Research on the Stress Characteristics of Reuse of Semi-Rigid Base

Abstract

:1. Introduction

2. Methodology

2.1. Typical Detection by Ground-Penetrating Radar

2.2. Strength Formation Mechanism

2.3. Mechanical Characteristics of Asphalt Overlay Under Different Crushing Effects

2.4. Finite Element Model

2.4.1. Pavement Structure Model and Parameters

2.4.2. MHB Drop Hammer Load and Acting Position

2.4.3. Stiffness Element Distribution

3. Results of the Research

3.1. Stress Distribution in All Directions

3.2. Analysis of Strength Attenuation of Pavement Structure

4. Discussion and Interpretation of Results Obtained

4.1. The Effect of Modulus Changes on Overlay

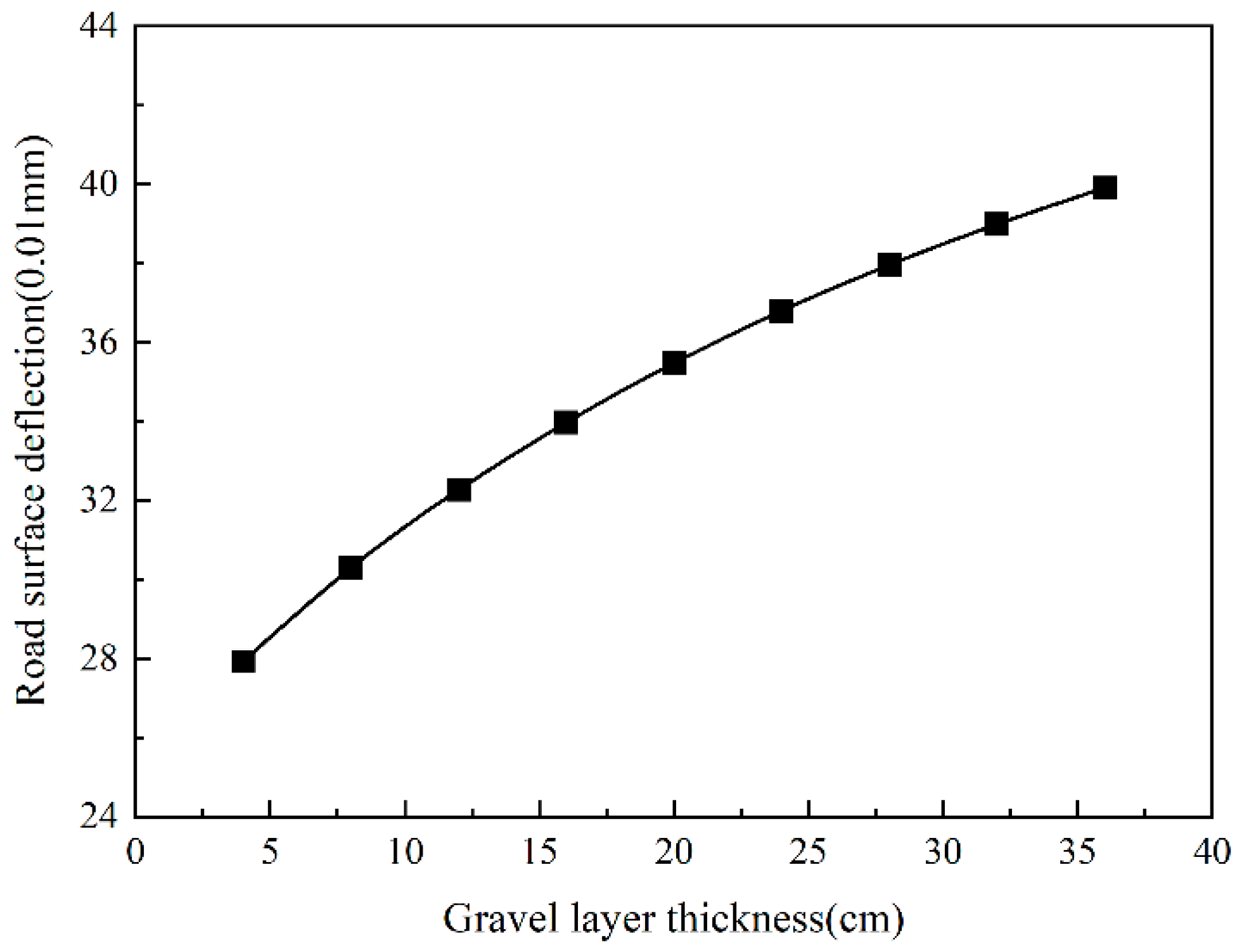

4.2. The Influence of Thickness Change on Overlay

4.3. Combination Structures

5. Conclusions

- After being crushed, the semi-rigid base layer is divided into three distinct layers: the loose layer, the gravel layer, and the cracked layer, each characterized by different mechanisms of shear strength. In the loose layer, shear strength is primarily governed by the material’s internal friction angle and the regular forces at the particle contact surfaces. For the gravel layer, the shear strength is mainly influenced by the internal friction angle and pre-compression stress. In contrast, the cracked layer’s shear strength is predominantly determined by the squeezing capacity between blocks and the arching effect.

