The Effects of Annealing at Different Temperatures on Microstructure and Mechanical Properties of Cold-Rolled Al0.3CoCrFeNi High-Entropy Alloy

Abstract

1. Introduction

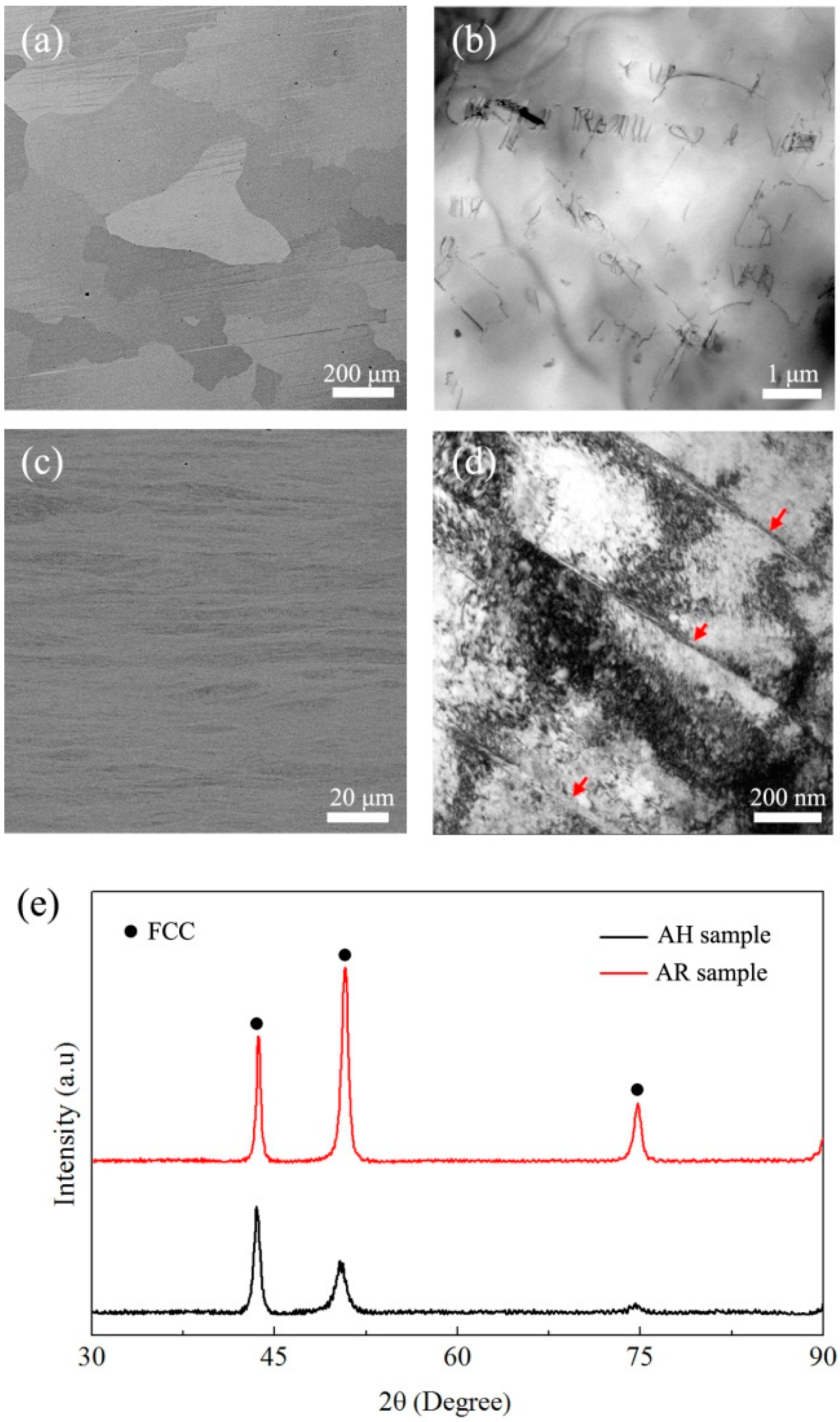

2. Materials and Methods

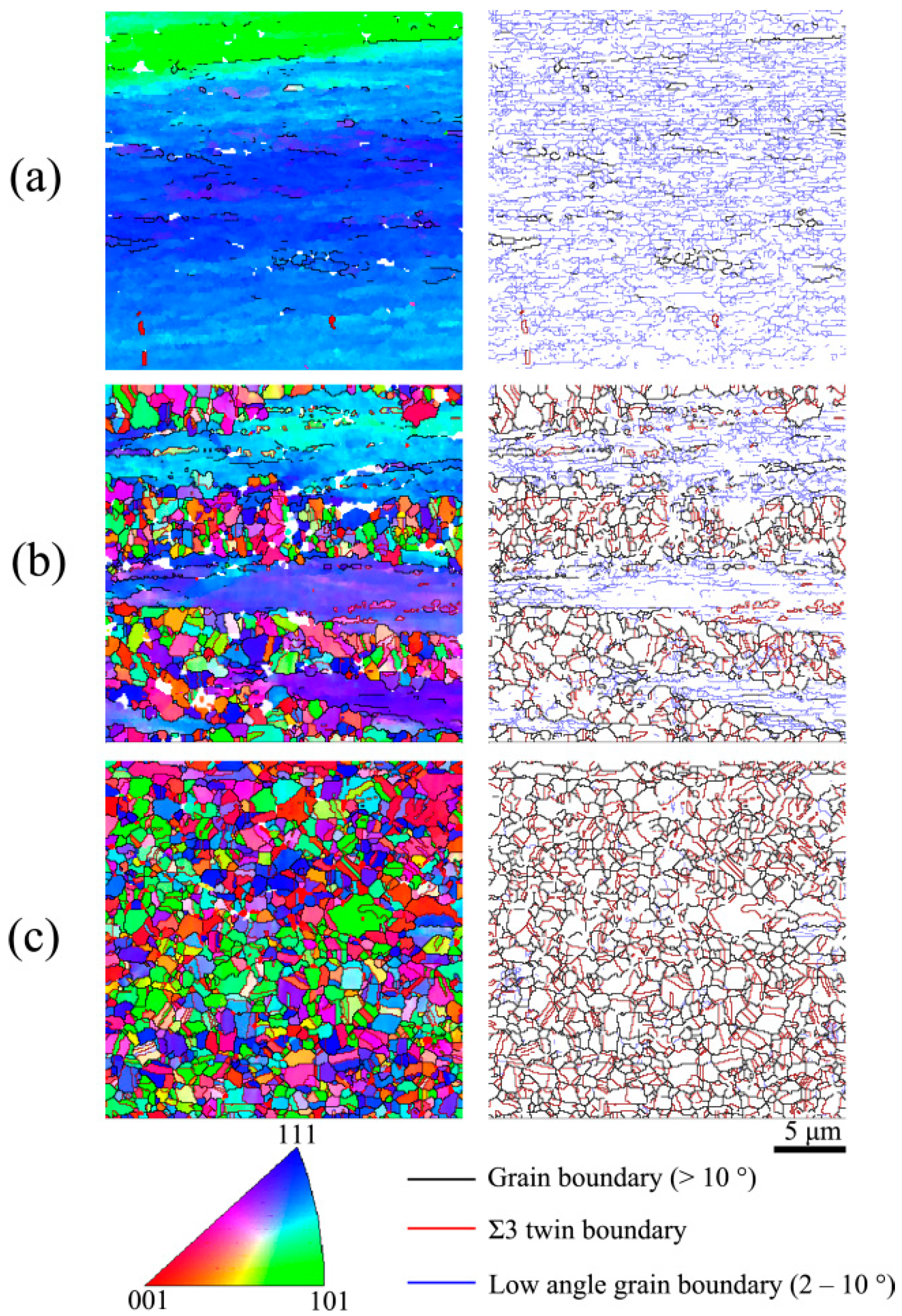

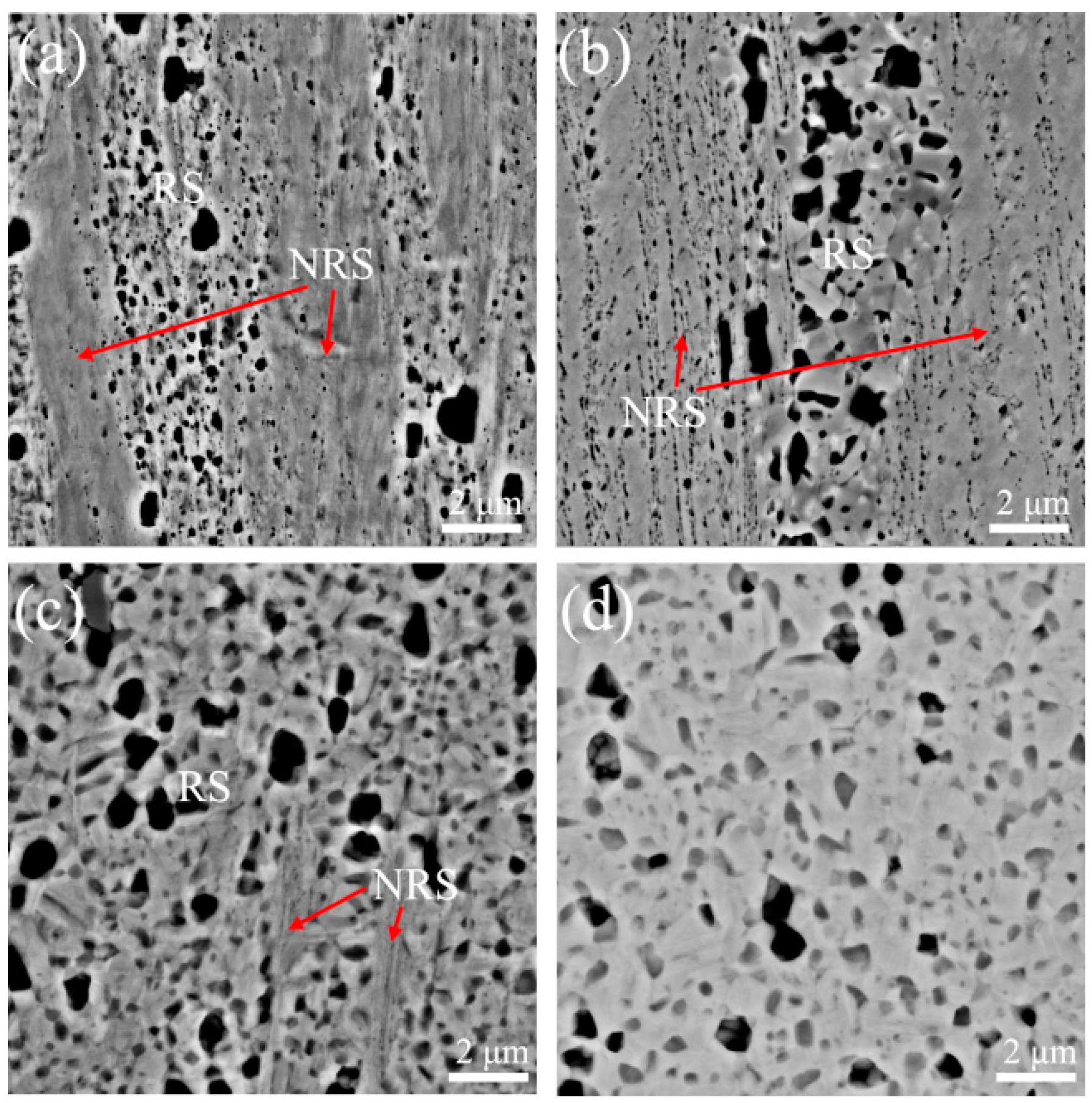

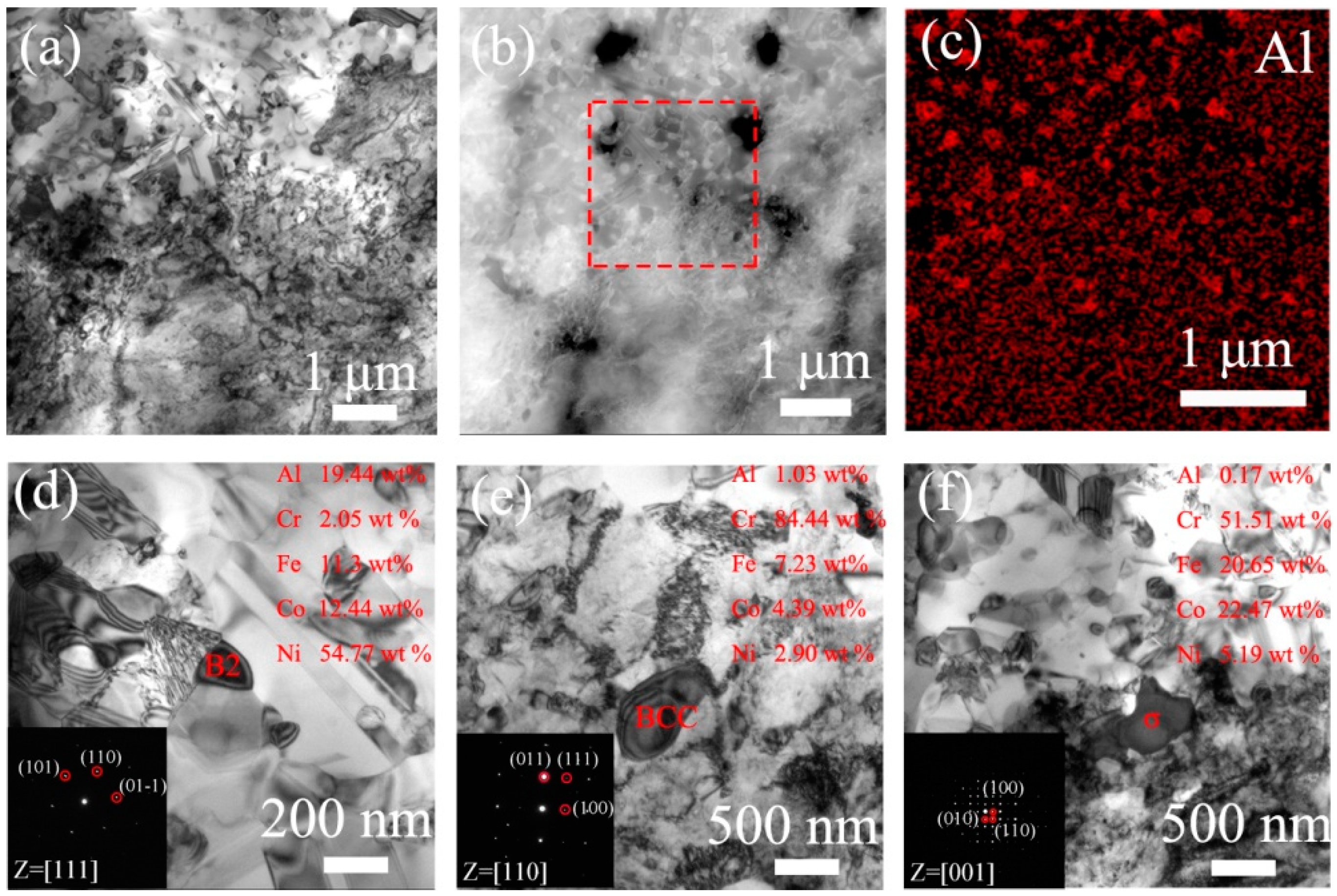

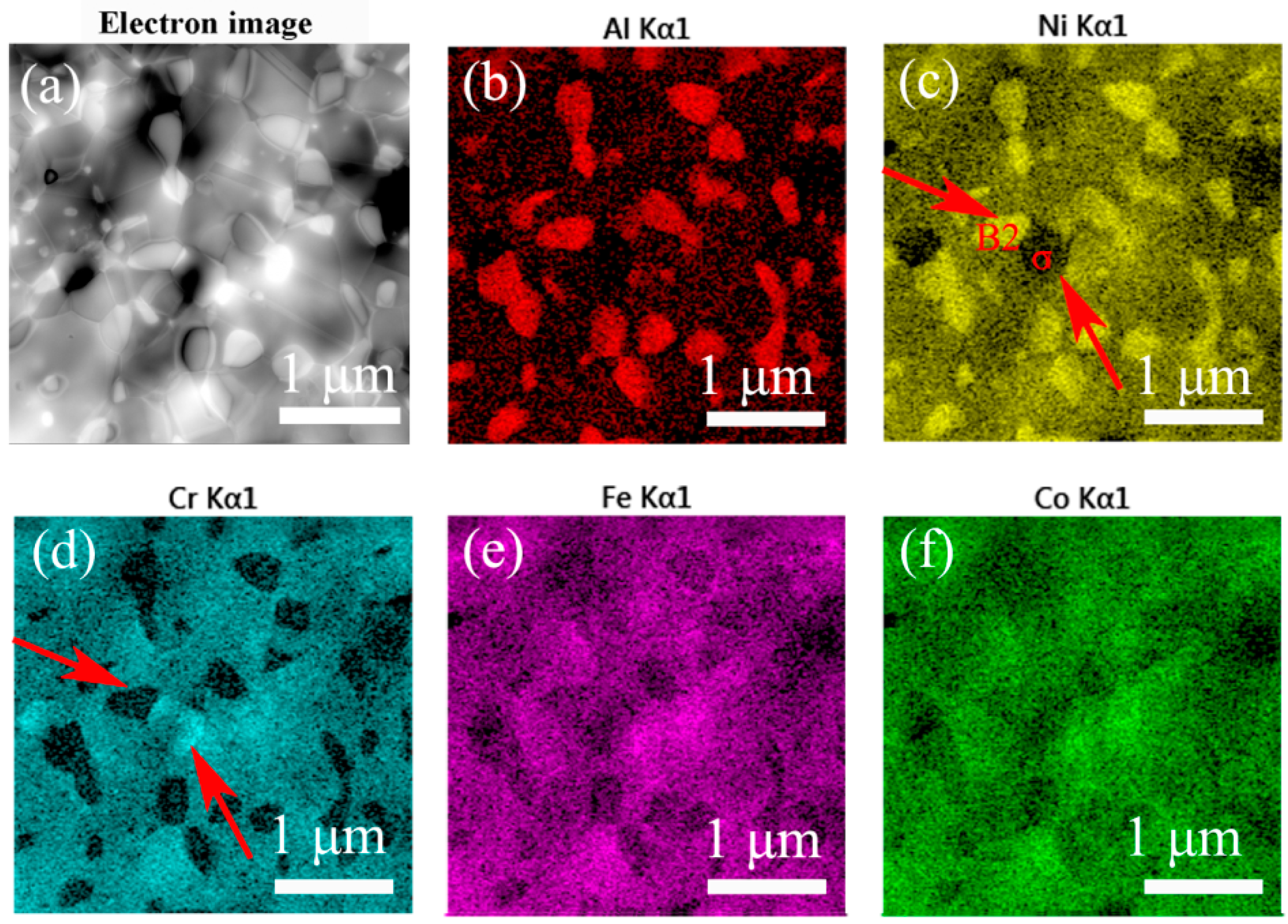

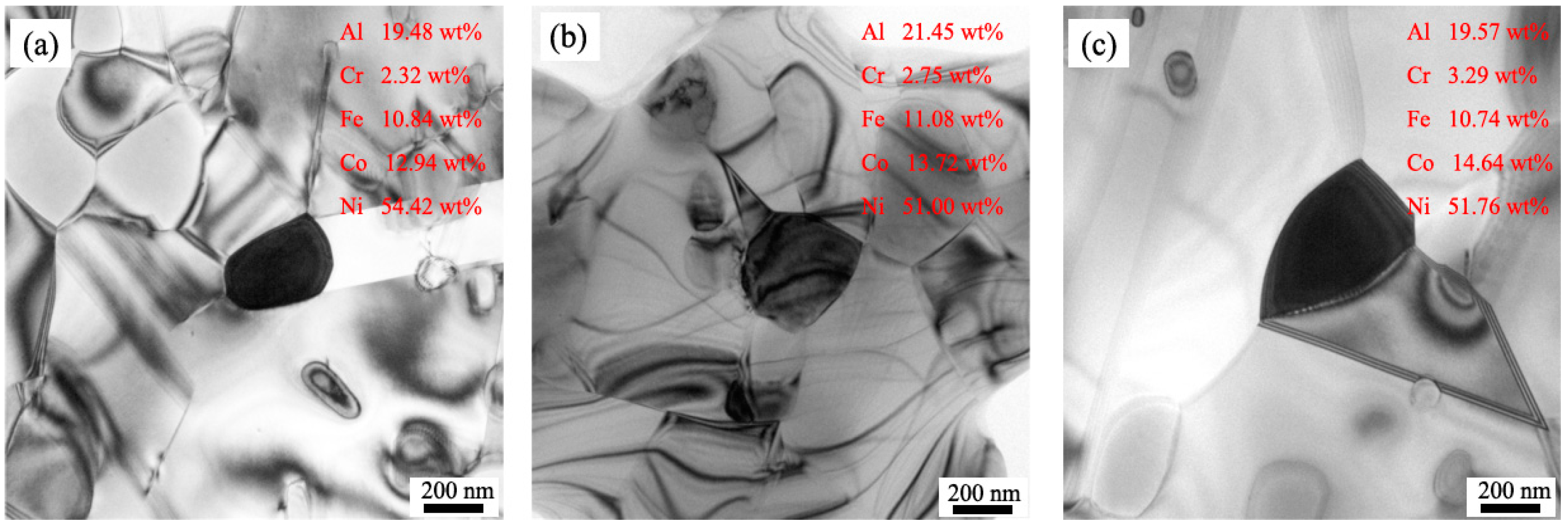

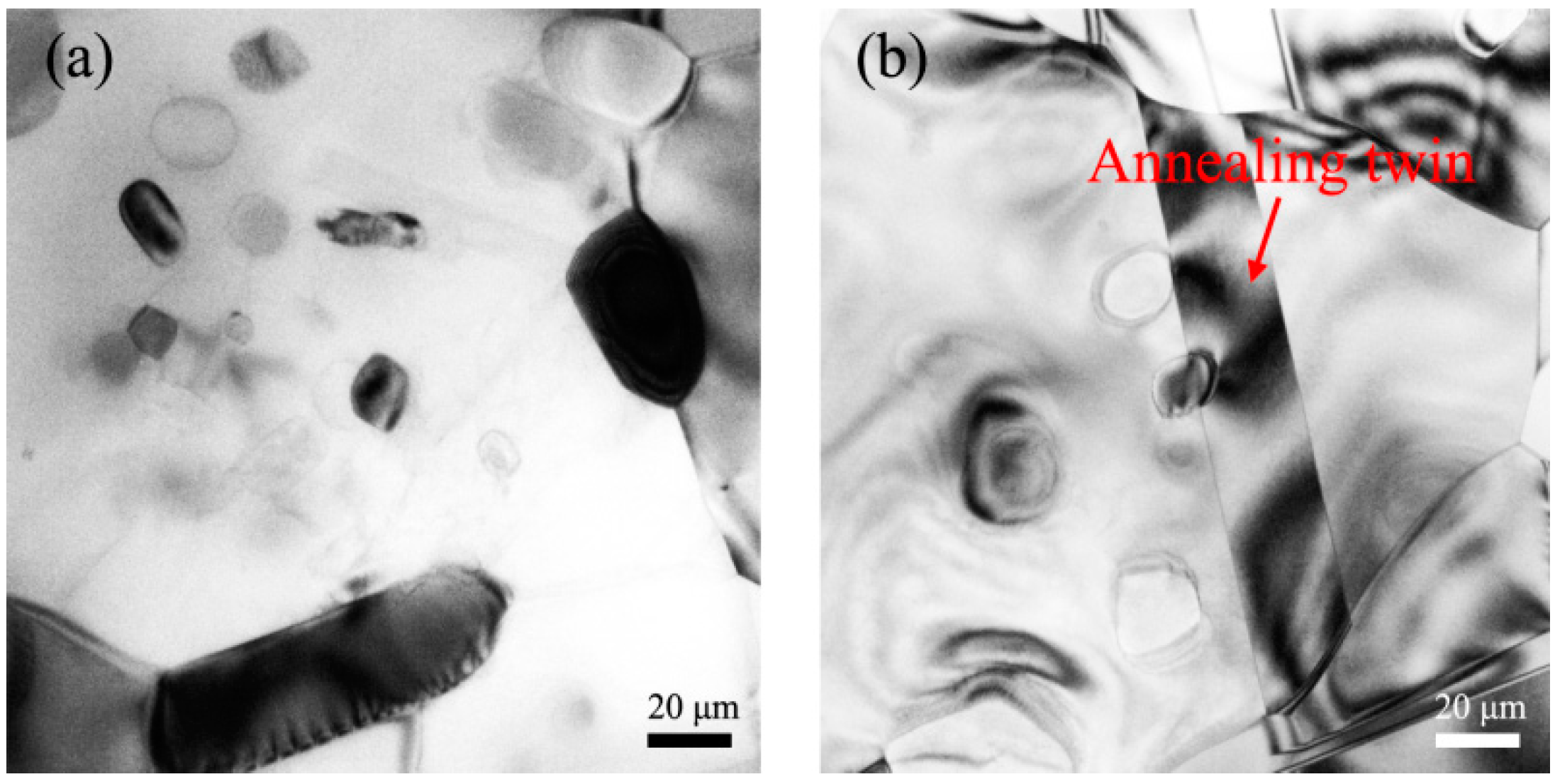

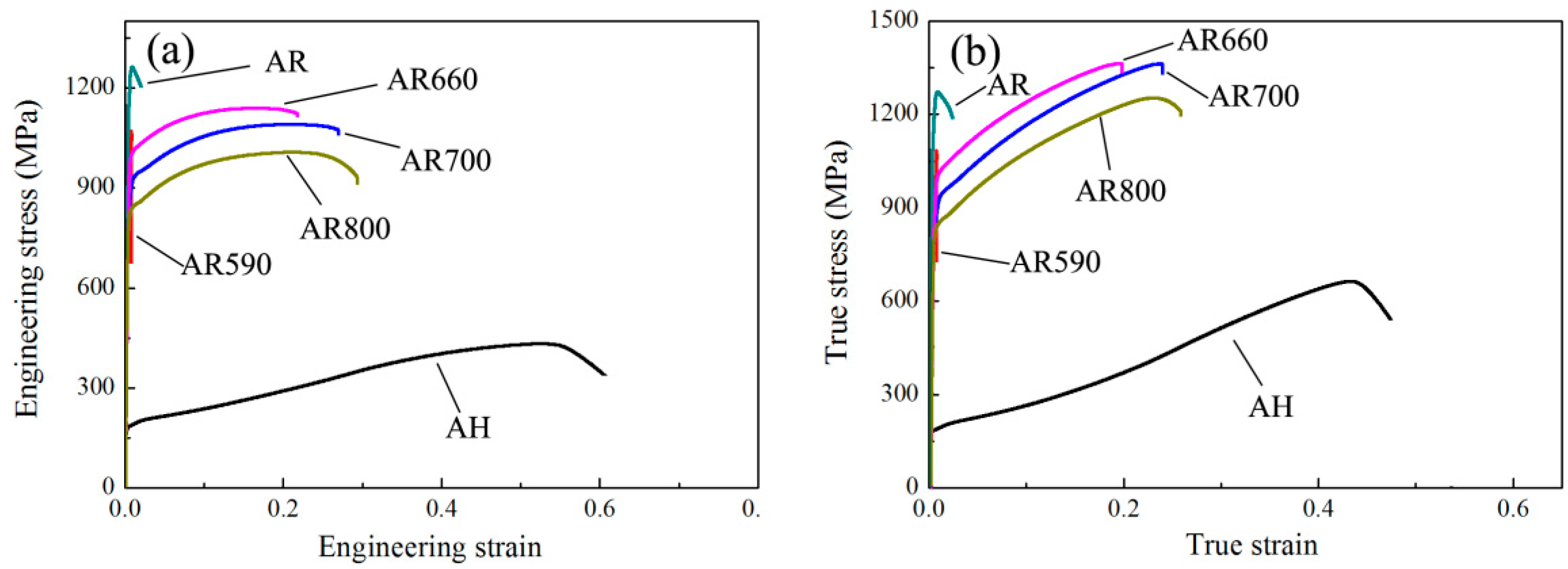

3. Results

4. Discussion

4.1. Influence of Cold-Rolling on Precipitation Behavior

