Biocides Used as Additives to Biodiesels and Their Risks to the Environment and Public Health: A Review

Abstract

:1. Introduction

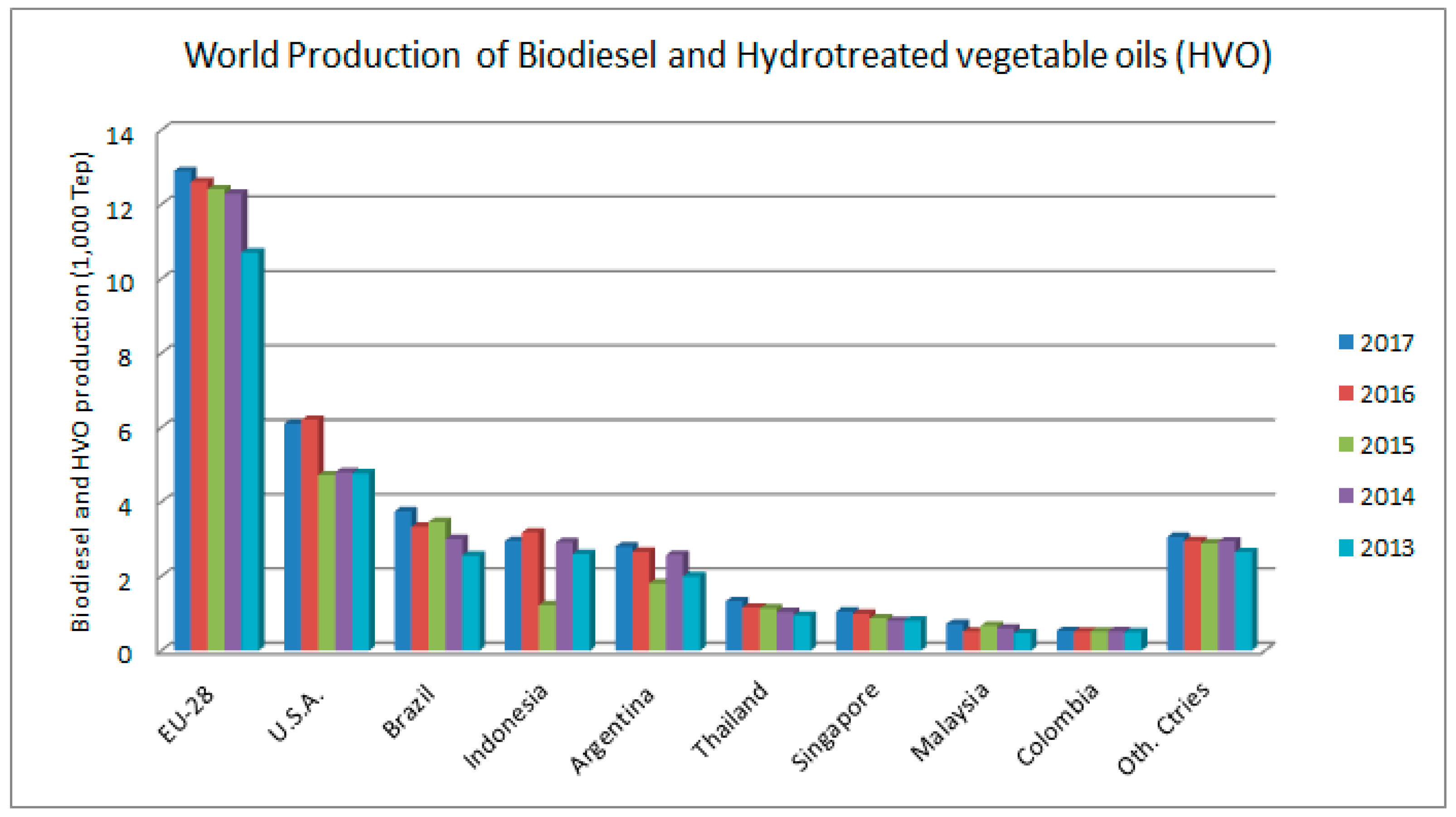

2. World Biodiesel Production

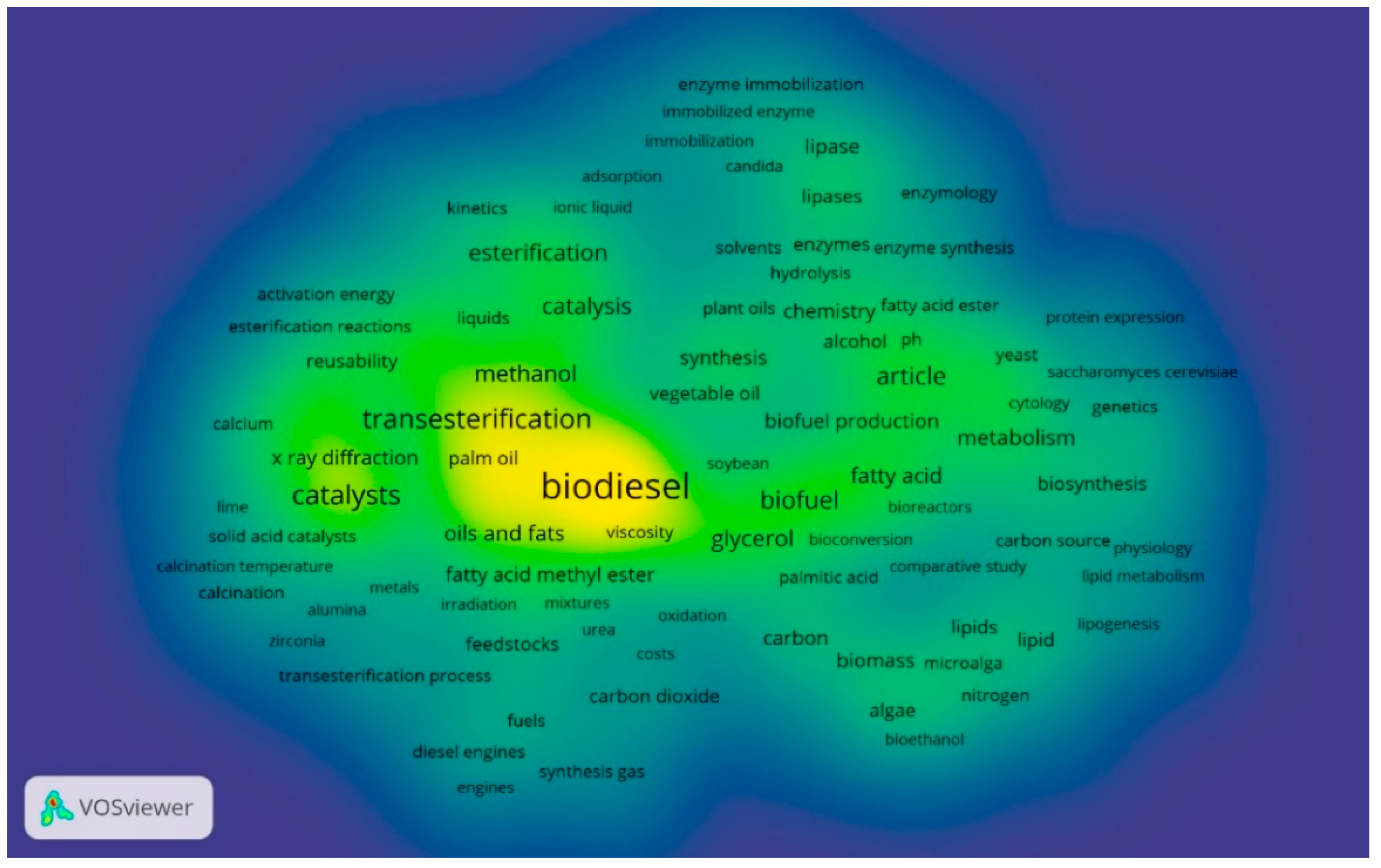

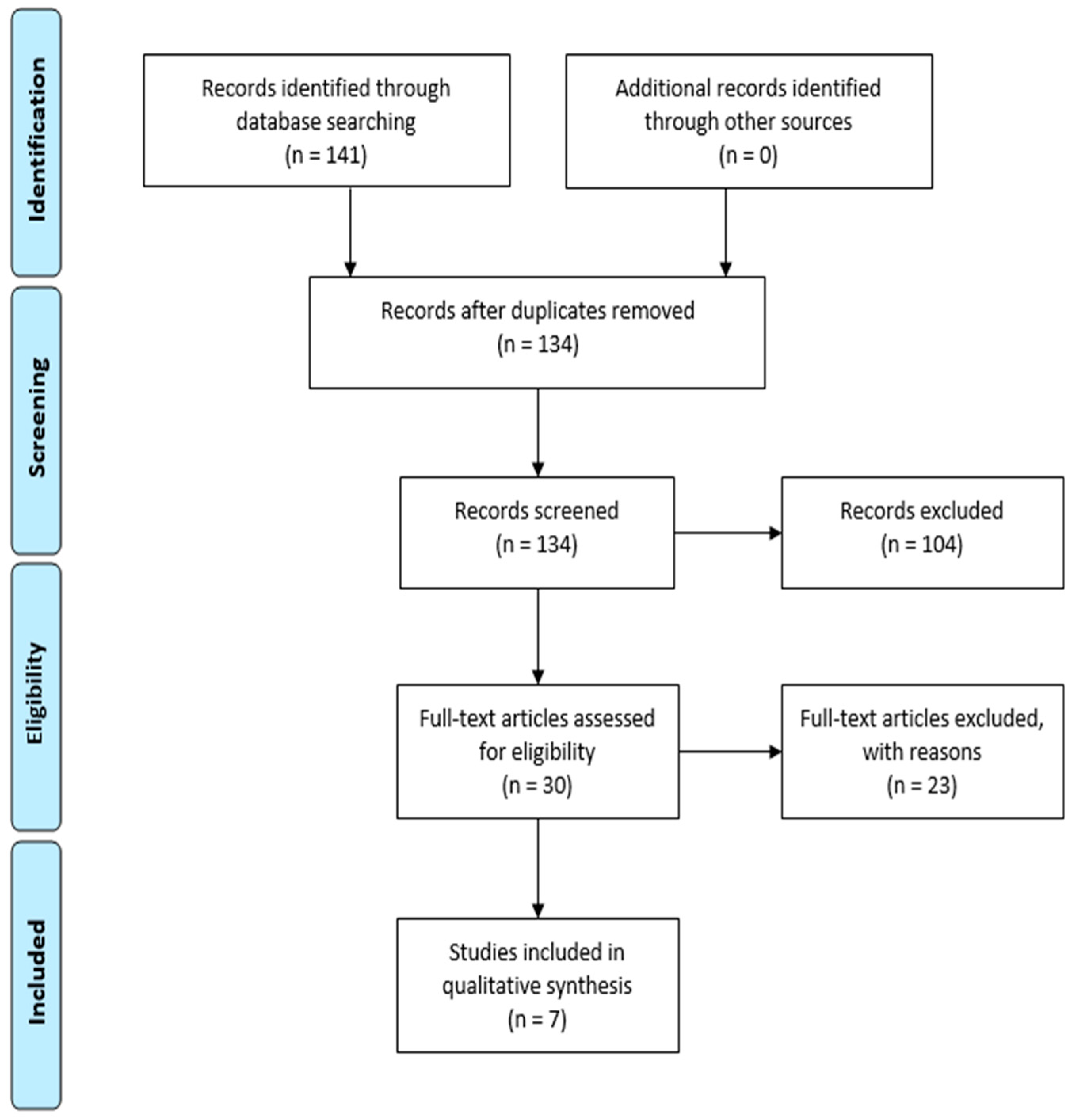

3. Materials and Methods

3.1. Eligibility Criteria

3.2. Data Items

3.3. Study Selection and Data Collection Process

3.4. Data Items

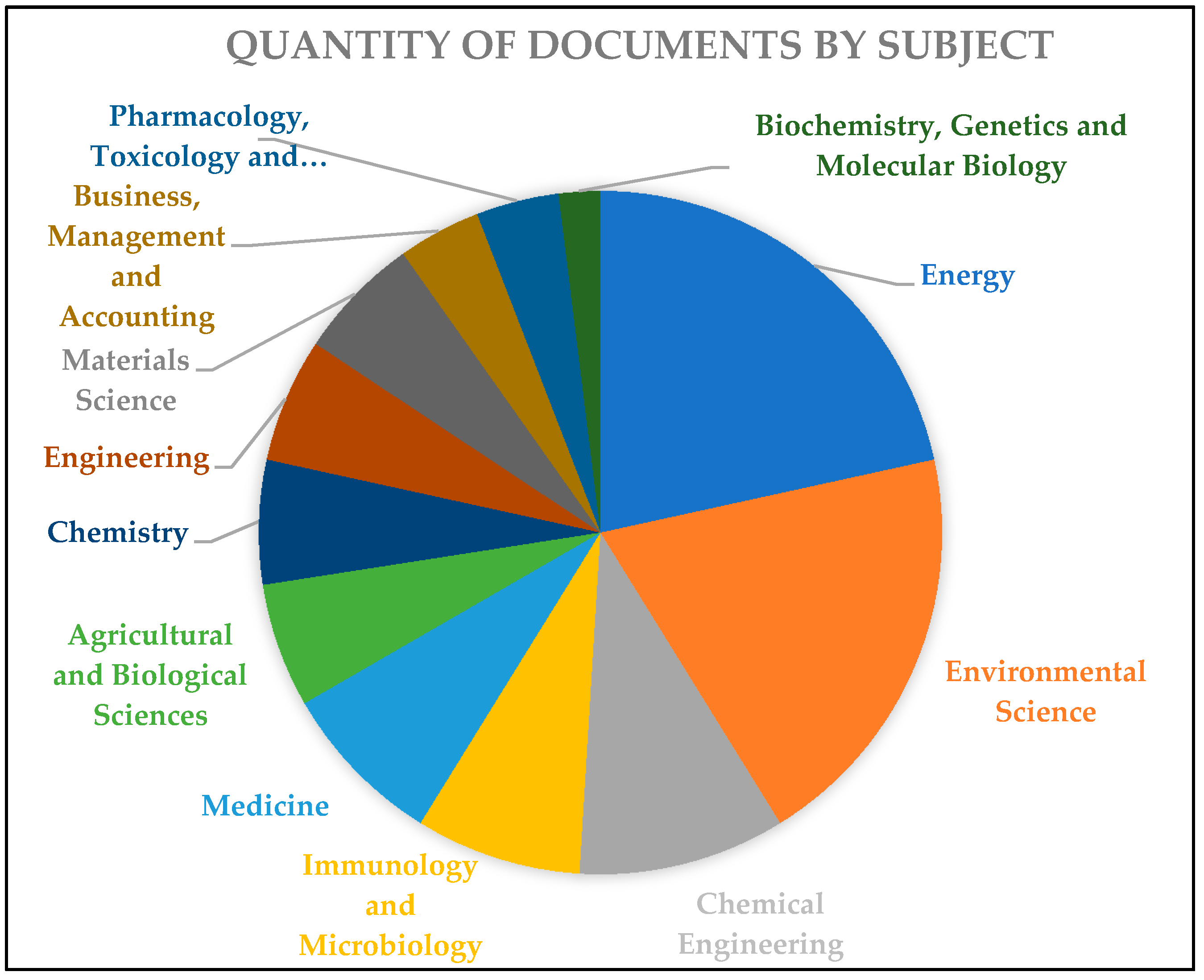

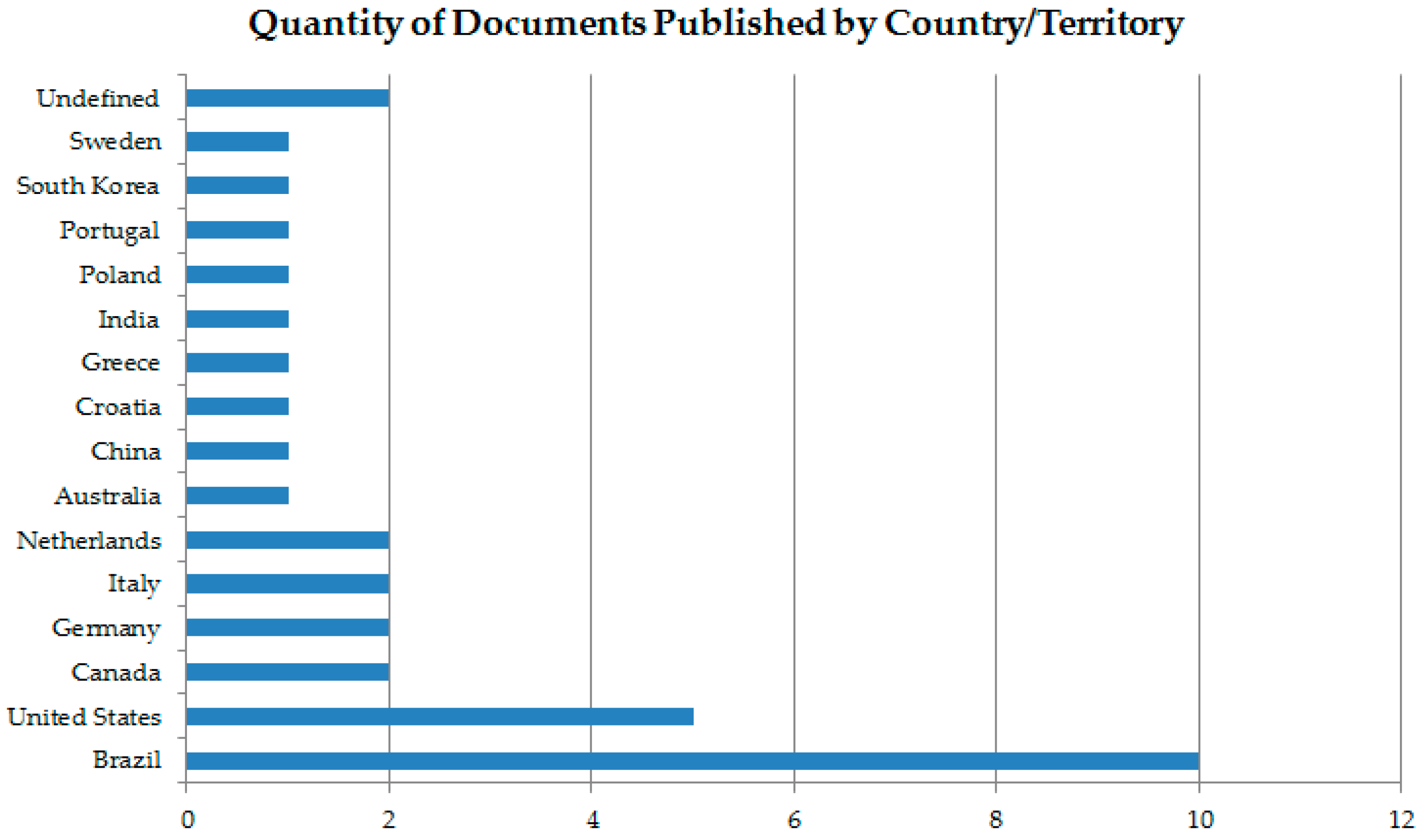

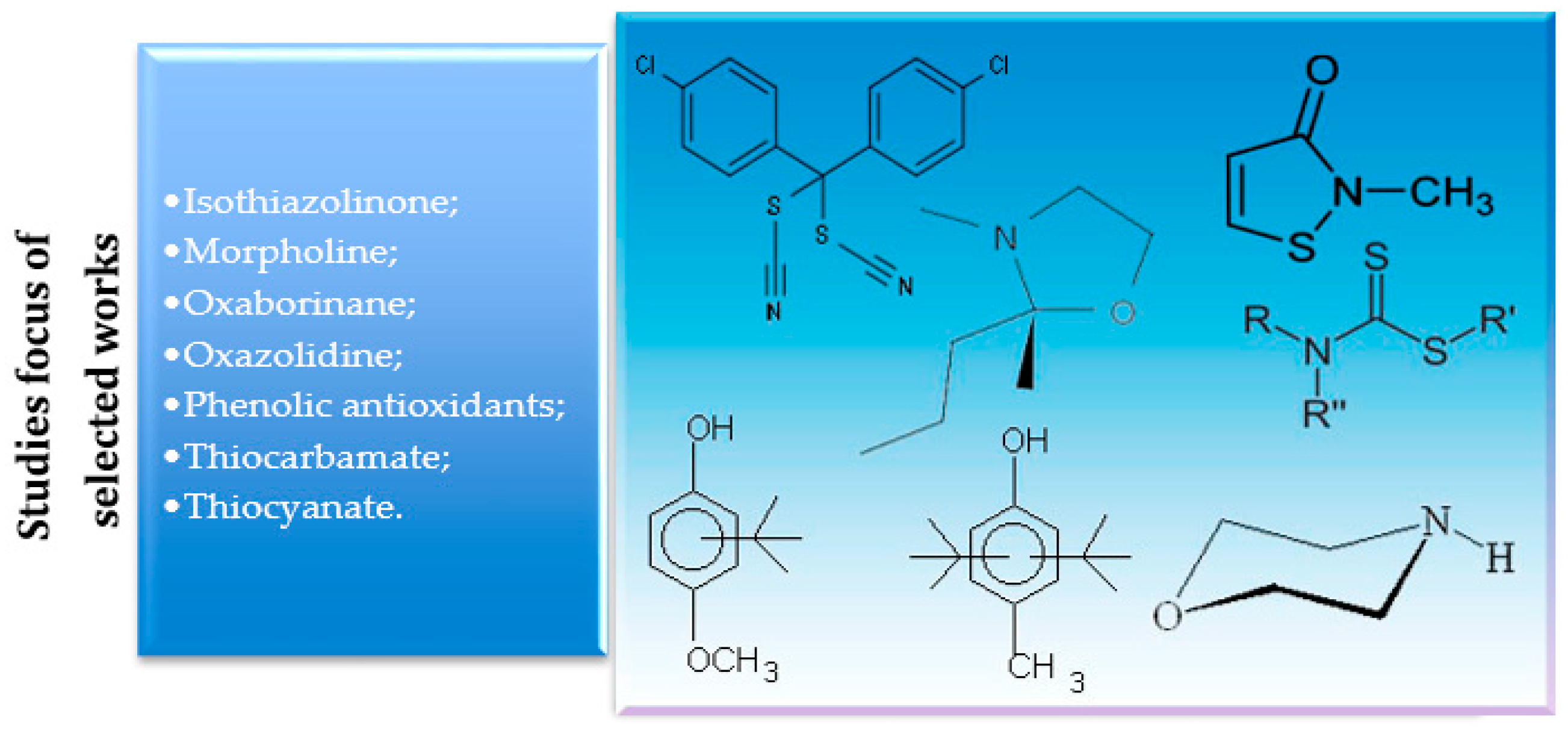

4. Results

5. Discussion

