A Fully Integrated Clocked AC-DC Charge Pump for Mignetostrictive Vibration Energy Harvesting

Abstract

:1. Introduction

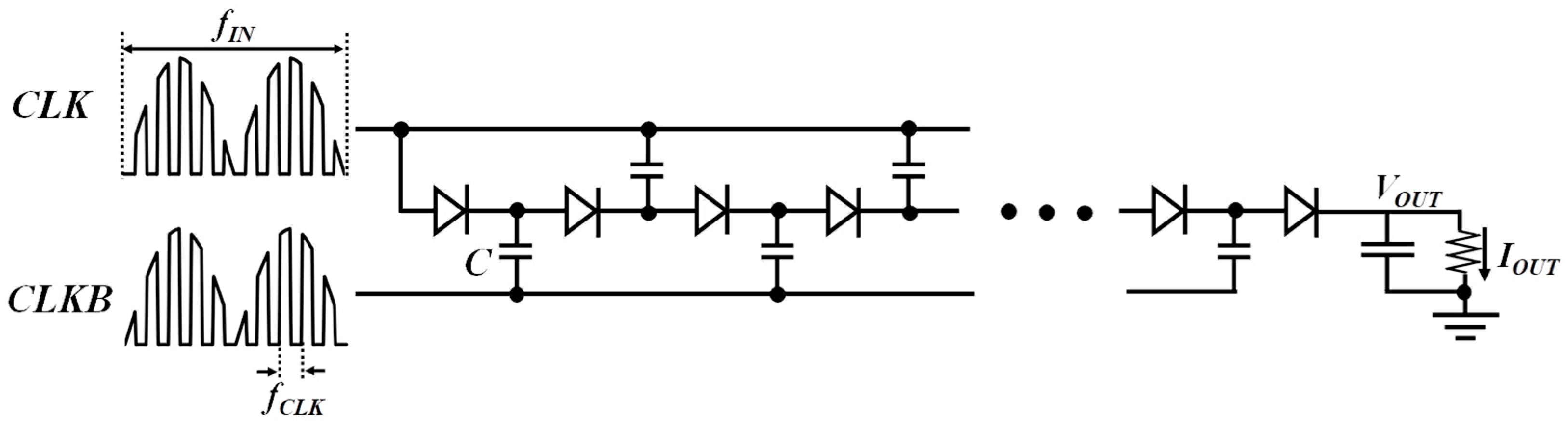

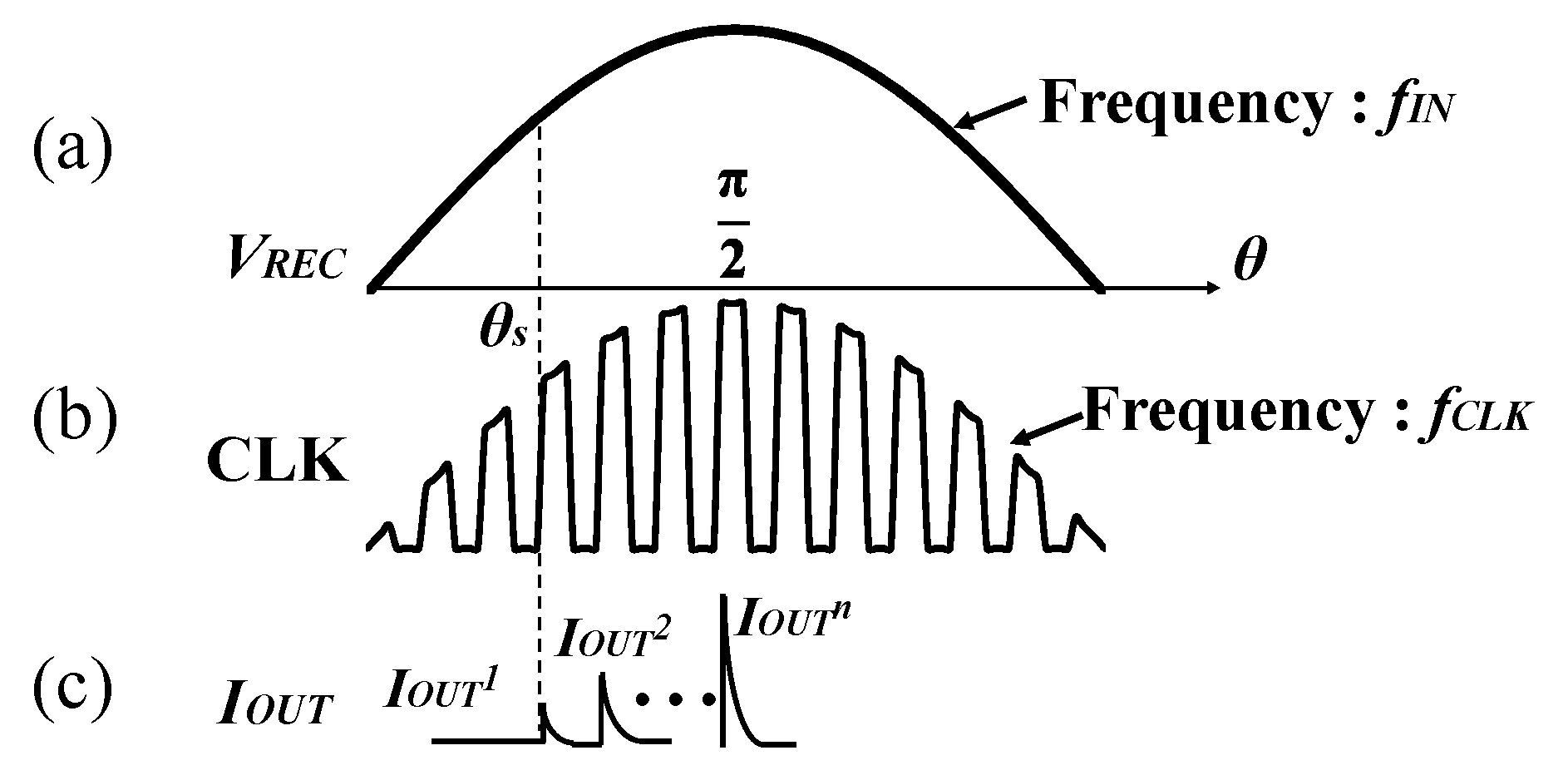

