Dynamic Shear Deformation of a Precipitation Hardened Al0.7CoCrFeNi Eutectic High-Entropy Alloy Using Hat-Shaped Specimen Geometry

Abstract

1. Introduction

- (1)

- Three stages exist during SHPB tests of hat-shaped specimens, namely: (i) the onset of strain localization, (ii) ASB formation, and (iii) micro-cracks initiation and propagation [14]. The width of shear band is narrowed down along the shear direction from top to bottom [15], and its width affects the homogeneity of stress and deformation in shear bands [14]. There is increased recrystallization with strain, which increases from the edge of the shear band and reaches a maximum at the center.

- (2)

- Dynamic recrystallization (DRX) is observed in most of the tested materials including copper [16], steel [17,18], pure titanium [15], titanium alloys [14,18], and aluminum alloy [19]. The shear texture is also observed in low-nickel-containing steel [17], pure titanium [15], and nickel alloy [20]. DRX is confirmed by the emergence of ultra-fined grains with low dislocation density within the shear band [17]. Meyer et al. showed the effect of temperature on shear band width and the extend of dynamic recrystallization in copper [18]. The room temperature shear band microstructure is rather broad (~300 µm) and its thickness is reduced to ~50 µm at 523 K [16]. Wang et al. showed that the grain boundaries in the shear band are geometrical necessary boundaries with high angles. The temperature in shear band is about 943 K which is high enough to meet the thermal needs of recrystallization.

- (3)

- (4)

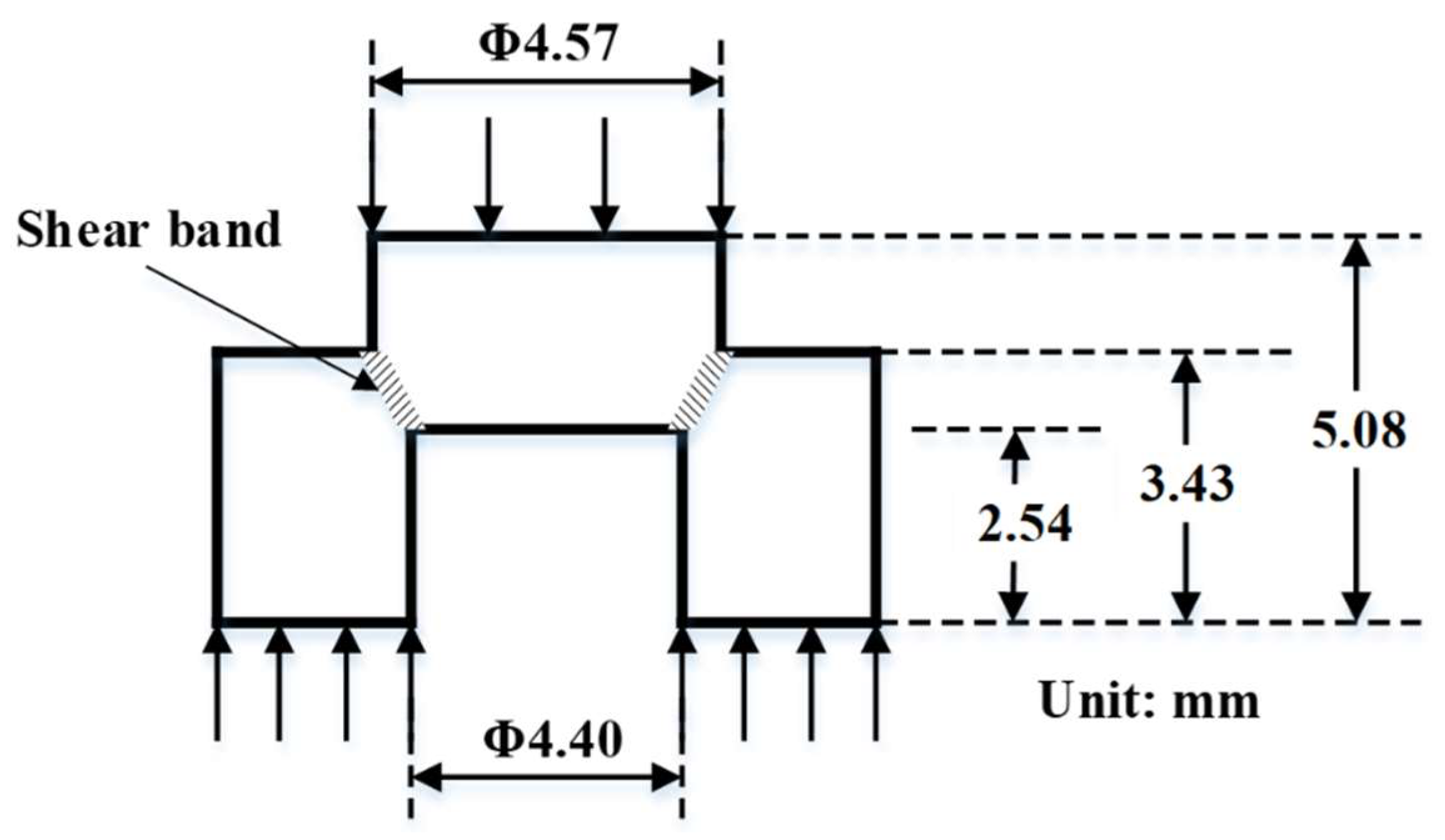

- The geometry of the specimen is key in restricting the deformation mode to shear. The major principal stress σI is compressive in nature initially. The evolution of hydrostatic stress from compressive to tensile is dictated by the ratio r1/r2 (top radius and bottom radius, refer Figure 1. The overlap between the top and bottom dictates how much the material is under compression initially before it undergoes shear. Peirs et al. showed that the lesser the ratio r1/r2 is from one (the outer diameter of the hat is larger than the inner diameter of the hole in the brim) the higher the force needed to deform the specimen [14]. When r1/r2 = 0.975, the shear stress is homogeneous. When r1/r2 is smaller, hydrostatic pressure becomes much more important. For a very small ratio r1/r2 the experiment is closer to a compression test than a shear test. For specimens with r1/r2 > 0.975, the hydrostatic stress is lower, but the shear stress is less homogeneous along the shear line. Consequently, the calculated average shear stress is not representative for actual shear stress in the center of the shear zone. A specimen with the outer diameter of the hat slightly larger than the inner diameter of the brim is the best compromise between good homogeneity of the shear stress, measurability of the shear stress and a stress state as close as possible to pure shear.

