Evaluation of Gamma Radiation Properties of Four Types of Surgical Stainless Steel in the Energy Range of 17.50–25.29 keV

Abstract

1. Introduction

2. Materials and Methods

2.1. Theory

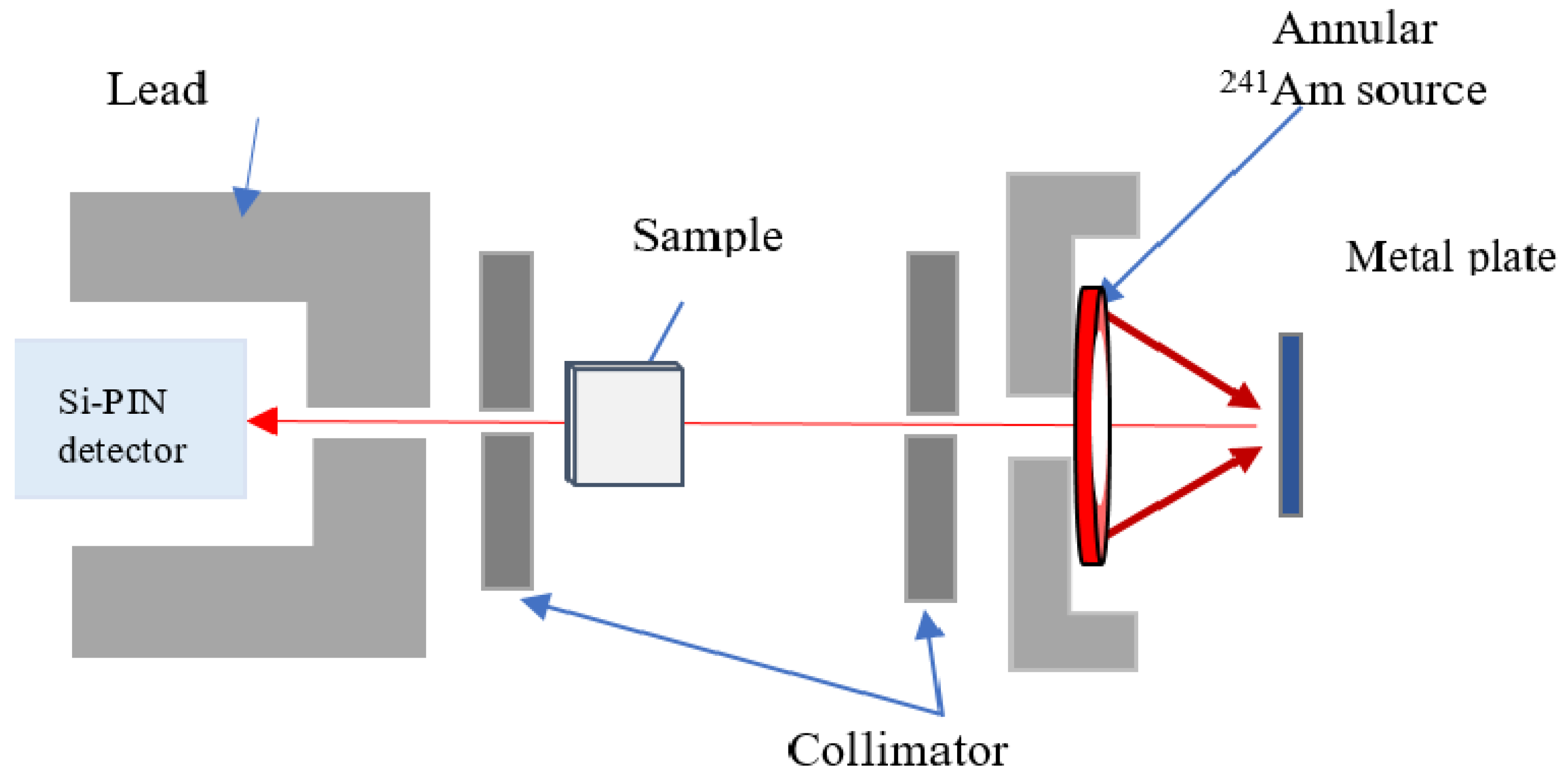

2.2. Experimental Setup

3. Results

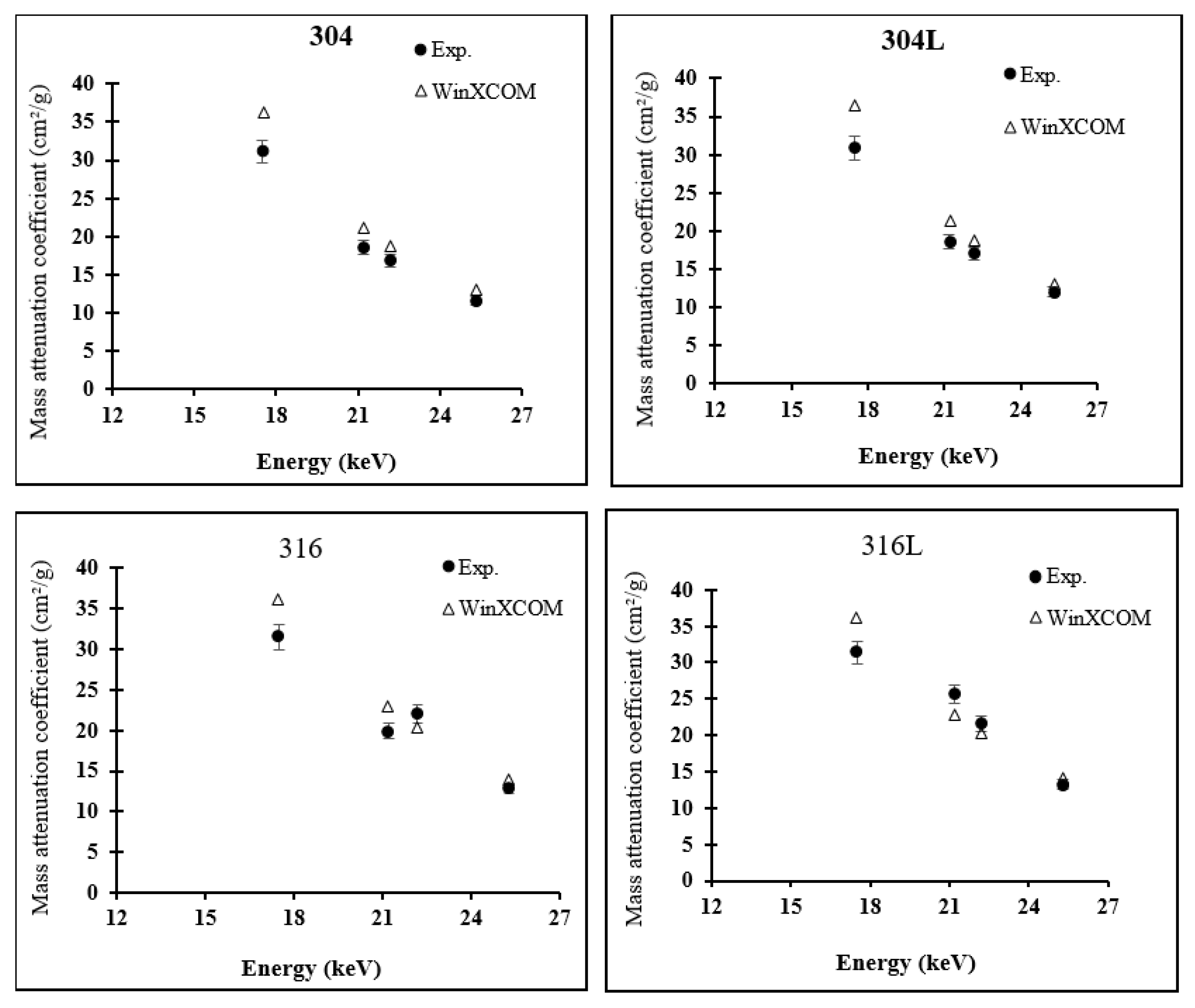

3.1. Mass Attenuation Coefficient

3.2. Effective Atomic Number () and Electron Density ()