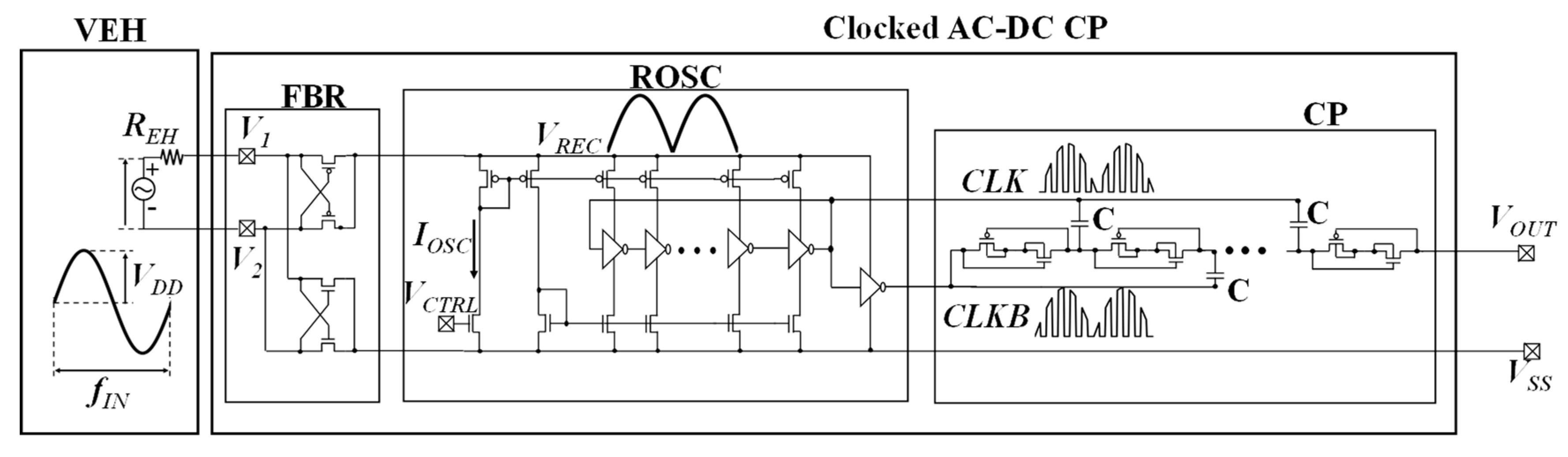

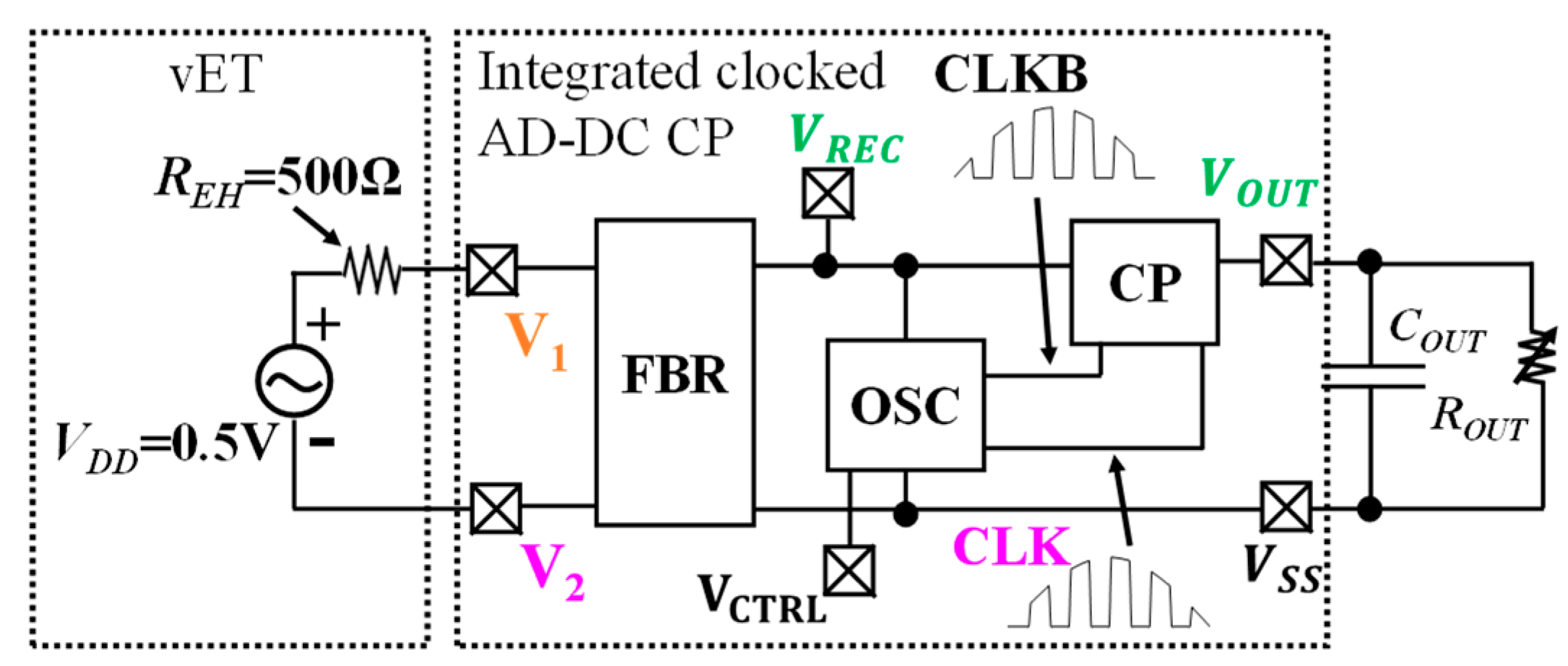

2. Clocked AC-DC Charge Pump

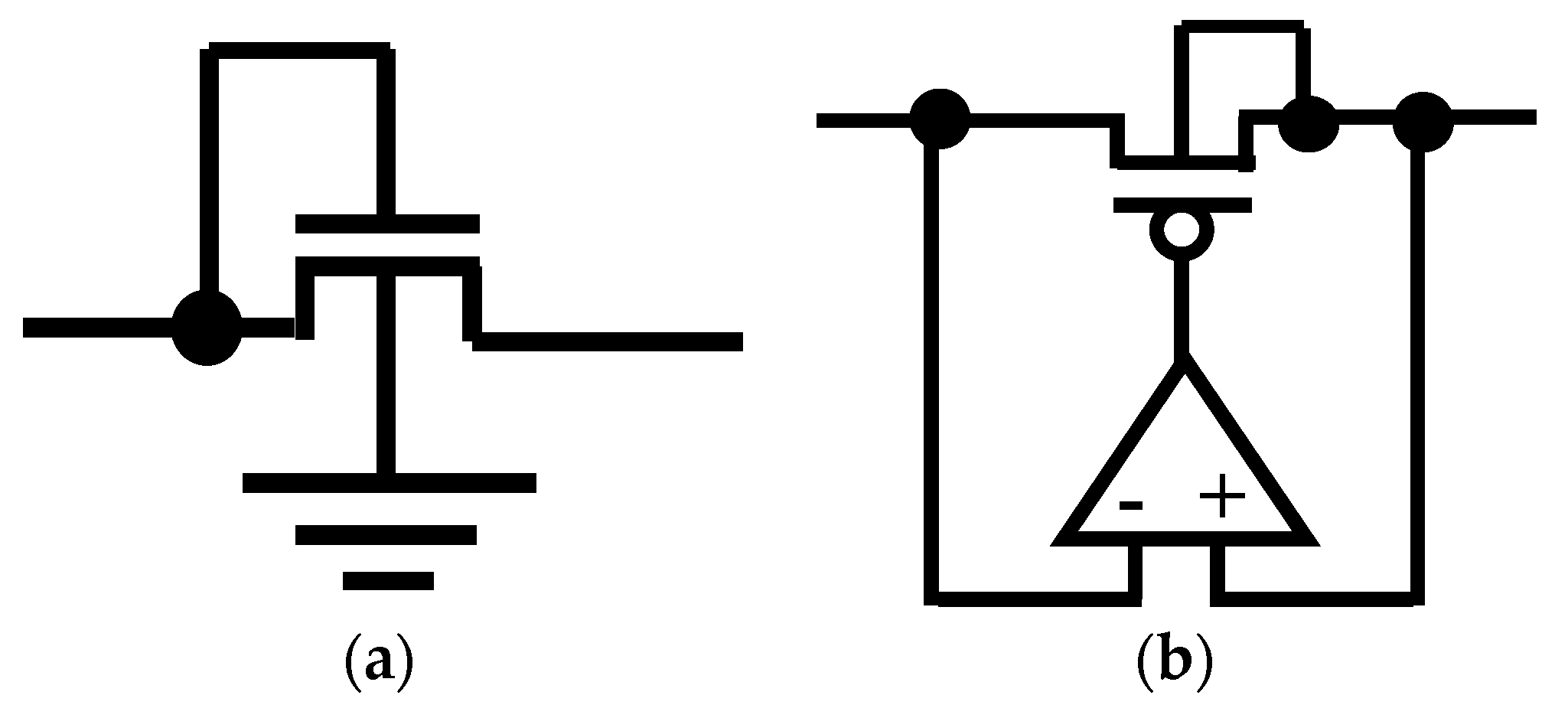

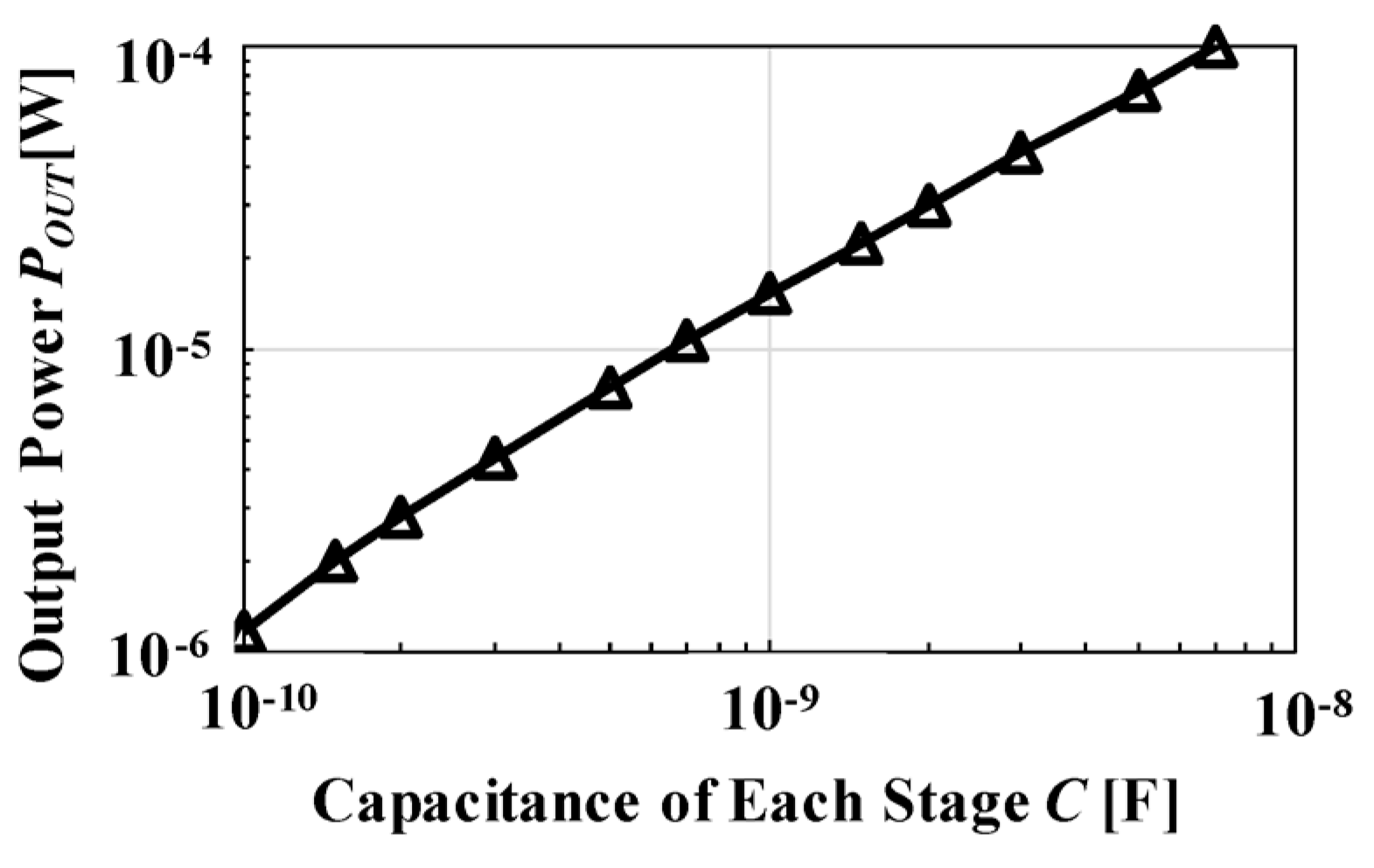

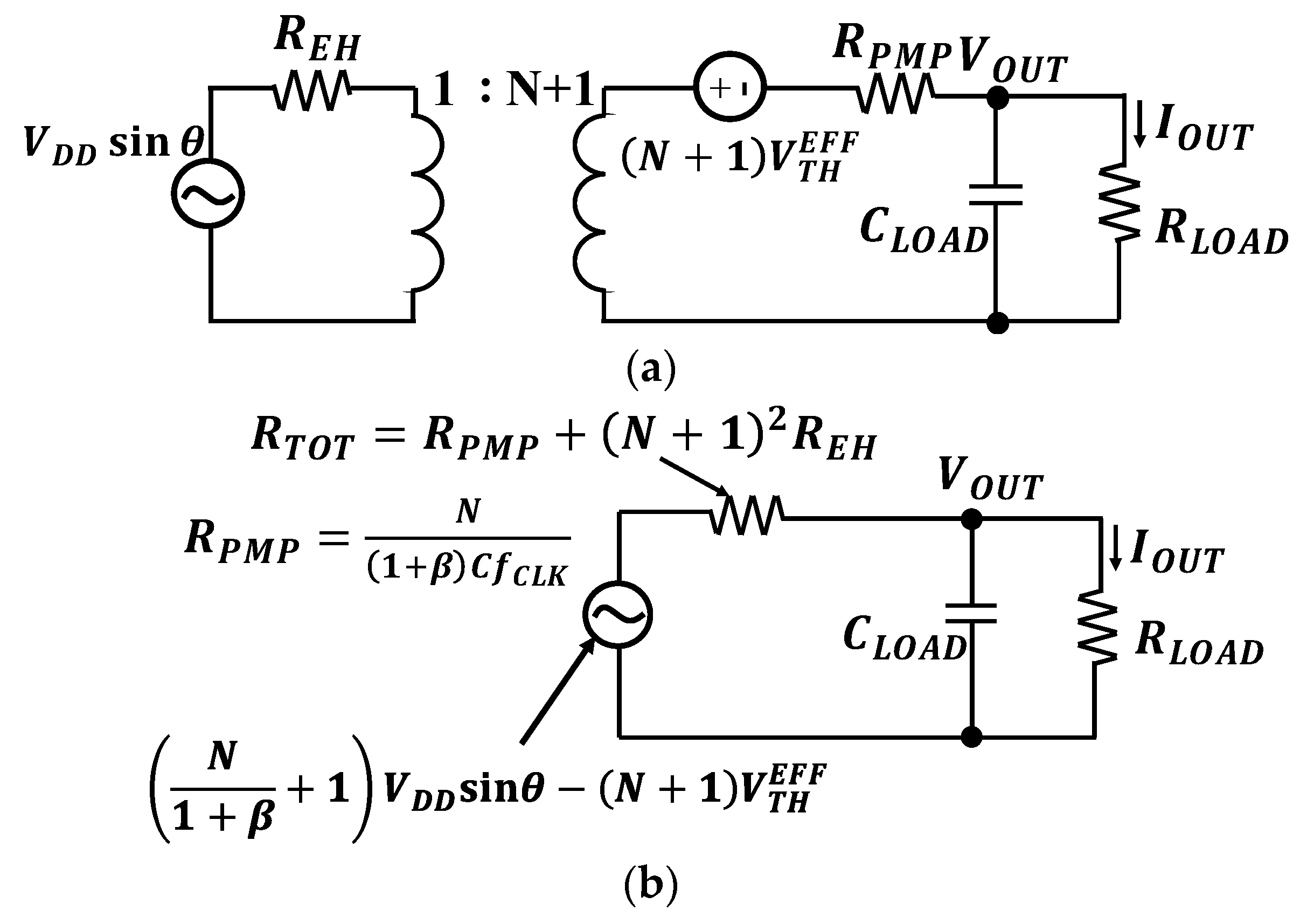

