Optimization of Enzymatic Process for Vanillin Extraction Using Response Surface Methodology

Abstract

:1. Introduction

2. Results and Discussion

2.1 Statistical Analysis

| Exp. number | Heating Time | Enzyme quantity | Temperature | Extraction yield |

|---|---|---|---|---|

| /X1(h) | /X2 (mL) | /X3(°C) | /(mg/g) | |

| 1 | 7.78 | 43.31 | 77.8 | 6.96 |

| 2 | 7.78 | 43.31 | 42.16 | 6.94 |

| 3 | 7.78 | 23.69 | 77.8 | 7.17 |

| 4 | 7.78 | 23.69 | 42.16 | 7.25 |

| 5 | 4.22 | 43.31 | 77.8 | 7.08 |

| 6 | 4.22 | 43.31 | 42.16 | 7.04 |

| 7 | 4.22 | 23.69 | 77.8 | 7.01 |

| 8 | 4.22 | 23.69 | 42.16 | 7.19 |

| 9 | 9 | 33.5 | 60 | 7.11 |

| 10 | 3 | 33.5 | 60 | 7.01 |

| 11 | 6 | 50 | 60 | 7.13 |

| 12 | 6 | 17 | 60 | 7.31 |

| 13 | 6 | 33.5 | 90 | 7.27 |

| 14 | 6 | 33.5 | 30 | 7.41 |

| 15 | 6 | 33.5 | 60 | 7.63 |

| 16 | 6 | 33.5 | 60 | 7.53 |

| 17 | 6 | 33.5 | 60 | 7.59 |

| 18 | 6 | 33.5 | 60 | 7.65 |

| 19 | 6 | 33.5 | 60 | 7.57 |

| 20 | 6 | 33.5 | 60 | 7.67 |

| R2 | 0.95 | |||

| CV (%) | 1.02 |

| Parameter | DF | Estimate | Standard Error | t Value | p-value | Parameter Estimate |