3.3. Half-Value Layer (HVL)

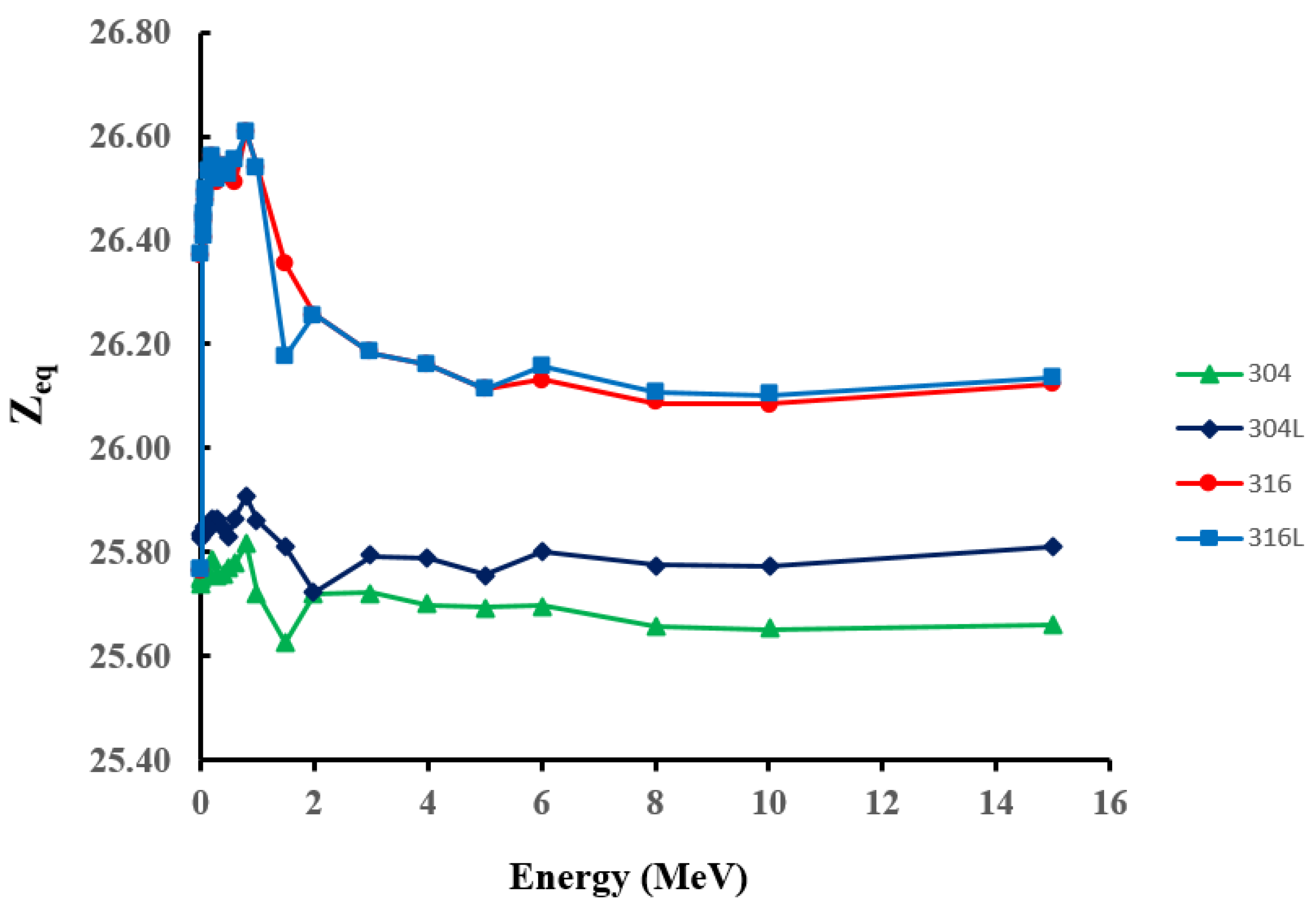

3.4. Equivalent Atomic Number () for the Investigated Surgical Stainless Steel

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Helsen, J.A.; Jürgen Breme, H. Metals as Biomaterials; Wiley: Chichester, UK; New York, NY, USA, 1998; pp. 456–462. [Google Scholar]

- Tandon, R. Net-shaping of Co-Cr-Mo (F-75) via metal injection molding. In Cobalt-Base Alloys for Biomedical Applications; ASTM International: West Conshehoken, PA, USA, 1999. [Google Scholar]

- Loto, R.T. Study of the corrosion behaviour of S32101 duplex and 410 martensitic stainless steel for application in oil refinery distillation systems. J. Mater. Res. Technol. 2017, 6, 203–212. [Google Scholar] [CrossRef]

