Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization

Abstract

:1. Introduction

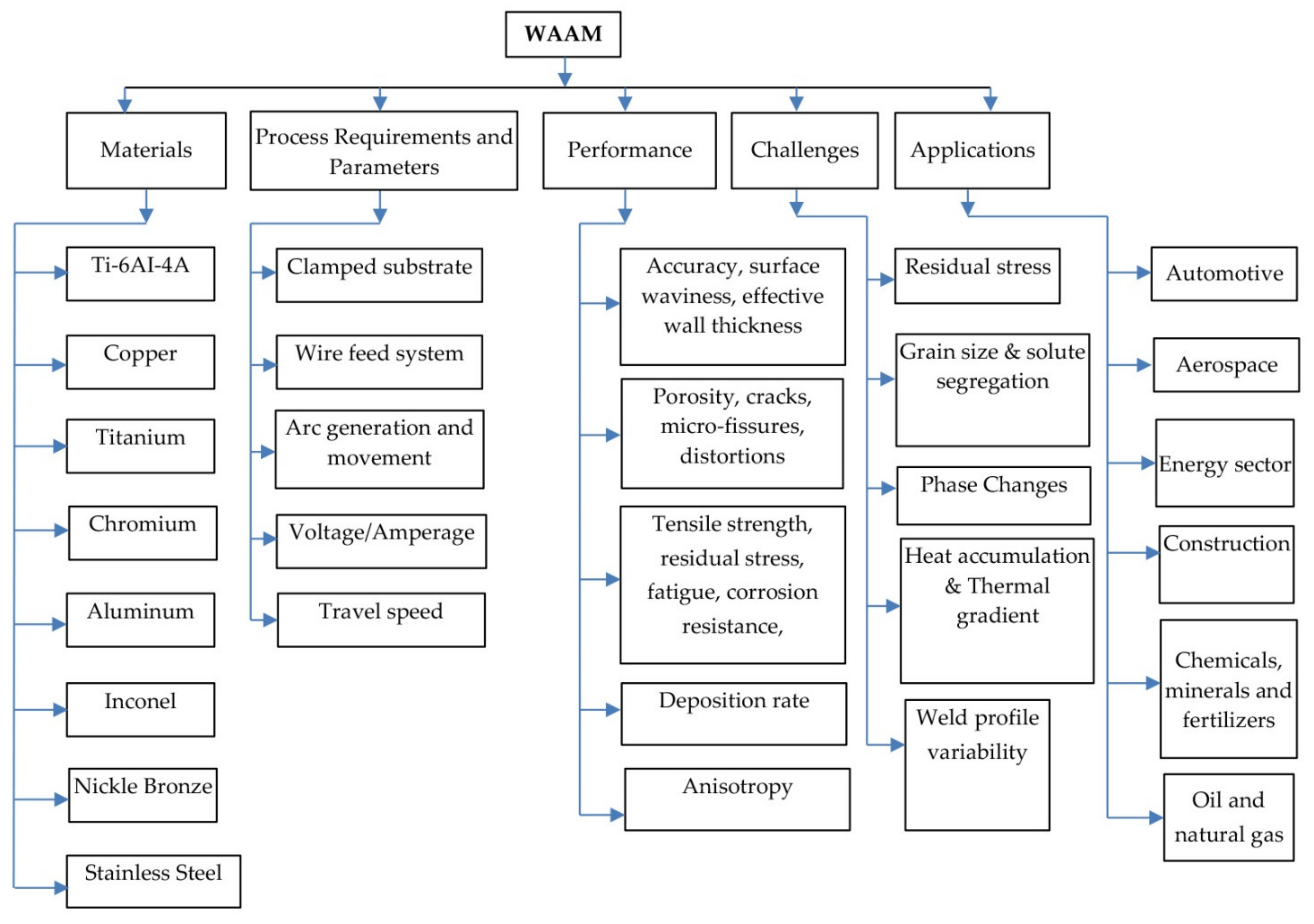

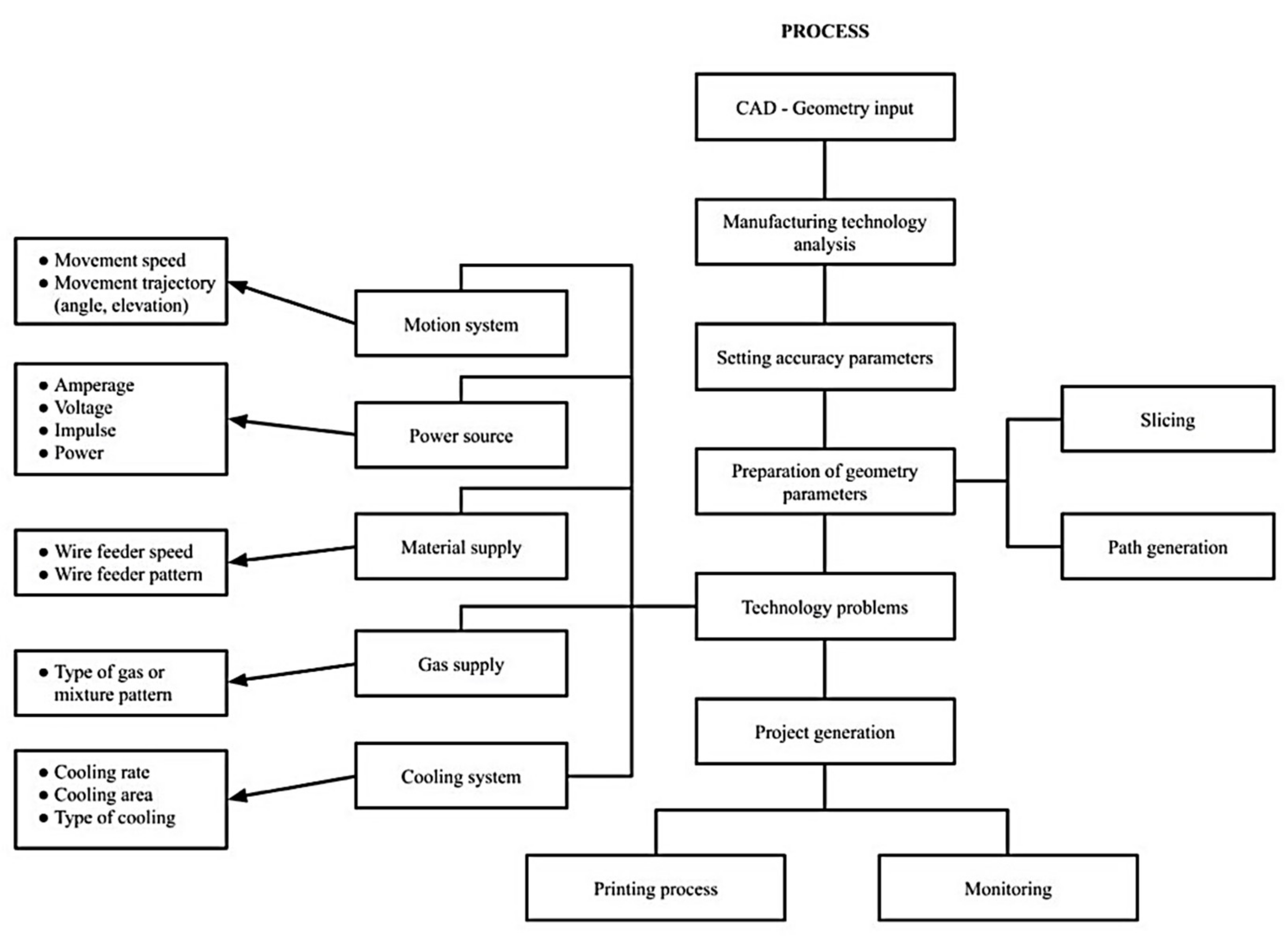

2. WAAM Applications

3. WAAM Methods

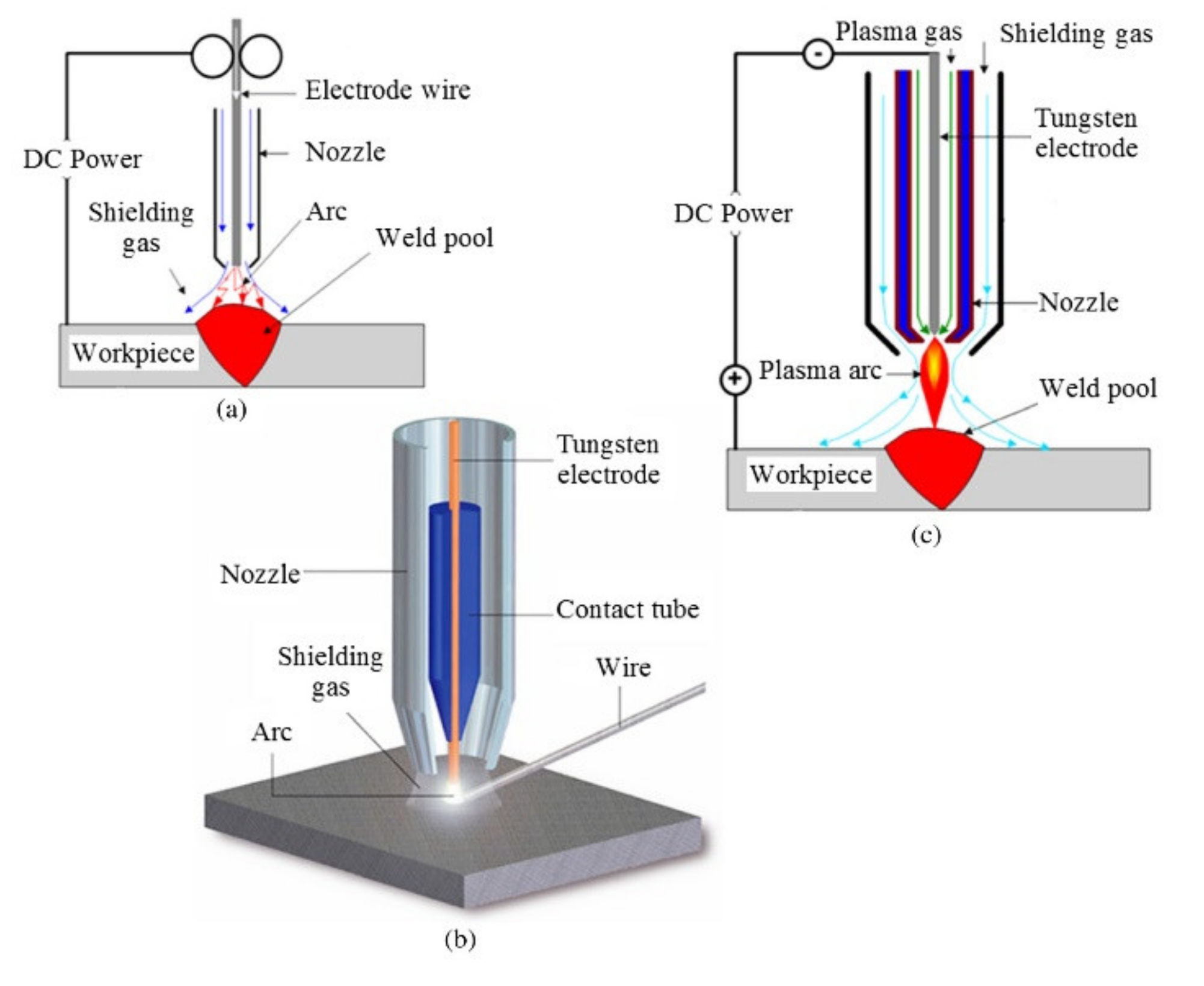

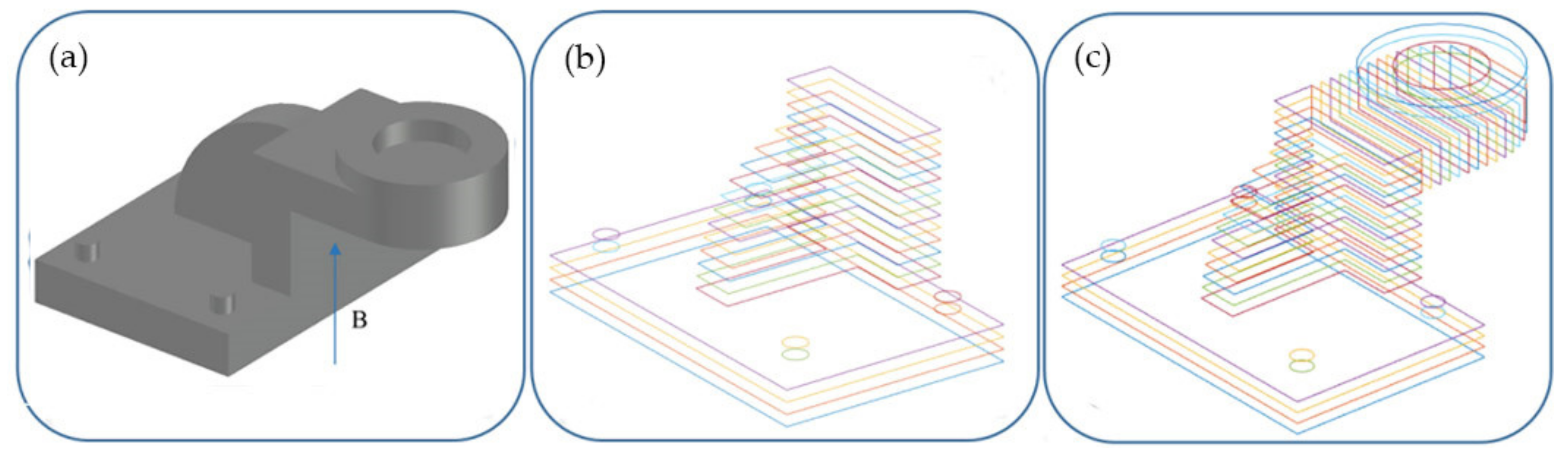

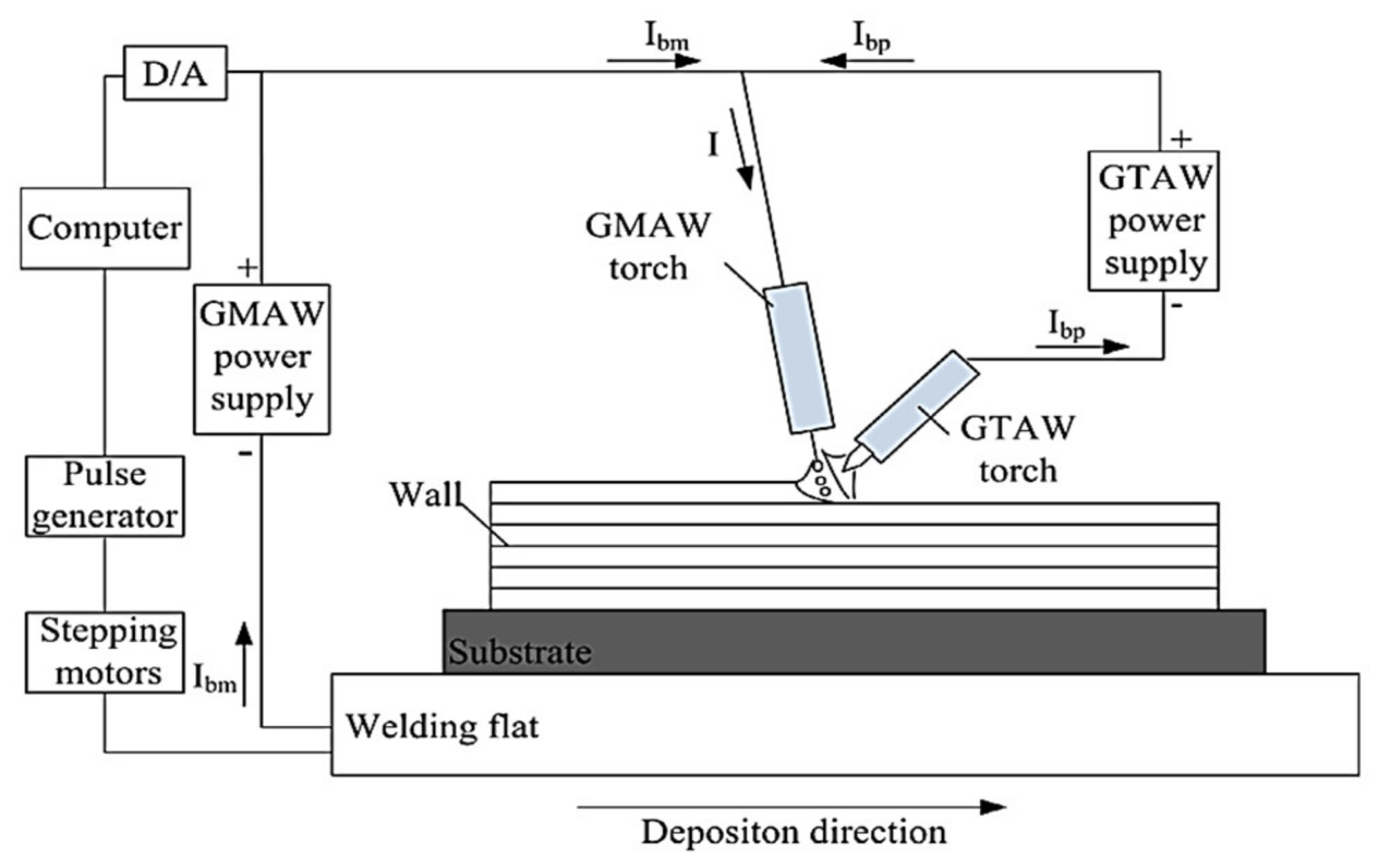

3.1. Heat Sources Employed for WAAM

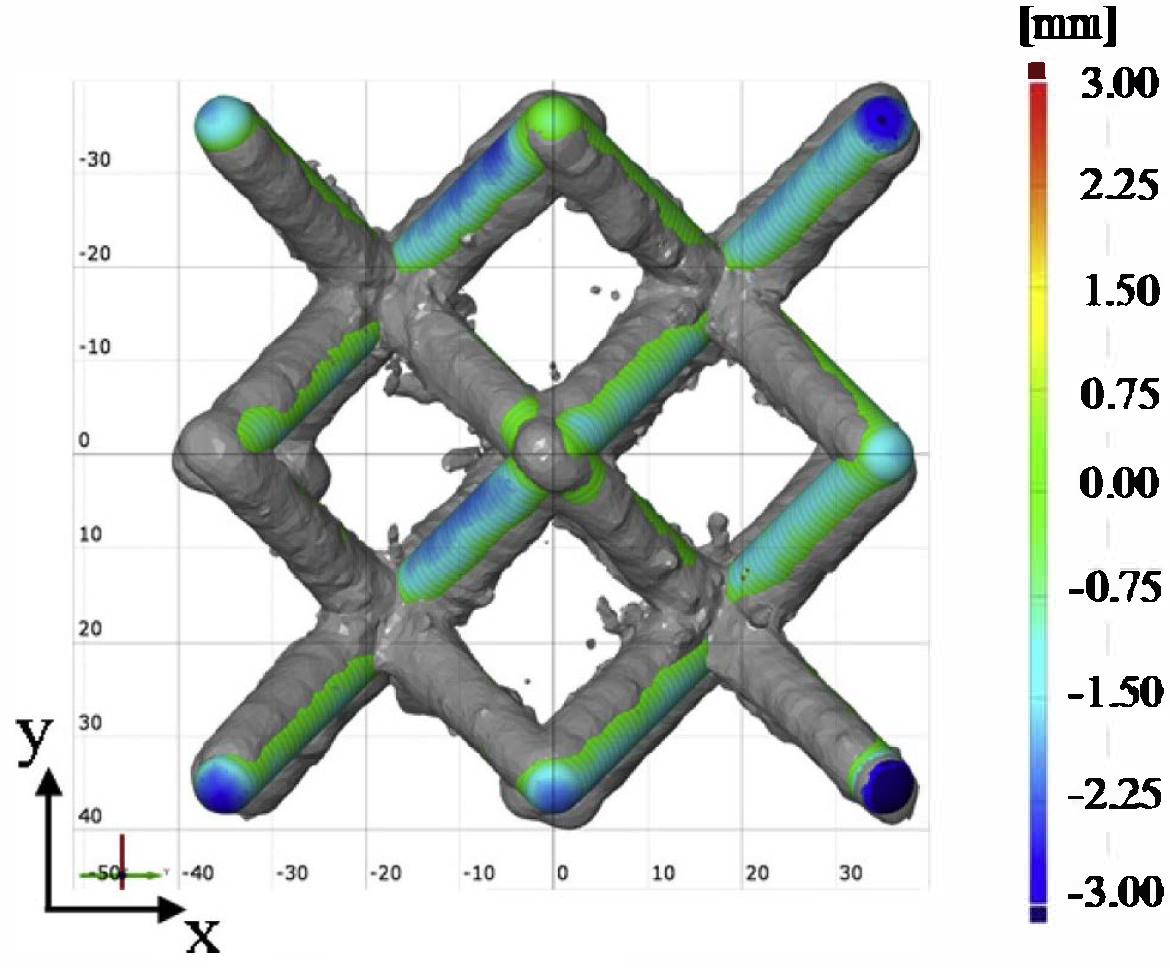

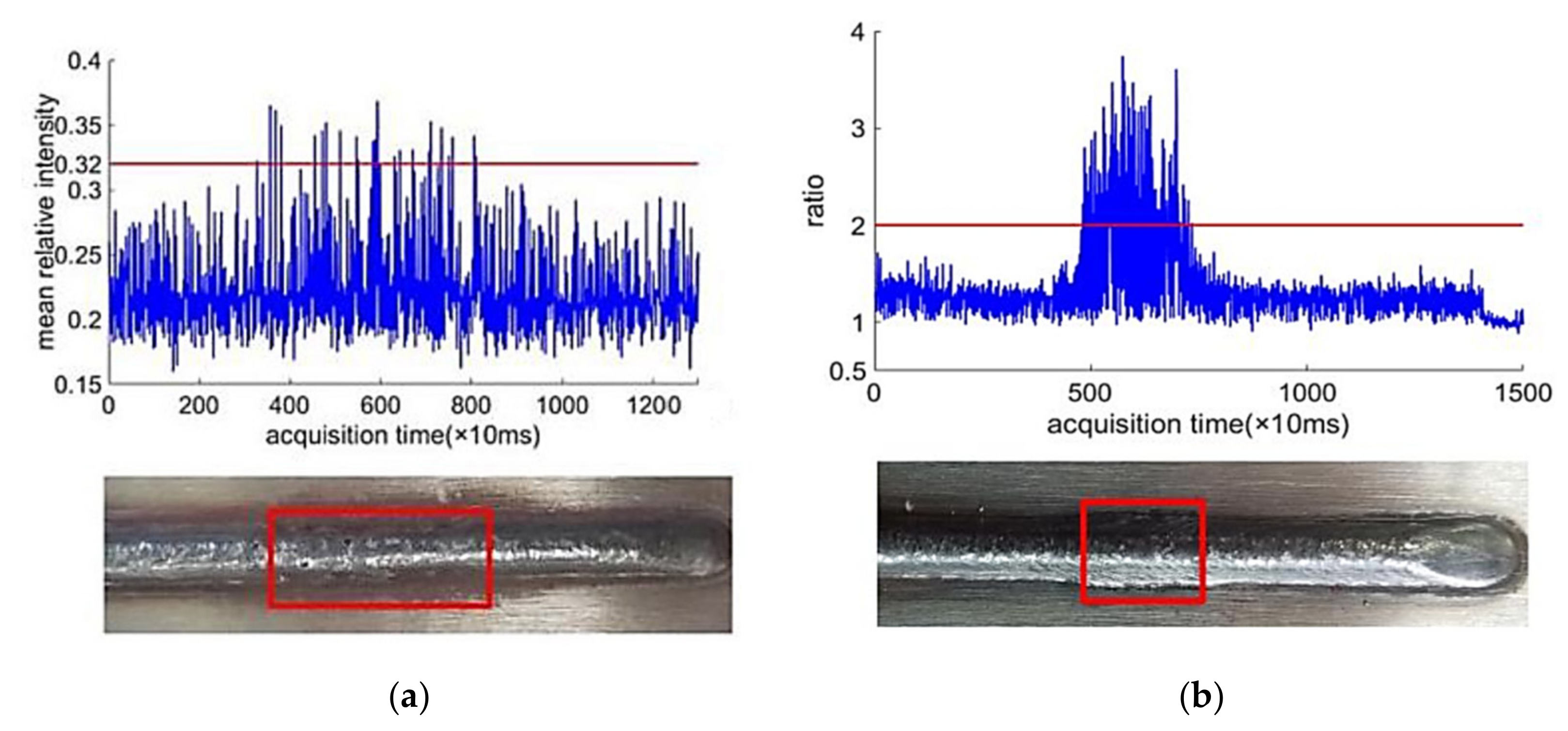

3.2. Process Monitoring and Control for Optimizing the WAAM

4. Discussion on Materials Behavior during WAAM

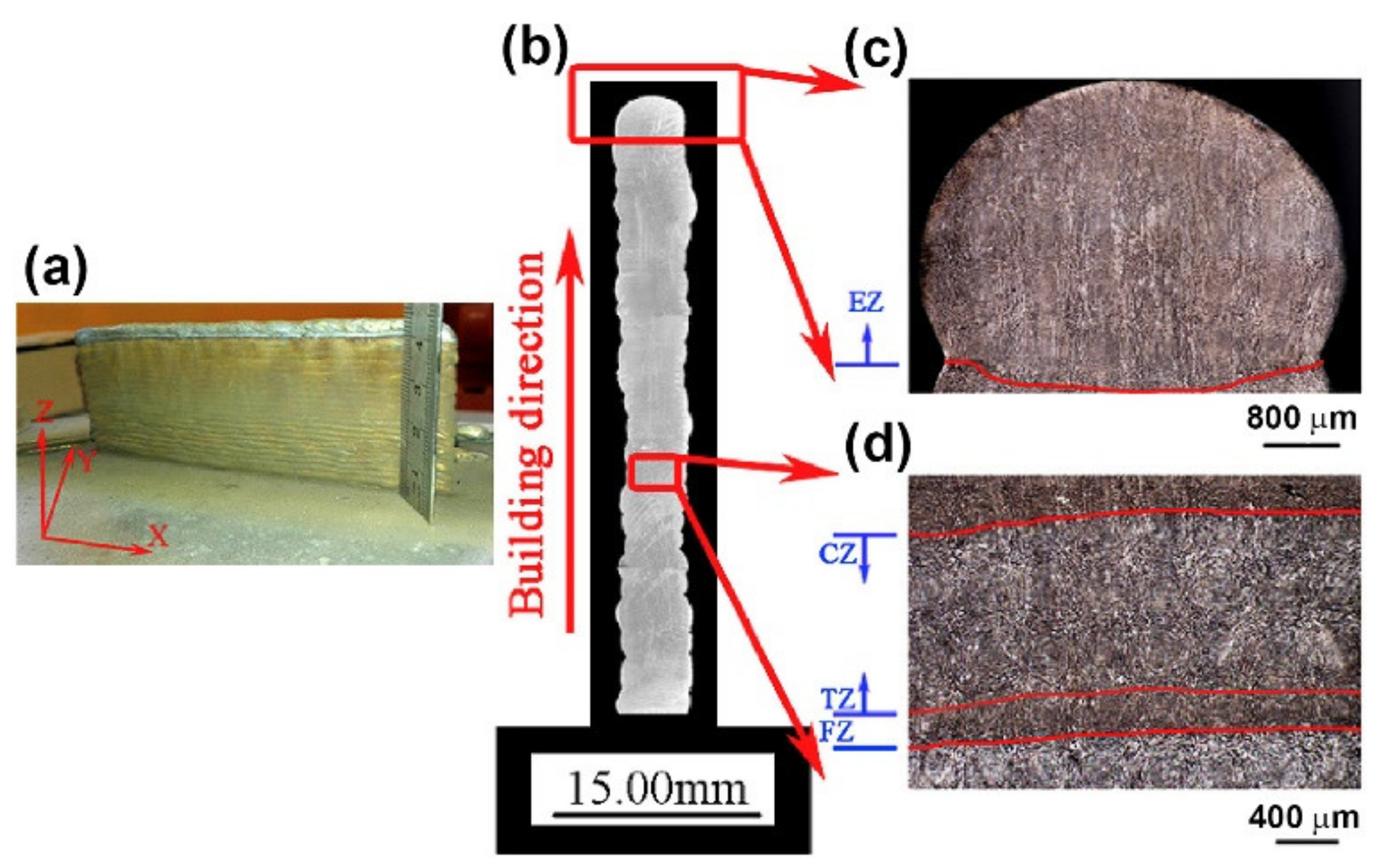

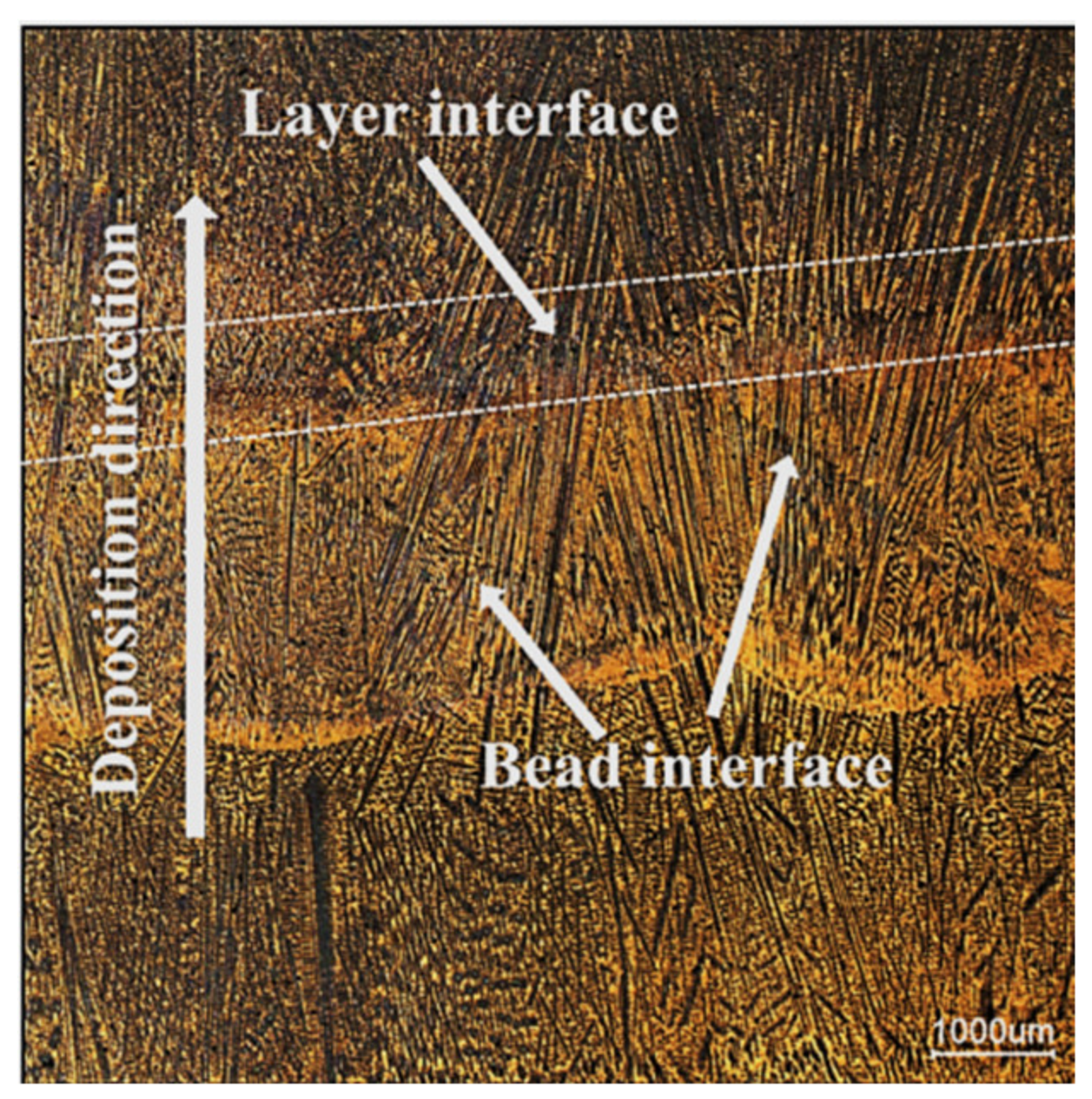

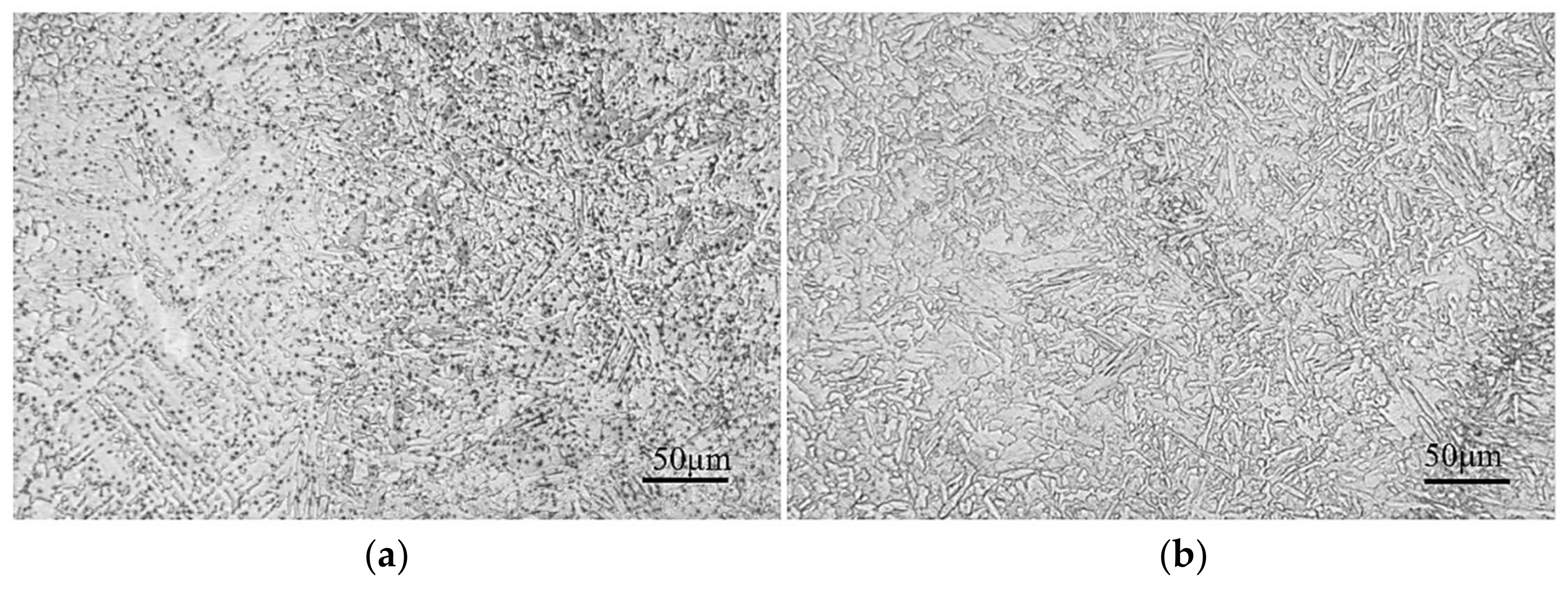

4.1. Ti-6Al-4V Alloy

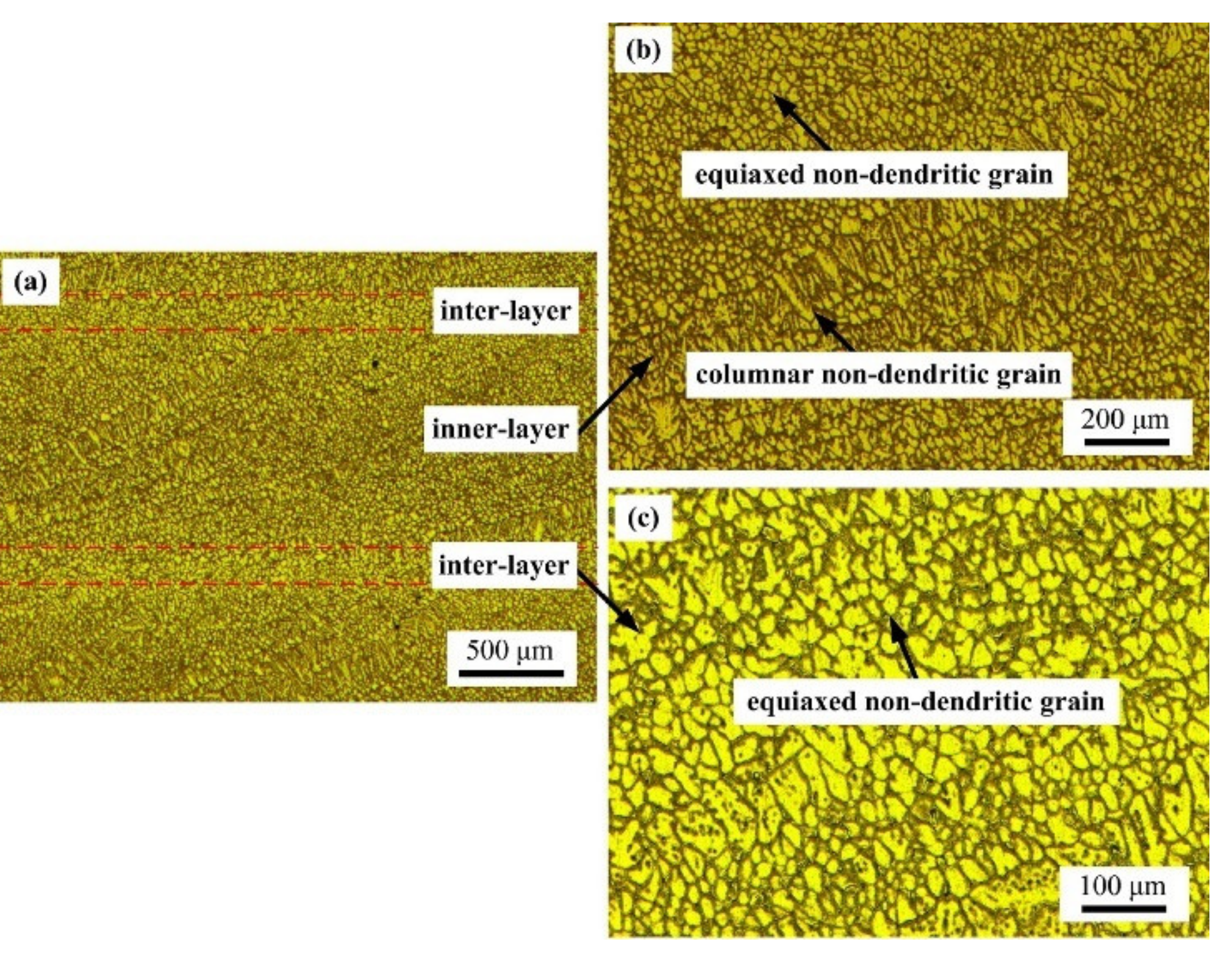

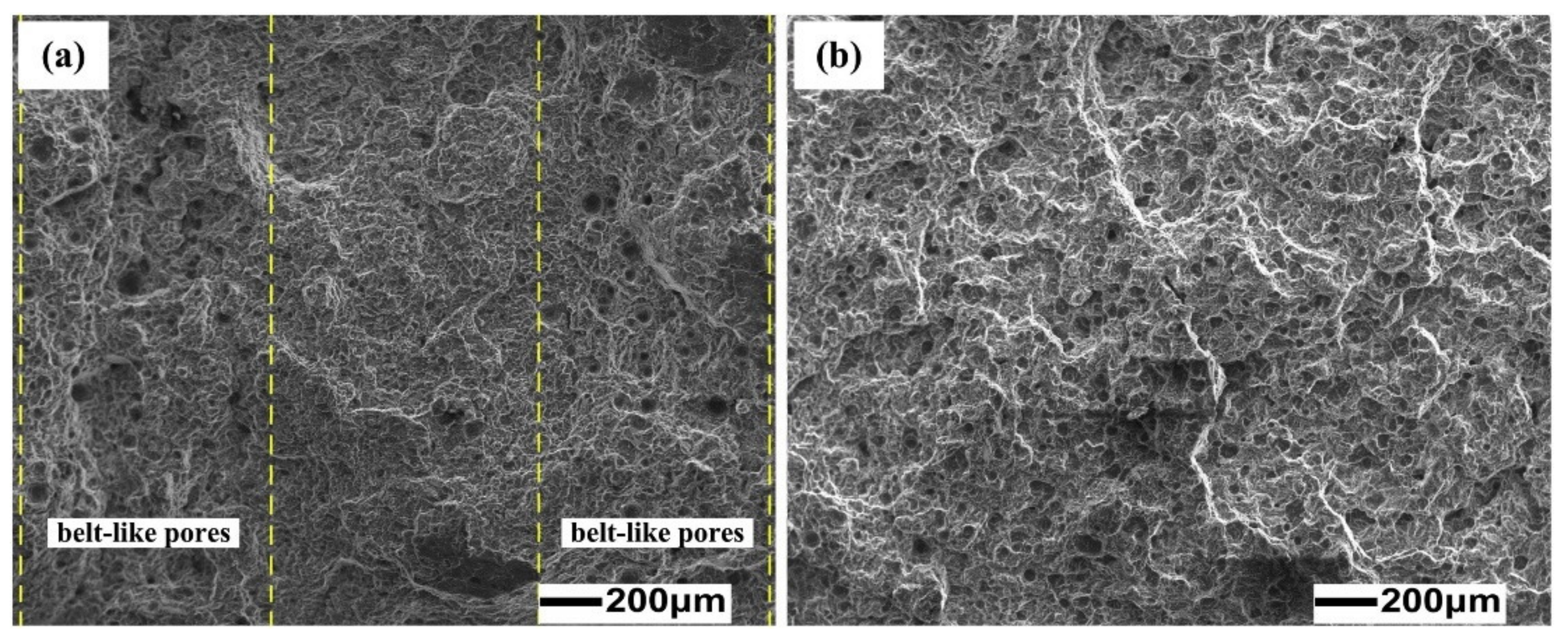

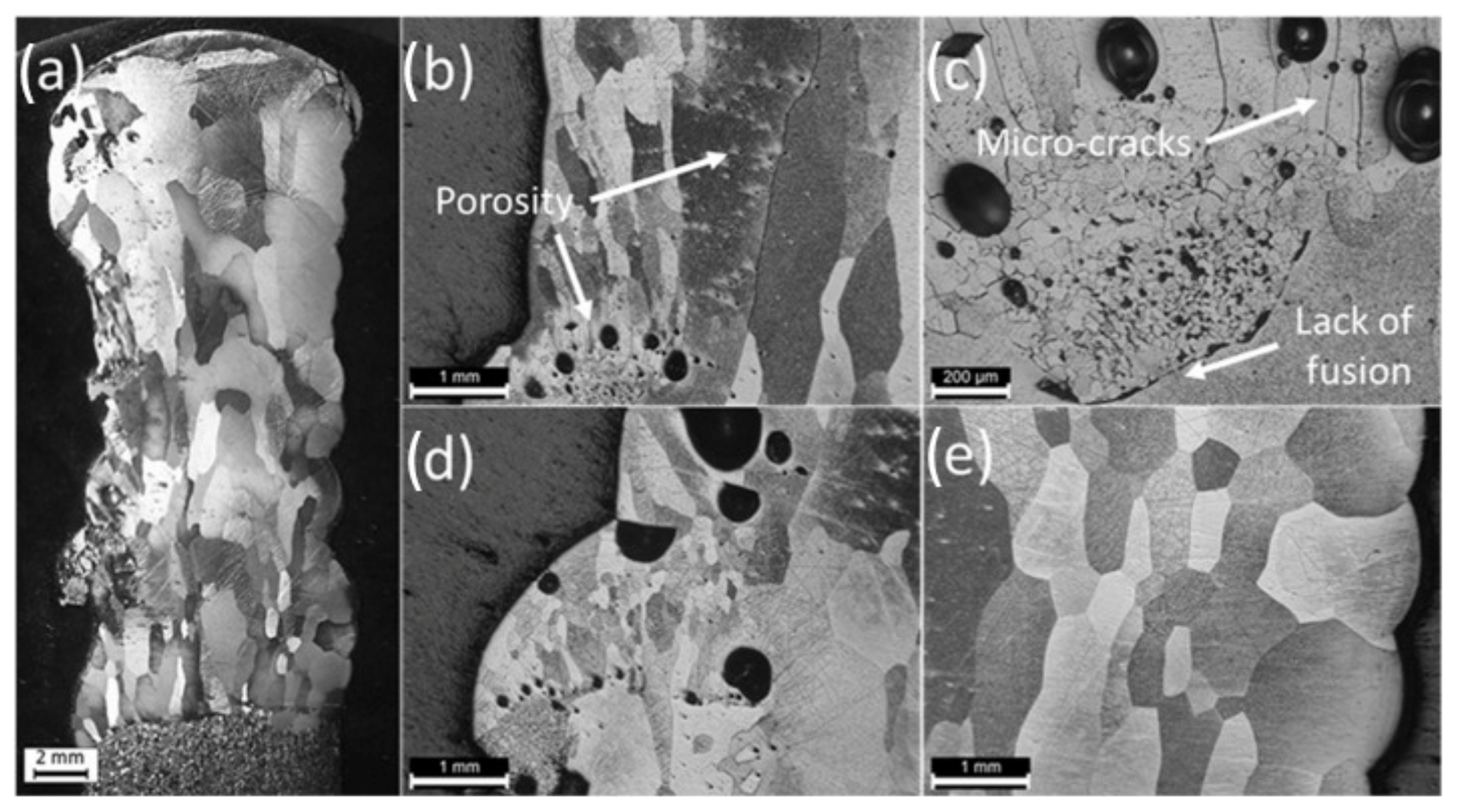

4.2. Aluminum Alloys

4.3. Chromium

4.4. Inconel

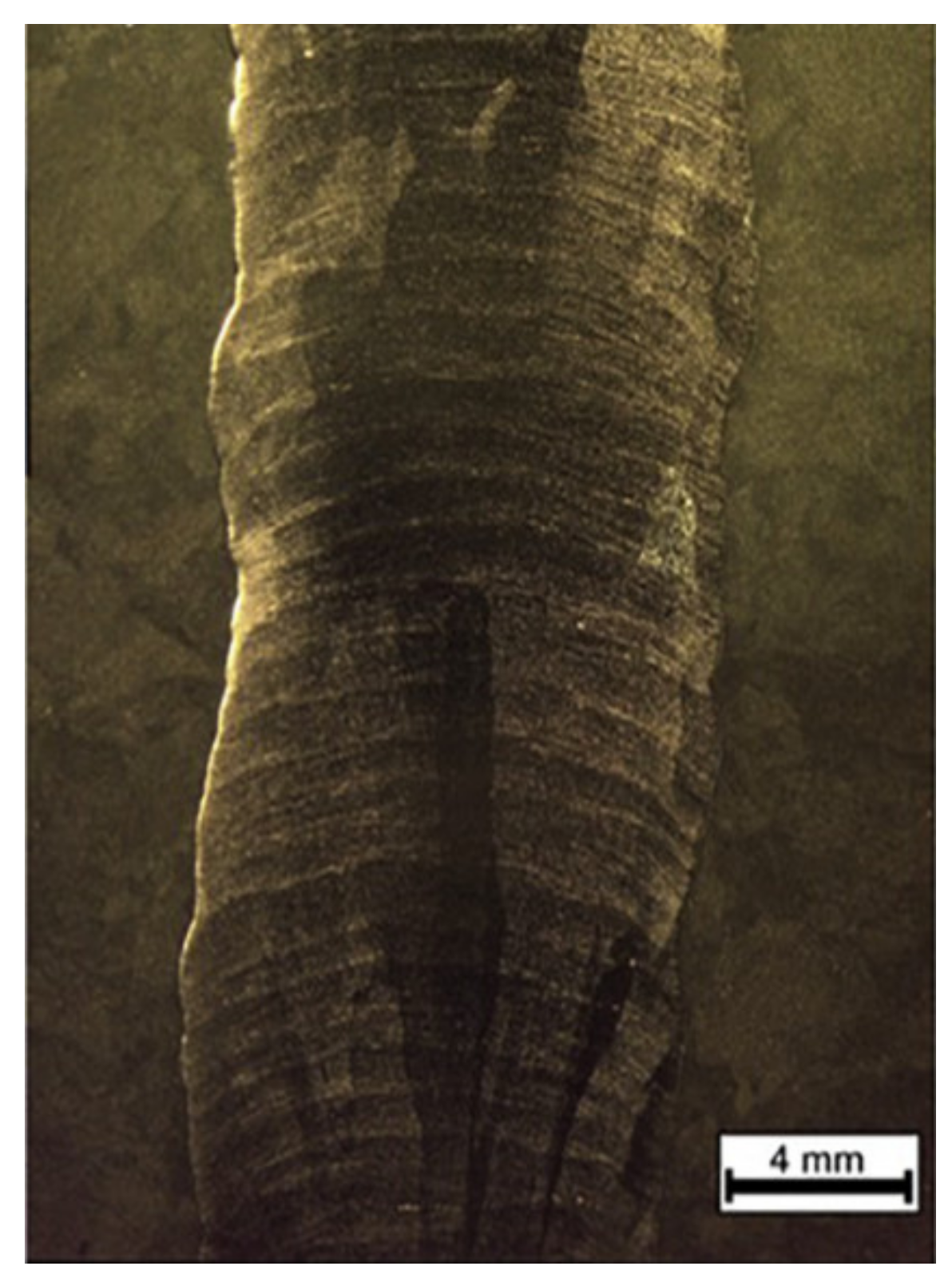

4.5. Tungsten

4.6. Tantalum

4.7. Copper

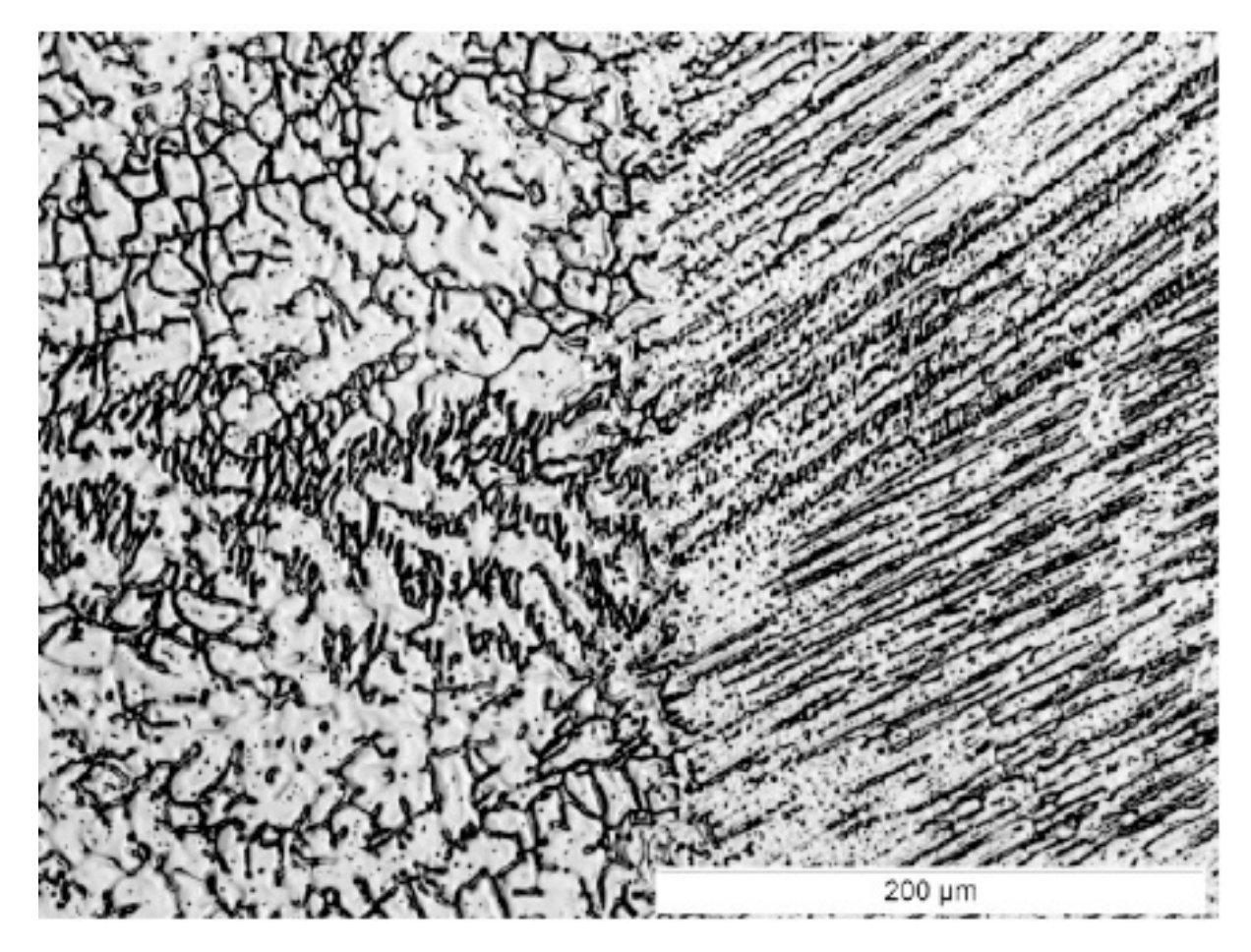

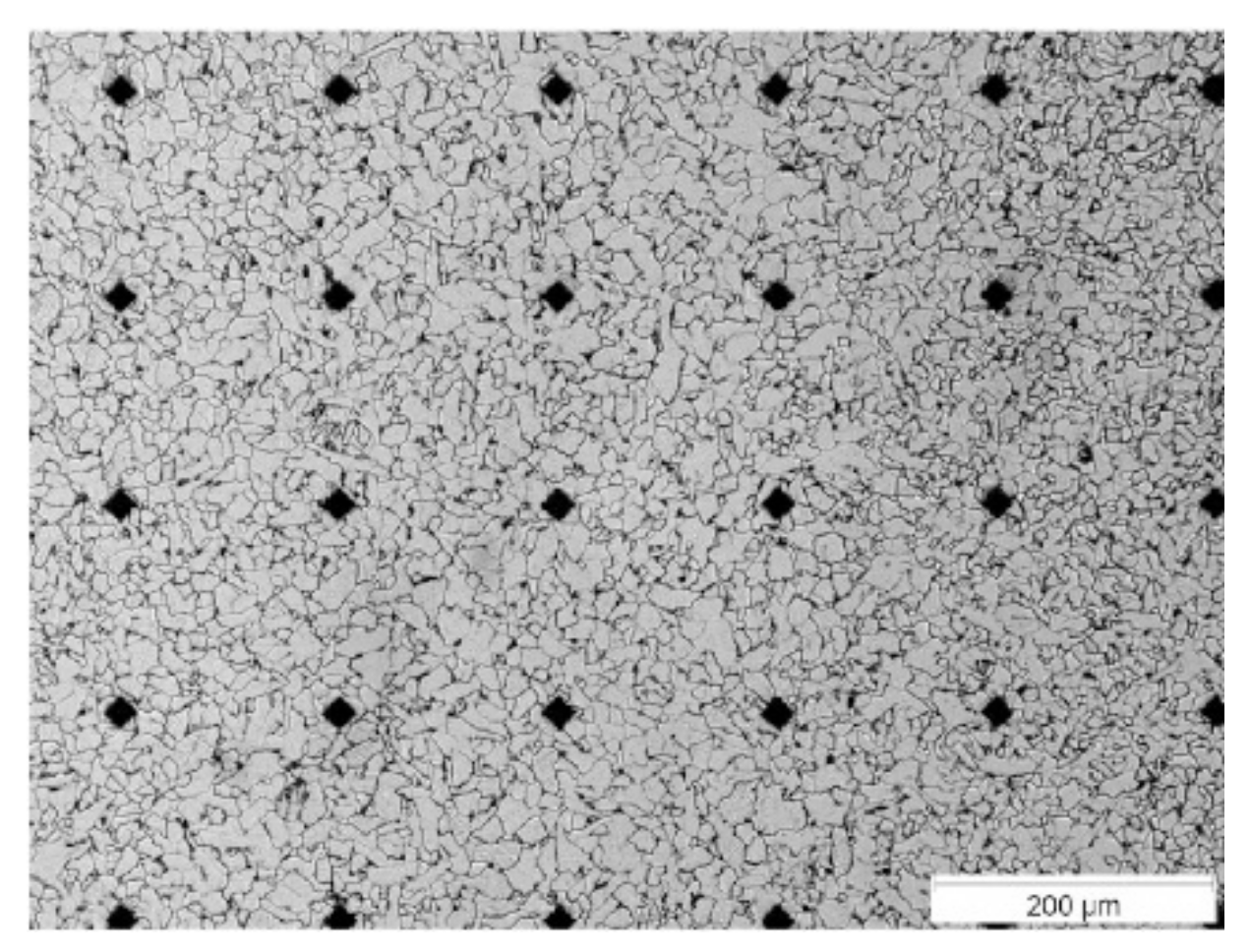

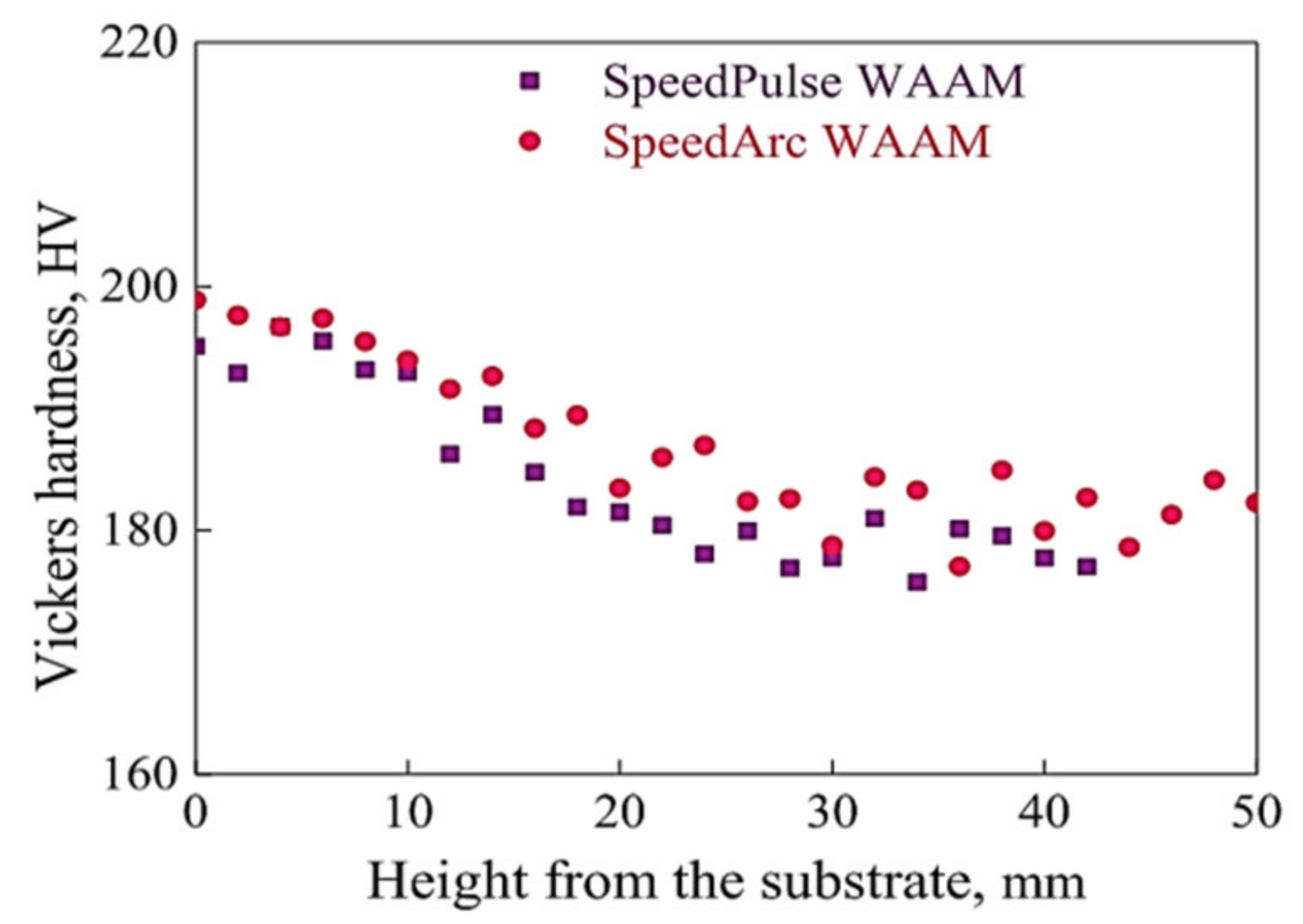

4.8. Steel Alloys

4.9. Technical Recommendations

5. Models Developed for Quality Improvement and Process Optimization

6. Constraints and Proposed Enhancements regarding the WAAM Process