|---|---|---|---|---|---|---|

| Pr > |t| | From coded data | |||||

| Intercept | 1 | 2.24726 | 0.668079 | 3.36 | 0.0072 | 7.609897 |

| X1 | 1 | 0.904467 | 0.103066 | 8.78 | <.0001 | 0.020774 |

| X2 | 1 | 0.108797 | 0.018803 | 5.79 | 0.0002 | −0.111128 |

| X3 | 1 | 0.032427 | 0.010301 | 3.15 | 0.0104 | −0.053873 |

| 1 | −0.067581 | 0.006165 | −10.96 | <0.0001 | −0.608226 |

| X1X2 | 1 | −0.003150 | 0.001506 | −2.09 | 0.063 | −0.155912 |

| 1 | −0.001647 | 0.000204 | −8.09 | <0.0001 | −0.448465 |

| X1X3 | 1 | 0.000316 | 0.000829 | 0.38 | 0.7114 | 0.028413 |

| X2X3 | 1 | 0.000229 | 0.00015 | 1.52 | 0.1592 | 0.113291 |

| 1 | −0.000365 | 0.000061626 | −5.92 | 0.0001 | −0.328379 |

| Regression | DF | Sum of Squares | R-Square | F Value | p-value |

|---|---|---|---|---|---|

| Pr > F | |||||

| Linear | 3 | 0.75522 | 0.0626 | 4.55 | 0.0295 |

| Quadratic | 3 | 1.036994 | 0.8601 | 62.44 | <.0001 |

| Cross product | 3 | 0.037809 | 0.0314 | 2.28 | 0.142 |

| Total Model | 9 | 1.150324 | 0.9541 | 23.09 | <.0001 |

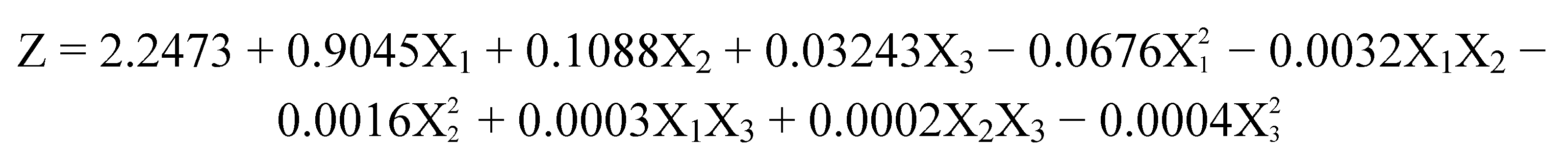

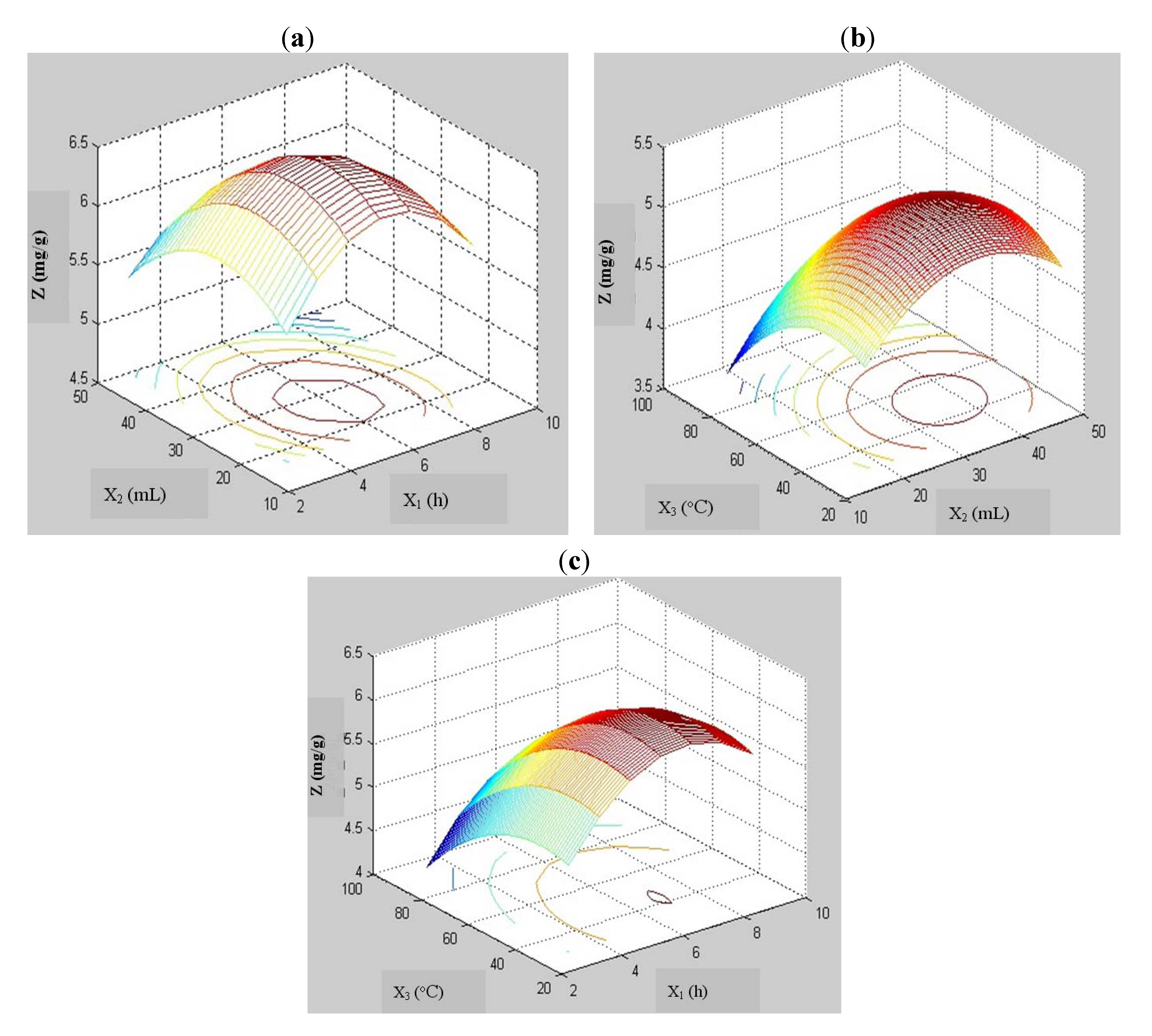

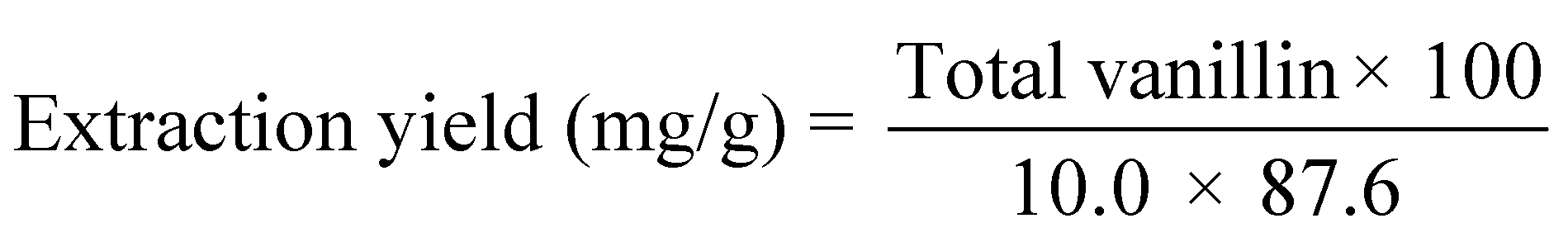

