Valorization of Mushroom By-Products as a Source of Value-Added Compounds and Potential Applications

Abstract

1. Introduction

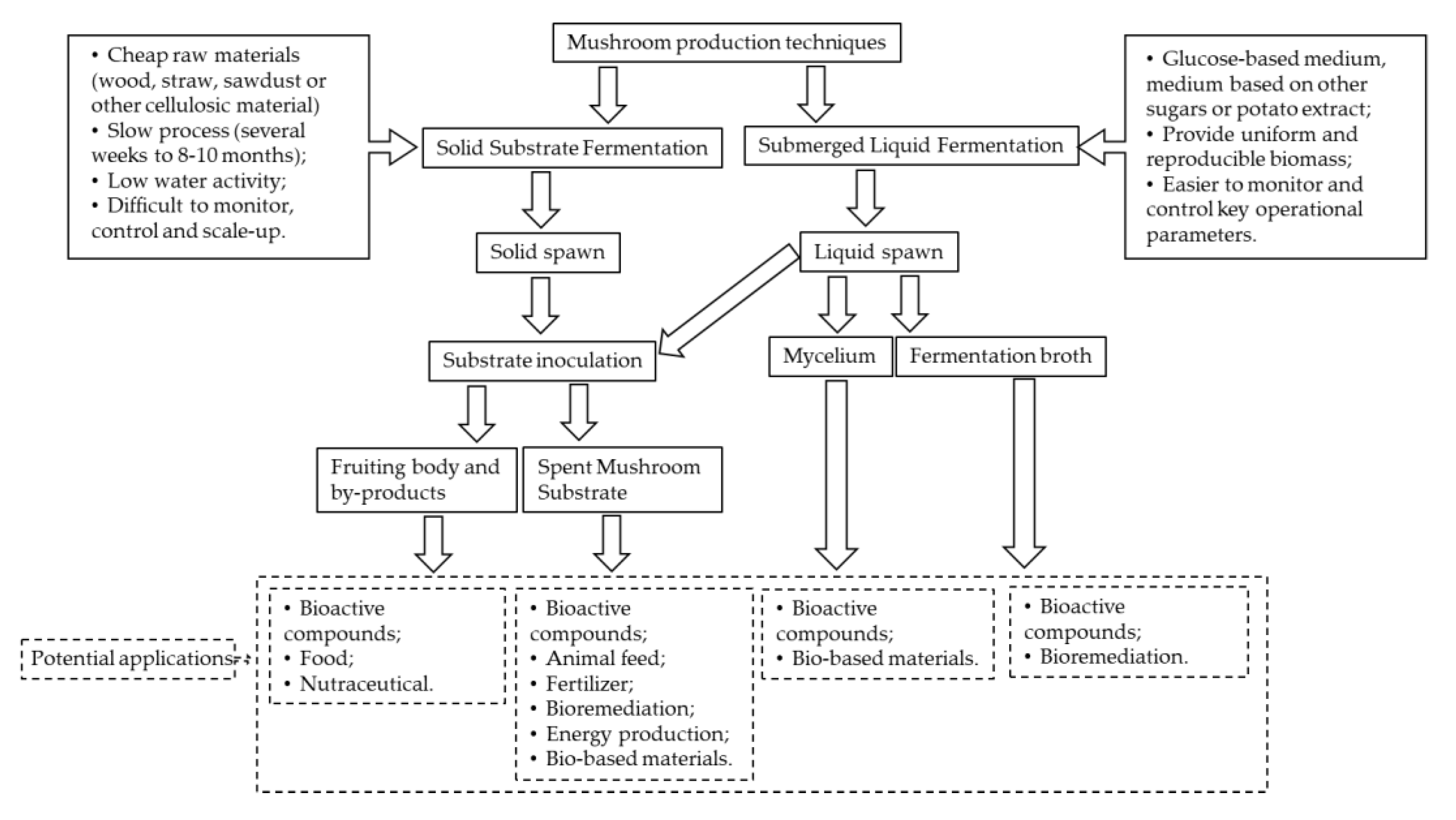

2. Mushroom Production

2.1. Solid Substrate Fermentation

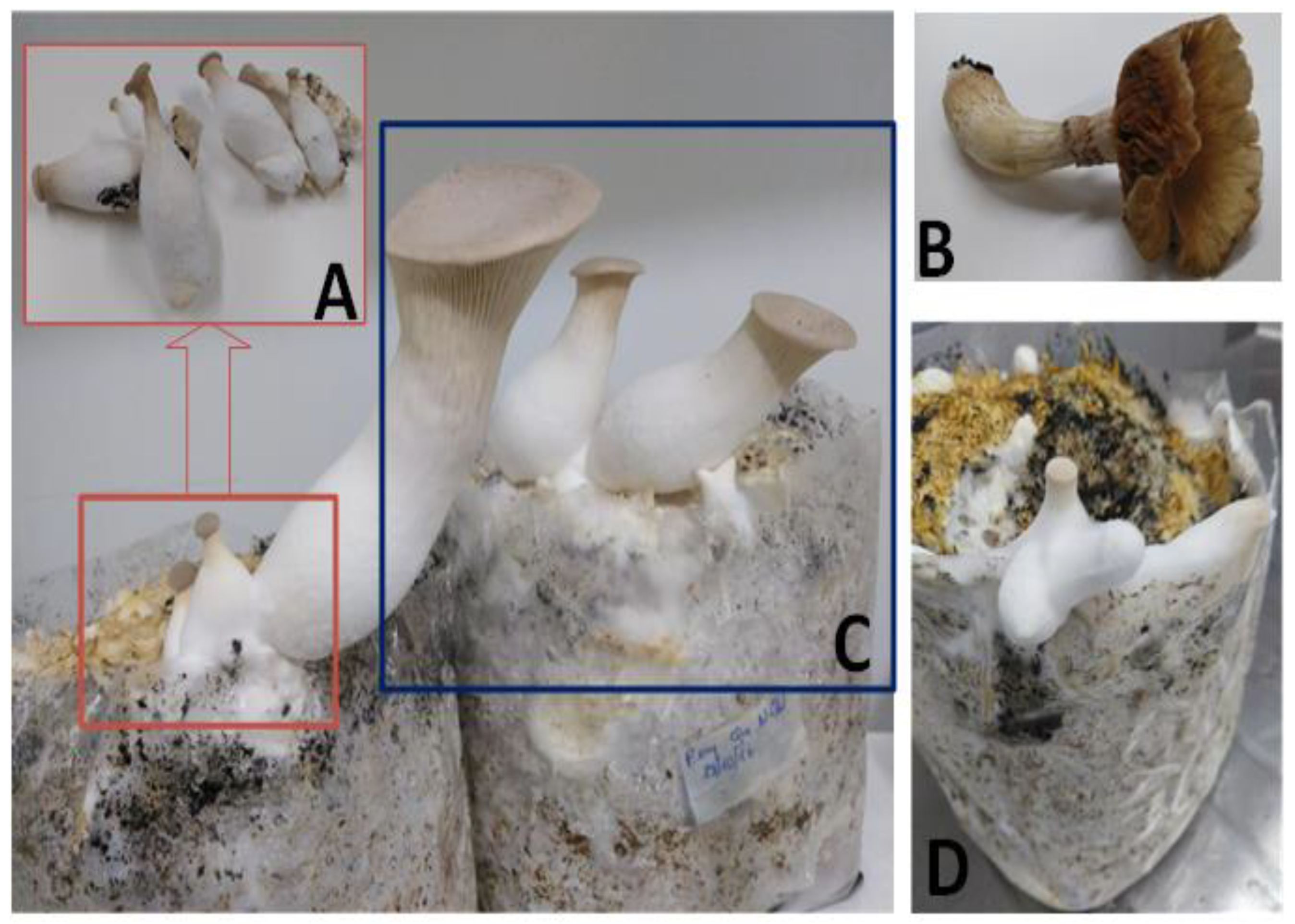

2.1.1. Fruiting Body

2.1.2. Spent Mushroom Substrate

2.2. Submerged Liquid Fermentation

2.2.1. Mycelium

2.2.2. Fermentation Broth

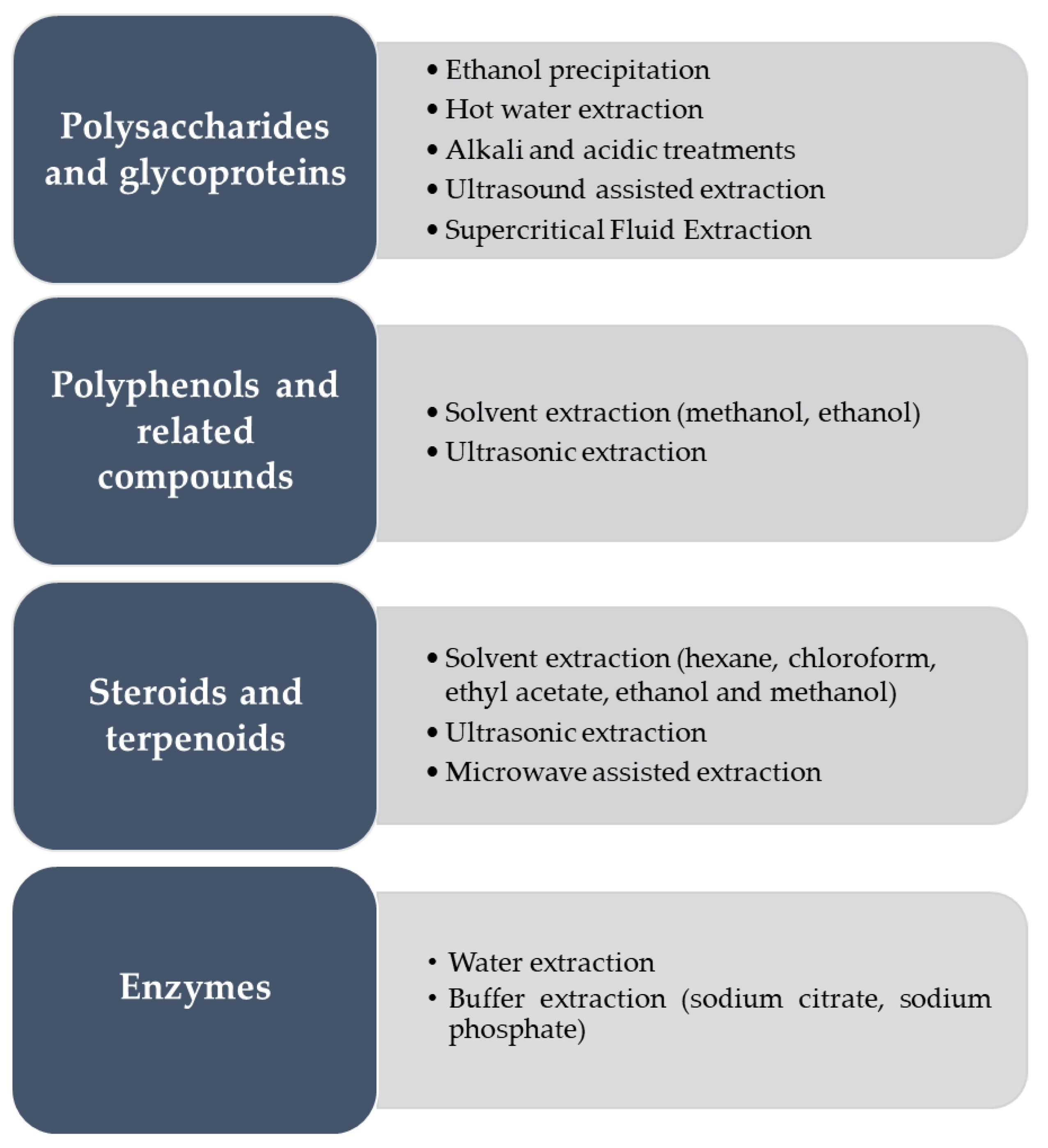

3. Bioactive Compounds and Extraction Methods

3.1. Polysaccharides and Glycoproteins

3.2. Polyphenols and Related Compounds

3.3. Steroids and Terpenoids

3.4. Enzymes

4. Potential Application of Mushroom By-Products

4.1. Food Uses

4.2. Animal Feed

4.3. Fertilizer and Partial Substrate for Mushroom Growth

4.4. Bioremediation and Biological Treatments

4.5. Energy Production

4.6. Cosmetics and Cosmeceuticals

4.7. Bio-Based Materials

5. Regulatory Challenges in Europe

6. Conclusions

Funding

Conflicts of Interest

References

- Fazenda, M.L.; Seviour, R.; McNeil, B.; Harvey, L.M. Submerged Culture Fermentation of “Higher Fungi”: The Macrofungi. Adv. Appl. Microbiol. 2008, 63, 33–103. [Google Scholar] [CrossRef] [PubMed]