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Almeida, P.S.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef] [Green Version]

- Ríos, S.; Colegrove, P.A.; Williams, S.W. Metal transfer modes in plasma Wire + Arc additive manufacture. J. Mater. Process. Technol. 2019, 264, 45–54. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Bekker, A.C.; Verlinden, J.C.; Galimberti, G. Challenges in assessing the sustainability of wire+ arc additive manufacturing for large structures. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016; pp. 406–418. [Google Scholar]

- Michel, F.; Lockett, H.; Ding, J.; Martina, F.; Marinelli, G.; Williams, S. A modular path planning solution for Wire + Arc Additive Manufacturing. Robot. Comput. Integr. Manuf. 2019, 60, 1–11. [Google Scholar] [CrossRef]

- Li, J.L.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; bin Ramli, F.R. Review of Wire Arc Additive Manufacturing for 3D Metal Printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F.W. Multi-Axis Planning of a Hybrid Material Deposition and Removal Combined Process. J. Mach. Manuf. Autom. 2013, 2, 46–57. [Google Scholar]

- Challenges & Latest Developments in Wire + Arc Additive Manufacturing. Available online: https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/challenges-latest-developments-wire-arc-additive-manufacturing (accessed on 25 December 2020).

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

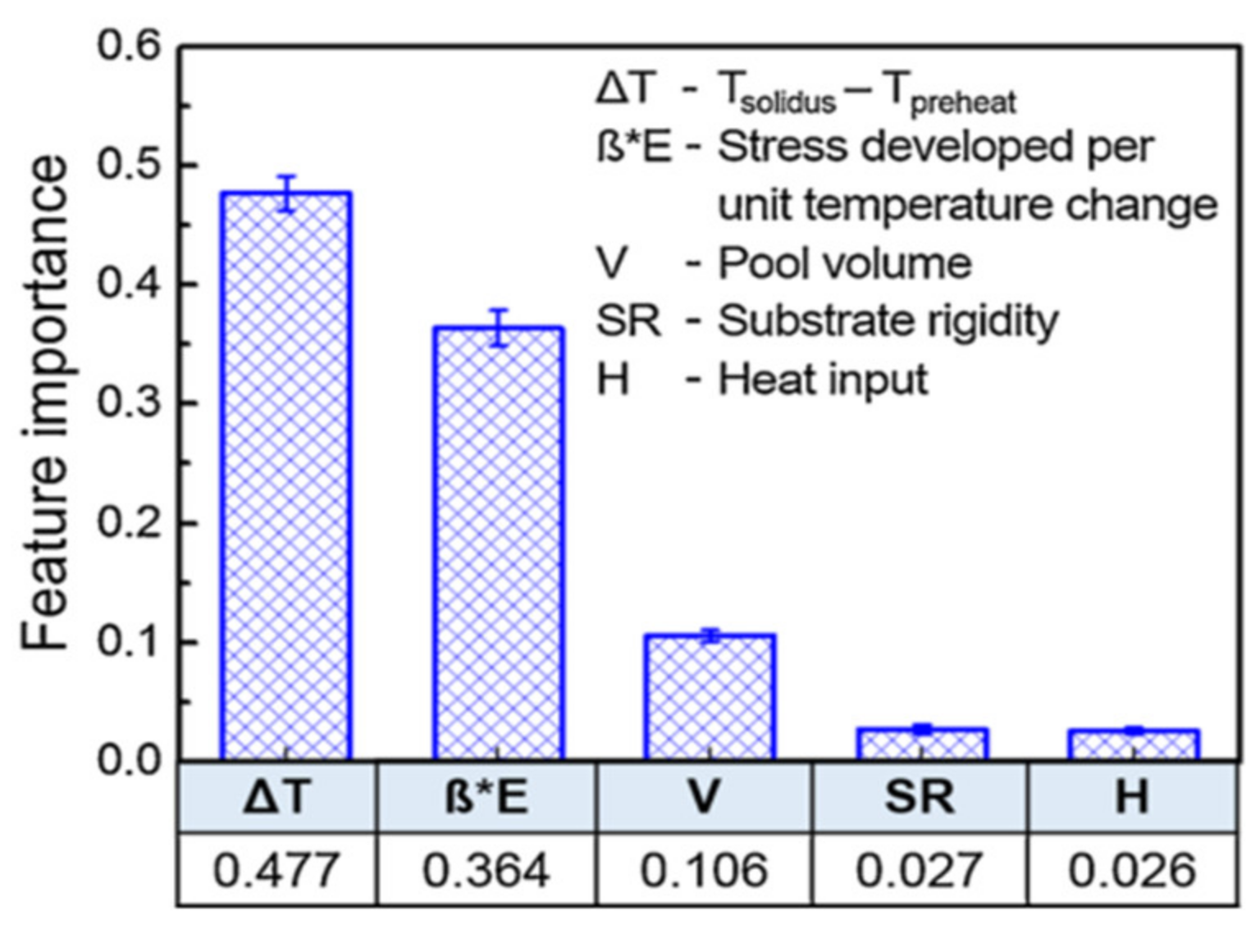

- Wu, Q.; Mukherjee, T.; De, A.; DebRoy, T. Residual stresses in wire-arc additive manufacturing—Hierarchy of influential variables. Addit. Manuf. 2020, 35, 101355. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Ding, J. Designing a WAAM Based Manufacturing System for Defence Applications. Procedia CIRP 2015, 37, 48–53. [Google Scholar] [CrossRef] [Green Version]

- Lockett, H.; Ding, J.; Williams, S.; Martina, F. Design for Wire + Arc Additive Manufacture: Design rules and build orientation selection. J. Eng. Des. 2017, 28, 568–598. [Google Scholar] [CrossRef] [Green Version]

- Yuan, L.; Ding, D.; Pan, Z.; Yu, Z.; Wu, B.; Van Duin, S.; Li, H.; Li, W. Application of Multidirectional Robotic Wire Arc Additive Manufacturing Process for the Fabrication of Complex Metallic Parts. IEEE Trans. Ind. Inform. 2019, 16, 454–464. [Google Scholar] [CrossRef]

- Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. Metals 2019, 9, 725. [Google Scholar] [CrossRef] [Green Version]

