Comparison of the Parameters of the Exergoeconomic Environmental Analysis of Two Combined Cycles of Three Pressure Levels with and without Postcombustion

Abstract

:1. Introduction

2. Materials and Methods

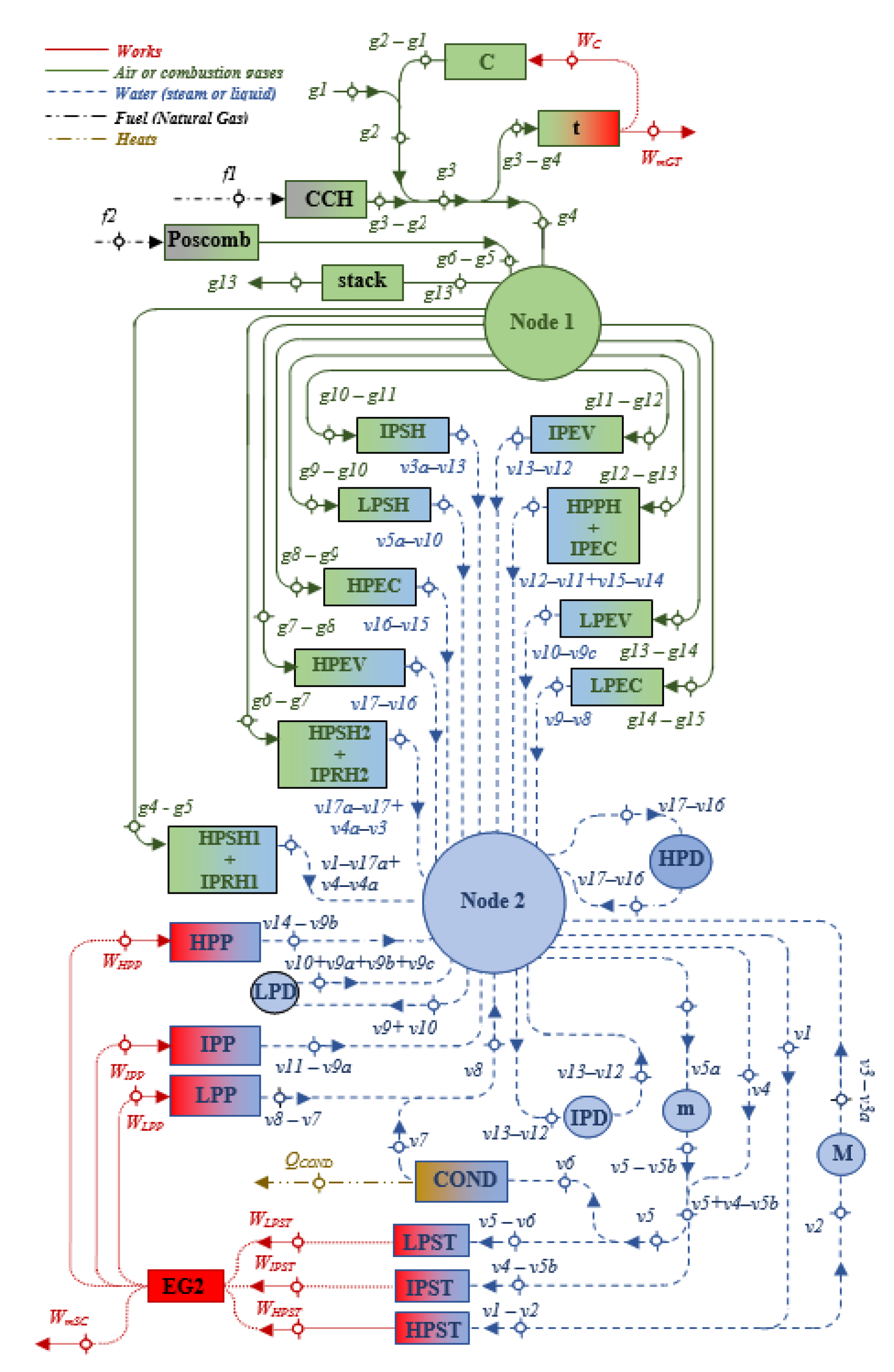

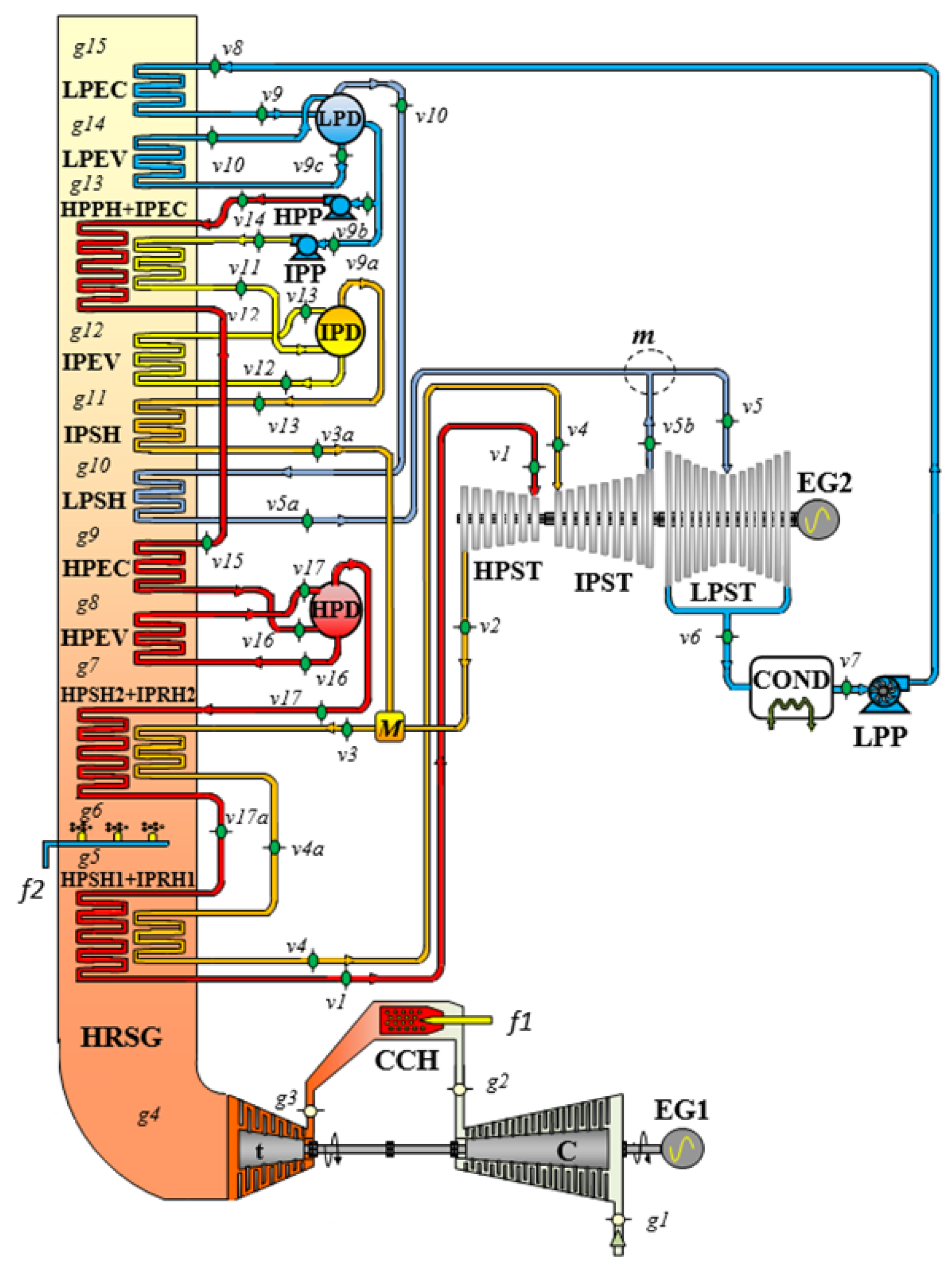

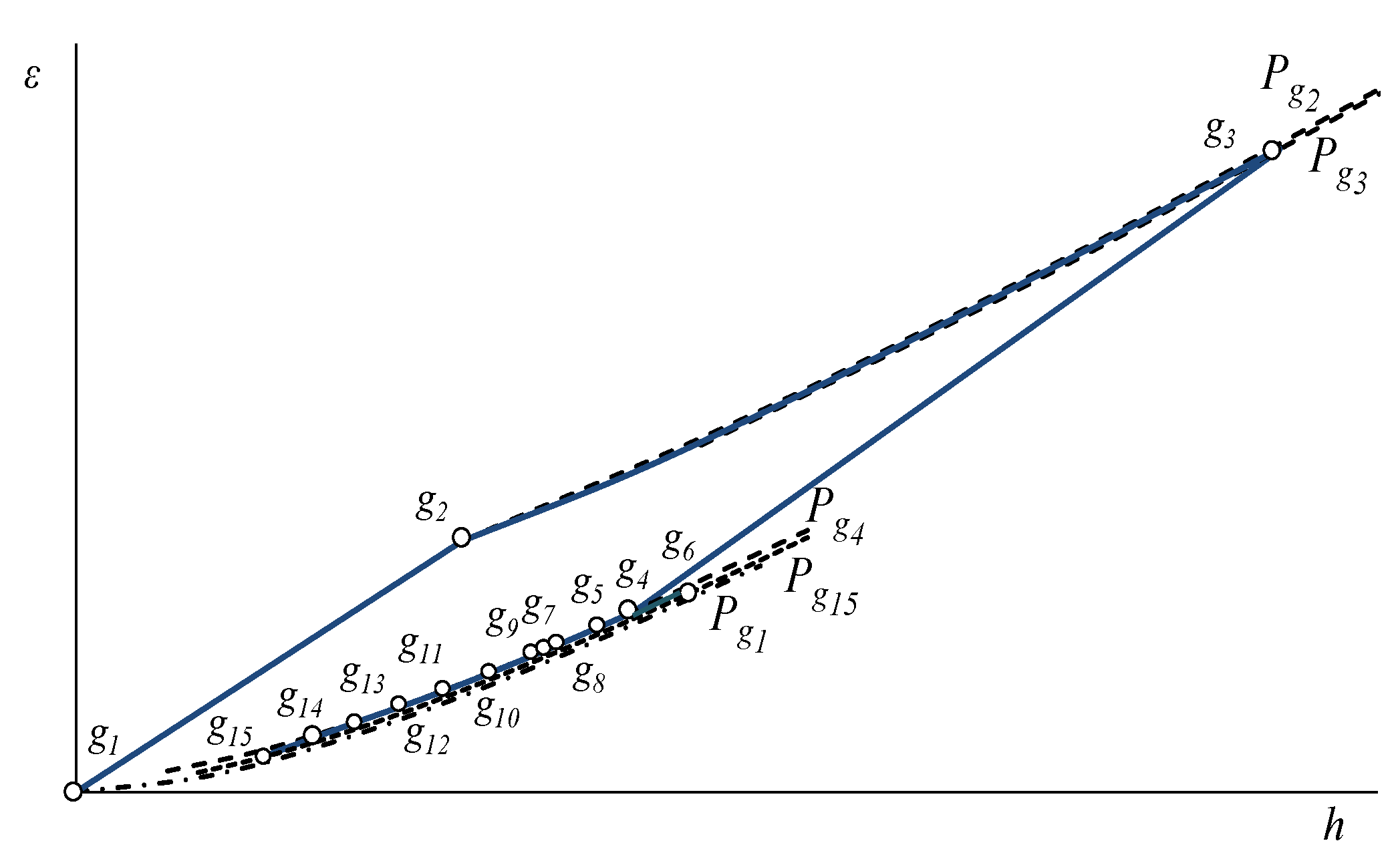

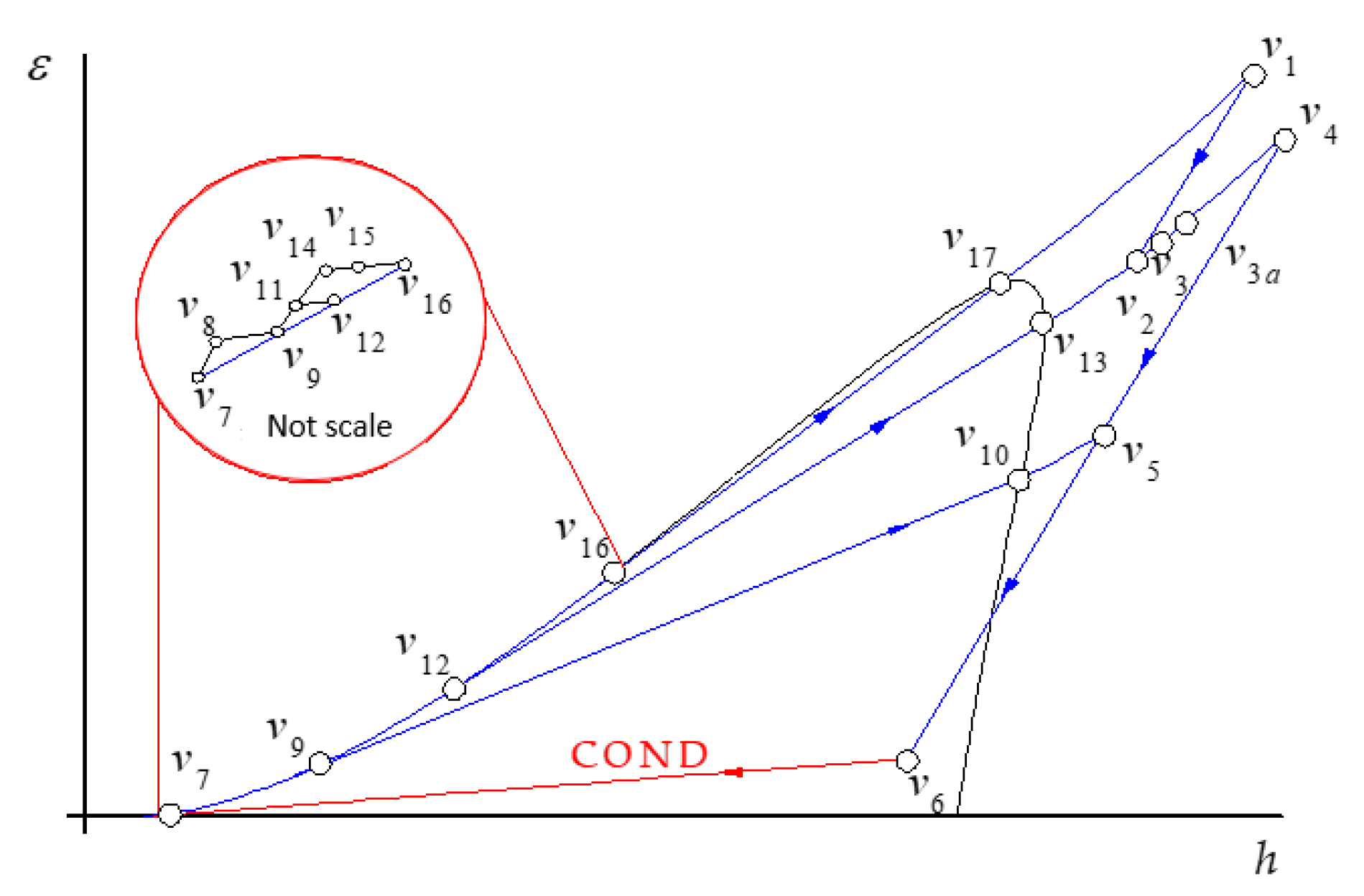

2.1. Description of the Combined Cycle