2. Experimental Section

3. Results and Discussion

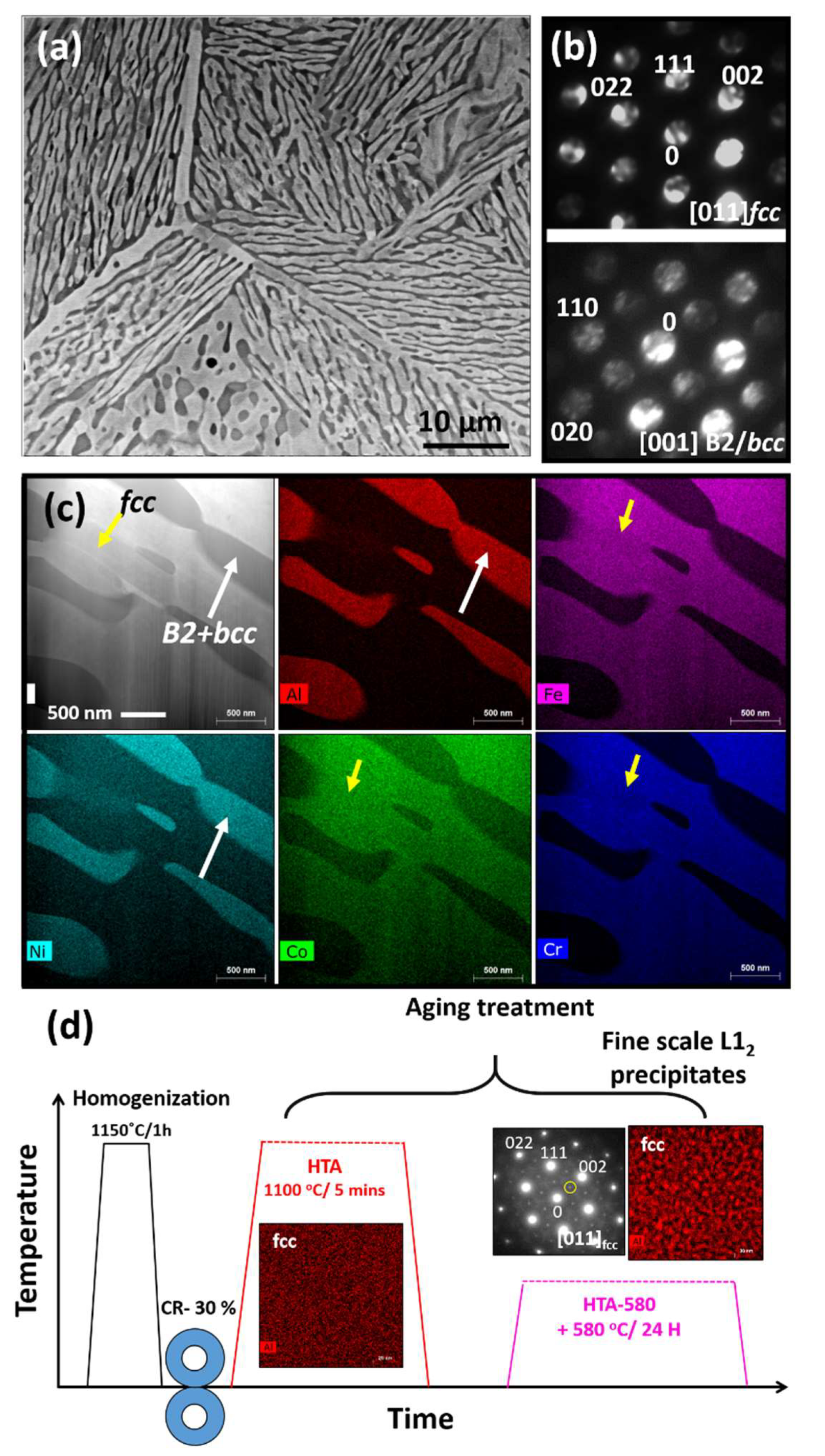

3.1. Isothermal Aging for Precipitation Strengthening

3.2. Mechanical Properties

3.2.1. Quasi-Static Tensile Test

3.2.2. Dynamic Shear Compression of Top Hat Specimen

3.2.3. Microscopic Analysis of the Shear Region in the Deformed Hat Shaped Specimen

3.2.4. Estimation of Instability Strain from Culver Criterion

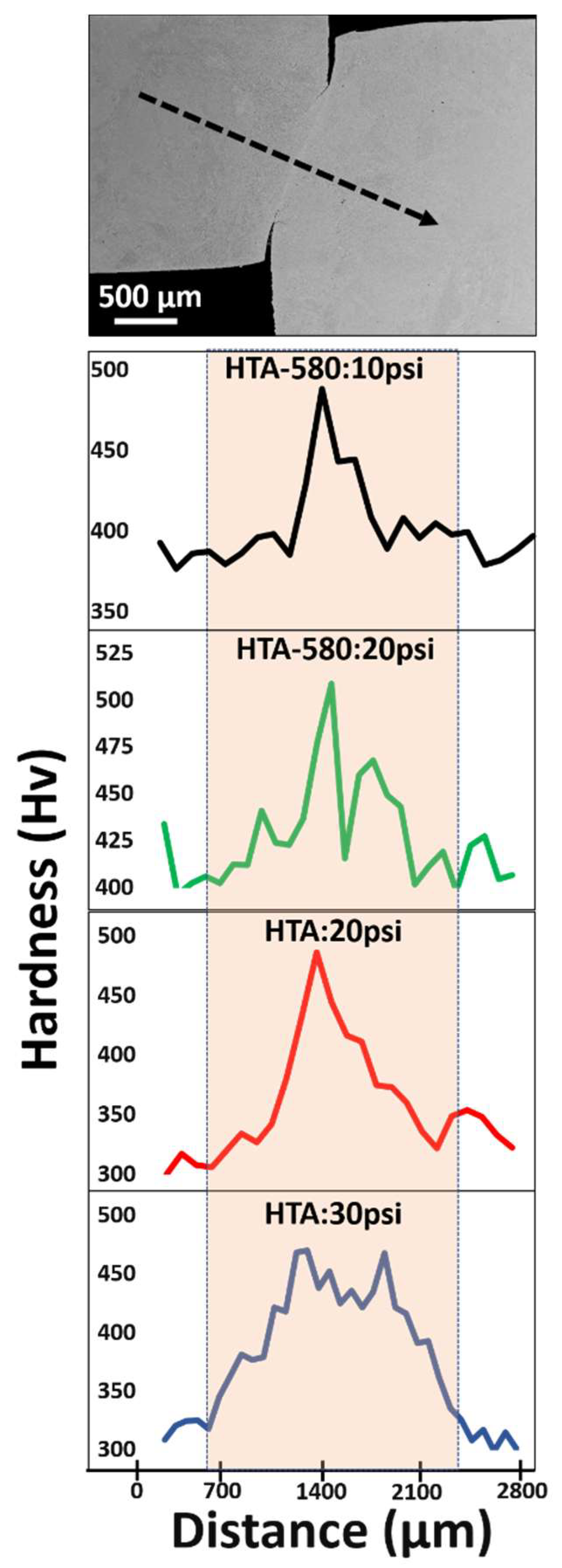

3.2.5. Microhardness Testing and Nanoindentation Details

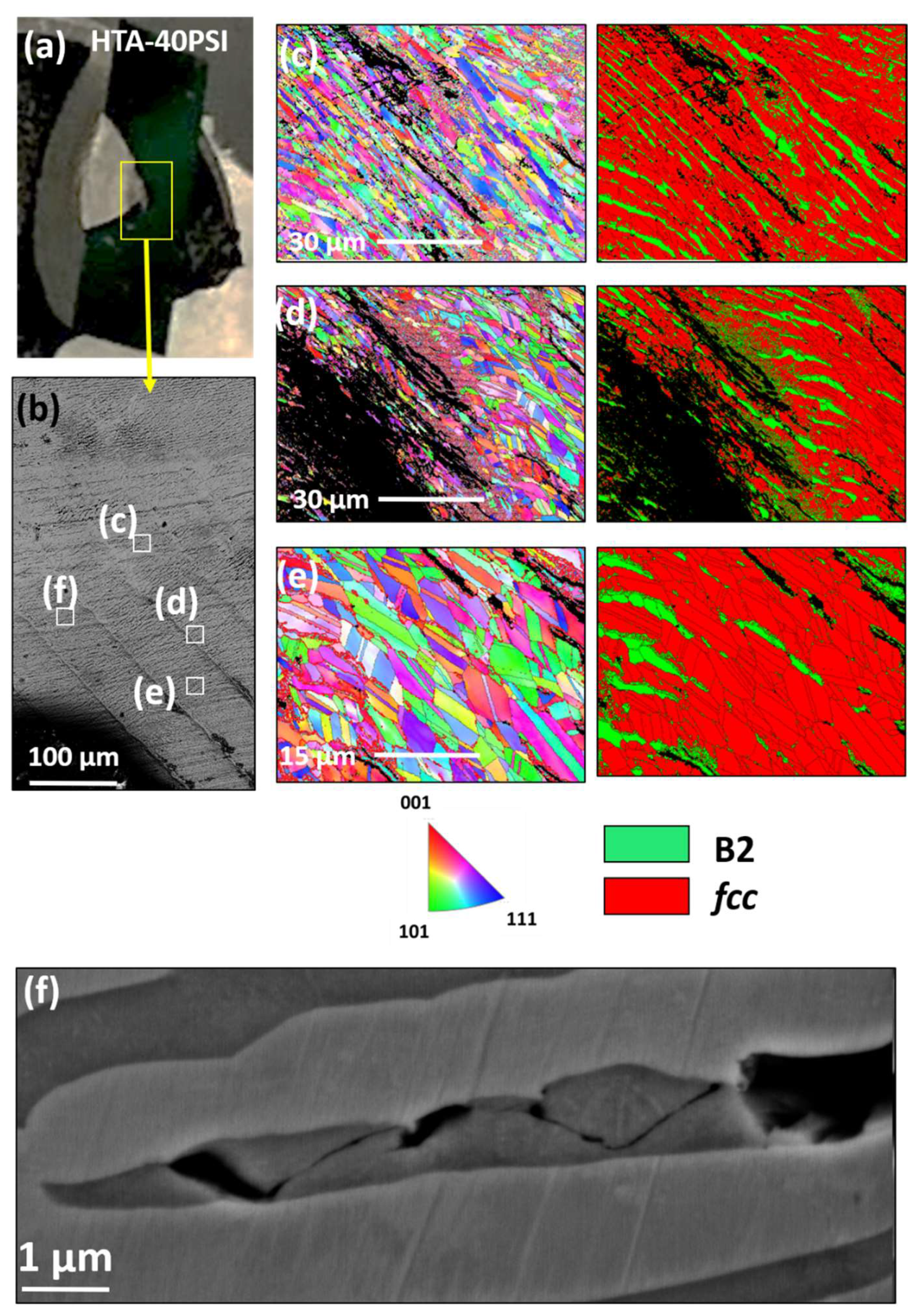