- Daghbouj, N.; Li, B.; Callisti, M.; Sen, H.; Karlik, M.; Polcar, T. Microstructural evolution of helium-irradiated 6H–SiC subjected to different irradiation conditions and annealing temperatures: A multiple characterization study. Acta Mater. 2019, 181, 160–172. [Google Scholar] [CrossRef]

- Daghbouj, N.; Li, B.; Callisti, M.; Sen, H.; Lin, J.; Ou, X.; Karlik, M.; Polcar, T. The structural evolution of light-ion implanted 6H-SiC single crystal: Comparison of the effect of helium and hydrogen. Acta Mater. 2020, 188, 609–622. [Google Scholar] [CrossRef]

- Li, B.; Liao, Q.; Zhang, H.; Shen, T.; Ge, F.; Daghbouj, N. The effects of stress on corrosion behavior of SIMP martensitic steel in static liquid lead-bismuth eutectic. Corros. Sci. 2021, 187, 109477. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Singh, G.; Thind, K.S. Gamma radiation shielding properties of steel and iron slags. New J. Glass Ceram. 2017, 7, 1. [Google Scholar] [CrossRef]

- Çalık, A.; Akbunar, Ş.; Uçar, N.; Yılmaz, N.; Karakaş, M.S.; Akkurt, İ. A comparison of radiation shielding of stainless steel with different magnetic properties. Nucl. Technol. Radiat. Prot. 2014, 29, 186–189. [Google Scholar] [CrossRef][Green Version]

- Buyuk, B. Gamma attenuation behavior of some stainless and boron steels. Acta Phys. Pol. A 2015, 127, 1342–1345. [Google Scholar] [CrossRef]

- Singh, V.P.; Medhat, M.; Shirmardi, S. Comparative studies on shielding properties of some steel alloys using Geant4, MCNP, WinXCOM and experimental results. Radiat. Phys. Chem. 2015, 106, 255–260. [Google Scholar] [CrossRef]

- Aygün, B.; Şakar, E.; Korkut, T.; Sayyed, M.; Karabulut, A.; Zaid, M. Fabrication of Ni, Cr, W reinforced new high alloyed stainless steels for radiation shielding applications. Results Phys. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Manjunatha, H.; Seenappa, L. Gamma and X-ray Shielding Properties of Various Types of Steels. J. Nucl. Eng. Radiat. Sci. 2019, 5, 044501. [Google Scholar] [CrossRef]

- Akkurt, I.; Akyıldırım, H.; Calik, A.; Aytar, O.; Uçar, N. Gamma ray attenuation coefficient of microalloyed stainless steel. Arab. J. Sci. Eng. 2011, 36, 145–149. [Google Scholar] [CrossRef]

- Eissa, M.; Salama, E.; El-Kameesy, S.; Tageldin, A. Gamma Rays Attenuation Properties of Tungsten Stainless Steel Alloys. Arab J. Nucl. Sci. Appl. (Online) 2018, 51, 85–92. [Google Scholar]

- Aygün, B. High alloyed new stainless steel shielding material for gamma and fast neutron radiation. Nucl. Eng. Technol. 2020, 52, 647–653. [Google Scholar] [CrossRef]

- Singh, V.; Badiger, N. Study of mass attenuation coefficients, effective atomic numbers and electron densities of carbon steel and stainless steels. Radioprotection 2013, 48, 431–443. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; Yu, P.; Dargusch, M.; StJohn, D.; Qian, M. Metal injection moulding of surgical tools, biomaterials and medical devices: A review. Powder Technol. 2020, 364, 189–204. [Google Scholar] [CrossRef]

- Khalili, E.; Sarafbidabad, M. Combination of laser patterning and nano PTFE sputtering for the creation a super-hydrophobic surface on 304 stainless steel in medical applications. Surf. Interfaces 2017, 8, 219–224. [Google Scholar] [CrossRef]

- Bait, L.; Azzouz, L.; Madaoui, N.; Saoula, N. Influence of substrate bias voltage on the properties of TiO2 deposited by radio-frequency magnetron sputtering on 304L for biomaterials applications. Appl. Surf. Sci. 2017, 395, 72–77. [Google Scholar] [CrossRef]

