The Impact of Enforcement Capabilities on the Effectiveness of Public Assessment on Occupational Safety

Abstract

:1. Introduction

1.1. The Olive Oil Mills Sector

1.2. Evaluation of Public Policies in Matters of Occupational Health and Safety: Assessment of Intervention Efficacy

- Technical interventions on the equipment and work installations;

- Organizational interventions on work procedures;

- Psychosocial interventions on the personnel, their behaviour, and training;

- Complex interventions, combining elements from the previous groups.

- Intervention design: necessary changes, better ways to achieve them, what the barriers are, who the decision-makers are, and so on;

- Implementation: components and target group, degree of success and extent of the application of the measures, and so on;

- Evaluation of effectiveness.

- Awareness of the requirements;

- Businesses’ understanding of what they need to do to comply;

- Concern for reputation;

- Perception of their level of risk.

- Specific deterrence—imposing sanctions deters individual businesses from repeating the offence;

- General deterrence—imposing sanctions deters further breaches by the business and by other businesses;

- Bounded rationality—suggests that sanctions have the effect of drawing the attention of managers to the issue of safety;

- Co-operation—assumes that businesses want to comply with regulations.

1.3. Interventions in Small and Medium Enterprises

1.4. Legal Regulation at the Time of the Research

1.5. Intervention Program by Authorized Technicians: Purpose of This Research

2. Materials and Methods

2.1. Olive Mills Sampling

2.2. Study Design and Data Collection

- Initial assessment of all companies in both the intervention and control groups within the 2006–2008 period. Therefore, this first evaluation took place before the interventions (before both interventions). Evaluations were made of 115 olive mills (43 from the intervention group and 72 from the control group);

- Assessment of the companies in the intervention group (i.e., companies with intervention by Authorized Technicians with enforcement capabilities) in the 2011–2013 period;

- Assessment of the companies in the control group (i.e., companies with intervention by technical advisors without enforcement capabilities) in the 2011–2013 period.

2.3. Measurement of the Intervention Group: Olive Mills Receiving Intervention by Authorized Technicians with Enforcement Capabilities (2011–2013)

- Initial visit, verifying the working conditions and whether they comply with the standards;

- Requiring the company to correct the deficiencies found and assigning a time period for their resolution (which, in any case, must not exceed six months);

- Final visit, verifying that the deficiencies have been remedied by the end of the designated time period. If this has not been done, the technician proposes the initiation of an infraction and sanction procedure.

2.4. Measurement in the Control Group: Olive Mills with No Intervention by Authorized Technicians, But in Which Intervention by Technical Advisors Did Take Place (2011–2013)

- Initial visit, verifying the work conditions and their compliance with the standards;

- Recommending that the company correct the deficiencies found and assigning a time period for their resolution (which, in any case, must not exceed six months);

- Final visit, verifying that the deficiencies have been remedied at the end of the designated time period.

