Efficient Extraction of Anti-Inflammatory Active Ingredients from Schefflera octophylla Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with HPLC

Abstract

1. Introduction

2. Results and Discussion

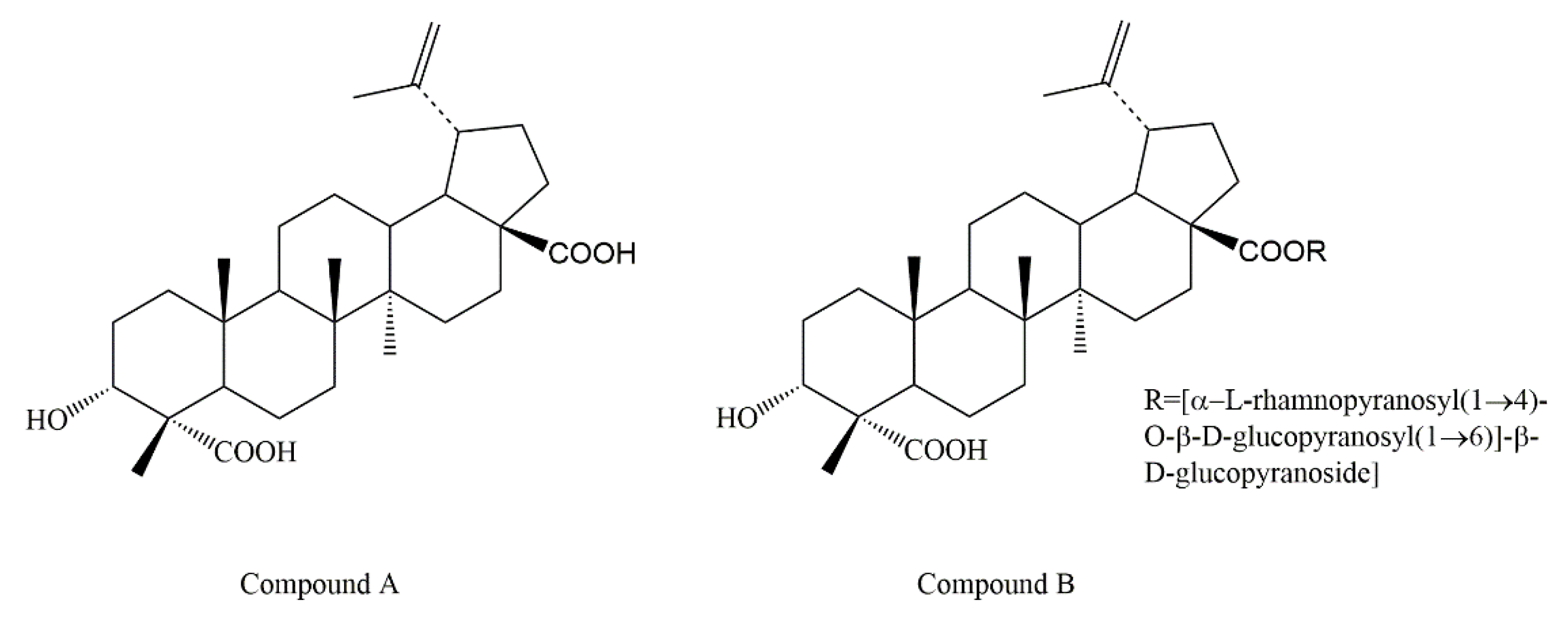

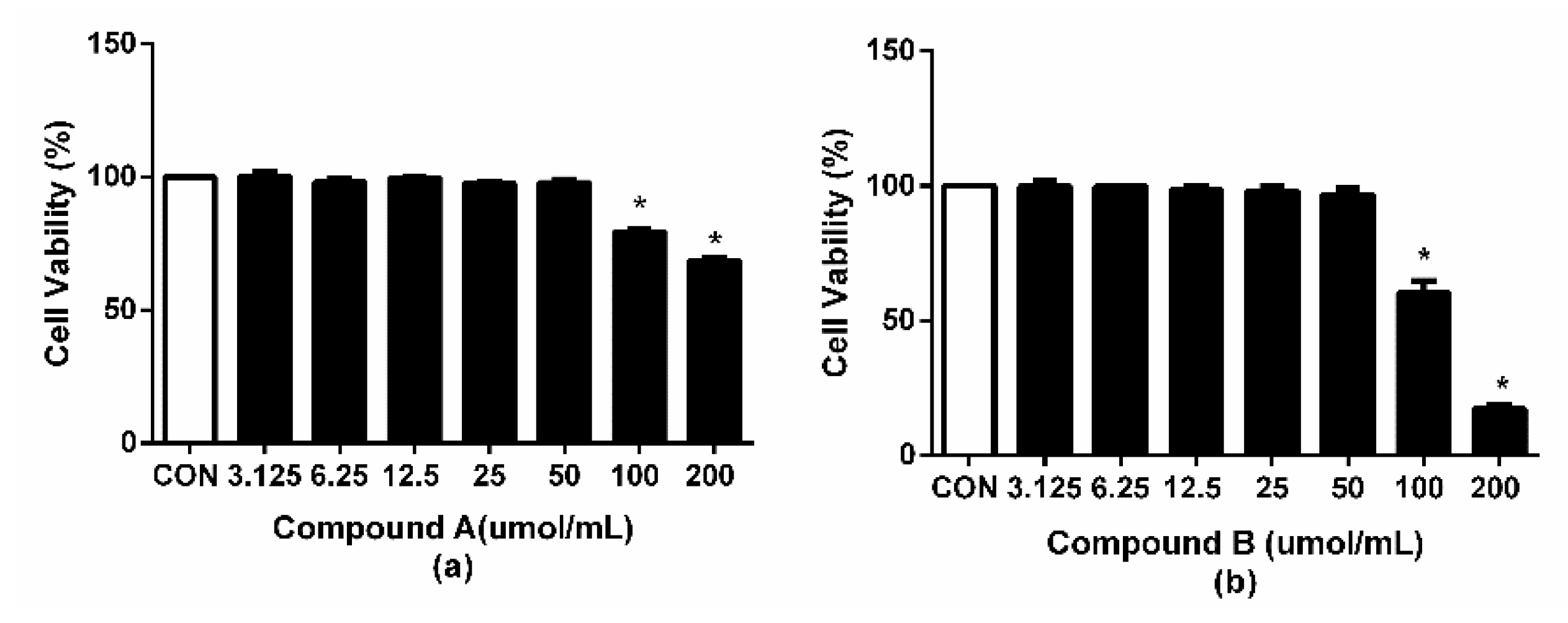

2.1. Effects of Compound A and Compound B on Cells Viability

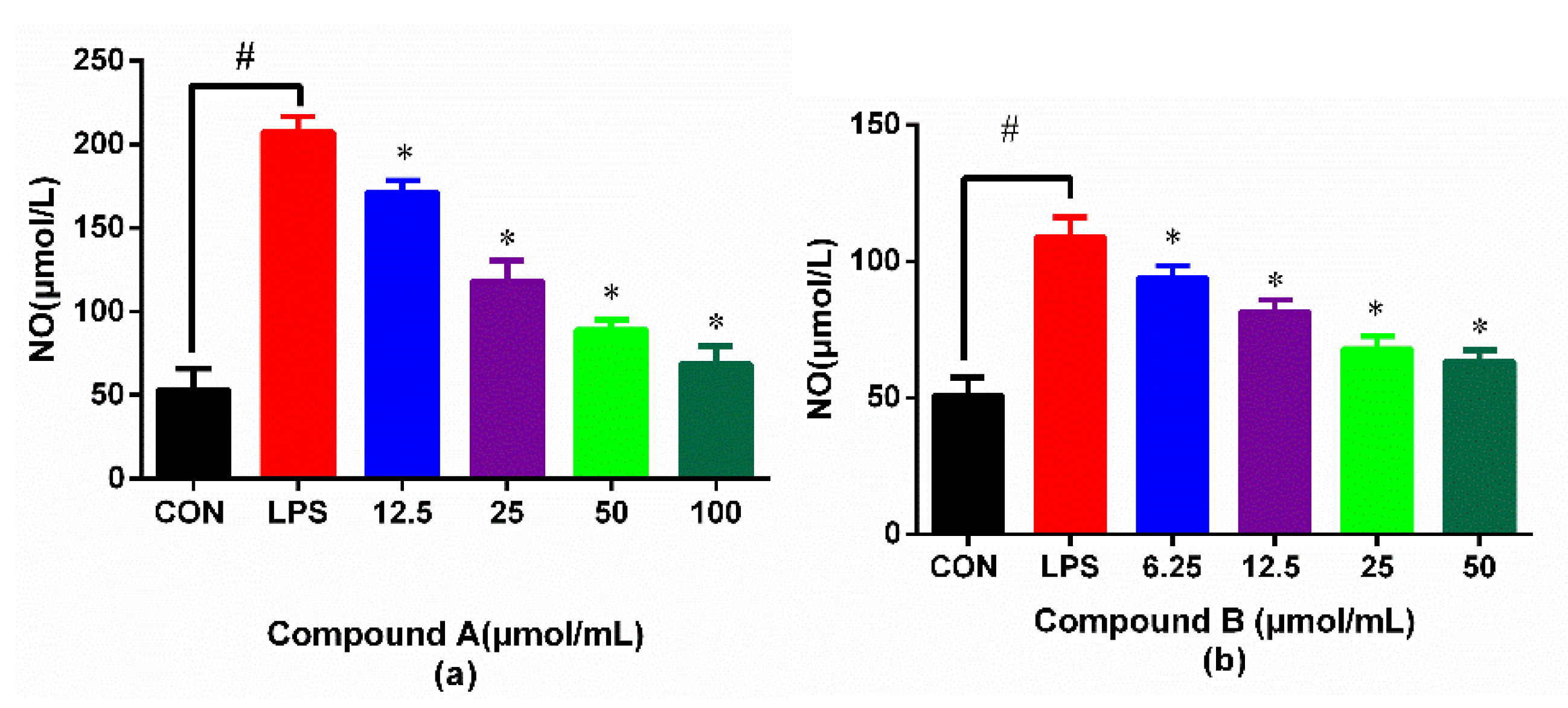

2.2. Effects of Compound A and Compound B on NO Production in Lipopolysaccharide (LPS)-Induced RAW 264.7 Macrophages

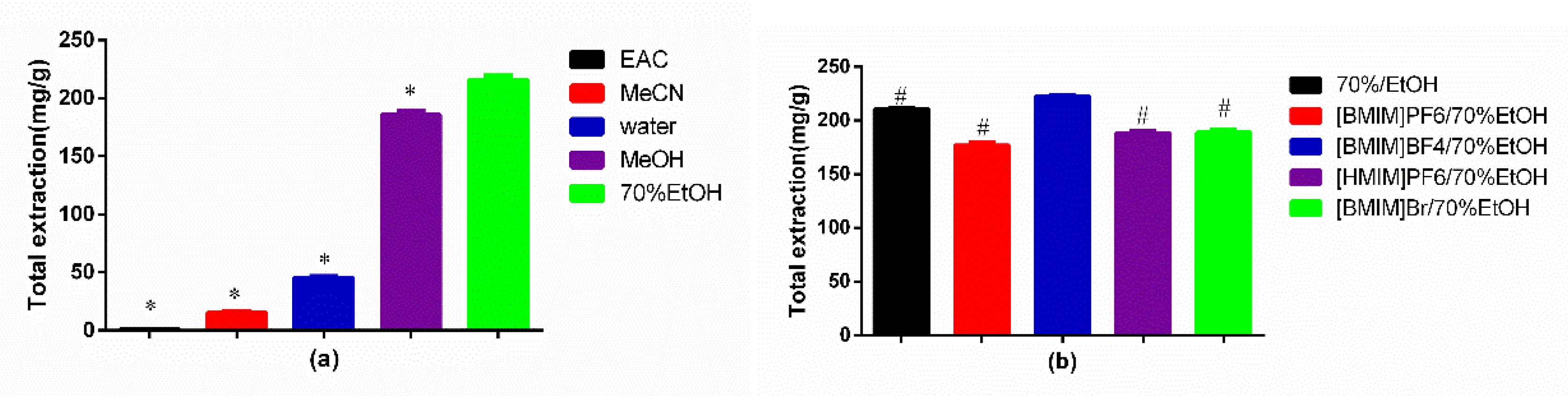

2.3. Selection of ILs

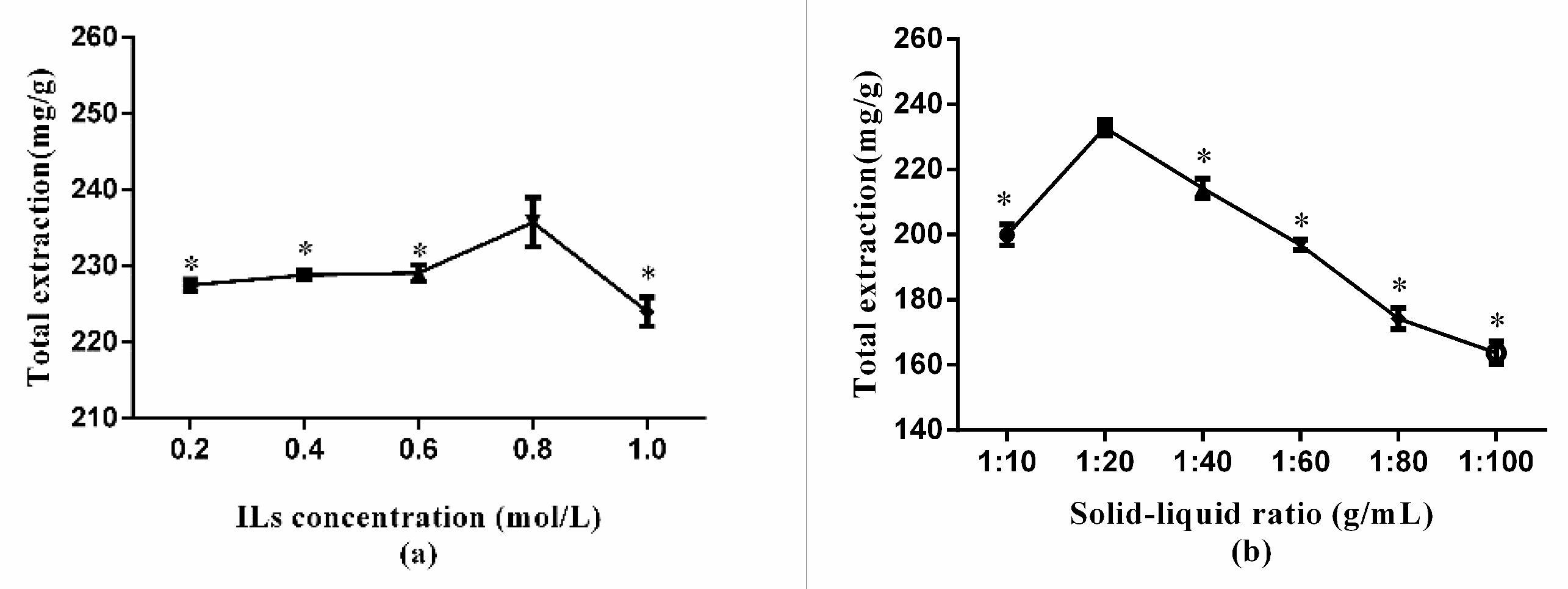

2.4. Single Factor Experiments