3.2.6. Microscopic Analysis of the Fractured Hat-Shaped Specimen

4. Conclusions

- (1)

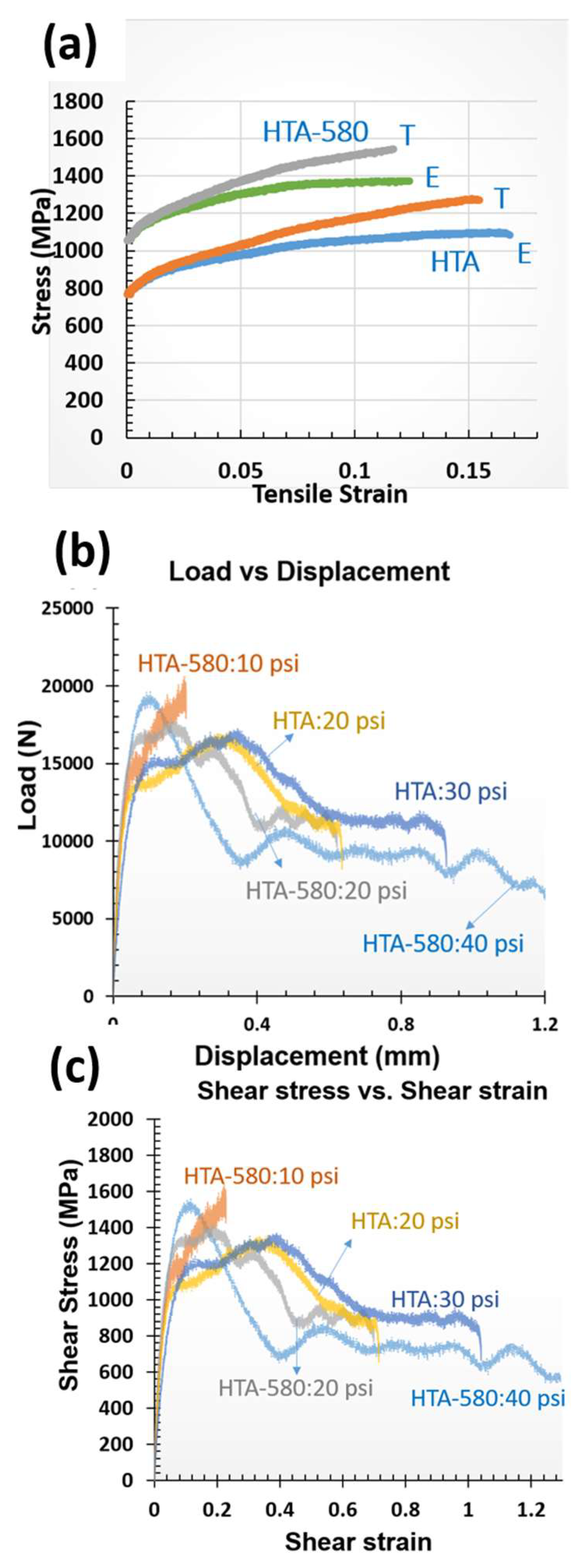

- The tensile yield strength (quasi-static testing at 10−3/sec) of the Al0.7CoCrFeNi eutectic HEA in HTA condition was 780 MPa which increased to 990 MPa after precipitation of L12 phase by aging at 580 °C for 24 h in the HTA-580 condition. Such an increase in mechanical properties was also noted in nanoindentation response of individual phases (fcc and B2) in the HTA-580 condition.

