Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy

Abstract

:1. Introduction

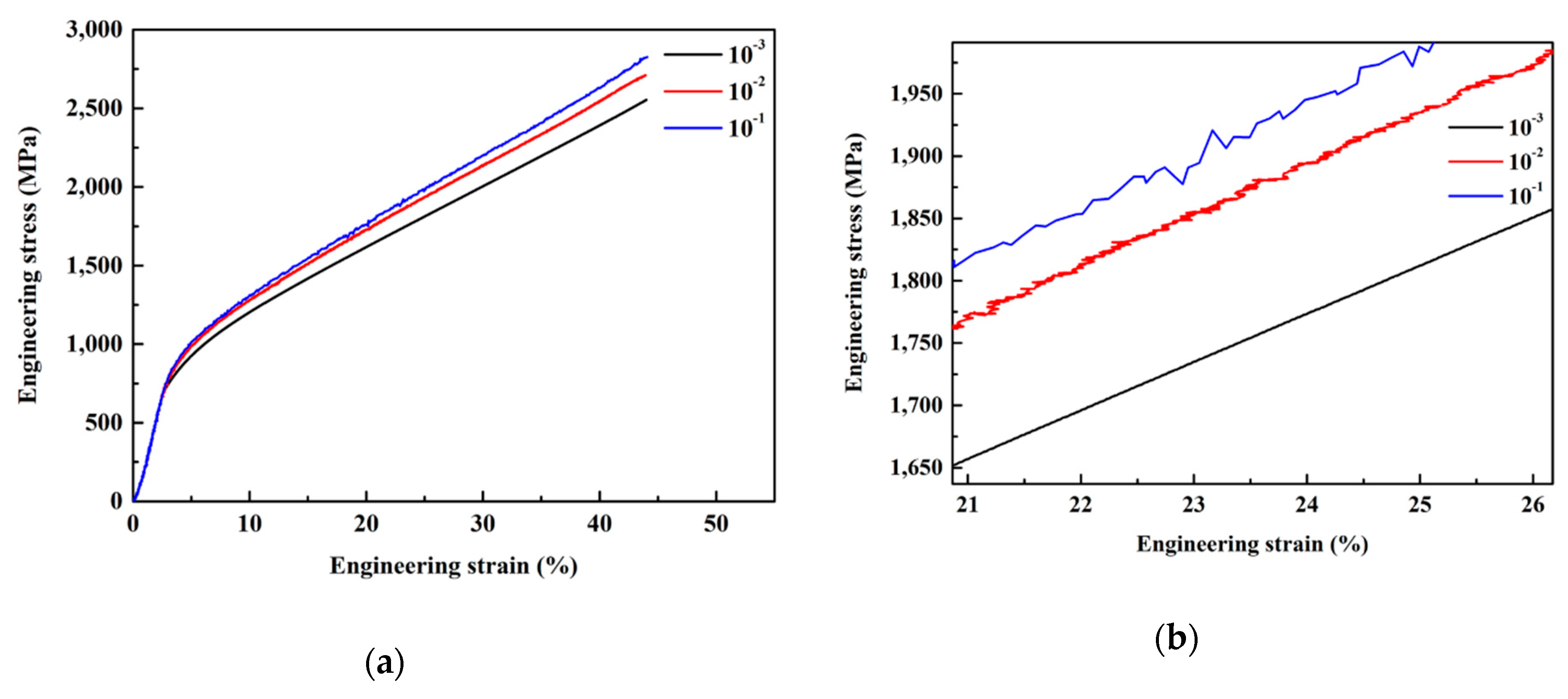

2. Materials and Methods

3. Results and Discussion

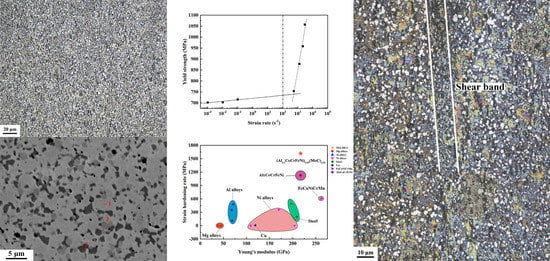

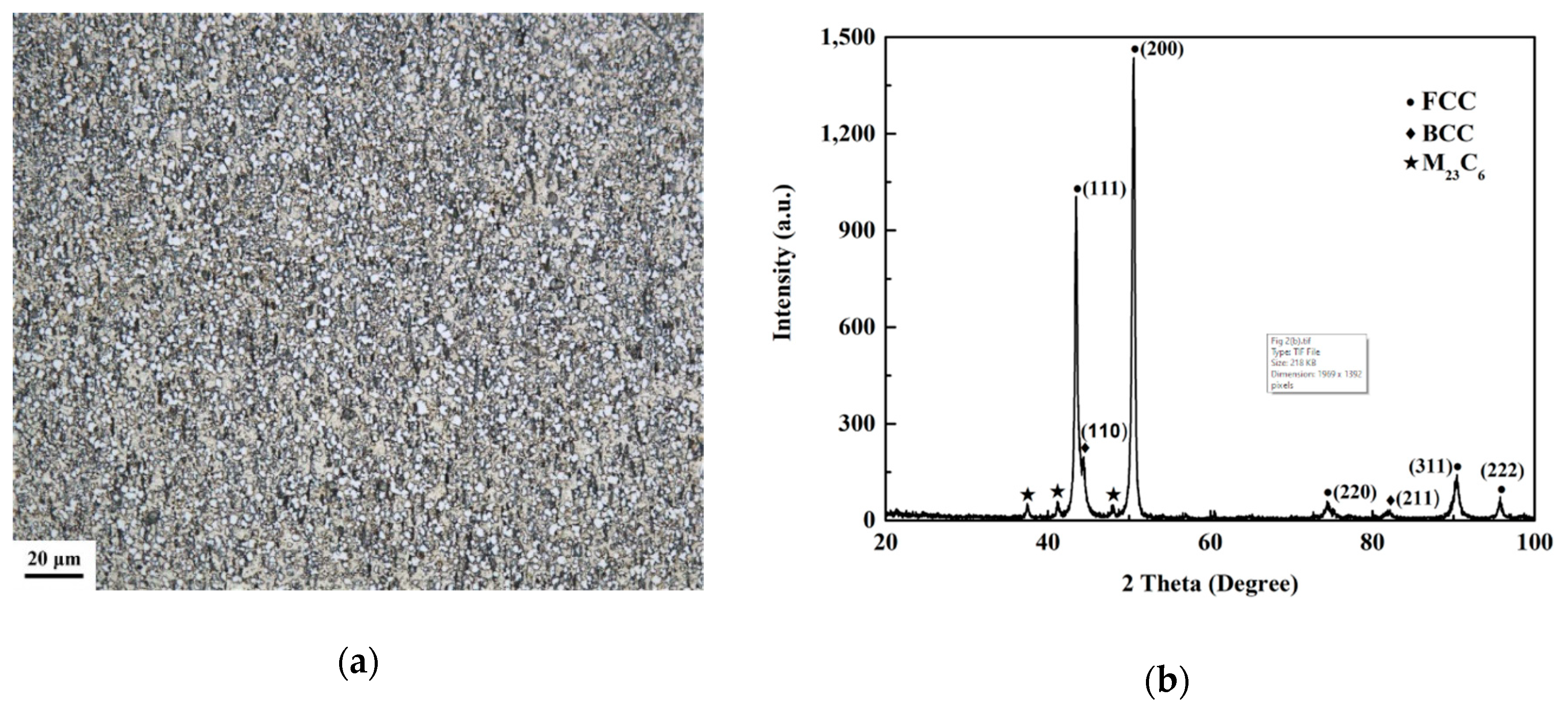

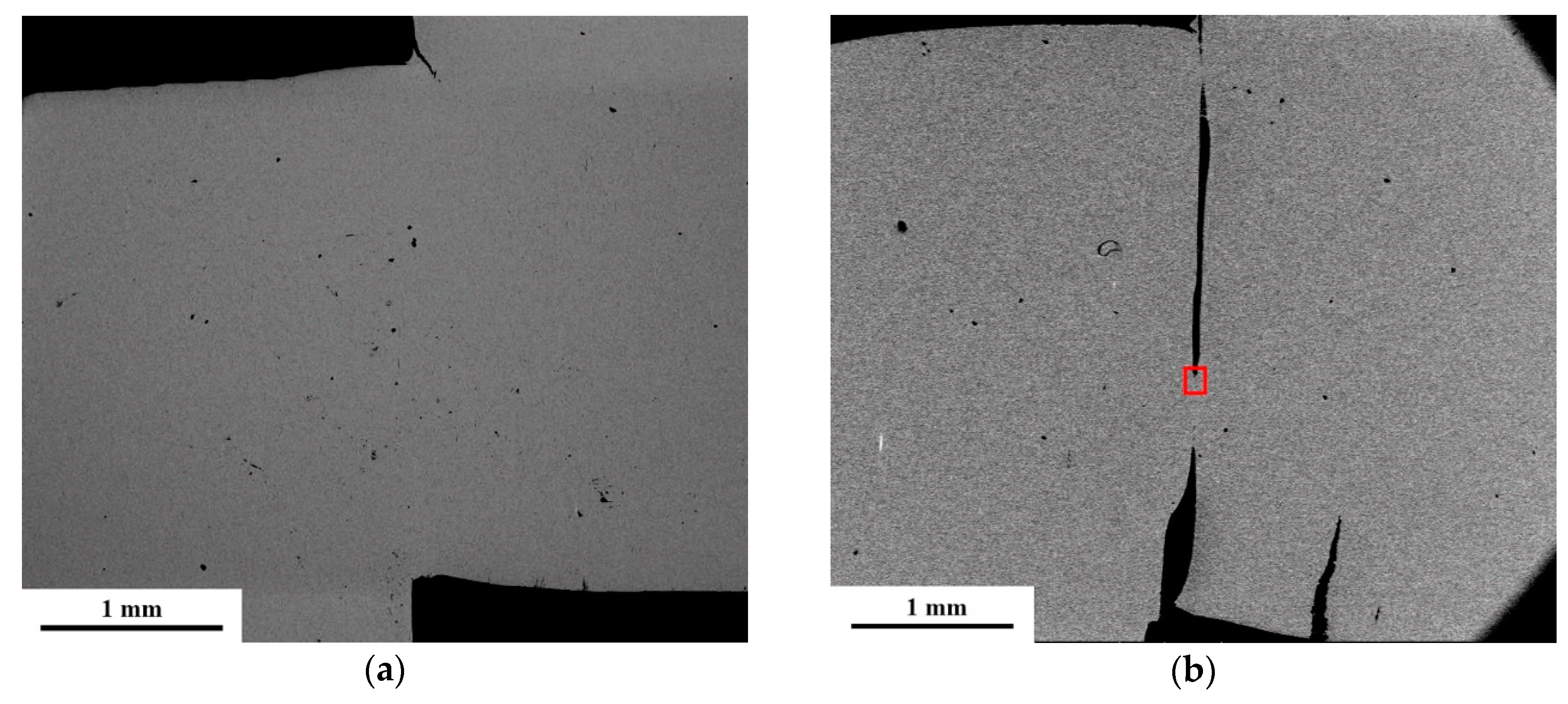

3.1. Microstructure of the High Entropy Alloy

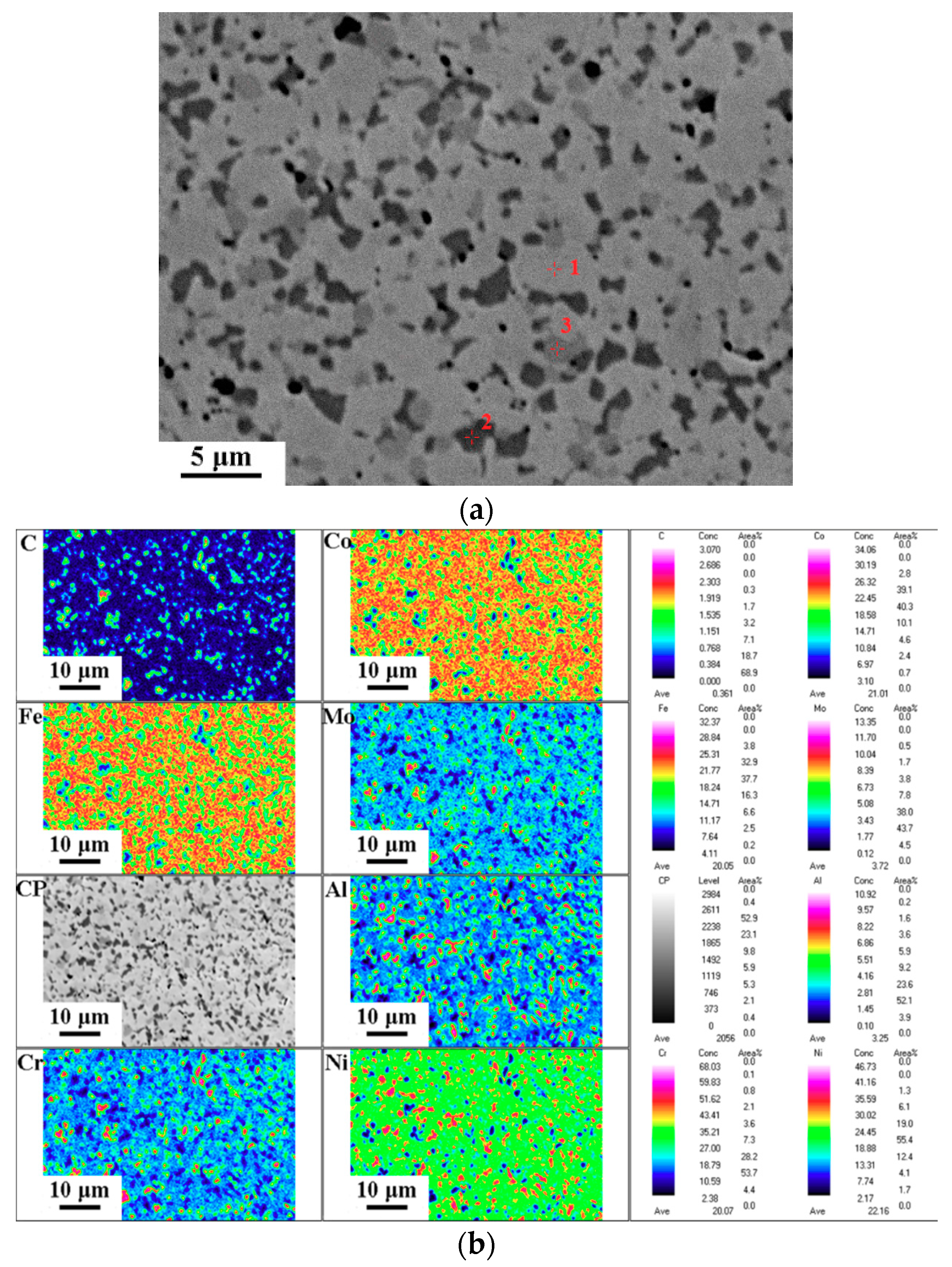

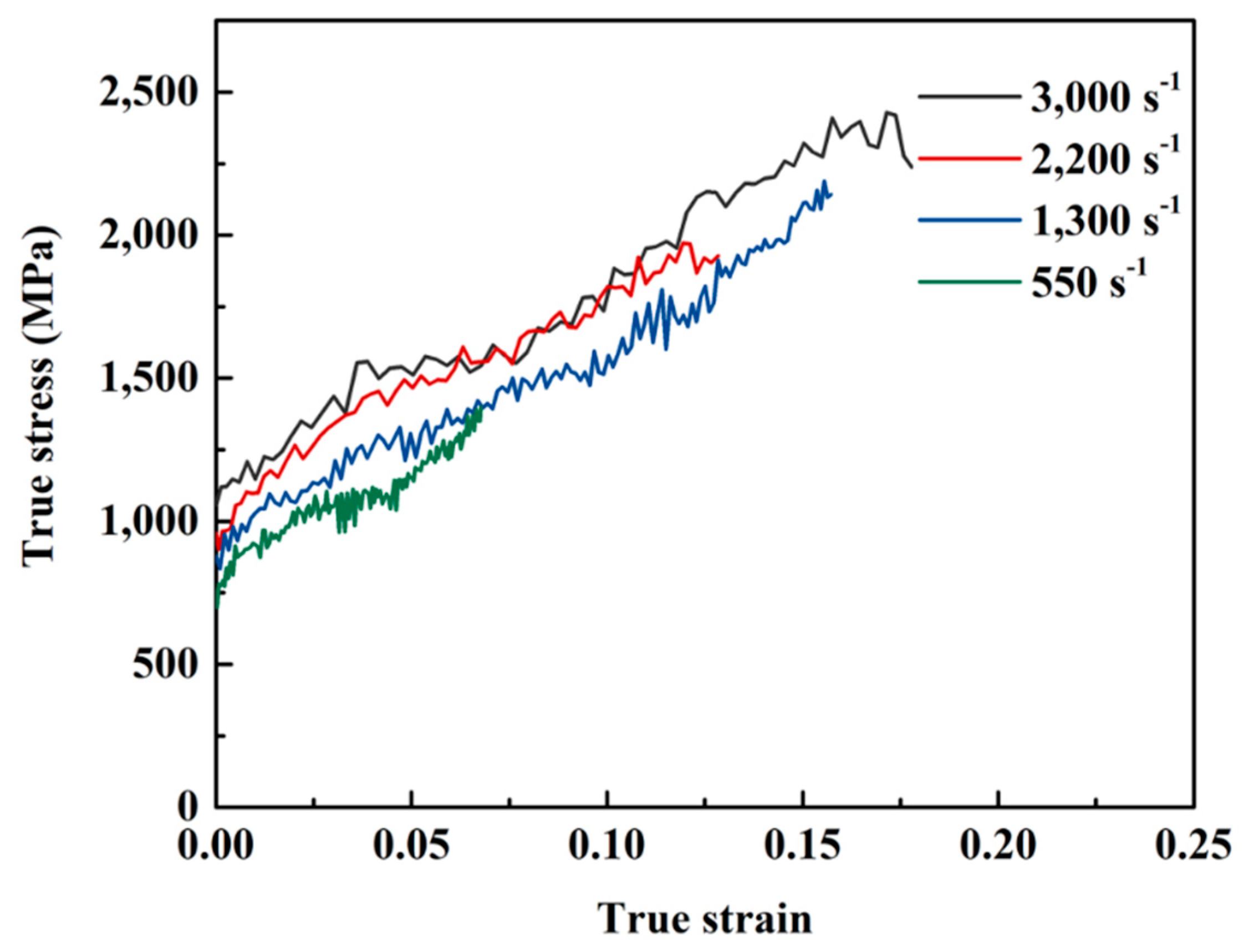

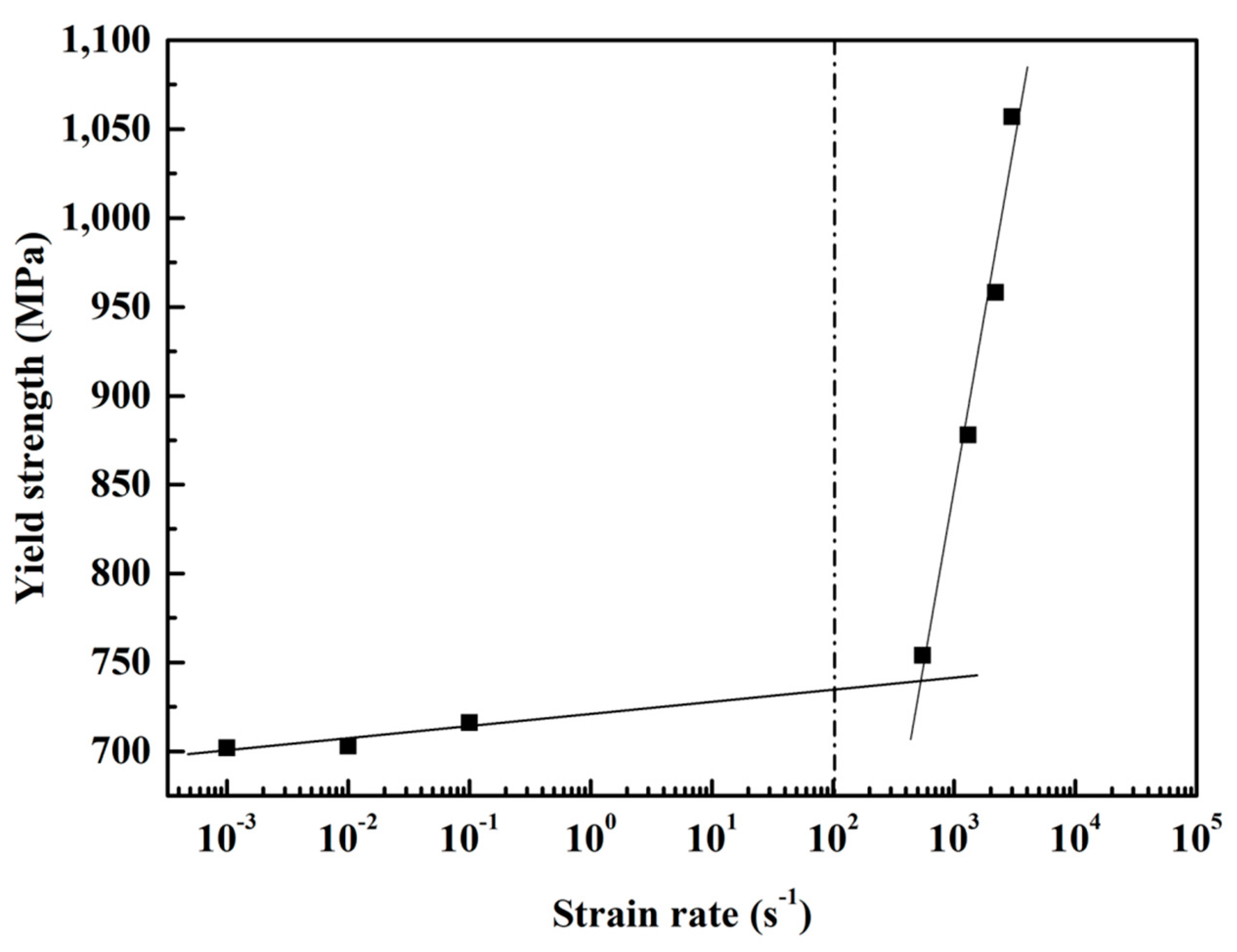

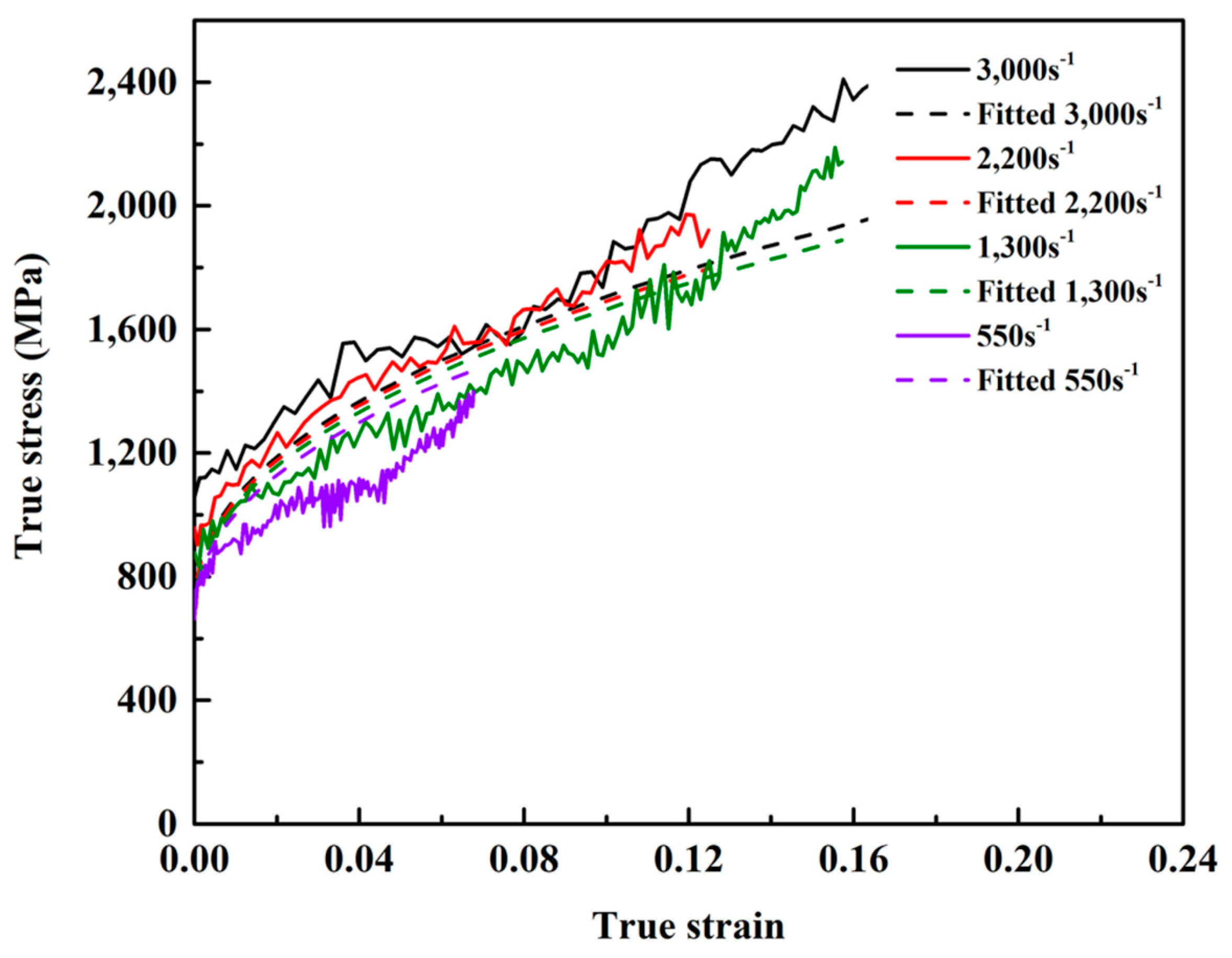

