Numerical and Metallurgical Analysis of Laser Welded, Sealed Lap Joints of S355J2 and 316L Steels under Different Configurations

Abstract

:1. Introduction

2. Material and Experimental Design

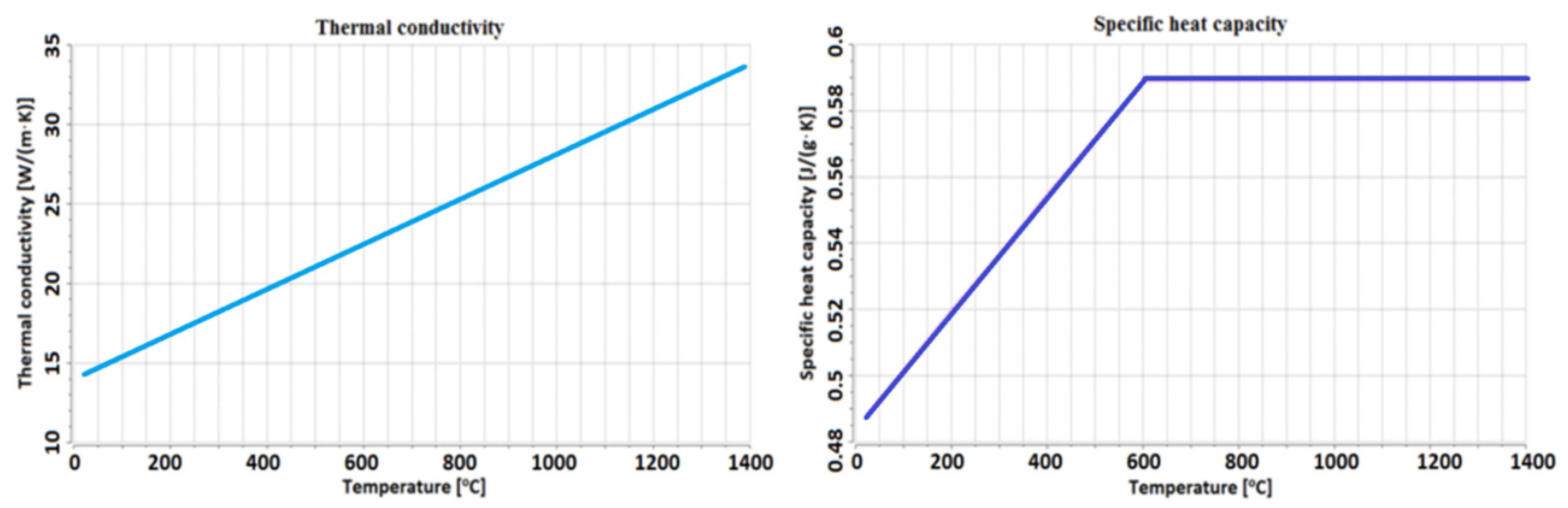

2.1. Materials

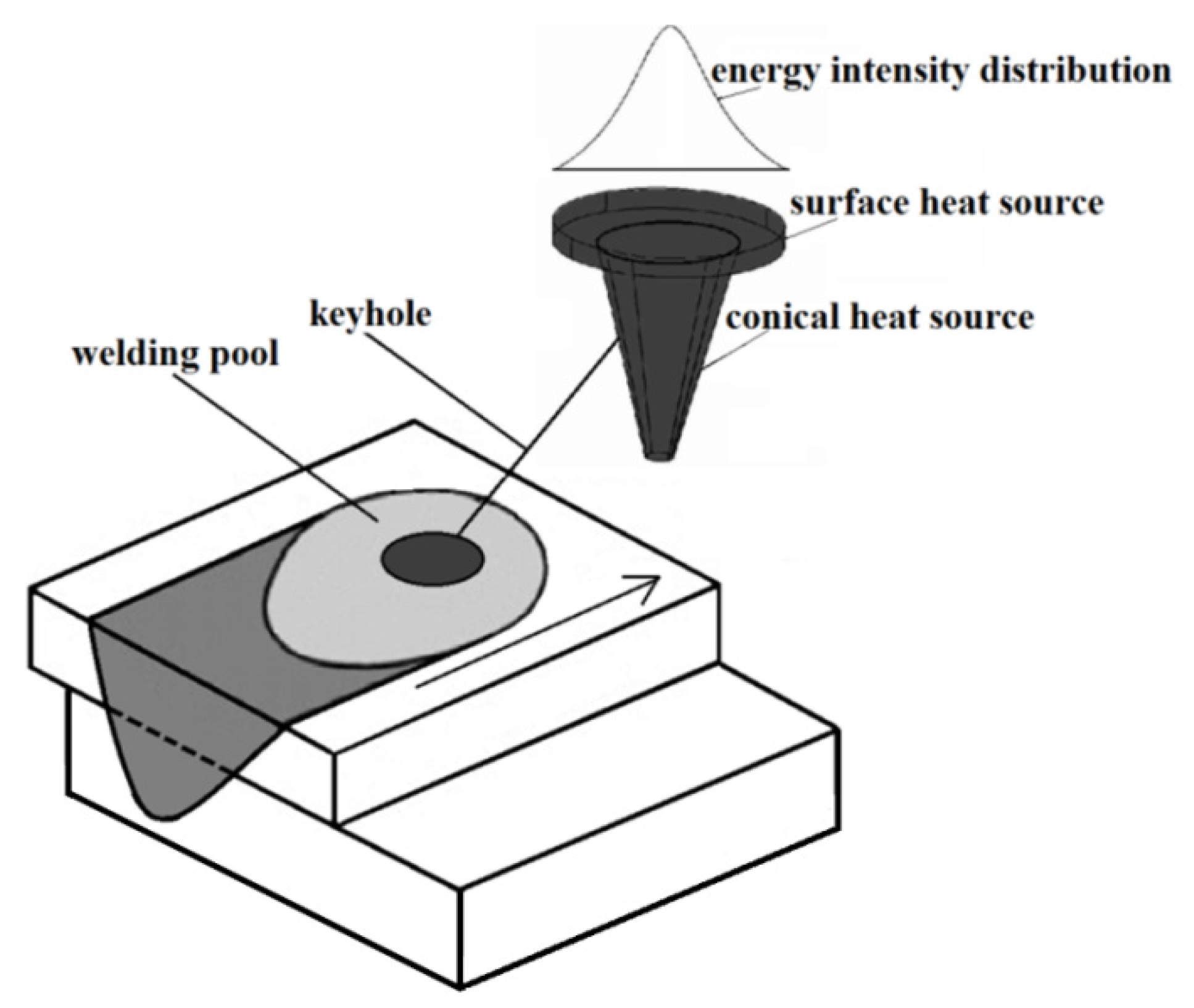

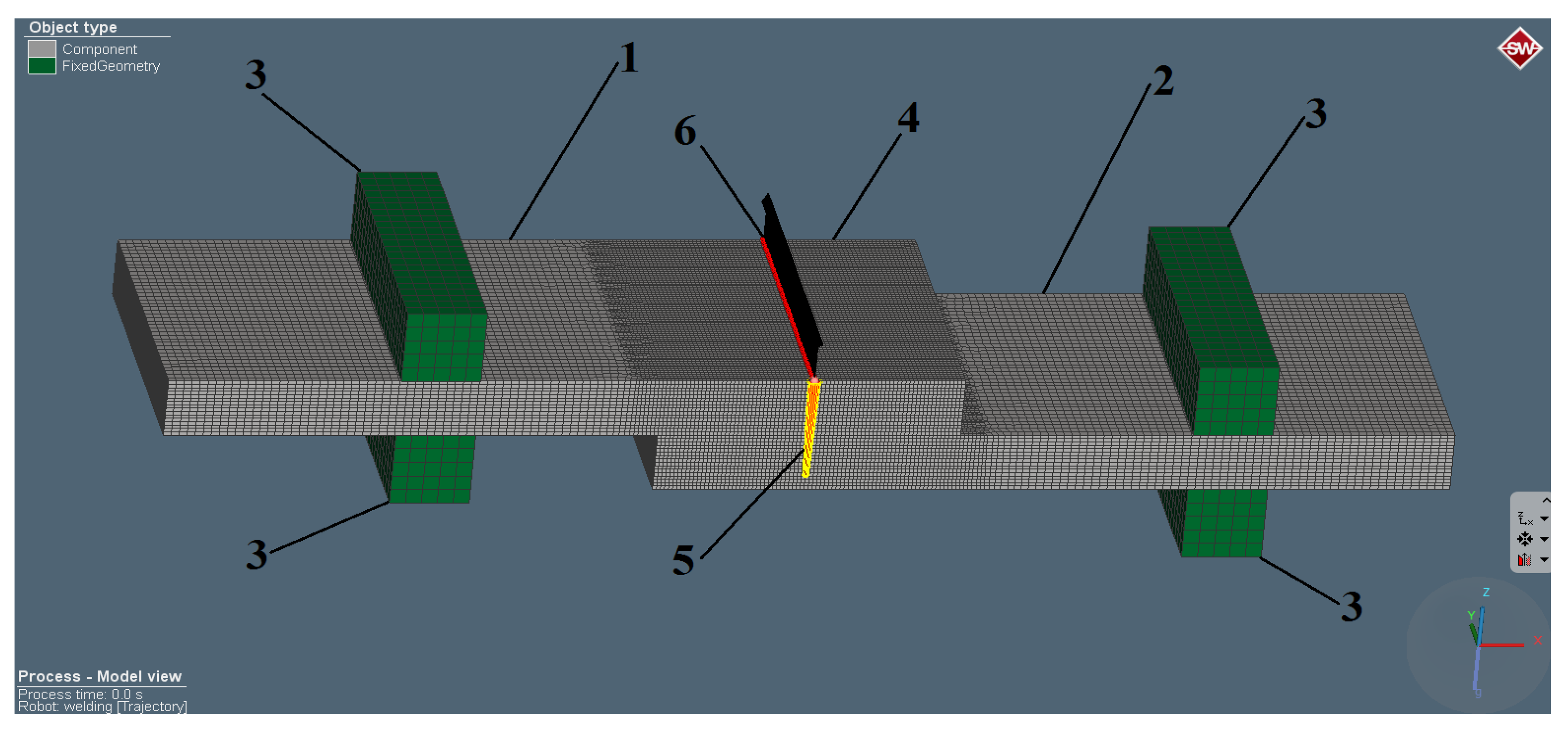

2.2. Numerical Simulation Procedure

2.3. Experimental Welding Procedure

2.4. Microstructure Analysis

3. Results

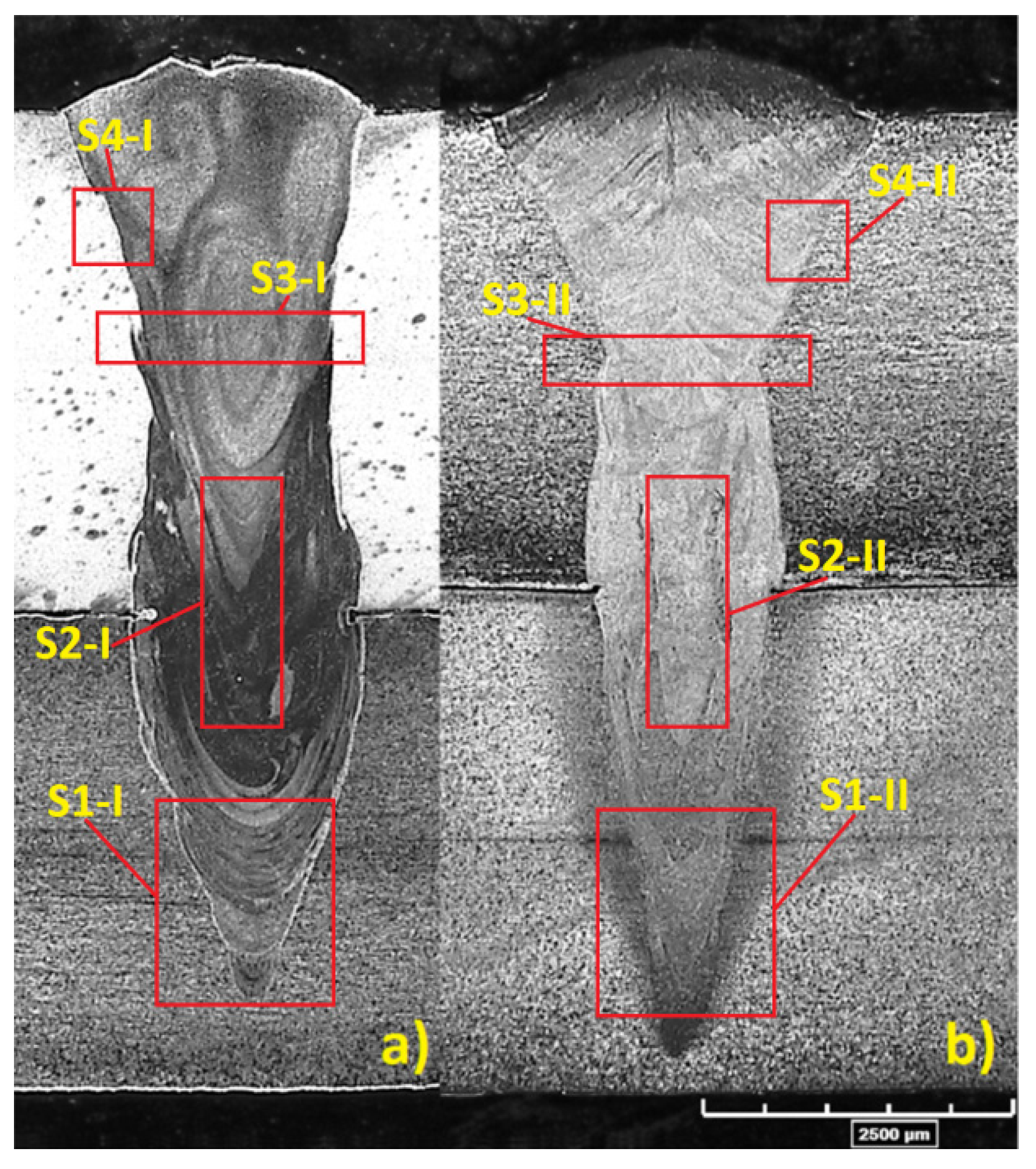

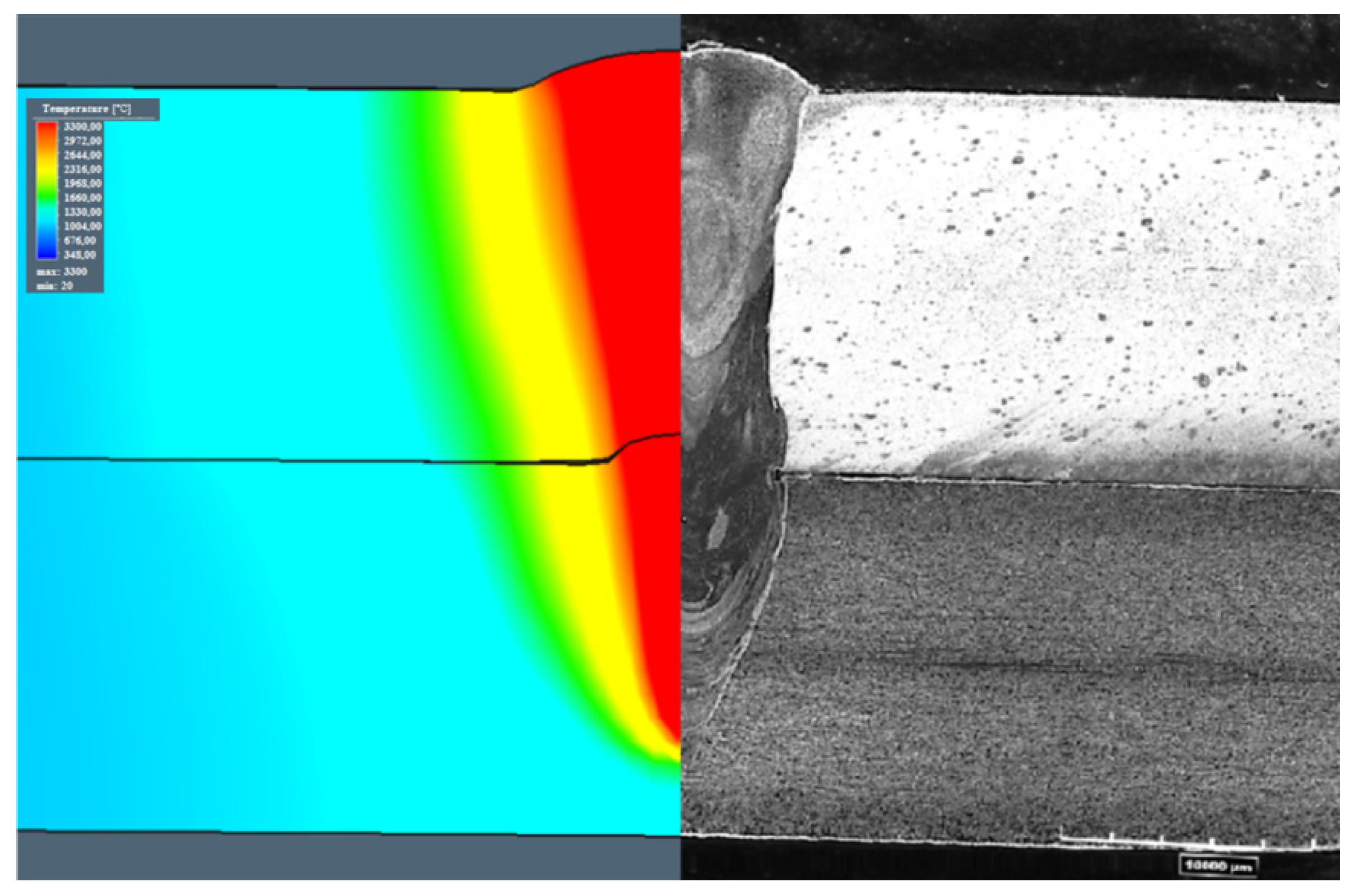

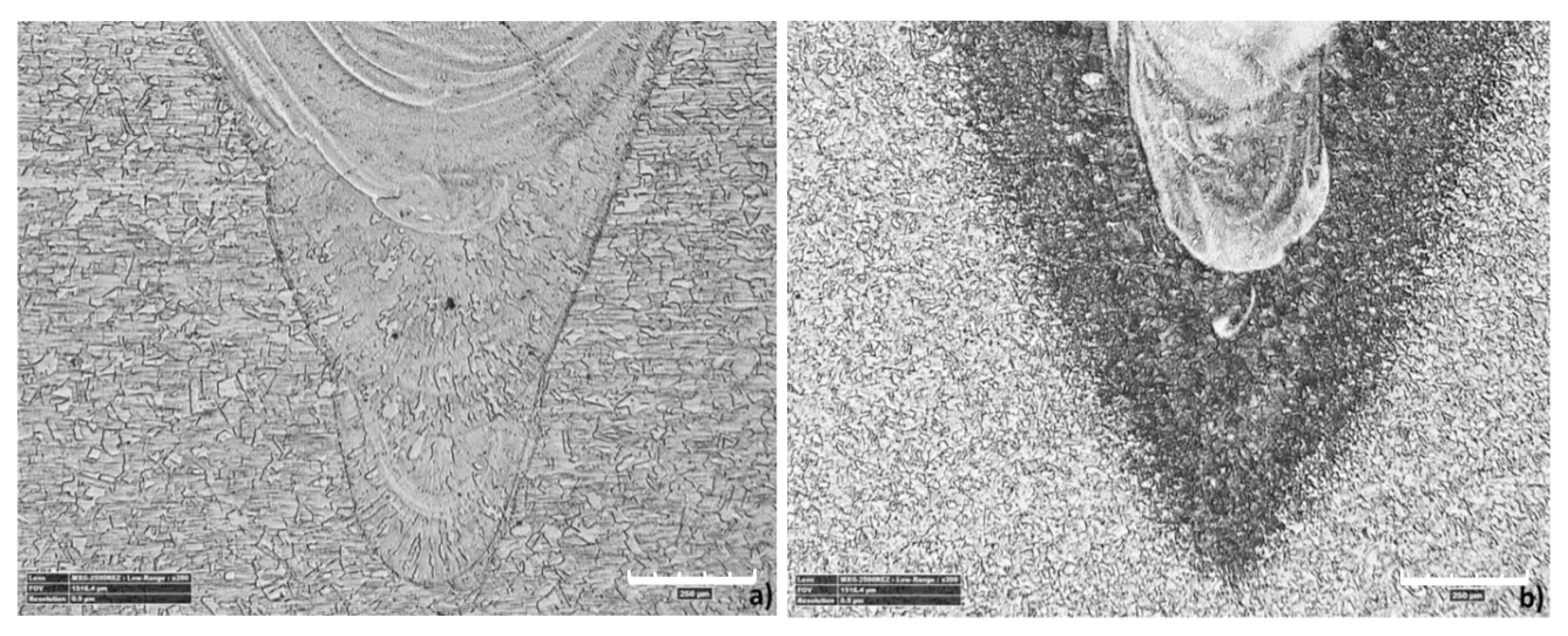

3.1. Global Observation

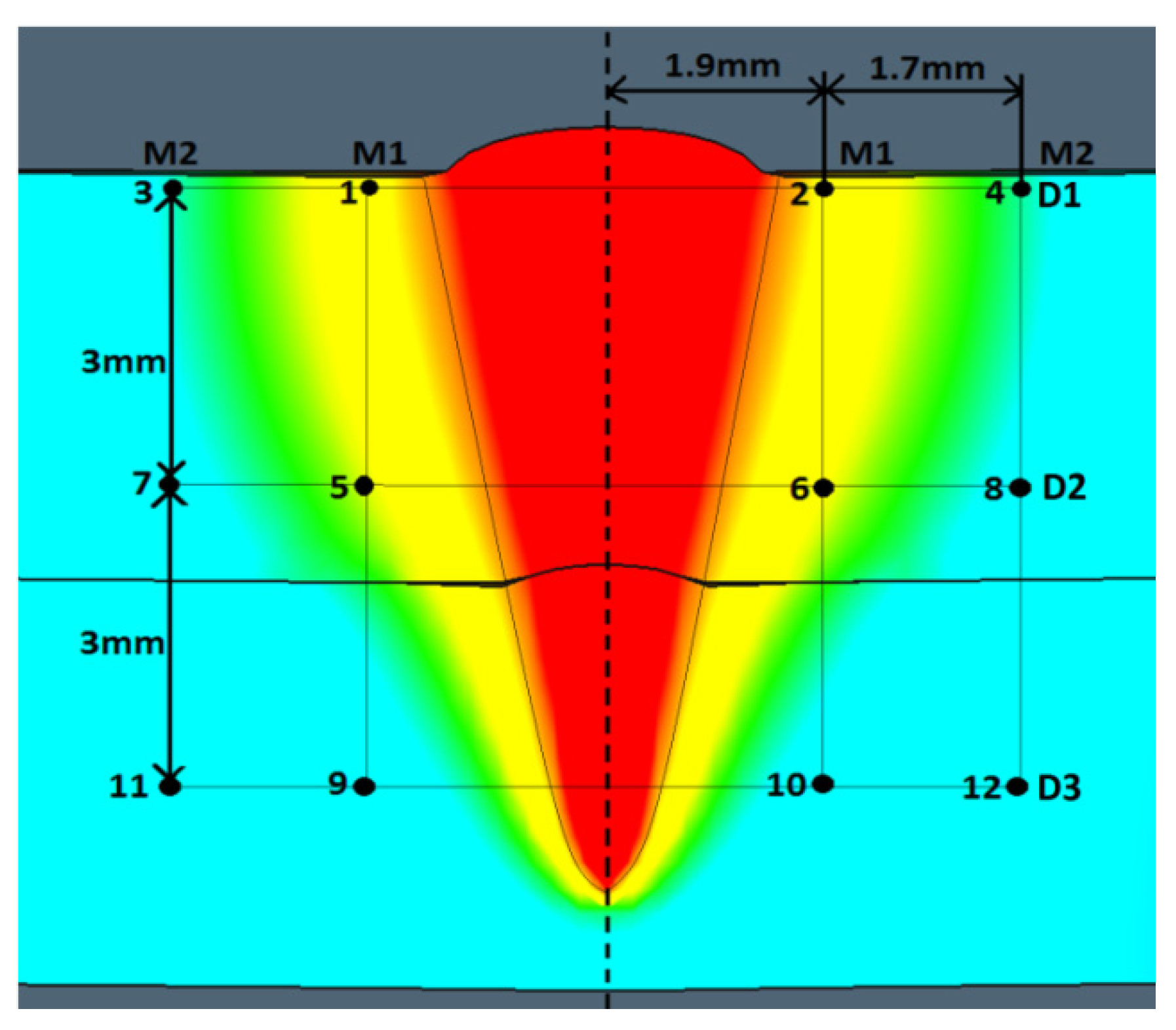

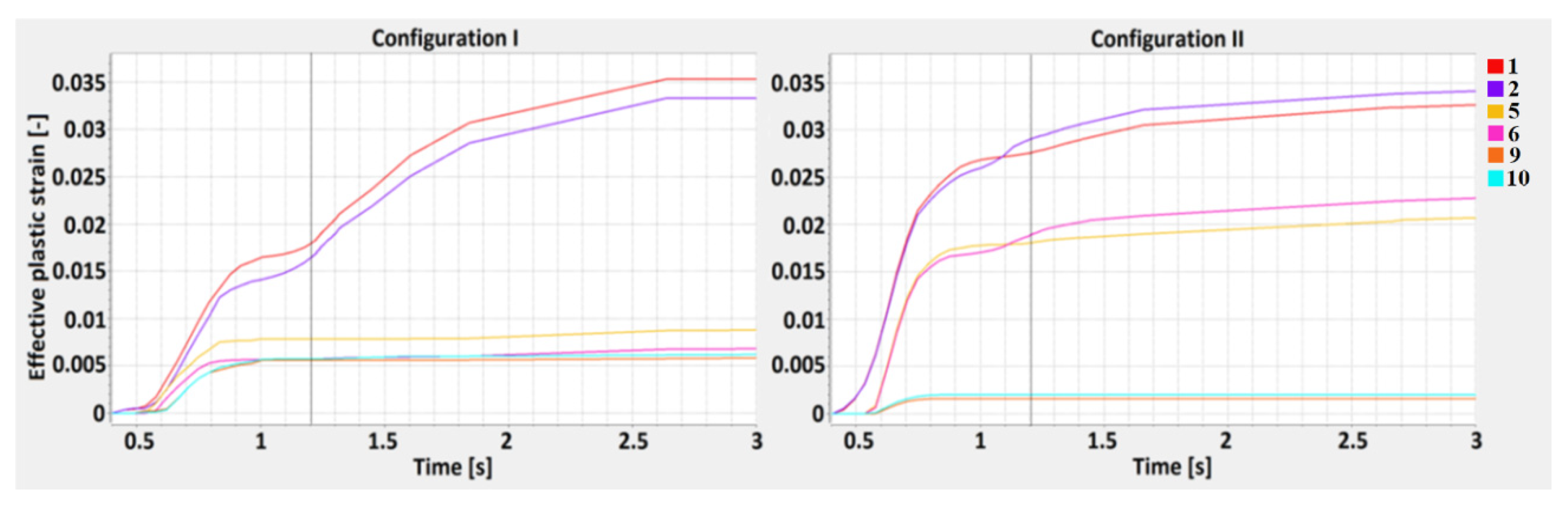

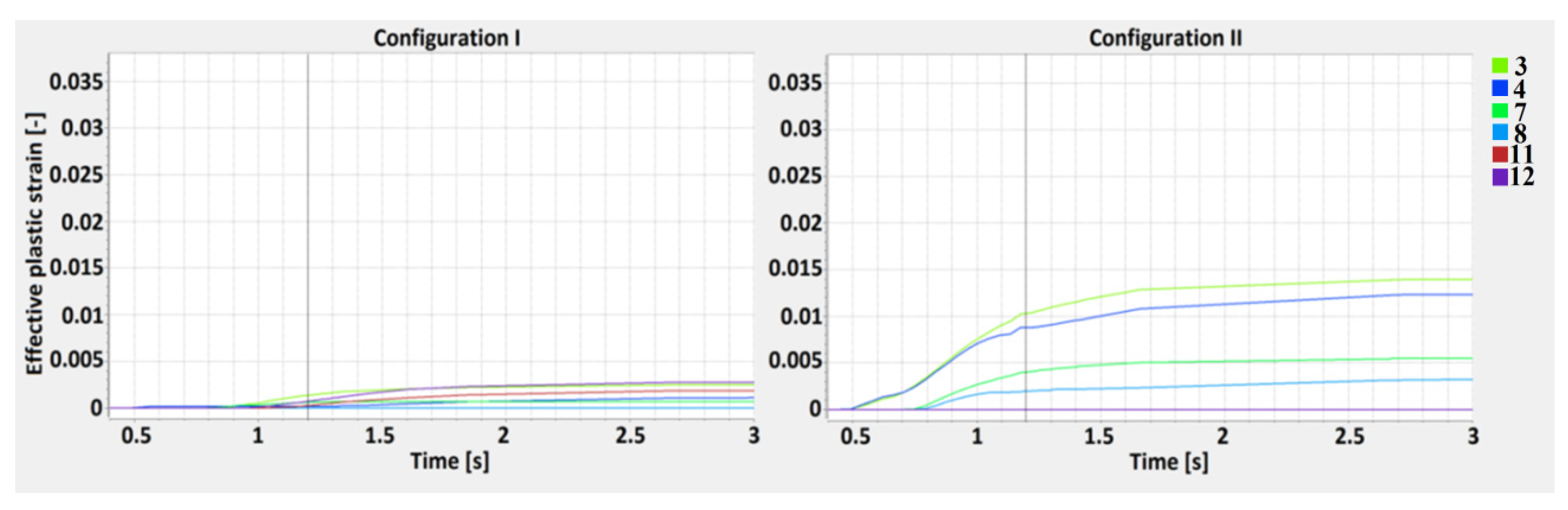

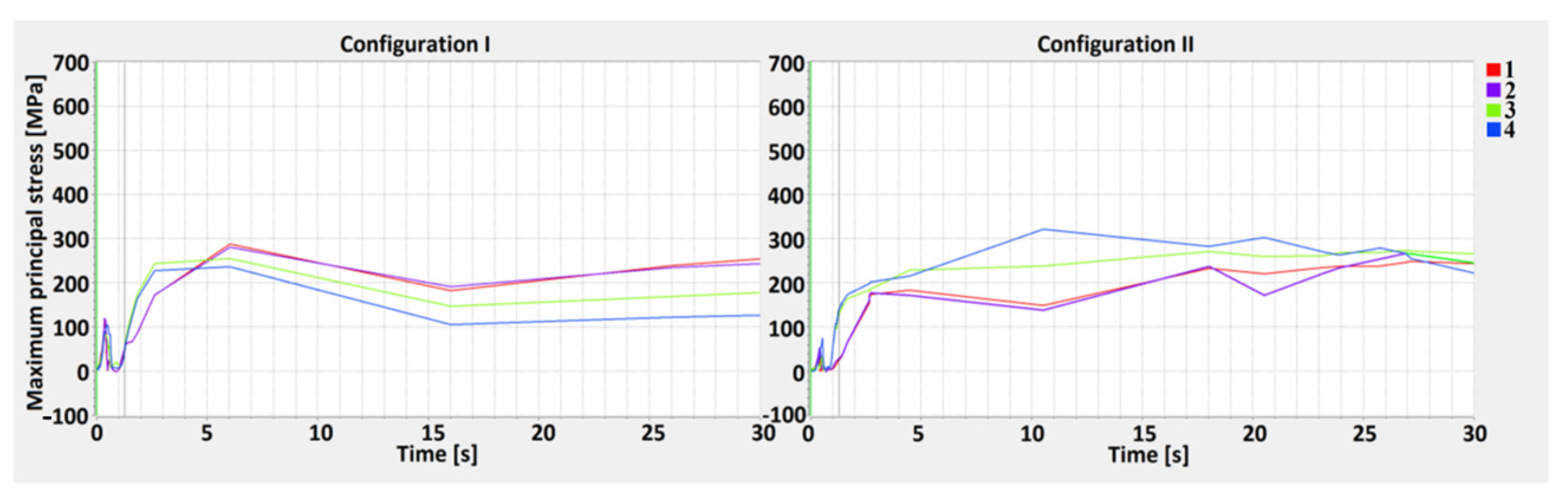

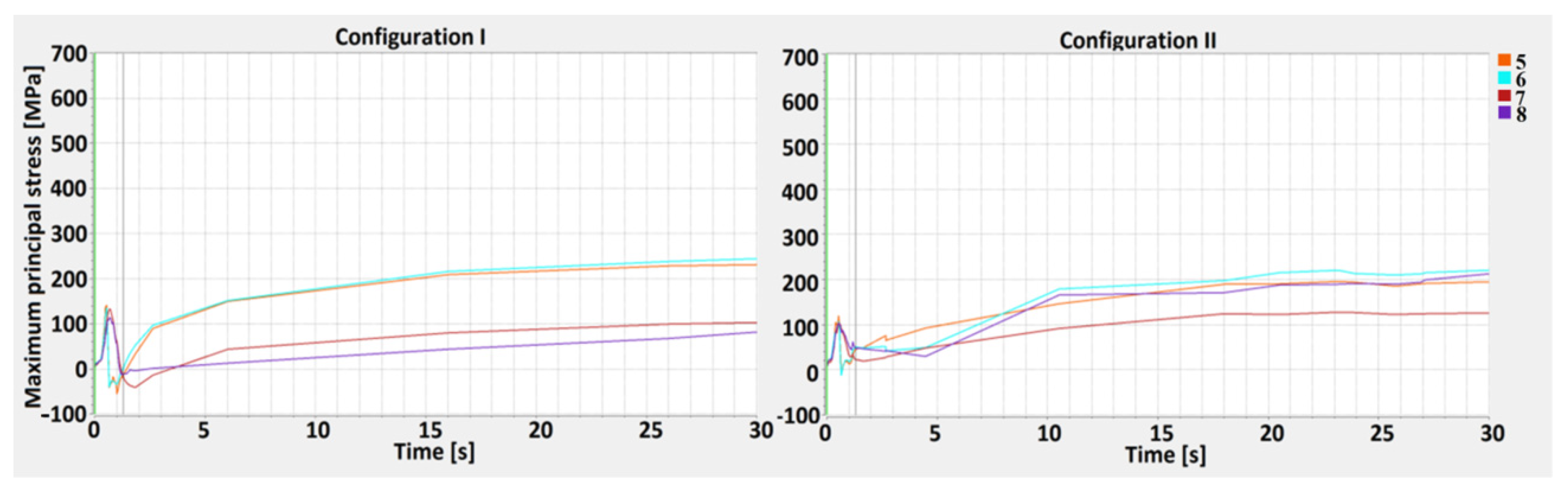

3.2. Numerical Simulation

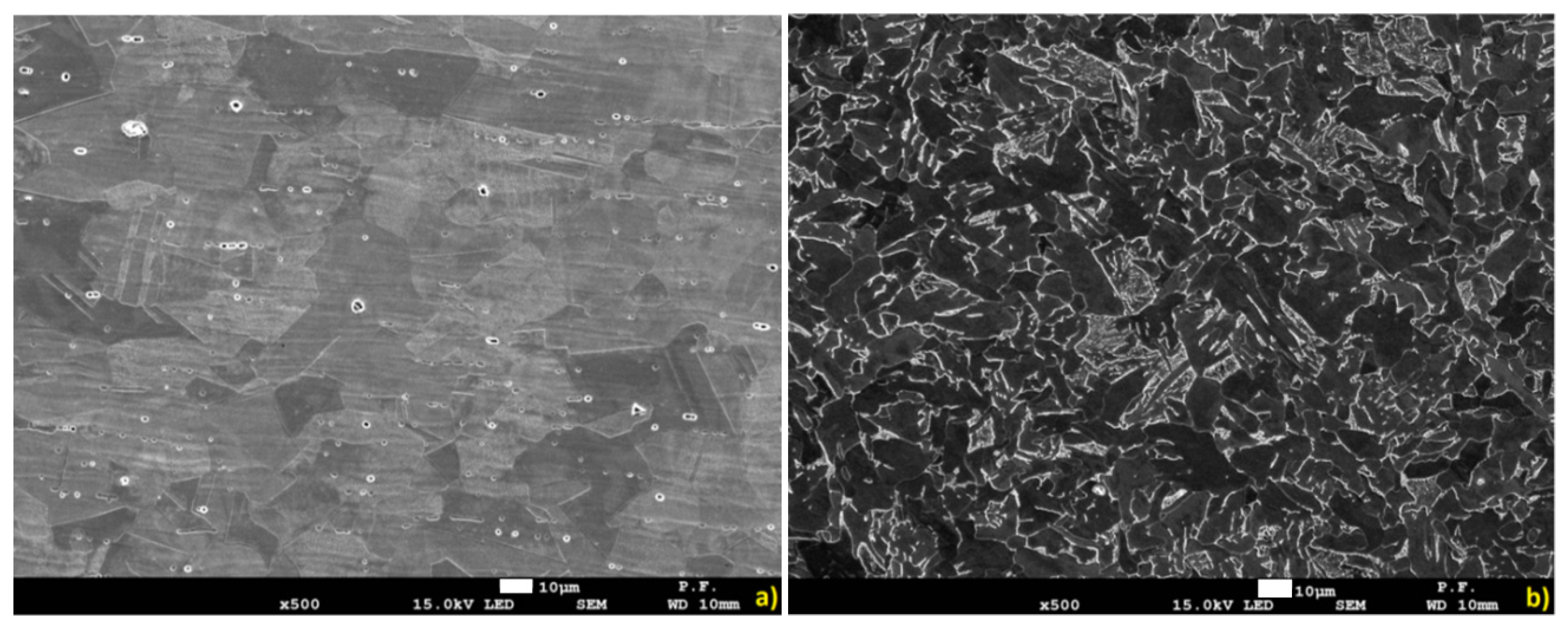

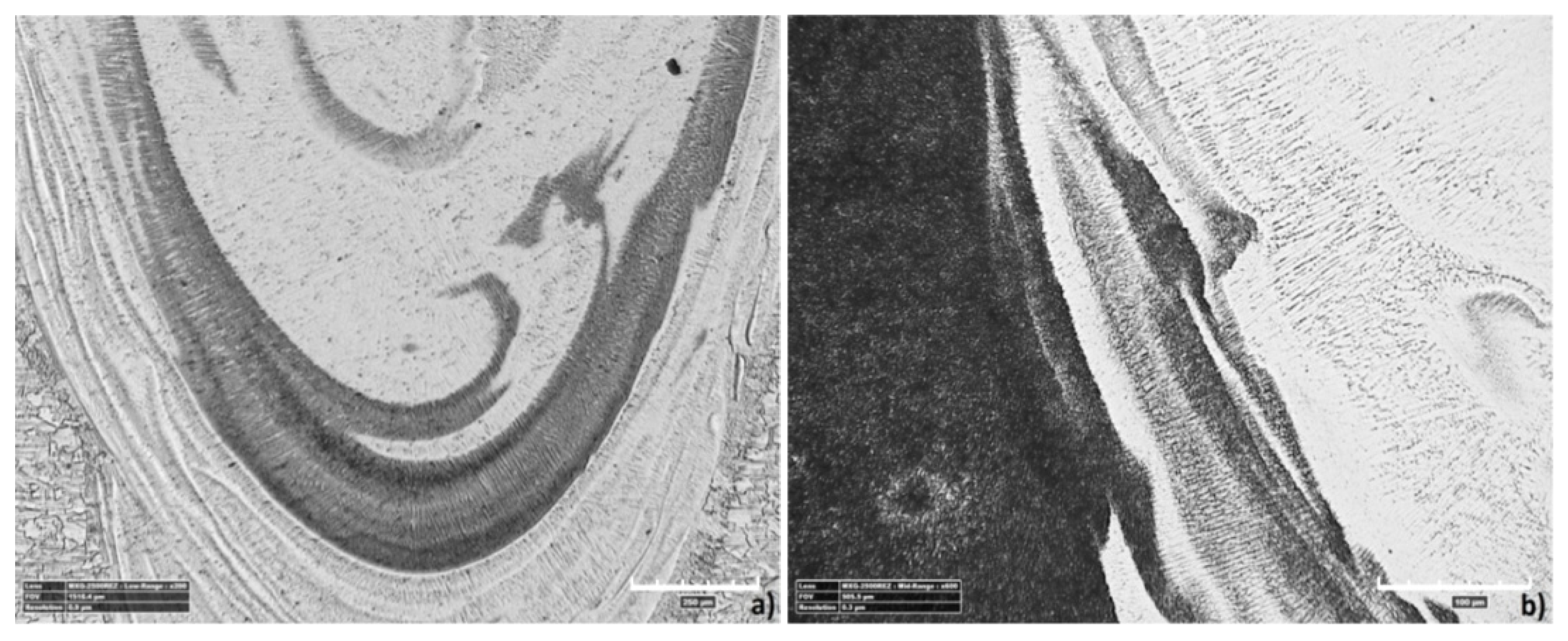

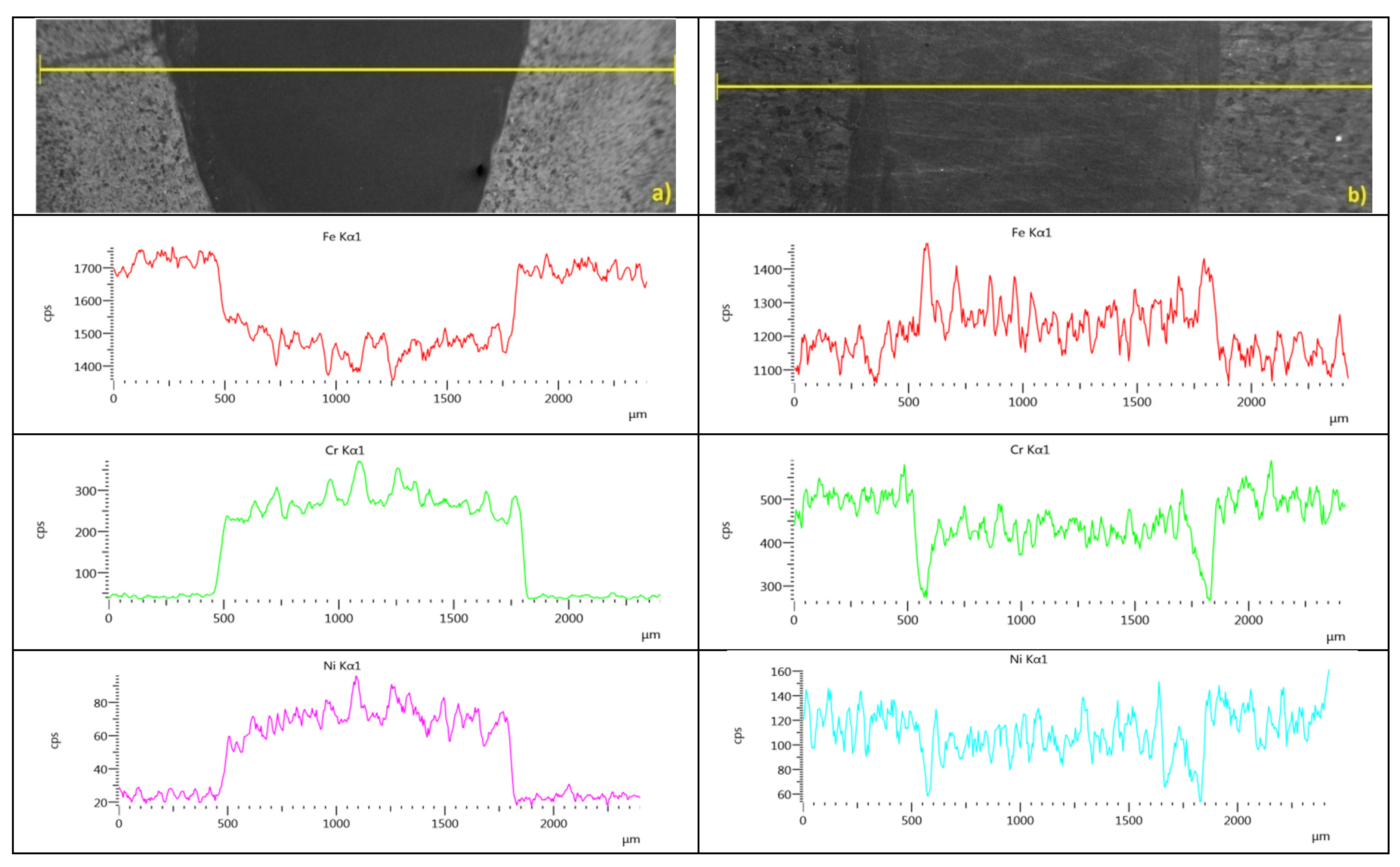

