Research on the Optimization and Regulation Mechanism of Waterproofing, Impermeability, and Water Vapor Transmission Property of Mortar Based on Different Modifiers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mortar and Paste

2.3. Methods

2.3.1. Capillary Water Absorption

2.3.2. Impermeability

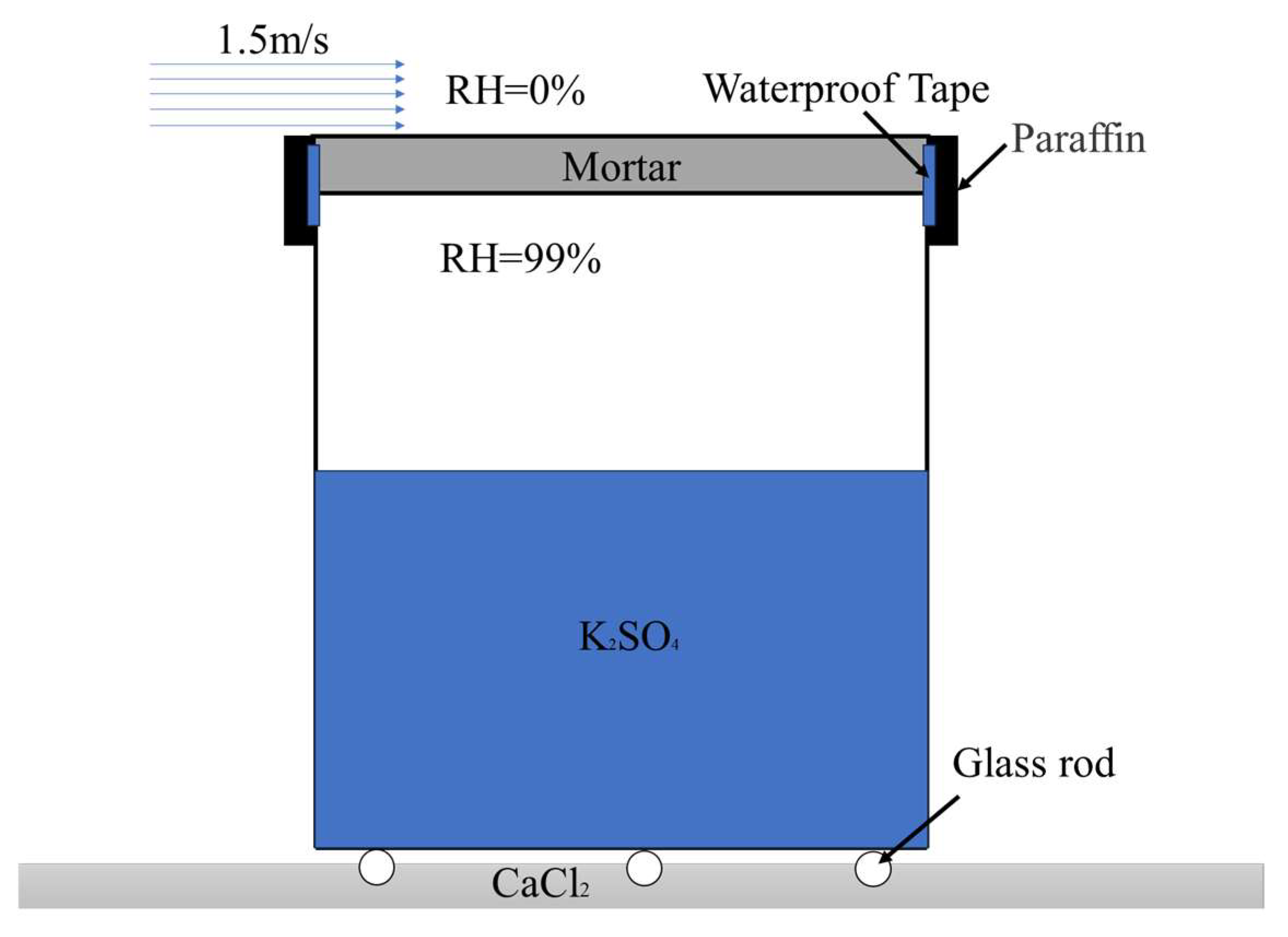

2.3.3. Water Vapor Transmission Property

2.3.4. Mercury Intrusion Porosimetry

2.3.5. Water Contact Angle

2.3.6. Scanning Electron Microscopy

2.3.7. Low-Field Nuclear Magnetic Resonance