2.4.1. Selection of the Concentrations of ILs

2.4.2. Selection of Solid–Liquid Ratio

2.4.3. Selection of Mesh Number

2.4.4. Selection of Ultrasonic Time

2.4.5. Selection of Centrifugal Speed

2.4.6. Selection of Ultrasonic Power

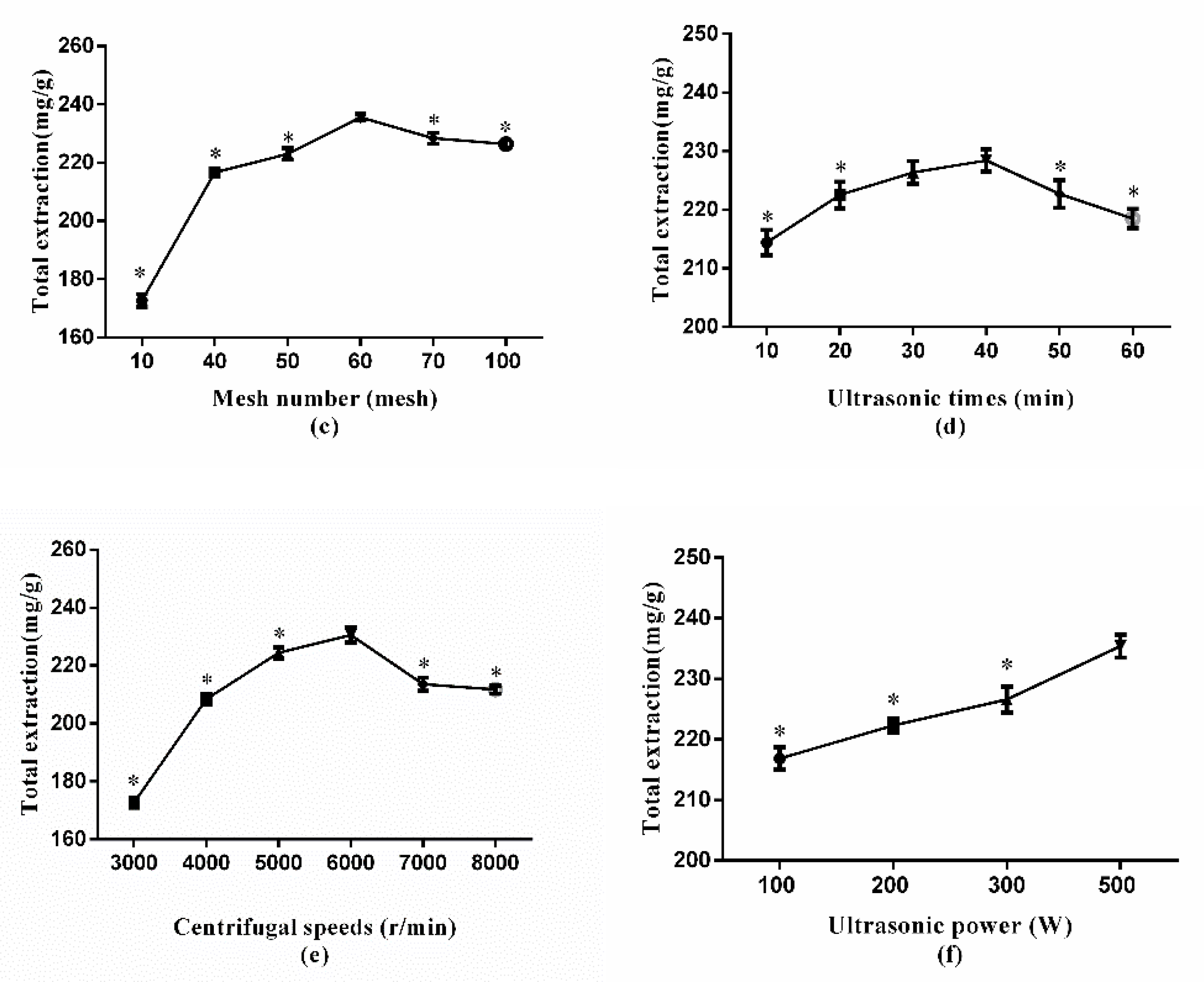

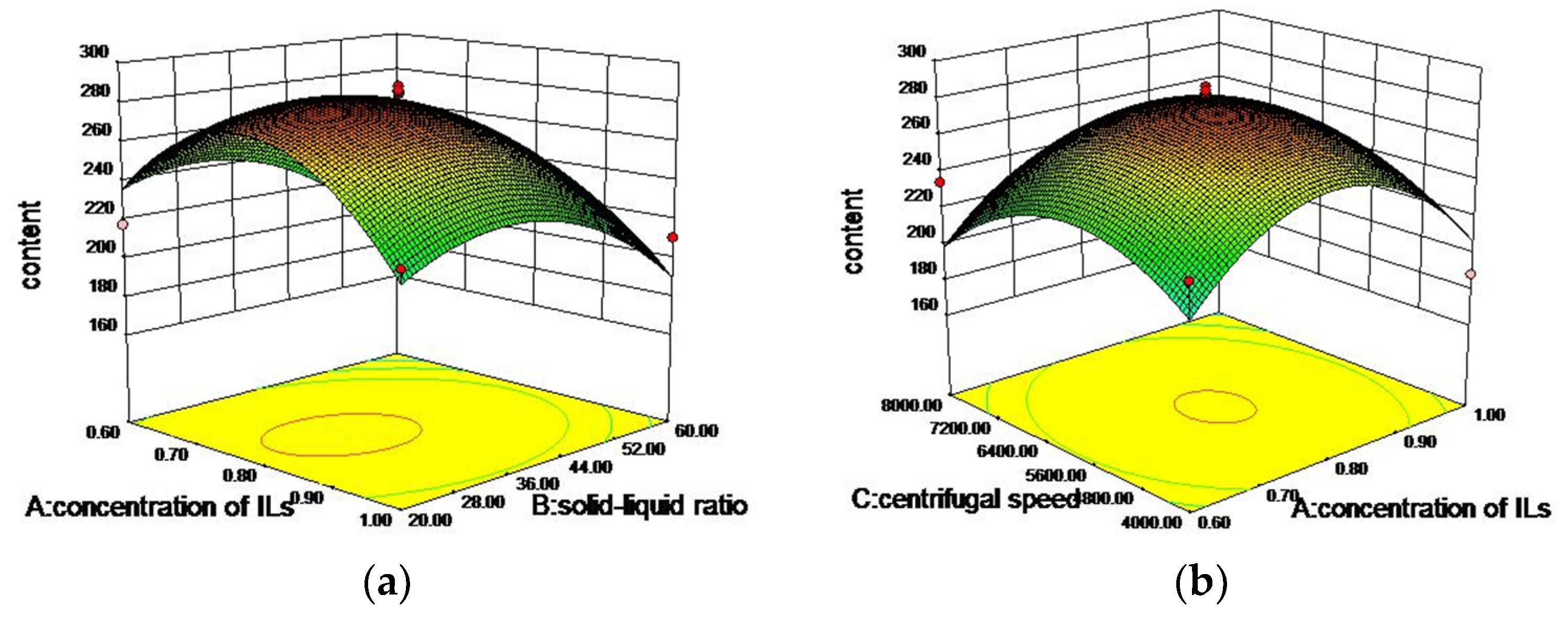

2.5. Using Response Surface Method (RSM) to Optimize the Experimental Design

2.6. Comparison with Conventional Solvents Extraction

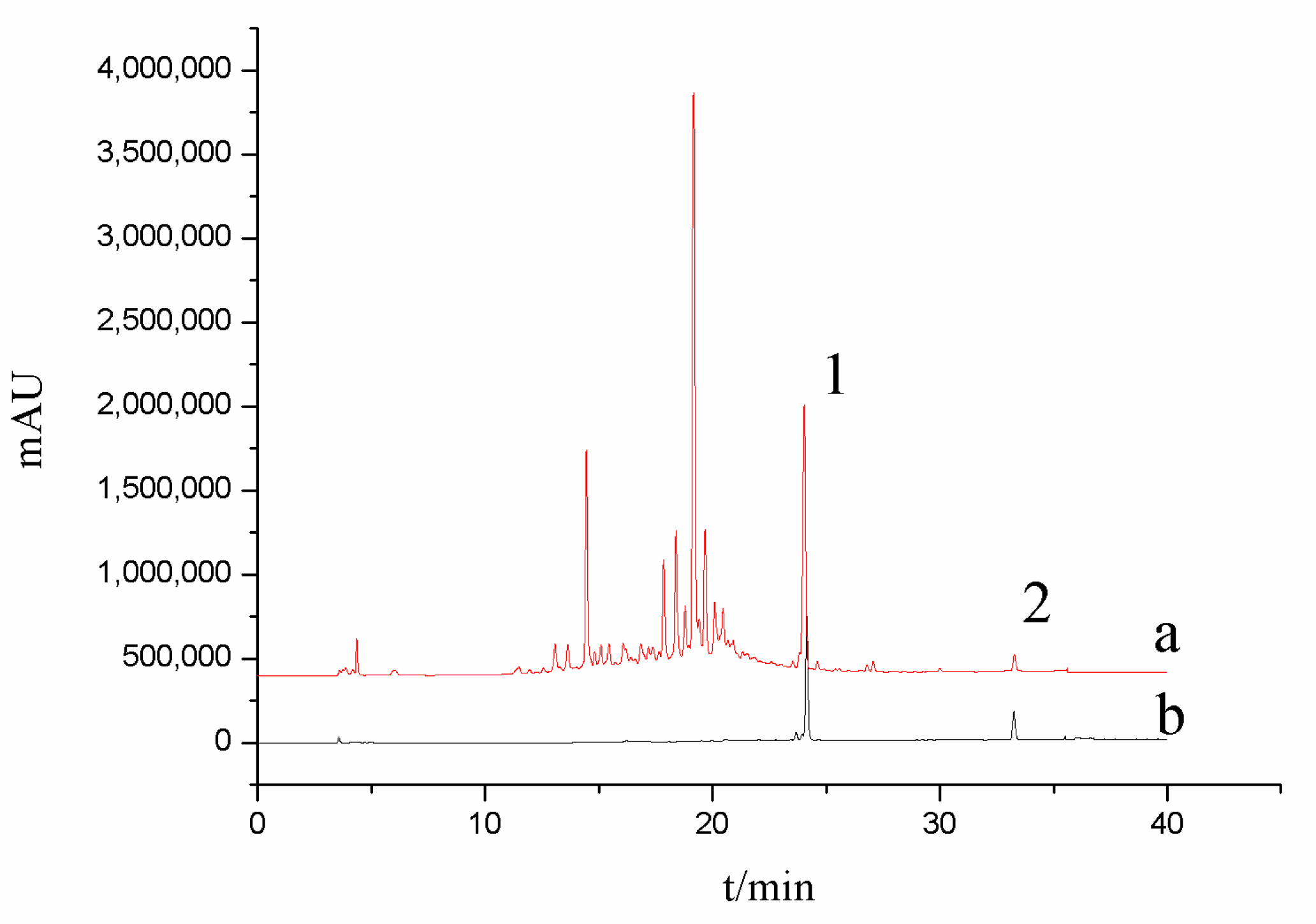

2.7. Method Validation

3. Materials and Methods

3.1. Chemicals and Materials

3.2. Plant Materials

3.3. Cell Culture and Treatment

3.4. Cell Viability Assay