3.3. Metallographic Analysis

4. Discussion

5. Conclusions

- −

- calculated maximum principal stress value.

- −

- lower differences in the chemical element distribution in theweld.

- −

- more uniform structure and fusion rate in the weld.

Author Contributions

Funding

Conflicts of Interest

References

- Mazumder, J. Laser Welding: State of the Art Review. JOM 1982, 34, 16–24. [Google Scholar] [CrossRef]

- Mohanty, P.S.; Mazumder, J. Workbench for keyhole laser welding. Sci. Technol. Weld. Join. 1997, 2, 133–138. [Google Scholar] [CrossRef]

- Matsunawa, A. Problems and solutions in deep penetration laser welding. Sci. Technol. Weld. Join. 2001, 6, 351–354. [Google Scholar] [CrossRef]

- Yang, R.-T.; Chen, Z.-W. A study on fiber laser lap welding of thin stainless steel. Int. J. Precis. Eng. Manuf. 2013, 14, 207–214. [Google Scholar] [CrossRef]

- Khan, M.; Romoli, L.; Fiaschi, M.; Sarri, F.; Dini, G. Experimental investigation on laser beam welding of martensitic stainless steels in a constrained overlap joint configuration. J. Mater. Process. Technol. 2010, 210, 1340–1353. [Google Scholar] [CrossRef]

- Meco, S.; Pardal, G.; Ganguly, S.; Williams, S.W.; McPherson, N. Application of laser in seam welding of dissimilar steel to aluminium joints for thick structural components. Opt. Lasers Eng. 2015, 67, 22–30. [Google Scholar] [CrossRef] [Green Version]

- Takano, K.; Koizumi, N.; Serizawa, H.; Tsubota, S.; Makino, Y. Development of laser welding technology for fully austenitic stainless steel. Weld. Int. 2017, 31, 827–836. [Google Scholar] [CrossRef]

- Tan, W.; Shin, Y.C. Laser keyhole welding of stainless steel thin plate stack for applications in fuel cell manufacturing. Sci. Technol. Weld. Join. 2015, 20, 313–318. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.; Cunningham, R.; Zhao, C.; Parab, N.; Sun, T.; Rollett, A.D.; Spear, A.D.; Tan, W. Effect of Laser-Matter Interaction on Molten Pool Flow and Keyhole Dynamics. Phys. Rev. Appl. 2019, 11, 064054. [Google Scholar] [CrossRef]