- Haidopoulos, M.; Turgeon, S.; Sarra-Bournet, C.; Laroche, G.; Mantovani, D. Development of an optimized electrochemical process for subsequent coating of 316 stainless steel for stent applications. J. Mater. Sci. Mater. Med. 2006, 17, 647–657. [Google Scholar] [CrossRef]

- Bandar, A.M.; Vo, P.; Mongrain, R.; Irissou, E.; Yue, S. Effect of heat treatment on the microstructure and mechanical properties of stainless steel 316L coatings produced by cold spray for biomedical applications. J. Therm. Spray Technol. 2014, 23, 641–652. [Google Scholar]

- Steels, A. Stainless Steel Grade Datasheets; Atlas Steels Technical Department: Melbourne, Australia, 2013; Available online: https://atlassteels.com.au/ (accessed on 1 August 2013).

- Hubbell, J.H. Photon mass attenuation and energy-absorption coefficients. Int. J. Appl. Radiat. Isot. 1982, 33, 1269–1290. [Google Scholar] [CrossRef]

- Harima, Y. An approximation of gamma-ray buildup factors by modified geometrical progression. Nucl. Sci. Eng. 1983, 83, 299–309. [Google Scholar] [CrossRef]

- Elsafi, M.; Alrashedi, M.; Sayyed, M.; Al-Hamarneh, I.F.; El-Nahal, M.; El-Khatib, M.; Khandaker, M.U.; Osman, H.; Askary, A.E. The Potentials of Egyptian and Indian Granites for Protection of Ionizing Radiation. Materials 2021, 14, 3928. [Google Scholar] [CrossRef] [PubMed]

- Marashdeh, M.; Bauk, S.; Tajuddin, A.; Hashim, R. Measurement of mass attenuation coefficients of Rhizophora spp. binderless particleboards in the 16.59–25.26 keV photon energy range and their density profile using x-ray computed tomography. Appl. Radiat. Isot. 2012, 70, 656–662. [Google Scholar] [CrossRef] [PubMed]

- Akhdar, H.; Marashdeh, M.; AlAqeel, M. Investigation of gamma radiation shielding properties of polyethylene glycol in the energy range from 8.67 to 23.19 keV. Nucl. Eng. Technol. 2021. [Google Scholar] [CrossRef]

- Lakshminarayana, G.; Kumar, A.; Dong, M.; Sayyed, M.; Long, N.V.; Mahdi, M. Exploration of gamma radiation shielding features for titanate bismuth borotellurite glasses using relevant software program and Monte Carlo simulation code. J. Non-Cryst. Solids 2018, 481, 65–73. [Google Scholar] [CrossRef]

| Element | Material | |||

|---|---|---|---|---|

| 304 [22] | 304L [22] | 316 [22] | 316L [22] | |

| C | 0.07 | 0.03 | 0.08 | 0.03 |

| Si | 0.75 | 0.75 | 0.75 | 0.75 |

| Mn | 2.0 | 2.0 | 2.0 | 2.0 |

| Cr | 18.5 | 18.5 | 17 | 17 |

| Ni | 9.25 | 10 | 12 | 12 |

| Mo | - | - | 2.5 | 2.5 |

| P | 0.045 | 0.045 | 0.045 | 0.045 |

| S | 0.03 | 0.03 | 0.03 | 0.03 |

| N | 0.10 | 0.10 | 0.10 | 0.10 |

| Fe | Balance | Balance | Balance | Balance |

| Relative density (g/cm) | 7.93 | 7.93 | 7.98 | 7.98 |

| Samples | Mo (17.50 keV) | Pd (21.20 keV) | Ag (22.19 keV) | Sn (25.29 keV) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Error (±%) | Error (±%) | Error (±%) | Error (±%) | |||||||||

| 304 | 246.78 | 31.12 | 1.74 | 146.70 | 18.50 | 1.53 | 133.06 | 16.78 | 1.27 | 92.24 | 11.63 | 1.07 |

| 304L | 244.80 | 30.87 | 1.85 | 147.34 | 18.58 | 1.49 | 134.48 | 16.96 | 1.00 | 95.24 | 12.01 | 1.07 |

| 316 | 251.57 | 31.53 | 2.06 | 155.55 | 19.95 | 1.28 | 176.22 | 22.08 | 1.36 | 102.45 | 12.84 | 1.58 |