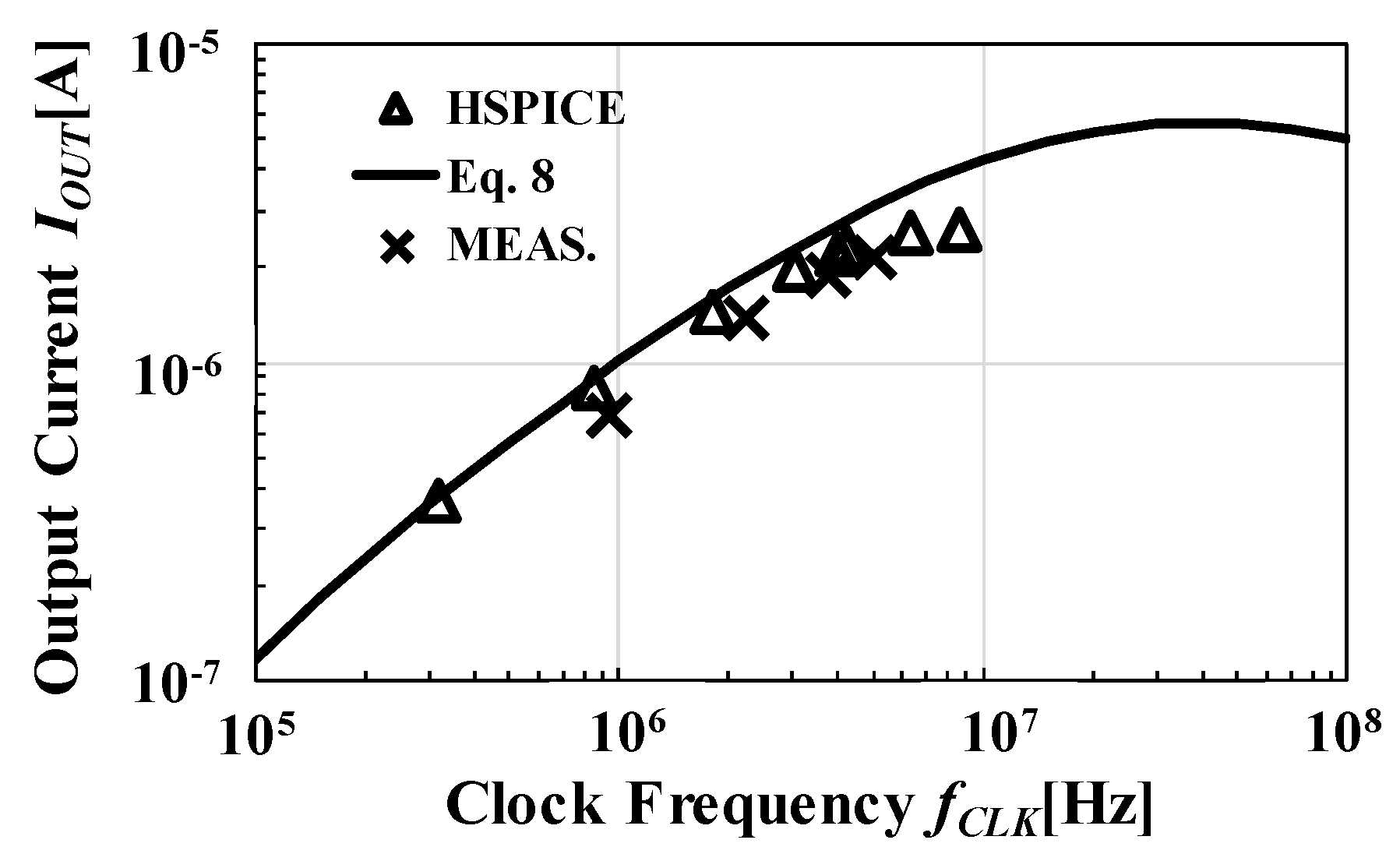

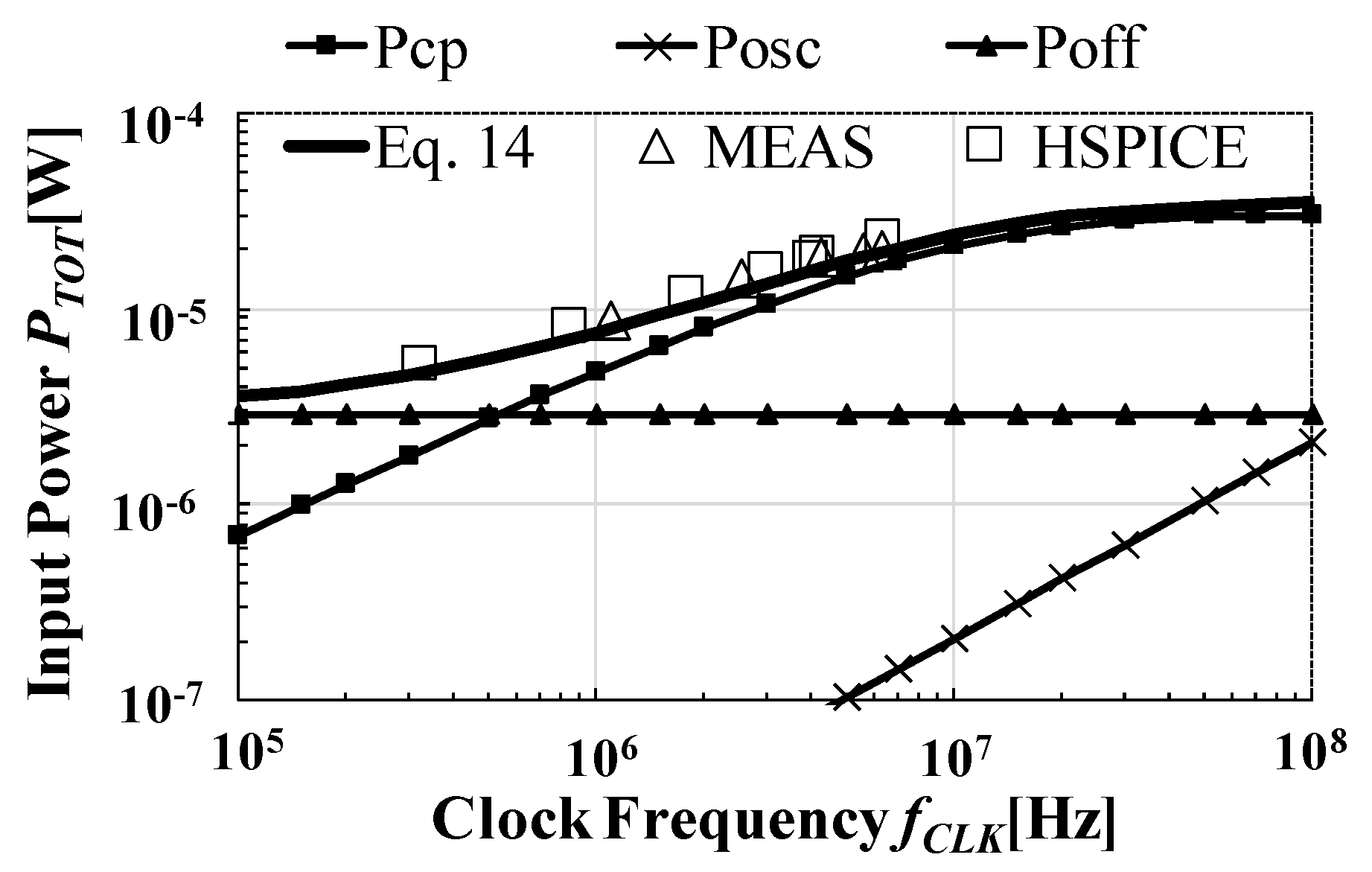

2.1. A Modeling of the Intrinsic Part of the System

2.2. Modeling of Additional Loss Components

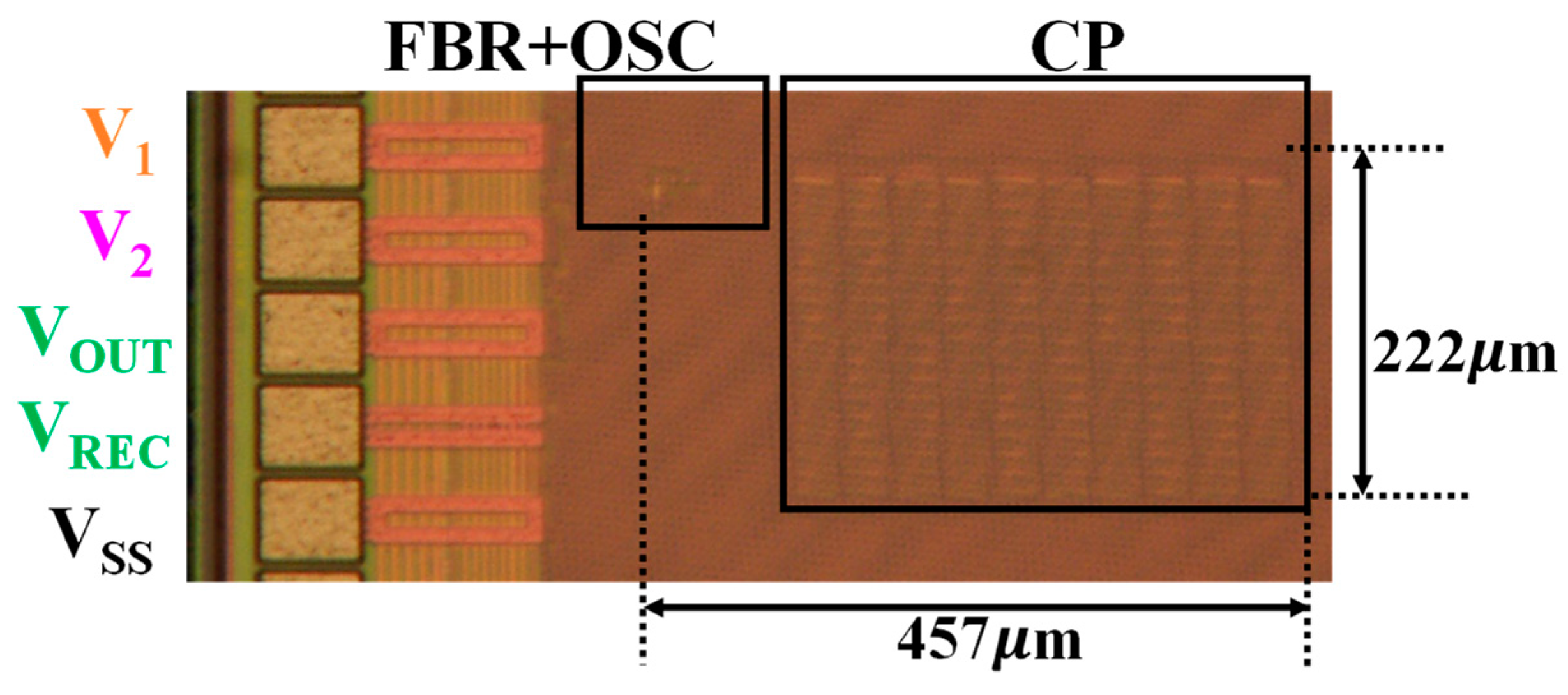