- Abe, T.; Sasahara, H. Layer geometry control for the fabrication of lattice structures by wire and arc additive manufacturing. Addit. Manuf. 2019, 28, 639–648. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Hari, S.; Amirthalingam, M. Wire arc additive manufacturing of functionally graded material for marine risers. Mater. Sci. Eng. A 2020, 792, 139530. [Google Scholar] [CrossRef]

- Lin, J.; Lv, Y.; Liu, Y.; Sun, Z.; Wang, K.; Li, Z.; Wu, Y.; Xu, B. Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment. J. Mech. Behav. Biomed. Mater. 2017, 69, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Priarone, P.C.; Pagone, E.; Martina, F.; Catalano, A.R.; Settineri, L. Multi-criteria environmental and economic impact assessment of wire arc additive manufacturing. CIRP Ann. 2020, 69, 37–40. [Google Scholar] [CrossRef]

- Prado-Cerqueira, J.; Diéguez, J.; Camacho, A. Preliminary development of a Wire and Arc Additive Manufacturing system (WAAM). Procedia Manuf. 2017, 13, 895–902. [Google Scholar] [CrossRef]

- Shukla, P.; Dash, B.; Kiran, D.V.; Bukkapatnam, S. Arc Behavior in Wire Arc Additive Manufacturing Process. Procedia Manuf. 2020, 48, 725–729. [Google Scholar] [CrossRef]

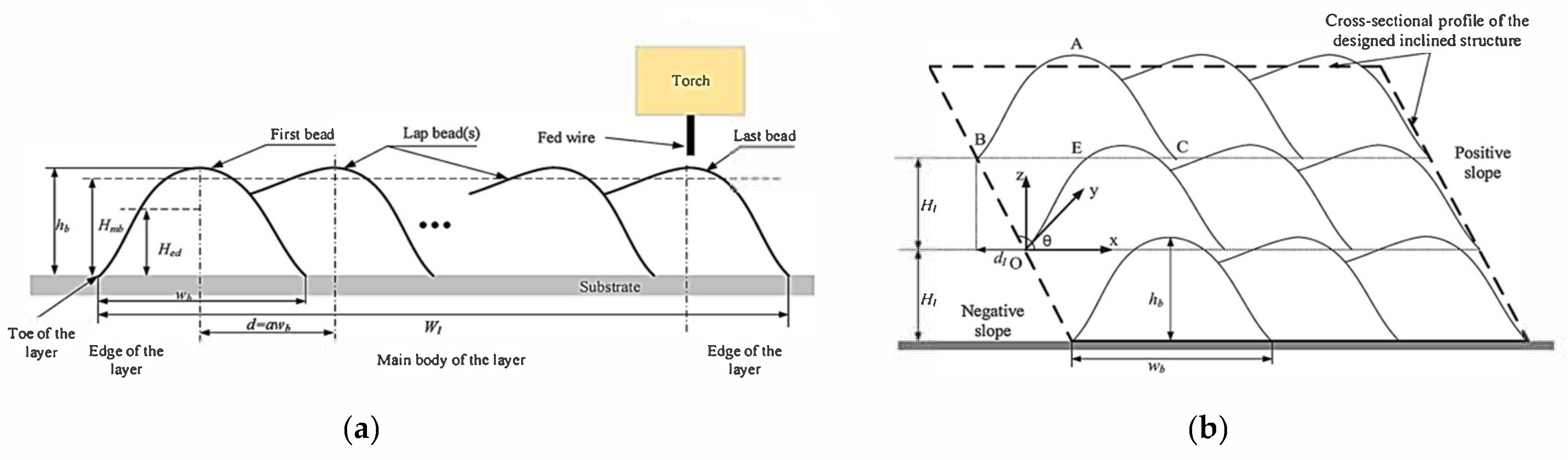

- Xiong, J.; Lei, Y.; Chen, H.; Zhang, G. Fabrication of inclined thin-walled parts in multi-layer single-pass GMAW-based additive manufacturing with flat position deposition. J. Mater. Process. Technol. 2017, 240, 397–403. [Google Scholar] [CrossRef]