2.5. Statistical Analysis

3. Results

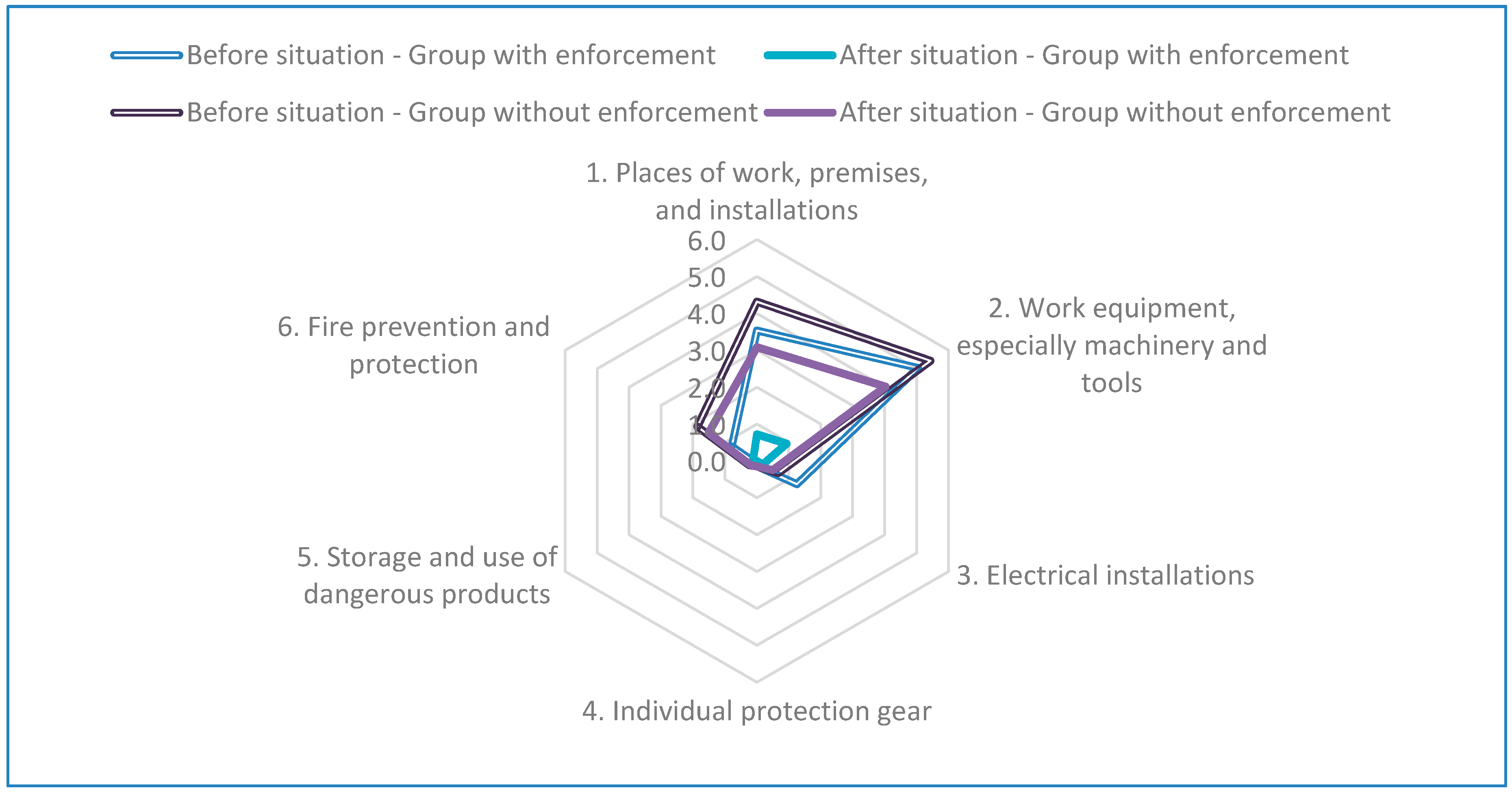

3.1. Effect of the Intervention by Authorized Technicians with Enforcement Capabilities (2011–2013)

3.2. Effect of the Intervention by Technical Advisors without Enforcement Capabilities (2011–2013)

3.3. Comparison of the Effects of the Two Interventions

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Glossary

References

- Parejo, J.M.; Rubio, J.C.; Pérez, S.; Soriano, M. Health and safety management in olive oil mills in Spain. Saf. Sci. 2013, 51, 101–108. [Google Scholar] [CrossRef]

- Soriano-Serrano, M. Evaluación de la Eficacia de la Intervención de la Administración Laboral en las Condiciones Materiales de Trabajo de las Almazaras de Aceite de Oliva. Ph.D. Thesis, Universidad de Málaga, Málaga, Spain, 2014. [Google Scholar]

- Rubio Romero, J.C.; Parejo Moscoso, J.M.; Pérez Cantó, S.; Soriano Serrano, M. De dónde proceden los principales riesgos laborales en las almazaras españolas? DYNA Ing. Ind. 2013, 88, 473–480. [Google Scholar] [CrossRef] [Green Version]