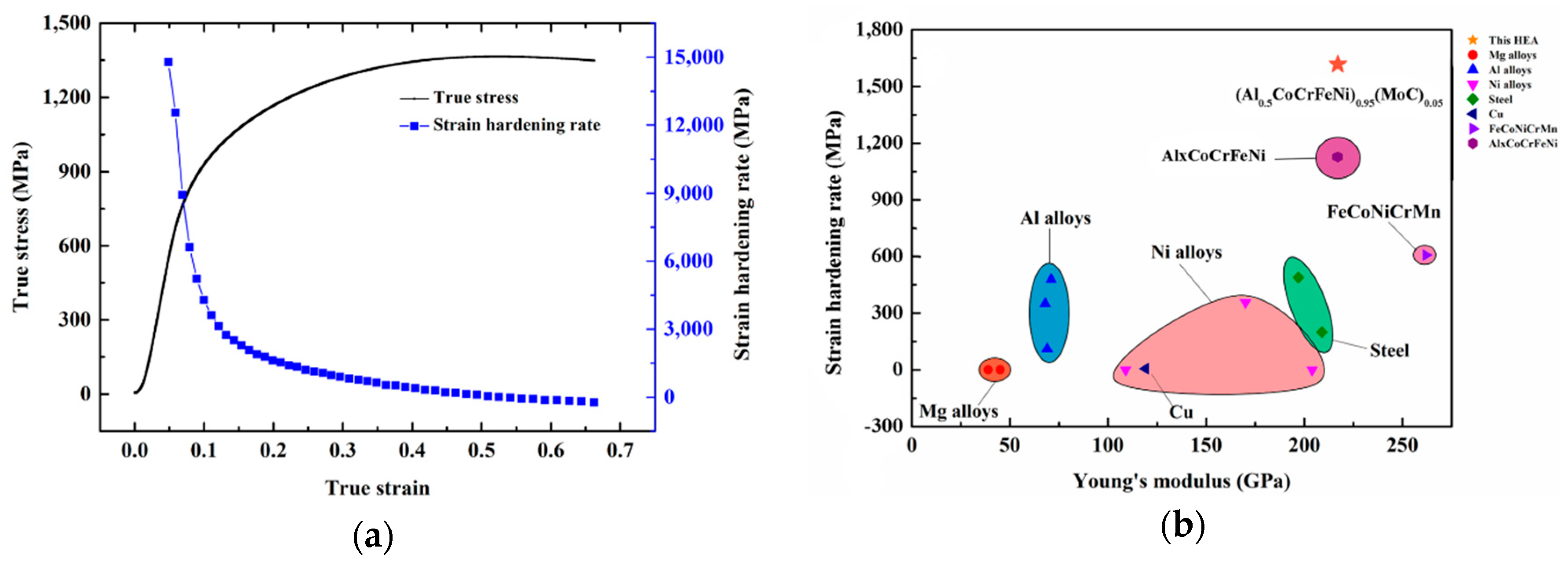

3.2. Stress–Strain Curves of the High Entropy Alloy

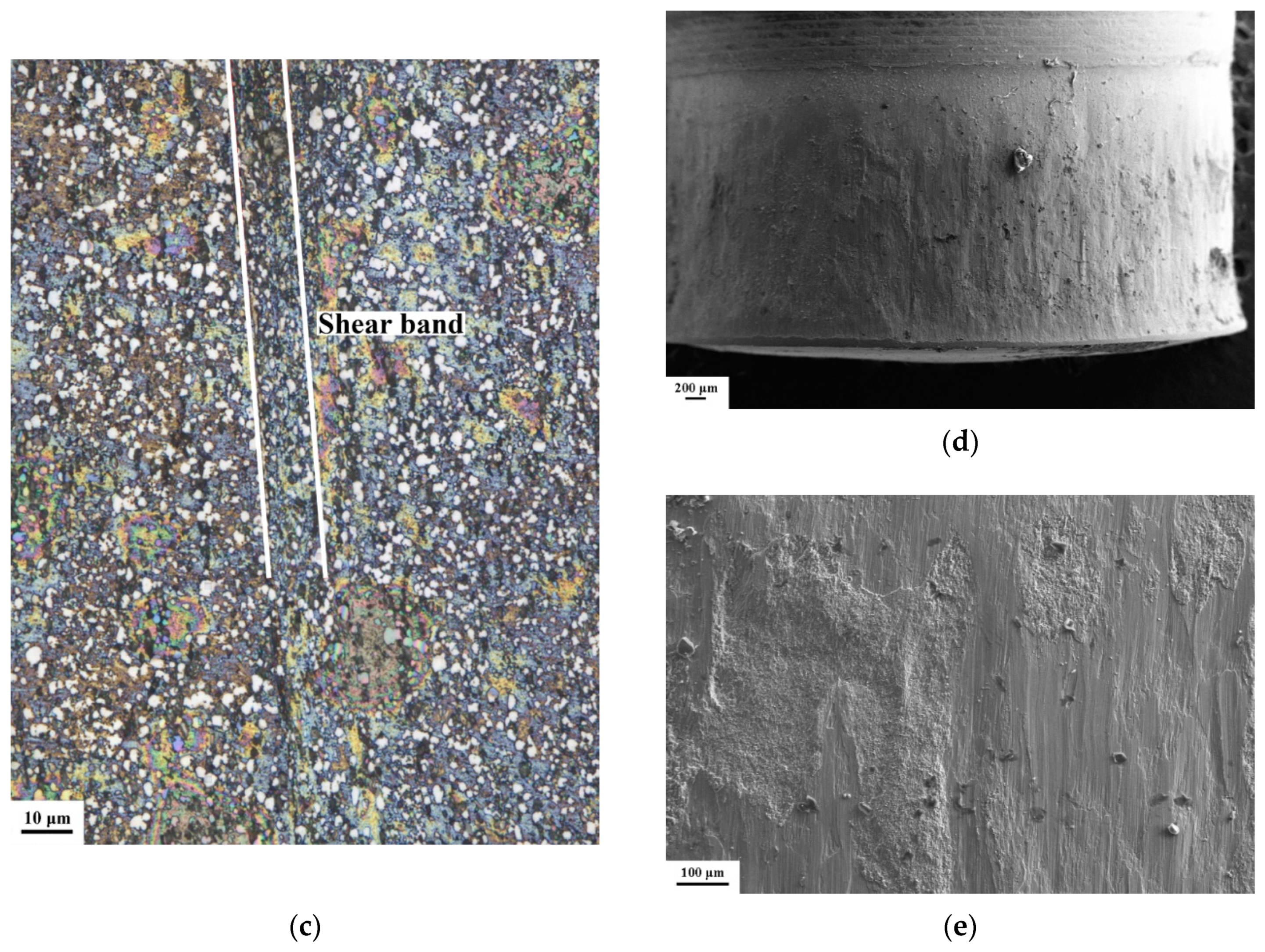

3.3. Shear Localization of the High Entropy Alloy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, S.; Li, W.; Li, X.Q.; Schönecker, S.; Bergqvist, L.; Holmström, E.; Varga, L.K.; Vitos, L. Mechanism of magnetic transition in FeCrCoNi-based high entropy alloys. Mater. Des. 2016, 103, 71–74. [Google Scholar] [CrossRef]