3.5. Nitric Oxide (NO) Assay

3.6. Preparation of the Standard Solution and Test Sample Solution

3.7. Graphic Conditions

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Editorial Committee of Chinese Materia Medica, Chinese Materia Medica, Frsted; Shanghai Science and Technology Press: Shanghai, China, 1999; Volume 5, pp. 859–867.

- Liu, P.P. Studies on the Anticancer Active Components of the Leaves of Panax senanus. Ph.D. Thesis, Liaoning University of Traditional Chinese Medicine, Shenyang, China, 2010. [Google Scholar]

- Li, Y.L.; Jiang, R.W.; Ooi, L.S.; But, P.P.; Ooi, V.E. Antiviral Triterpenoids from the Medicinal Plant Schefflera heptaphylla. Phytother. Res. 2007, 21, 466–470. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Q.; Zou, Q.P.; Huang, J.J.; Yook, C.S.; Whang, W.K.; Lee, H.K.; Kwon, O.K. Inhibitory effects of 3α-hydroxy-lup-20(29)-en-23, 28-dioic acid on lipopolysaccharide-induced TNF-α, IL-1β, and the high mobility group box 1 release in macrophages. Biosci. Biotechnol. Biochem. 2017, 81, 1305–1313. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.F.; Tao, S.H.; Zeng, F.L.; Xie, L.W.; Shen, Z.B. Antinociceptive and anti-inflammatory activities of Schefflera octophylla extracts. J. Ethnopharmacol. 