.

- The extensive scratches happened due to micro-abrasive wear. This wear occurs due to tribofilm losing on the worn surface and becoming rough during the sliding. These wear results indicate that there is an improvement of scuffing and micro-abrasive wear while using CNC-CuO nano lubricant. The wear is reduced with nanolubricant.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CNC | Cellulose Nanocrystal |

| MWCNT | Multi Wall Carbon Nanotube |

| TEM | Transmission Emission Microscope |

| FESEM | Field Emission Scanning Microscope |

| EDX | Energy Dispersive Xray |

| COF | Coefficient of Friction |

| VI | Viscosity Index |

| AlO2 | Aluminum Oxide |

| TiO2 | Titanium Oxide |

| EG | Ethanol Glycol |

| CuO | Copper (II) Oxide |

| MgO | Magnesium Oxide |

References

- Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V. Evalution of the tribological and thermo-physical properties of coconut oil added with MoS2 nanoparticle at elevated temperatures. Wear 2015, 330, 288–308. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. App. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Li, K.; Zhang, X.; Du, C.; Yang, J.; Wu, B.; Guo, Z.; Dong, C.; Lin, N.; Yuan, C. Friction reduction and viscosity modification of cellulose nanocrystals as biolubricant additives in polyalphaolefin oil. Carbohydr. Polym. 2019, 220, 228–235. [Google Scholar] [CrossRef]

- Ivanov, M.; Shenderova, O. Nanodiamond-based nanolubricants for motor oils. Curr. Opin. Solid State Mater. Sci. 2017, 21, 17–24. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Jiao, S.; Jiang, Z. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles on the tribological behaviour of oxidised high-speed steel. Tribol. Int. 2017, 110, 77–85. [Google Scholar] [CrossRef]

- Schütz, C.; Sort, J.; Bacsik, Z.; Oliynyk, V.; Pellicer, E.; Fall, A.; Salazar-Alvarez, G. Hard and transparent films formed by nanocellulose–TiO2 nanoparticle hybrids. PLoS ONE 2012, 7, e45828. [Google Scholar] [CrossRef]

- Rasheed, A.K.; Khalid, M.; Javeed, A.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Heat transfer and tribological performance of graphene nanolubricant in an internal combustion engine. Tribol. Int. 2016, 103, 504–515. [Google Scholar] [CrossRef]

- Alves, S.M.; Mello, V.S.; Faria, E.A.; Camargo, A.P.P. Nanolubricants developed from tiny CuO nanoparticles. Tribol. Int. 2016, 100, 263–271. [Google Scholar] [CrossRef]

- Wang, X.; Liu, W.; Wang, Q.; Chung, Y. Nanoparticle-based lubricant additives. In Encyclopedia of Tribology; Springer: Berlin, Germany, 2013; pp. 2369–2376. [Google Scholar]

- Babu, J.R.; Kumar, K.K.; Rao, S.S. State-of-art review on hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 77, 551–565. [Google Scholar] [CrossRef]

- Nabil, M.; Azmi, W.; Hamid, K.; Zawawi, N.; Priyandoko, G.; Mamat, R. Thermo-physical properties of hybrid nanofluids and hybrid nanolubricants: A comprehensive review on performance. Int. Commun. Heat Mass Transf. 2017, 83, 30–39. [Google Scholar] [CrossRef]

- Hanzel, O.; Lofaj, F.; Sedláček, J.; Kabátová, M.; Tatarková, M.; Šajgalík, P. Mechanical and tribological properties of alumina-MWCNTs composites sintered by rapid hot-pressing. J. Eur. Ceram. Soc. 2017, 37, 4821–4831. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Effective lubricant additive of nano-Ag/MWCNTs nanocomposite produced by supercritical CO2 synthesis. Tribol. Int. 2018, 118, 180–188. [Google Scholar] [CrossRef]

- Dong, S.; Sun, Y.; Zhang, X.; Li, H.; Luo, G.; Zhao, L. Nanocellulose crystals derivative-silica hybrid sol open tubular capillary column for enantioseparation. Carbohydr. Polym. 2017, 165, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Mohammadkazemi, F.; Faria, M.; Cordeiro, N. In situ biosynthesis of bacterial nanocellulose-CaCO3 hybrid bionanocomposite: One-step process. Mater. Sci. Eng. C 2016, 65, 393–399. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, K.; Kadirgama, K.; Ramasamy, D.; Azmi, W.; Tarlochan, F. Investigation on effective thermal conductivity and relative viscosity of cellulose nanocrystal as a nanofluidic thermal transport through a combined experimental-Statistical approach by using Response Surface Methodology. App. Therm. Eng. 2017, 122, 473–483. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; Garza, L.; Maldonado-Cortés, D.; Michalczewski, R.; Lapray, C. Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332, 1256–1261. [Google Scholar] [CrossRef]

- Ahmadi, H.; Rashidi, A.; Mohtasebi, S.S.; Alaei, M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar]

- Jia, B.; Mikalsen, R.; Smallbone, A.; Roskilly, A.P. A study and comparison of frictional losses in free-piston engine and crankshaft engines. App. Therm. Eng. 2018, 140, 217–224. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Jiao, S.; Zhao, X.; Zhang, X.; Xu, J.; Jiang, Z. Analysis of oil-in-water based nanolubricants with varying mass fractions of oil and TiO2 nanoparticles. Wear 2018, 396, 162–171. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.W. Experimental Methods in Tribology; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Almanassra, I.W.; Manasrah, A.D.; Al-Mubaiyedh, U.A.; Al-Ansari, T.; Malaibari, Z.O.; Atieh, M.A. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. J. Mol. Liq. 2019, 304, 111025. [Google Scholar] [CrossRef]