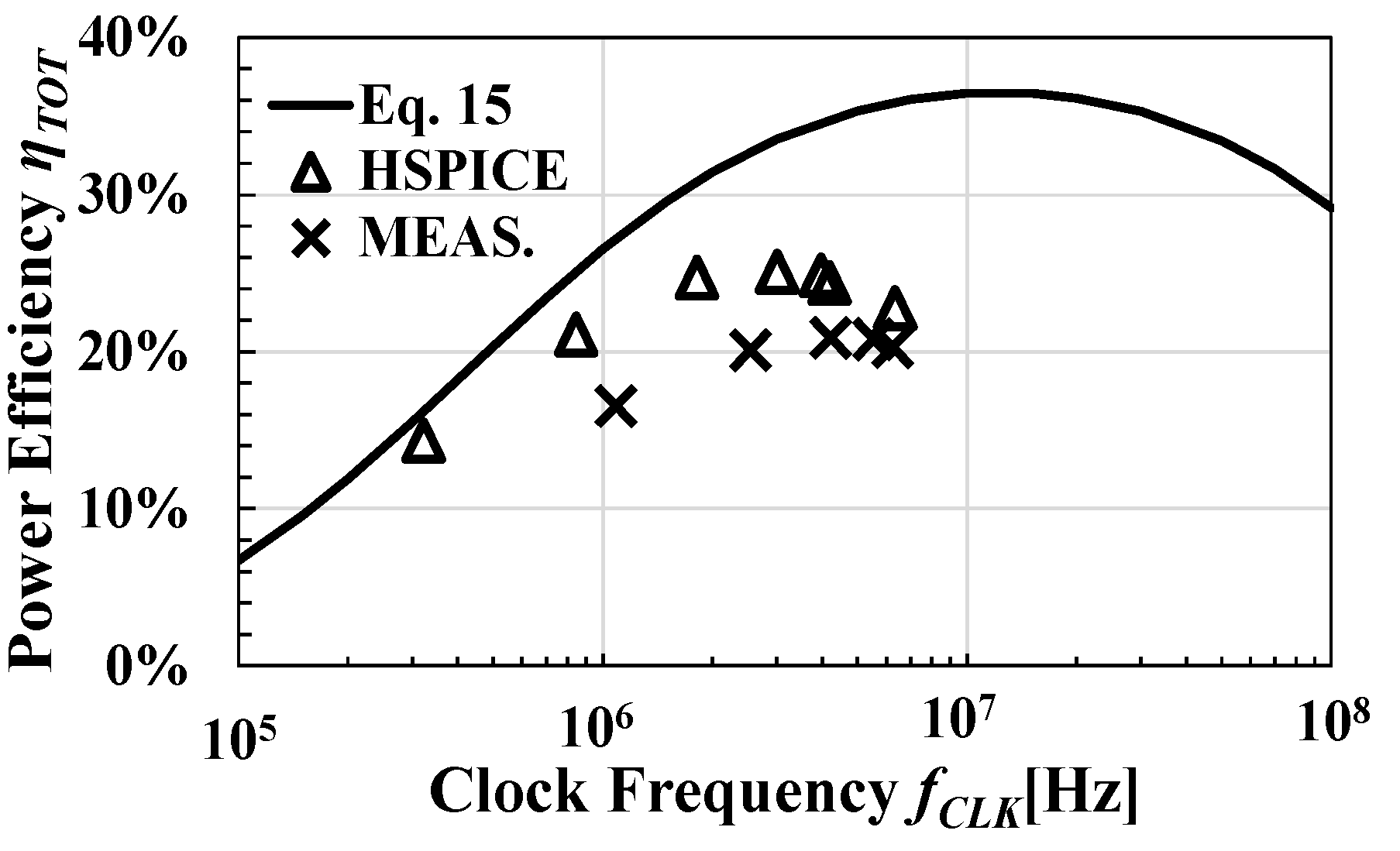

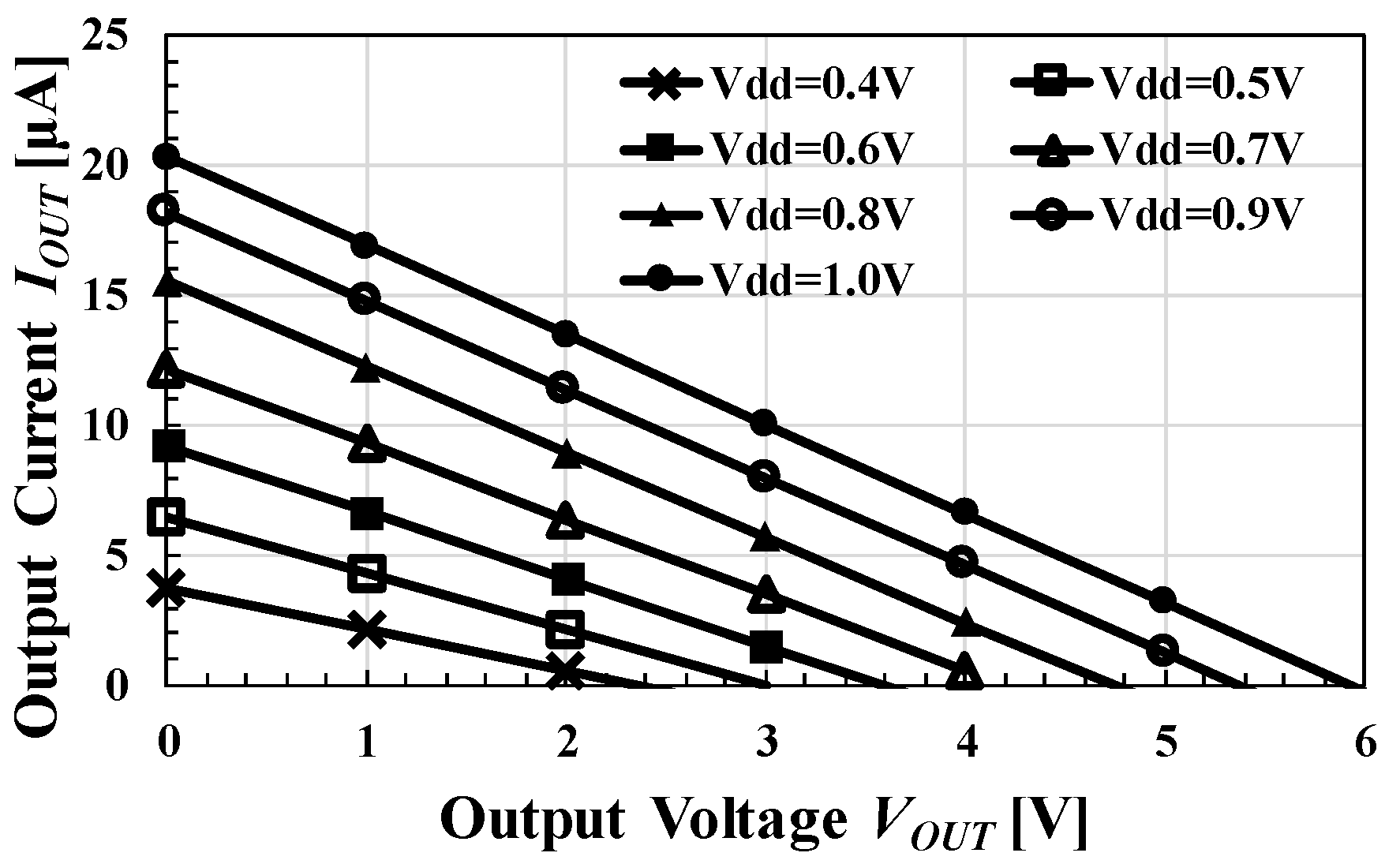

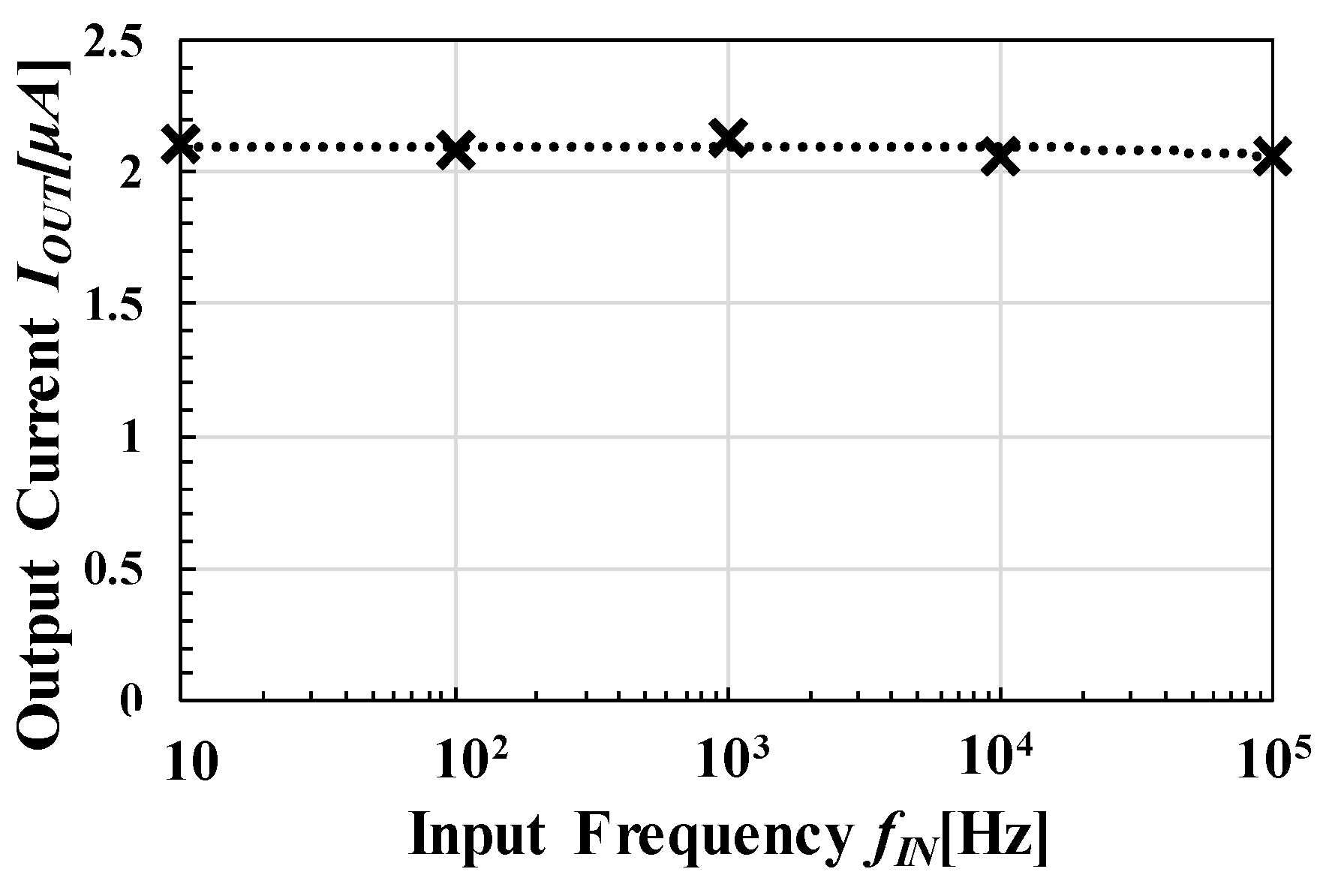

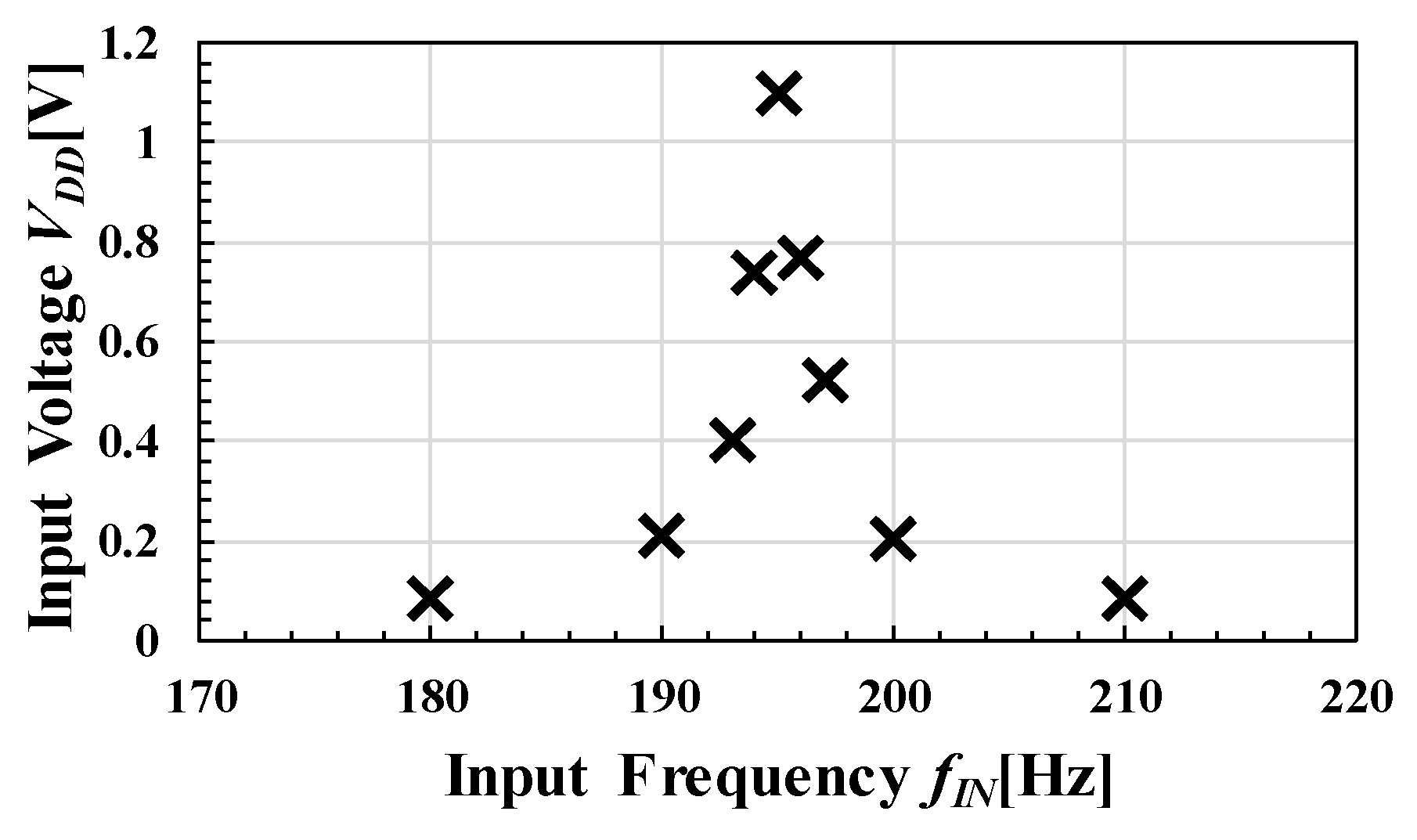

3. Validation

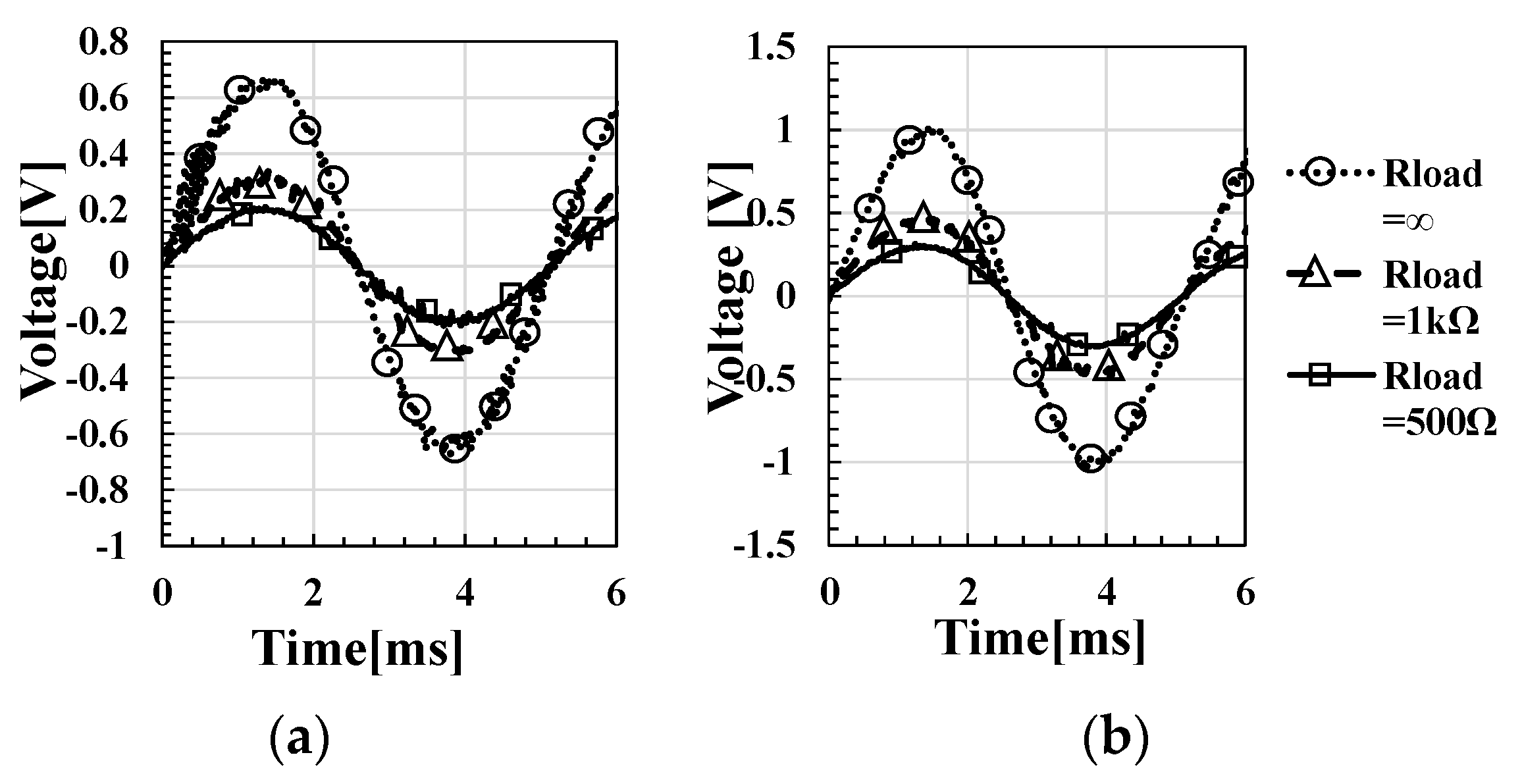

