The Polychromatic Woodburytype—Colour Tracking in Translucent, Patterned Gelatin/Pigment Films

Abstract

1. Introduction

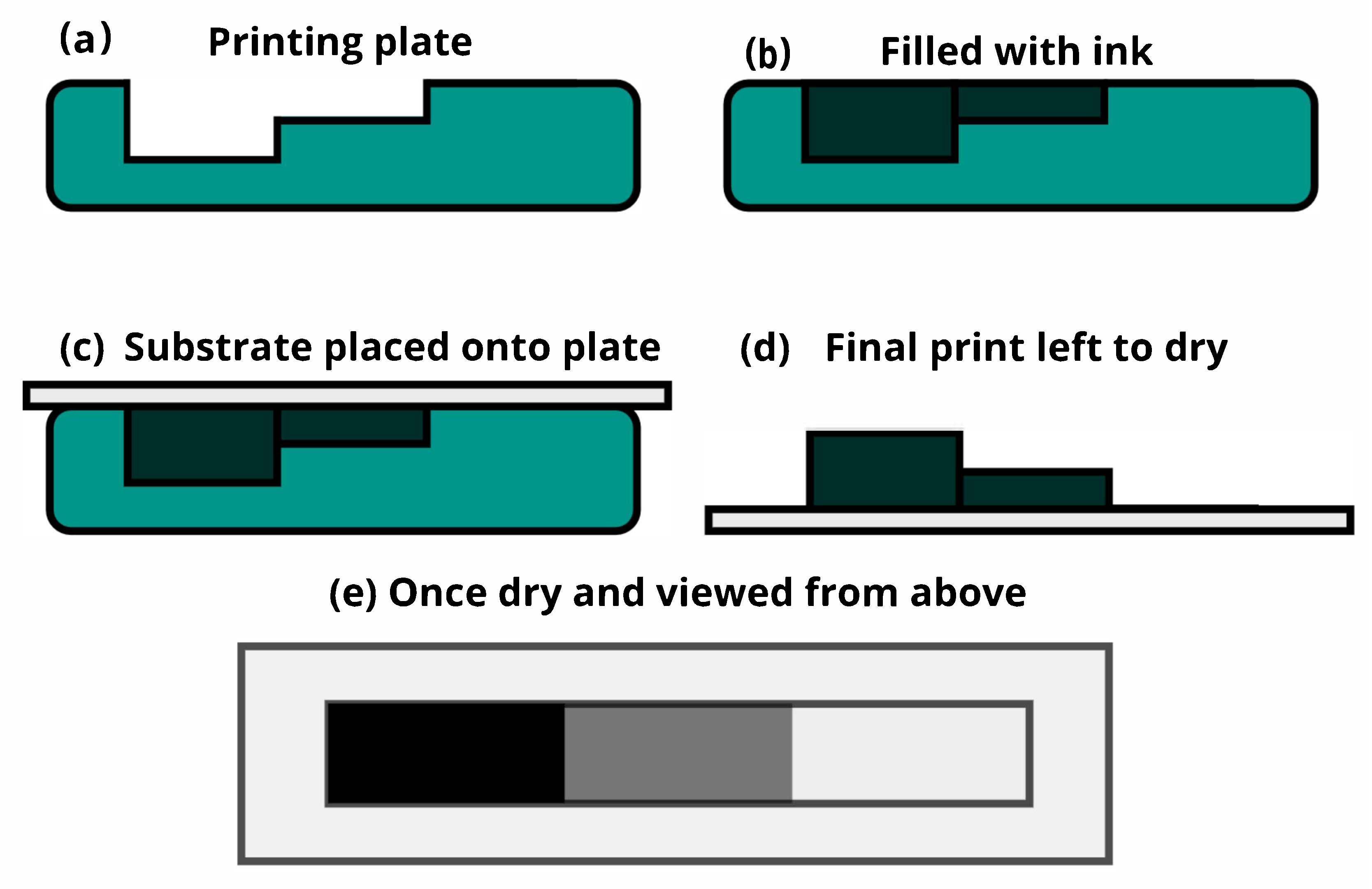

- A relief printing plate is constructed, with the aid of a CNC mill or photopolymer plate. The depth of the relief dictates the lightness of the print at each point. The deeper it is, the darker the print will be.

- A gelatin-based medium is mixed and pigmented to create the ink.

- The printing plate is filled with the gelatin ink, compressed against the substrate and left to set.

- Once set, the substrate is pulled from the plate and the print is left to dry in ambient conditions.