- Manzi, P.; Pizzoferrato, L. Beta-glucans in edible mushrooms. Food Chem. 2000, 68, 315–318. [Google Scholar] [CrossRef]

- Nakajima, V.M.; de Freitas Soares, F.E.; de Queiroz, J.H. Screening and decolorizing potential of enzymes from spent mushroom composts of six different mushrooms. Biocatal. Agric. Biotechnol. 2018, 13, 58–61. [Google Scholar] [CrossRef]

- Lim, S.-H.; Lee, Y.-H.; Kang, H.-W. Efficient Recovery of Lignocellulolytic Enzymes of Spent Mushroom Compost from Oyster Mushrooms, Pleurotus spp., and Potential Use in Dye Decolorization. Mycobiology 2013, 41, 214–220. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Grimm, D.; Wösten, H.A.B. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef]

- Phan, C.-W.; Sabaratnam, V. Potential uses of spent mushroom substrate and its associated lignocellulosic enzymes. Appl. Microbiol. Biotechnol. 2012, 96, 863–873. [Google Scholar] [CrossRef]

- Valverde, M.E.; Hernández-Pérez, T.; Paredes-López, O. Edible mushrooms: Improving human health and promoting quality life. Int. J. Microbiol. 2015, 2015, 376387. [Google Scholar] [CrossRef]

- Royse, D.J.; Baars, J.; Tan, Q. Current Overview of Mushroom Production in the World. In Edible and Medicinal Mushrooms: Technology and Applications; Diego, C.Z., Pardo-Giménez, A., Eds.; Wiley Blackwell: Chichester, UK, 2017. [Google Scholar]

- Tang, Y.-J.; Zhu, L.-W.; Li, H.-M.; Li, D.-S. Submerged Culture of Mushrooms in Bioreactors- Challenges, Current State-of-the-Art, and Future Prospects. Food Technol. Biotechnol. 2007, 45, 221–229. [Google Scholar]

- Smith, J.E.; Rowan, N.J.; Sullivan, R. Medicinal mushrooms: A rapidly developing area of biotechnology for cancer therapy and other bioactivities. Biotechnol. Lett. 2002, 24, 1839–1845. [Google Scholar] [CrossRef]

- Giavasis, I. Bioactive fungal polysaccharides as potential functional ingredients in food and nutraceuticals. Curr. Opin. Biotechnol. 2014, 26, 162–173. [Google Scholar] [CrossRef]

- Sánchez, C. Modern aspects of mushroom culture technology. Appl. Microbiol. Biotechnol. 2004, 64, 756–762. [Google Scholar] [CrossRef] [PubMed]

- Kalač, P. A review of chemical composition and nutritional value of wild-growing and cultivated mushrooms. J. Sci. Food Agric. 2012, 93, 209–218. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Zivanovic, S.; Draughon, F.A.; Sams, C.E. Chitin and Chitosan Value-Added Products from Mushroom Waste. J. Agric. Food Chem. 2004, 52, 7905–7910. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Yang, W.; Mariga, A.M.; Fang, Y.; Ma, N.; Pei, F.; Hu, Q. Purification, characterization and antitumor activity of polysaccharides from Pleurotus eryngii residue. Carbohydr. Polym. 2014, 114, 297–305. [Google Scholar] [CrossRef]

- Lou, Z.; Sun, Y.; Zhou, X.; Baig, S.A.; Hu, B.; Xu, X. Composition variability of spent mushroom substrates during continuous cultivation, composting process and their effects on mineral nitrogen transformation in soil. Geoderma 2017, 307, 30–37. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Walton, J.; Viñas, I.; Tiwari, B.K. Ultrasound assisted extraction of polysaccharides from mushroom by-products. LWT 2017, 77, 92–99. [Google Scholar] [CrossRef]

- Corrêa, R.; Barros, L.; Fernandes, A.; Sokovic, M.; Brachtc, A.; Peralta, R.M.; Ferreira, I.C.F.R. A natural food ingredient based on ergosterol: Optimization of the extraction from Agaricus blazei, evaluation of bioactive properties and incorporation in yogurts. Food Funct. 2018, 1465–1474. [Google Scholar] [CrossRef]

- Letti, L.A.J.; Vítola, F.M.D.; Pereira, G.V.D.M.; Karp, S.G.; Medeiros, A.B.P.; Da Costa, E.S.F.; Bissoqui, L.; Soccol, C.R. Solid-State Fermentation for the Production of Mushrooms. Curr. Dev. Biotechnol. Bioeng. 2018, 285–318. [Google Scholar] [CrossRef]

- Fan, L.; Soccol, C.R.; Pandey, A. Mushroom Production BT. In Current Developments in Solid-state Fermentation; Pandey, A., Soccol, C.R., Larroche, C., Eds.; Springer: New York, NY, USA, 2008; pp. 253–274. ISBN 978-0-387-75213-6. [Google Scholar]

- Bao, H.N.D.; Osako, K.; Ohshima, T. Value-added use of mushroom ergothioneine as a colour stabilizer in processed fish meats. J. Sci. Food Agric. 2010, 90, 1634–1641. [Google Scholar] [CrossRef]

- Cheng, P.-G.; Phan, C.-W.; Sabaratnam, V.; Abdullah, N.; Abdulla, M.A.; Kuppusamy, U.R. Polysaccharides-Rich Extract of Ganoderma lucidum (M.A. Curtis:Fr.) P. Karst Accelerates Wound Healing in Streptozotocin-Induced Diabetic Rats. Evid. Based. Complement. Altern. Med. 2013, 2013, 671252. [Google Scholar] [CrossRef] [PubMed]

- Taofiq, O.; Heleno, S.A.; Calhelha, R.C.; Alves, M.J.; Barros, L.; González-Paramás, A.M.; Barreiro, M.F.; Ferreira, I.C.F.R. The potential of Ganoderma lucidum extracts as bioactive ingredients in topical formulations, beyond its nutritional benefits. Food Chem. Toxicol. 2017, 108, 139–147. [Google Scholar] [CrossRef] [PubMed]

- Alquini, G.; Carbonero, E.R.; Rosado, F.R.; Cosentino, C.; Iacomini, M. Polysaccharides from the fruit bodies of the basidiomycete Laetiporus sulphureus (Bull.: Fr.) Murr. FEMS Microbiol. Lett. 2004, 230, 47–52. [Google Scholar] [CrossRef]

- Rodrigues, D.; Freitas, A.C.; Sousa, S.; Amorim, M.; Vasconcelos, M.W.; da Costa, J.P.; Silva, A.M.S.; Rocha-Santos, T.A.P.; Duarte, A.C.; Gomes, A.M.P. Chemical and structural characterization of Pholiota nameko extracts with biological properties. Food Chem. 2017, 216, 176–185. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yong, Y.; Xing, M.; Gu, Y.; Zhang, Z.; Zhang, S.; Lu, L. Characterization of polysaccharides with marked inhibitory effect on lipid accumulation in Pleurotus eryngii. Carbohydr. Polym. 2013, 97, 604–613. [Google Scholar] [CrossRef]

- Khan, I.; Huang, G.; Li, X.; Leong, W.; Xia, W.; Hsiao, W.L.W. Mushroom polysaccharides from Ganoderma lucidum and Poria cocos reveal prebiotic functions. J. Funct. Foods 2018, 41, 191–201. [Google Scholar] [CrossRef]

- Taofiq, O.; Calhelha, R.C.; Heleno, S.; Barros, L.; Martins, A.; Santos-Buelga, C.; Queiroz, M.J.R.P.; Ferreira, I.C.F.R. The contribution of phenolic acids to the anti-inflammatory activity of mushrooms: Screening in phenolic extracts, individual parent molecules and synthesized glucuronated and methylated derivatives. Food Res. Int. 2015, 76, 821–827. [Google Scholar] [CrossRef]

- Klaus, A.; Kozarski, M.; Niksic, M.; Jakovljevic, D.; Todorovic, N.; Van Griensven, L.J.L.D. Antioxidative activities and chemical characterization of polysaccharides extracted from the basidiomycete Schizophyllum commune. LWT 2011, 44, 2005–2011. [Google Scholar] [CrossRef]

- Lin, P.-H.; Huang, S.-Y.; Mau, J.-L.; Liou, B.-K.; Fang, T.J. A novel alcoholic beverage developed from shiitake stipe extract and cane sugar with various Saccharomyces strains. LWT 2010, 43, 971–976. [Google Scholar] [CrossRef]

- Hung, P.V.; Nhi, N.N.Y. Nutritional composition and antioxidant capacity of several edible mushrooms grown in the Southern Vietnam. Int. Food Res. J. 2012, 19, 611–615. [Google Scholar]

- Jordan, S.N.; Mullen, G.J.; Murphy, M.C. Composition variability of spent mushroom compost in Ireland. Bioresour. Technol. 2008, 99, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Jasińska, A. Spent mushroom compost (SMC)–retrieved added value product closing loop in agricultural production. Acta Agrar. Debr. 2018, 185–202. [Google Scholar] [CrossRef]

- Rinker, D. Spent Mushroom Substrate Uses: Technology and Applications. In Edible and Medicinal Mushrooms: Technology and Applications; Diego, C.Z., Pardo-Giménez, A., Eds.; Wiley Blackwell: Chichester, UK, 2017. [Google Scholar]

- Dias, E.S.; Brito, M.R. Mushrooms: Biology and Life Cycle. In Edible and Medicinal Mushrooms: Technology and Applications; Diego, C.Z., Pardo-Giménez, A., Eds.; Wiley Blackwell: Chichester, UK, 2017. [Google Scholar]

- Marshall, E.; Nair, N.G. Make money by growing mushrooms; Food and Agriculture Organization of the United Nations: Rome, Italy, 2009.