2.3.8. X-Ray Diffraction

3. Results and Discussion

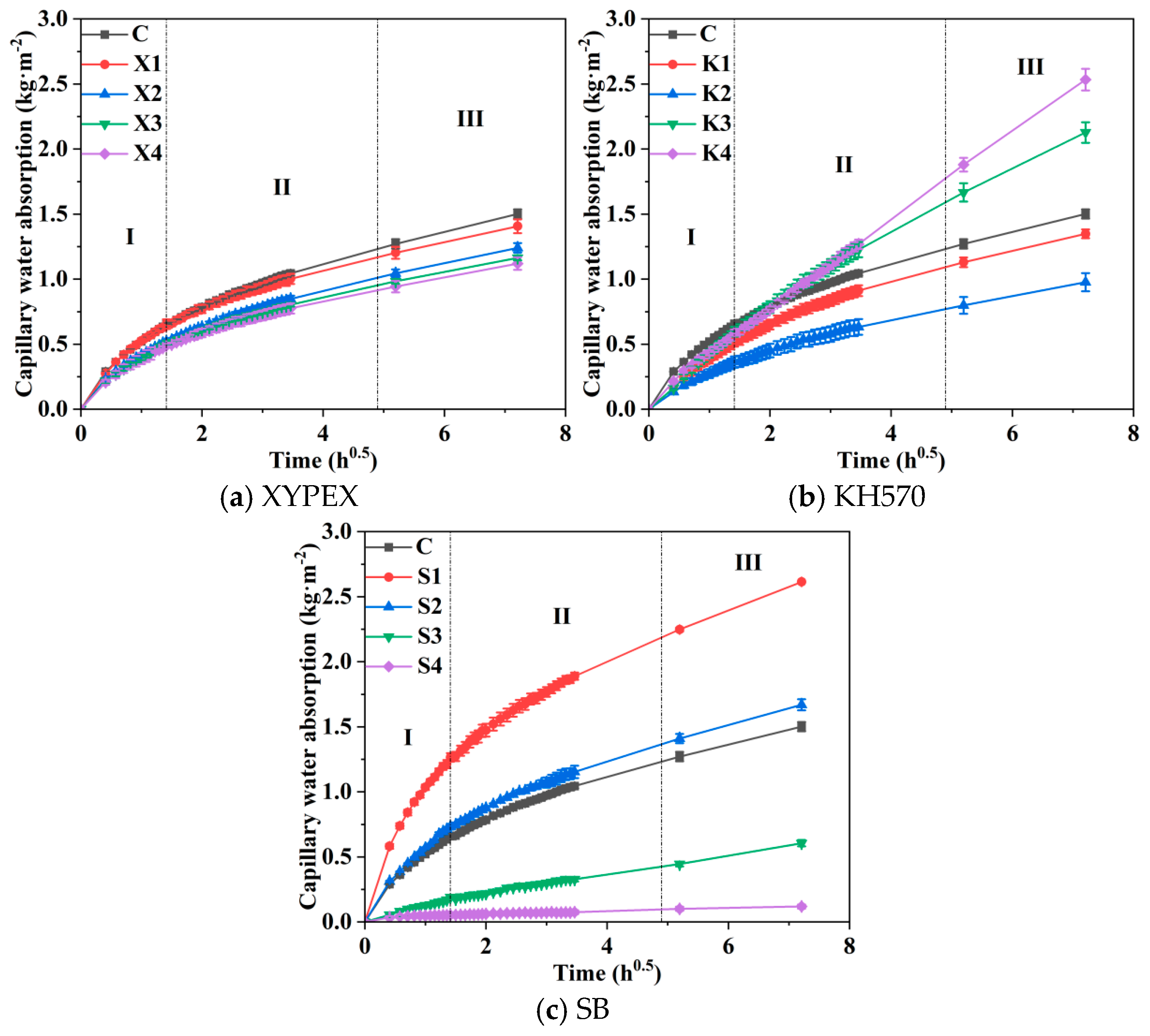

3.1. Capillary Water Absorption

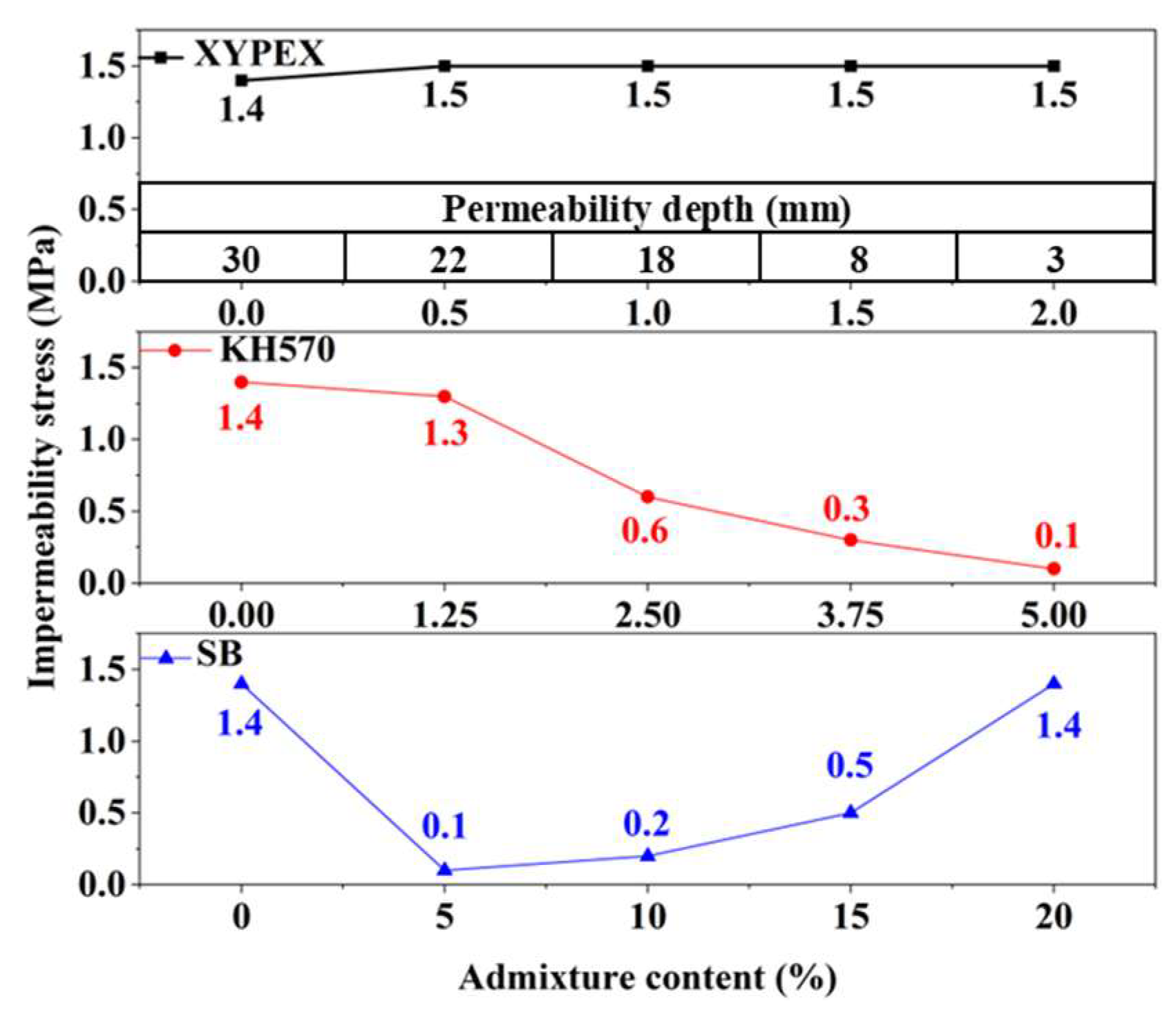

3.2. Impermeability

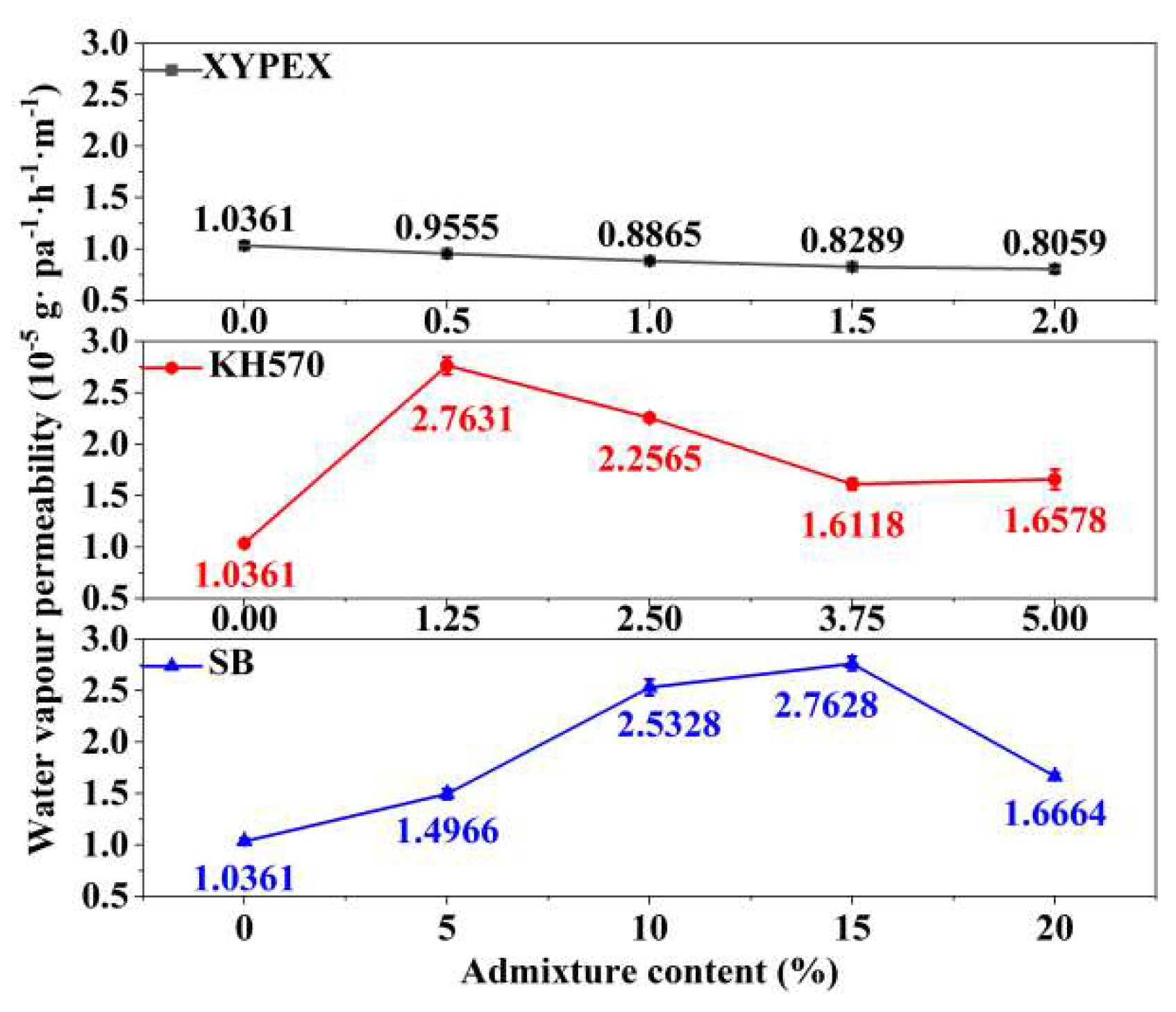

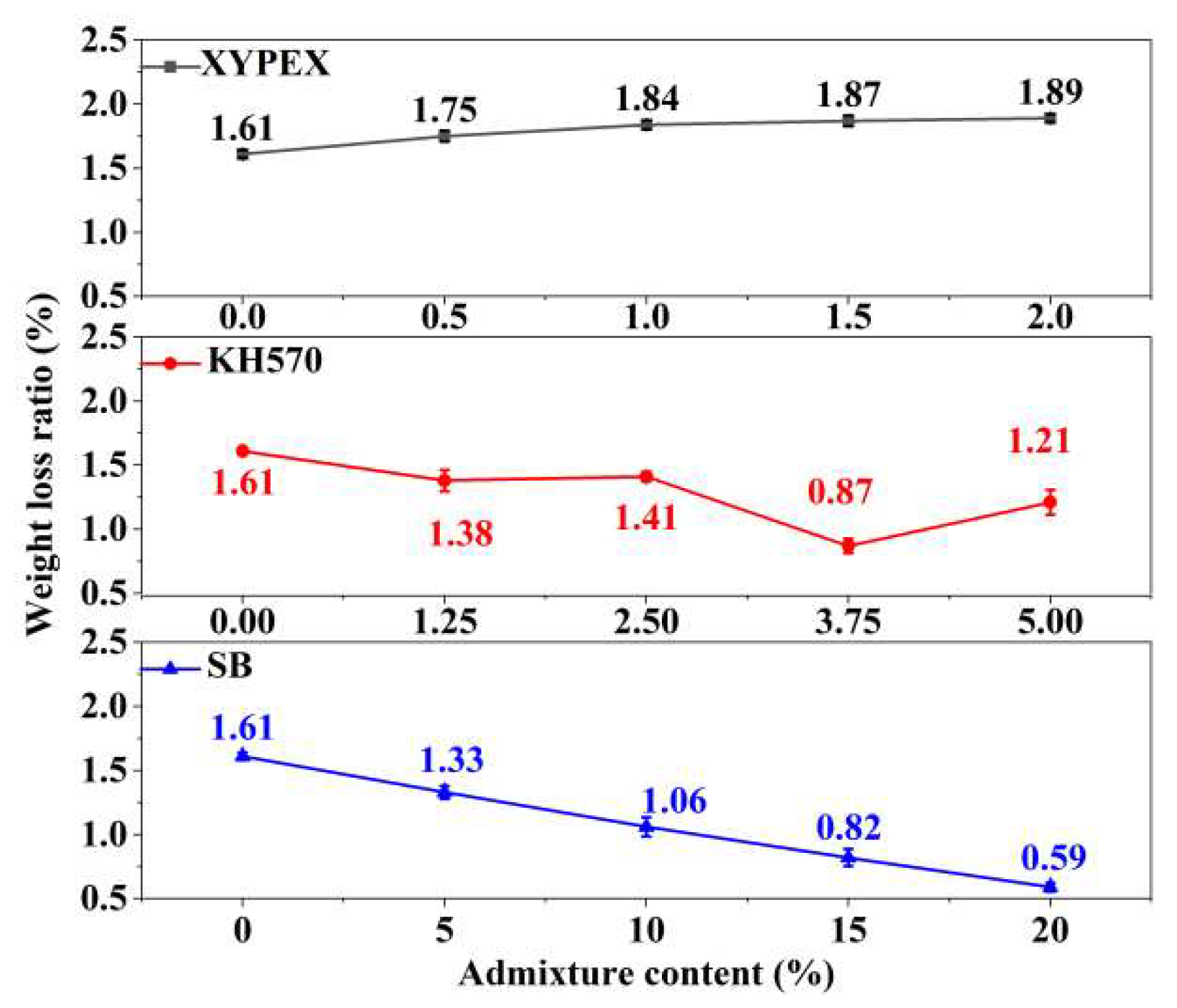