- Parejo, J.M.; Rubio-Romero, J.C.; Pérez, S. Occupational accident rate in olive oil mills. Saf. Sci. 2012, 50, 285–293. [Google Scholar] [CrossRef]

- Habicht, J.P.; Victora, C.G.; Vaughan, J.P. Evaluation designs for adequacy, plausibility and probability of public health programme performance and impact. Int. J. Epidemiol. 1999, 28, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Benavides, F.G.; García, A.M.; López-Ruiz, M.; Gil, J.; Boix, P.; Martínez, J.M.; Rodrigo, F. Effectiveness of Occupational Injury Prevention Policies in Spain. Public Health Rep. 2009, 124 (Suppl. S1), 180–187. [Google Scholar] [CrossRef] [Green Version]

- Zwerling, C.; Daltroy, L.H.; Fine, L.J.; Johnston, J.J.; Melius, J.; Silverstein, B.A. Design and Conduct of Occupational Injury Intervention Studies: A Review of Evaluation Strategies. Am. J. Ind. Med. 1997, 32, 164–179. [Google Scholar] [CrossRef]

- Goldenhar, L.M.; LaMontagne, A.D.; Katz, T.; Heaney, C.; Landsbergis, P. The intervention research process in occupational safety and health: An overview from the National Occupational Research Agenda Intervention Effectiveness Research team. J. Occup. Environ. Med. 2001, 43, 616–622. [Google Scholar] [CrossRef] [Green Version]

- Robson, L.S.; Shannon, H.; Goldenhar, L.; Hale, A. Guide to Evaluating the Effectiveness of Strategies for Preventing Work Injuries: How to Show Whether a Safety Intervention Really Works; National Institute for Occupational Safety and Health (NIOSH): Cincinati, OH, USA, 2001; DHHS (NIOSH) Publication No. 2001-119. Available online: https://www.cdc.gov/niosh/docs/2001-119/pdfs/2001-119.pdf (accessed on 28 April 2019).

- Breslin, F.C.; Kyle, N.; Bigelow, P.; Irvin, E.; Morassaei, S.; MacEachen, E.; Mahood, Q.; Couban, R.; Shannon, H.; Amick, B.C., 3rd. Effectiveness of health and safety in small enterprises: A systematic review of quantitative evaluations of interventions. J. Occup. Rehabil. 2010, 20, 163–179. [Google Scholar] [CrossRef]

- LaMontagne, A.; Barbeau, E.; Youngstrom, R.A.; Lewiton, M.; Stoddard, A.M.; McLellan, D.; Wallace, L.M.; Sorensen, G. Assessing and intervening on OSH programmes: Effectiveness evaluation of the Wellworks-2 intervention in 15 manufacturing worksites. Occup. Environ. Med. 2004, 61, 651–660. [Google Scholar] [CrossRef] [Green Version]

- Pedersen, L.M.; Nielsen, K.J.; Kines, P. Realistic Evaluation as a New Way to Design and to Evaluate Occupational Safety Interventions. Saf. Sci. 2012, 50, 48–54. [Google Scholar] [CrossRef]

- Kjellén, U. Prevention of Accidents through Experience Feedback; Taylor and Francis: London, UK, 2000. [Google Scholar]

- Rubio-Romero, J.C.; Carrillo-Castrillo, J.A.; Gibb, A. Prevention of falls to a lower level: Evaluation of an occupational health and safety intervention via subsidies for the replacement of scaffolding. Int. J. Inj. Control Saf. Promot. 2015, 24, 16–23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Safe Work Australia. The Effectiveness of Work Health and Safety Interventions by Regulators: A Literature Review; Safe Work Australia: Camberra, Australia, 2013; ISBN 978-1-74361-046-6. Available online: https://www.safeworkaustralia.gov.au/system/files/documents/1702/effectiveness-whs-interventions-by-regulators-literature-review.pdf (accessed on 28 April 2019).