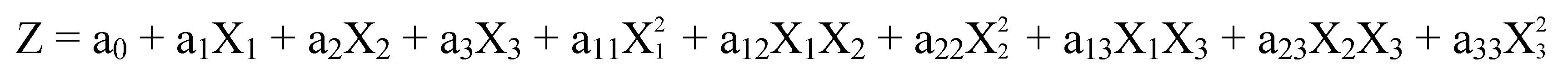

2.2. Extraction Yield

2.3. Optimization

3. Experimental

3.1 Materials

3.2. Hydrolysis and Vanillin Extraction

3.3. Determination of Vanillin by HPLC

3.4. Experimental Design

| Code levels | Variables | ||

|---|---|---|---|

| X1/Heating time (h) | X2/Enzyme quantity (mL) | X3/Temperature (°C) | |

| r = +1.682 | 9 | 50 | 90 |

| 1 | 7.78 | 43.31 | 77.8 |

| 0 | 6 | 33.5 | 60 |

| −1 | 4.22 | 23.69 | 42.2 |

| −r = −1.682 | 3 | 17 | 30 |

| △j | 1.78 | 9.81 | 17.8 |

4. Conclusions

Acknowledgments

References

- Hansen, E.H.; Møller, B.L.; Kock, G.R.; Bünner, C.M.; Kristensen, C.; Jensen, O.R.; Okkels, F.T.; Olsen, C.E.; Motawia, M.S.; Hansen, J. De novobiosynthesis of vanillin in fission yeast (Schizosaccharomyces pombe) andbaker’s yeast (Saccharomyces cerevisiae). Appl. Environ. Microbiol. 2009, 9, 2765–2774. [Google Scholar]

- Jager, L.S.D.; Perfetti, G.A.; Diachenko, G.W. Comparison of headspace-SPME-GC-MS and LC-MS for the detection and quantification of coumarin, vanillin, and ethyl vanillin in vanilla extract products. Food Chem. 2008, 107, 1701–1709. [Google Scholar] [CrossRef]