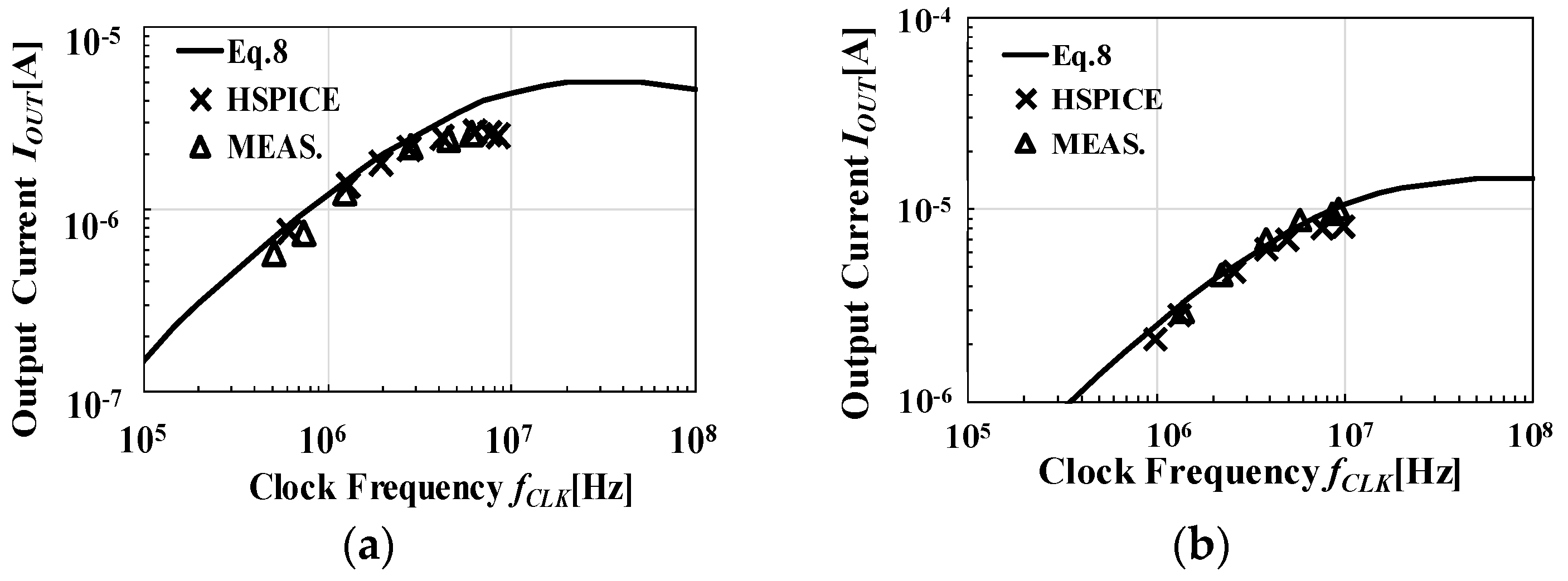

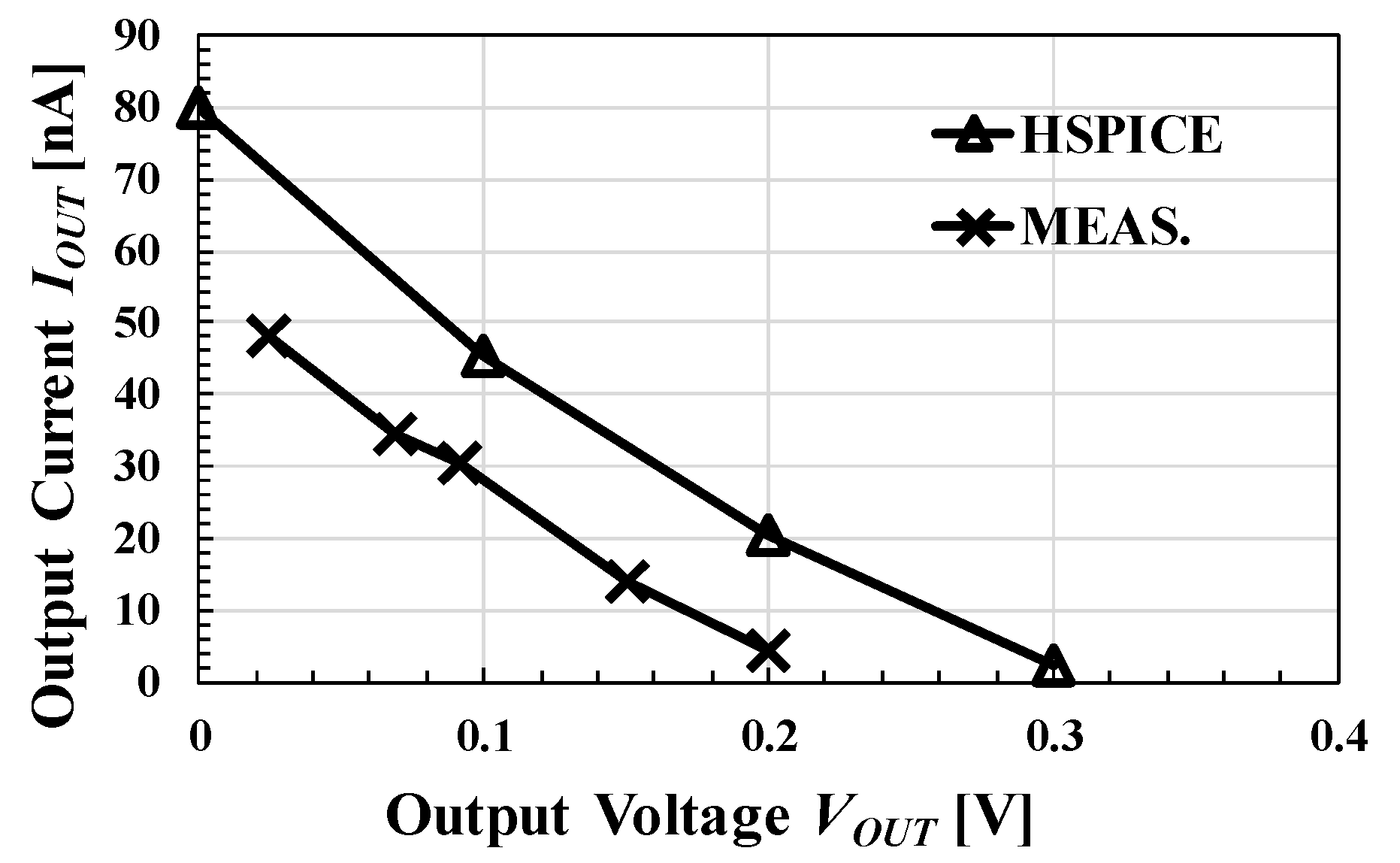

3.1. Validation with AC Power Source

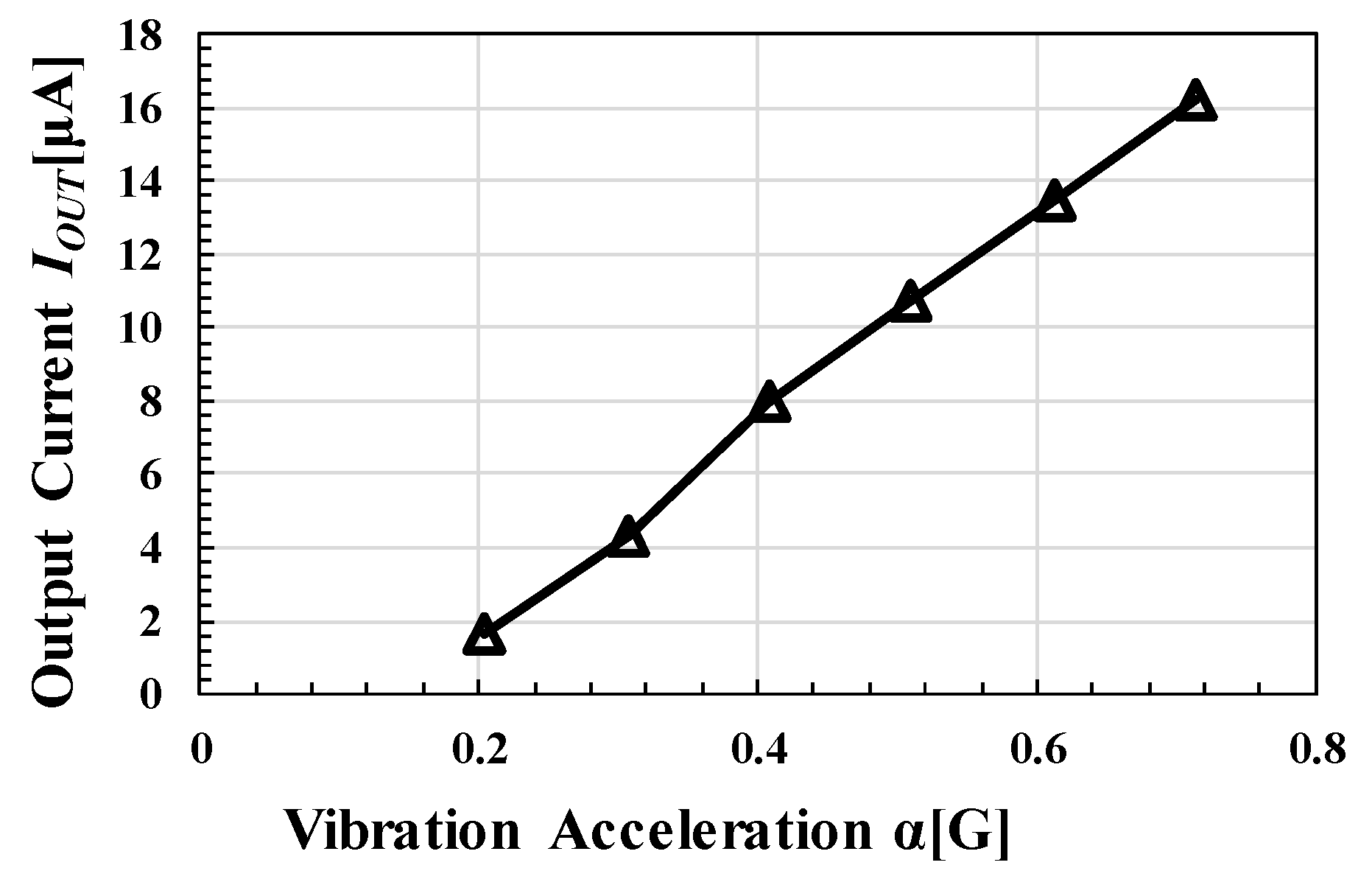

3.2. Validation with Magnetostrictive Energy Transducer