2015, 171, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Adam, G.; Lischewski, M.; Phiet, H.V.; Preiss, A.; Schmidt, J.; Sung, T.V. Natural products from Vietnamese plants. Part 6. 3-Hydroxy-lup-20(29)-ene-23, 28-dioic acid from Schefflera octophylla. Phytochemistry 1982, 21, 1385–1387. [Google Scholar] [CrossRef]

- Kitajima, J.; Tanaka, Y. Two new triterpenoid glycosides from the leaves of Schefflera octophylla. Chem. Pharm. Bull. 1989, 37, 2727–2730. [Google Scholar] [CrossRef]

- Kitajima, J.; Shindo, M.; Tanako, Y. Two new triterpenoid sulfates from the leaves of Schefflera octophylla. Chem. Pharm. Bull. 1990, 38, 714–716. [Google Scholar] [CrossRef]

- Maeda, C.; Ohtani, K.; Kasai, R.; Yamasaki, K.; Duc, N.M.; Nham, N.T.; Cu, N.K.Q. Oleanane and ursane glycosides from Schefflera octophylla. Phytochemistry 1994, 37, 1131–1137. [Google Scholar] [CrossRef]

- Sung, T.V.; Lavaud, C.; Porzel, A.; Steglich, W.; Adam, G. Triterpenoids and their glycosides from the bark of Schefflera octophylla. Phytochemistry 1992, 31, 227–231. [Google Scholar] [CrossRef]

- Sung, T.V.; Steglich, W.; Adam, G. Triterpene glycosides from Schefflera octophylla. Phytochemistry 1991, 30, 2349–2356. [Google Scholar] [CrossRef]

- Sung, T.V.; Adam, G. An acetylated bidesmosidic saponin from Schefflera octophylla. J. Nat. Prod. 1992, 55, 503–505. [Google Scholar] [CrossRef]