3.3. Water Vapor Transmission Property

3.4. Mechanism Analysis

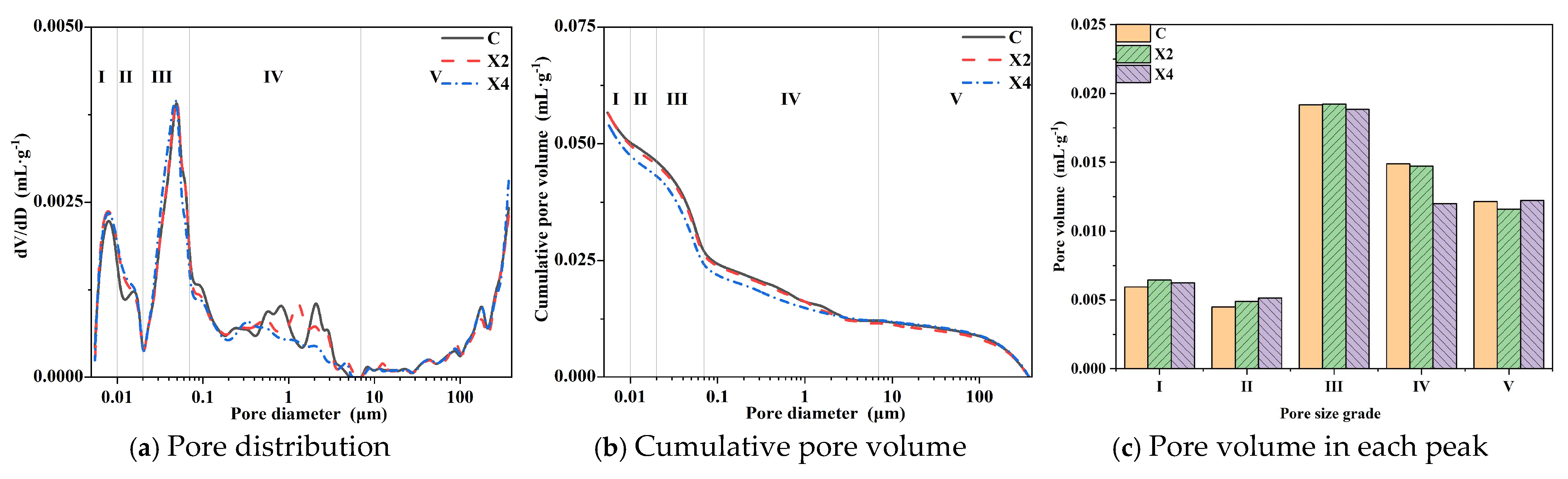

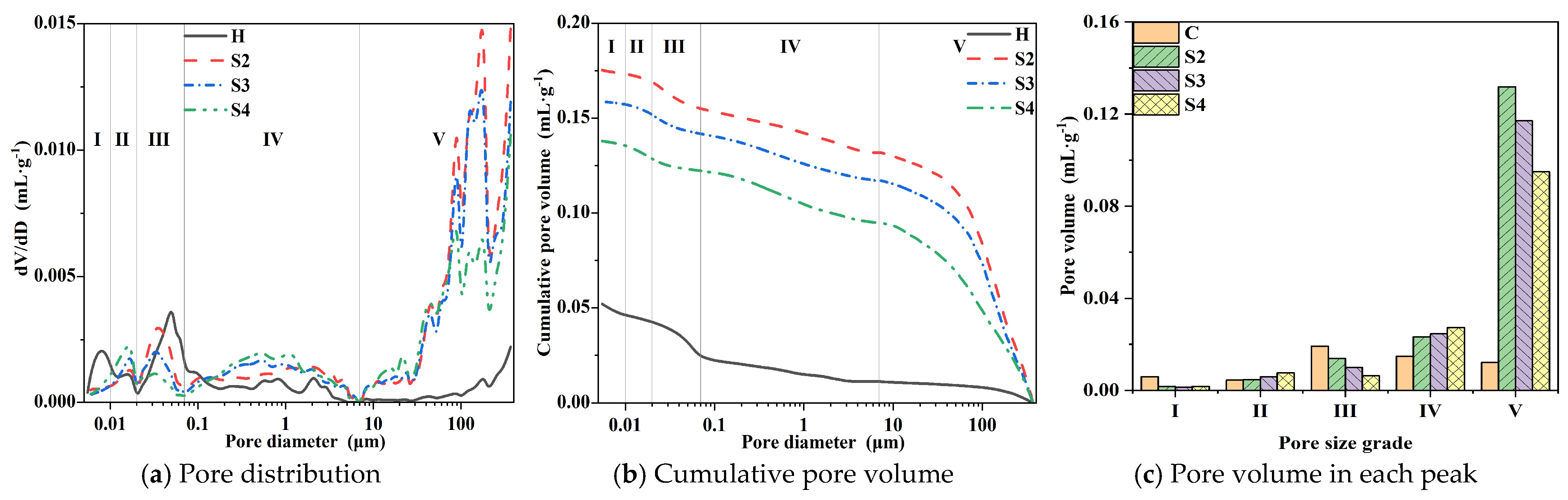

3.4.1. Porosity and Pore Size Distribution

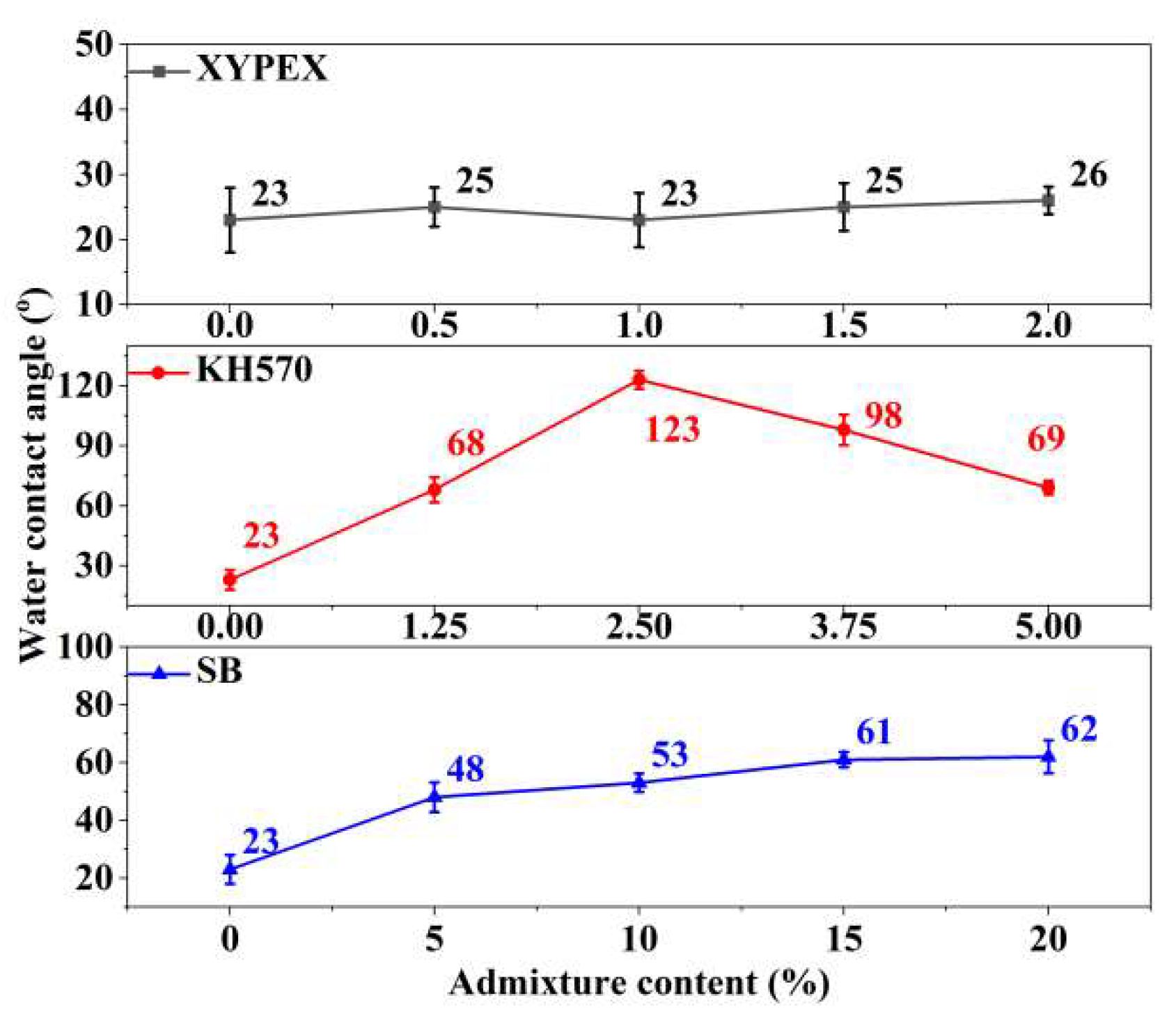

3.4.2. Water Contact Angles