2. Materials

2.1. Ink Formulation

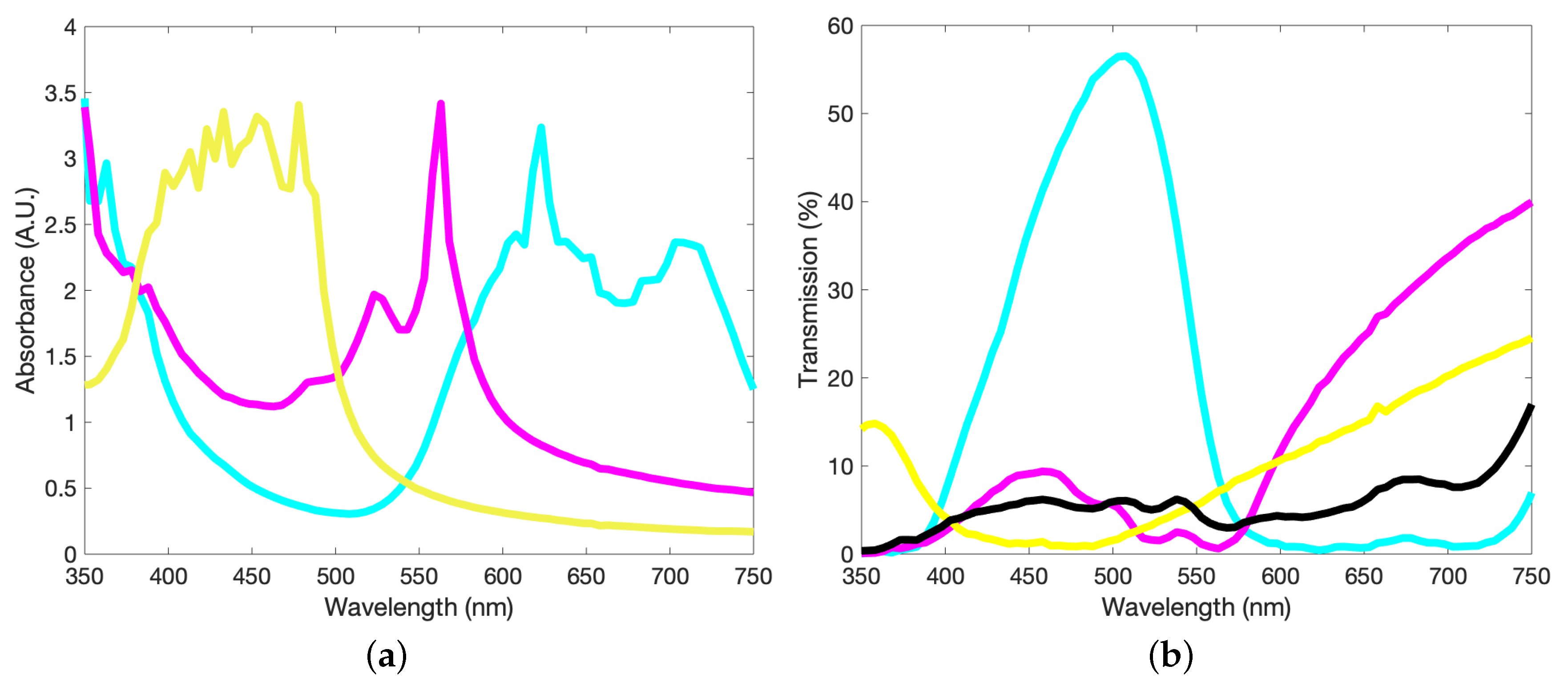

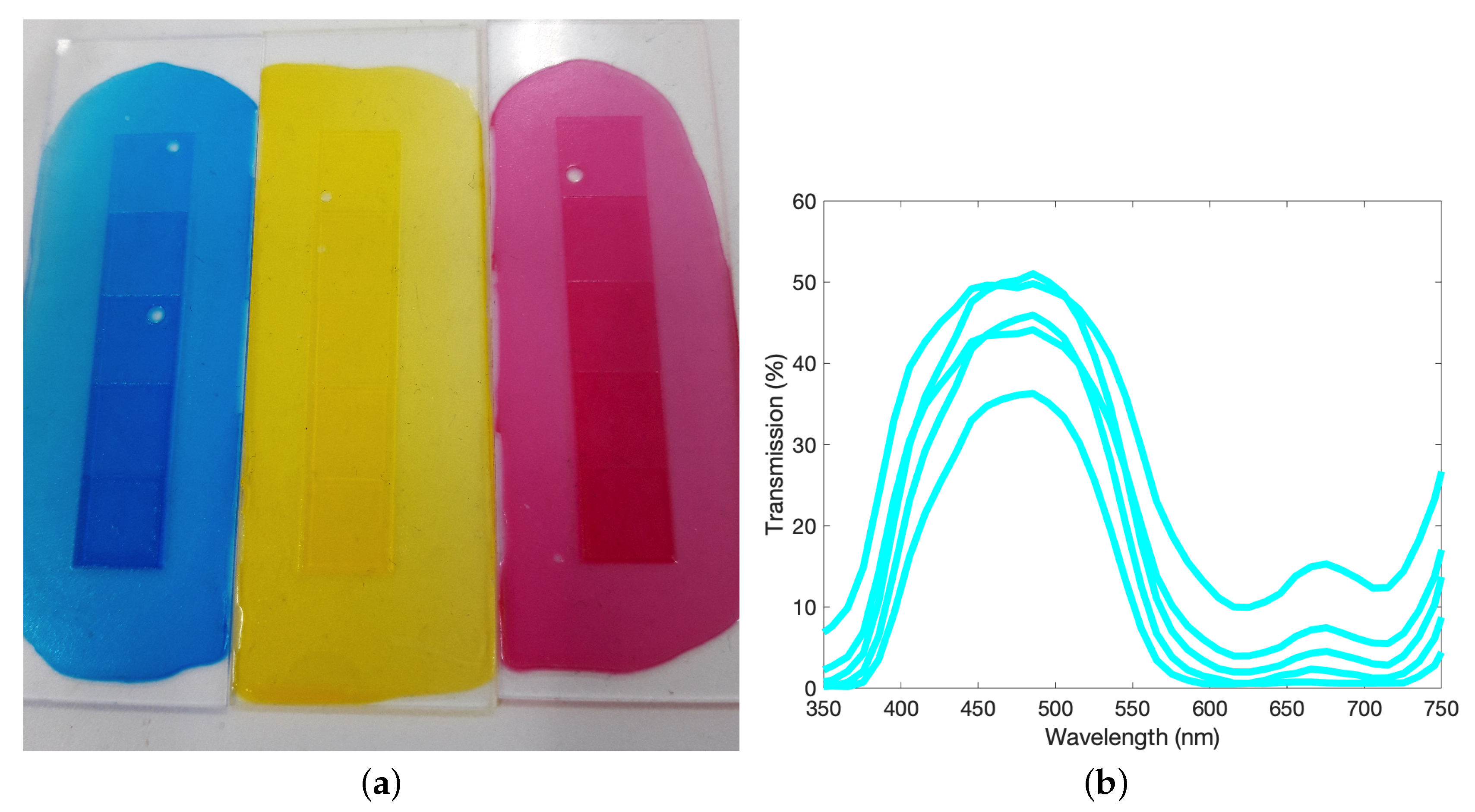

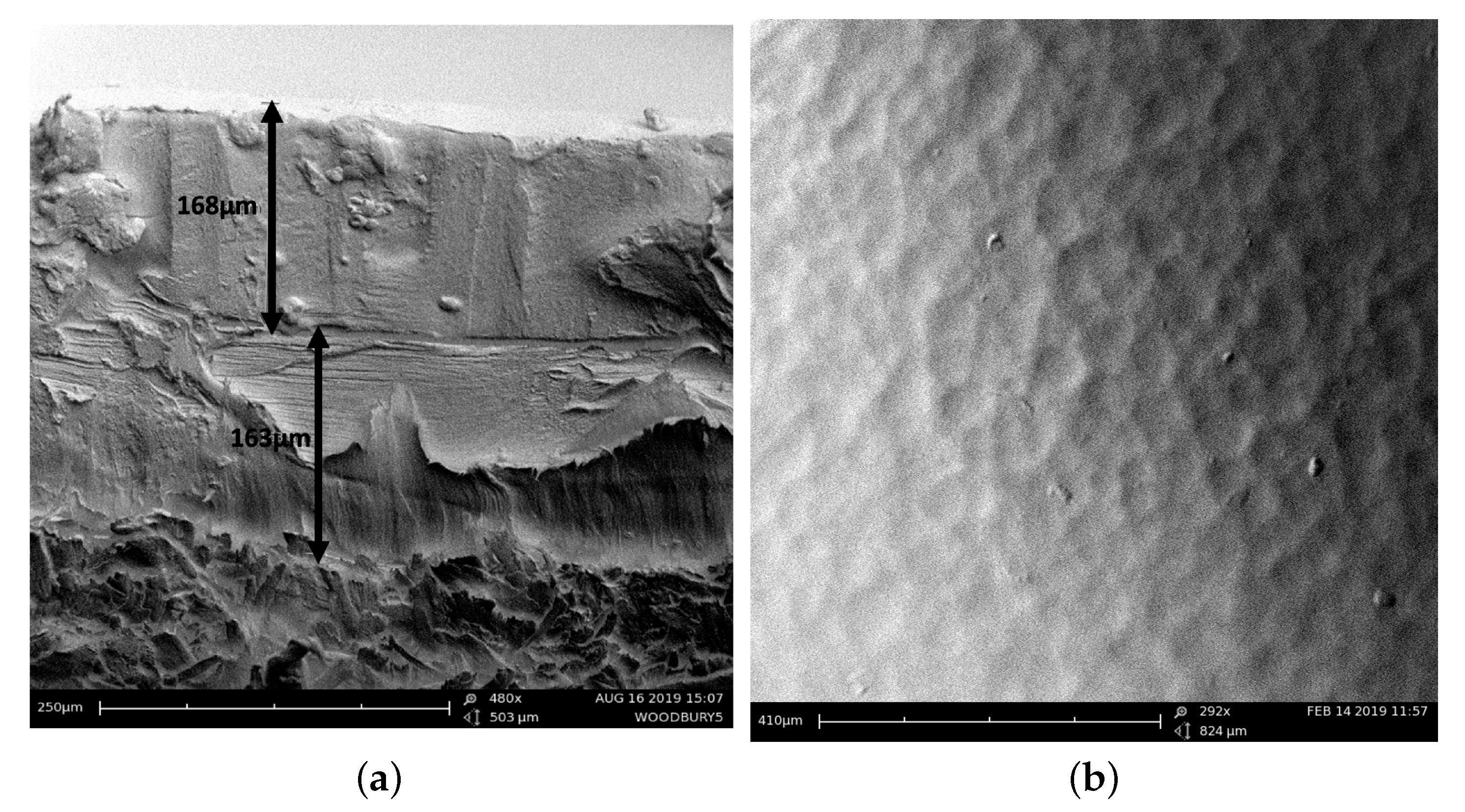

2.2. Ink Characterisation

3. Results and Discussion

3.1. Multi-Layer Printing Process

- Construct plates that colour separate the image and take into account the uneven print surface caused by prior printed layers.

- “Neutralise” the print topography by adding layers of un-pigmented gelatin to each print layer and ensuring we always print on a flat surface.