- (2)

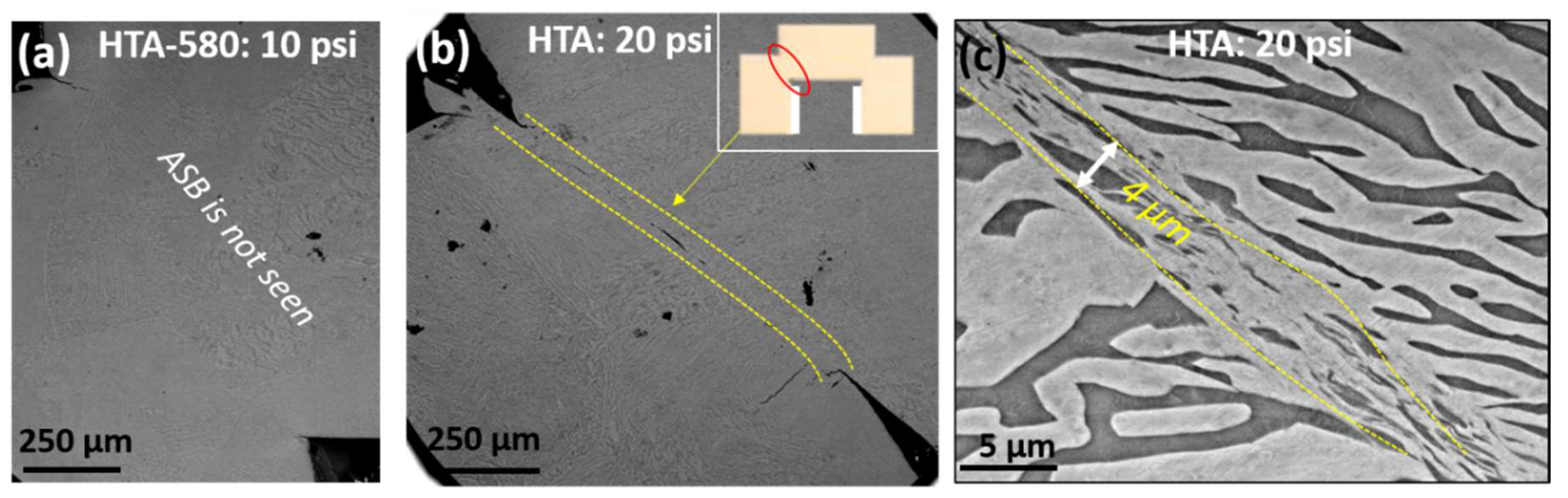

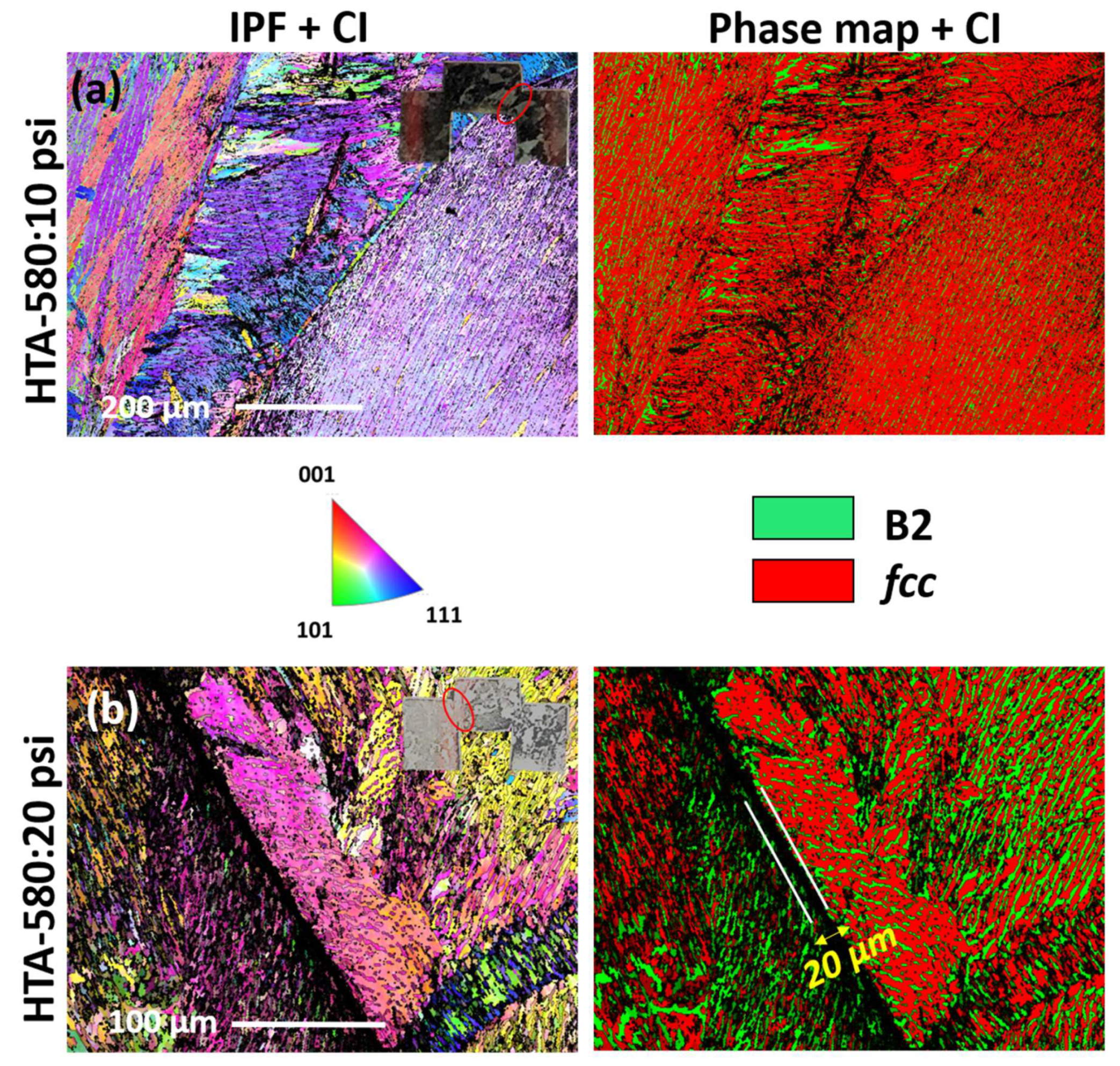

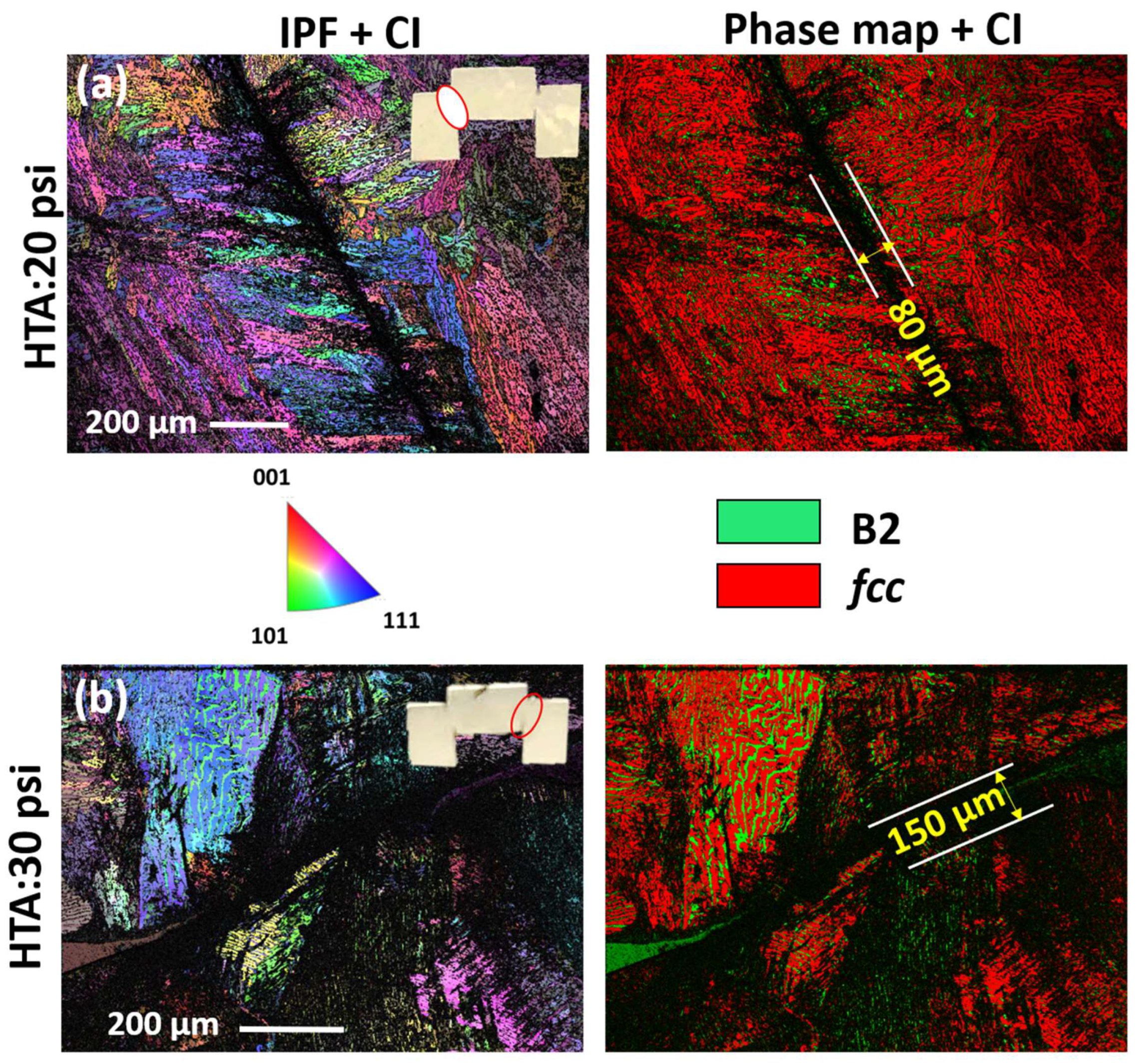

- The shear deformation tests were conducted using a split Hopkinson’s pressure bar apparatus. The HTA-580 condition was tested under 10 psi and 20 psi loading conditions and the HTA condition was tested under 20 psi, 30 psi, and 40 psi loading conditions. The 10-psi loading rate (1.6 m/s) was insufficient to cause the formation of ASB whereas the loading rate of 40 psi (2.3 m/s) resulted in the fracture of the specimen. The 20 psi loading rate was used to compare the deformation response in the HTA vs HTA-580 conditions.

- (3)