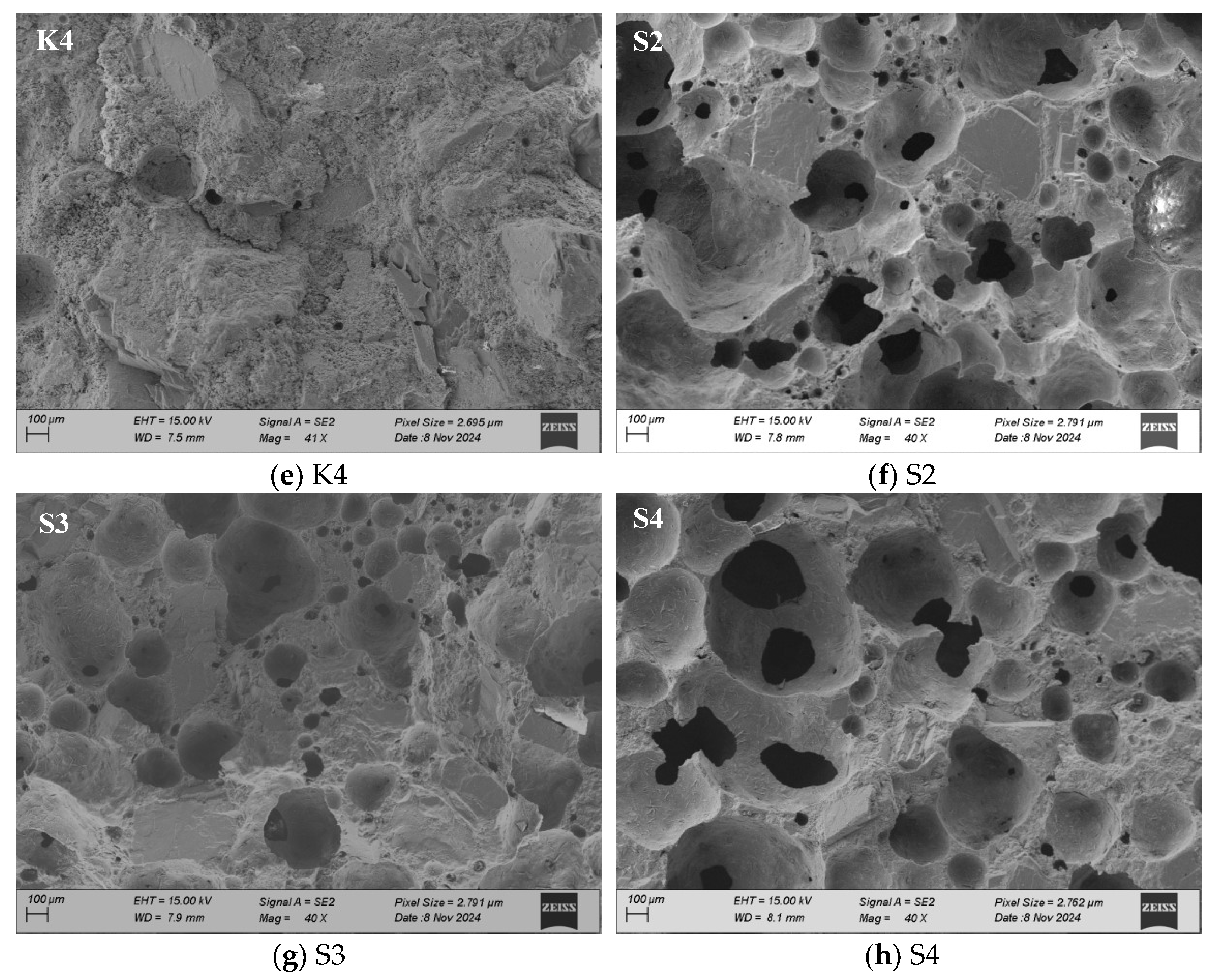

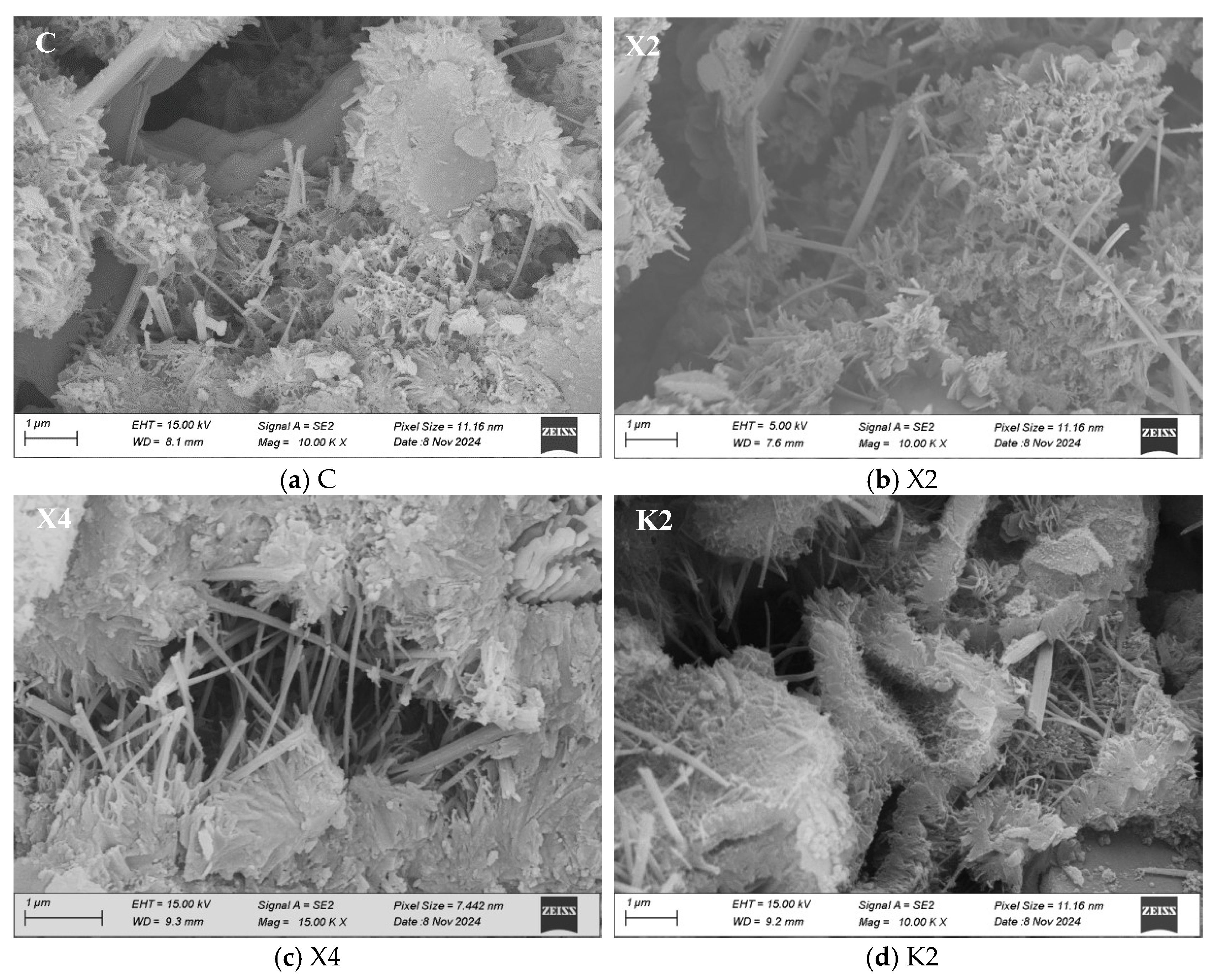

3.4.3. Micro-Morphology

3.4.4. LF-NMR

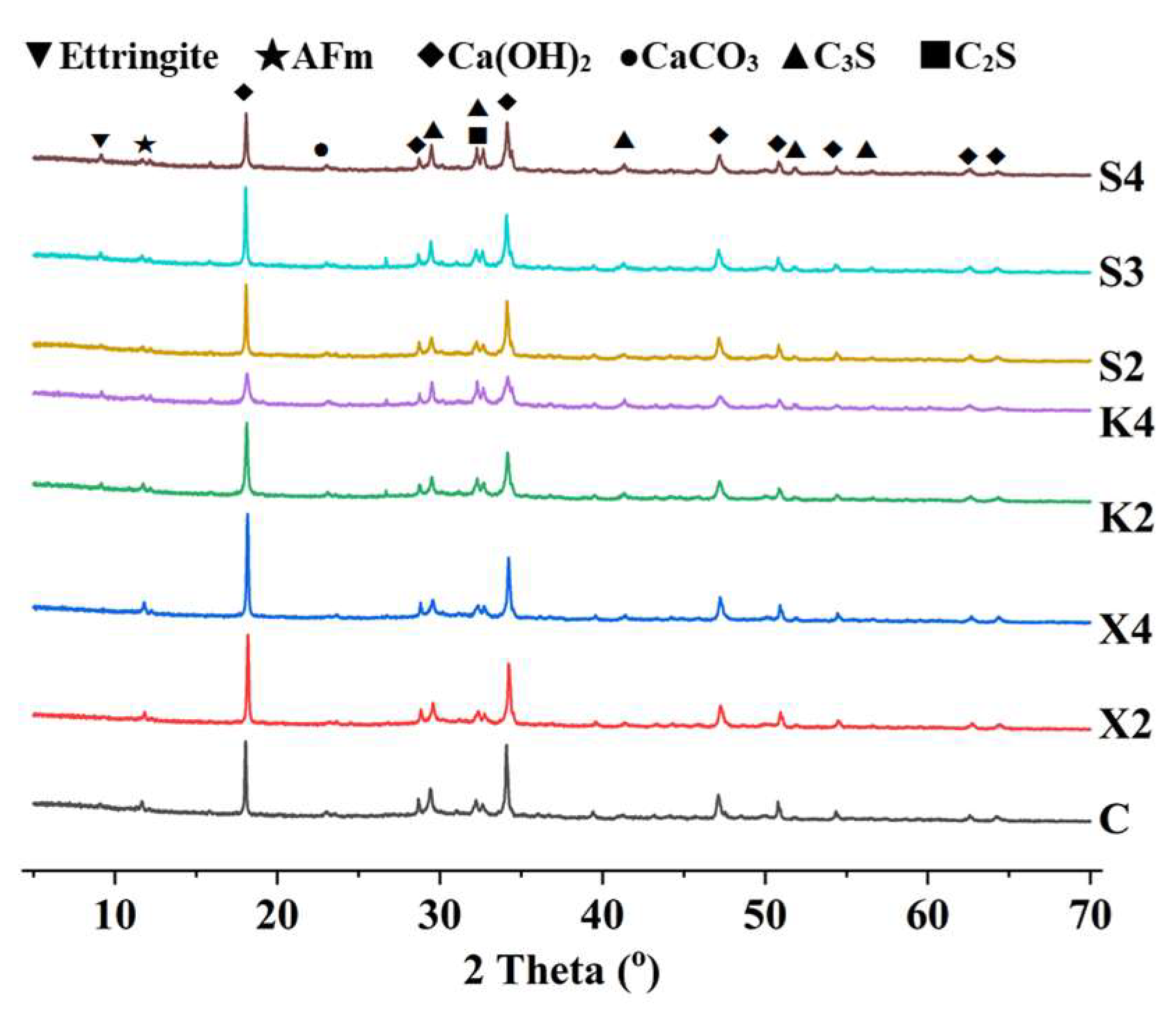

3.4.5. Hydration Product

3.5. Discussion

4. Conclusions and Future Work

4.1. Conclusions

4.2. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdou Ibro, M.; Verdier, J.; Geoffroy, S.; Cagnon, H.; Bourbon, X. Prediction of moisture transfer in cement-based materials: Use of a porous network model to access transfer parameters. Cem. Concr. Res. 2021, 142, 106310. [Google Scholar] [CrossRef]