- Biswas, S.; Datta, M.; Ngachan, S.V. Mushrooms: A Manual for Cultivation, First ed.; Prentice-Hall of India Pvt. Ltd: New Delhi, India, 2011. [Google Scholar]

- Alhujaily, A.; Yu, H.; Zhang, X.; Ma, F. Highly Efficient and Sustainable Spent Mushroom Waste Adsorbent Based on Surfactant Modification for the Removal of Toxic Dyes. Int. J. Environ. Res. Public Heal. 2018, 15, 1421. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Cui, F.; Zhang, J.; Gao, X.; Zhou, M.; Xu, N.; Zhao, H.; Liu, M.; Zhang, C.; Jia, L. Antioxidative and renoprotective effects of residue polysaccharides from Flammulina velutipes. Carbohydr. Polym. 2016, 146, 388–395. [Google Scholar] [CrossRef]

- He, P.; Li, F.; Huang, L.; Xue, D.; Liu, W.; Xu, C. Chemical characterization and antioxidant activity of polysaccharide extract from spent mushroom substrate of Pleurotus eryngii. J. Taiwan Inst. Chem. Eng. 2016, 69, 48–53. [Google Scholar] [CrossRef]

- Singh, A.D.; Abdullah, N.; Vikineswary, S. Optimization of extraction of bulk enzymes from spent mushroom compost. J. Chem. Technol. Biotechnol. 2003, 78, 743–752. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, B.; Shao, J.; Jia, J.; Tian, Y.; Shu, X.; Ren, X.; Guan, Y. Extraction, purification and physicochemical properties of a novel lectin from Laetiporus sulphureus mushroom. LWT 2018, 91, 151–159. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, G.; Zhai, G.; Yang, Y.; Zhao, H.; Jia, L. Extraction, characterization and antioxidant activity of polysaccharides of spent mushroom compost of Ganoderma lucidum. Int. J. Biol. Macromol. 2016, 82, 432–439. [Google Scholar] [CrossRef]

- Zhu, H.; Sheng, K.; Yan, E.; Qiao, J.; Lv, F. Extraction, purification and antibacterial activities of a polysaccharide from spent mushroom substrate. Int. J. Biol. Macromol. 2012, 50, 840–843. [Google Scholar] [CrossRef]

- Elisashvili, V. Submerged Cultivation of Medicinal Mushrooms: Bioprocesses and Products (Review) Int. J. Med. Mushrooms 2012, 14, 211–239. [Google Scholar] [CrossRef]

- Friel, M.T.; McLoughlin, A.J. Production of a liquid inoculum/spawn of Agaricus bisporus. Biotechnol. Lett. 2000, 22, 351–354. [Google Scholar] [CrossRef]

- Gregori, A.; Pohleven, J. Cultivation Techniques and Medicinal Properties of Pleurotus spp. Food Technol. Biotechnol. 2007, 45, 238–249. [Google Scholar]

- Petre, M.; Petre, V. Biotechnology of Mushroom Growth Through Submerged Cultivation. Mushroom Biotechnol. 2016, 1–18. [Google Scholar] [CrossRef]

- De Souza Kirsch, L.; de Macedo, A.J.P.; Teixeira, M.F.S. Production of mycelial biomass by the Amazonian edible mushroom Pleurotus albidus. Brazilian J. Microbiol. 2016, 47, 658–664. [Google Scholar] [CrossRef] [PubMed]

- Jingli, G.; Xu, L. Comparison between liquid culture and solid culture technologies for edible mushroom spawn production and analysis on their economic benefits. China Agric. Sci. 2011, 44, 835–841. [Google Scholar]

- Osińska-Jaroszuk, M.; Jarosz-Wilkołazka, A.; Jaroszuk-Ściseł, J.; Szałapata, K.; Nowak, A.; Jaszek, M.; Ozimek, E.; Majewska, M. Extracellular polysaccharides from Ascomycota and Basidiomycota: Production conditions, biochemical characteristics, and biological properties. World J. Microbiol. Biotechnol. 2015, 31, 1823–1844. [Google Scholar] [CrossRef]

- Mahapatra, S.; Banerjee, D. Fungal exopolysaccharide: Production, composition and applications. Microbiol. insights 2013, 6, 1–16. [Google Scholar] [CrossRef]

- Wasser, S.P. Medicinal mushrooms as a source of antitumor and immunomodulating polysaccharides. Appl. Microbiol. Biotechnol. 2002, 60, 258–274. [Google Scholar] [CrossRef]

- Sánchez, O.J.; Montoya, S.; Vargas, L.M. Polysaccharide Production by Submerged Fermentation. Polysaccharides 2015, 451–473. [Google Scholar]

- Shang, H.M.; Song, H.; Shen, S.J.; Yao, X.; Wu, B.; Wang, L.N.; Jiang, Y.Y.; Ding, G.D. Effects of dietary polysaccharides from the submerged fermentation concentrate of Hericium caput-medusae (Bull.:Fr.) Pers. on fat deposition in broilers. J. Sci. Food Agric. 2015, 95, 267–274. [Google Scholar] [CrossRef]

- Wang, L.; Xu, N.; Zhang, J.; Zhao, H.; Lin, L.; Jia, S.; Jia, L. Antihyperlipidemic and hepatoprotective activities of residue polysaccharide from Cordyceps militaris SU-12. Carbohydr. Polym. 2015, 131, 355–362. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, C.; Hsu, T.-H.; Yang, F.-C. Production of polysaccharides of Ganoderma lucidum (CCRC36021) by reusing thin stillage. Process Biochem. 2005, 40, 909–916. [Google Scholar] [CrossRef]

- Kim, H.O.; Yun, J.W. A comparative study on the production of exopolysaccharides between two entomopathogenic fungi Cordyceps militaris and Cordyceps sinensis in submerged mycelial cultures. J. Appl. Microbiol. 2005, 99, 728–738. [Google Scholar] [CrossRef] [PubMed]

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Galanakis, C. Nutraceutical and Functional Food Components; Academic Press: Chanina, Greece, 2017. [Google Scholar]

- Vuong, Q. Utilisation of Bioactive Compounds from Agricultural and Food Waste; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Patel, S.; Goyal, A. Recent developments in mushrooms as anti-cancer therapeutics: A review. 3 Biotech 2012, 2, 1–15. [Google Scholar] [CrossRef]

- Sánchez, C. Bioactives from Mushroom and Their Application. In Food Bioactives: Extraction and Biotechnology Applications; Puri, M., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 23–57. ISBN 978-3-319-51639-4. [Google Scholar]

- Lindequist, U.; Niedermeyer, T.H.J.; Jülich, W.-D. The pharmacological potential of mushrooms. Evid. Based. Complement. Alternat. Med. 2005, 2, 285–299. [Google Scholar] [CrossRef]

- Giavasis, I. Polysaccharides Natural Fibers in Food and Nutrition, First Edition; CRC Press: Boca Raton, FA, USA, 2014. [Google Scholar]

- Reis, F.S.; Martins, A.; Vasconcelos, M.H.; Morales, P.; Ferreira, I.C.F.R. Functional foods based on extracts or compounds derived from mushrooms. Trends Food Sci. Technol. 2017, 66, 48–62. [Google Scholar] [CrossRef]

- Papoutsis, K.; Grasso, S.; Menon, A.; Brunton, N.P.; Lyng, J.G.; Jacquier, J.-C.; Bhuyan, D.J. Recovery of ergosterol and vitamin D2 from mushroom waste - Potential valorization by food and pharmaceutical industries. Trends Food Sci. Technol. 2020, 99, 351–366. [Google Scholar] [CrossRef]

- Petrović, J.; Glamočlija, J.; Stojković, D.S.; Ćirić, A.; Nikolić, M.; Bukvički, D.; Guerzoni, M.E.; Soković, M.D. Laetiporus sulphureus, edible mushroom from Serbia: Investigation on volatile compounds, in vitro antimicrobial activity and in situ control of Aspergillus flavus in tomato paste. Food Chem. Toxicol. 2013, 59, 297–302. [Google Scholar] [CrossRef]

- Zhao, L.; Dong, Y.; Chen, G.; Hu, Q. Extraction, purification, characterization and antitumor activity of polysaccharides from Ganoderma lucidum. Carbohydr. Polym. 2010, 80, 783–789. [Google Scholar] [CrossRef]

- Carrasco-González, J.A.; Serna-Saldívar, S.O.; Gutiérrez-Uribe, J.A. Nutritional composition and nutraceutical properties of the Pleurotus fruiting bodies: Potential use as food ingredient. J. Food Compos. Anal. 2017, 58, 69–81. [Google Scholar] [CrossRef]

- Dimitrijevic, M.V.; Mitic, V.D.; Stankov-Jovanovic, V.P.; Nikolic, J.S.; Stojanovic, G.S. Comprehensive Evaluation of the Antioxidant Activity of six wild edible mushroom species. Adv. Technol. 2016, 5, 53–59. [Google Scholar] [CrossRef]

- Fan, L.; Li, J.; Deng, K.; Ai, L. Effects of drying methods on the antioxidant activities of polysaccharides extracted from Ganoderma lucidum. Carbohydr. Polym. 2012, 87, 1849–1854. [Google Scholar] [CrossRef]

- He, J.Z.; Ru, Q.M.; Dong, D.D.; Sun, P.L. Chemical characteristics and antioxidant properties of crude water soluble polysaccharides from four common edible mushrooms. Molecules 2012, 17, 4373–4387. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Shah, N.P. Antioxidant and antibacterial activities of sulphated polysaccharides from Pleurotus eryngii and Streptococcus thermophilus ASCC 1275. Food Chem. 2014, 165, 262–270. [Google Scholar] [CrossRef]

- Li, S.; Shah, N.P. Characterization, antioxidative and bifidogenic effects of polysaccharides from Pleurotus eryngii after heat treatments. Food Chem. 2016, 197, 240–249. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Y.; Liu, M.; Wang, Q.; Li, Y. Extraction optimization, characterization, antioxidant and immunomodulatory activities of a novel polysaccharide from the wild mushroom Paxillus involutus. Int. J. Biol. Macromol. 2018, 112, 326–332. [Google Scholar] [CrossRef]

- Nie, S.; Zhang, H.; Li, W.; Xie, M. Current development of polysaccharides from Ganoderma: Isolation, structure and bioactivities. Bioact. Carbohydr. Diet. Fibre 2013, 1, 10–20. [Google Scholar] [CrossRef]

- Yu, Y.; Shen, M.; Song, Q.; Xie, J. Biological activities and pharmaceutical applications of polysaccharide from natural resources: A review. Carbohydr. Polym. 2018, 183, 91–101. [Google Scholar] [CrossRef]

- Díaz Reinoso, B.; Domínguez González, H. Introduction. Water Extr. Bioact. Compd. 2017, 1–50. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, J.; Zhang, L.; Nakamura, Y.; Norisuye, T. Chemical Structure of the Water-Insoluble Polysaccharide Isolated from the Fruiting Body of Ganoderma lucidum. Polym. J. 1998, 30, 838–842. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Z.; Zhang, L.; Fang, Y.; Jiang, F.; Phillips, G.O. Structure and chain conformation of water-soluble heteropolysaccharides from Ganoderma lucidum. Carbohydr. Polym. 2011, 86, 844–851. [Google Scholar] [CrossRef]

