Extraction of Inulin from Andean Plants: An Approach to Non-Traditional Crops of Ecuador

Abstract

1. Introduction

2. Results

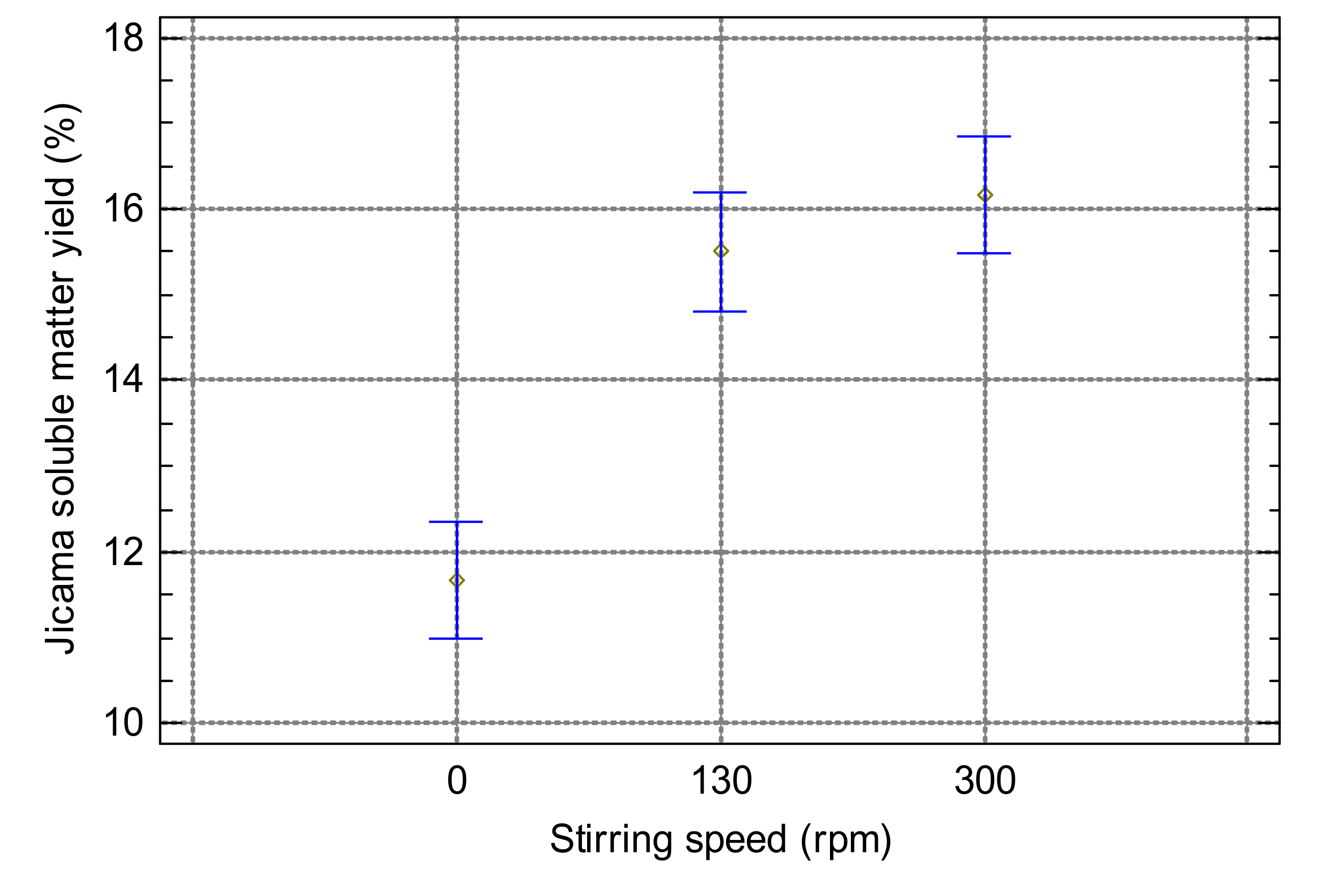

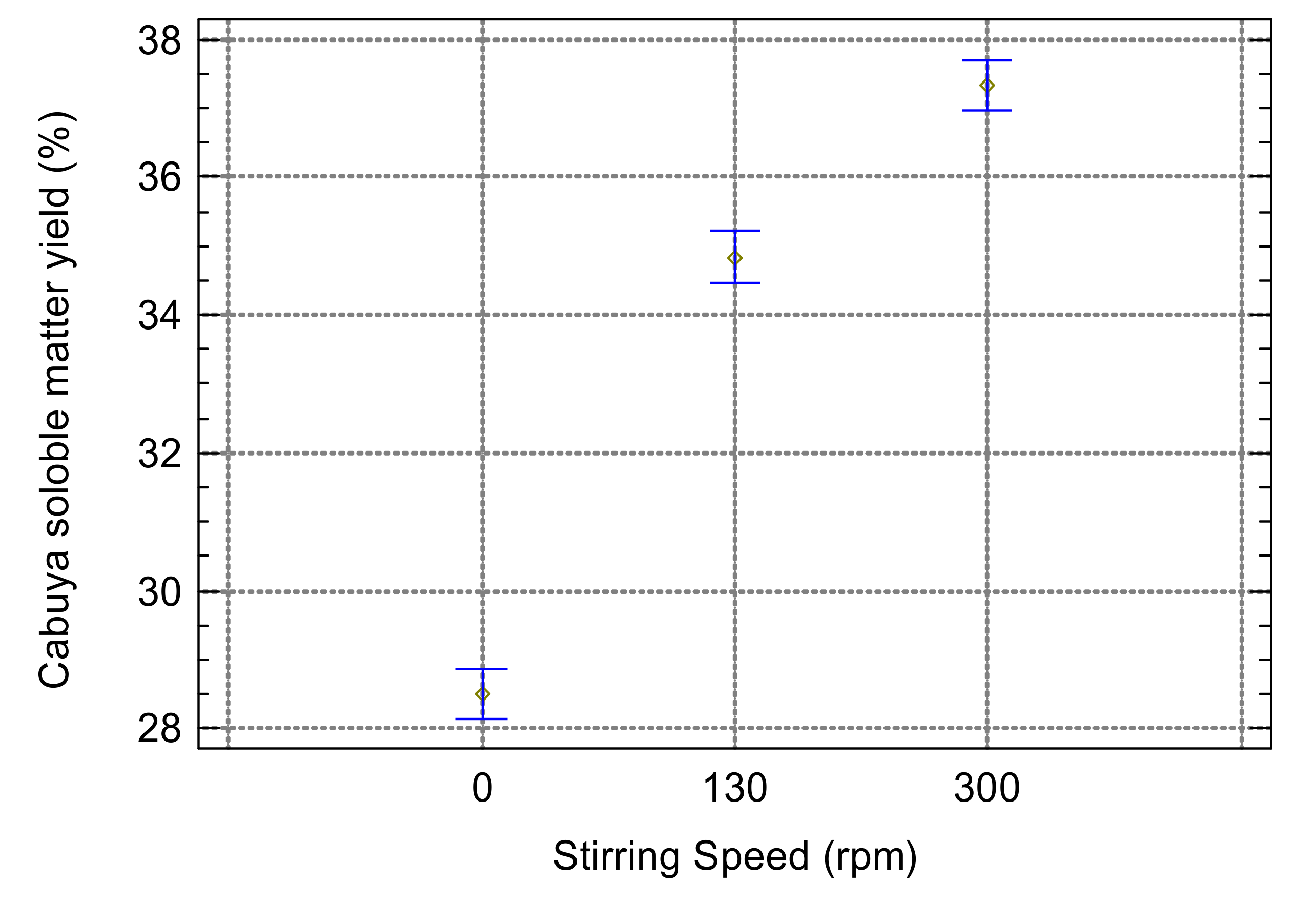

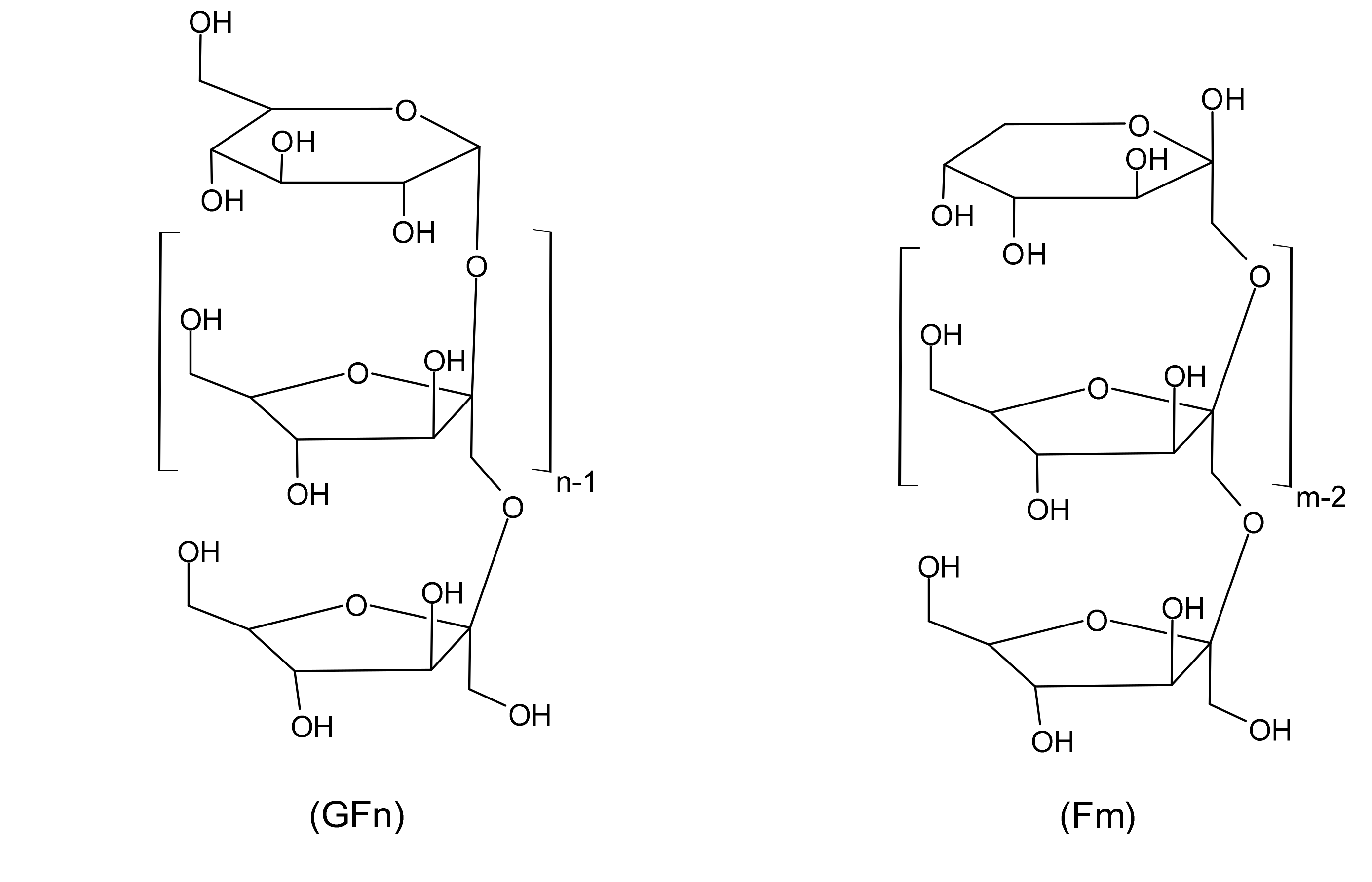

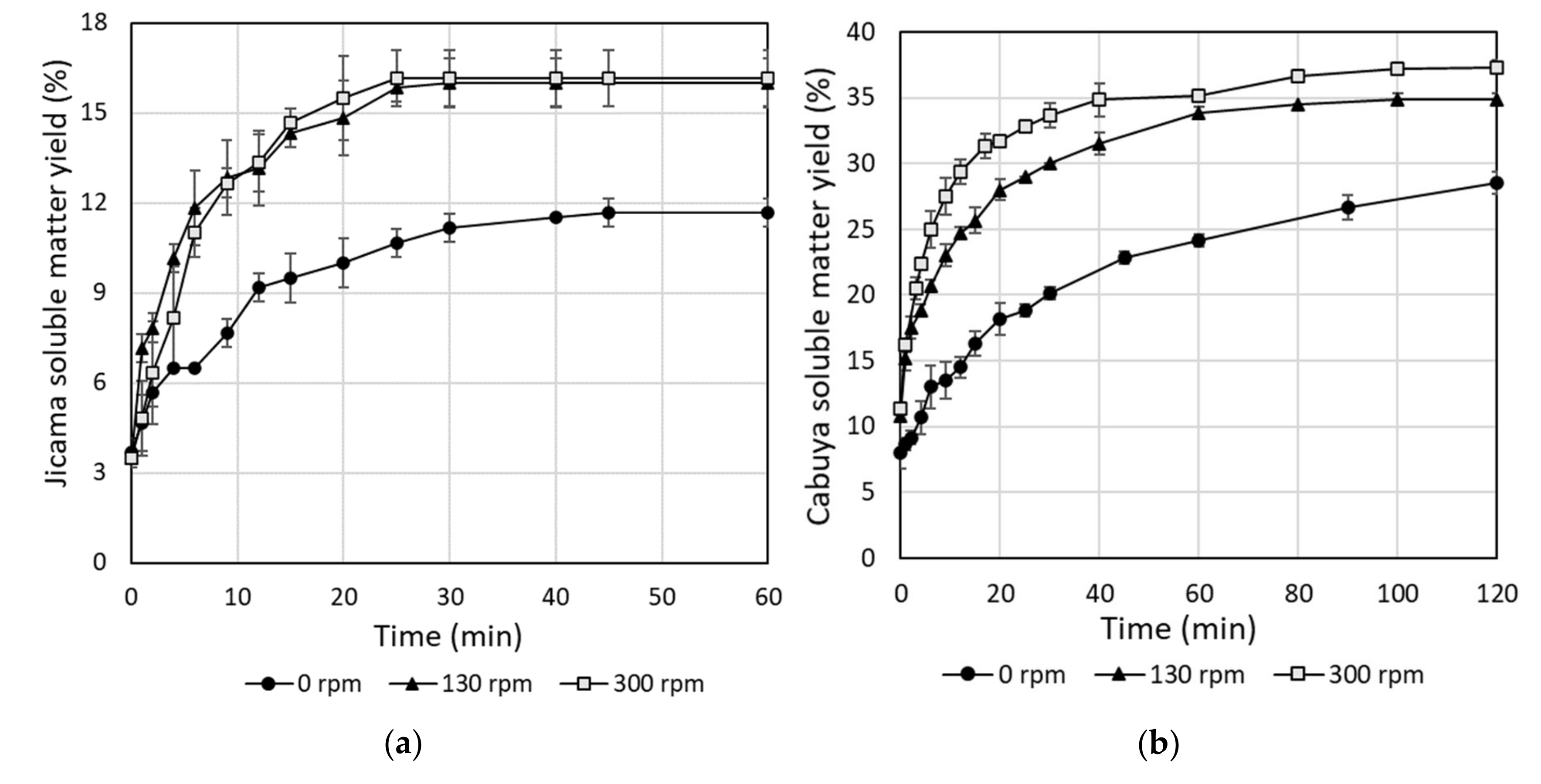