- Lisiecki, A.; Wójciga, P.; Kurc-Lisiecka, A.; Barczyk, M.; Krawczyk, S. Laser welding of panel joints of stainless steel heat exchangers. Weld. Technol. Rev. 2019, 91, 7–19. [Google Scholar] [CrossRef] [Green Version]

- Szczepaniak, A.; Fan, J.; Kostka, A.; Raabe, D. On the Correlation between Thermal Cycle and Formation of Intermetallic Phases at the Interface of Laser-Welded Aluminum-Steel Overlap Joints. Adv. Eng. Mater. 2012, 14, 464–472. [Google Scholar] [CrossRef]

- Oussaid, K.; El Ouafi, A.; Chebak, A. Experimental Investigation of Laser Welding Process in Overlap Joint Configuration. J. Mater. Sci. Chem. Eng. 2019, 7, 16–31. [Google Scholar] [CrossRef] [Green Version]

- Noga, P.; Węglowski, M.; Zimierska-Nowak, P.; Richert, M.; Dworak, J.; Rykała, J. Influence of welding techniques on microstructure and hardness of steel joints used in automotive air conditioners. Met. Foundry Eng. 2017, 43, 281. [Google Scholar] [CrossRef]

- Guo, W.; Kar, A. Determination of weld pool shape and temperature distribution by solving three-dimensional phase change heat conduction problem. Sci. Technol. Weld. Join. 2000, 5, 317–323. [Google Scholar] [CrossRef]

- Wang, R.; Lei, Y.; Shi, Y. Numerical simulation of transient temperature field during laser keyhole welding of 304 stainless steel sheet. Opt. Laser Technol. 2011, 43, 870–873. [Google Scholar] [CrossRef]

- Dal, M.; Fabbro, R. An overview of the state of art in laser welding simulation. Opt. Laser Technol. 2016, 78, 2–14. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K.; Manonmani, K. Some studies on temperature profiles in AISI 304 stainless steel sheet during laser beam welding using FE simulation. Int. J. Adv. Manuf. Technol. 2008, 43, 78–94. [Google Scholar] [CrossRef]