- Levine, D.I.; Toffel, M.W.; Johnson, M.S. Randomized Government Safety Inspections Reduce Worker Injuries with No Detectable Job Loss. Science 2012, 336, 907–911. [Google Scholar] [CrossRef] [PubMed]

- Haviland, A.; Burns, R.; Gray, W.; Ruder, T.; Mendeloff, J. What kinds of injuries do OSHA inspections prevent? J. Saf. Res. 2010, 41, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Mischke, C.; Verbeek, J.H.; Job, J.; Morata, T.C.; Alvesalo-Kuusi, A.; Neuvonen, K.; Clarke, S.; Pedlow, R.I. Occupational safety and health enforcement tools for preventing occupational diseases and injuries. Cochrane Database Syst. Rev. 2013. [Google Scholar] [CrossRef]

- Andersen, J.H.; Malmros, P.; Ebbehoej, N.E.; Flachs, E.M.; Bengtsen, E.; Bonde, J.P. Systematic literature review on the effects of occupational safety and health (OSH) interventions at the workplace. Scand. J. Work Environ. Health 2019, 45, 103–113. [Google Scholar] [CrossRef] [Green Version]

- Tompa, E.; Kalcevich, C.; Foley, M.; McLeod, C.; Hogg-Johnson, S.; Cullen, K.; MacEachen, E.; Mahood, Q.; Irvin, E. A systematic literature review of the effectiveness of occupational health and safety regulatory enforcement. Am. J. Ind. Med. 2016, 59, 919–933. [Google Scholar] [CrossRef]

- Sørensen, O.H.; Hasle, P.; Bach, E. Working in small enterprises—Is there a special risk? Saf. Sci. 2007, 45, 1044–1059. [Google Scholar] [CrossRef]

- Fabiano, B.; Currò, F.; Pastorino, R. A study of the relationship between occupational injuries and firm size and type in the Italian industry. Saf. Sci. 2004, 42, 587–600. [Google Scholar] [CrossRef]

- Lamm, F. Small businesses and OH&S advisors. Saf. Sci. 1997, 25, 361–373. [Google Scholar] [CrossRef]

- Vickers, I.; James, P.; Smallbone, D.; Baldock, R. Understanding small firm responses to regulation. Policy Stud. 2005, 26, 149–169. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and social Committee and the Committee of the Regions on an EU Strategic Framework on Health and Safety at Work 2014–2020; European Commission: Brussels, Belgium, 2014; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014DC0332&from=GA (accessed on 28 April 2019).

- Legg, S.J.; Olsen, K.B.; Hasle, P. Managing safety in small and medium enterprises. Saf. Sci. 2015, 71 Pt C, 189–196. [Google Scholar] [CrossRef] [Green Version]

- Elena, F.; Antonella, B.; Andrea, D. Impact on safety of a preventive intervention in metalworking micro-enterprises. Saf. Sci. 2015, 71 Pt C, 292–297. [Google Scholar] [CrossRef]

- Gobierno de España. REAL DECRETO 689/2005, de 10 de Junio, por el que se Modifica el Reglamento de Organización y Funcionamiento de la Inspección de Trabajo y Seguridad Social, Aprobado por el Real Decreto 138/2000, de 4 de Febrero, y el Reglamento General Sobre Procedimientos Para la Imposición de Sanciones por Infracciones de Orden Social y Para los Expedientes Liquidatorios de Cuotas a la Seguridad Social, Aprobado por el Real Decreto 928/1998, de 14 de Mayo, Para Regular las Actuaciones de los Técnicos Habilitados en Materia de Prevención de Riesgos Laborales; Gobierno de España: Madrid, Spain, 2005; pp. 21857–21863, Boletín Oficial del Estado, nº 149. [Google Scholar]