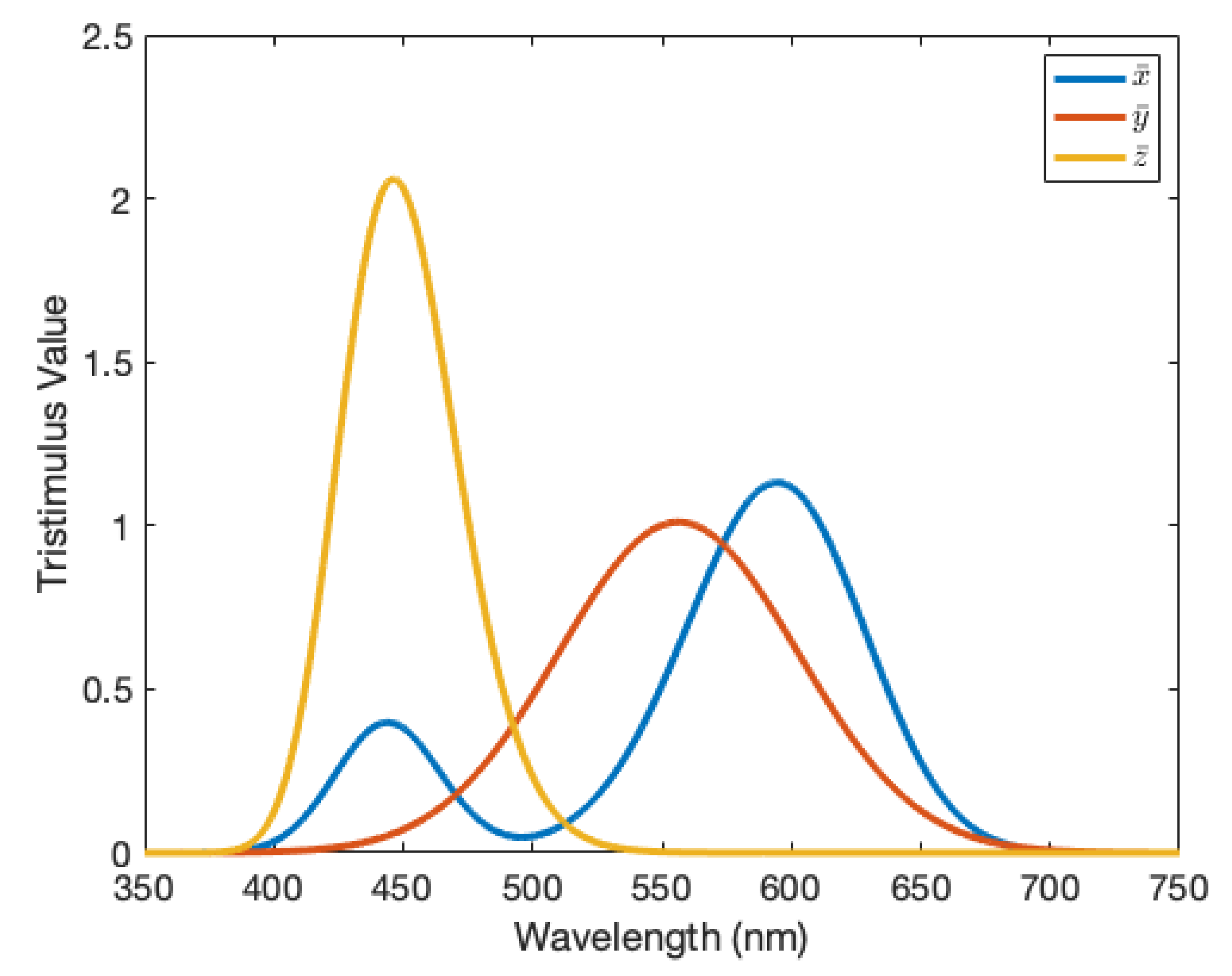

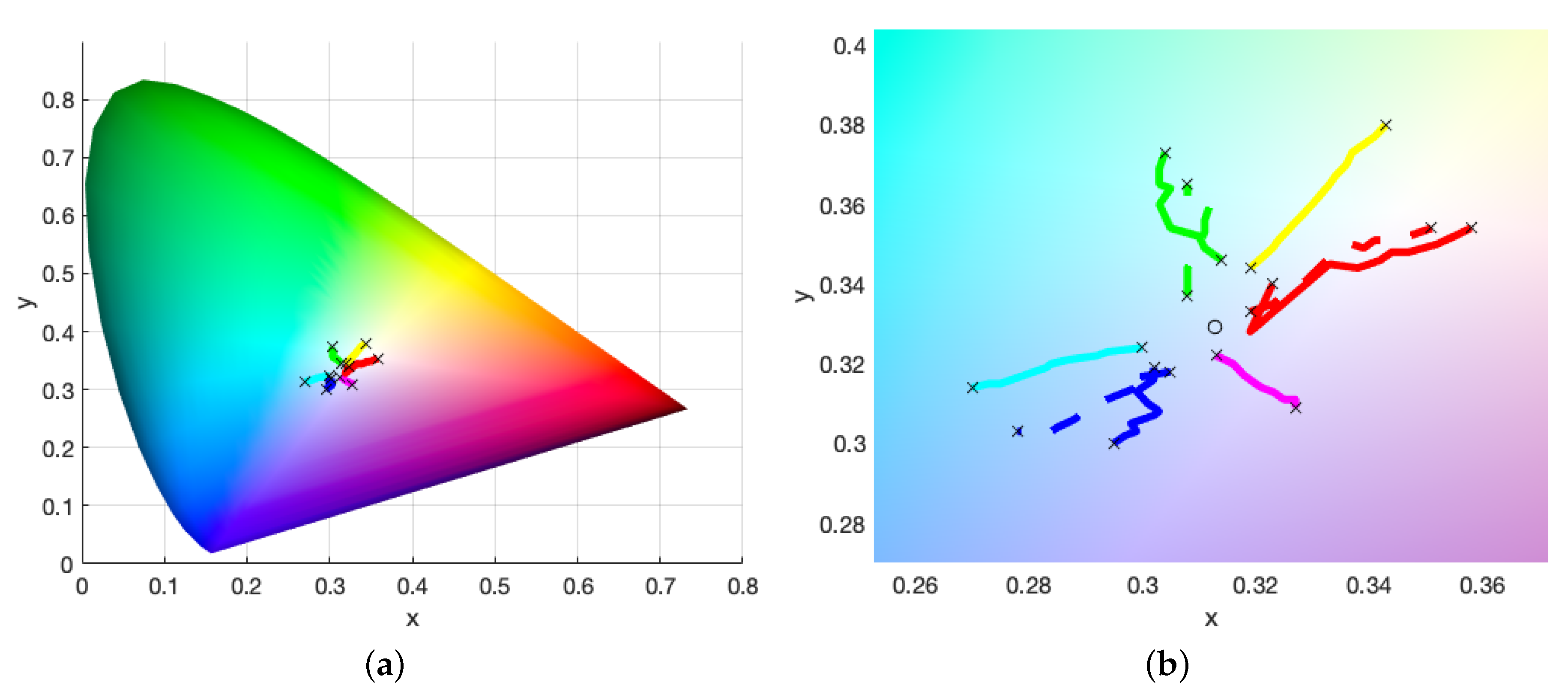

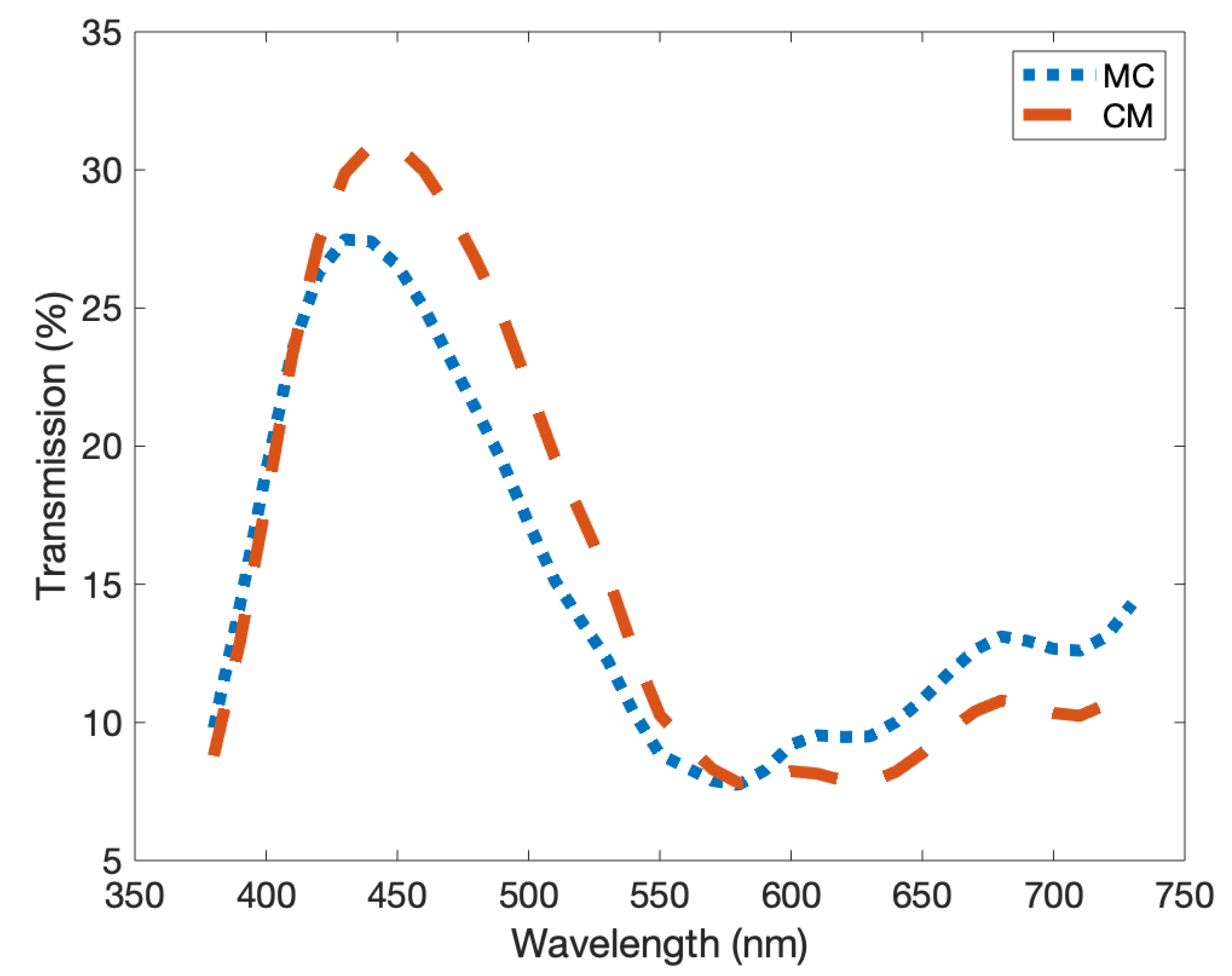

3.2. Colourimetric Measurements & Optical Models

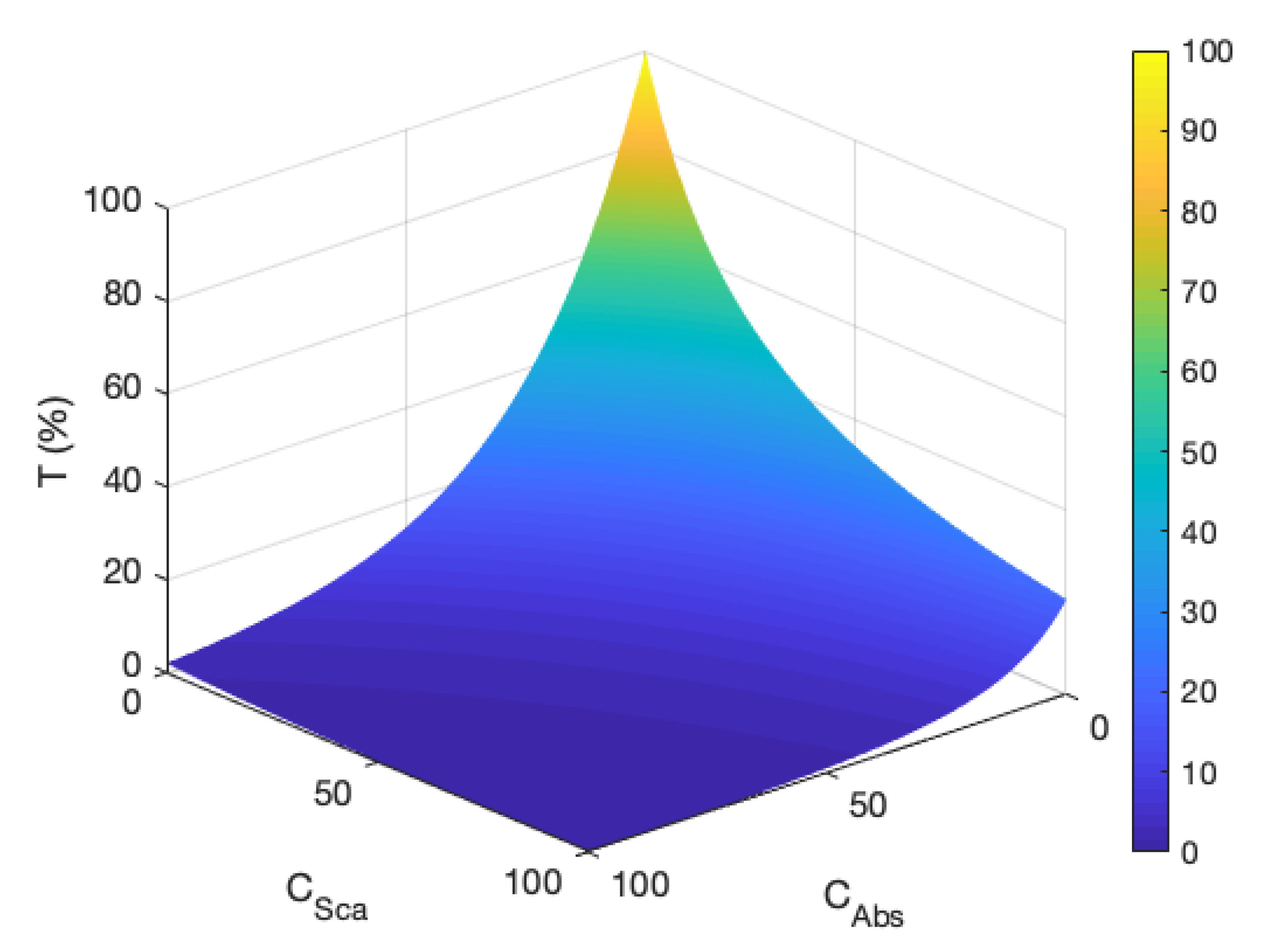

3.2.1. Kubelka–Munk Theory

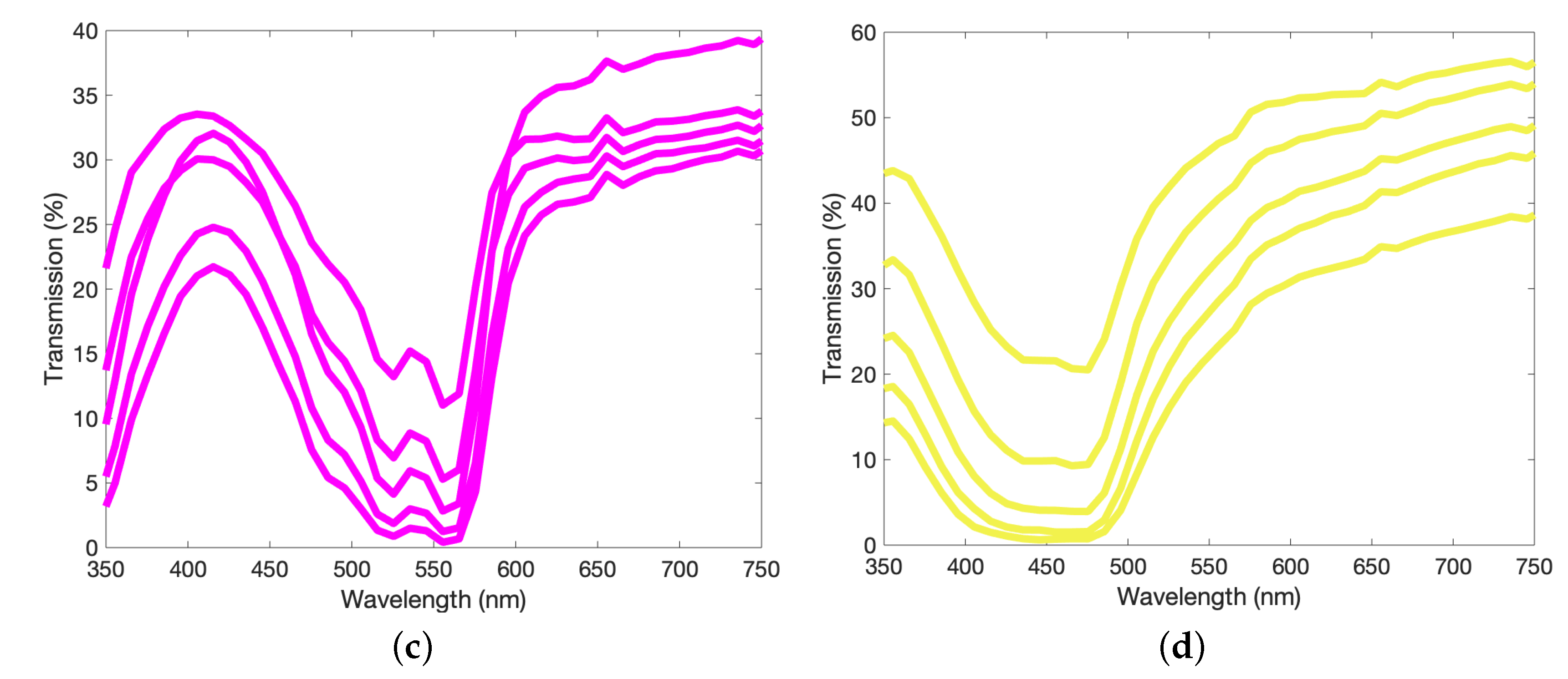

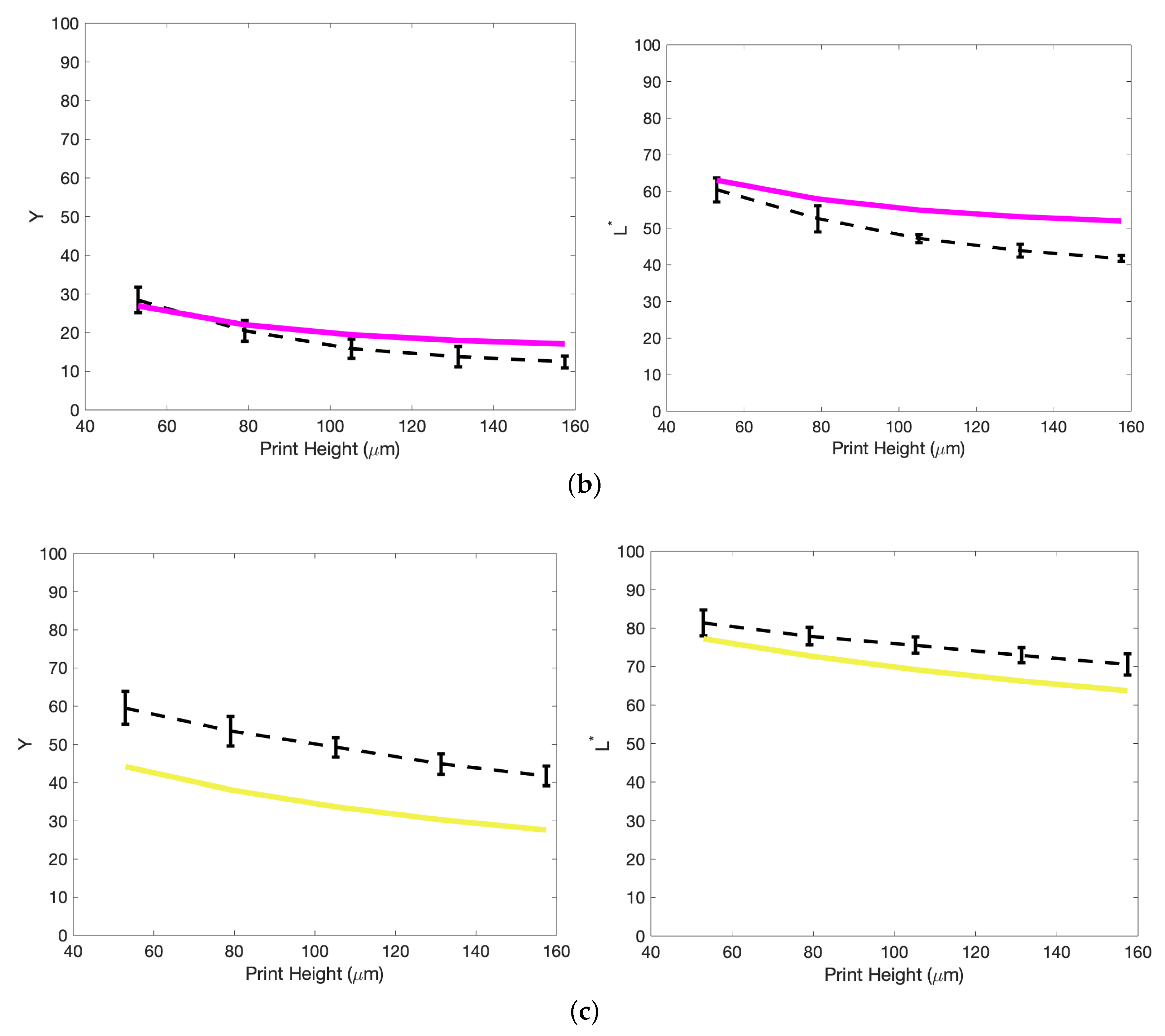

3.2.2. Colour Tracking with Print Height

3.2.3. Empirical Model

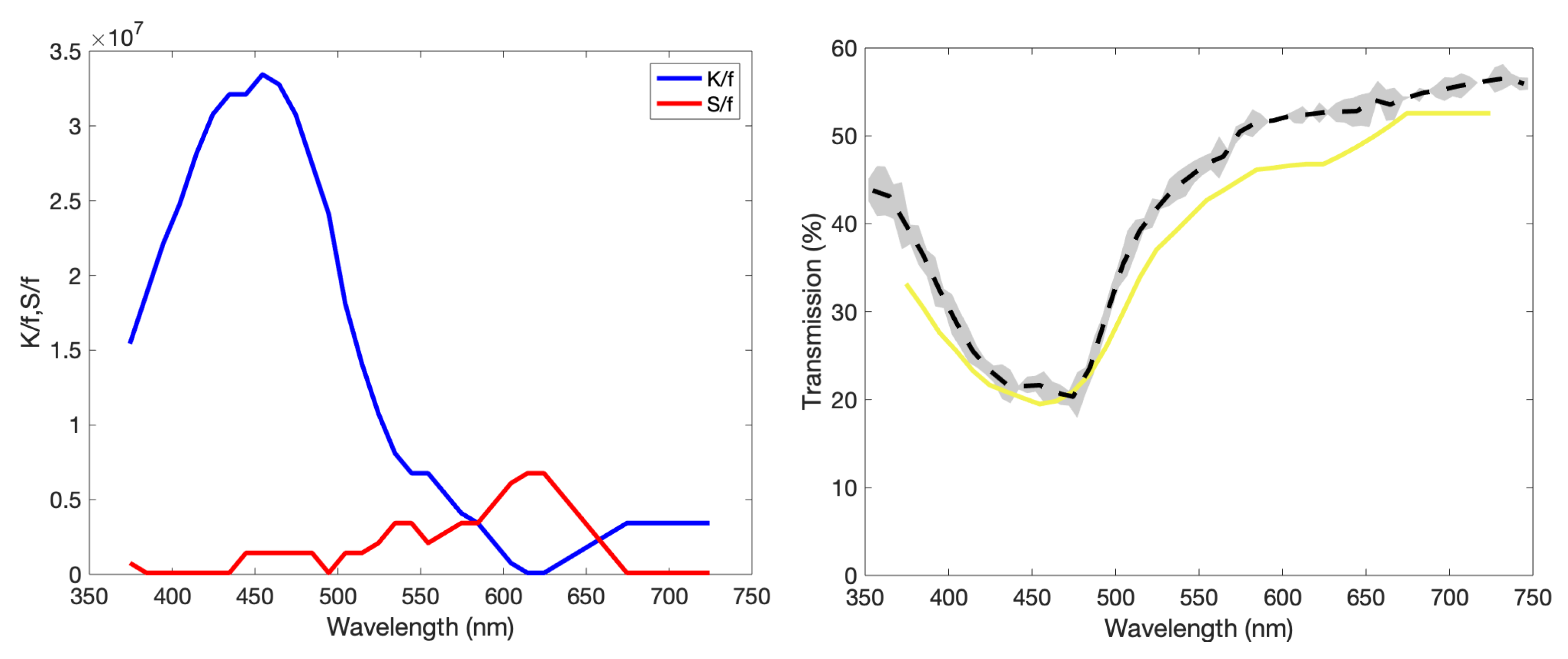

3.2.4. and Determination

3.2.5. Colour Prediction

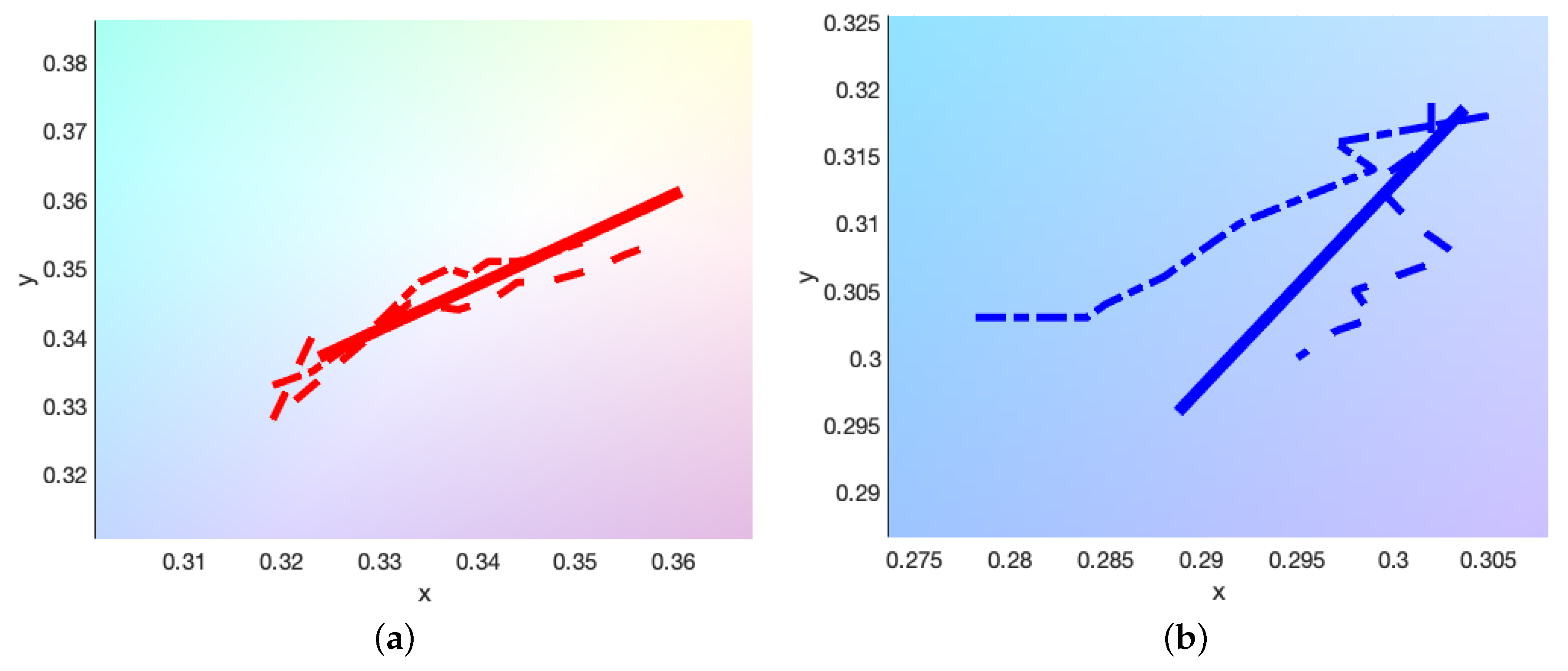

3.3. Colour Space

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Image Lightness Scaling

References

- Chen, G.; Chen, C.; Yu, Z.; Yin, H.; He, L.; Yuan, J. Color 3D Printing: Theory, method, and application. New Trends Print. 2016, 25–51. [Google Scholar] [CrossRef]

- Ming, L.W.; Gibson, I. Possibility of colouring SLS prototypes using the ink-jet method. Rapid Prototyp. J. 1999, 5, 152–154. [Google Scholar] [CrossRef]