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Poon, R.; Rigden, M.; Edmonds, N.; Charman, N.; Lamy, S. Effects of 5-chloro-2-methyl-4-isothiazolin-3-one and other candidate biodiesel biocides on rat alveolar macrophages and NR8383 cells. Arch. Toxicol. 2011, 85, 1419–1427. [Google Scholar] [CrossRef] [PubMed]

- McCormick, R.L. The Impact of Biodiesel on Pollutant Emissions and Public Health. Inhal. Toxicol. 2007, 19, 1033–1039. [Google Scholar] [CrossRef] [PubMed]

- Standards and Specifications for Residential and Commercial Water-Using Fixtures and Appliances; United States Environmental Protection Agency National Efficiency: Washington, DC, USA, 2007.

- Patel, A.; Mikes, F.; Matsakas, L. An overview of current pretreatment methods used to improve lipid extraction from oleaginous microorganisms. Molecules 2018, 23. [Google Scholar] [CrossRef] [PubMed]

- Suarez, P.A.Z.; Santos, A.L.F.; Rodrigues, J.P.; Alves, M.B. Biocombustíveis a partir de óleos e gorduras: Desafios tecnológicos para viabilizá-los. Quim. Nova 2009, 32, 768–775. [Google Scholar] [CrossRef]

- Zimmer, A.R. Monitoring and Control of Microbial Contamination during Storage of Mixtures Diesel/Biodiesel with use of Biocide; Federal University of Rio Grande do Sul-Brazil: Porto Alegre, Brazil, 2014. [Google Scholar]

- Soriano, A.U.; Martins, L.F.; Santos de Assumpção Ventura, E.; Teixeira Gerken de Landa, F.H.; de Araújo Valoni, É.; Dutra Faria, F.R.; Ferreira, R.F.; Kremer Faller, M.C.; Valério, R.R.; Catharine de Assis Leite, D.; et al. Microbiological aspects of biodiesel and biodiesel/diesel blends biodeterioration. Int. Biodeterior. Biodegrad. 2015, 99, 102–114. [Google Scholar] [CrossRef]

- Sørensen, G.; Pedersen, D.V.; Nørgaard, A.K.; Sørensen, K.B.; Nygaard, S.D. Microbial growth studies in biodiesel blends. Bioresour. Technol. 2011, 102, 5259–5264. [Google Scholar] [CrossRef] [PubMed]