4. Comparison with Other Designs

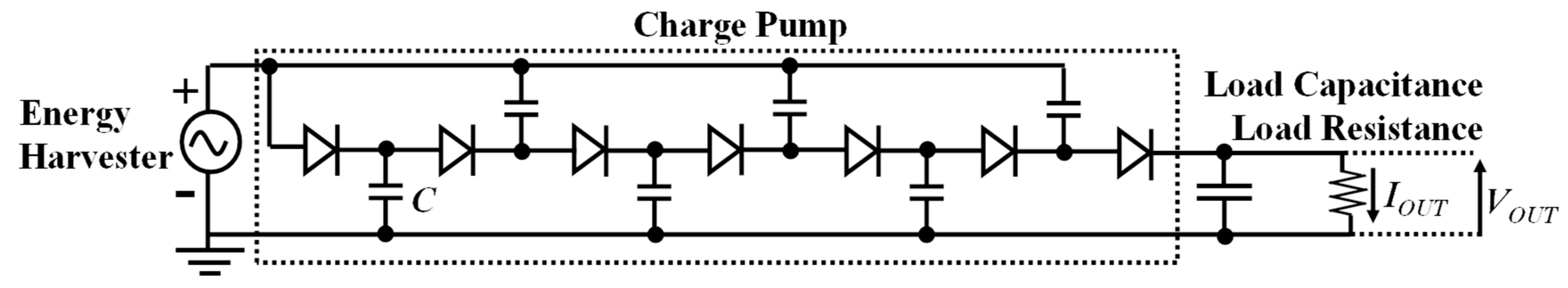

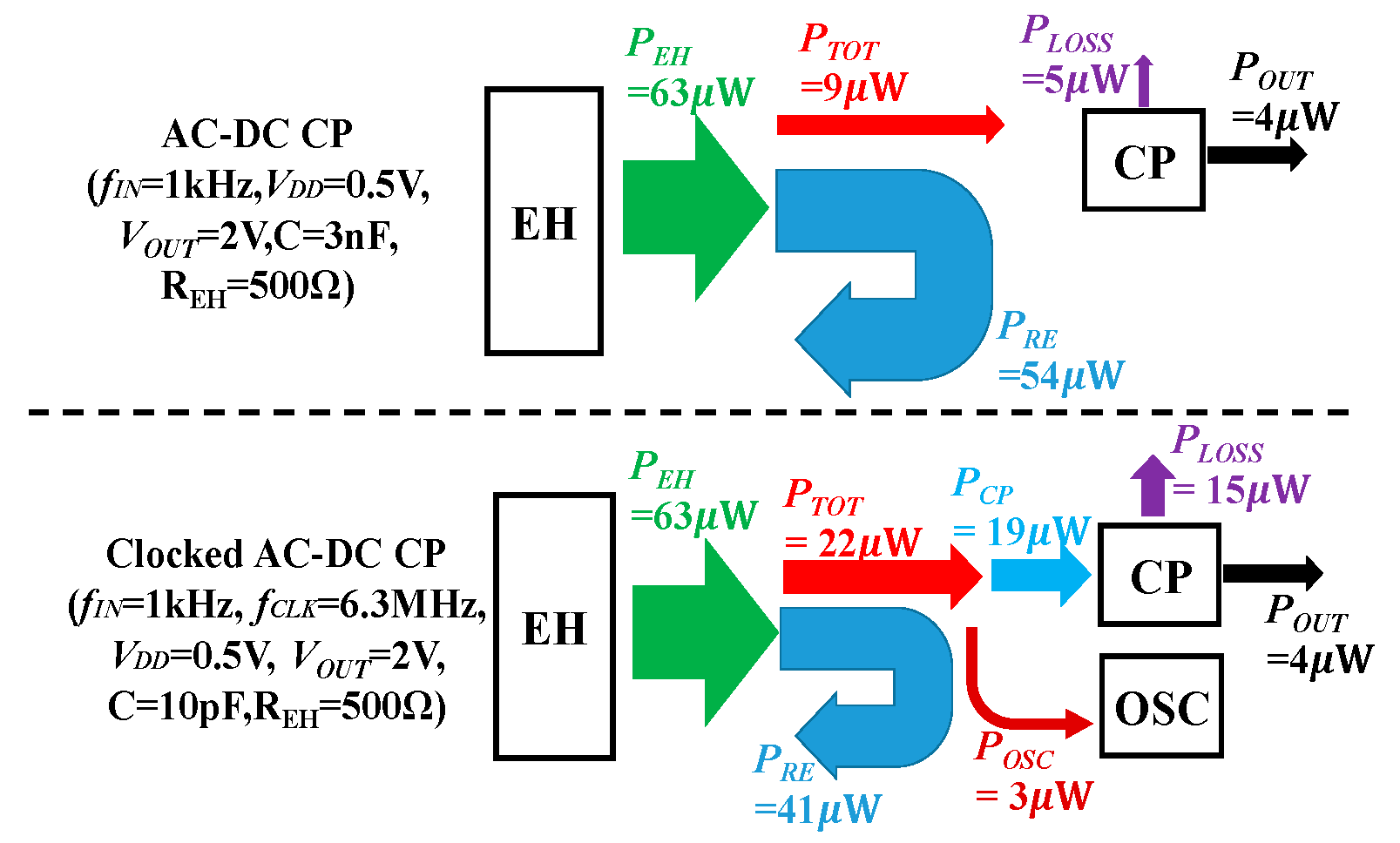

4.1. AC-DC CP

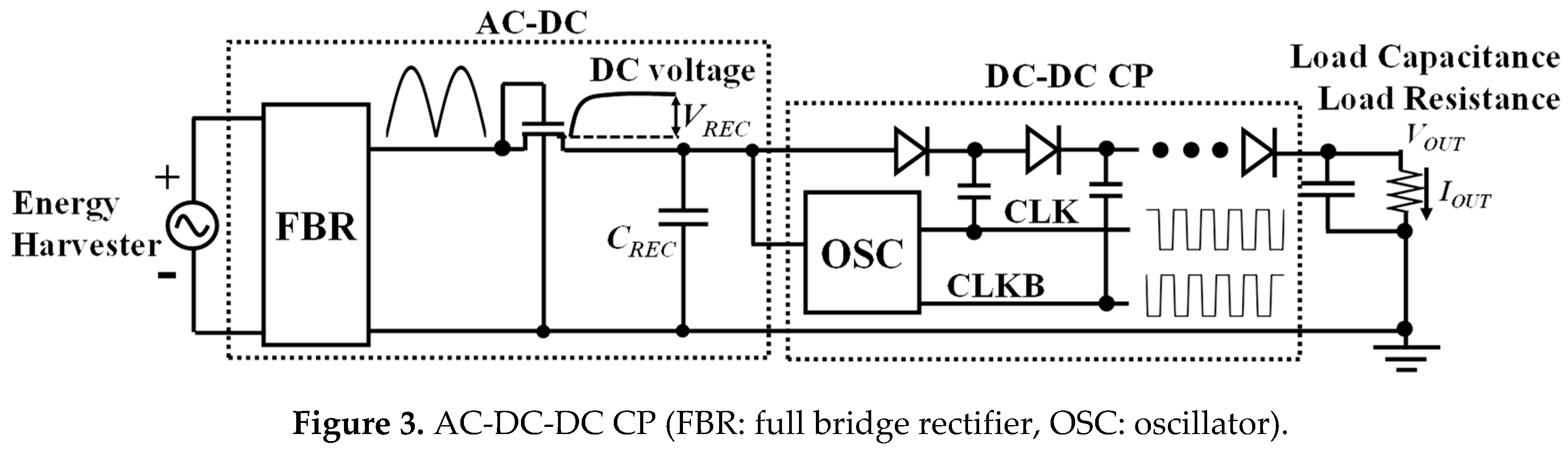

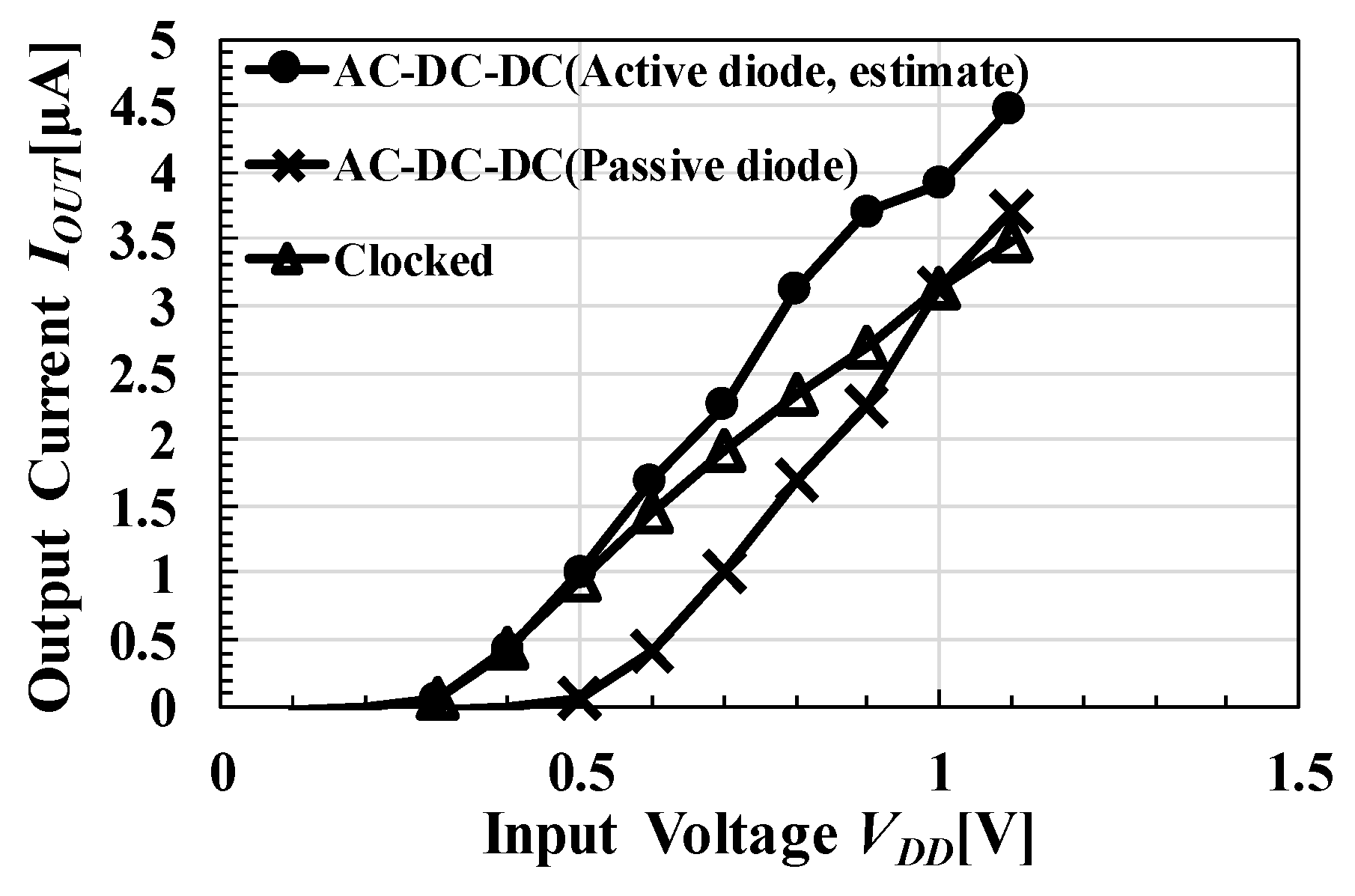