- Gobierno de Andalucía. ORDEN de 18 de Octubre de 2000, de la Consejería de Empleo y Desarrollo Tecnológico, por la que se Publica el Texto del Acuerdo Bilateral Suscrito Entre la Administración Andaluza y la Administración General del Estado, Regulador de la Comisión Territorial en Materia de Inspección de Trabajo y Seguridad Social en Andalucía. Junta de Andalucía: Sevilla, Spain, 2000; pp. 16970–16972, Boletín Oficial de la Junta de Andalucia nº 129. [Google Scholar]

- Carrillo-Castrillo, J.A.; Carballo-Pérez, D.; Rubio-Romero, J.C.; Salguero-Caparrós, F. Effectiveness of an Intervention in Small and Medium Enterprises by Safety Assessors with Enforcement Ability; Occupational Safety and Hygiene IV; CRC Press: Boca Raton, FL, USA, 2016; pp. 363–367. [Google Scholar] [CrossRef]

- Bestratén, M.; Pareja, F. NTP 330: Sistema Simplificado de Evaluación de Riesgos de Accidente; Instituto Nacional de Seguridad e Higiene en el Trabajo: Madrid, Spain, 1993. Available online: http://www.insht.es/InshtWeb/Contenidos/Documentacion/FichasTecnicas/NTP/Ficheros/301a400/ntp_330.pdf (accessed on 28 April 2019).

- British Standards Institution. BS 8800:2004. Guide to Occupational Health and Safety Management Systems; British Standards Institution: London, UK, 2004. [Google Scholar]

- Arezes, P.M.; Swuste, P. Occupational Health and Safety post-graduation courses in Europe: A general overview. Saf. Sci. 2012, 50, 433–442. [Google Scholar] [CrossRef]

| Province | Total | % of Andalusia |

|---|---|---|

| Almería | 25 | 3.06 |

| Cádiz | 14 | 1.72 |

| Córdoba | 182 | 22.3 |

| Granada | 109 | 13.4 |

| Huelva | 17 | 2.08 |

| Jaén | 323 | 39.6 |

| Málaga | 67 | 8.21 |

| Sevilla | 79 | 9.68 |

| Total general | 816 | 100 |

| Working Conditions | Risk Code | Risk Description | Frequency |

|---|---|---|---|

| 1. Places of work, premises, and installations | 1.1 | Stepping on objects | |

| 1.2 | Falls on the same level | ||

| 1.3 | Falls to a lower level | ||

| 1.4 | Crashing into moving objects | ||

| 1.5 | Falling loose objects | ||

| 1.6 | Insufficient lighting | ||

| 1.7 | Exp. to adverse climatic conditions | ||

| 1.8 | Exposure to noise | ||

| 1.9 | Risk of physical fatigue | ||

| 1.10 | Exposure to Chemical agents | ||

| 1.11 | Exposure to Biological agents | ||

| 1.12 | Exposure to oxygen-deficient atmosphere | ||

| 1.13 | Projection of particles | ||

| 2. Work equipment, especially machinery and tools | 2.1 | Blows/cuts with objects and tools | |

| 2.2 | Being trapped by or between objects | ||

| 2.3 | Over-exertion | ||

| 2.4 | Crashing into moving objects or being run over. | ||

| 2.5 | Contact with heat | ||

| 3. Electrical installations | 3.1 | Exposure to electrical risk | |

| 4. Individual protection gear | 4.1 | Exposure to noise | |

| 4.2 | Contact with heat | ||

| 4.3 | Mechanical contact | ||

| 4.4 | Electrical contact | ||

| 4.5 | Exposure to Chemical agents | ||

| 4.6 | Exposure to Biological agents | ||

| 4.7 | Exposure to oxygen-deficient atmosphere | ||

| 5. Storage and use of dangerous products | 5.1 | Exposure to Chemical agents | |