2.1. Chemical Composition of Vegetable Materials and Extraction of Soluble Matter

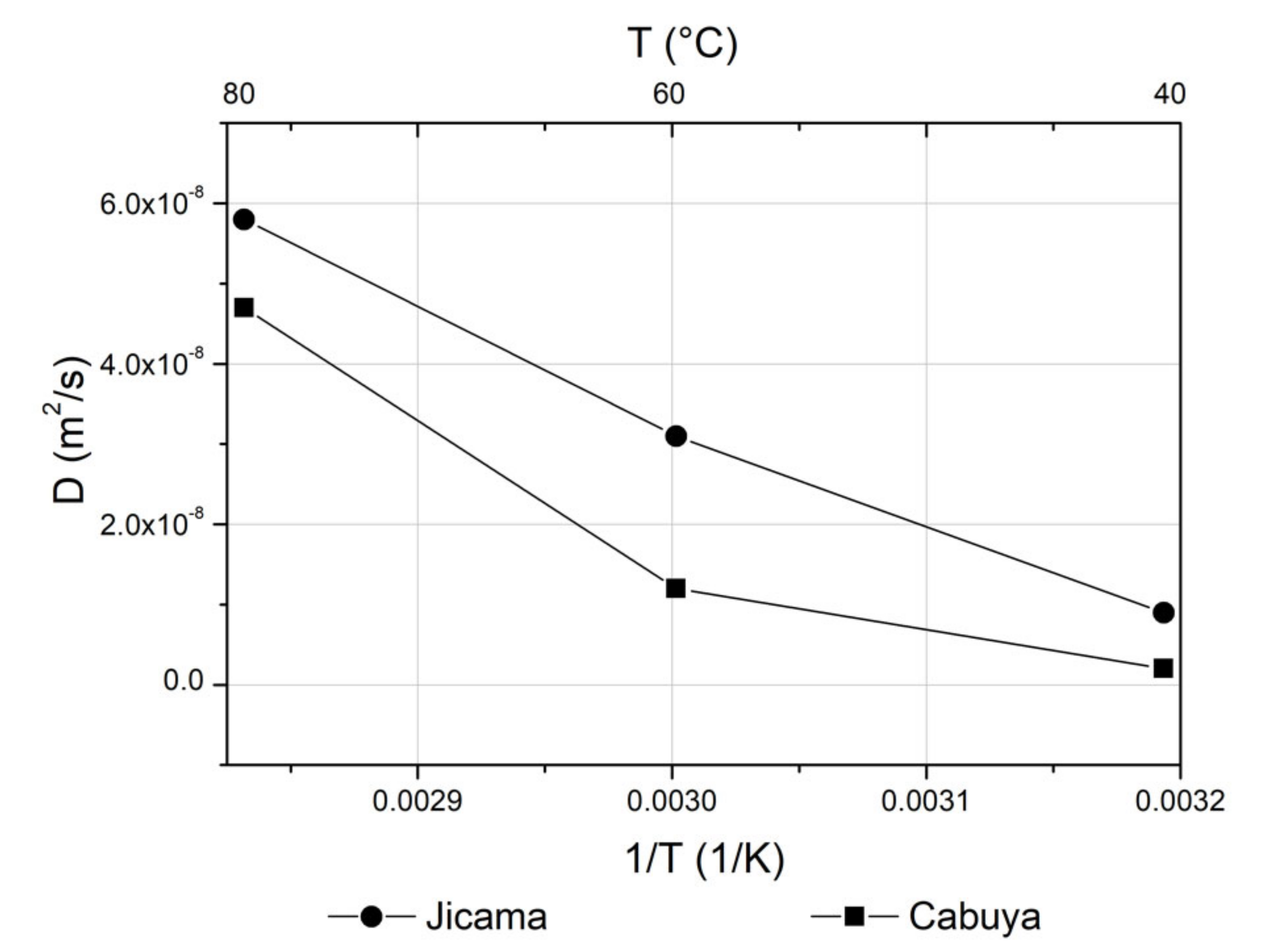