- Damle, R.M.; Singh, A.; Bhesaniya, N. On the hygrothermal environment of spaces with exposed walls—Thermal bridging effect of mortar layers of cement and lime. J. Build. Eng. 2024, 98, 111513. [Google Scholar] [CrossRef]

- Li, Q.; Gao, L.; Gao, Z. Discussion on waterproofing and air permeability of external wall coatings. Wall Mater. Innov. Energy Sav. Build. 2016, 02, 39–44. [Google Scholar]

- Zhao, J.; Gao, X.; Chen, S.; Lin, H.; Li, Z.; Lin, X. Hydrophobic or superhydrophobic modification of cement-based materials: A systematic review. Compos. Part B Eng. 2022, 243, 110104. [Google Scholar] [CrossRef]

- Hu, X.; Xiao, J.; Zhang, Z.; Wang, C.; Long, C.; Dai, L. Effects of CCCW on properties of cement-based materials: A review. J. Build. Eng. 2022, 50, 104184. [Google Scholar] [CrossRef]

- Jahandari, S.; Tao, Z.; Alim, M.A.; Li, W. Integral waterproof concrete: A comprehensive review. J. Build. Eng. 2023, 78, 107718. [Google Scholar] [CrossRef]

- Shao, L.; Feng, P.; Liu, Q.; Zhang, Y.; Yu, Z.; Yan, S. In-situ polymerization-modified cement composites: A critical review. Constr. Build. Mater. 2024, 449, 138294. [Google Scholar] [CrossRef]

- Menglu, L.; Peng, L.; Jun, W.; Zhiwu, Y.; Ying, C.; Xiang, C. Study on improvement of waterproofing performance of CCCW with silicone waterproof material and waterbased capillary inorganic waterproofer. Constr. Build. Mater. 2023, 400, 132842. [Google Scholar] [CrossRef]

- Hodul, J.; Žižková, N.; Drochytka, R.; Borg, R.P.; Dvorák, K.; Gazdic, D. Influence of crystallization admixture on mechanical parameters and microstructure of polymer-cement mortars with waste limestone. In Solid State Phenomena; Brno University of Technology: Brno, The Czech Republic, 2019; pp. 27–34. [Google Scholar]

- Li, G.; Huang, X.; Lin, J.; Jiang, X.; Zhang, X. Activated chemicals of cementitious capillary crystalline waterproofing materials and their self-healing behaviour. Constr. Build. Mater. 2019, 200, 36–45. [Google Scholar] [CrossRef]

- Zhong, J.; Zhang, H.; Mao, J.; Zhang, Y.; Lian, S.; Wang, J.; Zhou, H.; Song, Y.; Hu, J.; Wu, H.; et al. Influences of cementitious capillary crystalline waterproofing on the hydration products and properties of cement-based materials. J. Build. Eng. 2024, 98, 111451. [Google Scholar] [CrossRef]

- Yao, H.; Xie, Z.; Huang, C.; Yuan, Q.; Yu, Z. Recent progress of hydrophobic cement-based materials: Preparation, characterization and properties. Constr. Build. Mater. 2021, 299, 124255. [Google Scholar] [CrossRef]

- She, W.; Yang, J.; Hong, J.; Sun, D.; Mu, S.; Miao, C. Superhydrophobic concrete with enhanced mechanical robustness: Nanohybrid composites, strengthen mechanism and durability evaluation. Constr. Build. Mater. 2020, 247, 118563. [Google Scholar] [CrossRef]

- Wang, F.; Lei, S.; Ou, J.; Li, W. Effect of PDMS on the waterproofing performance and corrosion resistance of cement mortar. Appl. Surf. Sci. 2020, 507, 145016. [Google Scholar] [CrossRef]

- Han, S.; Wang, Y.; Wang, Q.; Han, L.; Han, G. Film-formation processes of polymer emulsions in polymer-cement waterproof coatings and their effect on coatings’ macroscopic properties. Constr. Build. Mater. 2024, 438, 137137. [Google Scholar] [CrossRef]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Composites. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Beeldens, A.; Van Gemert, D.; Schorn, H.; Ohama, Y.; Czarnecki, L. From microstructure to macrostructure: An integrated model of structure formation in polymer-modified concrete. Mater. Struct. Mater. Constr. 2005, 38, 601–607. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, Z.; Huang, T.; Wang, P. Effect of defoaming agent on the properties of cement mortars with hydroxyethyl methyl cellulose through adjusting air content gradient. Cem. Concr. Compos. 2023, 139, 105024. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, P. Effects of Ethylene/Vinyl Chloride/Vinyl laurate redispersible terpolymer on pore structure and properties of cement mortar. J. Build. Mater. 2013, 16, 111–114. [Google Scholar]

- Li, L.; Wang, R.; Lu, Q. Influence of polymer latex on the setting time, mechanical properties and durability of calcium sulfoaluminate cement mortar. Constr. Build. Mater. 2018, 169, 911–922. [Google Scholar] [CrossRef]

- Sun, K.; Wang, S.; Zeng, L.; Peng, X. Effect of styrene-butadiene rubber latex on the rheological behavior and pore structure of cement paste. Compos. Part B Eng. 2019, 163, 282–289. [Google Scholar] [CrossRef]

- Ramli, M.; Akhavan Tabassi, A. Effects of polymer modification on the permeability of cement mortars under different curing conditions: A correlational study that includes pore distributions, water absorption and compressive strength. Constr. Build. Mater. 2012, 28, 561–570. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.; Li, X. Physical and mechanical properties of styrene-butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Pascal, S.; Alliche, A.; Pilvin, P. Mechanical behaviour of polymer modified mortars. Mater. Sci. Eng. A 2004, 380, 1–8. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2005.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO method). Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2021.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011.

- ISO 15148: 2002/Amd 1:2016; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. International Organization for Standardization: Geneva, Switzerland, 2002.

- GB 23440-2009; Inorganic Waterproof and Leakage-Preventing Materials. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009.

- GB/T 17146-2015; Test Methods for Water Vapour Transmission Properties of Building Materials and Products. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2015.