- Zhang, A.J.; Han, J.S.; Su, B.; Li, P.D.; Meng, J.H. Microstructure, mechanical properties and tribological performance of CoCrFeNi high entropy alloy matrix self-lubricating composite. Mater. Des. 2017, 114, 253–263. [Google Scholar] [CrossRef]

- Tang, Q.H.; Huang, Y.; Cheng, H.; Liao, X.Z.; Langdon, T.G.; Dai, P.Q. The effect of grain size on the annealing-induced phase transformation in an Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2016, 105, 381–385. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chou, H.P.; Chang, Y.S.; Chen, S.K.; Yeh, J.W. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤2) high-entropy alloys. Mater. Sci. Eng. B 2009, 163, 184–189. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Yang, T.F.; Xia, S.Q.; Liu, S.; Wang, C.X.; Liu, S.S.; Zhang, Y.; Xue, J.M.; Yan, S.; Wang, Y.G. Effects of AL addition on microstructure and mechanical properties of AlxCoCrFeNi High-entropy alloy. Mater. Sci. Eng. A 2015, 648, 15–22. [Google Scholar] [CrossRef]

- Lin, C.M.; Tsai, H.L. Evolution of microstructure, hardness, and corrosion properties of high-entropy Al0.5CoCrFeNi alloy. Intermetallics 2011, 19, 288–294. [Google Scholar] [CrossRef]

- Niu, S.Z.; Kou, H.C.; Guo, T.; Zhang, Y.; Wang, J.; Li, J.S. Strengthening of nanoprecipitations in an annealed Al0.5CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2016, 671, 82–86. [Google Scholar] [CrossRef]

- Wang, J.; Niu, S.Z.; Guo, T.; Kou, H.C.; Li, J.S. The FCC to BCC phase transformation kinetics in an Al0.5CoCrFeNi high entropy alloy. J. Alloys Compd. 2017, 710, 144–150. [Google Scholar] [CrossRef]