- Passman, F.J.J. Microbial contamination and its control in fuels and fuel systems since 1980—A review. Int. Biodeterior. Biodegrad. 2013, 81, 88–104. [Google Scholar] [CrossRef]

- Passman, F.J. (Ed.) Fuel and Fuel System Microbiology: Fundamentals, Diagnosis, and Contamination Control; ASTM Manual; ASTM International: West Conshohocken, PA, USA, 2003; ISBN 0-8031-3357-X. [Google Scholar]

- Bento, F.M.; Gaylarde, C.C. Biodeterioration of stored diesel oil: Studies in Brazil. Int. Biodeterior. Biodegrad. 2001, 47, 107–112. [Google Scholar] [CrossRef]

- Silva, G.V. Da Experimental Characterization of the Combined Effect of Additives on the Diesel-Biodiesel Blends Performance; Faculdade de Tecnologia, Universidade de Brasília: Brasília, Brazil, 2013. [Google Scholar]

- World Health Organization. The WHO Recommended Classification of Pesticides by Hazard and Guidelines to Classification 2009; World Health Organization: Geneva, Switzerland, 2010; pp. 1–60. ISBN 978 92 4 154796 3. [Google Scholar]

- Passman, F.J. Standard Guide for Microbial Contamination in Fuels and Fuel Systems; ASTM D6469-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Protection of Environment. Part 152-Pesticide Registration and Classification Procedures; United States Environmental Protection Agency (USEPA): Washington, DC, USA, 2018.

- Concerning the Placing of Biocidal Products on the Market. In Regulation (EU) No. 528/2012 of the European Parliament and of the Council of 22 May 2012; The European Parliament and the Council of the European Union: Strasbourg, France, 2012.

- Brasil Resolução ANP; Agência Nacional do Petróleo, Gás natural e Biocombustíveis (ANP): Brasília, Brazil, 2017.

- Zimmer, A.R.; Oliboni, A.; Viscardi, S.L.C.; Teixeira, R.M.; Flores, M.; Bento, M.F. Biodiesel blend (B10) treated with a multifunctional additive (biocide) under simulated stored conditions: A field and lab scale monitoring. Biofuel Res. J. 2017, 14, 627–636. [Google Scholar] [CrossRef]

- Bücker, F. Biodeterioration of Diesel and Biodiesel Blends and its Control with Biocide; Universidade Federal do Rio Grande do Sul: Porto Alegre, Rio Grande do Sul, Brazil, 2009. [Google Scholar]

- Luz, G.V.d.S.; Allocca, L.; Montanaro, A.; Veras, C.; Falla, M.d.P. Physical-chemical characteristics of diesel-biodiesel blends with additives and their effects on the spray behavior. SAE Tech. Pap. Ser. 2013, 6, 12. [Google Scholar] [CrossRef]

- Luz, G.V.d.S.; Hidalgo, P.; Veras, C.G.; Merola, S.; Allocca, L.; Montanaro, A.; Marchitto, L. Studies of Exhaust Emissions and Optical Diagnostic of Spray for Biodiesel Samples with Additives Package using a Common-Rail System. SAE Int. Tech. Pap. 2013, 13, 12. [Google Scholar] [CrossRef]

- Yemashova, N.A.; Murygina, V.P.; Zhukov, D.V.; Zakharyantz, A.A.; Gladchenko, M.A.; Appanna, V.; Kalyuzhnyi, S.V. Biodeterioration of crude oil and oil derived products: A review. Rev. Environ. Sci. Bio/Techn. 2007, 6, 315–337. [Google Scholar] [CrossRef]

- Schleicher, T.; Werkmeister, R.; Russ, W.; Meyer-Pittroff, R. Microbiological stability of biodiesel–diesel-mixtures. Bioresour. Technol. 2009, 100, 724–730. [Google Scholar] [CrossRef] [PubMed]

- Ramos, L.P.; Kothe, V.; César-Oliveira, M.A.F.; Muniz-Wypych, A.S.; Nakagaki, S.; Krieger, N.; Wypych, F.; Cordeiro, C.S. Biodiesel: Raw materials, production technologies and fuel properties. Rev. Virtual Quim. 2017, 9, 317–369. [Google Scholar] [CrossRef]

- Rinaldi, R.; Garcia, C.; Marciniuk, L.L.; Rossi, A.V.; Schuchardt, U. Synthesis of biodiesel: A contextualized experiment proposal for the general chemistry laboratory. Quim. Nova 2007, 30, 1374–1380. [Google Scholar] [CrossRef]

- Urioste, D.; Castro, M.B.A.; Biaggio, F.C.; De Castro, H.F. Synthesis of chromatographic standards and establishment of a method for the quantification of the fatty ester composition of biodiesel from babassu oil. Quim. Nova 2008, 31, 407–412. [Google Scholar] [CrossRef]

- Murillo, G.; Sun, J.; Ali, S.S.; Yan, Y.; Bartocci, P.; He, Y. Evaluation of the kinematic viscosity in biodiesel production with waste vegetable oil, ultrasonic irradiation and enzymatic catalysis: A comparative study in two-reactors. Fuel 2018, 227, 448–456. [Google Scholar] [CrossRef]

- Welcome to Scopus. Available online: https://www.scopus.com/ (accessed on 17 August 2016).

- Kabbashi, N.A.; Mohammed, N.I.; Alam, M.Z.; Mirghani, M.E.S. Hydrolysis of Jatropha curcas oil for biodiesel synthesis using immobilized Candida cylindracea lipase. J. Mol. Catal. B Enzym. 2015, 116, 95–100. [Google Scholar] [CrossRef]

- Sirajuddin, M.; Tariq, M.; Ali, S. Organotin(IV) carboxylates as an effective catalyst for the conversion of corn oil into biodiesel. J. Organomet. Chem. 2015, 779, 30–38. [Google Scholar] [CrossRef]

- Dhawane, S.H.; Kumar, T.; Halder, G. Recent advancement and prospective of heterogeneous carbonaceous catalysts in chemical and enzymatic transformation of biodiesel. Energy Convers. Manag. 2018, 167, 176–202. [Google Scholar] [CrossRef]

- Mendonça, I.M.; Paes, O.A.R.L.; Maia, P.J.S.; Souza, M.P.; Almeida, R.A.; Silva, C.C.; Duvoisin, S.; de Freitas, F.A. New heterogeneous catalyst for biodiesel production from waste tucumã peels (Astrocaryum aculeatum Meyer): Parameters optimization study. Renew. Energy 2019, 130, 103–110. [Google Scholar] [CrossRef]