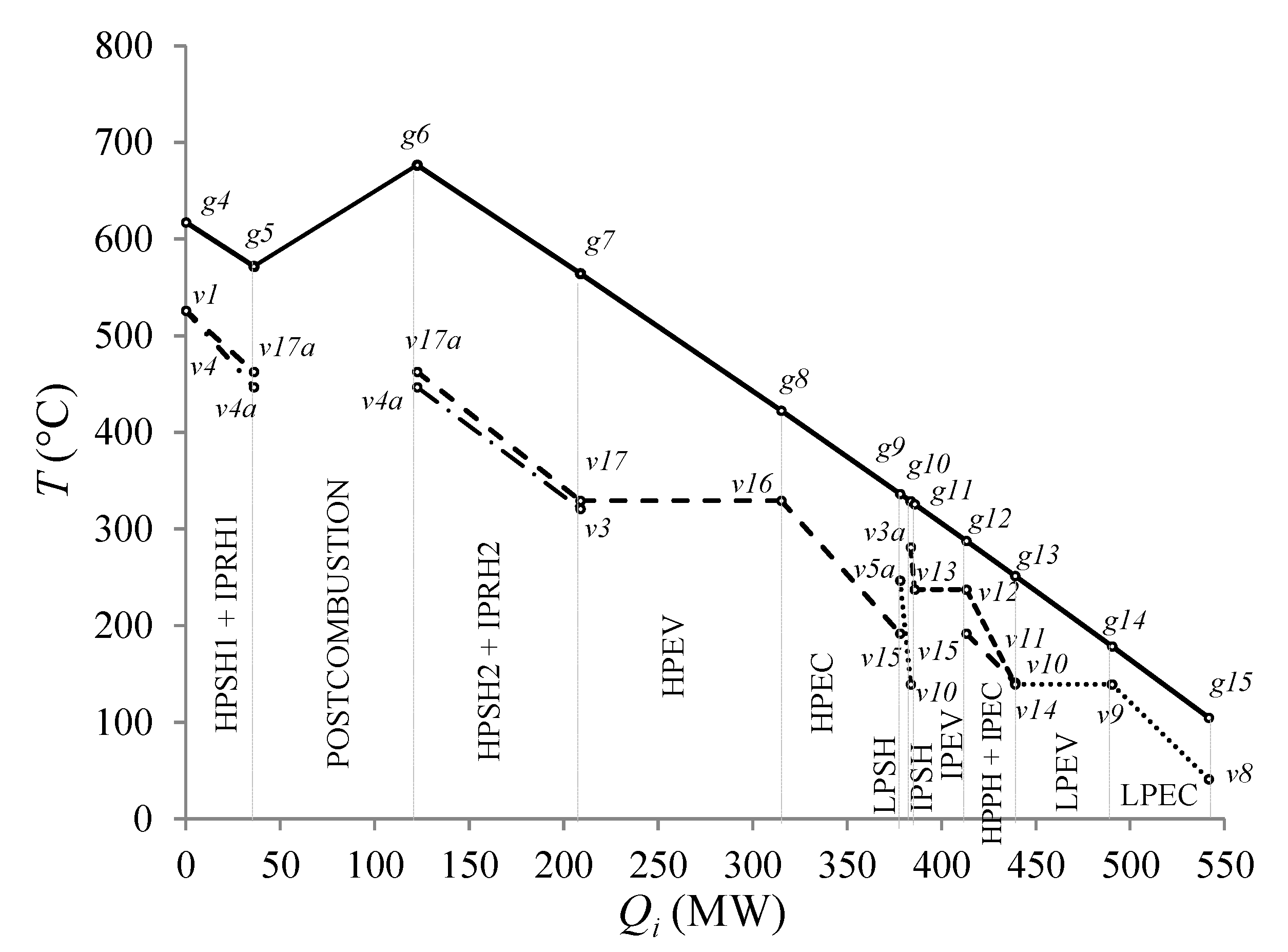

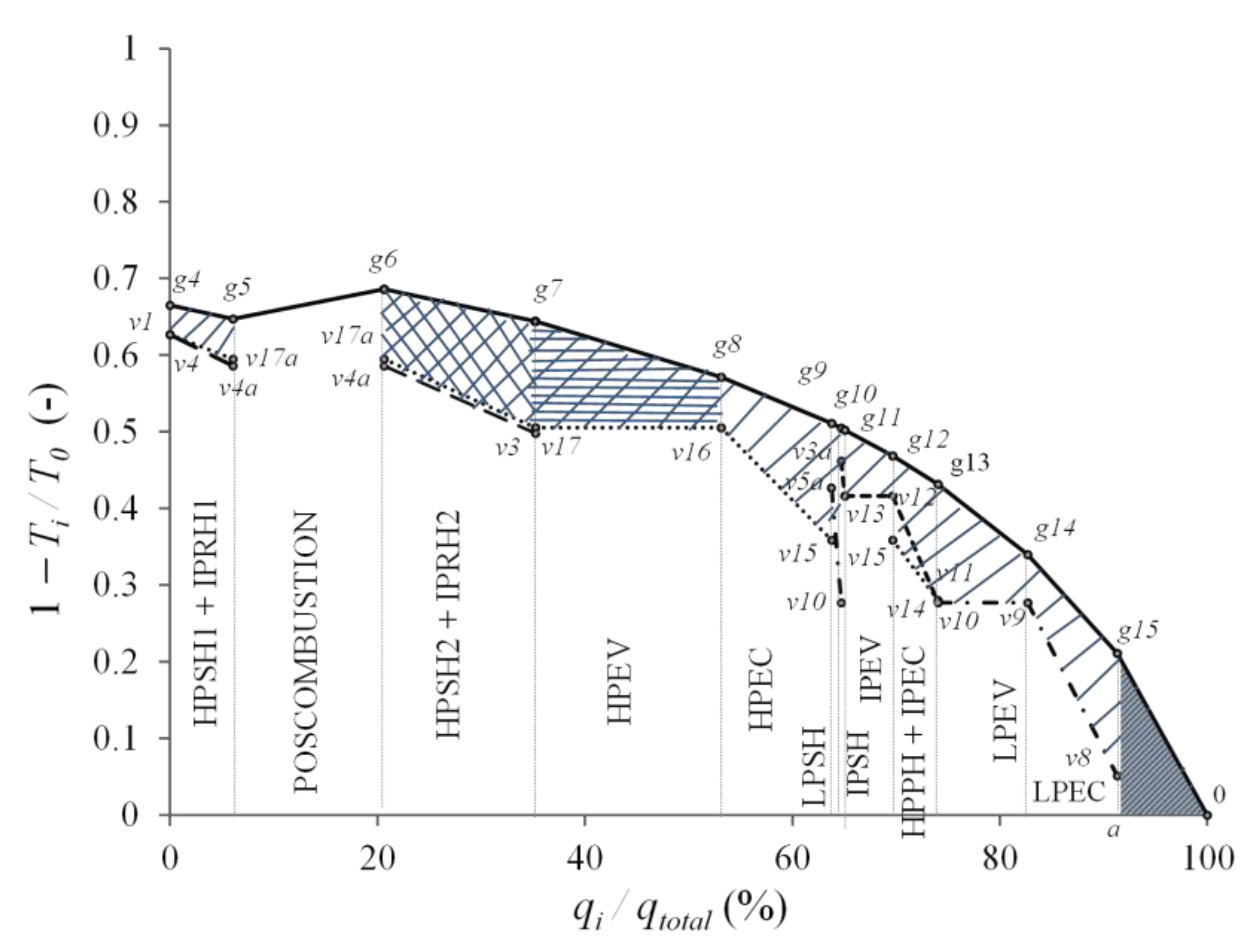

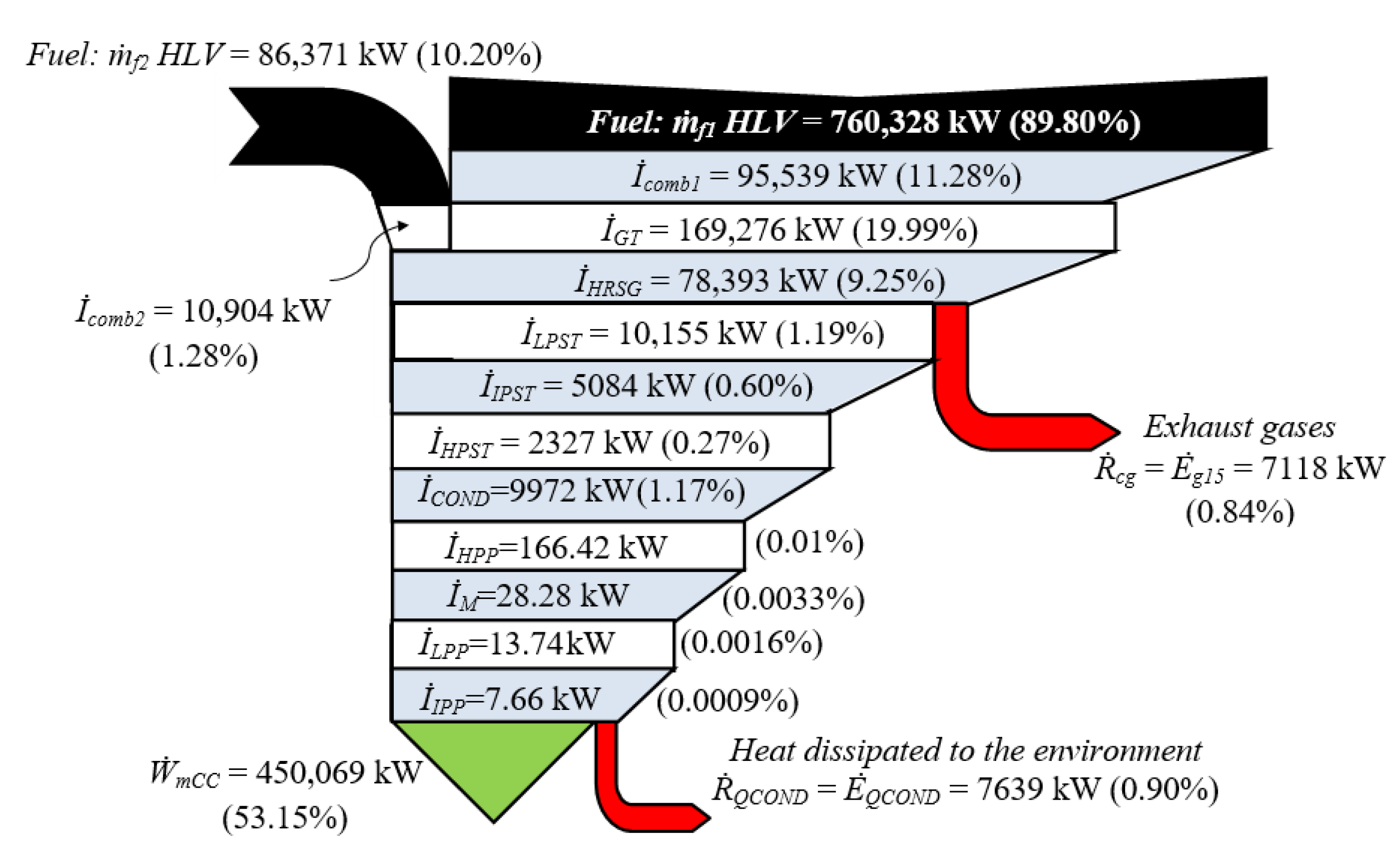

Thermodynamics of the Combined Cycle

2.2. Exergoeconomic Evaluation

2.3. Environmental Indicators of Pollutant Emissions

3. Operating Conditions

4. Comparative Analysis of Cycle Combined with and without Postcombustion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| afr | air-fuel ratio; [kga/kgf], |