- Huang, S.; Ning, Z. Extraction of polysaccharide from Ganoderma lucidum and its immune enhancement activity. Int. J. Biol. Macromol. 2010, 47, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Poverenov, E.; Arnon-Rips, H.; Zaitsev, Y.; Bar, V.; Danay, O.; Horev, B.; Bilbao-Sainz, C.; McHugh, T.; Rodov, V.; Arnon, H.; et al. Potential of chitosan from mushroom waste to enhance quality and storability of fresh-cut melons. Food Chem. 2018, 268, 233–241. [Google Scholar] [CrossRef] [PubMed]

- Bilbao-Sainz, C.; Chiou, B.S.; Williams, T.; Wood, D.; Du, W.X.; Sedej, I.; Ban, Z.; Rodov, V.; Poverenov, E.; Vinokur, Y.; et al. Vitamin D-fortified chitosan films from mushroom waste. Carbohydr. Polym. 2017, 167, 97–104. [Google Scholar] [CrossRef]

- Pang, X.; Yao, W.; Yang, X.; Xie, C.; Liu, D.; Zhang, J.; Gao, X. Purification, characterization and biological activity on hepatocytes of a polysaccharide from Flammulina velutipes mycelium. Carbohydr. Polym. 2007, 70, 291–297. [Google Scholar] [CrossRef]

- Zhu, H.; Tian, L.; Zhang, L.; Bi, J.; Song, Q.; Yang, H.; Qiao, J. Preparation, characterization and antioxidant activity of polysaccharide from spent Lentinus edodes substrate. Int. J. Biol. Macromol. 2018, 112, 976–984. [Google Scholar] [CrossRef]

- Ma, G.; Yang, W.; Fang, Y.; Ma, N.; Pei, F.; Zhao, L.; Hu, Q. Antioxidant and cytotoxicites of Pleurotus eryngii residue polysaccharides obtained by ultrafiltration. LWT 2016, 73, 108–116. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, K.; Li, C.; Cheng, S.; Zhou, J.; Wu, Z. A novel biodegradable film from edible mushroom (F. velutipes) by product: Microstructure, mechanical and barrier properties associated with the fiber morphology. Innov. Food Sci. Emerg. Technol. 2018, 47, 153–160. [Google Scholar] [CrossRef]

- Chiu, C.-H.; Peng, C.-C.; Ker, Y.-B.; Chen, C.-C.; Lee, A.; Chang, W.-L.; Chyau, C.-C.; Peng, Y.R. Physicochemical Characteristics and Anti-Inflammatory Activities of Antrodan, a Novel Glycoprotein Isolated from Antrodia cinnamomea Mycelia. Molecules 2014, 19, 22–40. [Google Scholar] [CrossRef]

- Yu, J.; Cui, P.-J.; Zeng, W.-L.; Xie, X.-L.; Liang, W.-J.; Lin, G.-B.; Zeng, L. Protective effect of selenium-polysaccharides from the mycelia of Coprinus comatus on alloxan-induced oxidative stress in mice. Food Chem. 2009, 117, 42–47. [Google Scholar] [CrossRef]

- Cui, F.; Zan, X.; Li, Y.; Yang, Y.; Sun, W.; Zhou, Q.; Yu, S.; Dong, Y. Purification and partial characterization of a novel anti-tumor glycoprotein from cultured mycelia of Grifola frondosa. Int. J. Biol. Macromol. 2013, 62, 684–690. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Gao, Y.; Xu, D.; Gao, Q. A polysaccharide from cultured mycelium of Hericium erinaceus and its anti-chronic atrophic gastritis activity. Int. J. Biol. Macromol. 2015, 81, 656–661. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.-Q.; Tian, J.-M.; Wei, J.; Gao, J.-M. Bioactive metabolites from the mycelia of the basidiomycete Hericium erinaceum. Nat. Prod. Res. 2014, 28, 1288–1292. [Google Scholar] [CrossRef]

- Xu, X.; Li, J.; Hu, Y. Polysaccharides from Inonotus obliquus sclerotia and cultured mycelia stimulate cytokine production of human peripheral blood mononuclear cells in vitro and their chemical characterization. Int. Immunopharmacol. 2014, 21, 269–278. [Google Scholar] [CrossRef]

- Xu, X.; Wu, Y.; Chen, H. Comparative antioxidative characteristics of polysaccharide-enriched extracts from natural sclerotia and cultured mycelia in submerged fermentation of Inonotus obliquus. Food Chem. 2011, 127, 74–79. [Google Scholar] [CrossRef]

- Ahmad, R.; Muniandy, S.; Shukri, N.; Alias, S.; Hamid, A.; Yusoff, W.; Senafi, S.; Daud, F. Antioxidant Properties and Glucan Compositions of Various Crude Extract from Lentinus squarrosulus Mycelial Culture. Adv. Biosci. Biotechnol. 2014, 805–814. [Google Scholar] [CrossRef]

- Su, C.-A.; Xu, X.-Y.; Liu, D.-Y.; Wu, M.; Zeng, F.-Q.; Zeng, M.-Y.; Wei, W.; Jiang, N.; Luo, X. Isolation and characterization of exopolysaccharide with immunomodulatory activity from fermentation broth of Morchella conica. DARU 2013, 21, 5. [Google Scholar] [CrossRef]

- Sarangi, I.; Ghosh, D.; Bhutia, S.K.; Mallick, S.K.; Maiti, T.K. Anti-tumor and immunomodulating effects of Pleurotus ostreatus mycelia-derived proteoglycans. Int. Immunopharmacol. 2006, 6, 1287–1297. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, L.; Cheung, P.C.K.; Ooi, V.E.C. Molecular weight and anti-tumor activity of the water-soluble polysaccharides isolated by hot water and ultrasonic treatment from the sclerotia and mycelia of Pleurotus tuber-regium. Carbohydr. Polym. 2004, 56, 123–128. [Google Scholar] [CrossRef]

- Du, B.; Yang, Y.; Bian, Z.; Xu, B. Characterization and Anti-Inflammatory Potential of an Exopolysaccharide from Submerged Mycelial Culture of Schizophyllum commune. Front. Pharmacol. 2017, 8, 252. [Google Scholar] [CrossRef]

- Scarpari, M.; Reverberi, M.; Parroni, A.; Scala, V.; Fanelli, C.; Pietricola, C.; Zjalic, S.; Maresca, V.; Tafuri, A.; Ricciardi, M.R.; et al. Tramesan, a novel polysaccharide from Trametes versicolor. Structural characterization and biological effects. PLoS ONE 2017, 12, e0171412. [Google Scholar] [CrossRef]

- Cho, E.J.; Oh, J.Y.; Chang, H.Y.; Yun, J.W. Production of exopolysaccharides by submerged mycelial culture of a mushroom Tremella fuciformis. J. Biotechnol. 2006, 127, 129–140. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-K.; Ho, W.-J.; Chang, S.-L.; Yeh, C.-H.; Liang, Z.-C.; Hsu, T.-H.; Hsieh, C.-W. Fractionation, characterization and antioxidant activity of exopolysaccharide from fermentation broth of a Xylaria nigripes. Bioact. Carbohydr. Diet. Fibre 2018, 16, 37–42. [Google Scholar] [CrossRef]

- Ospina, N.M.; Álvarez, S.P.O.; Sierra, D.M.E.; Vahos, D.F.R.; Ocampo, P.A.Z.; Ossa-Orozco, C.P. Isolation of chitosan from Ganoderma lucidum mushroom for biomedical applications. J. Mater. Sci. Mater. Med. 2015, 26, 135. [Google Scholar] [CrossRef]

- Barros, L.; Cruz, T.; Baptista, P.; Estevinho, L.M.; Ferreira, I.C.F.R. Wild and commercial mushrooms as source of nutrients and nutraceuticals. Food Chem. Toxicol. 2008, 46, 2742–2747. [Google Scholar] [CrossRef]

- Reis, F.S.; Martins, A.; Barros, L.; Ferreira, I.C.F.R. Antioxidant properties and phenolic profile of the most widely appreciated cultivated mushrooms: A comparative study between in vivo and in vitro samples. Food Chem. Toxicol. 2012, 50, 1201–1207. [Google Scholar] [CrossRef]

- Cardoso, R.V.C.; Fernandes, Â.; Oliveira, M.B.P.P.; Calhelha, R.C.; Barros, L.; Martins, A.; Ferreira, I.C.F.R. Development of nutraceutical formulations based on the mycelium of Pleurotus ostreatus and Agaricus bisporus. Food Funct. 2017, 8, 2155–2164. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, X. Stimulatory Effect of Different Lignocellulosic Materials for Phenolic Compound Production and Antioxidant Activity from Inonotus obliquus in Submerged Fermentation. Appl. Biochem. Biotechnol. 2013, 169, 2138–2152. [Google Scholar] [CrossRef]

- Xu, X.; Shen, M.; Quan, L. Stimulatory Agents Simultaneously Improving the Production and Antioxidant Activity of Polyphenols from Inonotus obliquus by Submerged Fermentation. Appl. Biochem. Biotechnol. 2015, 176, 1237–1250. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, M.; Zhao, Y.; Wang, Y.; Miao, K.; Wei, Z. Accumulation of antioxidant phenolic constituents in submerged cultures of Inonotus obliquus. Bioresour. Technol. 2009, 100, 1327–1335. [Google Scholar] [CrossRef] [PubMed]

- Souilem, F.; Fernandes, Â.; Calhelha, R.C.; Barreira, J.C.M.; Barros, L.; Skhiri, F.; Martins, A.; Ferreira, I.C.F.R. Wild mushrooms and their mycelia as sources of bioactive compounds: Antioxidant, anti-inflammatory and cytotoxic properties. Food Chem. 2017, 230, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Corrêa, R.C.G.; de Souza, A.H.P.; Calhelha, R.C.; Barros, L.; Glamoclija, J.; Sokovic, M.; Peralta, R.M.; Bracht, A.; Ferreira, I.C.F.R. Bioactive formulations prepared from fruiting bodies and submerged culture mycelia of the Brazilian edible mushroom Pleurotus ostreatoroseus Singer. Food Funct. 2015, 6, 2155–2164. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Xing, G.; Rui, X.; Li, W.; Chen, X.; Jiang, M.; Dong, M. Enhancement of the antioxidant capacity of chickpeas by solid state fermentation with Cordyceps militaris SN-18. J. Funct. Foods 2014, 10, 210–222. [Google Scholar] [CrossRef]

- Gasecka, M.; Mleczek, M.; Siwulski, M.; Niedzielski, P. Phenolic composition and antioxidant properties of Pleurotus ostreatus and Pleurotus eryngii enriched with selenium and zinc. Eur. Food Res. Technol. 2016, 242, 723–732. [Google Scholar] [CrossRef]

- Amoah, S.K.S.; Sandjo, L.P.; Kratz, J.M.; Biavatti, M.W. Rosmarinic Acid - Pharmaceutical and Clinical Aspects. Planta Med. 2016, 82, 388–406. [Google Scholar] [CrossRef]

- Kang, J.-H.; Jang, J.-E.; Mishra, S.K.; Lee, H.-J.; Nho, C.W.; Shin, D.; Jin, M.; Kim, M.K.; Choi, C.; Oh, S.H. Ergosterol peroxide from Chaga mushroom (Inonotus obliquus) exhibits anti-cancer activity by down-regulation of the β-catenin pathway in colorectal cancer. J. Ethnopharmacol. 2015, 173, 303–312. [Google Scholar] [CrossRef]