- Liu, W.H.; Lu, Z.P.; He, J.Y.; Luan, J.H.; Wang, Z.J.; Liu, B.; Liu, Y.; Chen, M.W.; Liu, C.T. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016, 116, 332–342. [Google Scholar] [CrossRef]

- Shun, T.T.; Chang, L.Y.; Shiu, M.H. Microstructure and mechanical properties of multiprincipal component CoCrFeNiMox alloys. Mater. Charact. 2012, 70, 63–67. [Google Scholar] [CrossRef]

- Li, W.P.; Wang, X.G.; Liu, B.; Fang, Q.H.; Jiang, C. Fracture mechanisms of a Mo alloyed CoCrFeNi high entropy alloy: In-situ SEM investigation. Mater. Sci. Eng. A 2018, 723, 79–88. [Google Scholar] [CrossRef]

- Cai, B.; Liu, B.; Kabra, S.; Wang, Y.Q.; Yan, K.; Lee, P.D.; Liu, Y. Deformation mechanisms of Mo alloyed FeCoCrNi high entropy alloy: In situ neutron diffraction. Acta Mater. 2017, 127, 471–480. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Zhang, X.L.; Gu, X.Y. Effect of molybdenum on phases, microstructure and mechanical properties of Al0.5CoCrFeMoxNi high entropy alloys. J. Alloys Compd. 2018, 743, 514–522. [Google Scholar] [CrossRef]