| ARP | acid rain potential; [kgSO2eq/kgi], |

| c | unit exergoeconomic cost; [USD/kJ], |

| cP | specific heat at constant pressure; [kJ/(kg K)], |

| DA | dry air, [mol] |

| Ė | exergy flow rate; [kW], |

| E* | exergetic cost; [kW], |

| EOC | exergoeconomic operating cost; [USD/s], |

| Ḟ | resource exergy flow rate; [kW], |

| fi | mass fraction of polluting gas; [kgi/kgcg], |

| far | fuel-air ratio; [kgf/kga], |

| GWP | global warming potential; [kgCO2eq/kgi], |

| h | specific enthalpy; [kJ/kg], |

| HTP | human toxicity potential; [kgPbeq/kgi], |

| I | environmental indicator; [gieq/kWh], |

| İ | irreversibility flow rate; [kW], |

| k* | unit exergy cost; [-], |

| LHV | lower heating value; [kJ/kmol], |

| m | número de hidrógenos en el gas natural; [kmoli/kmolf], |

| MM | molecular mass; [kg/kmol], |

| ṁ | mass flow rate; [kg/s], |

| n | número de carbonos en el gas natural; [kmoli/kmolf], |

| P | pressure; [bar or Pa], |

| Ṗ | product exergy cost; [kW], |

| heat transfer rate; [kW], | |

| q | heat per mass unit; [kJ/kg]; |

| qH | heat supplied per mass unit; [kJ/kg]; |

| qi/qCRC | fraction of heat recovered in each section of the heat recovery steam generator; [%], |

| R | gas constant; [kJ/(kg K)], |

| Ṙ | residue exergy flow rate; [kW], |

| R* | exergetic cost of the residue; [kW], |

| s | specific entropy; [kJ/(kg K)], |

| SFP | smog formation potential; [kgNOxeq/kgi], |

| T | temperature; [°C or K], |

| TIT | turbine inlet temperature; [°C o K], |

| w | specific work; [kJ/kg], |

| Ẇ | power output; [kW], |

| x | ratio of the particular gas constant to heat capacity of constant pressure, x = R/cP; [-], |

| Xi | volumetric fraction; [kmoli/kmolf or %], |

| y | temperature ratio, [=TIT/Tg1]; [-], |

| Yi | mass fraction; [gi/kgf], |

| Greek Letters | |

| Β | allocation factor of residue of heat dissipated by condenser assigned to the i-th component; [-]; |

| δi | stoichiometric coefficients, postcombustion; [kmoli/kmolf], |

| Δ | variation, |

| ε | specific exergy; [kJ/kg], |

| θi | stoichiometric coefficients, combustion chambre; [kmoli/kmolf], |

| η | efficiency; [%], |

| λ | excess air; [-], |

| μi | allocation factor of residue of exhaust gases i-th component; [-], |

| Π | exergoeconomic cost; [USD/h], |

| π | pressure ratio; [-]. |

| Superscripts | |

| prod | productive component, |

| cg | combustion gases, |

| v | liquid or vapor of water, |

| x | ratio of the particular gas constant to heat capacity of constant pressure, x = R/cP; [-]. |

| Subscripts | |

| 0 | dead state, |

| a | air, |

| af | adiabatic flame, |

| CCH | combustion chamber, |

| cg | combustion gases, |

| comb | combustion process, |

| COND | condenser, |

| DA | dry air, |

| estWA | stoichiometric of wet air, |

| ex | exergetic, |

| f1 | fuel supplied to the combustion chamber, |

| f2 | fuel supplied in the afterburner, |

| F | component fuel, |

| g1, … g5 | energy streams of flue gases in the gas turbine and heat recovery steam generator, |

| k | k-th component, |

| m | output, |

| P | component product, |

| pp | pinch point, |

| pz | primary zone of the combustion chambre, |

| sic | isentropic compressor, |

| sip | isentropic pump, |

| sit | isentropic gas turbine, |

| sitv | isentropic vapor turbine, |

| th | thermal, |

| v1, … v17 | energetic streams of the steam cycle, |

| WA | wet air. |

| Abbreviation | |

| C | compressor, |

| CC | combined cycle, |

| CCH | combustion chamber, |

| COND | condenser, |

| EG | electric generator, |

| f | fuel inlet to combustion chamber, |

| GT | gas turbine, |

| HRSG | auxiliary fired heat recovery steam generator, |

| HPEC | high pressure economizer, |

| HPEV | high pressure evaporator, |

| HPD | high pressure dome, |

| HPP | high pressure pump, |

| HPPH | high pressure preheater, |

| HPRH | high pressure reheater, |

| HPSH | high pressure superheater, |

| HPST | high pressure steam turbine |

| IPEC | intermediate pressure economizer, |

| IPEV | intermediate pressure evaporator. |

| IPD | intermediate pressure dome, |

| IPP | intermediate pressure pump, |

| IPRH | intermediate pressure reheater, |

| IPSH | intermediate pressure superheater, |

| IPST | intermediate pressure steam turbine |

| LPEC | low pressure economizer, |

| LPEV | low pressure evaporator, |

| LPD | low pressure dome, |

| LPP | low pressure pump, |

| LPRH | low pressure reheater, |

| LPSH | low pressure superheater, |

| LPST | low pressure steam turbine, |

| m | junction inlet of low pressure steam turbine, |

| M | junction at the inlet of intermediate pressure reheater, |

| SC | steam cycle, |

| ST | steam turbine, |

| t | turbine. |

Appendix A

| Heat supplied per unit mass in CCH of the GT | Fuel mass flow rate delivered in the CCH |

| Thermal efficiency of the GT | Exergy flow rate of flue gases |

| Exergy flow rate of air | Fuel exergy flow rate |

| Power output of the GT | Power supplied to the compressor |

| Exergetic efficiency of the GT | Exergy efficiency of GT and SC components |

Appendix B

| Work output of steam cycle | |

| Heat recovered per unit mass into the HRSG | |

| Power output for SC | Thermal efficiency of the SC |

| Exergy flow rate of stream of the SC ; i = 1, …, 17 | Exergy flow rate of heat rejected by the condenser |

| Exergy flow rate due to heat gained by the liquid-vapor stream of the HRSG | |

References

- Secretaría de Energía. Prospectiva del Sector Eléctrico 2018–2032; SENER: Ciudad de México, México, 2018. (In Spanish)

- Lugo-Leyte, R.; Zamora-Mata, J.; Toledo-Velázquez, M.; Salazar-Pereyra, M.; Torres-Aldaco, A. Methodology to determine the appropriate amount of excess air for the operation of a gas turbine in a wet environment. Energy 2010, 35, 550–555. [Google Scholar] [CrossRef]