- Schöler, C.; Haeusler, A.; Karyofylli, V.; Behr, M.; Schulz, W.; Gillner, A.; Niessen, M. Hybrid simulation of laser deep penetration welding. Mater. Werkst. 2017, 48, 1290–1297. [Google Scholar] [CrossRef]

- Miyashita, Y.; Mutoh, Y.; Akahori, M.; Okumura, H.; Nakagawa, I.; Jin-Quan, X. Laser welding of dissimilar metals aided by unsteady thermal conduction boundary element method analysis. Weld. Int. 2005, 19, 687–696. [Google Scholar] [CrossRef]

- Evdokimov, A.; Springer, K.; Doynov, N.; Ossenbrink, R.; Michailov, V. Heat source model for laser beam welding of steel-aluminum lap joints. Int. J. Adv. Manuf. Technol. 2017, 93, 709–716. [Google Scholar] [CrossRef]

- Ozkat, E.C.; Franciosa, P.; Ceglarek, D. Development of decoupled multi-physics simulation for laser lap welding considering part-to-part gap. J. Laser Appl. 2017, 29, 22423. [Google Scholar] [CrossRef] [Green Version]

- EN 10025-2: Hot rolled products of structural steels. In Technical Delivery Conditions for Non-Alloy Structural Steels; PKN: Warsaw, Poland, 2007.