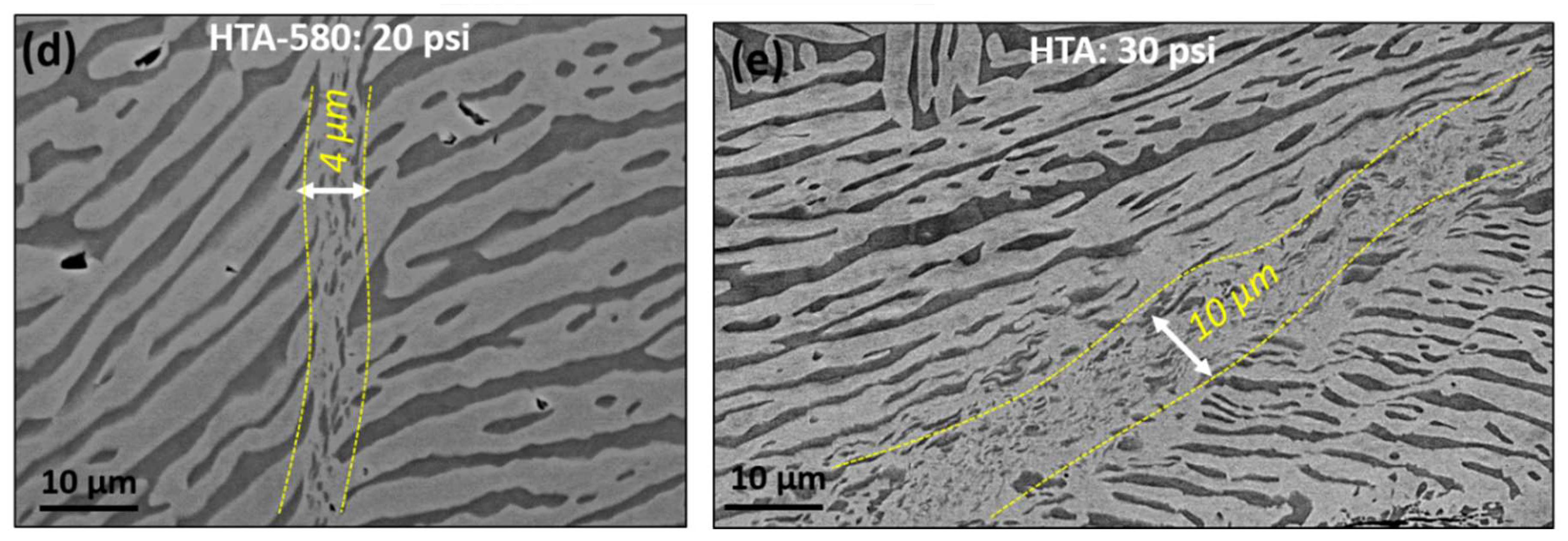

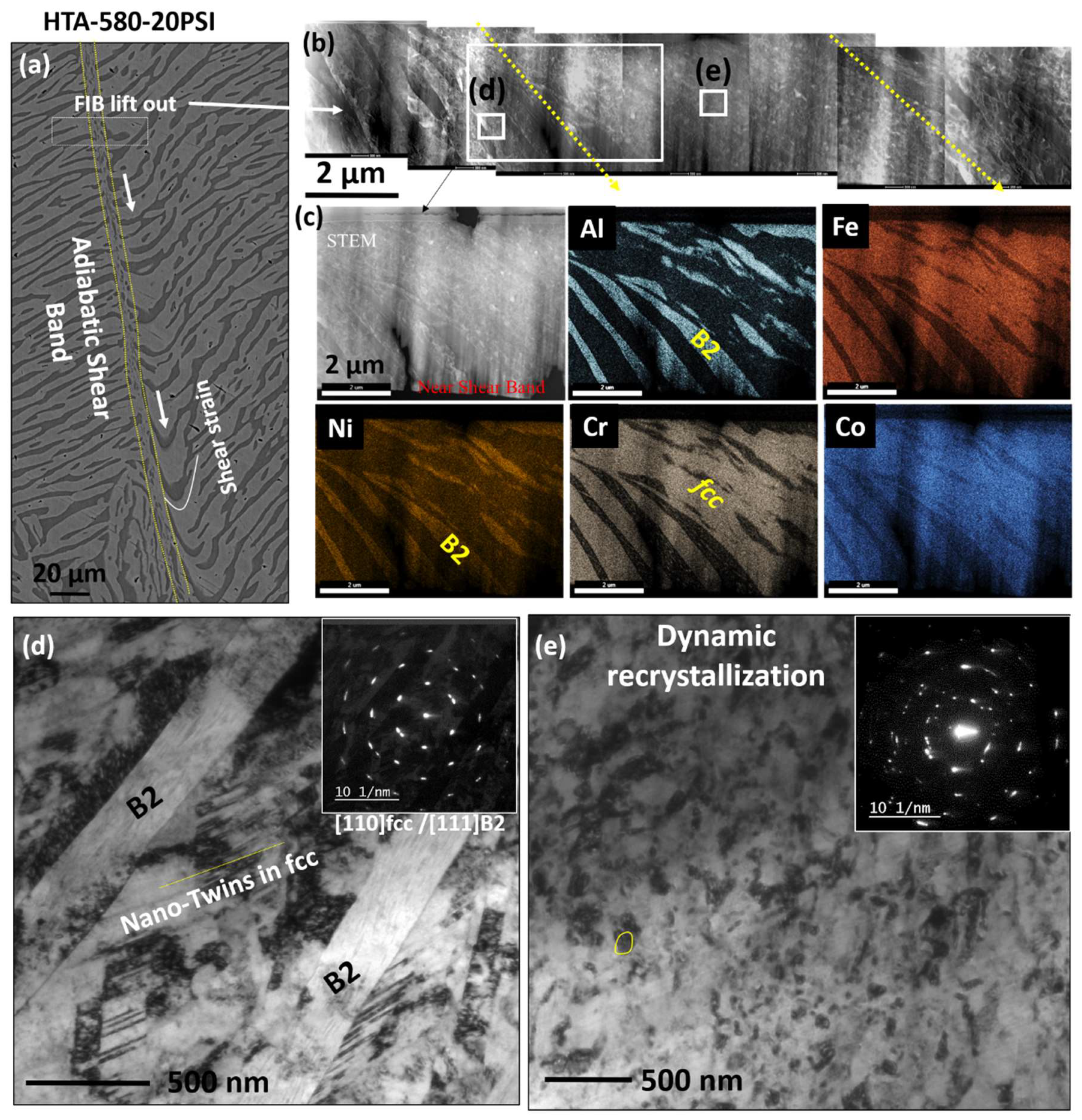

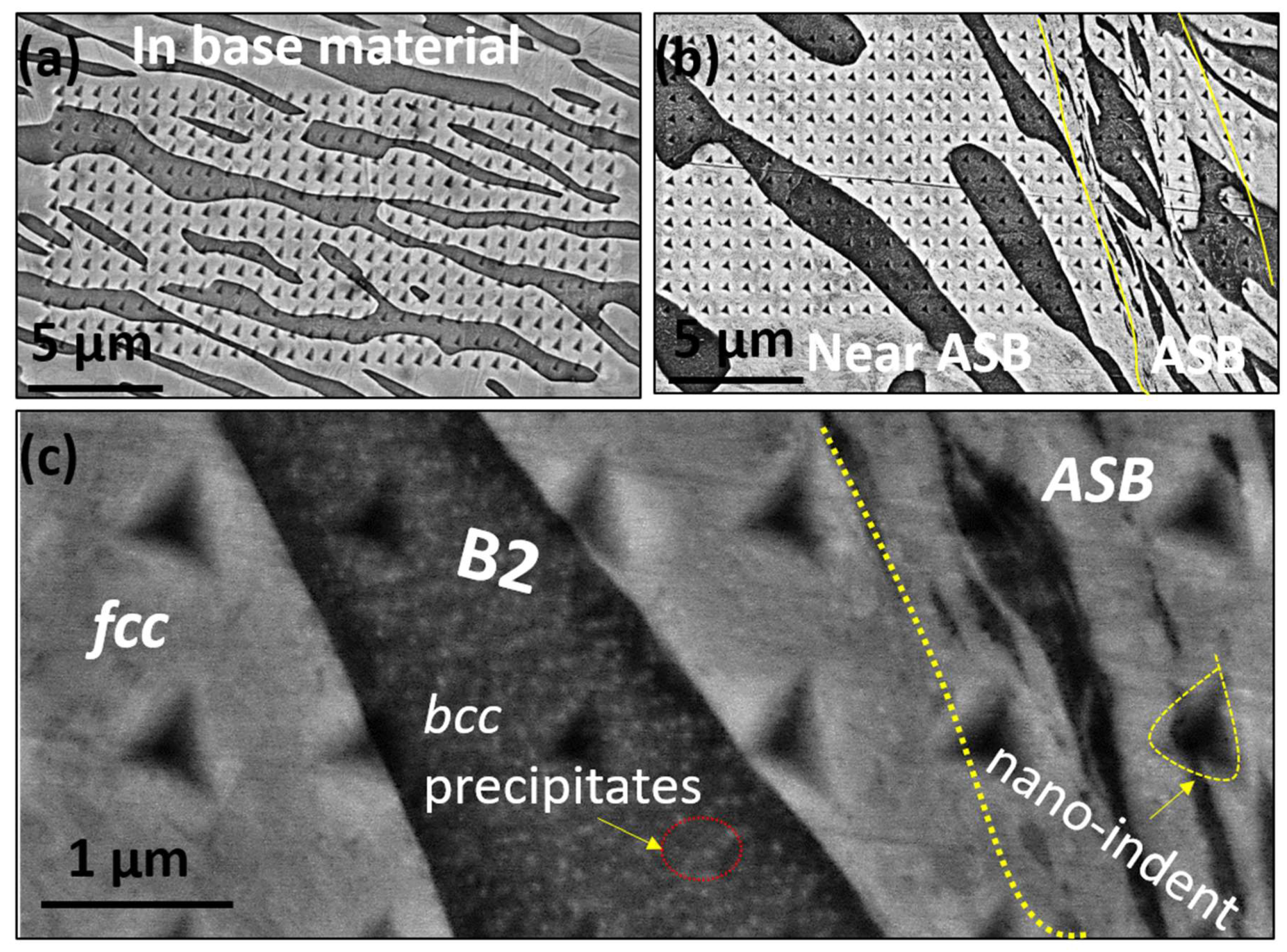

- Formation of ASBs led to a sudden decrease in flow stresses in both HTA and HTA-580 conditions, due to the thermal softening accompanied by dynamic recrystallization within the ASBs. Although the widths of ASB in HTA: 20 psi and HTA-580:20 psi were observed to be similar (~4 µm), the deformed region around the ASB was much less for HTA-580:20 psi specimen. Hence, the higher strength condition HTA-580 (precipitation strengthened condition) has narrower extend of deformation zone.

- (4)

- The adiabatic shear localization occurs at low strains for the high strength material, and the eutectic microstructure does not delay cracking. The precipitation of L12 phase in fcc increased the tensile strength of the alloy. However, no significant change was observed on formation of ASBs.

- (5)

- A high density of nano-twins was observed in the region around the ASB which may be responsible for strain hardening of the alloy before ABS formation. The nano-structuring within ABS suggests dynamic recrystallization and thermal softening. A local temperature of ~800 K is estimated to have reached during testing for a few µsec causing the recrystallization in the ASBs which are adiabatically restricted in diffusion and heat flow.

- (6)

- The microstructural characterization of the fractured specimen suggested the formation of multiple ASBs and local melting of the B2 phase and cracking within B2 phase. Pronounced recrystallization in the fcc phase consisting of equiaxed fcc grains with annealing twins were also noted. The lamellar structure seems to be broken in the region close to the fracture.

- (7)

- Microhardness testing across the shear band showed a ~20%–30% increase in the hardness values when comparing the base hardness to the hardness in the region deformed while shear band formation. Nanoindentation was used to characterize individual lamellae before and after deformation. The hardness within the ASBs is noted to drop in all specimen.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability

References

- Ma, Z.Y.; Sharma, S.R.; Mishra, R.S. Effect of friction stir processing on the microstructure of cast A356 aluminum. Mater. Sci. Eng. A 2006, 433, 269–278. [Google Scholar] [CrossRef]