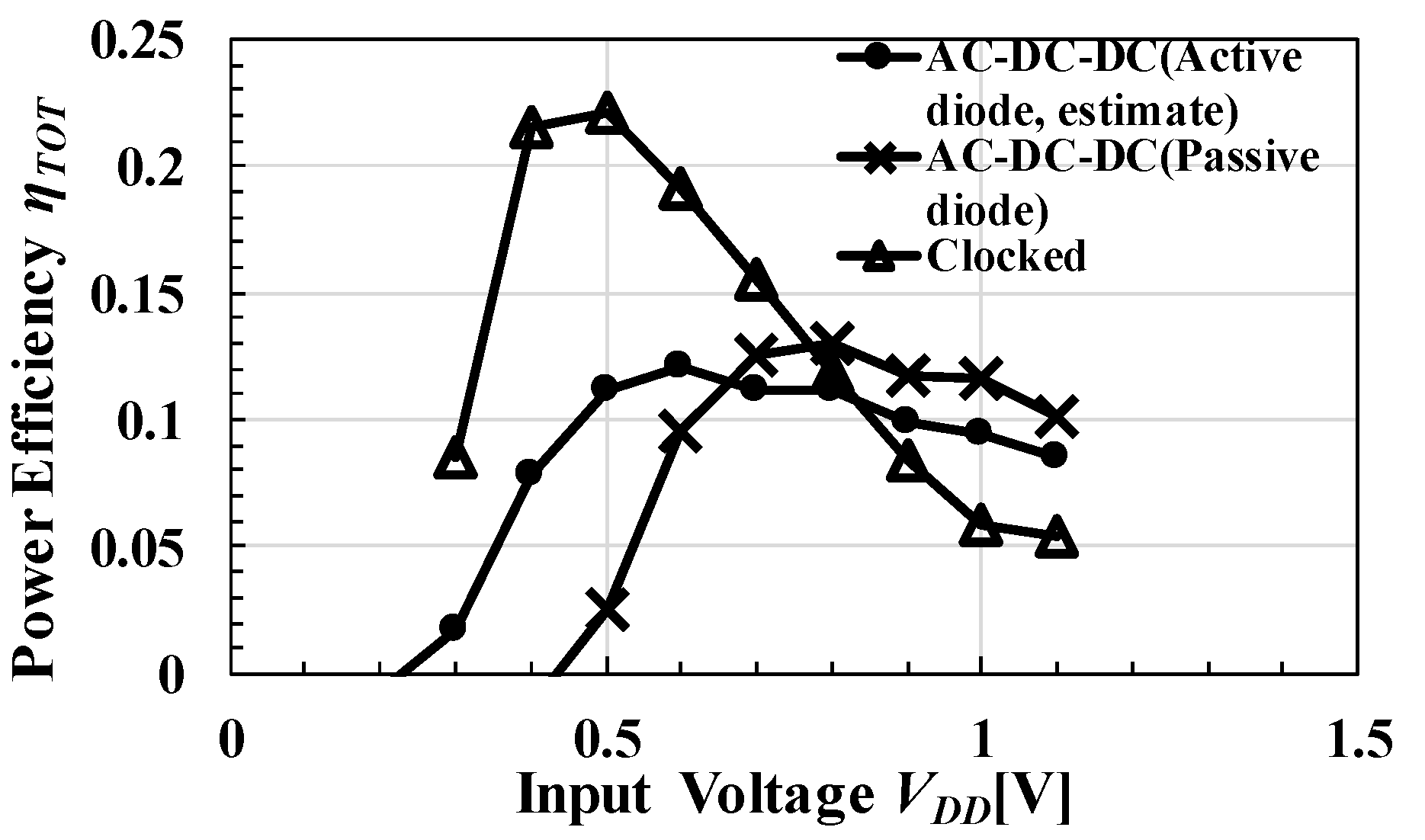

4.2. AC-DC-DC CP

4.3. Comparison with Previous Researche

5. Future Work

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Capacitance per stage | POUT | Output power of the charge pump |