- Tintino, S.R.; Oliveira-Tintino, C.D.M.; Campina, F.F.; Costa, M.S.; Cruz, R.P.; Pereira, R.L.S.; Andrade, J.C.; Sousa, E.O.; Siqueira-Junior, J.P.; Coutinho, H.D.M.; et al. Cholesterol and ergosterol affect the activity of Staphylococcus aureus antibiotic efflux pumps. Microb. Pathog. 2017, 104, 133–136. [Google Scholar] [CrossRef]

- Gil-Ramírez, A.; Aldars-García, L.; Palanisamy, M.; Jiverdeanu, R.M.; Ruiz-Rodríguez, A.; Marín, F.R.; Reglero, G.; Soler-Rivas, C. Sterol enriched fractions obtained from Agaricus bisporus fruiting bodies and by-products by compressed fluid technologies (PLE and SFE). Innov. Food Sci. Emerg. Technol. 2013, 18, 101–107. [Google Scholar] [CrossRef]

- Corrêa, R.C.G.; Peralta, R.M.; Bracht, A.; Ferreira, I.C.F.R. The emerging use of mycosterols in food industry along with the current trend of extended use of bioactive phytosterols. Trends Food Sci. Technol. 2017, 67, 19–35. [Google Scholar] [CrossRef]

- Shimizu, T.; Kawai, J.; Ouchi, K.; Kikuchi, H.; Osima, Y.; Hidemi, R. Agarol, an ergosterol derivative from Agaricus blazei, induces caspase-independent apoptosis in human cancer cells. Int. J. Oncol. 2016, 48, 1670–1678. [Google Scholar] [CrossRef]

- Wang, L.-X.; Lu, Z.-M.; Geng, Y.; Zhang, X.-M.; Xu, G.-H.; Shi, J.-S.; Xu, Z.-H. Stimulated production of steroids in Inonotus obliquus by host factors from birch. J. Biosci. Bioeng. 2014, 118, 728–731. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Sun, J.-E.; Lu, Z.-M.; Zhang, X.-M.; Dou, W.-F.; Xu, Z.-H. Beneficial effects of the ethanol extract from the dry matter of a culture broth of Inonotus obliquus in submerged culture on the antioxidant defence system and regeneration of pancreatic β -cells in experimental diabetes in mice. Nat. Prod. Res. 2010, 24, 542–553. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Lu, Z.-M.; Huang, W.; Xu, H.-Y.; Shi, J.-S.; Xu, Z.-H. Bioassay-Guided Isolation of DPP-4 Inhibitory Fractions from Extracts of Submerged Cultured of Inonotus obliquus. Molecules 2013, 18, 1150–1161. [Google Scholar] [CrossRef] [PubMed]

- Heleno, S.A.; Prieto, M.A.; Barros, L.; Rodrigues, A.A.; Barreiro, M.F.; Ferreira, I.C.F.R. Optimization of microwave-assisted extraction of ergosterol from Agaricus bisporus L. by-products using response surface methodology. Food Bioprod. Process. 2016, 100, 25–35. [Google Scholar] [CrossRef]

- Lu, X.; Chen, H.; Dong, P.; Fu, L.; Zhang, X. Phytochemical characteristics and hypoglycaemic activity of fraction from mushroom Inonotus obliquus. J. Sci. Food Agric. 2010, 90, 276–280. [Google Scholar] [CrossRef]

- Zhao, F.; Mai, Q.; Ma, J.; Xu, M.; Wang, X.; Cui, T.; Qiu, F.; Han, G. Triterpenoids from Inonotus obliquus and their antitumor activities. Fitoterapia 2015, 101, 34–40. [Google Scholar] [CrossRef]

- Lau, F.; Abdullah, N.; Aminudin, N.; Lee, H.B.; Yap, K.C.; Sabaratnam, V. The Potential of Mycelium and Culture Broth of Lignosus rhinocerotis as Substitutes for the Naturally Occurring Sclerotium with Regard to Antioxidant Capacity, Cytotoxic Effect, and Low-Molecular-Weight Chemical Constituents. PLoS ONE 2014, 9, e102509. [Google Scholar] [CrossRef]

- Ball, A.S.; Jackson, A.M. The recovery of lignocellulose-degrading enzymes from spent mushroom compost. Bioresour. Technol. 1995, 54, 311–314. [Google Scholar] [CrossRef]

- Li, X.; Lin, X.; Zhang, J.; Wu, Y.; Yin, R.; Feng, Y.; Wang, Y. Degradation of Polycyclic Aromatic Hydrocarbons by Crude Extracts from Spent Mushroom Substrate and its Possible Mechanisms. Curr. Microbiol. 2010, 60, 336–342. [Google Scholar] [CrossRef]

- Mayolo-Deloisa, K.; del Refugio Trejo-Hernandez, M.; Rito-Palomares, M. Recovery of laccase from the residual compost of Agaricus bisporus in aqueous two-phase systems. Process Biochem. 2009, 44, 435–439. [Google Scholar] [CrossRef]

- Ko, H.G.; Park, S.H.; Kim, S.H.; Park, H.G.; Park, W.M. Detection and recovery of hydrolytic enzymes from spent compost of four mushroom species. Folia Microbiol. 2005, 50, 103–106. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-L.; Kopparapu, N.-K.; Li, Y.; Deng, Y.; Zheng, X.-Q. Biochemical characterization of a novel fibrinolytic enzyme from Cordyceps militaris. Int. J. Biol. Macromol. 2017, 94, 793–801. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.J.; Lin, C.P.; Tsai, S.Y. Vitamin D2 content and antioxidant properties of fruit body and mycelia of edible mushrooms by UV-B irradiation. J. Food Compos. Anal. 2015, 42, 38–45. [Google Scholar] [CrossRef]

- Schimpf, U.; Schulz, R. Industrial by-products from white-rot fungi production. Part I: Generation of enzyme preparations and chemical, protein biochemical and molecular biological characterization. Process Biochem. 2016, 51, 2034–2046. [Google Scholar] [CrossRef]

- Bilbao-Sainz, C.; Chiou, B.-S.; Punotai, K.; Olson, D.; Williams, T.; Wood, D.; Rodov, V.; Poverenov, E.; McHugh, T. Layer-by-Layer Alginate and Fungal Chitosan Based Edible Coatings Applied to Fruit Bars. J. Food Sci. 2018, 83, 1880–1887. [Google Scholar] [CrossRef]

- Fazaeli, H.; Masoodi, A.R.T. Spent Wheat Straw Compost of Agaricus bisporus Mushroom as Ruminant Feed. Asian-Australas J. Anim. Sci. 2006, 19, 845–851. [Google Scholar] [CrossRef]

- Regulation EC. No 1069/2009 of the European Parliament and the Council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation). Official Journal of the European Union; European Parliament: Brussels, Belgium, 2009. [Google Scholar]

- Chu, G.-M.; Kang, S.-N.; Kim, H.-Y.; Ha, J.-H.; Kim, J.-H.; Jung, M.-S.; Ha, J.-W.; Lee, S.-D.; Jin, S.K.; Kim, I.-S.; et al. Effect of Substitution of Fermented King Oyster Mushroom By-Products Diet on Pork Quality during Storage. Food Sci. Anim. Resour. 2012, 32, 133–141. [Google Scholar] [CrossRef]

- Moon, B.; Lo, Y.M. Conventional and Novel Applications of Edible Mushrooms in Today’s Food Industry. J. Food Process. Preserv. 2013, 38, 2146–2153. [Google Scholar] [CrossRef]

- Chang, S.-C.; Lin, M.-J.; Chao, Y.-P.; Chiang, C.-J.; Jea, Y.-S.; Lee, T.-T. Effects of spent mushroom compost meal on growth performance and meat characteristics of grower geese. Rev. Bras. Zootec. 2016, 45, 281–287. [Google Scholar] [CrossRef]

- Foluke, A.; Olutayo, A.; Olufemi, A. Assessing Spent Mushroom Substrate as a Replacement to Wheat Bran in the Diet of Broilers. Am. Int. J. Contemp. Res. 2014, 4, 178–183. [Google Scholar]

- Van Doan, H.; Hoseinifar, S.H.; Dawood, M.A.O.; Chitmanat, C.; Tayyamath, K. Effects of Cordyceps militaris spent mushroom substrate and Lactobacillus plantarum on mucosal, serum immunology and growth performance of Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol. 2017, 70, 87–94. [Google Scholar] [CrossRef]

- Paula, F.S.; Tatti, E.; Abram, F.; Wilson, J.; O’Flaherty, V. Stabilisation of spent mushroom substrate for application as a plant growth-promoting organic amendment. J. Environ. Manag. 2017, 196, 476–486. [Google Scholar] [CrossRef]

- Kim, H.; Shimizu, T.; Kourakata, I.; Takahashi, Y. Topic: Energy Recovery from Mushroom Culture Waste and the Use of Its Ash as Fertilizer. In Energy Technology Roadmaps of Japan: Future Energy Systems Based on Feasible Technologies Beyond 2030; Kato, Y., Koyama, M., Fukushima, Y., Nakagaki, T., Eds.; Springer: Tokyo, Japan, 2016; pp. 455–458. ISBN 978-4-431-55951-1. [Google Scholar]

- Ünal, M. The utilization of spent mushroom compost applied at different rates in tomato (Lycopersiconesculentum mill.) seedling production. Emir. J. Food Agric. 2015, 27. [Google Scholar] [CrossRef]

- Owaid, M.N.; Abed, I.A.; Al-Saeedi, S.S.S. Applicable properties of the bio-fertilizer spent mushroom substrate in organic systems as a byproduct from the cultivation of Pleurotus spp. Inf. Process. Agric. 2017, 4, 78–82. [Google Scholar] [CrossRef]

- Giménez, A.P.; González, J.E.P. Evaluation of casing materials made from spent mushroom substrate and coconut fibre pith for use in production of Agaricus bisporus (Lange) Imbach. Spanish J. Agric. Res. 2008, 4, 683–690. [Google Scholar]

- Ashrafi, R.; Mian, M.H.; Rahman, M.M.; Jahiruddin, M. Recycling of Spent Mushroom Substrate for the Production of Oyster Mushroom. Res. Biotechnol. 2014, 5, 13–21. [Google Scholar]

- Chang, B.-V.; Fan, S.-N.; Tsai, Y.-C.; Chung, Y.-L.; Tu, P.-X.; Yang, C.-W. Removal of emerging contaminants using spent mushroom compost. Sci. Total Environ. 2018, 634, 922–933. [Google Scholar] [CrossRef]

- Law, W.; Lau, W.; Lo, K.; Wai, L.; Chiu, S. Removal of biocide pentachlorophenol in water system by the spent mushroom compost of Pleurotus pulmonarius. Chemosphere 2003, 52, 1531–1537. [Google Scholar] [CrossRef]

- Lau, K.L.; Tsang, Y.Y.; Chiu, S.W. Use of spent mushroom compost to bioremediate PAH-contaminated samples. Chemosphere 2003, 52, 1539–1546. [Google Scholar] [CrossRef]

- Molahid, V.L.M.; Mohd Kusin, F.; Madzin, Z. Role of multiple substrates (spent mushroom compost, ochre, steel slag, and limestone) in passive remediation of metal-containing acid mine drainage. Environ. Technol. 2018, 40, 1323–1336. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, T.; Chen, C.; Feng, L.; Su, X.; Zhou, L.; Chen, Y.; Xia, A.; Wang, X. Spent substrate of Ganodorma lucidum as a new bio-adsorbent for adsorption of three typical dyes. Bioresour. Technol. 2018, 266, 134–138. [Google Scholar] [CrossRef]