- Pereira, C.G.; Meireles, M.A.A. Supercritical fluid extraction ofbioactive compounds:Fundamentals, applications and economic perspectives. Food Bioprocess Tech. 2010, 3, 340–372. [Google Scholar]

- Waliszewski, K.N.; Ovando, S.L.; Pardio, V. Effect of hydration and enzymatic pretreatment of vanilla beans on the kinetics of vanillin extraction. J. Food Eng. 2007, 78, 1267–1273. [Google Scholar] [CrossRef]

- Delgado-Vargas, F.; Paredes-López, O. Effects of enzymatic treatments ofmarigold flowers on lutein isomeric profiles. J. Agric. Food Chem. 1997, 45, 1097–1102. [Google Scholar] [CrossRef]

- Ruiz-Terán, F.; Perez-Amador, I.; López-Munguia, A. Enzymatic extraction and transformation of glucovanillin to vanillin from vanilla green pods. J. Agric. Food. Chem. 2001, 49, 5207–5209. [Google Scholar]

- Gu, F.L.; Abbas, S.; Zhang, X.M. Optimization of maillard reaction products from casein-glucose using response surface methodology. LWT-Food Sci. Technol. 2009, 42, 1374–1379. [Google Scholar]

- Simsek, A.; Poyrazoglu, E.S.; Karacan, S.; Sedat, Y. Response surfacemethodological study on HMF and fluorescent accumulation in red and whitegrape juices and concentrates. Food Chem. 2007, 101, 987–994. [Google Scholar]

- Gallagher, E.; O’Brien, C.M.; Scannell, A.G.M.; Arendt, E.K. Use of response surface methodology to produce functional short dough biscuits. J. Food Eng. 2003, 56, 269–271. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Xu, S.Y. Optimization of processing parameters for cloudy ginkgo (Ginkgo biloba Linn.) juice. J. Food Eng. 2007, 80, 1226–1232. [Google Scholar]

- Walton, N.J.; Mayer, M.J.; Narbad, A. Vanillin. Phytochemistry 2003, 63, 505–515. [Google Scholar]

- Voisine, R.; Carmichael, L.; Chalier, P.; Cormier, F.; Morin, A. Determination of glucovanillin and vanillin in cured vanilla pods. J. Agric. Food. Chem. 1995, 43, 2658–2661. [Google Scholar]

- Wang, S.J.; Chen, F.; Wu, J.H.; Wang, Z.F.; Liao, X.J.; Hu, X.S. Optimization of pectin extraction assisted by microwave from apple pomace usingresponse surface methodology. J. Food Eng. 2007, 78, 693–700. [Google Scholar]

- Sample Availability: Samples of the materials are available from the authors.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Gu, F.; Xu, F.; Tan, L.; Wu, H.; Chu, Z.; Wang, Q. Optimization of Enzymatic Process for Vanillin Extraction Using Response Surface Methodology. Molecules 2012, 17, 8753-8761. https://doi.org/10.3390/molecules17088753

Gu F, Xu F, Tan L, Wu H, Chu Z, Wang Q. Optimization of Enzymatic Process for Vanillin Extraction Using Response Surface Methodology. Molecules. 2012; 17(8):8753-8761. https://doi.org/10.3390/molecules17088753

Chicago/Turabian StyleGu, Fenglin, Fei Xu, Lehe Tan, Huasong Wu, Zhong Chu, and Qinghuang Wang. 2012. "Optimization of Enzymatic Process for Vanillin Extraction Using Response Surface Methodology" Molecules 17, no. 8: 8753-8761. https://doi.org/10.3390/molecules17088753

APA StyleGu, F., Xu, F., Tan, L., Wu, H., Chu, Z., & Wang, Q. (2012). Optimization of Enzymatic Process for Vanillin Extraction Using Response Surface Methodology. Molecules, 17(8), 8753-8761. https://doi.org/10.3390/molecules17088753