- Wang, Z.; Mei, J.; Liao, Y.; Li, H.; Niu, Y. Durability of Cement-Based Materials with Nano SiO2 and VAE Composite Modification. J. Build. Mater. 2023, 26, 687–696. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhong, F.; Zuo, S.; Xie, Z.; Xue, K.; Yao, H. Understanding the water transport behaviors of hydrophobic cement mortar by paraffin modification. Constr. Build. Mater. 2024, 435, 136845. [Google Scholar] [CrossRef]

- Yang, J.; Zuo, W.; She, W. Towards a further understanding of cement hydration at the early-age stage in the presence of hydrophobic silane IBTEO. Cem. Concr. Compos. 2024, 153, 105712. [Google Scholar] [CrossRef]

- Yu, J.; Wang, H.; Sun, X.; Chen, Z.; Dong, W. Characterizing connectivity and tortuosity of pore network based on LF-NMR method to assess the water permeability of white cement mortar. J. Build. Eng. 2024, 93, 109862. [Google Scholar] [CrossRef]

- de Matos, P.R.; Andrade Neto, J.S.; Tambara, L.U.; Rodríguez, E.D.; Kirchheim, A.P.; Campos, C.E.M. Measuring the early-age volumetric change of cement paste through in-situ XRD. Mater. Today Commun. 2023, 36, 106857. [Google Scholar] [CrossRef]

- Martys, N.S.; Ferraris, C.F. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- Mosquera, M.J.; Silva, B.; Prieto, B.; Ruiz–Herrera, E. Addition of cement to lime-based mortars: Effect on pore structure and vapor transport. Cem. Concr. Res. 2006, 36, 1635–1642. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | SO3 | Fe2O3 | MgO | K2O | TiO2 | SrO | Na2O | SUM |

|---|---|---|---|---|---|---|---|---|---|---|

| 62.60 | 19.80 | 4.63 | 3.87 | 3.49 | 1.64 | 0.97 | 0.27 | 0.18 | 0.17 | 97.62 |

| Residual Size (mm) | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | <0.15 |

|---|---|---|---|---|---|---|

| Percentage retained (%) | 0 | 24.48 | 27.55 | 31.19 | 11.16 | 5.02 |

| Cumulative percentage retained (%) | 0 | 24.48 | 52.03 | 83.22 | 94.98 | 100 |

| CaO | SiO2 | MgO | Al2O3 | SO3 | Fe2O3 | Na2O | K2O | SUM |

|---|---|---|---|---|---|---|---|---|

| 58.53 | 16.10 | 13.30 | 4.36 | 2.79 | 1.84 | 1.29 | 0.44 | 98.65 |

| Abbreviation | Cement/Sand (Only Mortar) | Water/Cement | XYPEX (wt.%) | KH570 (wt.%) | SB (wt.%) |

|---|---|---|---|---|---|

| C | 1:3 | 0.500 | |||

| X1 | 0.494 | 0.5 | |||

| X2 | 0.490 | 1.0 | |||

| X3 | 0.487 | 1.5 | |||

| X4 | 0.483 | 2.0 | |||

| K1 | 0.480 | 1.25 | |||

| K2 | 0.530 | 2.50 | |||

| K3 | 0.570 | 3.75 | |||

| K4 | 0.600 | 5.00 | |||

| S1 | 0.463 | 5 | |||

| S2 | 0.421 | 10 | |||

| S3 | 0.380 | 15 | |||

| S4 | 0.320 | 20 |

| I | II | III | 48 h Capillary Water Absorption (kg/m2) | |

|---|---|---|---|---|

| C | 0.47 | 0.16 | 0.12 | 1.50 |

| X1 | 0.48 | 0.15 | 0.10 | 1.41 |

| X2 | 0.37 | 0.14 | 0.10 | 1.24 |

| X3 | 0.36 | 0.12 | 0.09 | 1.16 |

| X4 | 0.35 | 0.12 | 0.09 | 1.12 |

| K1 | 0.36 | 0.16 | 0.10 | 1.35 |

| K2 | 0.26 | 0.12 | 0.07 | 0.98 |

| K3 | 0.42 | 0.28 | 0.23 | 2.13 |

| K4 | 0.42 | 0.34 | 0.32 | 2.53 |

| S1 | 0.89 | 0.26 | 0.18 | 2.61 |

| S2 | 0.52 | 0.18 | 0.13 | 1.67 |

| S3 | 0.12 | 0.08 | 0.08 | 0.61 |

| S4 | 0.04 | 0.01 | 0.01 | 0.12 |

| Group | Average Pore Diameter | Medium Pore Diameter | Mode Diameter | Porosity (%) |

|---|---|---|---|---|

| C | 32.6 nm | 63.9 nm | 50.4 nm | 12.4 |

| X2 | 30.5 nm | 61.4 nm | 50.4 nm | 12.1 |

| X4 | 29.4 nm | 58.0 nm | 50.3 nm | 12.0 |

| K2 | 71.7 nm | 601.3 nm | 2.5 μm | 19.5 |

| K4 | 72.1 nm | 959.0 nm | 1.1 μm | 19.4 |

| S2 | 162.4 nm | 92.3 μm | 181.1 μm | 28.9 |

| S3 | 156.0 nm | 85.7 μm | 180.9 μm | 27.4 |

| S4 | 127.6 nm | 51.2 μm | 90.5 μm | 24.7 |

| Group | Gel Pores Water | Capillary Water | Free Water |

|---|---|---|---|

| C | 72 | 18 | 10 |

| X2 | 68 | 14 | 8 |

| X4 | 72 | 26 | 2 |

| K2 | 73 | 22 | 5 |

| K4 | 68 | 25 | 7 |

| S2 | 65 | 22 | 13 |

| S3 | 64 | 26 | 10 |

| S4 | 58 | 31 | 11 |

| Group | 48 h CWA (kg·m2) | Impermeability Stress (MPa) | Water Vapor Permeability (g·MPa−1·h−1·m−1) | 28 d Flexural Strength (MPa) | 28 d Compressive Strength (MPa) | 28 d Tensile Bond Strength (MPa) |

|---|---|---|---|---|---|---|

| C | 1.50 | 1.4 | 10.7 | 11.2 | 58.3 | 1.79 |

| X4 | 1.12 | >1.5 | 8.1 | 9.4 | 59.8 | 1.62 |

| K2 | 0.98 | 0.6 | 22.6 | 9.2 | 45.8 | 1.87 |

| S4 | 0.12 | 1.4 | 16.7 | 12.4 | 42.3 | 4.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Guo, C.; Xu, L.; Wang, R. Research on the Optimization and Regulation Mechanism of Waterproofing, Impermeability, and Water Vapor Transmission Property of Mortar Based on Different Modifiers. Materials 2025, 18, 2363. https://doi.org/10.3390/ma18102363

Li Z, Guo C, Xu L, Wang R. Research on the Optimization and Regulation Mechanism of Waterproofing, Impermeability, and Water Vapor Transmission Property of Mortar Based on Different Modifiers. Materials. 2025; 18(10):2363. https://doi.org/10.3390/ma18102363

Chicago/Turabian StyleLi, Zelei, Chuanchuan Guo, Lanlan Xu, and Ru Wang. 2025. "Research on the Optimization and Regulation Mechanism of Waterproofing, Impermeability, and Water Vapor Transmission Property of Mortar Based on Different Modifiers" Materials 18, no. 10: 2363. https://doi.org/10.3390/ma18102363

APA StyleLi, Z., Guo, C., Xu, L., & Wang, R. (2025). Research on the Optimization and Regulation Mechanism of Waterproofing, Impermeability, and Water Vapor Transmission Property of Mortar Based on Different Modifiers. Materials, 18(10), 2363. https://doi.org/10.3390/ma18102363