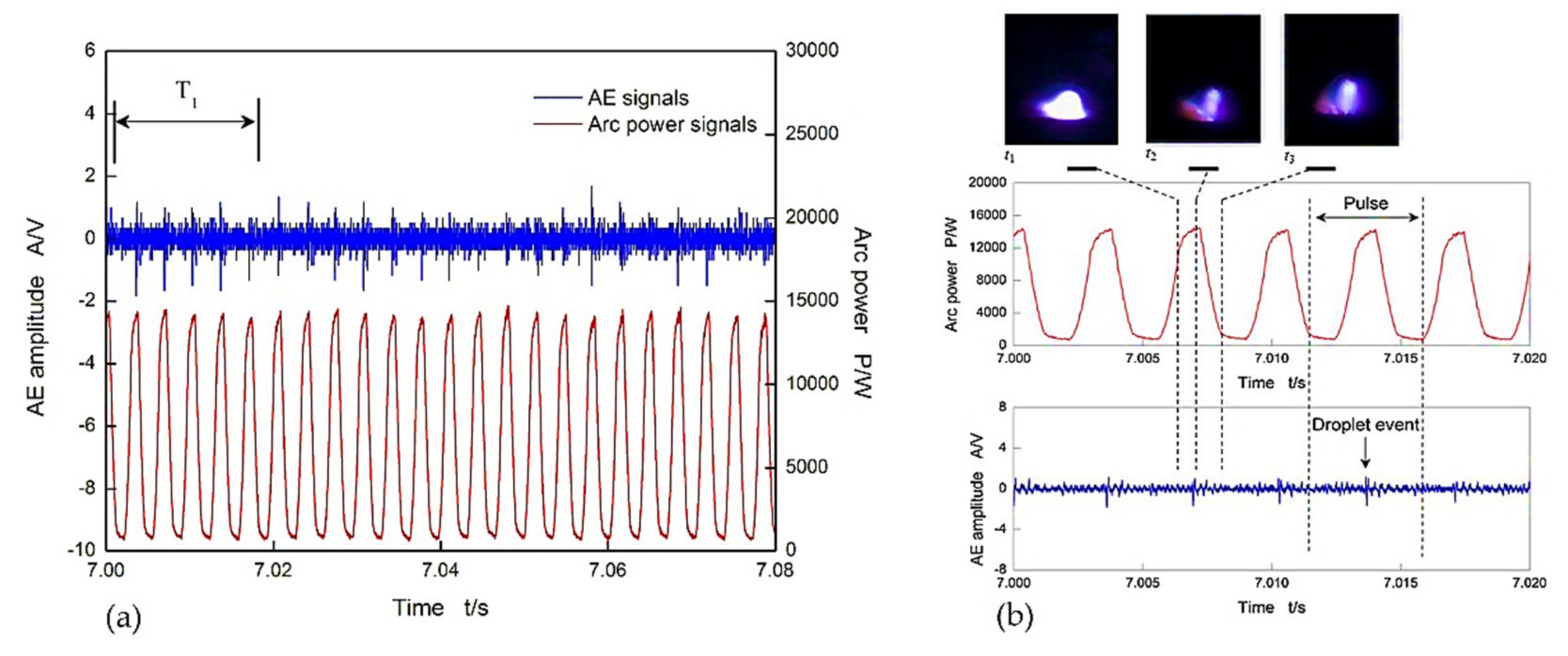

- Luo, Y.; Li, J.; Xu, J.; Zhu, L.; Han, J.; Zhang, C. Influence of pulsed arc on the metal droplet deposited by projected transfer mode in wire-arc additive manufacturing. J. Mater. Process. Technol. 2018, 259, 353–360. [Google Scholar] [CrossRef]

- Zhu, L.; Luo, Y.; Han, J.; Zhang, C.; Xu, J.; Chen, D. Energy characteristics of droplet transfer in wire-arc additive manufacturing based on the analysis of arc signals. Measurement 2019, 134, 804–813. [Google Scholar] [CrossRef]

- Guo, M.; Jia, C.; Zhou, J.; Liu, W.; Wu, C. Investigating the generation process of molten droplets and arc plasma in the confined space during compulsively constricted WAAM. J. Mater. Process. Technol. 2020, 275, 116355. [Google Scholar] [CrossRef]

- Marinelli, G.; Martina, F.; Ganguly, S.; Williams, S. Grain refinement in an unalloyed tantalum structure by combining Wire+Arc additive manufacturing and vertical cold rolling. Addit. Manuf. 2020, 32, 101009. [Google Scholar] [CrossRef]

- Abe, T.; Kaneko, J.; Sasahara, H. Thermal sensing and heat input control for thin-walled structure building based on numerical simulation for wire and arc additive manufacturing. Addit. Manuf. 2020, 35, 101357. [Google Scholar] [CrossRef]

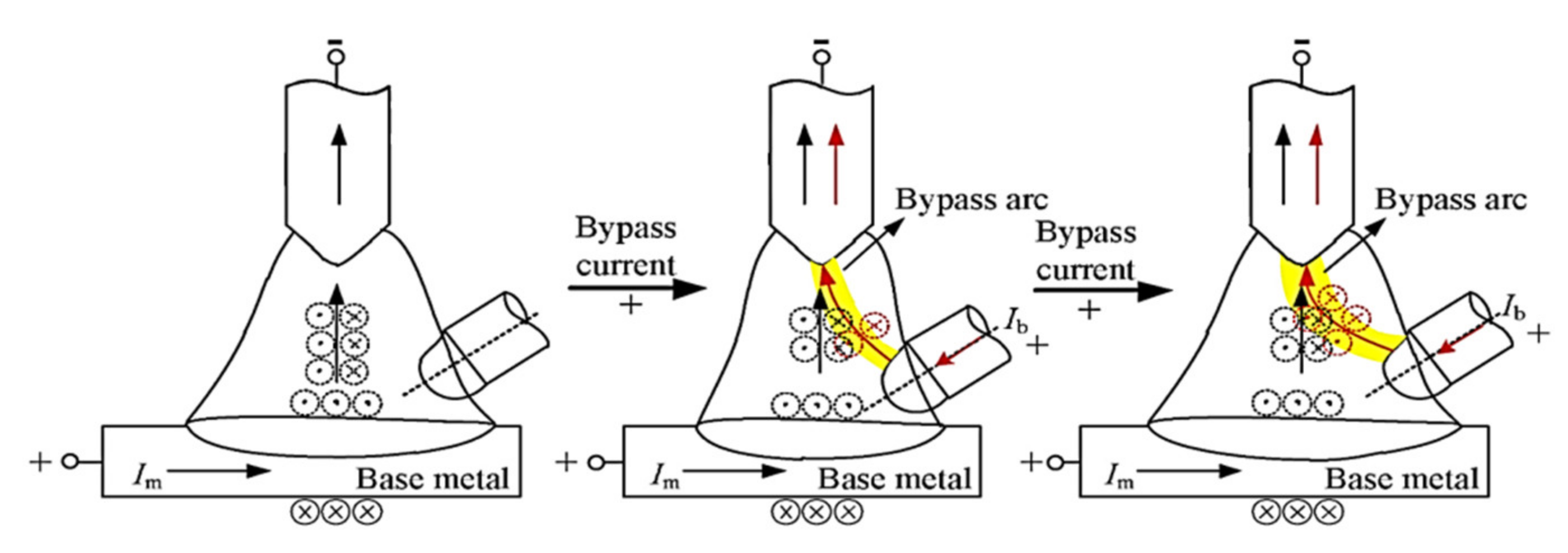

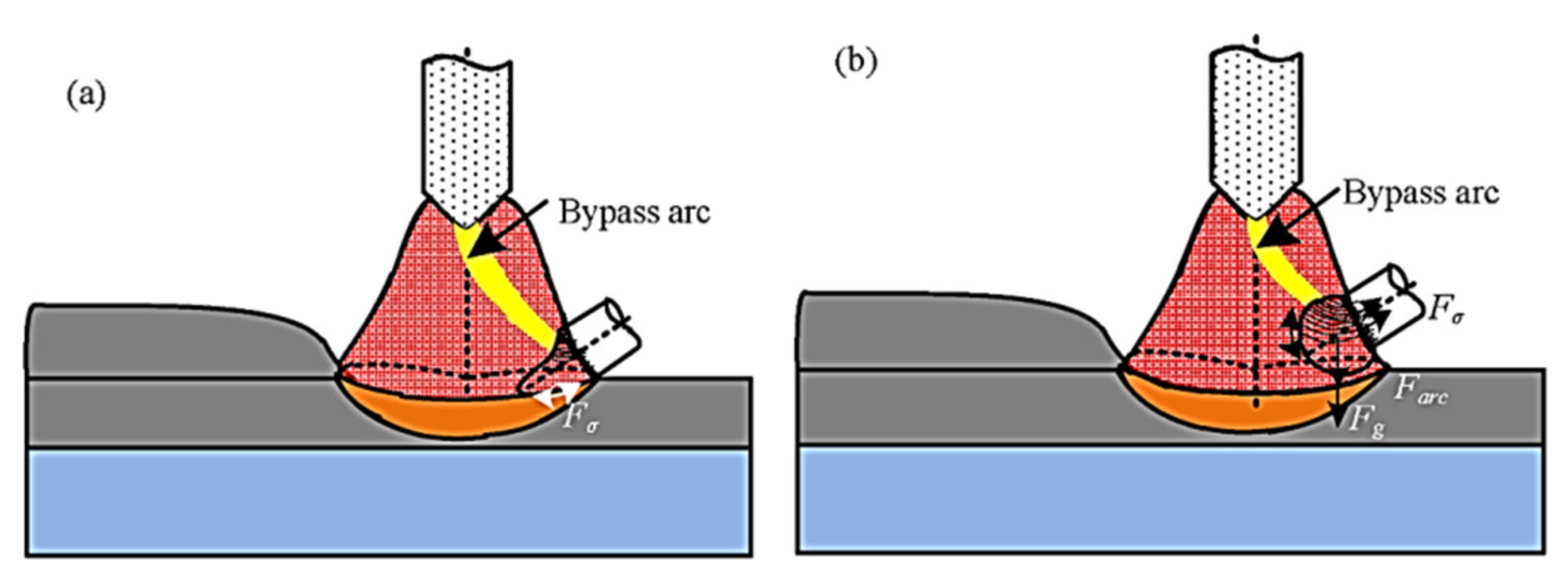

- Huang, J.; Yuan, W.; Yu, S.; Zhang, L.; Yu, X.; Fan, D. Droplet transfer behavior in bypass-coupled wire arc additive manufacturing. J. Manuf. Process. 2020, 49, 397–412. [Google Scholar] [CrossRef]

- Li, S.; Zhang, L.-J.; Ning, J.; Wang, X.; Zhang, G.-F.; Zhang, J.-X.; Na, S.-J.; Fatemeh, B. Comparative study on the microstructures and properties of wire+arc additively manufactured 5356 aluminium alloy with argon and nitrogen as the shielding gas. Addit. Manuf. 2020, 34, 101206. [Google Scholar] [CrossRef]

- Yang, D.; He, C.; Zhang, G. Forming characteristics of thin-wall steel parts by double electrode GMAW based additive manufacturing. J. Mater. Process. Technol. 2016, 227, 153–160. [Google Scholar] [CrossRef]

- Mok, S.H.; Bi, G.; Folkes, J.; Pashby, I. Deposition of Ti–6Al–4V using a high power diode laser and wire, Part I: Investigation on the process characteristics. Surf. Coat. Technol. 2008, 202, 3933–3939. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Wahsh, L.M.; ElShater, A.E.; Mansour, A.K.; Hamdy, F.A.; Turky, M.A.; Azzam, M.O.; Salem, H.G. Parameter Selection for Wire Arc Additive Manufacturing (Waam) Process. Mater. Sci. Technol. 2018. [Google Scholar] [CrossRef]

- Kumar, C.B.; Anandakrishnan, V. Experimental investigations on the effect of wire arc additive manufacturing process parameters on the layer geometry of Inconel 825. Mater. Today Proc. 2020, 21, 622–627. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Gao, C.; Wang, Y. Effect of heat input on microstructure and mechanical properties of Al-Mg alloys fabricated by WAAM. Appl. Surf. Sci. 2019, 486, 431–440. [Google Scholar] [CrossRef]

- Zhou, Y.; Lin, X.; Kang, N.; Huang, W.; Wang, J.; Wang, Z. Influence of travel speed on microstructure and mechanical properties of wire + arc additively manufactured 2219 aluminum alloy. J. Mater. Sci. Technol. 2020, 37, 143–153. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G. Adaptive control of deposited height in GMAW-based layer additive manufacturing. J. Mater. Process. Technol. 2014, 214, 962–968. [Google Scholar] [CrossRef]

- Artaza, T.; Alberdi, A.; Murua, M.; Gorrotxategi, J.; Frías, J.; Puertas, G.; Melchor, M.; Mugica, D.; Suárez, A. Design and integration of WAAM technology and in situ monitoring system in a gantry machine. Procedia Manuf. 2017, 13, 778–785. [Google Scholar] [CrossRef]

- Anikin, P.; Shilo, G.; Kulykovskyi, R.; Molochkov, D. Wire+ Arc Additive Manufacturing Automation Control System Architecture. In Proceedings of the Measuring and Computing Technology in Technological Processes Conference, Odessa, Ukraine, 26–29 June 2020; pp. 7–9. [Google Scholar]

- Silva, R.; Barbosa, G.; Carvalho, J. Additive Manufacturing of Metal Parts by Welding. IFAC-PapersOnLine 2015, 48, 2318–2322. [Google Scholar] [CrossRef]