- Walters, P.; Huson, D.; Parraman, C.; Stanić, M. 3D printing in colour: Technical evaluation and creative applications. In Proceedings of the Impact 6 International Printmaking Conference, Bristol, UK, 16–19 September 2009. [Google Scholar]

- Stanić, M.; Lozo, B.; Muck, T.; Jamnicki, S.; Kulčar, R. Color measurements of three-dimensional ink-jet prints. NIP Digit. Fabr. Conf. 2008, 2, 623–626. [Google Scholar]

- Cherdo, L. The 10 Best Full-Color 3D Printers in 2020 Aniwaa. Available online: https://www.aniwaa.com/buyers-guide/3d-printers/best-full-color-3d-printer/ (accessed on 7 March 2020).

- Fontaine, P. Multicolor 3D Printer—A Simple Guide All3DP. Available online: https://all3dp.com/2/color-3d-printer-how-to-get-colorful-3d-prints/ (accessed on 22 April 2020).

- McCallion, P. The Development of Methods for the Reproduction in Continuous Tone of Digitally Printed Colour Artworks. Ph.D. Thesis, University of the West of England, Bristol, UK, 2017. [Google Scholar]

- Leech, D.J.; Guy, W.; Klein, S. The Optical Properties of the Woodburytype—An Alternative Printing Technique Based on a Gelatine/Pigment Matrix. In Proceedings of the NIP & Digital Fabrication Conference, Printing for Fabrication 2019, San Francisco, CA, USA, 29 September–2 November 2019; pp. 42–47. [Google Scholar]

- Leech, D.J.; Guy, W.; Klein, S. The Optical Properties of the Woodburytype—An Alternative Printing Technique Based on a Gelatine/Pigment Matrix. J. Phys. Commun. 2020, 4, 015018. [Google Scholar] [CrossRef]

- Klein, S.; Guy, W.; Leech, D.; Argyle, J. Woodburytype: A historical process resurrected by modern methods. Impact 2020, 1. Available online: http://www.impactprintmaking.com/article/spring2020-woodburytype-a-historical-process-resurrected-by-modern-methods/ (accessed on 25 May 2020).