- Peng, J.; Li, Z.Y.; Fu, L.M.; Ji, X.B.; Pang, Z.R.; Shan, A.D. Carbide precipitation strengthening in fine-grained carbon-doped FeCoCrNiMn high entropy alloy. J. Alloys Compd. 2019, 803, 491–498. [Google Scholar] [CrossRef]

- Kumar, N.; Ying, Q.; Nie, X.; Mishra, R.S.; Tang, Z.; Liaw, P.K.; Brennan, R.E.; Doherty, K.J.; Cho, K.C. High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy. Mater. Des. 2015, 86, 598–602. [Google Scholar] [CrossRef]

- Dirras, G.; Couque, H.; Lilensten, L.; Heczel, A.; Tingaud, D.; Couzinie, J.P.; Perriere, L.; Gubicza, J.; Guillot, I. Mechanical behavior and microstructure of Ti20Hf20Zr20Ta20Nb20 high-entropy alloy loaded under quasi-static and dynamic compression conditions. Mater. Charact. 2016, 111, 106–113. [Google Scholar] [CrossRef]

- Wang, B.F.; Huang, X.X.; Fu, A.; Liu, Y.; Liu, B. Serration behavior and microstructure of high entropy alloy CoCrFeMnNi prepared by powder metallurgy. Mater. Sci. Eng. A 2018, 726, 37–44. [Google Scholar] [CrossRef]

- Wang, B.F.; Yao, X.R.; Wang, C.; Zhang, X.Y.; Huang, X.X. Mechanical Properties and Microstructure of a NiCrFeCoMn High-Entropy Alloy Deformed at High Strain Rates. Entropy 2018, 20, 892. [Google Scholar] [CrossRef]

- Ma, S.G.; Jiao, Z.M.; Qiao, J.W.; Yang, H.J.; Zhang, Y.; Wang, Z.H. Strain rate effects on the dynamic mechanical properties of the AlCrCuFeNi2 high-entropy alloy. Mater. Sci. Eng. A 2016, 649, 35–38. [Google Scholar] [CrossRef]

- Li, Z.Z.; Zhao, S.T.; Alotaibi, S.M.; Liu, Y.; Wang, B.F.; Meyers, M.A. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 151, 424–431. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Diao, H.; Liaw, P.K.; Meyers, M.A. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci. Rep. 2017, 7, 42742. [Google Scholar] [CrossRef]

- An, Q.; Wang, J.W.; Liu, Y.; Liu, B.; Guo, W.M.; Fang, Q.H.; Nie, Y. Effects of C and Mo on microstructures and mechanical properties of dual-phase high entropy alloys. Intermetallics 2019, 110, 106471. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, D.; Jin, X.; Zhang, L.; Du, X.Y.; Li, B.S. Design of non-equiatomic medium-entropy alloys. Sci. Rep. 2018, 8, 1236. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy design strategies and future trends in high-entropy alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

| Elements | Al | Co | Cr | Fe | Ni | Mo | C |

|---|---|---|---|---|---|---|---|

| (wt.%) | 4.54 | 23.92 | 23.25 | 20.90 | 22.19 | 4.49 | 0.71 |

| (at.%) | 9.0 | 21.7 | 23.9 | 20.0 | 20.2 | 2.5 | 2.7 |

| a | b | c | d | e | f | γnom. | ||

|---|---|---|---|---|---|---|---|---|

| 1 | before | 5.70 | 6.00 | 12.80 | 1.98 | 4.70 | 6.88 | 2.53 |

| after | 5.96 | 6.00 | 12.84 | 1.78 | 4.64 | 6.50 | ||

| 2 | before | 5.90 | 6.30 | 13.14 | 1.98 | 5.00 | 7.00 | 5.30 |

| after | 6.20 | 6.58 | 13.26 | 1.00 | 4.98 | 5.94 | ||

| 3 | before | 5.76 | 6.00 | 12.86 | 1.94 | 4.70 | 6.88 | 9.83 |

| after | 5.92 | 6.00 | 12.90 | 0.90 | 4.64 | 5.70 |

| Phases | Al | Co | Cr | Fe | Ni | Mo | C |

|---|---|---|---|---|---|---|---|

| FCC | 7.7 | 24.5 | 18.3 | 23.5 | 20.8 | 2.2 | 3.0 |

| BCC | 27.3 | 18.5 | 6.4 | 13.0 | 32.2 | 0.3 | 2.3 |

| M23C6 | 1.1 | 6.7 | 55.9 | 9.4 | 3.2 | 5.8 | 17.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Wang, C.; Liu, B.; Zhang, X. Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy. Entropy 2019, 21, 1154. https://doi.org/10.3390/e21121154

Wang B, Wang C, Liu B, Zhang X. Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy. Entropy. 2019; 21(12):1154. https://doi.org/10.3390/e21121154

Chicago/Turabian StyleWang, Bingfeng, Chu Wang, Bin Liu, and Xiaoyong Zhang. 2019. "Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy" Entropy 21, no. 12: 1154. https://doi.org/10.3390/e21121154

APA StyleWang, B., Wang, C., Liu, B., & Zhang, X. (2019). Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy. Entropy, 21(12), 1154. https://doi.org/10.3390/e21121154