- Kandelbauer, A.; Guebitz, G.M. Bioremediation for the Decolorization of Textile Dyes — A Review BT-Environmental Chemistry: Green Chemistry and Pollutants in Ecosystems; Lichtfouse, E., Schwarzbauer, J., Robert, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 269–288. ISBN 978-3-540-26531-3. [Google Scholar]

- Pandey, R.K.; Tewari, S.; Tewari, L. Lignolytic mushroom Lenzites elegans WDP2: Laccase production, characterization, and bioremediation of synthetic dyes. Ecotoxicol. Environ. Saf. 2018, 158, 50–58. [Google Scholar] [CrossRef]

- Rani, B.; Kumar, V.; Singh, J.; Bisht, S.; Teotia, P.; Sharma, S.; Kela, R. Bioremediation of dyes by fungi isolated from contaminated dye effluent sites for bio-usability. Braz. J. Microbiol. 2014, 45, 1055–1063. [Google Scholar] [CrossRef]

- Woo Kang, H.; Hui Yang, Y.; Kim, S.W.; Kim, S.; Ro, H.-S. Decolorization of triphenylmethane dyes by wild mushrooms. Biotechnol. Bioprocess Eng. 2014, 19, 519–525. [Google Scholar] [CrossRef]

- Nagai, M.; Sato, T.; Watanabe, H.; Saito, K.; Kawata, M.; Enei, H. Purification and characterization of an extracellular laccase from the edible mushroom Lentinula edodes, and decolorization of chemically different dyes. Appl. Microbiol. Biotechnol. 2002, 60, 327–335. [Google Scholar] [CrossRef]

- Wang, S.-N.; Chen, Q.-J.; Zhu, M.-J.; Xue, F.-Y.; Li, W.-C.; Zhao, T.-J.; Li, G.-D.; Zhang, G.-Q. An extracellular yellow laccase from white rot fungus Trametes sp. F1635 and its mediator systems for dye decolorization. Biochimie 2018, 148, 46–54. [Google Scholar] [CrossRef]

- Córdova Juárez, R.A.; Gordillo Dorry, L.L.; Bello-Mendoza, R.; Sánchez, J.E. Use of spent substrate after Pleurotus pulmonarius cultivation for the treatment of chlorothalonil containing wastewater. J. Environ. Manag. 2011, 92, 948–952. [Google Scholar] [CrossRef]

- Frutos, I.; García-Delgado, C.; Gárate, A.; Eymar, E. Biosorption of heavy metals by organic carbon from spent mushroom substrates and their raw materials. Int. J. Environ. Sci. Technol. 2016, 13, 2713–2720. [Google Scholar] [CrossRef]

- Demierege, S.; Toptas, A.; Mavioglu Ayan, E.; Yasa, I.; Yanik, J. Removal of textile dyes from aqueous solutions by biosorption on mushroom stump wastes. Chem. Ecol. 2015, 31, 365–378. [Google Scholar] [CrossRef]

- Kulshreshtha, S. Mushroom Biomass and Spent Mushroom Substrate As Adsorbent to Remove Pollutants. In Green Adsorbents for Pollutant Removal; Crini, G., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2018; pp. 281–325. [Google Scholar]

- Padolecchia, M.; Gallina, G.; Lombardi, A.; Puglisi, N.; Liberto, V.; Testa, G. The use of spent mushroom substrate in the production of thermal energy in terms of a circular economy. P-ESEM 2018, 5, 139–145. [Google Scholar]

- Uzun, I. Use of spent mushroom compost in sustainable fruit production. J. Fruit Ornam. Plant Res. 2004, 12, 157–165. [Google Scholar]

- Kim, M.-K.; Lee, H.-G.; Park, J.-A.; Kang, S.-K.; Choi, Y.-J. Recycling of Fermented Sawdust-based Oyster Mushroom Spent Substrate as a Feed Supplement for Postweaning Calves. Asian-Australasian J. Anim. Sci. 2011, 24, 493–499. [Google Scholar] [CrossRef]

- Vane, C.H.; Drage, T.C.; Snape, C.E. Biodegradation of Oak (Quercus alba) Wood during Growth of the Shiitake Mushroom (Lentinula edodes): A Molecular Approach. J. Agric. Food Chem. 2003, 51, 947–956. [Google Scholar] [CrossRef]

- Corrêa, R.C.G.; da Silva, B.P.; Castoldi, R.; Kato, C.G.; de Sá-Nakanishi, A.B.; Peralta, R.A.; de Souza, C.G.M.; Bracht, A.; Peralta, R.M. Spent mushroom substrate of Pleurotus pulmonarius: A source of easily hydrolyzable lignocellulose. Folia Microbiol. 2016, 61, 439–448. [Google Scholar] [CrossRef]

- Lee, J.-W.; Koo, B.-W.; Choi, J.-W.; Choi, D.-H.; Choi, I.-G. Evaluation of waste mushroom logs as a potential biomass resource for the production of bioethanol. Bioresour. Technol. 2008, 99, 2736–2741. [Google Scholar] [CrossRef]

- Li, Y.-C.; Wu, S.-Y.; Chu, C.-Y.; Huang, H.-C. Hydrogen production from mushroom farm waste with a two-step acid hydrolysis process. Int. J. Hydrogen Energy 2011, 36, 14245–14251. [Google Scholar] [CrossRef]

- Luo, X.; Yuan, X.; Wang, S.; Sun, F.; Hou, Z.; Hu, Q.; Zhai, L.; Cui, Z.; Zou, Y. Methane production and characteristics of the microbial community in the co-digestion of spent mushroom substrate with dairy manure. Bioresour. Technol. 2018, 250, 611–620. [Google Scholar] [CrossRef]

- Schiel-Bengelsdorf, B.; Montoya, J.; Linder, S.; Dürre, P. Butanol fermentation. Environ. Technol. 2013, 34, 1691–1710. [Google Scholar] [CrossRef]

- Al-Shorgani, N.K.N.; Al-Tabib, A.I.; Kadier, A.; Zanil, M.F.; Lee, K.M.; Kalil, M.S. Continuous Butanol Fermentation of Dilute Acid-Pretreated De-oiled Rice Bran by Clostridium acetobutylicum YM1. Sci. Rep. 2019, 9, 4622. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Chang, Y.; Guan, J.; Shanguan, G.; Xin, F. Butanol production from organosolv treated spent mushroom substrate integrated with in situ biodiesel extraction. Renew. Energy 2016, 96, 656–661. [Google Scholar] [CrossRef]

- Pérez-Chávez, A.M.; Mayer, L.; Albertó, E. Mushroom cultivation and biogas production: A sustainable reuse of organic resources. Energy Sustain. Dev. 2019, 50, 50–60. [Google Scholar] [CrossRef]

- Taofiq, O.; Rodrigues, F.; Barros, L.; Barreiro, M.F.; Ferreira, I.C.F.R.; Oliveira, M.B.P.P. Mushroom ethanolic extracts as cosmeceuticals ingredients: Safety and ex vivo skin permeation studies. Food Chem. Toxicol. 2019, 127, 228–236. [Google Scholar] [CrossRef]

- Wu, Y.; Choi, M.-H.; Li, J.; Yang, H.; Shin, H.-J. Mushroom Cosmetics: The Present and Future. Cosmetics 2016, 3, 22. [Google Scholar] [CrossRef]

- Hyde, K.D.; Bahkali, A.H.; Moslem, M.A. Fungi—An unusual source for cosmetics. Fungal Divers. 2010, 43, 1–9. [Google Scholar] [CrossRef]

- Fangkrathok, N.; Junlatat, J.; Sripanidkulchai, B. In vivo and in vitro anti-inflammatory activity of Lentinus polychrous extract. J. Ethnopharmacol. 2013, 147, 631–637. [Google Scholar] [CrossRef]

- Huang, H.C.; Hsu, T.F.; Chao, H.L.; Chen, C.C.; Chiu, S.W.; Chang, T.M. Inhibition of melanogenesis in murine melanoma cells by Agaricus brasiliensis methanol extract and anti-reactive oxygen species (ROS) activity. African J. Microbiol. Res. 2014, 8, 519–524. [Google Scholar] [CrossRef]

- Chien, C.C.; Tsai, M.L.; Chen, C.C.; Chang, S.J.; Tseng, C.H. Effects on tyrosinase activity by the extracts of Ganoderma lucidum and related mushrooms. Mycopathologia 2008, 166, 117–120. [Google Scholar] [CrossRef]

- Taofiq, O.; Rodrigues, F.; Barros, L.; Peralta, R.M.; Barreiro, M.F.; Ferreira, I.C.; Oliveira, M.B.P. Agaricus blazei Murrill from Brazil: An ingredient for nutraceutical and cosmeceutical applications. Food Funct. 2019, 10, 565–572. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef]

- Jones, M.P.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium composites: A review of engineering characteristics and growth kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef] [PubMed]

- Appels, F.V.W.; Dijksterhuis, J.; Lukasiewicz, C.E.; Jansen, K.M.B.; Wösten, H.A.B.; Krijgsheld, P. Hydrophobin gene deletion and environmental growth conditions impact mechanical properties of mycelium by affecting the density of the material. Sci. Rep. 2018, 8, 4703. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.J.; Zhang, F.; Still, B.; White, M.; Amstislavski, A. Physical and Mechanical Properties of Fungal Mycelium-Based Biofoam. J. Mater. Civ. Eng. 2017, 29, 4017030. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Abhijith, R.; Ashok, A.; Rejeesh, C.R. Sustainable packaging applications from mycelium to substitute polystyrene: A review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Velasco, P.M.; Ortiz, M.P.M.; Giro, M.A.M.; Castelló, M.C.J.; Velasco, L.M. Development of better insulation bricks by adding mushroom compost wastes. Energy Build. 2014, 80, 17–22. [Google Scholar] [CrossRef]

- Kim, Y.; Ruedy, D. Mushroom Packages An Ecovative Approach in Packaging Industry. In Handbook of Engaged Sustainability; Springer: Burbank, CA, USA, 2019; pp. 1–25. ISBN 978-3-319-53121-2. [Google Scholar]

- EC. Regulation (EC) No 1924/2006 of the European Parliament and of the Council on Nutrition and Health Claims Made on Foods; Official Journal of the European Union; European Parliament: Brussels, Belgium, 1924; pp. 9–24.

- Harland, J. 2-Authorised EU health claims for barley and oat beta-glucans. In Sadler Nutrients and Food Ingredients with Authorised EU Health Claims; Sadler, M.J., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 25–45. ISBN 978-0-85709-842-9. [Google Scholar]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the safety of “Lentinus edodes extract” (Lentinex®) as a Novel Food ingredient. EFSA J. 2010, 8, 1685. [Google Scholar] [CrossRef]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of health claims related to chitosan and reduction in body weight (ID 679, 1499), maintenance of normal blood LDL-cholesterol concentrations (ID 4663), reduction of intestinal transit time (ID 4664) and reduction. EFSA J. 2011, 9, 2214. [Google Scholar] [CrossRef]

- EC. Regulation (EU) No 376/2010 of 3 May 2010 Amending Regulation (EC) No 983/2009 on the Authorisation and Refusal of Authorisation of Certain Health Claims Made on Food and Referring to the Reduction of Disease Risk and to Children’s Development and Health; Official Journal of the European Union; European Parliament: Brussels, Belgium, 2010; pp. 3–4.