- Sung, T.V.; Katalinic, P.; Adam, G. A bidesmosidic triterpenoid saponin from Scheflerra octophylla. Phytochemistry 1991, 30, 3717–3720. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Zu, Y.G.; Zhao, C.J.; Zhang, L.; Chen, X.Q.; Zhang, Z.H. Ultrasound-assisted extraction of the three terpenoid indole alkaloids vindoline, catharanthine and vinblastine from Catharanthus roseus using ionic liquid aqueous solutions. Chem. Eng. J. 2011, 172, 705–712. [Google Scholar] [CrossRef]

- Tan, Z.J.; Yi, Y.J.; Wang, H.Y.; Zhou, W.L.; Wang, C.Y. Extraction, Preconcentration and Isolation of Flavonoids from Apocynum venetum L. Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with an Aqueous Biphasic System. Molecules 2016, 21, 262. [Google Scholar] [CrossRef]

- Wang, L.L.; Bai, M.G.; Qin, Y.C.; Liu, B.T.; Wang, Y.B. Application of Ionic Liquid-Based Ultrasonic-Assisted Extraction of Flavonoids from Bamboo Leaves. Molecules 2018, 23, 2309. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, J.S.; Su, X.G.; Meng, Q.W.; Dou, J.P. Extraction and Separation of Eight Ginsenosides from Flower Buds of Panax Ginseng Using Aqueous Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with an Aqueous Biphasic System. Molecules 2019, 24, 778. [Google Scholar] [CrossRef]

- Zhang, X.F.; Li, X.; He, Q.; Zhang, B.; Zheng, X. Ionic Liquid Based Ultrasonic-Assisted Extraction of Oleanolic Acid from Grape Seeds. Open Access Libr. J. 2017, 4, e4148. [Google Scholar] [CrossRef]

- Zhu, X.J. Studies of Ionic Liquids in Microwave-assisted Extractw2ion of Active Ingredients of Chinese Herbal Drugs and Adsorption Removal. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2010. [Google Scholar]

- Zhang, Y.F.; Liu, Z.; Li, Y.L.; Chi, R. Optimization of ionic liquid-based microwave-assisted extraction of isoflavones from Radix puerariae by response surface methodology. Sep. Purif. Technol. 2014, 129, 71–79. [Google Scholar] [CrossRef]

- Albishri, H.M.; Abd El-Hady, D. Eco-friendly ionic liquid based ultrasonic assisted selective extraction coupled with a simple liquid chromatography for the reliable determination of acrylamide in food samples. Talanta 2014, 118, 129–136. [Google Scholar] [CrossRef]

- Duan, M.H.; Luo, M.; Zhao, C.J.; Wang, W.; Zu, Y.G.; Zhang, D.Y.; Yao, X.H.; Fu, Y.J. Ionic liquid-based negative pressure cavitation-assisted extraction of three main flavonoids from the pigeonpea roots and its pilot-scale application. Sep. Purif. Technol. 2013, 107, 26–36. [Google Scholar] [CrossRef]

- Stroescu, M.; Stoica-Guzun, A.; Ghergu, S.; Chira, N.; Jipa, I. Optimization of fatty acids extraction from Portulaca oleracea seed using response surface methodology. Ind. Crops Prod. 2013, 43, 405–411. [Google Scholar] [CrossRef]

- Wei, J.F.; Cao, P.R.; Wang, J.M.; Kang, W.Y. Analysis of tilianin and acacetin in Agastache rugosa, by high-performance liquid chromatography with ionic liquids-ultrasound based extraction. Chem. Cent. J. 2016, 10, 76. [Google Scholar] [CrossRef]

- Wei, J.F.; Zhang, Z.J.; Cui, L.L.; Kang, W.Y. Flavonoids in different parts of lysimachia clethroides duby extracted by ionic liquid: analysis by HPLC and antioxidant activity assay. J. Chem. 2017, 5, 1–10. [Google Scholar] [CrossRef]

- Li, W.J.; Shi, M.J.; Wang, P.Y.; Guo, X.C.; Li, C.Q.; Kang, W.Y. Efficient determination of three flavonoids in Malus pumila flowers by ionic liquid-HPLC. J. Mol. Liq. 2018, 263, 139–146. [Google Scholar] [CrossRef]

- Shi, M.J.; He, N.; Li, W.J.; Li, C.Q.; Kang, W.Y. Simultaneous determination of myricetrin, quercitrin and afzelin in leaves of Cercis chinensis by a fast and effective method of ionic liquid microextraction coupled with HPLC. Chem. Cent. J. 2018, 12, 23. [Google Scholar] [CrossRef]

- Xia, Z.Y.; Li, D.D.; Li, Q.; Zhang, Y.; Kang, W.Y. Simultaneous determination of brazilin and protosappanin B in Caesalpinia sappan by ionic-liquid dispersive liquid-phase microextraction method combined with HPLC. Chem. Cent. J. 2017, 11, 114. [Google Scholar] [CrossRef]

- Shi, M.J.; Zhang, J.J.; Liu, C.Y.; Cui, Y.P.; Liu, Z.H.; Kang, W.Y. Ionic Liquid-Based Ultrasonic-Assisted Extraction to Analyze Seven Compounds in Psoralea Fructus Coupled with HPLC. Molecules 2019, 24, 1699. [Google Scholar] [CrossRef]