- ASTM A240/A240M-18: Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications; ASTM: West Conshohocken, PA, USA, 2018.

- Chen, C.; Lin, Y.-J.; Ou, H.; Wang, Y. Study of Heat Source Calibration and Modelling for Laser Welding Process. Int. J. Precis. Eng. Manuf. 2018, 19, 1239–1244. [Google Scholar] [CrossRef]

- Derakhshan, E.D.; Yazdian, N.; Craft, B.; Smith, S.; Kovacevic, R. Numerical simulation and experimental validation of residual stress and welding distortion induced by laser-based welding processes of thin structural steel plates in butt joint configuration. Opt. Laser Technol. 2018, 104, 170–182. [Google Scholar] [CrossRef]

- De, A.; Maiti, S.K.; Walsh, C.A.; Bhadeshia, H.K.D.H. Finite element simulation of laser spot welding. Sci. Technol. Weld. Join. 2003, 8, 377–384. [Google Scholar] [CrossRef]

- Phanikumar, G.; Chattopadhyay, K.; Dutta, P. Joining of dissimilar metals: Issues and modelling techniques. Sci. Technol. Weld. Join. 2011, 16, 313–317. [Google Scholar] [CrossRef]

- Mayboudi, L.; Birk, A.; Zak, G.; Bates, P. A Three-Dimensional Thermal Finite Element Model of Laser Transmission Welding for Lap-Joint. Int. J. Model. Simul. 2009, 29, 149–155. [Google Scholar] [CrossRef]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K.; Kumar, S.R. A Transient Finite Element Simulation of the Temperature Field and Bead Profile of T-Joint Laser Welds. Int. J. Model. Simul. 2010, 30, 108–122. [Google Scholar] [CrossRef]

- Farrokhi, F.; Endelt, B.; Kristiansen, M. A numerical model for full and partial penetration hybrid laser welding of thick-section steels. Opt. Laser Technol. 2019, 111, 671–686. [Google Scholar] [CrossRef]

- Mazumder, J.; Steen, W.M. Heat transfer model for cw laser material processing. J. Appl. Phys. 1980, 51, 941. [Google Scholar] [CrossRef]

- Torkamany, M.J.; Sabbaghzadeh, J.; Hamedi, M. Effect of laser welding mode on the microstructure and mechanical performance of dissimilar laser spot welds between low carbon and austenitic stainless steels. Mater. Des. 2012, 34, 666–672. [Google Scholar] [CrossRef]

- Sudnik, W.; Radaj, D.; Breitschwerdt, S.; Erofeew, W. Numerical simulation of weld pool geometry in laser beam welding. J. Phys. D Appl. Phys. 2000, 33, 662–671. [Google Scholar] [CrossRef]

- Phaonaim, R.; Yamamoto, M.; Shinozaki, K.; Yamamoto, M.; Kadoi, K. Development of a Heat Source Model for Narrow-gap Hot-wire Laser Welding. Q. J. Jpn. Weld. Soc. 2013, 31, 82s–85s. [Google Scholar] [CrossRef] [Green Version]

- Carmignani, C.; Mares, R.; Toselli, G. Transient finite element analysis of deep penetration laser welding process in a singlepass butt-welded thick steel plate. Comput. Methods Appl. Mech. Eng. 1999, 179, 197–214. [Google Scholar] [CrossRef]

- Kano, S.; Oba, A.; Yang, H.-L.; Matsukawa, Y.; Satoh, Y.; Serizawa, H.; Sakasegawa, H.; Tanigawa, H.; Abe, H. Experimental assessment of temperature distribution in heat affected zone (HAZ) in dissimilar joint between 8Cr-2W steel and SUS316L fabricated by 4 kW fiber laser welding. Mech. Eng. Lett. 2016, 2, 15. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, N.S.; Buvanashekaran, G.; Sankaranarayanasamy, K. Experimental investigation and finite element simulation of laser beam welding of AISI 304 stainless steel sheet. Exp. Tech. 2009, 34, 25–36. [Google Scholar] [CrossRef]

- Danielewski, H.; Skrzypczyk, A. Steel Sheets Laser Lap Joint Welding—Process Analysis. Materials 2020, 13, 2258. [Google Scholar] [CrossRef]

- Oh, R.; Kim, D.Y.; Ceglarek, D. The Effects of Laser Welding Direction on Joint Quality for Non-Uniform Part-to-Part Gaps. Materials 2016, 6, 184. [Google Scholar] [CrossRef] [Green Version]

- PN-EN ISO 15609-4: 2009: Specification and Qualification of Welding Procedures for Metallic Materials-Welding Procedure Specification-Part 4: Laser Beam Welding; PKN: Warsaw, Poland, 2009.

- PN-EN ISO 13919-1: 2002: Welding-Electrons and Laser Beam Welded Joints-Guidance on Quality Levels for Imperfections-Part 1: Steel; PKN: Warsaw, Poland, 2002.

- PN-EN ISO 17639:2013: Destructive Tests on Welds in Metallic Materials-Macroscopic and Microscopic Examination of Welds; PKN: Warsaw, Poland, 2013.

- Rong, Y.; Xu, J.; Lei, T.; Wang, W.; Sabbar, A.A.; Huang, Y.; Wang, C.; Chen, Z. Microstructure and alloy element distribution of dissimilar joint 316L and EH36 in laser welding. Sci. Technol. Weld. Join. 2018, 23, 454–461. [Google Scholar] [CrossRef]

- Kuryntsev, S.V. Microstructure, mechanical and electrical properties of laser-welded overlap joint of CP Ti and AA2024. Opt. Lasers Eng. 2019, 112, 77–86. [Google Scholar] [CrossRef]

- Tsoukantas, G.; Chryssolouris, G. Theoretical and experimental analysis of the remote welding process on thin, lap-joined AISI 304 sheets. Int. J. Adv. Manuf. Technol. 2008, 35, 880–894. [Google Scholar] [CrossRef]

- Kubiak, M.; Piekarska, W.; Stano, S.; Saternus, Z. Numerical Modelling of Thermal And Structural Phenomena In Yb:YAG Laser Butt-Welded Steel Elements. Arch. Met. Mater. 2015, 60, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Ferro, P.; Bonollo, F.; Tiziani, A. Laser welding of copper–nickel alloys: A numerical and experimental analysis. Sci. Technol. Weld. Join. 2005, 10, 299–310. [Google Scholar] [CrossRef]

- Huang, B.-S.; Yang, J.; Lu, D.-H.; Bin, W.-J. Study on the microstructure, mechanical properties and corrosion behaviour of S355JR/316L dissimilar welded joint prepared by gas tungsten arc welding multi-pass welding process. Sci. Technol. Weld. Join. 2016, 21, 381–388. [Google Scholar] [CrossRef]

- Brand, M.; Siegele, D. Numerical Simulation of Distortion and Residual Stresses of Dual Phase Steels Weldments. Weld. World 2010, 51, 56–62. [Google Scholar] [CrossRef]

- Mochizuki, M.; Katsuyama, J.; Higuchi, R.; Toyoda, M. Study of Residual Stress Distribution at Start-Finish Point of Circumferential Welding Studied by 3D-Fem Analysis. Weld. World 2005, 49, 40–49. [Google Scholar] [CrossRef]