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of a health claim related to 3 g/day plant sterols/stanols and lowering blood LDL-cholesterol and reduced risk of (coronary) heart disease pursuant to Article 19 of Regulation (EC) No 1924/2006. EFSA J. 2012, 10, 2693. [Google Scholar] [CrossRef]

| Production Technique | Species | By-Products | Bioactive Compound | Extraction Method | Fractionation and Purification | Bioactivities | Reference |

|---|---|---|---|---|---|---|---|

| Solid Substrate Fermentation | Agaricus bisporus | Dried and powder caps and stipes | Chitin | Alkali treatment (2 M sodium hydroxide, 2 h at 100 °C); Oxalic solution treatment (1% w/v, 1 h at 100 °C); Alkali treatment (2 M sodium hydroxide, 2 h at 100 °C); Acidic treatment (2% acetic acid, 90 °C for 2 h). | nd | Antimicrobial activity | [84] |

| Dried and powder caps and stipes | Beta-glucan | Ultrasound-assisted extraction; precipitation with ethanol 80% (1:2 v/v, 1 h at room temperature). | nd | nd | [18] | ||

| Dried and powder stipes | Chitosan | Precipitation with 96% ethanol; Treatment with sodium metabisulfite; Treatment with alkali (2% sodium hydroxide, 56 °C for 2 h) NaOH added to the insoluble phase and treatment with hydrogen peroxide (final concentration 3%, stirring at 45 °C for 0.5 h); Treatment with sodium hydroxide (2 h at 104 °C); Treatment with hydrochloric acid. | nd | Good film-forming properties with antimicrobial activity | [85] | ||

| Dried and powder stipes | Chitin-glucan complex | Alkali treatment (1 M sodium hydroxide, 95 °C, reflux 30 min); Acidic treatment (2% acetic acid, 95 °C, reflux 6 h). | nd | nd | [15] | ||

| Flammulina velutipes | SMS | Polysaccharide | Hydrochloric acid extraction (0.5 M, 1:10, w/v), sodium hydroxide (0.5 M, 1:10, w/v) at 80 °C and snailase solution (4%, 1:4, w/v) at 37 °C for 6 h, respectively. After centrifugation (3600 r/min, 15 min), the supernatant was mixed with 3 volumes of ethanol (95%, v/v) at 4 °C overnight. | Sevag method | Antioxidant activity; hypoglycemic and renoprotective effects | [40] | |

| F. velutipes | Dried and powder mycelium from SMS | Polysaccharide | Hot water extraction (1:20 w/v) for 8 h at 70–80 °C; Concentration in a rotary vapor. | Sevag method; Dialysis; DEAE–Sephadex elution; Sephacryl S-400 column elution. | Antitumor activity | [86] | |

| Ganoderma lucidum | Dried and powder SMS | Polysaccharide | Water extraction (1:35 (v/w)); Precipitation (20 h). | Sevag method; DEAE cellulose colum; Sephadex G-100 size-exclusion chromatography. | Antioxidant activity | [44] | |

| Laetiporus sulphureus | Stipe | Lectin | Sodium chloride concentration, 0.50; liquid−solid ratio, 20:1 (mL/g); extraction temperature, 35 °C; extraction time, 20 h; and extraction pH, 7.5. | Dialysis; DEAE-cellulose-52; HPGFC (High Performance Gel Filtration Chromatography) | Agglutinating activity | [43] | |

| Lentinus edodes | SMS | Lentinan | Hot water extraction (80 °C for 1 h); Ethanol precipitation (95%); Ethanol washing (75%). | Sevag method; Dialysis (30 °C for 16 h). | Antibacterial activity | [45] | |

| L. edodes | Dried and powder SMS | Polysaccharide | Hot water extraction (1:20 (w/v), 100 °C, 100 min, repeated 3 times). | Deproteinization–combination of Sevag method and enzymatic hydrolysis (papain); Sephadex G-150 size exclusion chromatography. | Antioxidant activity | [87] | |

| Pleurotus eryngii | SMS | Heteropolysaccharide (mainly composed of xylose, glucose and arabinose) | Alkali treatment (0.5 M NaOH, 90 °C for 300 min); Ethanol precipitation (65%). | Sevag method Dialysis (24 h at room temperature); Ethanol precipitation Sepharose CL-6B column chromatography. | Antioxidant activity | [41] | |

| P. eryngii | Dried and powder mycelium from SMS and fruiting bodies | Polysaccharide | Precipitation with 85% ethanol; Ultrasonic extraction (70 °C, 140 min); Precipitation with ethanol (12 h, 4 °C). | Dialysis; Ultrafiltration (membranes cut off of 100 KDa and 10 KDa). | Antioxidant activity | [88] | |

| P. eryngii | Dried and powder mycelium from SMS and fruiting bodies | Heteropolysaccharide (mainly composed of glucose) | Precipitation with 85% ethanol at room temperature for 12 h; Hot water extraction (70 °C for 140 min). | Sevag method; Dialysis. | Antitumor activity | [16] | |

| Submerged Liquid Fermentation | Agaricus blazei | Fermentantion broth and mycelium | Polysaccharide | Hot water extraction (boiling, 1 h); Precipitation with 95% ethanol. | DEAE column; Gel filtration; chromatography HW-65F column. | nd | [89] |

| Antrodia cinnamomea | Mycelium | Antrodan | Supercritical Fluid Extraction (reflux 3 times, 90 °C for 2 h); Hot alkali treatment (80 °C, 3 times for 2 h); Ethanol precipitation (95%). | Gel Permeation Chromatography (Sephadex G-100 Column) | Anti-inflammatory activity | [90] | |

| Coprinus comatus | Mycelium | Polysaccharide | Microwave for 3 min; Hot water extraction (1:2 w/v) for 4 h at 70 °C; Concentration in a rotary vapor. | Sevag method; Dialysis in a DEAE cellulose bag; Precipitation with ethanol (48 h at 4 °C). | Antioxidant activity | [91] | |

| Grifola frondosa | Mycelium | Glycoprotein | Extraction with water (4 °C); Precipitation with 80% ammonium sulfate (overnight at 4 °C). | Dialysis; DEAE-Sepharose. | Antitumor activity | [92] | |

| Hericium erinaceum | Mycelium | Polysaccharide (heteroglycan) | Hot water extraction (70 °C for 12 h); Precipitation with ethanol (80%). | Hollow-fiber ultrafiltration; Ion-exchange chromatography (DEAE-Sephadex column). | Antichronic atrophic gastritis activity | [93] | |

| H. erinaceum | Mycelium | 12b-hydroxyverruculogen TR-2, fumitremorgin C and methylthiogliotoxin, two hetero-spirocyclic glactam alkaloids, pseurotin A and FD-838 and cerevisterol and herierin IV | Ultrasound assisted extraction with ethyl acetate. | Column chromatography over silica gel Sephadex LH-20; reversed-phase silica gel column chromatography; preparative thin-layer chromatography (PTLC). | Antioxidant and antifungal activities | [94] | |

| Inonotus obliquus | Fermentation broth and mycelium | Polysaccharide | Fermentation broth:Extraction with 95% (v/v) ethanol (4 °C, overnight); Treatment with Neutrase (3% w/w, 42 °C for 3 h). Mycelium: Hot water extraction (3 h at 121 °C); Ethanol precipitation. | Sevag method; Dialysis; DEAE-52 chromatography; Sephadex G-200 chromatography. | Antioxidant and immunomodulator properties | [95] | |

| I. obliquus | Fermentation broth and mycelium | Polysaccharide | Fermentation broth: Ethanol precipitation (95%, overnight at 4 °C). Mycelium:Hot water extraction (3 h in an autoclave at 121 °C); Ethanol precipitation. | Fermentation broth: Sevag Method. Mycelium: Dialysis. | Antioxidant activity | [96] | |

| Lentinus squarrosulus | Fermentation broth and dried mycelium powder | Polysaccharide | Ethanol precipitation; Cold water extraction (3 h at room temperature); Hot water extraction (3 h at 100 °C). | nd | Antitumor and antioxidant activities | [97] | |

| Morchella conica | Fermentation broth | Exopolysaccharides | Centrifugation at 3000 rpm for 20 min from the culture; Sevag method;95% ethanol precipitation. | Dialysis; DEAE-Cellulose 52 anion-exchange chromatography column. | Immunomodulatory activity | [98] | |

| P. ostreatus | Mycelium | Proteoglycan | Phosphate-buffered saline treatment and centrifugation (8000 rpm for 15 min); Ethanol precipitation. | Dialysis; Anion exchanger column (DEAE-Sephadex); Cation exchanger column (CM-Sephadex); Gel filtration chromatography (Sephadex G-100) | Antitumor activity | [99] | |

| Pleurotus tuber-regium | Mycelium | Polysaccharide | Hot water extraction (100 °C for 3 h); Ultrasound assisted extraction (2 h). | Dialysis (2 days) | Antitumor activity | [100] | |

| Schizophyllum commune | Fermentation broth | Exopolysaccharide | Absolute ethanol precipitation. | Sevag method; DEAE-52 column; Dialysis; Sephadex G-150 column. | Anti-inflammatory activity | [101] | |

| Trametes versicolor | Fermentation broth | Tramesan (Exopolysaccharide) | Precipitation with ethanol; Treatment with pronase E (16 h at 37 °C). | Dialysis; Low pressure size exclusion chromatography on a Sephacryl S-300 column. | Antioxidant activity | [102] | |

| Tremella fuciformis | Fermentation broth | Exopolysaccharides | Absolute ethanol precipitation | nd | nd | [103] | |

| Xylaria nigripes | Fermentation broth | Polysaccharide | Gradient ethanol precipitation (40%, 50% and 80%, 4 °C, overnight) | nd | Antioxidant activity | [104] |

| Production Technique | Species | By-Products | Bioactive Compound | Extraction Method | Bioactivities | Reference |

|---|---|---|---|---|---|---|

| Submerged Liquid Fermentation | Agaricus bisporus | Mycelia | Gallic, p-coumaric, cinnamic and p-hydroxybenzoic acid | Extraction with methanol:water (80:20, v/v) at −20 °C for 1.5 h. | Antioxidant | [107] |

| mycelia and culture media | p-Hydroxybenzoic, p-coumaric and cinnamic acid | Extraction with methanol at 25 °C, 150 rpm for 1 h. | Anti-inflammatory Cytotoxic Antioxidant | [108] | ||

| Inonotus obliquus | Fermentation Broth, Mycelia | Gallic, ferulic, Epigallocatechin gallate, Phelligridin G, Davallialactone and Inoscavin B | Fermentation Broth -Extraction with 95% ethanol (1:4, v/v) at 4 °C overnight, Supernatant re-extracted with ethyl acetate (1:3, v/v) thrice Mycelial-Extraction by ultrasonication for 10 min in 70% aqueous acetone (v/v). | Antioxidant | [109] | |

| I. obliquus | Fermentation Broth, Mycelia | Epicatechin-3-gallate, epigallocatechin-3-gallate, phelligridin G, davallialactone and inoscavin B | Fermentation Broth -Extraction with 95% ethanol (1:4, v/v) at 4 °C overnight, Supernatant re-extracted with ethyl acetate and n-butanol (1:3, v/v) thrice Mycelial-Extraction by ultrasonication for 10 min in 70% aqueous acetone (v/v). | DPPH radical scavenging | [110] | |