| fCLK | Frequency of a clock generated by ring oscillator | PRE | Reactive power |

| fIN | Frequency of harvester’s output power | PTOT | Power of the system |

| Input current of the charge pump | REH | Output impedance of energy harvester | |

| IOSC | Current driving the oscillator | RTOT | Total output impedance of the system |

| Output current of the charge pump | VDD | AC input voltage amplitude | |

| IS | Diode saturation current | VOUT | Output voltage of the charge pump |

| N | Stage number of the charge pump | VREC | Rectified voltage |

| PCP | Input power of the charge pump | VSS | Ground |

| PEH | Power generated by energy harvesting | VTHEFF | Effective threshold voltage of diode |

| PLOSS | Power loss in the charge pump | VT | Thermal voltage |

| POSC | Power of the oscillator | β | Ratio of parasitic capacitance to C |

| CINV | Load capacitance of the oscillator | θS | Phase at which the output current begins to flow |

| α | Vibration acceleration |

References

- Mitcheson, P.D.; Rao, G.K.; Green, T.C. Energy Harvesting from Human and Machine Motion for Wireless Electronic Devices. Proc. IEEE 2008, 96, 1457–1486. [Google Scholar] [CrossRef] [Green Version]

- Manoli, Y. Energy harvesting from devices to systems. In Proceedings of the 2010 Proceedings of ESSCIRC, Institute of Electrical and Electronics Engineers (IEEE), Seville, Spain, 14–16 September 2010; pp. 27–36. [Google Scholar]

- Chao, L.; Tsui, C.-Y.; Ki, W.-H. A Batteryless Vibration-based Energy Harvesting System for Ultra Low Power Ubiquitous Applications. In Proceedings of the 2007 IEEE International Symposium on Circuits and Systems, Institute of Electrical and Electronics Engineers (IEEE), New Orleans, LA, USA, 27–30 May 2007; pp. 1349–1352. [Google Scholar]

- Arakawa, Y.; Suzuki, Y.; Kasagi, N. Micro Seismic Power Generator Using Electret Polymer Film. Proc. Natl. Symp. Power Energy Syst. 2004, 2005, 37–38. [Google Scholar] [CrossRef]

- Ueno, T. Magnetostrictive vibrational power generator for battery-free IoT application. AIP Adv. 2019, 9, 35018. [Google Scholar] [CrossRef] [Green Version]

- Stanzlone, S.; Liempd, C.; Schaijk, R. A Self-Biased 5-to-60V Input Voltage and 25-to- 1600μW Integrated DC-DC Buck Converter with Fully Analog MPPT Algorithm Reaching up to 88% End-to-End Efficiency. IEEE Int. Solid-State Circuits Conf. 2013, 2, 74–76. [Google Scholar]

- Tom, J.; Kaźmiersuki, S.B. Energy Harvesting Systems: Principles, Modeling and Applications; Springer: Berlin/Heidelberg, Germany, 2010; Chapter 1. [Google Scholar]

- Rahimi, A.; Zorlu, O.; Külah, H.; Muhtaroglu, A. An interface circuit prototype for a vibration-based electromagnetic energy harvester. In Proceedings of the 2010 International Conference on Energy Aware Computing, Institute of Electrical and Electronics Engineers (IEEE), Cairo, Egypt, 16–18 December 2010; pp. 1–4. [Google Scholar]

- Maurath, D.; Becker, P.F.; Spreemann, D.; Manoli, Y. Efficient Energy Harvesting with Electromagnetic Energy Transducers Using Active Low-Voltage Rectification and Maximum Power Point Tracking. IEEE J. Solid-State Circuits 2012, 47, 1369–1380. [Google Scholar] [CrossRef]

- Ulusan, H.; Gharehbaghi, K.; Zorlu, O.; Muhtaroglu, A.; Külah, H. A Fully Integrated and Battery-Free Interface for Low-Voltage Electromagnetic Energy Harvesters. IEEE Trans. Power Electron. 2014, 30, 3712–3719. [Google Scholar] [CrossRef]

- Wang, S.-W.; Ke, Y.-W.; Huang, P.-C.; Hsieh, P.-H. Electromagnetic Energy Harvester Interface Design for Wearable Applications. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 667–671. [Google Scholar] [CrossRef]

- Karthaus, U.; Fischer, M. Fully integrated passive uhf rfid transponder ic with 16.7-μ minimum rf input power. IEEE J. Solid-State Circuits 2003, 38, 1602–1608. [Google Scholar] [CrossRef]

- Papotto, G.; Carrara, F.; Palmisano, G. A 90-nm CMOS Threshold-Compensated RF Energy Harvester. IEEE J. Solid-State Circuits 2011, 46, 1985–1997. [Google Scholar] [CrossRef]

- Kawauchi, H.; Tanzawa, T. A clocked AC-DC voltage multiplier for increasing the power conversion efficiency in vibration energy harvesting. In Proceedings of the IEICE General Conference, Tokyo, Japan, 20–23 March 2018; Available online: http://hdl.handle.net/10297/00025812 (accessed on 20 March 2018).

- Kawauchi, H.; Tanzawa, T. A 2V 3.8 µW Fully-Integrated Clocked AC-DC Charge Pump with 0.5 V 500 Ω Vibration Energy Harvester. In Proceedings of the IEEE Asia Pacific Conference on Circuits and Systems, Bangkok, Thailand, 11–14 November 2019; pp. 329–332. [Google Scholar]

- Tanzawa, T. An Analytical Model of Charge Pump DC-DC Voltage Multiplier Using Diodes. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2017, 1137–1144. [Google Scholar] [CrossRef]

- Tanzawa, T. Design of DC-DC Switched-Capacitor Voltage Multiplier driven by DC Energy Harvester. In Proceedings of the IEEE International Conference on Electronics Circuits and Systems, Marseille, France, 7–10 December 2014; pp. 327–330. [Google Scholar]

- Tanzawa, T. An Optimum Design for Integrated Switched-Capacitor Dickson Charge Pump Multipliers with Area Power Balance. IEEE Trans. Power Electron. 2014, 29, 534–538. [Google Scholar] [CrossRef]

- Peters, C.; Kessling, O.; Henrici, F.; Ortmanns, M.; Manoli, Y. CMOS Integrated Highly Efficient Full Wave Rectifier. IEEE Int. Symp. Circuits Syst. 2007, 2415–2418. [Google Scholar] [CrossRef]

- Haddad, P.; Gosset, G.; Raskin, J.; Flandre, D. Automated Design of a 13.56 MHz 19 μW Passive Rectifier with 72% Efficiency Under 10 μA load. IEEE J. Solid-State Circuits 2016, 51, 5. [Google Scholar] [CrossRef]

- Tokuda, S.; Tanzawa, T. Toward a Minimum-Operating-Voltage Design of DC-DC Charge Pump Circuits for Energy Harvesting. IEEE Int. Symp. Circuits Syst. (ISCAS) 2019, 1–4. [Google Scholar] [CrossRef]

- Leicht, J. CMOS Circuits for Electromagnetic Vibration Energy Harvesters: System Modeling, Interface Design and Implementation. Ph.D. Thesis, University of Freiburg, Fahnenbergplatz, Germany, July 2019. Chapter 2. [Google Scholar] [CrossRef]

- Tanzawa, T. A Behavior Model of an On-Chip High Voltage Generator for Fast, System-Level Simulation. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2011, 20, 2351–2355. [Google Scholar] [CrossRef]

| Piezoelectric [3] | Electrostatic [4] | Magnetostrictive [5] | |

|---|---|---|---|

| Nominal output impedance | 100 kΩ–1 MΩ | 100 MΩ–1 GΩ | 100 Ω–1 kΩ |

| Nominal output voltage | 1 V–10 V | 10 V–100 V | 0.1 V–1 V |

| Output power (mW/cm3) | 0.74–3 [7] | 0.08–0.6 [7] | 20 [5] |

| ET * | Boosting Method | Discrete Element (Values) * | Circuit Area | Maximum fIN | Power Efficiency | CMOS | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| VDD | VOUT | POUT | REH | |||||||

| [8] | EM | AC-DC CP | 3C + 4D (N.A.) | Discrete | N.A. | 25% (ηTOT) | - | |||

| N.A. | 2 V | 30 μW | N.A. | |||||||

| [9] | EM | AC-DC-DC CP | 1C (10 nF) | 0.58 mm2 + 4.84 mm2 | 10 kHz (Est.) | 37% (ηSYS) | 0.35 μm | |||

| 1.2 V | 2 V | 33 μW | 2k Ω | |||||||

| [10] | EM | AC-DC-DC CP | 1C (1 μF) | N.A. | 30kHz | 13% (ηTOT) | 90 nm | |||

| 0.5 V | 1.8 V | 3.2 μW | 180 Ω | |||||||

| [11] | EM | Rectifier + switching regulator | 1L (N.A.) | 1.6 × 1.6 mm2 | N.A. | 67% (ηSYS) | 0.18 μm | |||

| 0.6 V | 1 V | 1 mW | 120 Ω | |||||||

| This work | MS | Clocked AC-DC CP | None | 0.11 mm2 | 100 kHz or higher | 23% (ηTOT), 6% (ηSYS) | 65 nm | |||

| 0.5 V | 2 V | 4.2 μW | 500 Ω | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawauchi, H.; Tanzawa, T. A Fully Integrated Clocked AC-DC Charge Pump for Mignetostrictive Vibration Energy Harvesting. Electronics 2020, 9, 2194. https://doi.org/10.3390/electronics9122194

Kawauchi H, Tanzawa T. A Fully Integrated Clocked AC-DC Charge Pump for Mignetostrictive Vibration Energy Harvesting. Electronics. 2020; 9(12):2194. https://doi.org/10.3390/electronics9122194

Chicago/Turabian StyleKawauchi, Hayato, and Toru Tanzawa. 2020. "A Fully Integrated Clocked AC-DC Charge Pump for Mignetostrictive Vibration Energy Harvesting" Electronics 9, no. 12: 2194. https://doi.org/10.3390/electronics9122194