- Karimi, S.; Tahir, P.M.; Dufresne, A.; Karimi, A.; Abdulkhani, A. A comparative study on characteristics of nanocellulose reinforced thermoplastic starch biofilms prepared with different techniques. Nord. Pulp Pap. Res. J. 2014, 29, 41–45. [Google Scholar] [CrossRef]

- Jiang, F.; Zhu, J.; Xin, G. Experimental investigation on Al2O3-R123 nanorefrigerant heat transfer performances in evaporator based on organic Rankine cycle. Int. J. Heat Mass Transf. 2018, 127, 145–153. [Google Scholar] [CrossRef]

- Richardson, J.; Zaki, W. The sedimentation of a suspension of uniform spheres under conditions of viscous flow. Chem. Eng. Sci. 1954, 3, 65–73. [Google Scholar] [CrossRef]

- Hajjar, Z.; morad Rashidi, A.; Ghozatloo, A. Enhanced thermal conductivities of graphene oxide nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 128–131. [Google Scholar] [CrossRef]

- Srivatsa, J.T.; Ziaja, M.B. An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant-polymer based drilling fluid. In Proceedings of the IPTC 2012, International Petroleum Technology Conference, European Association of Geoscientists & Engineers, Bangkok, Thailand, 7–9 February 2012. [Google Scholar]

- Klamann, D.; Rost, R.; Killer, A. Lubricants and Related Products: Synthesis, Properties, Applications, International Standards; Verlag Chemie: Weinheim, Germany, 1984. [Google Scholar]

- Wang, Y.; Wan, Z.; Lu, L.; Zhang, Z.; Tang, Y. Friction and wear mechanisms of castor oil with addition of hexagonal boron nitride nanoparticles. Tribol. Int. 2018, 124, 10–22. [Google Scholar] [CrossRef]

- Liu, L.; Yang, C.; Sheng, Y. Wear model based on real-time surface roughness and its effect on lubrication regimes. Tribol. Int. 2018, 126, 16–20. [Google Scholar] [CrossRef]

- Paul, G.; Shit, S.; Hirani, H.; Kuila, T.; Murmu, N.C. Tribological behavior of dodecylamine functionalized graphene nanosheets dispersed engine oil nanolubricants. Tribol. Int. 2019, 131, 605–619. [Google Scholar] [CrossRef]

- Awang, N.W.; Ramasamy, D.; Kadirgama, K.; Najafi, G.; Che Sidik, N.A. Study on friction and wear of Cellulose Nanocrystal (CNC) nanoparticle as lubricating additive in engine oil. Int. J. Heat Mass Transf. 2019, 131, 1196–1204. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Parameter | Value (nm) | Test Method |

|---|---|---|

| Crystal length | 100–150 | TEM |

| Crystal diameter | 9–14 | TEM |

| Hydrodynamic diameter | 150 | DLS |

| Elements | Spectrum 1 (CNC-CuO) | Spectrum 2 (Non-Sliding Area) | ||

|---|---|---|---|---|

| Weight (%) | Atomic (%) | Weight (%) | Atomic (%) | |

| Carbon | 29.827 | 48.160 | 41.662 | 60.978 |

| Oxygen | 5.635 | 6.831 | 3.215 | 3.533 |

| Magnesium | 0.752 | 0.600 | 0.666 | 0.482 |

| Aluminum | 59.997 | 43.123 | 52.922 | 34.481 |

| Silicon | 0.421 | 0.290 | 0.318 | 0.199 |

| Argon | 0.258 | 0.125 | 0.370 | 0.163 |

| Iron | 0.912 | 0.317 | - | - |

| Copper | 1.263 | 0.386 | - | - |

| Silver | 0.936 | 0.168 | 0.691 | 0.113 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hisham, S.; Kadirgama, K.; Mohammed, H.A.; Kumar, A.; Ramasamy, D.; Samykano, M.; Rahman, S. Hybrid Nanocellulose-Copper (II) Oxide as Engine Oil Additives for Tribological Behavior Improvement. Molecules 2020, 25, 2975. https://doi.org/10.3390/molecules25132975

Hisham S, Kadirgama K, Mohammed HA, Kumar A, Ramasamy D, Samykano M, Rahman S. Hybrid Nanocellulose-Copper (II) Oxide as Engine Oil Additives for Tribological Behavior Improvement. Molecules. 2020; 25(13):2975. https://doi.org/10.3390/molecules25132975

Chicago/Turabian StyleHisham, Sakinah, Kumaran Kadirgama, Hussein A. Mohammed, Amit Kumar, Devarajan Ramasamy, Mahendran Samykano, and Saidur Rahman. 2020. "Hybrid Nanocellulose-Copper (II) Oxide as Engine Oil Additives for Tribological Behavior Improvement" Molecules 25, no. 13: 2975. https://doi.org/10.3390/molecules25132975

APA StyleHisham, S., Kadirgama, K., Mohammed, H. A., Kumar, A., Ramasamy, D., Samykano, M., & Rahman, S. (2020). Hybrid Nanocellulose-Copper (II) Oxide as Engine Oil Additives for Tribological Behavior Improvement. Molecules, 25(13), 2975. https://doi.org/10.3390/molecules25132975