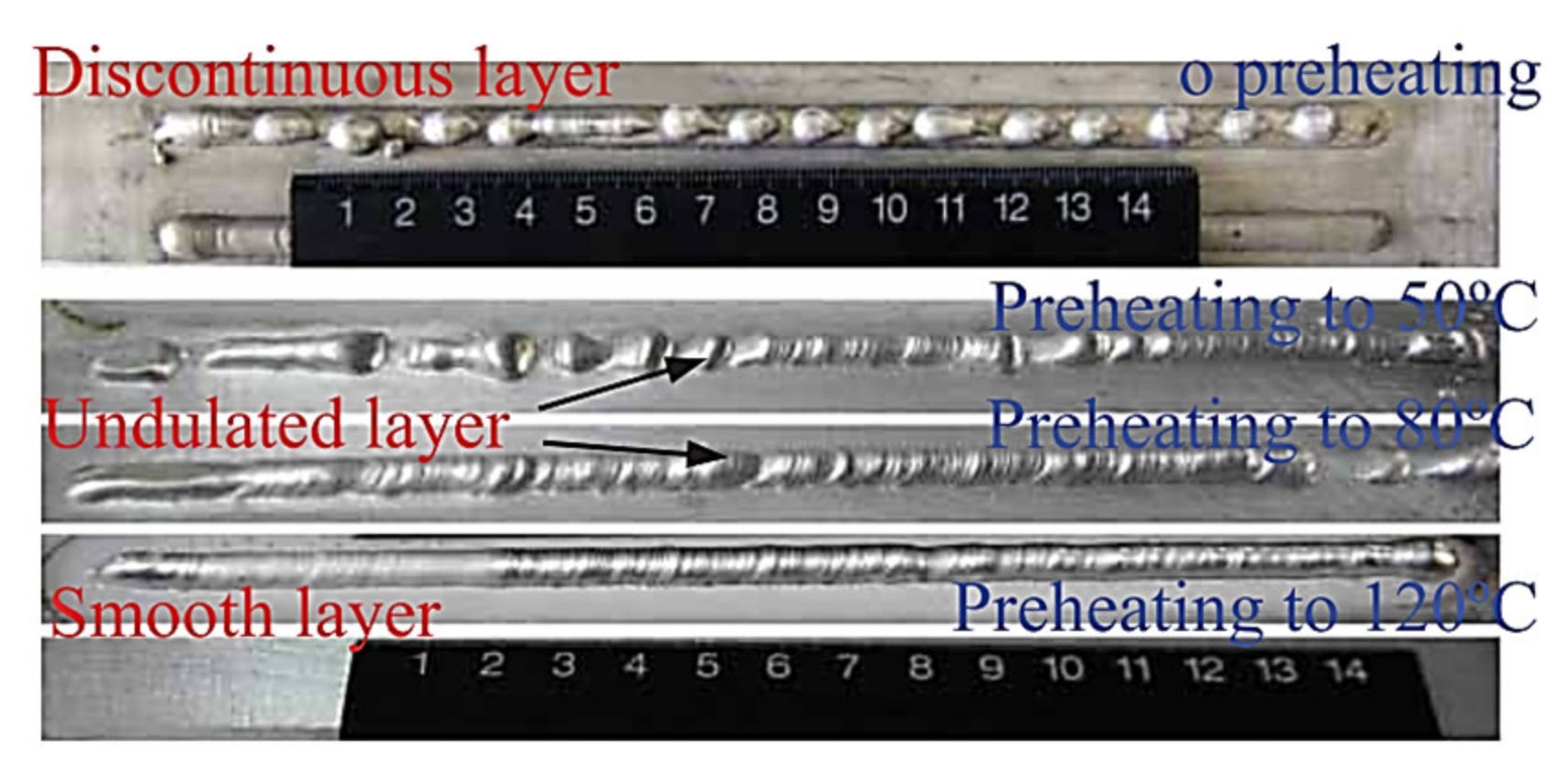

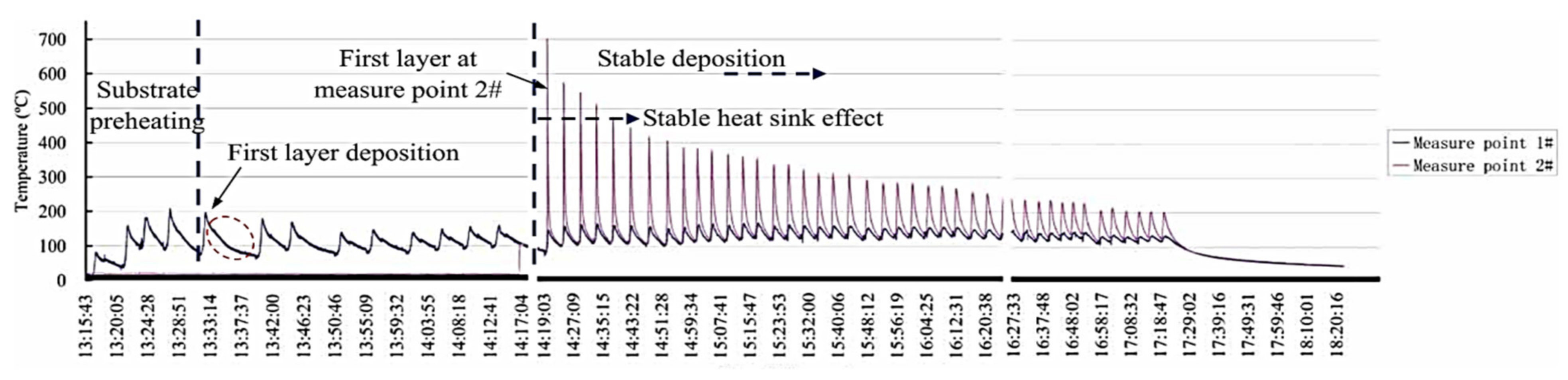

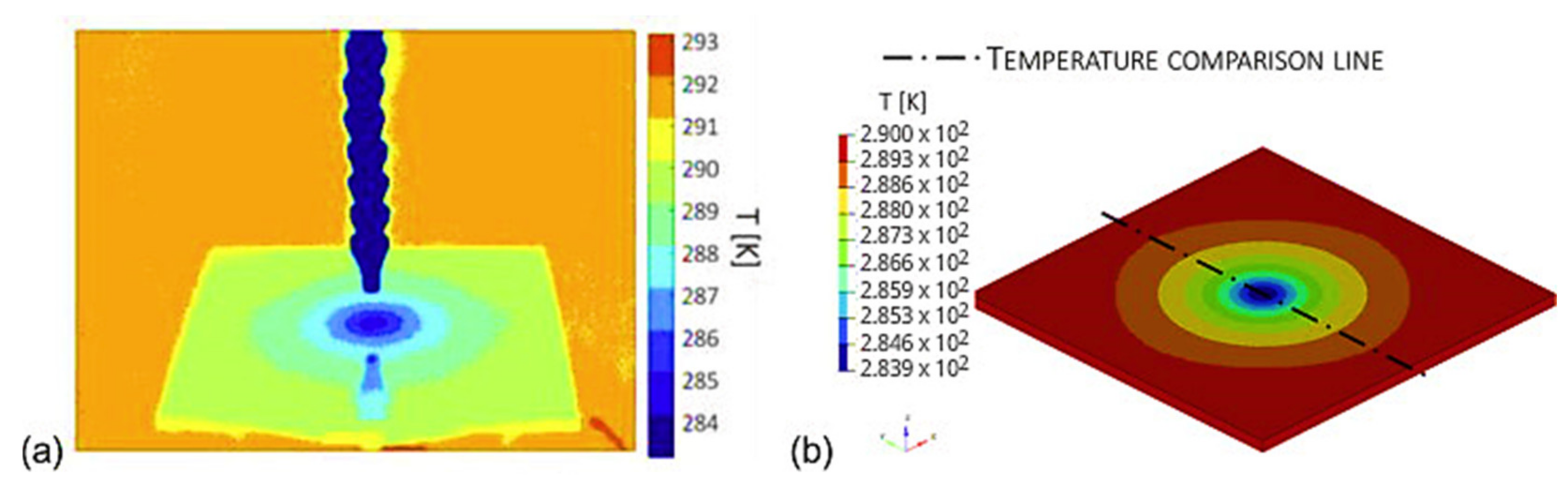

- Xiong, J.; Lei, Y.; Li, R. Finite element analysis and experimental validation of thermal behavior for thin-walled parts in GMAW-based additive manufacturing with various substrate preheating temperatures. Appl. Therm. Eng. 2017, 126, 43–52. [Google Scholar] [CrossRef]

- Radel, S.; Bordreuil, C.; Soulie, F.; Company, O. CAM for On-line Control for Wire Arc Additive Manufacturing. Comput. Des. Appl. 2018, 16. [Google Scholar] [CrossRef]

- Ali, Y.; Henckell, P.; Hildebrand, J.; Reimann, J.; Bergmann, J.; Barnikol-Oettler, S. Wire arc additive manufacturing of hot work tool steel with CMT process. J. Mater. Process. Technol. 2019, 269, 109–116. [Google Scholar] [CrossRef]

- Derekar, K.S.; Addison, A.; Joshi, S.S.; Zhang, X.; Lawrence, J.; Xu, L.; Melton, G.; Griffiths, D. Effect of pulsed metal inert gas (pulsed-MIG) and cold metal transfer (CMT) techniques on hydrogen dissolution in wire arc additive manufacturing (WAAM) of aluminium. Int. J. Adv. Manuf. Technol. 2020, 107, 311–331. [Google Scholar] [CrossRef]

- Ortega, A.G.; Galvan, L.C.; Deschaux-Beaume, F.; Rouquette, S. Effect of welding parameters on the quality of multilayer deposition of aluminum alloy. Adv. Mater. Process. Technol. Conf. 2017, 23, 316–332. [Google Scholar] [CrossRef] [Green Version]

- Ryan, E.; Sabin, T.; Watts, J.; Whiting, M. The influence of build parameters and wire batch on porosity of wire and arc additive manufactured aluminium alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Brandl, E.; Michailov, V.; Viehweger, B.; Leyens, C. Deposition of Ti–6Al–4V using laser and wire, part I: Microstructural properties of single beads. Surf. Coat. Technol. 2011, 206, 1120–1129. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Shen, C.; Li, H.; Pan, Z. Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Addit. Manuf. 2015, 8, 71–77. [Google Scholar] [CrossRef]

- Huang, J.; Liu, S.; Yu, S.; Yu, X.; Chen, H.; Fan, D. Arc deposition of wear resistant layer TiN on Ti6Al4V using simultaneous feeding of nitrogen and wire. Surf. Coatings Technol. 2020, 381, 125141. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Li, J.; Hu, Y.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Effects of deposition strategies on macro/microstructure and mechanical properties of wire and arc additive manufactured Ti6Al4V. Mat Sci. Eng. A. 2019, 754, 735–749. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Cuiuri, D.; Li, H. Phase constituent control and correlated properties of titanium aluminide intermetallic alloys through dual-wire arc additive manufacturing. Mater. Lett. 2019, 242, 111–114. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric Limitation and Tensile Properties of Wire and Arc Additive Manufacturing 5A06 Aluminum Alloy Parts. J. Mater. Eng. Perform. 2016, 26, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Horgar, A.; Fostervoll, H.; Nyhus, B.; Ren, X.; Eriksson, M.; Akselsen, O. Additive manufacturing using WAAM with AA5183 wire. J. Mater. Process. Technol. 2018, 259, 68–74. [Google Scholar] [CrossRef]

- Qi, Z.; Cong, B.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. Microstructure and mechanical properties of double-wire + arc additively manufactured Al-Cu-Mg alloys. J. Mater. Process. Technol. 2018, 255, 347–353. [Google Scholar] [CrossRef]

- Gu, J.; Yang, S.; Gao, M.; Bai, J.; Zhai, Y.; Ding, J. Micropore evolution in additively manufactured aluminum alloys under heat treatment and inter-layer rolling. Mater. Des. 2020, 186, 108288. [Google Scholar] [CrossRef]

- Li, C.; Gu, H.; Wang, W.; Wang, S.; Ren, L.; Wang, Z.; Ming, Z.; Zhai, Y. Effect of Heat Input on Formability, Microstructure, and Properties of Al–7Si–0.6Mg Alloys Deposited by CMT-WAAM Process. Appl. Sci. 2019, 10, 70. [Google Scholar] [CrossRef] [Green Version]

- Qi, Z.; Qi, B.; Cong, B.; Sun, H.; Zhao, G.; Ding, J. Microstructure and mechanical properties of wire + arc additively manufactured 2024 aluminum alloy components: As-deposited and post heat-treated. J. Manuf. Process. 2019, 40, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Ünsal, I.; Hirtler, M.; Sviridov, A.; Bambach, M. Material Properties of Features Produced from EN AW 6016 by Wire-Arc Additive Manufacturing. Procedia Manuf. 2020, 47, 1129–1133. [Google Scholar] [CrossRef]

- Wang, S.; Gu, H.; Wang, W.; Li, C.; Ren, L.; Wang, Z.; Zhai, Y.; Ma, P. The Influence of Heat Input on the Microstructure and Properties of Wire-Arc-Additive-Manufactured Al-Cu-Sn Alloy Deposits. Metals 2020, 10, 79. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Liu, J.; Wang, Z.; Lin, X.; Liu, F.; Huang, W.; Liang, E. Microstructure and mechanical properties of wire and arc additive manufactured AZ31 magnesium alloy using cold metal transfer process. Mater. Sci. Eng. A 2020, 774, 138942. [Google Scholar] [CrossRef]

- Ge, J.; Lin, J.; Chen, Y.; Lei, Y.; Fu, H. Characterization of wire arc additive manufacturing 2Cr13 part: Process stability, microstructural evolution, and tensile properties. J. Alloy Compd. 2018, 748, 911–921. [Google Scholar] [CrossRef]

- Xu, X.; Ganguly, S.; Ding, J.; Seow, C.E.; Williams, S. Enhancing mechanical properties of wire + arc additively manufactured INCONEL 718 superalloy through in-process thermomechanical processing. Mater. Des. 2018, 160, 1042–1051. [Google Scholar] [CrossRef]

- Seow, C.E.; Coules, H.; Wu, G.; Khan, R.H.; Xu, X.; Williams, S. Wire + Arc Additively Manufactured Inconel 718: Effect of post-deposition heat treatments on microstructure and tensile properties. Mater. Des. 2019, 183, 108157. [Google Scholar] [CrossRef]

- Yangfan, W.; Xizhang, C.; Chuanchu, S. Microstructure and mechanical properties of Inconel 625 fabricated by wire-arc additive manufacturing. Surf. Coatings Technol. 2019, 374, 116–123. [Google Scholar] [CrossRef]

- Marinelli, G.; Martina, F.; Ganguly, S.; Williams, S. Development of Wire + Arc additive manufacture for the production of large-scale unalloyed tungsten components. Int. J. Refract. Met. Hard Mater. 2019, 82, 329–335. [Google Scholar] [CrossRef] [Green Version]

- Marinelli, G.; Martina, F.; Ganguly, S.; Williams, S. Microstructure, hardness and mechanical properties of two different unalloyed tantalum wires deposited via wire + arc additive manufacture. Int. J. Refract. Met. Hard Mater. 2019, 83, 104974. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Chen, X.; Konovalov, S.; Su, C.; Siddiquee, A.N.; Gangil, N. In-situ wire-feed additive manufacturing of Cu-Al alloy by addition of silicon. Appl. Surf. Sci. 2019, 487, 1366–1375. [Google Scholar] [CrossRef]

- Haden, C.V.; Zeng, G.; Carter, F.M., III; Ruhl, C.; Krick, B.A.; Harlow, D.G. Wire and arc additive manufactured steel: Tensile and wear properties. Addit. Manuf. 2017, 16, 115–123. [Google Scholar] [CrossRef]

- Feng, Y.; Zhan, B.; He, J.; Wang, K. The double-wire feed and plasma arc additive manufacturing process for deposition in Cr-Ni stainless steel. J. Mater. Process. Technol. 2018, 259, 206–215. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Dirisu, P.; Supriyo, G.; Martina, F.; Xu, X.; Williams, S. Wire plus arc additive manufactured functional steel surfaces enhanced by rolling. Int. J. Fatigue 2020, 130, 105237. [Google Scholar] [CrossRef]

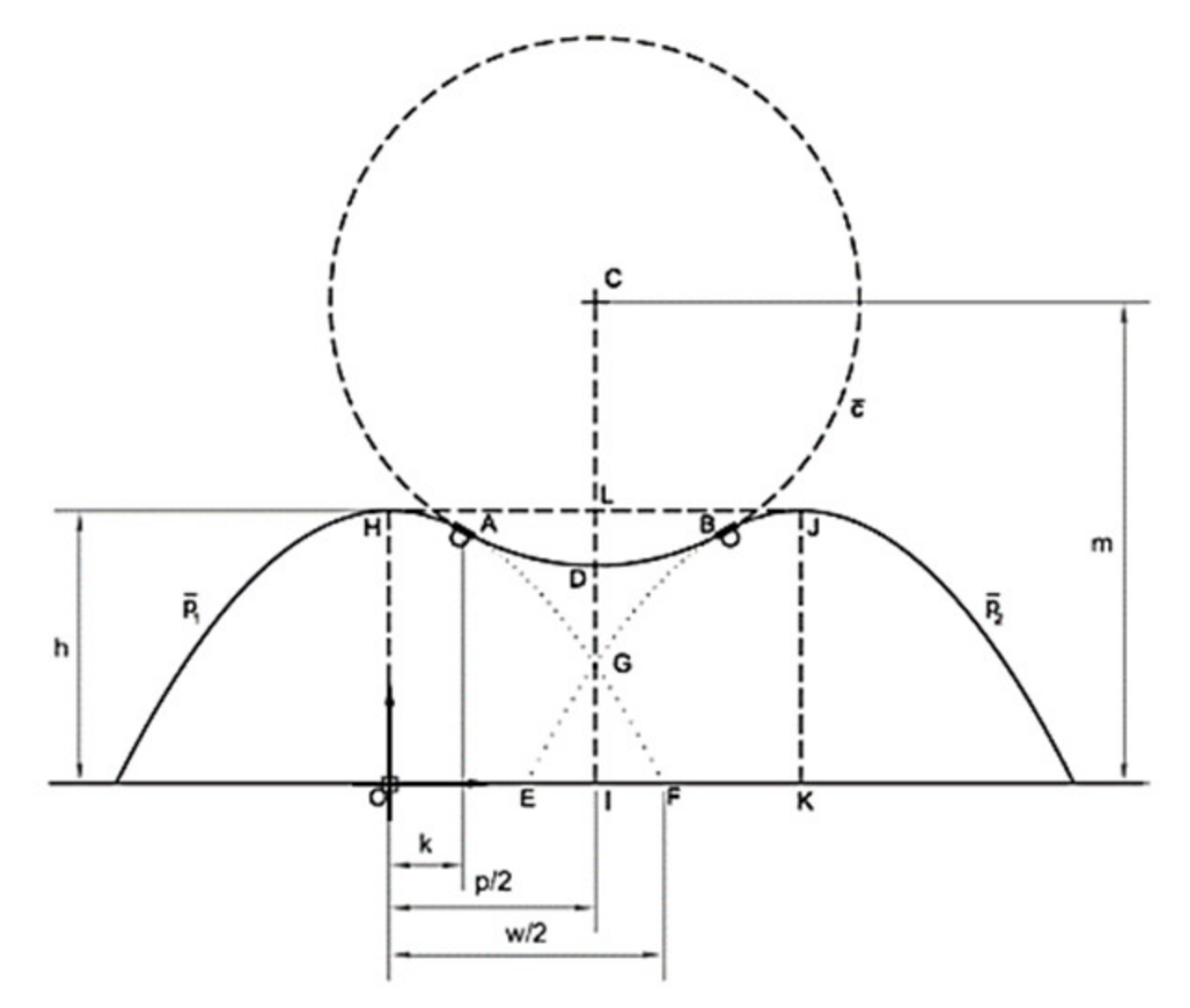

- Suryakumar, S.; Karunakaran, K.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in Hybrid Layered Manufacturing. Comput. Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