4.2. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Diogo, C.; Pedro, J.; Catarina, B.A.; Pedro, O.J. An overview of high-entropy alloys as biomaterials. Metals 2021, 11, 648. [Google Scholar]

- Laurent-Brocq, M.; Akhatova, A.; Perriere, L.; Chebini, S.; Sauvage, X.; Leroy, E.; Champion, Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy. Acta Mater. 2015, 88, 355–365. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: The effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Lee, C.F.; Shun, T.T. Age heat treatment of Al0.5CoCrFe1.5NiTi0.5 high-entropy alloy. Metals 2021, 11, 91. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhy, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Nene, S.S.; Frank, M.; Liu, K.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Extremely high strength and work hardening ability in a metastable high entropy alloy. Sci. Rep. 2018, 8, 9920. [Google Scholar] [CrossRef]

- Juan, C.C.; Tsai, M.H.; Tsai, C.W.; Hsu, W.L.; Lin, C.M.; Chen, S.K.; Lin, S.; Yeh, J.W. Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 2016, 184, 200–203. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Q.; Chen, X.; Jayalakshmi, S.; Singh, R.A.; Konovalov, S.; Deev, V.B.; Prusov, E.S. Strengthening mechanisms in CoCrFeNiX0.4 (Al, Nb, Ta) high entropy alloys fabricated by powder plasma arc additive manufacturing. Nanomaterials 2021, 11, 721. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Shim, S.H.; Kim, Y.K.; Rizi, M.S.; Noh, H.; Hong, S.I. Microstructure evolution and mechanical properties of (CoCrNi)90(AlTiZr)5(CuFeMo)5 multicomponent alloy: A pathway through multicomponent alloys toward new superalloys. J. Alloys Compd. 2021, 860, 158412. [Google Scholar] [CrossRef]

- Song, J.S.; Lee, B.J.; Moon, W.J.; Hong, S.I. Mechanical performance and microstructural evolution