- Feng, A.H.; Ma, Z.Y. Enhanced mechanical properties of Mg–Al–Zn cast alloy via friction stir processing. Scr. Mater. 2007, 56, 397–400. [Google Scholar] [CrossRef]

- Raabe, D.; Choi, P.P.; Li, Y.; Kostka, A.; Sauvage, X.; Lecouturier, F.; Hono, K.; Kirchheim, R.; Pippan, R.; Embury, D. Metallic composites processed via extreme deformation: Toward the limits of strength in bulk materials. MRS Bull. 2010, 35, 982–991. [Google Scholar] [CrossRef]

- Saha, R.L.; Nandy, T.K.; Misra, R.D.K.; Jacob, K.T. Microstructural changes induced by ternary additions in a hypo-eutectic titanium-silicon alloy. J. Mater. Sci. 1991, 26, 2637–2644. [Google Scholar] [CrossRef]

- Gwalani, B.; Salloom, R.; Alam, T.; Valentin, S.G.; Zhou, X.; Thompson, G.; Srinivasan, S.G.; Banerjee, R. Composition-dependent apparent activation-energy and sluggish grain-growth in high entropy alloys. Mater. Res. Lett. 2019, 7, 267–274. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z.; et al. A promising new class of high-temperature alloys: Eutectic high-entropy alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef]

- Giwa, A.M.; Liaw, P.K.; Dahmen, K.A.; Greer, J.R. Microstructure and small-scale size effects in plasticity of individual phases of Al 0.7 CoCrFeNi High Entropy alloy. Extrem. Mech. Lett. 2016, 8, 220–228. [Google Scholar] [CrossRef]

- Gwalani, B.; Sindhura, G.; Yufeng, Z.; Vishal, S.; Rajiv, S.M.; Rajarshi, B. Influence of ordered L1 2 precipitation on strain-rate dependent mechanical behavior in a eutectic high entropy alloy. Sci. Rep. 2019, 9, 6371. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Wei, Q.; Kecskes, L.; Jiao, T.; Hartwig, K.T.; Ramesh, K.T.; Ma, E. Adiabatic shear banding in ultrafine-grained Fe processed by severe plastic deformation. Acta Mater. 2004, 52, 1859–1869. [Google Scholar] [CrossRef]

- Xue, Q.; Gray, G.T.; Henrie, B.L.; Maloy, S.A.; Chen, S.R. Influence of shock prestraining on the formation of shear localization in 304 stainless steel. Metall. Mater. Trans. A 2005, 36, 1471–1486. [Google Scholar] [CrossRef]

- Yuan, F.; Jiang, P.; Wu, X. Annealing effect on the evolution of adiabatic shear band under dynamic shear loading in ultra-fine-grained iron. Int. J. Impact Eng. 2012, 50, 1–8. [Google Scholar] [CrossRef]