- Ullah, Z.; Khan, A.S.; Muhammad, N.; Ullah, R.; Alqahtani, A.S.; Shah, S.N.; Ghanem, O.B.; Bustam, M.A.; Man, Z. A review on ionic liquids as perspective catalysts in transesterification of different feedstock oil into biodiesel. J. Mol. Liq. 2018, 266, 673–686. [Google Scholar] [CrossRef]

- Liu, C.X.; Zhang, S.P.; Su, Z.G.; Wang, P. LiCl-induced improvement of multilayer nanofibrous lipase for biodiesel synthesis. Bioresour. Technol. 2012, 103, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Ali, B.; Yusup, S.; Quitain, A.T.; Alnarabiji, M.S.; Kamil, R.N.M.; Kida, T. Synthesis of novel graphene oxide/bentonite bi-functional heterogeneous catalyst for one-pot esterification and transesterification reactions. Energy Convers. Manag. 2018, 171, 1801–1812. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B. Development of biodiesel: Current scenario. Renew. Sustain. Energy Rev. 2009, 13, 1646–1651. [Google Scholar] [CrossRef]

- Tran, D.T.; Chen, C.L.; Chang, J.S. Effect of solvents and oil content on direct transesterification of wet oil-bearing microalgal biomass of Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized lipase as the biocatalyst. Bioresour. Technol. 2013, 135, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Mansir, N.; Teo, S.H.; Rabiu, I.; Taufiq-Yap, Y.H. Effective biodiesel synthesis from waste cooking oil and biomass residue solid green catalyst. Chem. Eng. J. 2018, 347, 137–144. [Google Scholar] [CrossRef]

- Gao, W.W.; Zhang, F.X.; Zhang, G.X.; Zhou, C.H. Key factors affecting the activity and stability of enzymes in ionic liquids and novel applications in biocatalysis. Biochem. Eng. J. 2015, 99, 67–84. [Google Scholar] [CrossRef]

- Guldhe, A.; Singh, P.; Ansari, F.A.; Singh, B.; Bux, F. Biodiesel synthesis from microalgal lipids using tungstated zirconia as a heterogeneous acid catalyst and its comparison with homogeneous acid and enzyme catalysts. Fuel 2017, 187, 180–188. [Google Scholar] [CrossRef]

- Popp, J.; Harangi-Rákos, M.; Gabnai, Z.; Balogh, P.; Antal, G.; Bai, A. Biofuels and their co-products as livestock feed: Global economic and environmental implications. Molecules 2016, 21, 285. [Google Scholar] [CrossRef] [PubMed]

- Drabik, D.; de Gorter, H.; Timilsina, G.R. The effect of biodiesel policies on world biodiesel and oilseed prices. Energy Econ. 2014, 44, 80–88. [Google Scholar] [CrossRef]

- Regulamento Sobre as Especificação do Biodiesel e as Obrigações Quanto ao Controle da Qualidade; Resolução ANP N°11.097/2005; Agência Nacional do Petróleo (ANP): Brasília, Brazil, 2005.

- Dispõe Sobre a Adição Obrigatória de Biodiesel ao óleo Diesel Comercial Izado ao Consumidor Final, e dá Outras Providências; Brasil Medida Provisória No. 647, de 28 de Maio de 2014; O Conselho Nacional de Pol í t ica Energét ica (CNPE): Brasil, Brazil, 2014.

- Para Dispor Sobre os Percentuais de Adição de Biodiesel ao Óleo Diesel Comercializado no Território Nacional. Brasil Lei No. 13.263, de 23 de Março de 2016. Brasília-DF. Available online: http://www2.camara.leg.br/legin/fed/lei/2016/lei-13263-23-marco-2016-782625-publicacaooriginal-149818-pl.html (accessed on 23 March 2016).

- Brasil Lei No. 13.033, de 24 de setembro de 2014. Brasília-DF. 2014. Available online: www2.camara.leg.br/legin/fed/lei/2014/lei-13033-24-setembro-2014-779372-norma-pl.html (accessed on 24 September 2014).

- Mielke, T. Global price outlook for palm & lauric oils and impacts from the severe argentine drought losses. In Price Outlook Conference (POC) 2018; ISTA Mielke GmbH, Ed.; OIL WORLD: Kuala Lumpur, Malasya, 2018; pp. 1–25. [Google Scholar]

- Union zur Förderung von oel- und Proteinpflanzen E.V. UFOP Report on Global Market Supply 2017/2018; UFOP: Berlin, Germany, 2018. [Google Scholar]

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review, 2nd ed.; Steeele, M., Owen, A., Eds.; SAGE Publications Ltd.: Los Angeles, CA, USA, 2016; ISBN 9781473912458. [Google Scholar]

- Passman, F.J. Specialty Biocides North America 1995; Kline & Company, Inc.: Little Falls, NJ, USA, 1995. [Google Scholar]

- Leite, J.G.D.B.; Silva, J.V.; van Ittersum, M.K. Integrated assessment of biodiesel policies aimed at family farms in Brazil. Agric. Syst. 2014, 131, 64–76. [Google Scholar] [CrossRef]

- Bautista, L.F.; Vargas, C.; González, N.; Molina, M.C.; Simarro, R.; Salmerón, A.; Murillo, Y. Assessment of biocides and ultrasound treatment to avoid bacterial growth in diesel fuel. Fuel Process. Technol. 2016, 152, 56–63. [Google Scholar] [CrossRef]

- Zimmer, A.; Cazarolli, J.; Teixeira, R.M.; Viscardi, S.L.C.; Cavalcanti, E.S.H.; Gerbase, A.E.; Ferrão, M.F.; Piatnicki, C.M.S.; Bento, F.M. Monitoring of efficacy of antimicrobial products during 60 days storage simulation of diesel (B0), biodiesel (B100) and blends (B7 and B10). Fuel 2013, 112, 153–162. [Google Scholar] [CrossRef]

- Zimmer, A.R.; Cazarolli, J.; Bucker, F.; Teixeira, R.M.; Viscardi, S.L.C.; Cavalcanti, E.S.H.; Gerbase, A.E.; Ferrão, M.F.; Piatnicki, C.M.S.; Bento, F.M. Monitoring of efficacy of biocides during storage simulation of diesel (B0), biodiesel (B100) and blends (B7 and B10). In 12th International Conference on Stability, Handling and Use of Liquid Fuels 2011; Universidade Federal Do Rio Grande Do Sul: Rio Grande do Sul, Brazil, 2011; Volume 2, pp. 1642–1681. [Google Scholar]