| 5.2 | Risk of fire | ||

| 5.3 | Risk of explosion | ||

| 6. Fire prevention and protection | 6.1 | Risk of fire | |

| 6.2 | Risk of explosion |

| Period/Group | Intervention Group | Control Group | Total |

|---|---|---|---|

| Before Intervention | ni1 | nc1 | ni1 + nc1 |

| After intervention | ni2 | nc2 | ni2 + nc2 |

| Total | ni1 + ni2 | nc1 + nc2 | ni2 + ni2 + nc1 + nc2 |

| Work Conditions | Risks Detected | Risks Corrected | Percentage Corrected |

|---|---|---|---|

| 1. Places of work, premises, and installations | 152 | 121 | 80% |

| 2. Work equipment, especially machinery and tools | 217 | 177 | 82% |

| 3. Electrical installations | 54 | 46 | 85% |

| 4. Individual protection gear | 6 | 6 | 100% |

| 5. Storage and use of dangerous products | 3 | 2 | 67% |

| 6. Fire prevention and protection | 34 | 29 | 85% |

| TOTAL | 466 | 381 | 82% |

| Work Conditions | Risks Detected | Risks Corrected | Percentage Corrected |

|---|---|---|---|

| 1. Places of work, premises, and installations | 311 | 89 | 29% |

| 2. Work equipment, especially machinery and tools | 391 | 101 | 26% |

| 3. Electrical installations | 48 | 12 | 25% |

| 4. Individual protection gear | 11 | 0 | 0% |

| 5. Storage and use of dangerous products | 17 | 2 | 12% |

| 6. Fire prevention and protection | 134 | 25 | 19% |

| TOTAL | 912 | 229 | 25% |

| Work Conditions | Chi-Square p-Value | Percentage of Corrected Risks | |

|---|---|---|---|

| Authorized Technicians (with Enforcement) | Technical Advisors (without Enforcement) | ||

| 1. Places of work, premises, and installations | <0.001 | 80% | 29% |

| 2. Work equipment, especially machinery and tools | <0.001 | 82% | 26% |

| 3. Electrical installations | <0.001 | 85% | 25% |

| 4. Individual protection gear | <0.001 | 100% | 0% |

| 5. Storage and use of dangerous products | <0.001 | 67% | 12% |

| 6. Fire prevention and protection | <0.001 | 85% | 19% |

| TOTAL | <0.001 | 82% | 25% |

| Period | Olive Mills | Measurements | Intervention | Results |

|---|---|---|---|---|

| 2006–2008 | All | Risk Assessment | General advice, no enforcement | Risk map |

| 2011–2013 | Intervention group | Working Conditions | Requirements, with enforcement | Risk reduction |

| 2011–2013 | Control group | Working Conditions | Requirements, no enforcement | Risk reduction |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soriano-Serrano, M.; Carrillo-Castrillo, J.A.; Rubio-Romero, J.C.; García-Jiménez, M. The Impact of Enforcement Capabilities on the Effectiveness of Public Assessment on Occupational Safety. Int. J. Environ. Res. Public Health 2020, 17, 6426. https://doi.org/10.3390/ijerph17176426

Soriano-Serrano M, Carrillo-Castrillo JA, Rubio-Romero JC, García-Jiménez M. The Impact of Enforcement Capabilities on the Effectiveness of Public Assessment on Occupational Safety. International Journal of Environmental Research and Public Health. 2020; 17(17):6426. https://doi.org/10.3390/ijerph17176426

Chicago/Turabian StyleSoriano-Serrano, Manuel, Jesús Antonio Carrillo-Castrillo, Juan Carlos Rubio-Romero, and Manuel García-Jiménez. 2020. "The Impact of Enforcement Capabilities on the Effectiveness of Public Assessment on Occupational Safety" International Journal of Environmental Research and Public Health 17, no. 17: 6426. https://doi.org/10.3390/ijerph17176426

APA StyleSoriano-Serrano, M., Carrillo-Castrillo, J. A., Rubio-Romero, J. C., & García-Jiménez, M. (2020). The Impact of Enforcement Capabilities on the Effectiveness of Public Assessment on Occupational Safety. International Journal of Environmental Research and Public Health, 17(17), 6426. https://doi.org/10.3390/ijerph17176426