- Peirs, J.; Verleysen, P.; Degrieck, J.; Coghe, F. The use of hat-shaped specimens to study the high strain rate shear behaviour of Ti–6Al–4V. Int. J. Impact Eng. 2010, 37, 703–714. [Google Scholar] [CrossRef]

- Kuang, L.; Chen, Z.; Jiang, Y.; Wang, Z.; Wang, R.; Liu, C. Adiabatic shear behaviors in rolled and annealed pure titanium subjected to dynamic impact loading. Mater. Sci. Eng. A 2017, 685, 95–106. [Google Scholar] [CrossRef]

- Andrade, U.; Meyers, M.A.; Vecchio, K.S.; Chokshi, A.H. Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper. Acta Metal. Mater. 1994, 42, 3183–3195. [Google Scholar] [CrossRef]

- Wang, B.F.; Liu, Z.L.; Wang, X.Y.; Li, Z.Z. An EBSD investigation on deformation-induced shear bands in a low nickel austenitic stainless steel under controlled shock-loading conditions. Mater. Sci. Eng. A 2014, 610, 301–308. [Google Scholar] [CrossRef]

- Meyer, L.W.; Staskewitsch, E.; Burblies, A. Adiabatic shear failure under biaxial dynamic compression/shear loading. Mech. Mater. 1994, 17, 203–214. [Google Scholar] [CrossRef]

- Edwards, N.J.; Song, W.; Cimpoeru, S.J.; Ruan, D.; Lu, G.; Herzig, N. Mechanical and microstructural properties of 2024-T351 aluminium using a hat-shaped specimen at high strain rates. Mater. Sci. Eng. A 2018, 720, 203–213. [Google Scholar] [CrossRef]

- Johansson, J.; Persson, C.; Lai, H.; Colliander, M.H. Microstructural examination of shear localization during high strain rate deformation of alloy 718. Mater. Sci. Eng. A 2016, 662, 363–372. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Diao, H.; Liaw, P.K.; Meyers, M.A. High-velocity deformation of Al 0.3 CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci. Rep. 2017, 7, 42742. [Google Scholar] [CrossRef] [PubMed]

- Meyers, M.A.; Xu, Y.B.; Xue, Q.; Perez-Prado, M.T.; McNelley, T.R. Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater. 2003, 51, 1307–1325. [Google Scholar] [CrossRef]

- Yang, Y.; Xinming, Z.; Zhenghua, L.; Qingyun, L. Adiabatic shear band on the titanium side in the Ti/mild steel explosive cladding interface. Acta Mater. 1996, 44, 561–565. [Google Scholar] [CrossRef]

- Rittel, D.; Wang, Z.G. Thermo-mechanical aspects of adiabatic shear failure of AM50 and Ti6Al4V alloys. Mech. Mater. 2008, 40, 629–635. [Google Scholar] [CrossRef]

- Dodd, B.; Bai, Y. Width of adiabatic shear bands formed under combined stresses. Mater. Sci. Tech. 1989, 5, 557–559. [Google Scholar] [CrossRef]

- Rentenberger, C.; Mangler, C.; Karnthaler, H.P. TEM study of localized deformation-induced disorder in intermetallic alloys of L1 2 structure. In EMC 2008 14th European Microscopy Congress 1–5 September 2008, Aachen, Germany; Springer: Berlin/Heidelberg, Germany, 2008; pp. 481–482. [Google Scholar]

- Rentenberger, C.; Karnthaler, H.P. On the evolution of a deformation induced nanostructure in a Ni3Al alloy. Acta Mater. 2005, 53, 3031–3040. [Google Scholar] [CrossRef]

- Walley, S.M. Shear localization: A historical overview. Metall. Mater. Trans. A 2007, 38, 2629–2654. [Google Scholar] [CrossRef]

- Staker, M.R. The relation between adiabatic shear instability strain and material properties. Acta Metall. 1981, 29, 683–689. [Google Scholar] [CrossRef]

- Gorsse, S.; Nguyen, M.H.; Senkov, O.N.; Miracle, D.B. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Brief 2018, 21, 2664–2678. [Google Scholar] [CrossRef]

| Nano Indentation Hardness (GPa) | |||||

|---|---|---|---|---|---|

| Sample Condition | fcc | B2 | In ASB | ||

| Base | Near ASB | Base | Near ASB | ||

| HTA:20 psi | 4.1 ± 0.4 | 3.5 ± 1.1 | 6.1 ± 0.9 | 4.1 ± 1.2 | 3.4 ± 1.1 |

| HTA-580:20 psi | 5.2 ± 0.4 | 4.4 ± 0.2 | 6.9 ± 0.8 | 5.6 ± 0.4 | 3.7 ± 0.4 |

| HTA:30 psi | 4.2 ± 0.6 | 5.2 ± 0.7 | 6.0 ± 0.4 | 6.5 ± 1.0 | 5.9 ± 1.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gwalani, B.; Wang, T.; Jagetia, A.; Gangireddy, S.; Muskeri, S.; Mukherjee, S.; Lloyd, J.T.; Banerjee, R.; Mishra, R.S. Dynamic Shear Deformation of a Precipitation Hardened Al0.7CoCrFeNi Eutectic High-Entropy Alloy Using Hat-Shaped Specimen Geometry. Entropy 2020, 22, 431. https://doi.org/10.3390/e22040431

Gwalani B, Wang T, Jagetia A, Gangireddy S, Muskeri S, Mukherjee S, Lloyd JT, Banerjee R, Mishra RS. Dynamic Shear Deformation of a Precipitation Hardened Al0.7CoCrFeNi Eutectic High-Entropy Alloy Using Hat-Shaped Specimen Geometry. Entropy. 2020; 22(4):431. https://doi.org/10.3390/e22040431

Chicago/Turabian StyleGwalani, Bharat, Tianhao Wang, Abhinav Jagetia, Sindhura Gangireddy, Saideep Muskeri, Sundeep Mukherjee, Jeffrey T. Lloyd, Rajarshi Banerjee, and Rajiv S. Mishra. 2020. "Dynamic Shear Deformation of a Precipitation Hardened Al0.7CoCrFeNi Eutectic High-Entropy Alloy Using Hat-Shaped Specimen Geometry" Entropy 22, no. 4: 431. https://doi.org/10.3390/e22040431

APA StyleGwalani, B., Wang, T., Jagetia, A., Gangireddy, S., Muskeri, S., Mukherjee, S., Lloyd, J. T., Banerjee, R., & Mishra, R. S. (2020). Dynamic Shear Deformation of a Precipitation Hardened Al0.7CoCrFeNi Eutectic High-Entropy Alloy Using Hat-Shaped Specimen Geometry. Entropy, 22(4), 431. https://doi.org/10.3390/e22040431