of (NiCo)75Cr17Fe8Cx (x = 0~0.83) medium entropy alloys at room and cryogenic temperatures. Metals 2020, 10, 1646. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Y.X.; Cui, S.G.; Yi, Y.L.; Xing, X.W.; Wang, X.J.; Li, W. Effect of Mo element on the mechanical properties and tribological responses of CoCrFeNiMox high-entropy alloys. Metals 2021, 11, 486. [Google Scholar] [CrossRef]

- Wang, J.; Wei, C.; Yang, H.X.; Guo, T.; Xu, T.T.; Li, J.S. Phase transformation kinetics of a FCC Al0.25CoCrFeNi high-entropy alloy during isochronal heating. Metals 2018, 8, 1015. [Google Scholar] [CrossRef]

- Osintsev, K.A.; Konovalov, S.V.; Glezer, A.M.; Gromov, V.E.; Ivanov, Y.F.; Panchenko, I.A.; Sundeev, R.V. Research on the structure of Al2.1Co0.3Cr0.5FeNi2.1 high-entropy alloy at submicro- and nano-scale levels. Mater. Lett. 2021, 294, 129717. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Asghari-Rad, P.; Park, J.M.; Moon, J.; Bae, J.W.; Zargaran, A.; Kim, H.S. Exceptional cryogenic strength-ductility synergy in Al0.3CoCrNi medium-entropy alloy through heterogeneous grain structure and nano-scale precipitates. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2019, 766, 138372. [Google Scholar] [CrossRef]