- Hempel, N.; Nitschke-Pagel, T.; Dilger, K. Residual stresses in multi-pass butt-welded ferritic-pearlitic steel pipes. Weld. World 2015, 59, 555–563. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M. Residual Stresses Prediction for CO2 Laser Butt-Welding of 304-Stainless Steel. Appl. Mech. Mater. 2006, 3–4, 125–130. [Google Scholar] [CrossRef]

- Rong, Y.; Xu, J.; Huang, Y.; Zhang, G. Review on finite element analysis of welding deformation and residual stress. Sci. Technol. Weld. Join. 2018, 23, 198–208. [Google Scholar] [CrossRef]

- Kong, F.; Ma, J.; Kovacevic, R. Numerical and experimental study of thermally induced residual stress in the hybrid laser–GMA welding process. J. Mater. Process. Technol. 2011, 211, 1102–1111. [Google Scholar] [CrossRef]

- Buschenhenke, F.; Hofmann, M.; Seefeld, T.; Vollertsen, F. Distortion and residual stresses in laser beam weld shaft-hub joints. Phys. Procedia 2010, 5, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, P.; Hedegård, J.; Al-Emrani, M.; Atashipour, S.R. The impact of production-dependent geometric properties on fatigue-relevant stresses in laser-welded corrugated core steel sandwich panels. Weld. World 2019, 63, 1801–1818. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Ren, L.; Xie, L.; Xie, H.; Ai, T. Maximum mean principal stress criterion for three-dimensional brittle fracture. Int. J. Solids Struct. 2016, 102–103, 142–154. [Google Scholar] [CrossRef]

- Ben Salem, G.; Chapuliot, S.; Blouin, A.; Bompard, P.; Jacquemoud, C. Brittle fracture analysis of Dissimilar Metal Welds between low-alloy steel and stainless steel at low temperatures. ProcediaStruct. Integr. 2018, 13, 619–624. [Google Scholar] [CrossRef]

- Casalino, G.; Angelastro, A.; Perulli, P.; Casavola, C.; Moramarco, V. Study on the fiber laser/TIG weldability of AISI 304 and AISI 410 dissimilar weld. J. Manuf. Process. 2018, 35, 216–225. [Google Scholar] [CrossRef]

- Eisazadeh, H.; Achuthan, A.; Goldak, J.; Aidun, D. Effect of material properties and mechanical tensioning load on residual stress formation in GTA 304-A36 dissimilar weld. J. Mater. Process. Technol. 2015, 222, 344–355. [Google Scholar] [CrossRef]

- Anawa, E.; Olabi, A.-G. Control of welding residual stress for dissimilar laser welded materials. J. Mater. Process. Technol. 2008, 204, 22–33. [Google Scholar] [CrossRef] [Green Version]

- Yao, C.; Xu, B.; Zhang, X.; Huang, J.; Fu, J.; Wu, Y. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint. Opt. Lasers Eng. 2009, 47, 807–814. [Google Scholar] [CrossRef]

- Prabakaran, M.; Kannan, G.R. Optimization and metallurgical studies of CO2 laser welding on austenitic stainless steel to carbon steel joint. Ferroelectrics 2017, 519, 223–235. [Google Scholar] [CrossRef]

- Perricone, M.J.; Dupont, J.N.; Anderson, T.D.; Robino, C.V.; Michael, J.R. An Investigation of the Massive Transformation from Ferrite to Austenite in Laser-Welded Mo-Bearing Stainless Steels. Met. Mater. Trans. A 2010, 42, 700–716. [Google Scholar] [CrossRef]

- Nikulina, A.A.; Bataev, I.; Smirnov, A.I.; Popelyukh, A.I.; Burov, V.; Veselov, S.V. Microstructure and fracture behaviour of flash butt welds between dissimilar steels. Sci. Technol. Weld. Join. 2014, 20, 138–144. [Google Scholar] [CrossRef]

- Taban, E.; Deleu, E.; Dhooge, A.; Kaluc, E. Laser welding of modified 12% Cr stainless steel: Strength, fatigue, toughness, microstructure and corrosion properties. Mater. Des. 2009, 30, 1193–1200. [Google Scholar] [CrossRef]

- Rossini, M.; Spena, P.R.; Cortese, L.; Matteis, P.; Firrao, D. Investigation on dissimilar laser welding of advanced high strength steel sheets for the automotive industry. Mater. Sci. Eng. A 2015, 628, 288–296. [Google Scholar] [CrossRef]

- Ceglarek, D.; Colledani, M.; Váncza, J.; Kim, D.Y.; Marine, C.; Kogel-Hollacher, M.; Mistry, A.; Bolognese, L. Rapid deployment of remote laser welding processes in automotive assembly systems. CIRP Ann. 2015, 64, 389–394. [Google Scholar] [CrossRef]

- Bakir, N.; Üstündağ, Ö.; Gumenyuk, A.; Rethmeier, M. Experimental and numerical study on the influence of the laser hybrid parameters in partial penetration welding on the solidification cracking in the weld root. Weld. World 2020, 64, 501–511. [Google Scholar] [CrossRef] [Green Version]

- Kik, T.; Górka, J. Numerical Simulations of Laser and Hybrid S700MC T-Joint Welding. Materials 2019, 12, 516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nagaraju, U.; Gowd, G.H.; Ahmad, R.M.I. Parametric analysis and evaluation of tensile strength for laser welding of dissimilar metal. Mater. Today Proc. 2018, 5, 7898–7907. [Google Scholar] [CrossRef]

- Prabakaran, M.P.; Kannan, G.; Lingadurai, K. Microstructure and mechanical properties of laser-welded dissimilar joint of AISI316 stainless steel and AISI1018 low alloy steel. Caribb. J. Sci. 2019, 53, 978–998. [Google Scholar]

- Ki, H.; Mazumder, J.; Mohanty, P.S. Modeling of laser keyhole welding: Part II. Simulation of keyhole evolution, velocity, temperature profile, and experimental verification. Met. Mater. Trans. A 2002, 33, 1831–1842. [Google Scholar] [CrossRef]

- Esfahani, M.R.N.; Coupland, J.; Marimuthu, S. Microstructure and mechanical properties of a laser welded low carbon–stainless steel joint. J. Mater. Process. Technol. 2014, 214, 2941–2948. [Google Scholar] [CrossRef]

- Pekkarinen, J.; Kujanpää, V. The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. Phys. Procedia 2010, 5, 517–523. [Google Scholar] [CrossRef] [Green Version]

- Vitek, J.M.; Dasgupta, A.; David, S.A. Microstructural modification of austenitic stainless steels by rapid solidification. Met. Mater. Trans. A 1983, 14, 1833–1841. [Google Scholar] [CrossRef]

- Sinha, A.K.; Kim, D.Y.; Ceglarek, D. Correlation analysis of the variation of weld seam and tensile strength in laser welding of galvanized steel. Opt. Lasers Eng. 2013, 51, 1143–1152. [Google Scholar] [CrossRef]

| Material | Elements (wt %) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Al | Fe | Cu | CEV | |

| S355J2 | 0.17 | 1.6 | 0.02 | 0.017 | 0.011 | 0.02 | - | 0.05 | 98.1 | 0.06 | 0.45% |

| 316L | 0.018 | 1.57 | 0.48 | 0.04 | 0.002 | 16.7 | 11.2 | - | balance | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Danielewski, H.; Skrzypczyk, A.; Hebda, M.; Tofil, S.; Witkowski, G.; Długosz, P.; Nigrovič, R. Numerical and Metallurgical Analysis of Laser Welded, Sealed Lap Joints of S355J2 and 316L Steels under Different Configurations. Materials 2020, 13, 5819. https://doi.org/10.3390/ma13245819

Danielewski H, Skrzypczyk A, Hebda M, Tofil S, Witkowski G, Długosz P, Nigrovič R. Numerical and Metallurgical Analysis of Laser Welded, Sealed Lap Joints of S355J2 and 316L Steels under Different Configurations. Materials. 2020; 13(24):5819. https://doi.org/10.3390/ma13245819

Chicago/Turabian StyleDanielewski, Hubert, Andrzej Skrzypczyk, Marek Hebda, Szymon Tofil, Grzegorz Witkowski, Piotr Długosz, and Rastislav Nigrovič. 2020. "Numerical and Metallurgical Analysis of Laser Welded, Sealed Lap Joints of S355J2 and 316L Steels under Different Configurations" Materials 13, no. 24: 5819. https://doi.org/10.3390/ma13245819