- Bücker, F.; Barbosa, C.S.; Quadros, P.D.; Bueno, M.K.; Fiori, P.; te Huang, C.; Frazzon, A.P.G.; Ferrão, M.F.; de Oliveira Camargo, F.A.; Bento, F.M. Fuel biodegradation and molecular characterization of microbial biofilms in stored diesel/biodiesel blend B10 and the effect of biocide. Int. Biodeterior. Biodegrad. 2014, 95. [Google Scholar] [CrossRef]

- Cazarolli, J.C.; Guzatto, R.; Samios, D.; Peralba, M.D.C.R.; de Siqueira Cavalcanti, E.H.; Bento, F.M. Susceptibility of linseed, soybean, and olive biodiesel to growth of the deteriogenic fungus Pseudallescheria boydii. Int. Biodeterior. Biodegrad. 2014, 95, 364–372. [Google Scholar] [CrossRef]

- Dal Belo Leite, J.G.; Justino, F.B.; Silva, J.V.; Florin, M.J.; van Ittersum, M.K. Socioeconomic and environmental assessment of biodiesel crops on family farming systems in Brazil. Agric. Syst. 2015, 133, 22–34. [Google Scholar] [CrossRef]

- Pelletier, G.; Valli, V.E.; Rigden, M.; Poon, R. Effects of a 28-day oral exposure to a 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one biocide formulation in Sprague-Dawley rats. Drug Chem. Toxicol. 2014, 37, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Finch, G.L.; Hobbs, C.H.; Blair, L.F.; Barr, E.B.; Hahn, F.F.; Jaramillo, R.J.; Kubatko, J.E.; March, T.H.; White, R.K.; Krone, J.R.; et al. Effects of Subchronic Inhalation Exposure of Rats to Emissions from a Diesel Engine Burning Soybean Oil-Derived Biodiesel Fuel. Inhal. Toxicol. 2002, 14, 1017–1048. [Google Scholar] [CrossRef] [PubMed]

- Swanson, K.J.; Madden, M.C.; Ghio, A.J. Biodiesel exhaust: The need for health effects research. Environ. Health Perspect. 2007, 115, 496–499. [Google Scholar] [CrossRef] [PubMed]

- Brito, J.M.; Belotti, L.; Toledo, A.C.; Antonangelo, L.; Silva, F.S.; Alvim, D.S.; Andre, P.A.; Saldiva, P.H.N.; Rivero, D.H.R.F. Acute cardiovascular and inflammatory toxicity induced by inhalation of diesel and biodiesel exhaust particles. Toxicol. Sci. 2010, 116, 67–78. [Google Scholar] [CrossRef] [PubMed]

- Mehus, A.A.; Reed, R.J.; Lee, V.S.T.; Littau, S.R.; Hu, C.; Lutz, E.A.; Burgess, J.L. Comparison of Acute Health Effects from Exposures to Diesel and Biodiesel Fuel Emissions. J. Occup. Environ. Med. 2015, 57, 705–712. [Google Scholar] [CrossRef] [PubMed]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Rashed, M.M.; Rashedul, H.K.; Monirul, I.M.; Mosarof, M.H. A comprehensive review on the assessment of fuel additive effects on combustion behavior in CI engine fuelled with diesel biodiesel blends. RSC Adv. 2015, 5, 67541–67567. [Google Scholar] [CrossRef]

- Shahir, V.K.; Jawahar, C.P.; Suresh, P.R. Comparative study of diesel and biodiesel on CI engine with emphasis to emissions—A review. Renew. Sustain. Energy Rev. 2015, 45, 686–697. [Google Scholar] [CrossRef]

| Research Base | Strings |

|---|---|

| PubMed/MEDLINE | biodiesel AND additive AND biocide AND toxicity |

| Scielo | biodiesel AND additive AND biocide AND toxicity |

| LILACS/BVS | biodiesel [Palavras] and additive [Palavras] and biocide [Palavras] and toxicity [Palavras] |

| IEEE | biodiesel AND additive AND biocide AND toxicity |

| ACM | biodiesel AND additive AND biocide AND toxicity |

| ScienceDirect | biodiesel AND additive AND biocide AND toxicity |

| Cochrane Library | biodiesel AND additive AND biocide AND toxicity |

| Periódicos CAPES | biodiesel AND additive AND biocide AND toxicity |

| Web of Science | TOPIC: (biodiesel) AND TOPIC: (additive) AND TOPIC: (biocide) AND TOPIC: (toxicity) |

| Scopus | TITLE-ABS-KEY (biodiesel AND additive AND biocide AND toxicity) |

| Research Base | Number of Scientific Papers Found |

|---|---|

| PubMed/MEDLINE | 0 |

| Scielo | 0 |

| LILACS/BVS | 0 |

| IEEE | 32 |

| ACM | 0 |

| ScienceDirect | 94 |

| Cochrane Library | 0 |

| Periódicos CAPES | 15 |

| Web of Science | 0 |

| Scopus | 0 |

| Ref. Number | Authors (year) | Type of Study | Objective of Work | Biocide(s) Cited in the Work | Type of Study Carried out with the Biocide | Does this Study Provide Data on the Toxicity of Biocides in Biodiesel? | Work Result(s) |

|---|---|---|---|---|---|---|---|

| [1] | Poon et al. (2011) | Article | This study is on the effects of 5-chloro-2-methyl-4-isothiazolin-3-one (CMIT). | 5-Chloro-2-methyl-4-isothiazolin-3-one (CMIT), 2-methyl-4-isothazolin-3-one (MIT), methylene dithiocyanate (MDC) and dimethyl acetylenedicarboxylate (DMAD) | Studies about organic biocides using freshly isolated rat alveolar macrophages (AM) and NR8383 cell line. | Toxicity studies four types of biocides. | The 50% inhibition concentration (LC50) for CMIT was 0.002–0.004 mM for both cellular functions. With the AM testing system, the toxicity for the biocides were CMIT = MDC > MIT > DMAD. The authors suggested that CMIT added in biodiesel might provoke respiratory impairment, and more studies using animal subjects are warranted. |