- Gwalani, B.; Soni, V.; Lee, M.; Mantri, S.A.; Ren, Y.; Banerjee, R. Optimizing the coupled effects of Hall-Petch and precipitation strengthening in a Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2017, 121, 254–260. [Google Scholar] [CrossRef]

- Dasari, S.; Sarkar, A.; Sharma, A.; Gwalani, B.; Choudhuri, D.; Soni, V.; Manda, S.; Samajdar, I.; Banerjee, R. Recovery of cold-worked Al0.3CoCrFeNi complex concentrated alloy through twinning assisted B2 precipitation. Acta Mater. 2021, 202, 448–462. [Google Scholar] [CrossRef]

- Shun, T.T.; Du, Y.C. Microstructure and tensile behaviors of FCC Al0.3CoCrFeNi high entropy alloy. J. Alloys Compd. 2009, 479, 157–160. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Zheng, Y.; Mishra, R.S.; Banerjee, R. Tensile yield strength of a single bulk Al 0.3 CoCrFeNi high entropy alloy can be tuned from 160 MPa to 1800 MPa. Scr. Mater. 2019, 162, 18–23. [Google Scholar] [CrossRef]

- Tang, Q.H.; Huang, Y.; Cheng, H.; Liao, X.Z.; Langdon, T.G.; Dai, P.Q. The effect of grain size on the annealing-induced phase transformation in an Al0.3CoCrFeNi high entropy alloy. Mater. Des. 2016, 105, 381–385. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, W.; Song, S.; Reddy, K.M.; Wang, X. Effect of deformation induced B2 precipitates on the microstructure and mechanical property of Al0.3CoCrFeNi high-entropy alloy. J. Alloys Compd. 2020, 821, 153445. [Google Scholar] [CrossRef]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Recrystallization of two-phase alloys, recrystallization and related annealing phenomena. Elsevier 2017, 321–359. Available online: https://www.sciencedirect.com/science/article/pii/B9780080982359000094?via%3Dihub (accessed on 7 June 2021).

- Li, Q.; Zhang, T.W.; Qiao, J.W.; Ma, S.G.; Zhao, D.; Lu, P.; Xu, B.; Wang, Z.H. Superior tensile properties of Al0.3CoCrFeNi high entropy alloys with B2 precipitated phases at room and cryogenic temperatures. Mater. Sci. Eng. A 2019, 767, 138424. [Google Scholar] [CrossRef]

- Kivy, M.B.; Zaeem, M.A. Generalized stacking fault energies, ductilities, and twinnabilities of CoCrFeNi-based face-centered cubic high entropy alloys. Scr. Mater. 2017, 139, 83–86. [Google Scholar] [CrossRef]

- Song, B.; Du, Z.W.; Guo, N.; Yang, Q.S.; Wang, F.; Guo, S.F.; Xin, R.L. Effect of free-end torsion on microstructure and mechanical properties of AZ31 bars with square section. J. Mater. Sci. Technol. 2021, 69, 20–31. [Google Scholar] [CrossRef]

- Yasuda, H.Y.; Miyamoto, H.; Cho, K.; Nagase, T. Formation of ultrafine-grained microstructure in Al0.3CoCrFeNi high entropy alloys with grain boundary precipitates. Mater. Lett. 2017, 199, 120–123. [Google Scholar] [CrossRef]

- Klimova, M.V.; Semenyuk, A.O.; Shaysultanov, D.G.; Salishchev, G.A.; Zherebtsov, S.V.; Stepanov, N.D. Effect of carbon on cryogenic tensile behavior of CoCrFeMnNi-type high entropy alloys. J. Alloys Compd. 2019, 811, 152000. [Google Scholar] [CrossRef]

- Barbier, D.; Gey, N.; Allain, S.; Bozzolo, N.; Humbert, M. Analysis of the tensile behavior of a TWIP steel based on the texture and microstructure evolutions. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2009, 500, 196–206. [Google Scholar] [CrossRef]

- Dasari, S.; Jagetia, A.; Chang, Y.J.; Soni, V.; Gwalani, B.; Gorsse, S.; Yeh, A.C.; Banerjee, R. Engineering multi-scale B2 precipitation in a heterogeneous FCC based microstructure to enhance the mechanical properties of a Al0.5Co1.5CrFeNi1.5 high entropy alloy. J. Alloys Compd. 2020, 830, 154707. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Furuhara, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Gwalani, B.; Gorsse, S.; Choudhuri, D.; Styles, M.; Zheng, Y.F.; Mishra, R.S.; Banerjee, R. Modifying transformation pathways in high entropy alloys or complex concentrated alloys via thermo-mechanical processing. Acta Mater. 2018, 153, 169–185. [Google Scholar] [CrossRef]

- Li, S.J.; Zhu, Q.S.; Zheng, B.D.; Yuan, J.; Wang, X.J. Nano-scale twinned Cu with ultrahigh strength prepared by direct current electrodeposition. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2019, 758, 1–6. [Google Scholar] [CrossRef]

- Kumar, N.; Komarasamy, M.; Nelaturu, P.; Tang, Z.; Liaw, P.K.; Mishra, R.S. Friction Stir Processing of a High Entropy Alloy Al0.1CoCrFeNi. JOM 2015, 67, 1007–1013. [Google Scholar] [CrossRef]