- Bogdanov, M.G.; Svinyarov, I. Ionic Liquid-Supported Solid-Liquid Extraction of Bioactive Alkaloids. II. Kinetics, Modeling and Mechanism of Glaucine Extraction from Glaucium flavum Cr. (Papaveraceae). Sep. Purify Technol. 2013, 103, 279–288. [Google Scholar] [CrossRef]

- Jin, R.H.; Fan, L.; An, X.N. Ionic Liquid-Assisted Extraction of Paeonol from Cynanchum paniculatum. Chromatographia 2011, 73, 787–792. [Google Scholar] [CrossRef]

- Lin, H.M.; Zhang, Y.G.; Han, M.; Yang, L.M. Aqueous Ionic Liquid Based Ultrasonic Assisted Extraction of Eight Ginsenosides from Ginseng Root. Ultrason. Sonochem. 2013, 20, 680–684. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds A and B are available from the authors. |

| Independent Variable | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| ILs concentration (mol/L) | 0.6 | 0.8 | 1.0 |

| Solid–liquid ratio (g/mL) | 1:20 | 1:40 | 1:60 |

| Centrifugal speed (r/min) | 4000 | 6000 | 8000 |

| Mesh number (mesh) | 40 | 50 | 60 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob. F | |

|---|---|---|---|---|---|---|

| Model | 27581.58 | 14 | 1970.11 | 5.24 | 0.0019 | ** |

| A | 57.51 | 1 | 57.51 | 0.15 | 0.7016 | |

| B | 5301.24 | 1 | 5301.24 | 14.10 | 0.0021 | ** |

| C | 483.24 | 1 | 483.24 | 1.29 | 0.2760 | |

| D | 383.75 | 1 | 383.75 | 1.02 | 0.3295 | |

| AB | 184.28 | 1 | 184.28 | 0.49 | 0.4953 | |

| AC | 0.16 | 1 | 0.16 | 4.255 × 10−4 | 0.9838 | |

| AD | 1290.25 | 1 | 1290.25 | 3.43 | 0.0852 | |

| BC | 47.61 | 1 | 47.61 | 0.13 | 0.7273 | |

| BD | 193.071 | 1 | 1193.07 | 0.51 | 0.4854 | |

| CD | 0.63 | 1 | 0.63 | 1.681 × 10−3 | 0.9679 | |

| A2 | 13986.72 | 1 | 13986.72 | 37.20 | <0.0001 | *** |

| B2 | 5516.28 | 1 | 5516.28 | 14.67 | 0.0018 | ** |

| C2 | 6785.46 | 1 | 6785.46 | 18.05 | 0.0008 | *** |

| D2 | 1193.50 | 1 | 1193.50 | 3.17 | 0.0965 | |

| Residual | 5263.98 | 14 | 376.00 | |||

| Lack of fit | 4910.78 | 10 | 491.08 | 5.56 | 0.0563 | No significant |

| Pure error | 353.20 | 4 | 88.30 | |||

| Cor total | 32845.58 | 28 | ||||

| NO. | Regression Equation | Linear Range (μg/mL) | Correlation Coefficients |

|---|---|---|---|

| Compound A | Y = 336721 X+112706 | 0.98~14.7 | R2 = 0.9997 |

| Compound B | Y = 134770 X+2456878 | 14.136~212.04 | R2 = 0.9948 |

| Chromatographic Conditions | Parameter |

|---|---|

| Column | Thermo ODS-2 HYPERSIL column (4.6 mm × 250 mm, 5 μm) |

| Mobile phase | Acetonitrile (A)0.1% phosphoric acid aqueous solution (B) gradient elution: 0–40 min 5%~100% A 95%~0% B |

| Flow rate | 0.8 mL·min−1 |

| Column temperature | 25 °C |

| Wavelength | 210 nm |

| Sample volume | 10 μL |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Niu, Y.; Liu, J.; Shi, M.; Xu, R.; Kang, W. Efficient Extraction of Anti-Inflammatory Active Ingredients from Schefflera octophylla Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with HPLC. Molecules 2019, 24, 2942. https://doi.org/10.3390/molecules24162942

Liu X, Niu Y, Liu J, Shi M, Xu R, Kang W. Efficient Extraction of Anti-Inflammatory Active Ingredients from Schefflera octophylla Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with HPLC. Molecules. 2019; 24(16):2942. https://doi.org/10.3390/molecules24162942

Chicago/Turabian StyleLiu, Xuqiang, Yun Niu, Jieqing Liu, Mengjun Shi, Ruian Xu, and Wenyi Kang. 2019. "Efficient Extraction of Anti-Inflammatory Active Ingredients from Schefflera octophylla Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with HPLC" Molecules 24, no. 16: 2942. https://doi.org/10.3390/molecules24162942

APA StyleLiu, X., Niu, Y., Liu, J., Shi, M., Xu, R., & Kang, W. (2019). Efficient Extraction of Anti-Inflammatory Active Ingredients from Schefflera octophylla Leaves Using Ionic Liquid-Based Ultrasonic-Assisted Extraction Coupled with HPLC. Molecules, 24(16), 2942. https://doi.org/10.3390/molecules24162942