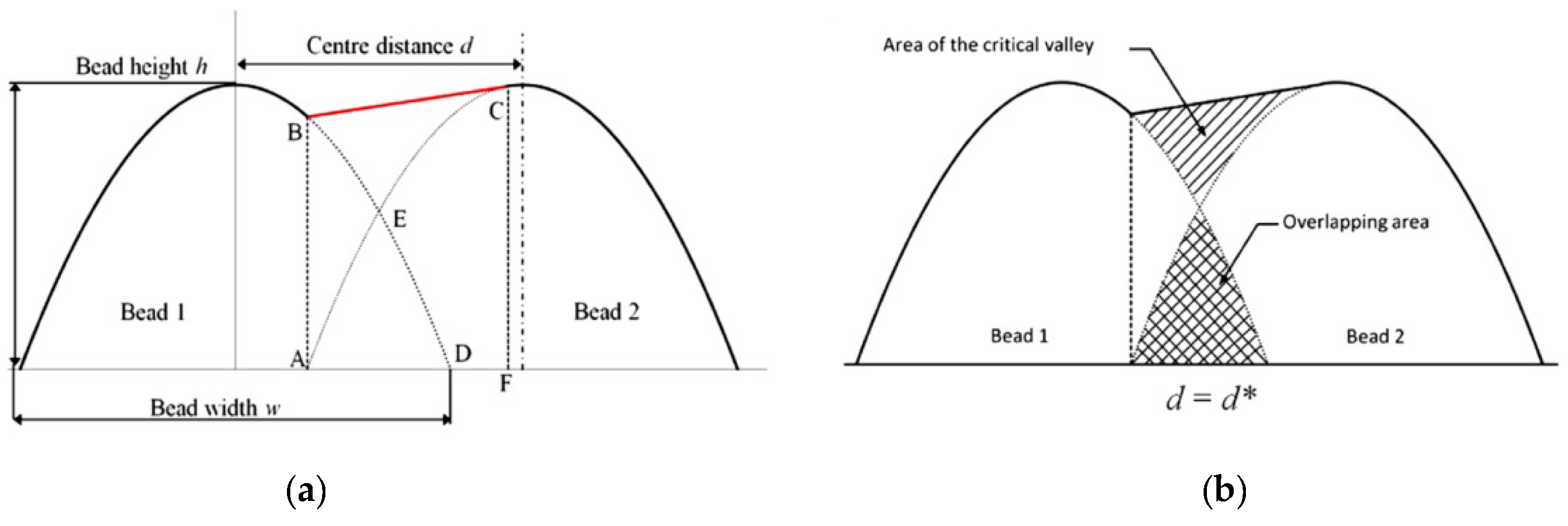

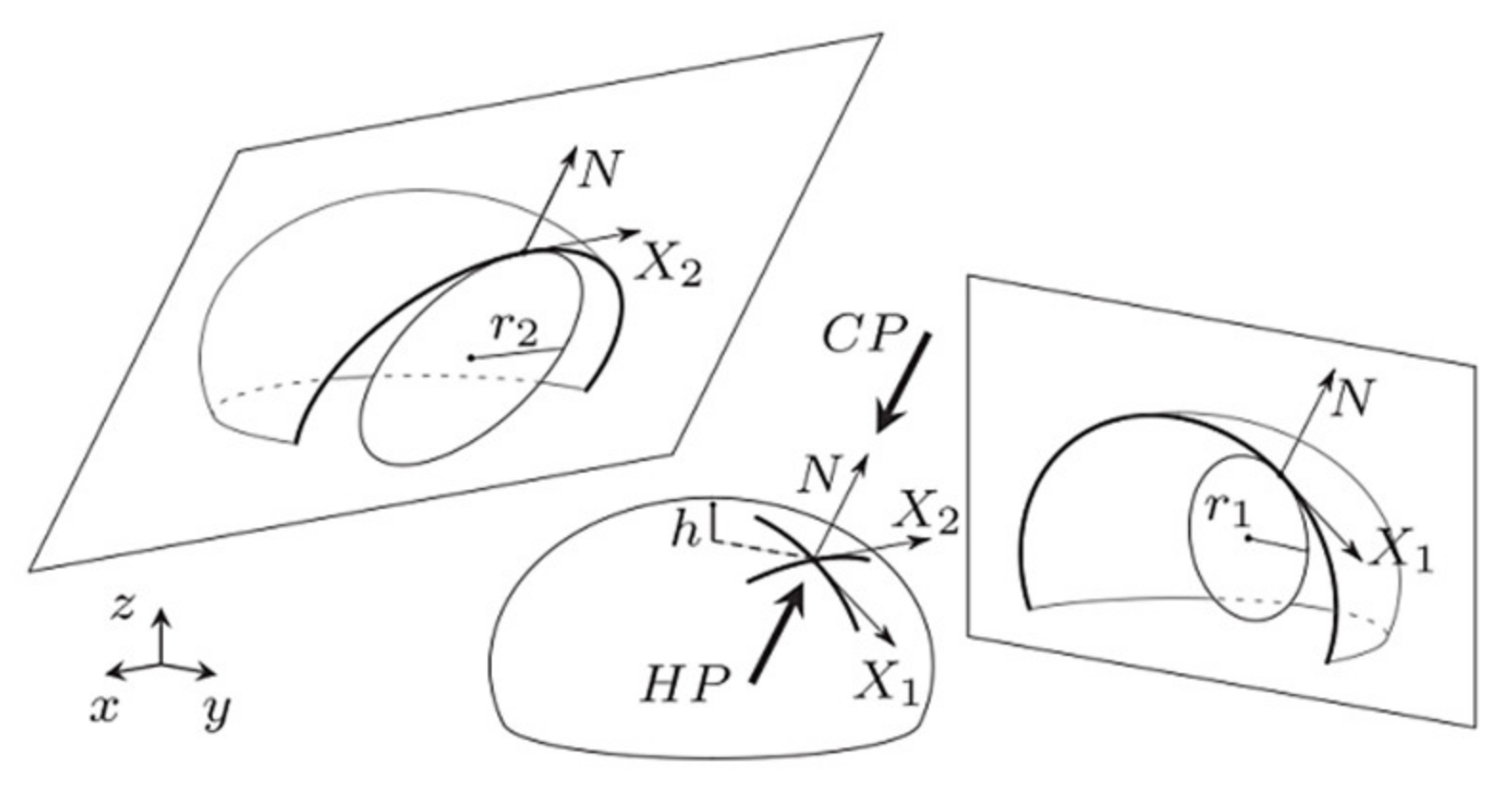

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Geng, H.; Li, J.; Xiong, J.; Lin, X. Optimisation of interpass temperature and heat input for wire and arc additive manufacturing 5A06 aluminium alloy. Sci. Technol. Weld. Join. 2017, 22, 472–483. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, Z.; Han, J.; Bai, L. Quality Monitoring in Wire-Arc Additive Manufacturing Based on Spectrum. In Proceedings of the 2018 the 2nd International Conference on Video and Image Processing, ICVIP 2018, Hong Kong, China, 18–21 December 2018; pp. 240–244. [Google Scholar]

- Ríos, S.; Colegrove, P.; Martina, F.; Williams, S.W. Analytical process model for wire + arc additive manufacturing. Addit. Manuf. 2018, 21, 651–657. [Google Scholar] [CrossRef]

- Tian, H.; Lu, Z.; Li, F.; Chen, S. Predictive Modeling of Surface Roughness Based on Response Surface Methodology after WAAM; Atlantis Press: Paris, France, 2019; pp. 47–50. [Google Scholar]

- Teja, K.; Tokala, S.C.V.; Reddy, Y.P.; Narayana, K.L. Optimization of mechanical properties of wire arc additive manufactured specimens using grey-based taguchi method. J. Crit. Rev. 2020, 7, 808–817. [Google Scholar]

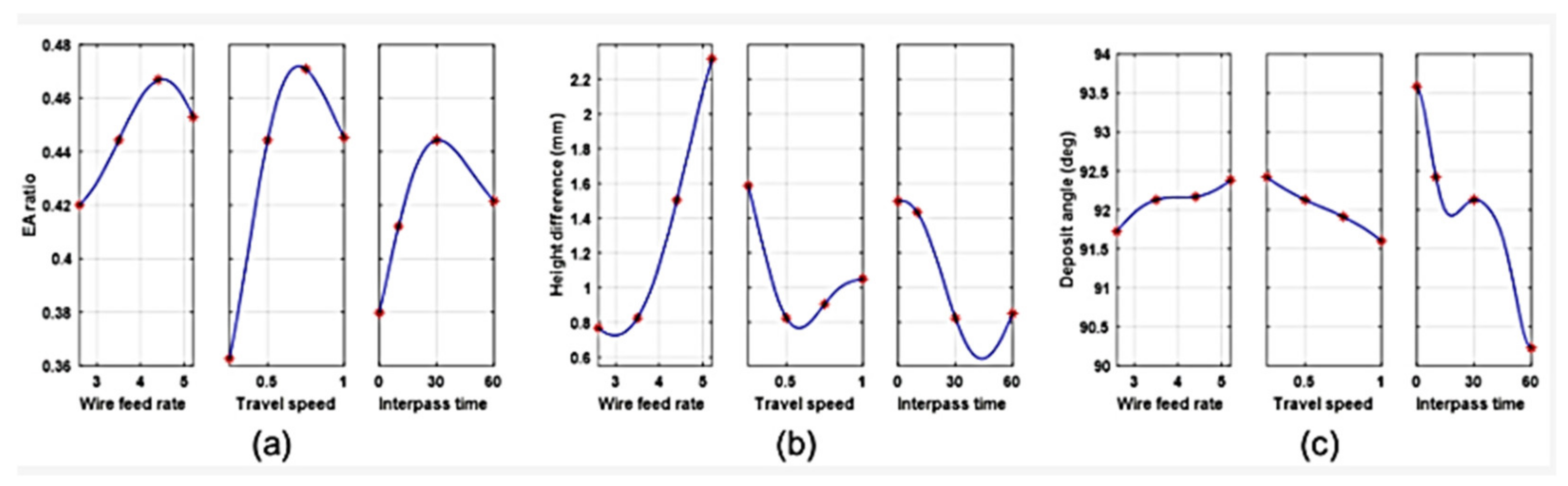

- Lee, S.H. Optimization of Cold Metal Transfer-Based Wire Arc Additive Manufacturing Processes Using Gaussian Process Regression. Metals 2020, 10, 461. [Google Scholar] [CrossRef] [Green Version]

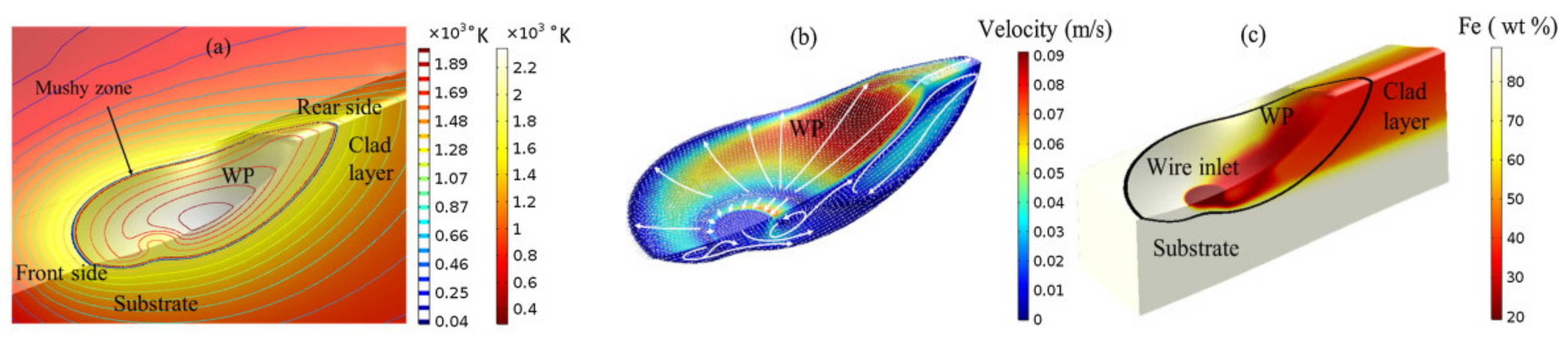

- Hejripour, F.; Valentine, D.T.; Aidun, D.K. Study of mass transport in cold wire deposition for Wire Arc Additive Manufacturing. Int. J. Heat Mass Transf. 2018, 125, 471–484. [Google Scholar] [CrossRef]

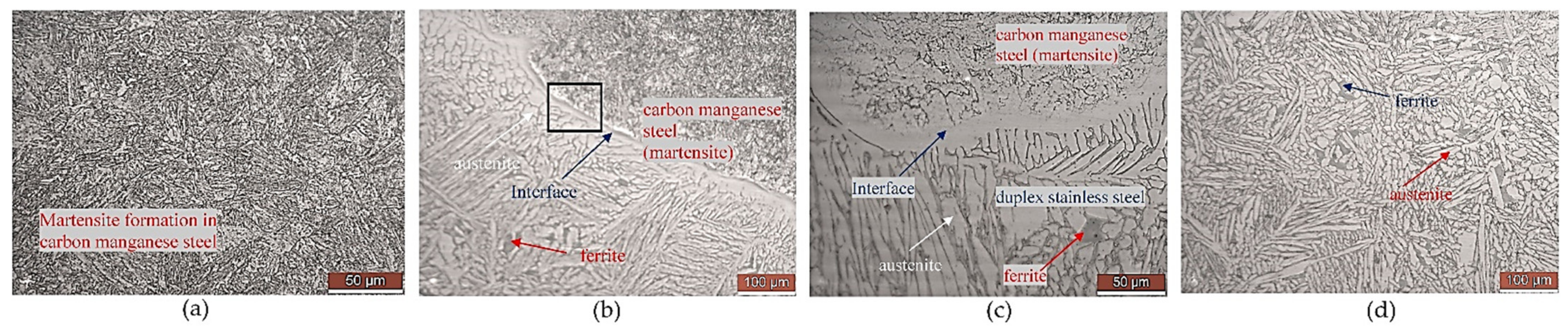

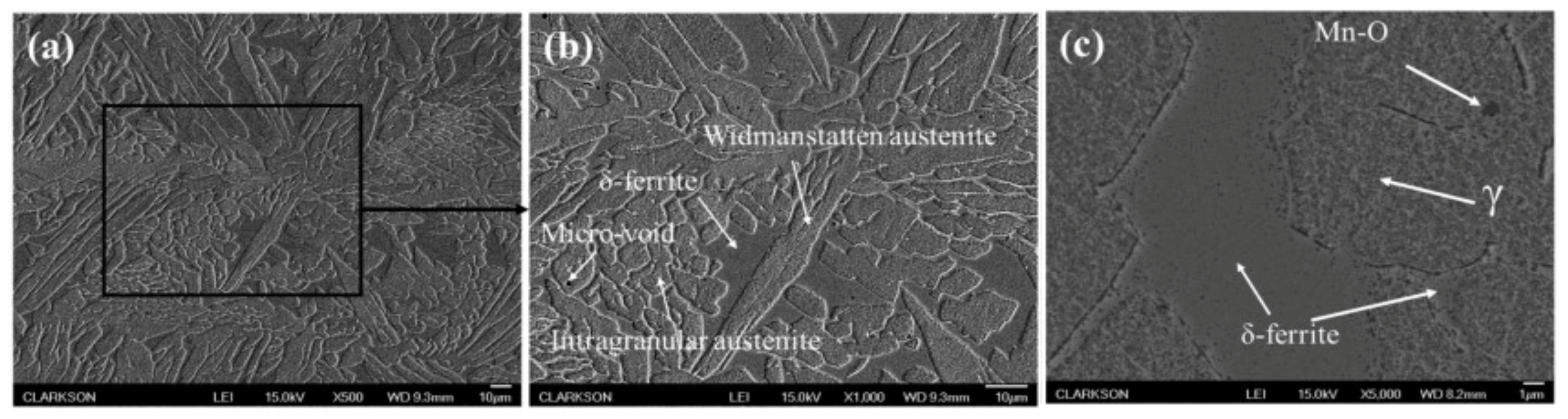

- Hejripour, F.; Binesh, F.; Hebel, M.; Aidun, D.K. Thermal modeling and characterization of wire arc additive manufactured duplex stainless steel. J. Mater. Process. Technol. 2019, 272, 58–71. [Google Scholar] [CrossRef]

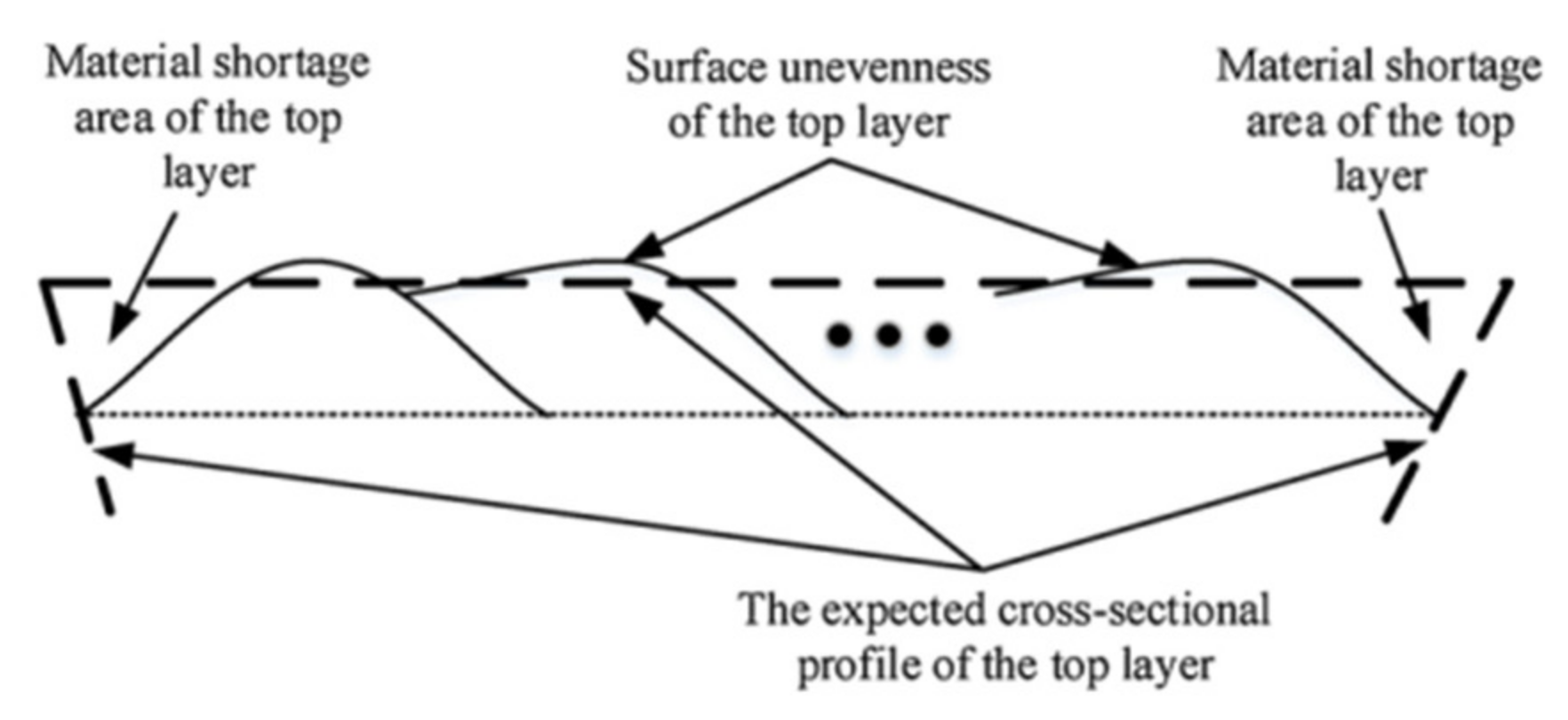

- Li, Y.; Sun, Y.; Han, Q.; Zhang, G.; Horváth, I. Enhanced beads overlapping model for wire and arc additive manufacturing of multi-layer multi-bead metallic parts. J. Mater. Process. Technol. 2018, 252, 838–848. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Horváth, I.; Zhang, G. GMAW-based additive manufacturing of inclined multi-layer multi-bead parts with flat-position deposition. J. Mater. Process. Technol. 2018, 262, 359–371. [Google Scholar] [CrossRef]