- Song, B.; Xin, R.L.; Chen, G.; Zhang, X.Y.; Liu, Q. Improving tensile and compressive properties of magnesium alloy plates by pre-cold rolling. Scripta Mater. 2012, 66, 1061–1064. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Park, J.M.; Moon, J.; Bae, J.W.; Asghari-Rad, P.; Zargaran, A.; Kim, H.S. Achieving high strength and high ductility in Al0.3CoCrNi medium-entropy alloy through multi-phase hierarchical microstructure. Materialia 2019, 8. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.Y.; Harrington, T.; Vecchio, K. Design of non-equiatomic high entropy alloys with heterogeneous lamella structure towards strength-ductility synergy. Scripta Mater. 2018, 154, 78–82. [Google Scholar] [CrossRef]

- Shukla, S.; Choudhuri, D.; Wang, T.; Liu, K.; Wheeler, R.; Williams, S.; Gwalani, B.; Mishra, R.S. Hierarchical features infused heterogeneous grain structure for extraordinary strength-ductility synergy. Mater. Res. Lett. 2018, 6, 676–682. [Google Scholar] [CrossRef]

- Yang, M.X.; Pan, Y.; Yuan, F.P.; Zhu, Y.T.; Wu, X.L. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Wani, I.S.; Sheikh, S.; Clark, I.T.; Okawa, T.; Guo, S.; Bhattacharjee, P.P.; Tsuji, N. Simultaneous strength-ductility enhancement of a nano-lamellar AlCoCrFeNi2.1 eutectic high entropy alloy by cryo-rolling and annealing. Sci. Rep. 2018, 8, 3276. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.K.; Lee, B.J.; Hong, S.K.; Hong, S.I. Strengthening and fracture of deformation-processed dual fcc-phase CoCrFeCuNi and CoCrFeCu1.71Ni high entropy alloys. Mater. Sci. Eng. A 2020, 781, 139241. [Google Scholar] [CrossRef]

| Sample | Processing History |

|---|---|

| AH | The as-cast sample |

| AR | AH sample cold-rolled by a thickness reduction of 90% |

| AR590 | AR sample annealed at 590 °C for 24 h |

| AR660 | AR sample annealed at 660 °C for 24 h |

| AR700 | AR sample annealed at 700 °C for 10 h |

| AR800 | AR sample annealed at 800 °C for 10 h |

| Sample | LABs (μm−1) | Σ3Bs (μm−1) |

|---|---|---|

| AR | 0.265 | 0.001 |

| AR660-RS | 0.011 | 0.031 |

| AR660-NRS | 0.141 | 0.007 |

| AR800 | 0.009 | 0.034 |

| Sample | AR660 | AR800 | |

|---|---|---|---|

| RS | NRS | ||

| Ap (μm2) | 0.018 ± 0.002 | 0.005 ± 0.003 | 0.019 ± 0.001 |

| Af (%) | 35.2 ± 5.1 | 19.9 ± 3.3 | 32.1 ± 2.1 |

| Sample | AR | AR590 | AR660 | AR700 | AR800 |

|---|---|---|---|---|---|

| fRS | 0% | 26.9% ± 0.3% | 74.3% ± 0.7% | 87.7% ± 0.2% | 95.9% ± 0.3% |

| Sample | YS (MPa) | PS (MPa) | UE |

|---|---|---|---|

| AH | 170 | 659 | 43.3% |

| AR | 1060 | 1273 | 0.4% |

| AR590 | 995 | 1065 | 0.1% |

| AR660 | 1020 | 1366 | 19.4% |

| AR700 | 939 | 1362 | 23.3% |

| AR800 | 837 | 1248 | 22.7% |

| Sample | AH | AR | AR590 | AR660 | AR700 | AR800 |

|---|---|---|---|---|---|---|

| UT (MJ/m3) | 223 | 27 | 5 | 238 | 280 | 281 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Yang, T.; Shi, R.; Quan, X.; Zhang, J.; Qiu, R.; Song, B.; Liu, Q. The Effects of Annealing at Different Temperatures on Microstructure and Mechanical Properties of Cold-Rolled Al0.3CoCrFeNi High-Entropy Alloy. Metals 2021, 11, 940. https://doi.org/10.3390/met11060940

Zhu Z, Yang T, Shi R, Quan X, Zhang J, Qiu R, Song B, Liu Q. The Effects of Annealing at Different Temperatures on Microstructure and Mechanical Properties of Cold-Rolled Al0.3CoCrFeNi High-Entropy Alloy. Metals. 2021; 11(6):940. https://doi.org/10.3390/met11060940

Chicago/Turabian StyleZhu, Zichao, Tongtong Yang, Ruolan Shi, Xuantong Quan, Jinlong Zhang, Risheng Qiu, Bo Song, and Qing Liu. 2021. "The Effects of Annealing at Different Temperatures on Microstructure and Mechanical Properties of Cold-Rolled Al0.3CoCrFeNi High-Entropy Alloy" Metals 11, no. 6: 940. https://doi.org/10.3390/met11060940

APA StyleZhu, Z., Yang, T., Shi, R., Quan, X., Zhang, J., Qiu, R., Song, B., & Liu, Q. (2021). The Effects of Annealing at Different Temperatures on Microstructure and Mechanical Properties of Cold-Rolled Al0.3CoCrFeNi High-Entropy Alloy. Metals, 11(6), 940. https://doi.org/10.3390/met11060940