- Tytgat, L.; Kollert, M.R.; Van Damme, L.; Thienpont, H.; Ottevaere, H.; Duda, G.N.; Geissler, S.; Dubruel, P.; Van Vlierberghe, S.; Qazi, T.H. Evaluation of 3D Printed Gelatin-Based Scaffolds with Varying Pore Size for MSC-Based Adipose Tissue Engineering. Macromol. Biosci. 2020, 20, 1900364. [Google Scholar] [CrossRef]

- Hoch, E.; Hirth, T.; Tovar, G.E.; Borchers, K. Chemical tailoring of gelatin to adjust its chemical and physical properties for functional bioprinting. J. Mater. Chem. B 2013, 1, 5675–5685. [Google Scholar] [CrossRef]

- Chen, Q.; Tian, X.; Fan, J.; Tong, H.; Ao, Q.; Wang, X. An Interpenetrating Alginate/Gelatin Network for Three-Dimensional (3D) Cell Cultures and Organ Bioprinting. Molecules 2020, 25, 756. [Google Scholar] [CrossRef]

- Panwar, A.; Tan, L.P. Current status of bioinks for micro-extrusion-based 3D bioprinting. Molecules 2016, 21, 685. [Google Scholar] [CrossRef]

- Lei, M.; Wang, X. Biodegradable polymers and stem cells for bioprinting. Molecules 2016, 21, 539. [Google Scholar] [CrossRef]

- Duconseille, A.; Gaillard, C.; Santé-Lhoutellier, V.; Astruc, T. Molecular and structural changes in gelatin evidenced by Raman microspectroscopy. Food Hydrocoll. 2018, 77, 777–786. [Google Scholar] [CrossRef]

- Duconseille, A.; Wien, F.; Audonnet, F.; Traore, A.; Refregiers, M.; Astruc, T.; Santé-Lhoutellier, V. The effect of origin of the gelatine and ageing on the secondary structure and water dissolution. Food Hydrocoll. 2017, 66, 378–388. [Google Scholar] [CrossRef]

- Tosh, S.M.; Marangoni, A.G.; Hallett, F.R.; Britt, I.J. Aging dynamics in gelatin gel microstructure. Food Hydrocoll. 2003, 17, 503–513. [Google Scholar] [CrossRef]