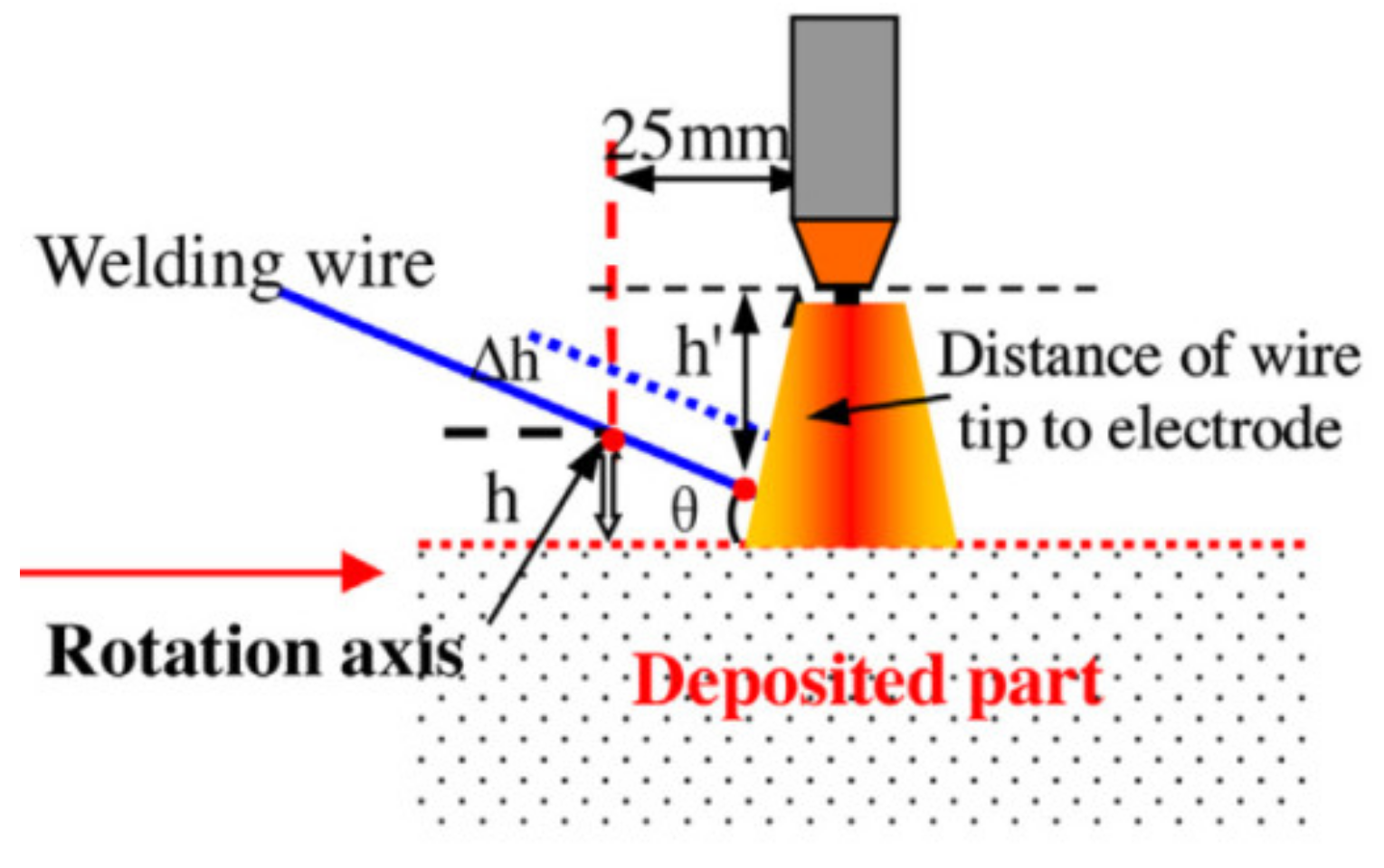

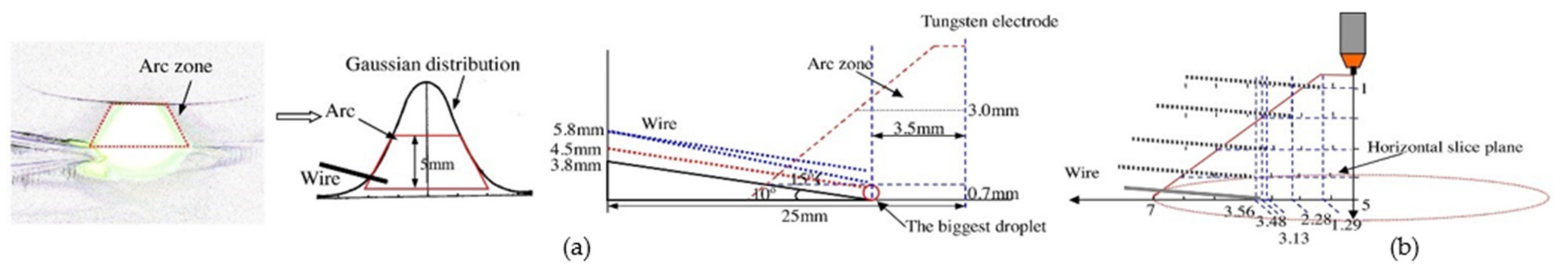

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Optimization of wire feed for GTAW based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

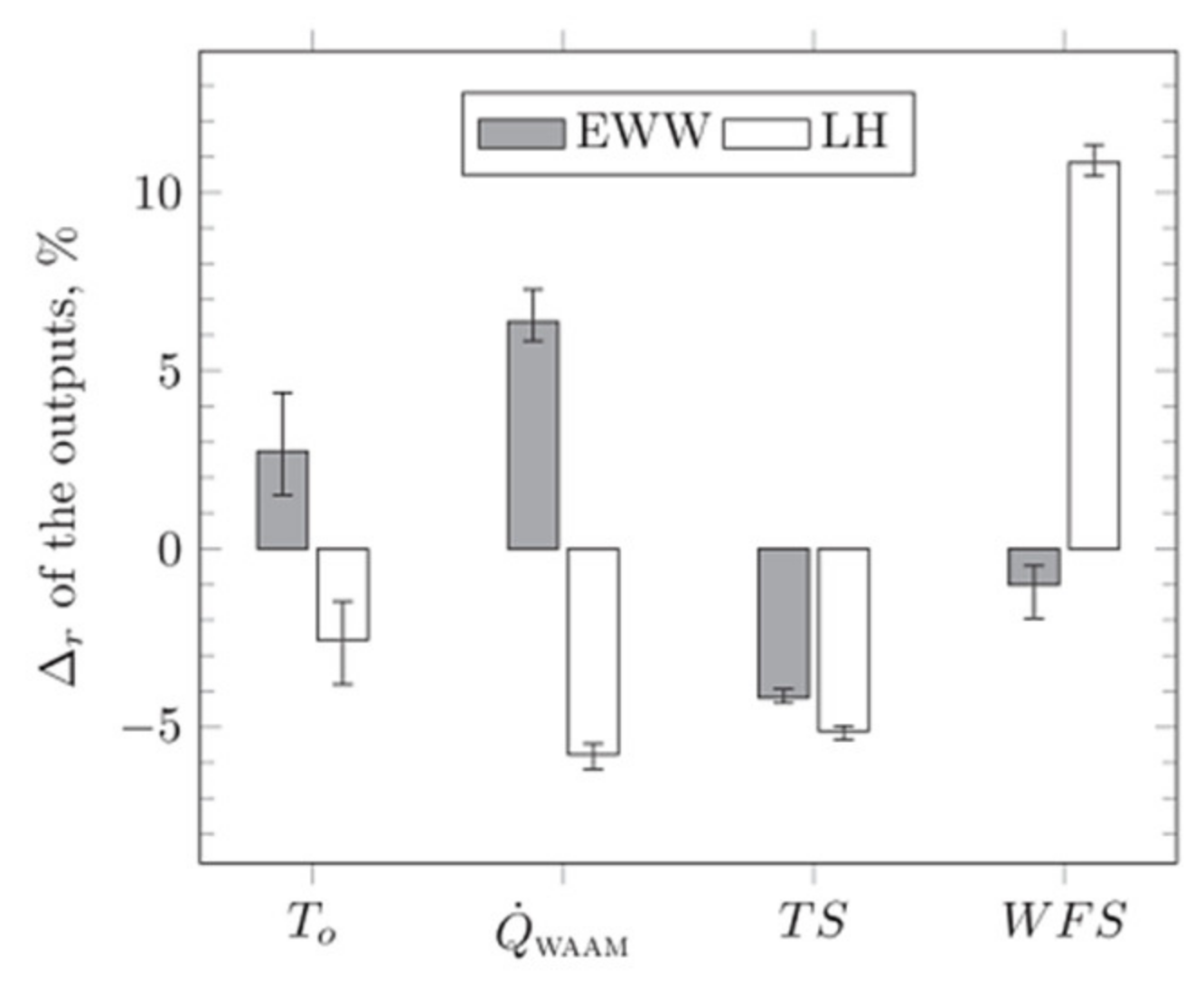

- Oyama, K.; Diplas, S.; M’Hamdi, M.; Gunnæs, A.E.; Azar, A.S. Heat source management in wire-arc additive manufacturing process for Al-Mg and Al-Si alloys. Addit. Manuf. 2019, 26, 180–192. [Google Scholar] [CrossRef]

- Montevecchi, F.; Venturini, G.; Grossi, N.; Scippa, A.; Campatelli, G. Heat accumulation prevention in Wire-Arc-Additive-Manufacturing using air jet impingement. Manuf. Lett. 2018, 17, 14–18. [Google Scholar] [CrossRef]

- Li, X.; Reynolds, A.P.; Baoqiang, C.; Jialuo, D.; Williams, S. Production and properties of a wire-arc additive manufacturing part made with friction extruded wire. In Proceedings of the TMS 2015 144th Annual Meeting & Exhibition, Orlando, FL, USA, 15–19 March 2015; Springer: Cham, Germany, 2015; pp. 445–452. [Google Scholar]

- Dharmendra, C.; Shakerin, S.; Ram, G.J.; Mohammadi, M. Wire-arc additive manufacturing of nickel aluminum bronze/stainless steel hybrid parts – Interfacial characterization, prospects, and problems. Materialia 2020, 13, 100834. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM Deposition Patterns for T-crossing Features. Procedia CIRP 2016, 55, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Martina, F.; Roy, M.J.; Szost, B.A.; Terzi, S.; Colegrove, P.A.; Williams, S.W.; Withers, P.J.; Meyer, J.; Hofmann, M. Residual stress of as-deposited and rolled wire+ arc additive manufacturing Ti–6Al–4V components. Mater. Sci. Technol. 2016, 32, 1439–1448. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Gao, M.; Zeng, X. Workpiece vibration augmented wire arc additive manufacturing of high strength aluminum alloy. J. Mater. Process. Technol. 2019, 271, 85–92. [Google Scholar] [CrossRef]

- Hönnige, J.; Colegrove, P.; Ahmad, B.; Fitzpatrick, M.; Ganguly, S.; Lee, T.; Williams, S. Residual stress and texture control in Ti-6Al-4V wire + arc additively manufactured intersections by stress relief and rolling. Mater. Des. 2018, 150, 193–205. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Pan, Z.; Chen, G.; Ding, D.; Yuan, L.; Cuiuri, D.; Li, H. Mitigation of thermal distortion in wire arc additively manufactured Ti6Al4V part using active interpass cooling. Sci. Technol. Weld. Join. 2019, 24, 484–494. [Google Scholar] [CrossRef]

- Gu, J.; Bai, J.; Ding, J.; Williams, S.; Wang, L.; Liu, K. Design and cracking susceptibility of additively manufactured Al-Cu-Mg alloys with tandem wires and pulsed arc. J. Mater. Process. Technol. 2018, 262, 210–220. [Google Scholar] [CrossRef]

- Näsström, J.; Brueckner, F.; Kaplan, A.F.H. Laser enhancement of wire arc additive manufacturing. J. Laser Appl. 2019, 31, 022307. [Google Scholar] [CrossRef]

- Corradi, D.R.; Bracarense, A.Q.; Wu, B.; Cuiuri, D.; Pan, Z.; Li, H. Effect of Magnetic Arc Oscillation on the geometry of single-pass multi-layer walls and the process stability in wire and arc additive manufacturing. J. Mater. Process. Technol. 2020, 283, 116723. [Google Scholar] [CrossRef]

- Hauser, T.; Da Silva, A.; Reisch, R.T.; Volpp, J.; Kamps, T.; Kaplan, A.F. Fluctuation effects in Wire Arc Additive Manufacturing of aluminium analysed by high-speed imaging. J. Manuf. Process. 2020, 56, 1088–1098. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Mann, S.; Oster, L. Increasing the manufacturing efficiency of WAAM by advanced cooling strategies. Weld. World 2020, 64, 1409–1416. [Google Scholar] [CrossRef]

| Ref No. | WAAM Constraint Addressed | Proposed Redressal Scheme | Effect on Microstructure/Mechanical Properties | Demerits/Limitations |

|---|---|---|---|---|

| Raw Material | ||||

| [86] | Limited availability of feedstock wires | Production of AA6061 by friction extrusion | Microstructure-strength and hardness comparable to standard WAAM with AA6061 base metal | Presence of voids and bends in extruded wires. To eliminate twisting, drawing wire more than once required |

| [87] | Feasibility and crack sensitivity of hybrid parts manufacturing | Production of Nickel Aluminum Bronze-Stainless Steel hybrid parts | Fine equiaxed alpha dendrites, good surface properties | Inter-metallics formation, penetration of NAB along the HAZ cracks, rosette like particles due to dilution defects-negatively affecting toughness and ductility |

| Deposition Method | ||||

| [41] | To overcome freeform manufacturing issues of collision, deposited material causing obstruction and overlapping points at intersections. | Local control on geometry of deposition by on-line adaptive slicing and deposition strategies to manage branch intersections | Yielded appropriate positioning of skeleton freeform branches in intersection. In-situ monitoring enables online gap-checking and required weld torch orientation. | - |

| [83] | Deposition Accuracy inside feed orientation | Displacement compensation & wire feed angle manipulation | Consistent layer deposition, control of droplet landing position | Chance of wire getting flexed through the arc column |

| [88] | Residual Stress, manual control for the same layer height | Deposition path definition for T-cross builds | Increased utilization, increased failure of? free parts, deposition efficiency | Balance between productivity and material usage efficiency |

| Stress & Distortion | ||||

| [89] | Residual stresses and distortion | Inter-pass rolling | Increase in wall width, uniform layer height | Increased manufacturing time |

| [90] | High porosity, coarse microstructure, low mechanical performance | Workpiece vibration | Dendrite breakage and grain refinement, reduced porosity, improved tensile properties | Elongation and anisotropy negatively affected |

| [91] | Tensile stresses | Interpass rolling and thermal stress relief | Improved mechanical properties with reduced grain size | Dominant thermal history, no significant difference to final residual stress |

| [92] | Part Distortion | Inter-pass cooling using compressed CO2. To be considered in the path planning strategy for improved geometry | Improved dimensional accuracy | Change in CO2 gas flow rate may cause in-homogenous stress and distortion to the build. Unrestrained shrinkage prevents complete distortion elimination |

| Heat Source Design | ||||

| [85] | Heat Accumulation | Impinging air jets through a vortex to increase convective heat transfer | Effective control of the inter-pass temperature, excessive increase in molten pool size | Needs to be investigated for complex configurations |

| [93] | Surface Cracking because of various factors such as alloy composition, high wire feed speed | Influence of composition, heat input, mechanical properties studied | Proposed model can predict solidification cracking tendency, higher microhardness reduces crack susceptibility | Insufficient feed causes crack initiation |

| [94] | Dimensional inaccuracy | Laser assisted WAAM-leading/trailing laser beam | Improved surface topology, dense samples with no porosity | Increased experimentation and simulation trials, excessive melting may cause premature deposition |

| [95] | Process instability, inaccurate build geometry | Magnetic arc oscillation | Homogenous thin wall depositions achieved, reduced power density, reduced volume and weight of weld pool, reduced solidification time | Surface variation due to varying arc position |

| [96] | Irregularities in the build structure because of thermal gradients | Multilayer laser assisted WAAM to study impact of different lead angles and interlayer temperatures. Also studied effect of variation in dragging and pushing WAAM process | Wider melt pool, better track wetting on the substrate, optimum lead angle identified as 10 degrees | Fluctuations observed at lead angles other than 10 degrees and at higher interlayer temperatures in dragging WAAM processsmakal |

| [97] | Slow manufacturing Speed because of cooling techniques | Aerosol cooling during the manufacturing | No porosity or weld defects highlighted, Weld seam shape and dendritic structure are similar, smaller dendrites and higher hardness compared to uncooled weld | Unsteady drops in temperature, asymmetric weld seam shape |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals 2021, 11, 939. https://doi.org/10.3390/met11060939

Chaturvedi M, Scutelnicu E, Rusu CC, Mistodie LR, Mihailescu D, Subbiah AV. Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals. 2021; 11(6):939. https://doi.org/10.3390/met11060939

Chicago/Turabian StyleChaturvedi, Mukti, Elena Scutelnicu, Carmen Catalina Rusu, Luigi Renato Mistodie, Danut Mihailescu, and Arungalai Vendan Subbiah. 2021. "Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization" Metals 11, no. 6: 939. https://doi.org/10.3390/met11060939

APA StyleChaturvedi, M., Scutelnicu, E., Rusu, C. C., Mistodie, L. R., Mihailescu, D., & Subbiah, A. V. (2021). Wire Arc Additive Manufacturing: Review on Recent Findings and Challenges in Industrial Applications and Materials Characterization. Metals, 11(6), 939. https://doi.org/10.3390/met11060939