- The Abaqus finite element software was used to construct a multi-hammer crushing equipment model acting on a semi-rigid base pavement structure. The mechanical response of the semi-rigid base pavement under the impact load of the multi-hammer crushing equipment was analyzed. The results indicate that the maximum principal stress at the bottom of the semi-rigid base reaches 0.7 MPa, which exceeds its splitting strength of 0.6 MPa. Consequently, multi-hammer crushing equipment is adequate for crushing semi-rigid base pavement structures.

- An analysis of the strength attenuation of the semi-rigid base layer after crushing reveals a clear relationship between the particle size and equivalent strength. As the particle size decreases, the equivalent strength of the base layer diminishes significantly. This trend highlights the particle size’s critical influence on the crushed layer’s structural integrity. Specifically, the decay in the equivalent strength becomes particularly pronounced when the particle size is reduced to less than 1.25 mm. At this threshold, the rapid degradation in the strength can compromise the load-bearing capacity of the layer, emphasizing the need for careful control and monitoring of the particle size during the crushing process to ensure the stability and functionality of the semi-rigid base.

- An analysis of the asphalt overlay’s force characteristics under varying degrees of crushing revealed that the optimal design parameters include a gravel layer with a thickness of 20 cm and a modulus of 400 MPa and a crack layer with a thickness of 20 cm and a modulus of 1000 MPa. This configuration, particularly in its fractured state, effectively suppresses the formation of reflective cracks while maintaining the structural integrity and strength of the gravel and crack layers.

- A comparison was conducted to analyze the changes in the structural mechanics of crushed petrified layers used as a subgrade and sub-base. The findings indicate that using the crushed petrified layer as the base layer results in excessive tensile strain at the bottom of the asphalt layer and compressive strain at the top of the road base. Consequently, utilizing the crushed petrified layer as a semi-rigid base layer is recommended. Additionally, a base layer should be incorporated beneath the asphalt surface layer when designing the structure of the additional pavement layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Wang, Y. Reflective cracking in asphalt pavements: Mechanisms and mitigation strategies. J. Pavement Res. 2020, 15, 123–135. [Google Scholar]

- Li, Z.; Liu, X. Semi-rigid base materials and their application in asphalt pavements. Int. J. Road Mater. 2018, 22, 215–228. [Google Scholar]

- Huang, Y.H. Pavement Analysis and Design; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Tanaka, K.; Ogawa, S. Reflective cracking analysis in asphalt overlays: A Japanese perspective. J. Pavement Eng. 2017, 19, 98–108. [Google Scholar]

- Nakamura, T.; Ito, M. Laboratory testing of cracking resistance in semi-rigid base pavements. Pavement Mech. Des. 2015, 12, 405–420. [Google Scholar]

- Müller, R.; Schumann, A. Advanced overlay materials for semi-rigid base applications. Ger. J. Pavement Sci. 2019, 10, 55–68. [Google Scholar]

- Kim, J.; Lee, Y. Structural behavior of semi-rigid bases under dynamic loads. Int. J. Pavement Res. 2017, 18, 215–230. [Google Scholar]

- Gao, W.; Zhao, H. Study on the modulus of crushed layers in semi-rigid base pavements. J. Civ. Eng. Mater. 2019, 23, 98–109. [Google Scholar]

- Lin, F.; Chen, X. Finite element modeling of crushed semi-rigid base pavements. J. Road Mech. 2018, 17, 150–162. [Google Scholar]

- Wang, L.; Zhang, X. Optimal parameters for crushed layers in semi-rigid bases. J. Pavement Des. Maint. 2020, 12, 345–362. [Google Scholar]

- Zhou, X.; Li, D. Application of crushing technology in China: Challenges and opportunities. Road Constr. Res. 2021, 24, 34–47. [Google Scholar]

- Luo, J.; Chen, S. Effect of crushed layer modulus on pavement performance in China. Civ. Eng. J. 2019, 18, 98–105. [Google Scholar]

- Smith, R.; Brown, P. Advances in asphalt pavement maintenance. J. Constr. Eng. 2017, 10, 212–225. [Google Scholar]

- Carter, T.; Wang, Q. Crushing technology applications in Australia. Aust. J. Road Eng. 2018, 15, 89–101. [Google Scholar]

- Johnson, L. Dynamic response of semi-rigid bases under multi-hammer loading. ASCE J. Mater. Eng. 2019, 31, 155–162. [Google Scholar]

- Chen, F.; Gao, H. Finite element simulations of semi-rigid base layers. J. Civ. Eng. Des. 2020, 26, 78–90. [Google Scholar]

- Zhang, T.; Wu, L. Pavement cracking mechanisms under varying conditions. Int. J. Pavement Res. 2019, 15, 105–112. [Google Scholar]