- Basha, M.A.F. Optical properties and colorimetry of gelatine gels prepared in different saline solutions. J. Adv. Res. 2019, 16, 55–65. [Google Scholar] [CrossRef]

- Kubelka, P.; Munk, F. Ein Beitrag zur Optik der Farbanstriche. Zeitschrift für Technische Physik 1931, 12, 593–601. [Google Scholar]

- De la Osa, R.A.; Iparragirre, I.; Ortiz, D.; Saiz, J.M. The extended Kubelka–Munk theory and its application to spectroscopy. ChemTexts 2020, 6, 2. [Google Scholar] [CrossRef]

- Bajpai, P. Biermann’s Handbook of Pulp and Paper: Volume 2: Paper and Board Making; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- McNeil, L.E.; French, R.H. Light scattering from red pigment particles: Multiple scattering in a strongly absorbing system. J. Appl. Phys. 2000, 89, 1. [Google Scholar] [CrossRef]

- Mudgett, P.S.; Richards, L.W. Multiple Scattering Calculations for Technology. Appl. Opt. 1971, 10, 1485–1502. [Google Scholar] [CrossRef]

- Quinten, M. The color of finely dispersed nanoparticles. Appl. Phys. B 2001, 73, 317–326. [Google Scholar] [CrossRef]

- Yang, L.; Kruse, B. Revised Kubelka–Munk theory. I. Theory and application. J. Opt. Soc. Am. A 2004, 21, 1933–1941. [Google Scholar] [CrossRef]

- Granberg, H.; Edström, P. Quantification of the Intrinsic Error of the Kubelka–Munk Model Caused by Strong Light Absorption. J. Pulp Pap. Sci. 2003, 29, 386–390. [Google Scholar]

- Slovick, B.; Flom, Z.; Zipp, L.; Krishnamurthy, S. Transfer matrix method for four-flux radiative transfer. Appl. Opt. 2017, 56, 5890–5896. [Google Scholar] [CrossRef]

- Rozé, C.; Girasole, T.; Tafforin, A.G. Multilayer four-flux model of scattering, emitting and absorbing media. Atmos. Environ. 2001, 35, 5125–5130. [Google Scholar] [CrossRef]

- Simonot, L.; Thoury, M.; Delaney, J. Extension of the Kubelka–Munk theory for fluorescent turbid media to a non-opaque layer on a background. JOSA A 2011, 28, 1349–1357. [Google Scholar] [CrossRef]

- Orel, Z.C.; Gunde, M.K.; Orel, B. Application of the Kubelka–Munk theory for the determination of the optical properties of solar absorbing paints. Prog. Org. Coat. 1997, 30, 59–66. [Google Scholar] [CrossRef]

- Orel, Z.C.; Gunde, M.K.; Hutchins, M.G. Spectrally selective solar absorbers in different non-black colours. Sol. Energy Mater. Sol. Cells 2005, 85, 41–50. [Google Scholar]

- Koirala, P.; Hauta-Kasari, M.; Martinkauppi, B.; Hiltunen, J. Color Mixing and Color Separation of Pigments with Concentration Prediction. Color Res. Appl. 2008, 33, 461–469. [Google Scholar] [CrossRef]

- Schanda, J. Colorimetry: Understanding the CIE System; CIE Central Bureau: Vienna, Austria, 2006. [Google Scholar]

- Vega Gutierrez, S.M.; Stone, D.W.; Konkler, M.J.; Groth, E.N.; Robinson, S.C. Relationship between molarity and color in the crystal (‘dramada’) produced by Scytalidium cuboideum, in two solvents. Molecules 2018, 23, 2581. [Google Scholar] [CrossRef]

- Wyman, C.; Sloan, P.P.; Shirley, P. Simple Analytic Approximations to the CIE XYZ Color Matching Functions. J. Comput. Graph. Tech. 2013, 2, 2. [Google Scholar]

- Diana, R.; Caruso, U.; Piotto, S.; Shikler, R.; Panunzi, B. Spectroscopic Behaviour of Two Novel Azobenzene Fluorescent Dyes and Their Polymeric Blends. Molecules 2020, 25, 1368. [Google Scholar] [CrossRef]

- MacAdam, D.L. Visual sensitivities to color differences in daylight. JOSA 1942, 32, 247–274. [Google Scholar] [CrossRef]

- Goldstein, P. Non-MacAdam color discrimination ellipses. Nov. Opt. Syst. Des. Optim. XV Int. Soc. Opt. Photonics 2012, 8487, 84870A. [Google Scholar]

- Lucchese, L.; Mitra, S.K. Filtering color images in the xyY color space. In Proceedings of the IEEE International Conference on Image Processing, Vancouver, BC, Canada, 10–13 September 2000; Volume 3, pp. 500–503. [Google Scholar]

- Tesfamichael, T.; Hoel, A.; Niklasson, G.A.; Wäckelgård, E.; Gunde, M.K.; Orel, Z.C. Optical characterization method for black pigments applied to solar-selective absorbing paints. Appl. Opt. 2001, 40, 1672–1681. [Google Scholar] [CrossRef] [PubMed]

- Optprop—A Color Properties Toolbox. Available online: https://uk.mathworks.com/matlabcentral/fileexchange/13788-optprop-a-color-properties-toolbox (accessed on 26 March 2020).

| Cyan | Magenta | Yellow | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Print Height (mm) | |||||||||

| 0.049 | 59.96 | −36.20 | −38.90 | 60.46 | 53.61 | −20.40 | 81.43 | −12.30 | 42.65 |

| 0.075 | 54.83 | −34.03 | −44.17 | 52.57 | 67.05 | −20.14 | 77.92 | −15.10 | 60.11 |

| 0.101 | 50.46 | −30.41 | −47.43 | 47.17 | 71.18 | −15.04 | 75.62 | −16.48 | 74.69 |

| 0.127 | 47.08 | −26.08 | −49.21 | 43.89 | 71.23 | −9.48 | 72.93 | −17.02 | 87.68 |

| 0.154 | 43.79 | −22.04 | −49.89 | 41.73 | 69.50 | −3.67 | 70.58 | −16.92 | 92.77 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leech, D.J.; Guy, W.; Klein, S. The Polychromatic Woodburytype—Colour Tracking in Translucent, Patterned Gelatin/Pigment Films. Molecules 2020, 25, 2468. https://doi.org/10.3390/molecules25112468

Leech DJ, Guy W, Klein S. The Polychromatic Woodburytype—Colour Tracking in Translucent, Patterned Gelatin/Pigment Films. Molecules. 2020; 25(11):2468. https://doi.org/10.3390/molecules25112468

Chicago/Turabian StyleLeech, Damien Jon, Walter Guy, and Susanne Klein. 2020. "The Polychromatic Woodburytype—Colour Tracking in Translucent, Patterned Gelatin/Pigment Films" Molecules 25, no. 11: 2468. https://doi.org/10.3390/molecules25112468

APA StyleLeech, D. J., Guy, W., & Klein, S. (2020). The Polychromatic Woodburytype—Colour Tracking in Translucent, Patterned Gelatin/Pigment Films. Molecules, 25(11), 2468. https://doi.org/10.3390/molecules25112468