| 316L | 239.05 | 31.40 | 2.30 | 204.18 | 25.59 | 1.92 | 172.15 | 21.57 | 1.55 | 105.20 | 13.18 | 0.95 |

| Material | Energy (keV) | (cm/g) | ||

|---|---|---|---|---|

| Experimental | Theoretical (WinXCOM) | Percentage Deviation % | ||

| 304 | 17.50 | 31.12 | 36.24 | −14.13 |

| 21.20 | 18.50 | 21.2 | −12.74 | |

| 22.19 | 16.78 | 18.65 | −10.03 | |

| 25.29 | 11.63 | 12.89 | −9.76 | |

| 304L | 17.50 | 30.87 | 36.58 | −15.61 |

| 21.20 | 18.58 | 21.41 | −13.22 | |

| 22.19 | 16.96 | 18.83 | −9.94 | |

| 25.29 | 12.01 | 13.02 | −7.76 | |

| 316 | 17.50 | 31.53 | 36.12 | −12.72 |

| 21.20 | 19.95 | 22.94 | −13.03 | |

| 22.19 | 22.08 | 20.28 | 8.89 | |

| 25.29 | 12.84 | 14.04 | −8.56 | |

| 316L | 17.50 | 31.40 | 36.14 | −13.11 |

| 21.20 | 25.59 | 22.95 | 11.49 | |

| 22.19 | 21.57 | 20.29 | 6.32 | |

| 25.29 | 13.18 | 14.05 | −6.17 | |

| Material | Energy (keV) | (×10 Electrons g) | |||

|---|---|---|---|---|---|

| Experimental | Theoretical (WinXCOM) | Experimental | Theoretical (WinXCOM) | ||

| 304 | 17.50 | 21.95 | 25.56 | 2.40 | 2.79 |

| 21.20 | 22.30 | 25.55 | 2.44 | 2.79 | |

| 22.19 | 23.03 | 25.57 | 2.52 | 2.80 | |

| 25.29 | 23.06 | 25.55 | 2.52 | 2.79 | |

| 304L | 17.50 | 21.69 | 25.69 | 2.36 | 2.80 |

| 21.20 | 22.30 | 25.70 | 2.43 | 2.80 | |

| 22.19 | 23.16 | 25.71 | 2.52 | 2.80 | |

| 25.29 | 23.71 | 25.71 | 2.58 | 2.80 | |

| 316 | 17.50 | 22.77 | 26.07 | 2.44 | 2.79 |

| 21.20 | 22.92 | 26.36 | 2.46 | 2.82 | |

| 22.19 | 28.82 | 26.47 | 3.09 | 2.84 | |

| 25.29 | 24.17 | 26.43 | 2.59 | 2.83 | |

| 316L | 17.50 | 22.67 | 26.09 | 2.43 | 2.80 |

| 21.20 | 29.40 | 26.37 | 3.15 | 2.83 | |

| 22.19 | 28.16 | 26.49 | 3.02 | 2.84 | |

| 25.29 | 24.81 | 26.45 | 2.66 | 2.83 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marashdeh, M.; Al-Hamarneh, I.F. Evaluation of Gamma Radiation Properties of Four Types of Surgical Stainless Steel in the Energy Range of 17.50–25.29 keV. Materials 2021, 14, 6873. https://doi.org/10.3390/ma14226873

Marashdeh M, Al-Hamarneh IF. Evaluation of Gamma Radiation Properties of Four Types of Surgical Stainless Steel in the Energy Range of 17.50–25.29 keV. Materials. 2021; 14(22):6873. https://doi.org/10.3390/ma14226873

Chicago/Turabian StyleMarashdeh, Mohammad, and Ibrahim F. Al-Hamarneh. 2021. "Evaluation of Gamma Radiation Properties of Four Types of Surgical Stainless Steel in the Energy Range of 17.50–25.29 keV" Materials 14, no. 22: 6873. https://doi.org/10.3390/ma14226873

APA StyleMarashdeh, M., & Al-Hamarneh, I. F. (2021). Evaluation of Gamma Radiation Properties of Four Types of Surgical Stainless Steel in the Energy Range of 17.50–25.29 keV. Materials, 14(22), 6873. https://doi.org/10.3390/ma14226873