- Fischer, P. Crushed layers and their effects on overlay life cycles. Ger. Road Sci. J. 2020, 28, 200–213. [Google Scholar]

- Zhao, Y.; Lin, J. Mechanical properties of crushed semi-rigid base layers. J. Road Technol. 2018, 13, 220–230. [Google Scholar]

- Zhao, H.; Xu, T. Optimization of multi-layer crushing techniques. Transp. Eng. J. 2019, 23, 90–110. [Google Scholar]

- Lee, J.; Park, K. Numerical analysis of crushed base behavior. Int. J. Road Maint. 2020, 22, 145–160. [Google Scholar]

- Clark, R.; Taylor, M. Sustainability in pavement rehabilitation. Environ. Eng. Rev. 2018, 14, 121–135. [Google Scholar]

- Yan, W.; Han, X. Innovations in crushing technology for rigid pavements. Eng. Rev. 2021, 12, 155–172. [Google Scholar]

- Bell, T. Economic implications of advanced road maintenance. J. Civ. Econ. 2019, 25, 65–80. [Google Scholar]

- Du, Y.; Qiu, J. Advances in pavement fracture modeling. Pavement Mech. Des. 2020, 19, 300–315. [Google Scholar]

- Pan, L.; Zhao, F. Finite element studies on pavement repair. J. Struct. Eng. 2021, 17, 200–220. [Google Scholar]

- Lijun, S. Modern Interlocking Block Pavement; Statistics University Press: Shanghai, China, 2000; pp. 64–74. [Google Scholar]

- Anhua, X. Research on the applicability of multi-hammer crusher in reconstructing old cement pavement. Highw. Eng. 2012, 37, 6–9. [Google Scholar]

- Jieng, Q.; Yan, L.; Juan, Z. Discuss the principle and application of crushing old MHB and RPB cement pavements. Highw. Transp. Sci. Technol. (Appl. Technol. Ed.) 2019, 15, 102–104. [Google Scholar]

- Liu, X. Analysis of Mechanical Properties of Asphalt Overlay Based on MHB Crushing Technology. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2010. [Google Scholar]

- Yu, L.; Wu, Y.; Meng, Y.; Huang, G.; Li, R.; Pei, J. Study on fatigue crack propagation failure in semi-rigid base. Constr. Build. Mater. 2023, 409, 134007. [Google Scholar] [CrossRef]

- Yu, L.; Wang, L.; Pei, J.; Li, R.; Zhang, J.; Cheng, S. Structural optimization study based on crushing of semi-rigid base. Electron. Res. Arch. 2023, 31, 1769–1788. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, B.; Hu, S.; Xu, W.; Wang, S. Mechanical behavior and instability mechanism of sandstones with impact tendency under different loading paths. Int. J. Min. Reclam. Environ. 2024, 1–20. [Google Scholar] [CrossRef]

| Maximum Drop Height | Hammer Weight | Single-Hammer Working Area |

|---|---|---|

| 160 cm | 445~500 kg | (20.32 × 2.54) cm2 |

| Layer | Crushing on Sub-Base | Crushing on Subgrade |

|---|---|---|

| Asphalt layer thickness (cm) | 18 | 18 |

| Modulus of asphalt layer (MPa) | 1200 | 1200 |

| Thickness of substrate (cm) | 20 | None |

| Modulus of substrate (MPa) | 1000 | None |

| Thickness of fractured layer (cm) | 20 | 20 |

| Modulus of fractured layer (MPa) | 200/300/400/500/600 | 200/300/400/500/600 |

| Cracked layer thickness (cm) | 20 | 20 |

| Cracked layer modulus (MPa) | 400/600/800/1000/1200 | 400/600/800/1000/1200 |

| Modulus of soil base (MPa) | 60 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Tang, D.; Kang, H.; He, H.; Hu, D.; Li, R.; Pei, J.; Cheng, S. Research on the Stress Characteristics of Reuse of Semi-Rigid Base. Sensors 2024, 24, 8004. https://doi.org/10.3390/s24248004

Yu L, Tang D, Kang H, He H, Hu D, Li R, Pei J, Cheng S. Research on the Stress Characteristics of Reuse of Semi-Rigid Base. Sensors. 2024; 24(24):8004. https://doi.org/10.3390/s24248004

Chicago/Turabian StyleYu, Liting, Dong Tang, Haoyi Kang, Haiqi He, Donliang Hu, Rui Li, Jianzhong Pei, and Shihui Cheng. 2024. "Research on the Stress Characteristics of Reuse of Semi-Rigid Base" Sensors 24, no. 24: 8004. https://doi.org/10.3390/s24248004

APA StyleYu, L., Tang, D., Kang, H., He, H., Hu, D., Li, R., Pei, J., & Cheng, S. (2024). Research on the Stress Characteristics of Reuse of Semi-Rigid Base. Sensors, 24(24), 8004. https://doi.org/10.3390/s24248004