| I. obliquus | Mycelia | Kaempferol, quercetin, isorhamnetin, luteolin, naringenin, apigenin, fortuneletin | Mycelial biomass was dried in a microwave oven for 10 min, extracted with 95% ethanol and stored at 4 °C overnight Centrifugation at 4500× g for 10 min. | Superoxide and DPPH radical Scavenging | [111] | |

| Lentinula edodes | Mycelia | Protocatechuic and p-hydroxybenzoic acid | Extracted with methanol:water (80:20, v/v) at −20 °C for 1.5 h. | Antioxidant | [107] | |

| Pleurotus eryngii | Mycelia and culture media | p-Hydroxybenzoic and cinnamic acid | Extracted with methanol at 25 °C, 150 rpm for 1 h. | Anti-inflammatory Cytotoxic Antioxidant | [112] | |

| Pleurotusostreatoroseus | Mycelia | Cinnamic acid | Extracted with ethanol (70%) at 25 °C and at 130 rpm for 3 h. | Antioxidant Anti-inflammatory Antimicrobial Hepatotoxicity | [113] | |

| Suillus belinii | Mycelia and culture media | p-Hydroxybenzoic acid, Cinnamic acid | Extracted with methanol at 25 °C, 150 rpm for 1 h. | Anti-inflammatory Cytotoxic Antioxidant activity | [112] | |

| Solid Substrate Fermentation | Cordyceps militaris | Dried powder | Shikmic, chlorogenic, syringic, p-coumaric and ferulic acid, rutin, genistin, daidzein, luteolin, genistein, Biochanin A | Extraction with methanol (80%) and ethanol (80%) at 50 °C for 4 h. Refluxing at 40 °C, at 150 rpm for 4 h. Centrifuged at 15,000× g, for 15 min at 4 °C | Antioxidant activities Inhibition of oxidative DNA damage | [114] |

| Pleurotus eryngii | Substrate | Chlorogenic, syringic, ferulic, p-coumaric, caffeic, t-cinnamic, vanillic acid and naringenin | Extraction in 80% methanol under sonication for 8 h. | Antioxidant activity | [115] | |

| Pleurotus ostreatus | Substrate | Chlorogenic, syringic, ferulic, p-coumaric, caffeic, t-cinnamic, vanillic acid and naringenin | Extraction in 80% methanol under sonication for 8 h. | Antioxidant activity | [115] |

| Part A—Triterpenes and Steroidal Compounds Obtained from Mushroom By-Products | |||||||

|---|---|---|---|---|---|---|---|

| Production Technique | Species | By-Products | Bioactive Compound | Extraction Method | Fractionation and Purification | Bioactivity | Reference |

| Submerged Liquid Fermentation | I. obliquus | mycelia | betulin, ergosterol, cholesterol, lanosterol, stigmasterol and sitosterol | Ultrasonic extraction with methanol for 2 h. | nd | nd | [122] |

| I. obliquus | dry matter culture broth | Ergosterol, cholesterol, lanosterol and β-sitosterol | Extracted with 80% ethanol at room temperature overnight. | nd | In vivo antioxidantAnti-cholesteremic | [123] | |

| I. obliquus | Fermentation Broth, Mycelia | (22E)-stigmasta-7,22,25-trien-3-yl acetate, (3β)-olean-12-en-3-yl-(4hydroxyphenyl) propanoate, ligudentatol, | Extraction with hexane, chloroform, ethyl acetate and methanol three times for 12 h at room temperature | Fractionated on a silica gel column yielding four fractions further separated using a Sephadex LH-20 column | Dipeptidyl peptidase-4 inhibitory activity | [124] | |

| Solid Substrate Fermentation | A. bisporus | Fruiting body | Ergosterol | Microwave-assisted extraction with ethanol at 19.4 ± 2.9 min,132.8 ± 12.4 °C and 1.6 ± 0.5 g/L | nd | nd | [125] |

| I. obliquus | sclerotia | lanosterol, 3β-hydroxy-lanosta-8,24-diene-21-al, inotodiol, ergosterol peroxide and trametenolic acid | Extracted three times with ethanol at 78 °C. The ethanol extract was fractionated using petroleum ether and ethyl acetate as solvents. | nd | Anti-hyperglycemic α-amylase inhibitory activity DPPH radical scavenging effect | [126] | |

| I. obliquus | sclerotia | inonotusanes A, B and C, 3β-hydroxy-25,26,27-trinorlanosta-8,22E-dien-24-oic acid (4), lupanes and oleanane-type triterpene | Extracted under reflux with 95% EtOH for 1 h, further extracted with petroleum ether, EtOAc and n-BuOH | Silica gel Column chromatography [petroleum ether-EtOAc (25:1 to 1:1) and then MeOH] to obtain different fractions | Antitumor and cytotoxicity | [127] | |

| Lignosus rhinocerotis | Mycelium and sclerotium | Ergosterol Ergosta-4,7,22-trien-3b-ol | Extraction in 80% (v/v) methanol for 3 Days | nd | Antitumor and cytotoxicity | [128] | |

| Part B—Enzymes obtained from mushroom by-products | |||||||

| Mushroom Production Technique | Mushroom Specie | By-Product | Bioactive Compound | Extraction Method | Reference | ||

| Solid Substrate Fermentation | A. bisporus | SMS | Lignocellulose-degrading enzymes | Treatment with five different solutions: distilled water, quarter-strength Ringer solution, sodium hydroxide, hydrochloric acid and potassium phosphate buffer. Incubation at 37 °C for 1 h with shaking before being clarified by centrifugation. | [129] | ||

| Flammulina velutipes, P. eryngii, Lentinula edodes, P. ostreatus and Pleurotus sp. | SMS | Cellulose-degrading enzymes: Cellulases, β-glucosidase, dextranase, amylase and laccase | Samples of the compost (wet weight) were mixed with distilled water (1:10 w/v). Incubation at 30 °C for 1 h with shaking at 180 rpm, filtrated through gauze and centrifuged at 10000× g at 4 °C for 100 min. | [3] | |||

| Pleurotus spp. | SMS | Lignocellulolytic Enzymes | Extracellular enzymes were extracted using four solutions from P. ostreatus SMS: tap water, distilled water, 50 mM sodium citrate buffer (pH 4.5) and 50 mM sodium phosphate buffer (pH 8.0). The SMS-buffer mixtures were incubated with shaking at 200 rpm for 2, 4, 6, 8, 10 or 12 h at 4 °C or 20 °C. Each sample was filtered through miracloth (pore size: 22~25 µm) and then centrifuged at 10,000× g at 4 °C for 15 min. | [4] | |||

| A. bisporus, P. eryngii, P. ostreatus and C. comatus | SMS | Laccase | Extraction with Buffer A, which contained 0.1 M sodium acetate, 5 mM calcium chloride, 0.05% Tween80 and 1% polyvinylpolypyrrolidone, on rotary shaker (180 rpm, 25 °C) for 1 h. The aqueous suspensions were centrifuged (11,000× g, 30 min) and the supernatants were used | [130] | |||

| Agaricus bisporus | SMS | Laccase | The residual compost (2.0 g) was mixed with distilled water (3.0 mL). The resulting mixture was kept at 4 °C for 24 h. The solid phase was recovered and pressed manually to increase the amount of liquid phase obtained. Liquid phase was passed through a mesh (0.8 mm) and centrifuged (10,000× g). | [131] | |||

| P. ostreatus, Lentinula edodes, Flammulina velutipes and Hericium erinaceum | SMS | α-amylase, cellulase, β-glucosidase, laccase and xylanase | Suspension in 100 mL of 6 solutions: 1% (w/v) NaCl, 0.1 mol/L phosphate, 0.5% (v/v) Triton X-100, 0.1 mol/L phosphate buffer supplemented with 10% (v/v) glycerol, 0.1 mol/L phosphate buffer supplemented with 0.25% (v/v) Triton X-100, and tap water. Incubation at room temperature for 1 h and centrifugation at 10,000× g for 5 min. In the case of using tap water, the four SMS samples were suspended in 100 mL and blended with a blender for 3 min until the suspensions were homogeneous. Filtration and incubation at room temperature for 1 h before centrifugation. | [132] | |||

| Submerged Liquid Fermentation | Cordyceps militaris | Submerged culture supernatant | Fibrinolytic enzymes | After fermentation, the broth was centrifuged at 9700× g for 10 min. | [133] | ||

| Health claims | Mushroom Specie/Compound | Health Claim | Health Effect |

|---|---|---|---|

| Non-authorized | Ganoderma lucidum | Stimulates the body in exhaustion | Physical well-being |

| Lentinus edodes | Contributes to natural immunological defenses | Stimulation of immunological responses | |

| Pleurotus eryngii | Regulates physiology of pancreas and fat metabolism | Improvement of the digestion of macronutrients (e.g., carbohydrates, proteins and lipids) | |

| Pleurotus ostreatus | Antioxidants can protect from radicals which cause cell damage; antioxidants can protect cells and tissues from oxidative damage. | Protection of DNA, proteins and lipids from oxidative damage. | |

| Contributes to natural immunological defenses. | Immune function/immune system. | ||

| Authorized | Beta-glucan | Beta-glucans contribute to the maintenance of normal blood cholesterol levels; Consumption of beta-glucans from oats or barley as part of a meal contributes to the reduction of the blood glucose rise after that meal. | Maintenance of normal blood cholesterol concentrations. Reduction of postprandial glycemic responses. |

| Chitosan | Chitosan contributes to the maintenance of normal blood cholesterol levels. | Maintenance of normal blood LDL-cholesterol concentrations. | |

| Plant sterols and plant stanols | Plant sterols/stanols contribute to the maintenance of normal blood cholesterol levels. | Maintenance of normal blood cholesterol concentrations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antunes, F.; Marçal, S.; Taofiq, O.; M. M. B. Morais, A.; Freitas, A.C.; C. F. R. Ferreira, I.; Pintado, M. Valorization of Mushroom By-Products as a Source of Value-Added Compounds and Potential Applications. Molecules 2020, 25, 2672. https://doi.org/10.3390/molecules25112672

Antunes F, Marçal S, Taofiq O, M. M. B. Morais A, Freitas AC, C. F. R. Ferreira I, Pintado M. Valorization of Mushroom By-Products as a Source of Value-Added Compounds and Potential Applications. Molecules. 2020; 25(11):2672. https://doi.org/10.3390/molecules25112672

Chicago/Turabian StyleAntunes, Filipa, Sara Marçal, Oludemi Taofiq, Alcina M. M. B. Morais, Ana Cristina Freitas, Isabel C. F. R. Ferreira, and Manuela Pintado. 2020. "Valorization of Mushroom By-Products as a Source of Value-Added Compounds and Potential Applications" Molecules 25, no. 11: 2672. https://doi.org/10.3390/molecules25112672

APA StyleAntunes, F., Marçal, S., Taofiq, O., M. M. B. Morais, A., Freitas, A. C., C. F. R. Ferreira, I., & Pintado, M. (2020). Valorization of Mushroom By-Products as a Source of Value-Added Compounds and Potential Applications. Molecules, 25(11), 2672. https://doi.org/10.3390/molecules25112672