- Lugo-Leyte, R.; Salazar-Pereyra, M.; Méndez, H.D.L.; Aguilar-Adaya, I.; Ambriz-García, J.J.; Vargas, J.E.R. Parametric analysis of a two-shaft aeroderivate gas turbine of 11.86 MW. Entropy 2015, 17, 5829–5847. [Google Scholar] [CrossRef] [Green Version]

- Lugo-Leyte, R.; Salazar-Pereyra, M.; Bonilla-Blancas, A.E.; Lugo-Mendez, H.D.; Ruíz-Ramírez, O.A.; Toledo-Velázquez, M. Exergetic analysis of triple-level pressure combined power plant with supplementary firing. J. Energy Eng. 2016, 142, 05016001. [Google Scholar] [CrossRef]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Butterworths: London, UK, 1995; pp. 99–150. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development; Elsevier: Amsterdam, The Netherlands, 2007; pp. 50–75. [Google Scholar]

- Valero, A.; Correas, L.; Zaleta, A.; Lazzaretto, A.; Verda, V.; Reini, M.; Rangel, V. On the thermoeconomic approach to the diagnosis of energy system malfunctions: Part 1: The TADEUS problem. Energy 2004, 29, 1875–1887. [Google Scholar] [CrossRef]

- Valero, A.; Correas, L.; Zaleta, A.; Lazzaretto, A.; Verda, V.; Reini, M.; Rangel, V. On the thermoeconomic approach to the diagnosis of energy system malfunctions: Part 2. Malfunction definitions and assessment. Energy 2004, 29, 1889–1907. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Thermoeconomic analysis and optimization of energy systems. Prog. Energy Combust. Sci. 1993, 19, 227–257. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronics, G.; Moran, M. Thermal Design and Optimization; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Torres-González, E.V.; Lugo-Leyte, R.; Salazar-Pereyra, M.; Lugo-Méndez, H.D.; Aguilar Adaya, I. Análisis paramétrico del costo exergético del residuo de una turbine de gas. Rev. Fac. Cienc. Químicas 2014, 10, 29–41. (In Spanish) [Google Scholar]

- Aydin, H. Exergetic sustainability analysis of LM6000 gas turbine power plant with steam cycle. Energy 2013, 57, 766–774. [Google Scholar] [CrossRef]

- Vučković, G.D.; Stojiljković, M.M.; Vukić, M.V.; Stefanović, G.M.; Dedeić, E.M. Advanced exergy analysis and exergoeconomic performance evaluation of thermal processes in an existing industrial plant. Energy Convers. Manag. 2014, 85, 655–662. [Google Scholar] [CrossRef]

- Torres, C.; Valero, A. The exergy cost theory revisited. Energies 2021, 14, 1594. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, Q.; Wang, X.; Song, D.; Liu, W.; Liu, W. Exergy and exergoeconomic analyses with modeling for CO2 allocation of coal-fired CHP plants. Energy 2018, 152, 562–575. [Google Scholar] [CrossRef]

- Valero, A.; Usón, S.; Torres, C.; Valero, A. Application of thermoeconomics to industrial ecology. Entropy 2010, 12, 591–612. [Google Scholar] [CrossRef]

- Lugo, R.; Salazar, M.; Ruíz, O.A.; Zamora, J.M.; Torres, E.V. Análisis de costos de operación exergoeconómicos a un ciclo teórico de refrigeración por compresión de vapor usando HFC-134a. Rev. Mex. De Ing. Química 2013, 12, 361–370. (In Spanish) [Google Scholar]

- Torres, E.V.; Lugo, R.; Lugo, H.D.; Salazar, M.; Torres, A. Parametric analysis of the exergoeconomic operation costs, environmental and human toxicity indexes of the MF501F3 turbine. Entropy 2016, 18, 286. [Google Scholar] [CrossRef] [Green Version]

- Bonilla, A.E.; Salazar, M.; Mora, A.; Lugo, R.; Lugo, H.D.; Torres, E.V. Operation cost exergoeconomic of transcritical refrigeration cycle with carbon dioxide. Int. J. Ambient Energy 2020, 41, 409–417. [Google Scholar] [CrossRef]

- Agudelo, A.; Valero, A.; Torres, C. Allocation of waste cost in thermoeconomic analysis. Energy 2012, 45, 634–643. [Google Scholar] [CrossRef]

- Lugo, H.D.; Torres, E.V.; Castro, S.; Salazar, M.; López, T.; Lugo, R. An irreversibility based criterion to determine the cost formation of residues in a three-pressure-level combined cycle. Entropy 2020, 22, 299. [Google Scholar]

- Lugo, H.D.; Castro, S.; Salazar, M.; Valencia, J.; Torres, E.V.; Lugo, R. Residue cost formation of a high bypass turbofan engine. Appl. Sci. 2020, 10, 9060. [Google Scholar]

- Torres, C.; Valero, A.; Rangel, V.; Zaleta, A. On the cost formation process of the residues. Energy 2008, 33, 144–152. [Google Scholar] [CrossRef]

- Keshavarzian, S.; Rocco, M.V.; Gardumi, F.; Colombo, E. Practical approaches for applying thermoeconomic analysis to energy conversion systems: Benchmarking and comparative application. Energy Convers. Manag. 2017, 150, 532–544. [Google Scholar] [CrossRef]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- Rocha, D.H.D.; Silva, R.J. Exergoenvironmental analysis of a ultra-supercritical coal-fired power plant. J. Clean. Prod. 2019, 231, 671–682. [Google Scholar] [CrossRef]

- Comisión Federal de Electricidad. Balance térmico de la Central de Ciclo Combinado Tuxpan II; Comisión Federal de Electricidad: Ciudad de México, México, 2018. (In Spanish) [Google Scholar]

- Lefebvre, A.H.; Ballal, D.R. Gas Turbines Combustion; CRC Press, Taylor and Francis Group: London, UK, 2010. [Google Scholar]

- PEMEX. Available online: http://www.gas.pemex.com.mx (accessed on 11 June 2021).

- CRE. Available online: http://www.cre.gob.mx (accessed on 11 June 2021).