| [9] | Passman (2013) | Review | This work relates informations about the factors involved in fuel to the fuel system biodeterioration. | Diiodomethyl-p-tolylsulfone; Ethylene glycol monomethyl ether (EGME); Diethylene glycol monomethyl ether (DiEGME); Triethylene glycol monomethyl ether (TriEGME-M); dioxaborinane blend; Isothazolinone blend; morpholine-dinitromorphiline blend; 3,3’-methylenebis(5-methyloxazolidine) (MBO; 95–100% a.i.) | Studies about remediation strategies with biocide treatment. | The work provides information on antimicrobial studies, among others. | One of the results is that the fuel treatment represents a tiny fraction (<0.1%; Passman, 1995 [50]) of the total industrial microbiocides market. Although the use of fuel-treatment microbiocides is likely to increase, new chemistries are unlikely to emerge. |

| [35] | Zimmer (2014) | Master Thesis | This work was made to select antimicrobials to be used in the control of microbial contamination of diesel/biodiesel. | Oxazolidine, isothiazolone and morpholine. | Studies on microbial control and microbial contamination. | The work only provides data regarding microorganisms. | It was found that an additive containing 50% oxazolidine in its formulation was effective for the preventive control of microbial contamination in B10 mixtures. In addition, testing containing isothiazolones or morpholines may be a good option for corrective treatments. The toxicity results show that both water, which was in contact with the treated (with the additive) and untreated, showed toxicity to the organisms used. However, the water that was in contact with the biocidal additive fuel showed high acute toxicity for both test organisms studied. |

| [51] | Pelletier et al. (2014) | Article | This study reported the health effects of CMIT/MIT ingestion in rats to give information about the potential health risks that may arise from the grow up in the use of biocides in biodiesels or biodiesel blends. | 2-Methyl-4-isothiazolin-3-one (MIT), 5-chloro-2-methyl-4-isothiazolin-3-one (CMIT). | Randomized study in male and female rats. | An oral dose study was conducted to assess a potential risk arising from ingestion of isothiazolinone biocides in biodiesels. | Based on recommended levels of biocides for the microbial treatment in fuels, CMIT/MIT contained in this accidentally ingested biofuel is not expected to express a significant health risk. |

| [52] | Bautista et al. (2016) | Article | Compare and evaluate the efficiency of several chemical and physical treatments on the growth of microorganisms found in real samples of diesel fuel from different storage tanks from petrol stations in Spain | Isothiazolone; oxazolidine; thiocyanate; thiocarbamate; morpholine; oxaborinane. | Studies about organic biocides. | Studies on remediation strategies with biocide treatment. | According to the results, water-soluble biocides (especially B2 with oxazolidine group in the active compound) showed higher performance in controlling bacterial growth in the studied diesel fuel storage tanks. However, the effectiveness of biocides very much relies on biodiversity and physicochemical properties of the medium. In order to control growth of microorganisms in oil storage tanks, some preliminary studies, (on a case-to-case basis) on the microbial population and physicochemical characteristics inside tanks and in the surrounding area where the tank is located (soil composition, environmental conditions, climate, etc.) must be performed. |

| [48] | Dodos; Tsesmeli, and Zannikos (2017) | Article | This study aimed to investigate the effect of phenolic type antioxidants on the microbial stability of biodiesel fuel, along with their relative efficiency to improve the oxidation and storage stability. | Ten commercially available phenolic compounds, either of synthetic or natural origin. | Studies about antimicrobial properties. | The work only provides data regarding microorganisms. | Overall, the results demonstrate that certain phenolic antioxidants primarily added to biodiesel in order to improve oxidative stability could also provide a satisfactory level of antimicrobial protection at the same time. Although these substances do not necessarily possess biocidal properties, they appear as non-supportive to active biomass. This suggests that by properly selecting a FAME antioxidant agent, the microbial stability of bio-diesel can be upgraded up to a point. |

| [53] | Zimmer et al. (2017) | Article | The objective of this study was to assess the effectiveness of an additive multifunctional biocide to treat microbial contamination under simulated storage conditions. | 3,3-methylenebis(5-methyloxazolidine) (MBO) | The tests were managed under two conditions: at lab-scale and in the field (real-world condition). | Experiments were carried out in the laboratory (lab-scale; 250 mL microcosms) and in the field (field-scale; 20 L tanks) under real-world conditions. | The lab-scale study showed that this product was able to inhibit biomass formation in the range of 40% to 60% during simulated fuel storage in the microcosms, at a 400 ppm concentration. In the field-scale study, the multifunctional additive at a 1000 ppm concentration showed a biocide action after 7 d in the tanks with low microbial contamination and a biostatic action in the tanks receiving microbial inoculum (high contamination). |

| University | Publications | References |

|---|---|---|

| Universidade Federal do Rio Grande do Sul | 4 | [18,53,54,55] |

| Instituto Nacional de Tecnologia do Rio de Janeiro | 3 | [53,54,56] |

| Ipiranga Produtos Petróleo | 2 | [18,53] |

| Wageningen University and Research Centre | 2 | [51,57] |

| Universidade Federal de Viçosa | 2 | [51,57] |

| Health Canada | 2 | [1,58] |

| Consiglio Nazionale Delle Ricerche | 2 | [20,21] |

| Universidade de Brasília | 2 | [20,21] |

| Istituto Motori | 2 | [20,21] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luz, G.V.S.; Sousa, B.A.S.M.; Guedes, A.V.; Barreto, C.C.; Brasil, L.M. Biocides Used as Additives to Biodiesels and Their Risks to the Environment and Public Health: A Review. Molecules 2018, 23, 2698. https://doi.org/10.3390/molecules23102698

Luz GVS, Sousa BASM, Guedes AV, Barreto CC, Brasil LM. Biocides Used as Additives to Biodiesels and Their Risks to the Environment and Public Health: A Review. Molecules. 2018; 23(10):2698. https://doi.org/10.3390/molecules23102698

Chicago/Turabian StyleLuz, Glécia V. S., Breno A. S. M. Sousa, Adevilton V. Guedes, Cristine C. Barreto, and Lourdes M. Brasil. 2018. "Biocides Used as Additives to Biodiesels and Their Risks to the Environment and Public Health: A Review" Molecules 23, no. 10: 2698. https://doi.org/10.3390/molecules23102698

APA StyleLuz, G. V. S., Sousa, B. A. S. M., Guedes, A. V., Barreto, C. C., & Brasil, L. M. (2018). Biocides Used as Additives to Biodiesels and Their Risks to the Environment and Public Health: A Review. Molecules, 23(10), 2698. https://doi.org/10.3390/molecules23102698