- Allen, D.T.; Shonnard, D.R. Green Engineering: Environmentally Conscious Design of Chemical Processes; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

| Exhaust Gases | δi (kmoli/kmolf) | Xi′ (%) | fi′ (kgi/kggc) |

|---|---|---|---|

| CO2 | 0.0472 | 4.70 | 0.07345 |

| H2O | 0.1025 | 10.22 | 0.06525 |

| N2 | 0.7473 | 74.41 | 0.74011 |

| O2 | 0.1063 | 10.59 | 0.12031 |

| CO | 0.000377 | 0.0375 | 0.00037 |

| CnHm | 0.000017 | 0.0001 | 0.00001 |

| NOx | 0.000428 | 0.0424 | 0.00046 |

| Component | Exergoeconomic Costs |

|---|---|

| External resources | |

| Compressor | |

| Combustion chamber | |

| Turbine | |

| Poscombustion |

| Component | Exergoeconomic Costs |

|---|---|

| HPSH1 + IPRH1 | , |

| HPSH2 + IPRH2 | |

| HPEV | , |

| HPEC | , |

| LPSH | , |

| Component | Exergoeconomic Costs |

|---|---|

| IPSH | |

| IPEV | |

| HPPH + IPEC | |

| LPEV | , |

| LPEC | , |

| Emitted Gas | GWP (kgCO2eq/kgi) | ARP (kgSO2eq/kgi) | SFP (kgNOxeq/kgi) | HTP (kgPbeq/kgi) |

|---|---|---|---|---|

| CO | 3 | 0 | 0 | 0.00014 |

| CO2 | 1 | 0 | 0 | 0 |

| CnHm | CH4-21 | 0 | 0.015-CH4 | 0 |

| NOx | NO2-40 | 1.07-NO 0.7-NO2 | 1 | 0.002-NO2 |

| Global warming indicator |

| Smog formation indicator |

| Acid rain indicator |

| Human toxicity indicator |

| ẆmGT, (MW) | 139.2 |

| TIT or Tg3, (°C) | 1300 |

| πC, (-) | 16 |

| ηsic, (-) | 0.88 |

| ηsit, (-) | 0.9 |

| ΔPCCH/Pg2, (%) | 2 |

| ΔPt/Patm, (%) | 1 |

| Tamb and T0, (°C) | 25 |

| Patm and P0, (bar) | 1.013 |

| Tv1, (°C) | 525.8 |

| HP, (bar) | 127.38 |

| IP, (bar) | 32.06 |

| LP, (bar) | 3.53 |

| PCOND, (bar) | 0.078 |

| ηsitv, (-) | 0.88 |

| ηsip, (-) | 0.85 |

| ΔTppLP, (°C) | 39.43 |

| ΔTppIP, (°C) | 50.24 |

| ΔTppHP, (°C) | 93.42 |

| Components | Ḟ (kW) | Ṗ (kW) | i (kW) | Ṙ (kW) | fexd (-) | ηex (%) |

|---|---|---|---|---|---|---|

| Gas turbine (GT) | ||||||

| C | 279,167 | 253,544 | 25,623 | 0 | 0.0917 | 90.82 |

| CCH | 664,788 | 536,977 | 127,811 | 0 | 0.1922 | 80.77 |

| t | 573,410 | 557,567 | 15,842 | 0 | 0.0276 | 97.23 |

| Heat recovery steam generator (HRSG) | ||||||

| HPSH1 + IPRH1 | 24,403 | 22,563 | 1840 | 0 | 0.0754 | 92.45 |

| Postcombustion | 75,466.40 | 47,274.09 | 28,192.31 | 0 | 0.3735 | 62.64 |

| HPSH2 + IPRH2 | 58,583 | 47,863 | 10,720 | 0 | 0.1829 | 81.70 |

| HPEV | 67,579 | 55,926 | 11,652 | 0 | 0.1724 | 82.75 |

| HPEC | 36,663 | 29,912 | 6750 | 0 | 0.1841 | 81.58 |

| LPSH | 3097.76 | 2144.84 | 952.92 | 0 | 0.3076 | 69.23 |

| IPSH | 1169.25 | 983.97 | 185.28 | 0 | 0.1584 | 84.15 |

| IPEV | 14,520 | 12,407 | 2113 | 0 | 0.1455 | 85.44 |

| HPPH + IPEC | 12,929 | 9397 | 3531 | 0 | 0.2731 | 72.68 |

| LPEV | 22,141 | 15,769 | 6371 | 0 | 0.2877 | 71.22 |

| LPEC | 16,179 | 10,096 | 6082 | 0 | 0.3759 | 62.40 |

| Chimney | 7118 | 0 | 0 | 7118 | - | - |

| Steam cycle (SC) | ||||||

| HPST | 36,208 | 33,880 | 2327 | 0 | 0.0642 | 93.57 |

| IPST | 67,765 | 62,680 | 5084 | 0 | 0.0750 | 92.49 |

| LPST | 88,631 | 78,475 | 10,155 | 0 | 0.1145 | 88.54 |

| M | 104,732 | 104,732 | 0 | 0 | - | - |

| LPP | 54.43 | 40.69 | 13.74 | 0 | 0.2524 | 74.74 |

| IPP | 61.03 | 53.36 | 7.66 | 0 | 0.1255 | 87.43 |

| LPP | 1512.18 | 1345.76 | 166.42 | 0 | 0.1100 | 88.99 |

| LPD | 28,104 | 28,104 | 0 | 0 | - | - |

| IPD | 20,175 | 20,175 | 0 | 0 | - | - |

| HPD | 146,376 | 146,376 | 0 | 0 | - | - |

| m | 17,275.43 | 17,247.14 | 28.29 | 0 | - | - |

| COND | 15,871 | - | 8232 | 7639 | 0.5186 | - |

| Components | µ (-) | β (-) | ||

|---|---|---|---|---|

| Gas turbine (GT) | ||||

| C | 0.1289 | 1279 | 0 | 0 |

| CCH | 0.6431 | 6380 | 0 | 0 |

| t | 0.0797 | 790.94 | 0 | 0 |

| Heat recovery steam generator (HRSG) | ||||

| HPSH1 + IPRH1 | 0.0004 | 4.01 | 0.0263 | 785.81 |

| Postcombustion | 0.1418 | 1407 | 0 | 0 |

| HPSH2 + IPRH2 | 0.0005 | 5.13 | 0.1590 | 4741 |

| HPEV | 0.0014 | 14.30 | 0.1702 | 5075 |

| HPEC | 0.0006 | 6.48 | 0.0992 | 2956 |

| LPSH | 0.0002 | 1.98 | 0.0136 | 407.74 |

| IPSH | 0.0001 | 1.98 | 0.0021 | 64.98 |

| IPEV | 0.0002 | 2.53 | 0.0309 | 920.88 |

| HPPH + IPEC | 0.0005 | 4.22 | 0.0516 | 1539 |

| LPEV | 0.0008 | 8.46 | 0.0929 | 2769 |

| LPEC | 0.0013 | 13.03 | 0.0872 | 2599 |

| Steam cycle (SC) | ||||

| HPST | 0 | 0 | 0.0348 | 1039 |

| IPST | 0 | 0 | 0.0761 | 2270 |

| LPST | 0 | 0 | 0.1521 | 4534 |

| LPP | 0 | 0 | 0.0002 | 6.13 |

| IPP | 0 | 0 | 0.0001 | 3.42 |

| HPP | 0 | 0 | 0.0024 | 74.31 |

| M | 0 | 0 | 0.0004 | 12.63 |

| Total | 1.0 | 9920 | 1.0 | 29,801 |

| Components | ΠF (USD/h) | ΠP (USD/h) | ΠRcg (USD/h) | ΠRQCOND (USD/h) | cF (USD/GJ) | COE (USD/h) |

|---|---|---|---|---|---|---|

| Gas turbine (GT) | ||||||

| C | 4040.48 | 4053.94 | 13.45 | - | 4.02 | 370.85 |

| CCH | 6992.84 | 7059.96 | 67.12 | - | 2.92 | 1344.43 |

| t | 8061.54 | 8069.86 | 8.31 | - | 3.90 | 222.73 |

| Heat recovery steam generator (HRSG) | ||||||

| HPSH1 + IPRH1 | 343.09 | 351.46 | 0.04 | 8.32 | 3.90 | 25.87 |

| Postcombustion | 793.82 | 47,274.09 | 14.80 | - | 2.92 | 296.55 |

| HPSH2 + IPRH2 | 858.78 | 909.08 | 0.05 | 50.24 | 4.07 | 157.15 |

| HPEV | 990.64 | 1044.58 | 0.15 | 53.78 | 4.07 | 170.81 |

| HPEC | 537.44 | 568.84 | 0.06 | 31.33 | 4.07 | 98.95 |

| LPSH | 45.41 | 49.75 | 0.02 | 4.32 | 4.07 | 13.96 |

| IPSH | 17.14 | 17.84 | 0.02 | 0.68 | 4.07 | 2.71 |

| IPEV | 212.85 | 222.64 | 0.02 | 9.75 | 4.07 | 30.97 |

| HPPH + IPEC | 189.53 | 205.89 | 0.04 | 16.31 | 4.07 | 51.77 |

| LPEV | 324.56 | 354.00 | 0.08 | 29.35 | 4.07 | 93.40 |

| LPEC | 237.17 | 264.85 | 0.13 | 27.54 | 4.07 | 89.16 |

| Chimney | 104.35 | - | 104.35 | - | - | - |

| Steam cycle (SC) | ||||||

| HPST | 693.35 | 704.36 | - | 11.01 | 5.31 | 44.57 |

| IPST | 1277.89 | 1301.96 | - | 24.06 | 5.23 | 95.89 |

| LPST | 1738.52 | 1786.58 | - | 48.05 | 5.44 | 199.19 |

| M | 2054.36 | 2054.36 | - | - | 5.44 | - |

| LPP | 1.19 | 1.25 | - | 0.06 | 6.07 | 0.30 |

| IPP | 1.33 | 1.37 | - | 0.03 | 6.07 | 0.16 |

| HPP | 33.09 | 33.88 | - | 0.78 | 6.07 | 3.64 |

| LPD | 670.63 | 670.63 | - | - | 6.62 | - |

| IPD | 390.01 | 390.01 | - | - | 5.36 | - |

| HPD | 2928.38 | 2928.38 | - | - | 5.55 | - |

| m | 324.17 | 324.31 | - | 0.13 | 5.21 | - |

| COND | 315.84 | - | - | 315.84 | - | - |

| Indicators | CC without Postcombustion | CC with Postcombustion |

|---|---|---|

| Operating parameters of the CC | ||

| ẆmGT, (MW) | 278.4 | 278.4 |

| ẆmSC, (MW) | 134.48 | 171.67 |

| ẆmCC, (MW) | 273.68 | 310.87 |

| ṁa, (kga/s) | 626.81 | 626.81 |

| ṁf, (kgf/s) | 15.36 | 17.10 |

| ṁHP, (kgv/s) | 76.77 | 96.44 |

| ṁIP, (kgv/s) | 11.28 | 16.77 |

| ṁLP, (kgv/s) | 21.99 | 26.52 |

| , (MW) | 381.22 | 542.90 |

| Thermodynamic indicators | ||

| ηthGT, (%) | 35.16 | 35.16 |

| ηexGT, (%) | 40.25 | 40.25 |

| ηthSC, (%) | 35.27 | 31.94 |

| ηexSC, (%) | 65.15 | 52.11 |

| ηthCC, (%) | 54.30 | 53.36 |

| ηexCC, (%) | 62.15 | 61.07 |

| Indicators | CC without Postcombustion | CC with Postcombustion |

|---|---|---|

| Environmental and human toxicity indicators | ||

| IGW, (gCO2eq/kWh) | 373.25 | 392.77 |

| ISF, (gNOxeq/kWh) | 2.53 | 2.67 |

| IAR, (gSO2eq/kWh) | 2.64 | 2.78 |

| IHT, (gPbeq/kWh) | 0.00067 | 0.000704 |

| Exergoeconomic indicators | ||

| ΠWmGT, (USD/h) | 4058 | 4029 |

| cWmGT, (USD/GJ) | 4.05 | 4.02 |

| ΠWmST, (USD/h) | 2933 | 3757 |

| cWmST, (USD/GJ) | 6.05 | 6.07 |

| Πcg, (USD/h) | 98.95 | 104.35 |

| ccg, (USD/GJ) | 3.93 | 4.07 |

| ΠQCOND, (USD/h) | 291.40 | 315.84 |

| cQCOND, (USD/GJ) | 6.47 | 11.48 |

| EOCGT, (USD/h) | 1 941 | 1941 |

| EOCHRSG,(USD/h) | 618.25 | 1402 |

| EOCSC, (USD/h) | 271.12 | 1031 |

| EOCCC, (USD/h) | 2830.37 | 4374 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres González, E.V.; Castro Hernández, S.; Lugo Méndez, H.D.; Arroyo Cabañas, F.G.; Valencia López, J.; Lugo Leyte, R. Comparison of the Parameters of the Exergoeconomic Environmental Analysis of Two Combined Cycles of Three Pressure Levels with and without Postcombustion. Entropy 2022, 24, 636. https://doi.org/10.3390/e24050636

Torres González EV, Castro Hernández S, Lugo Méndez HD, Arroyo Cabañas FG, Valencia López J, Lugo Leyte R. Comparison of the Parameters of the Exergoeconomic Environmental Analysis of Two Combined Cycles of Three Pressure Levels with and without Postcombustion. Entropy. 2022; 24(5):636. https://doi.org/10.3390/e24050636

Chicago/Turabian StyleTorres González, Edgar Vicente, Sergio Castro Hernández, Helen Denise Lugo Méndez, Fernando Gabriel Arroyo Cabañas, Javier Valencia López, and Raúl Lugo Leyte. 2022. "Comparison of the Parameters of the Exergoeconomic Environmental Analysis of Two Combined Cycles of Three Pressure Levels with and without Postcombustion" Entropy 24, no. 5: 636. https://doi.org/10.3390/e24050636

APA StyleTorres González, E. V., Castro Hernández, S., Lugo Méndez, H. D., Arroyo Cabañas, F. G., Valencia López, J., & Lugo Leyte, R. (2022). Comparison of the Parameters of the Exergoeconomic Environmental Analysis of Two Combined Cycles of Three Pressure Levels with and without Postcombustion. Entropy, 24(5), 636. https://doi.org/10.3390/e24050636