2.2. Determination of Temperature and Solid:Liquid Ratio

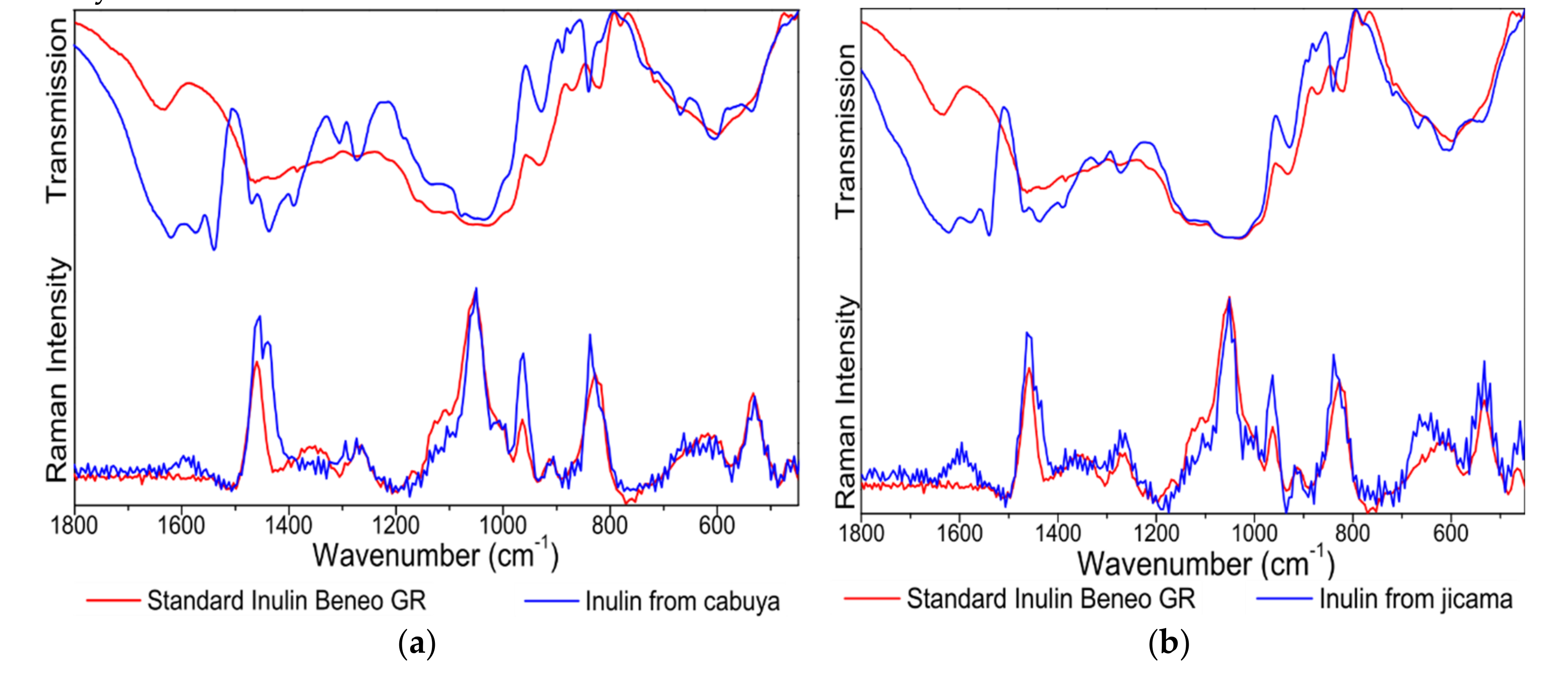

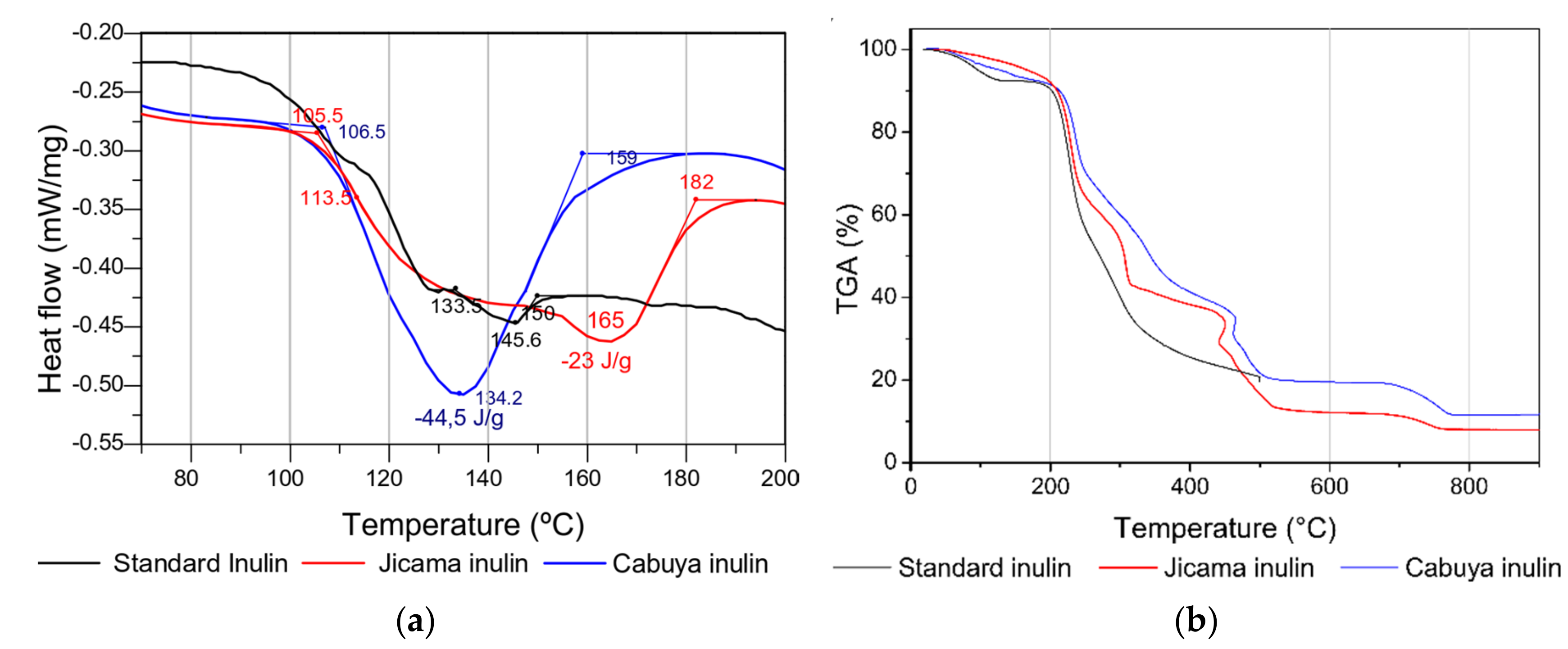

2.3. Characterization of the Inulin Powder Obtained from the Fructan Extract

3. Materials and Methods

3.1. Vegetable Materials and Reagent

3.2. Characterization of the Vegetable Materials and Soluble Matter Extraction Conditions

3.3. Characterization of Inulin Powder

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between groups | 35.3 | 2 | 17.7 | 37.47 | 0.0004 |

| Within groups | 2.8 | 6 | 0.4 | --- | --- |

| Total | 38.2 | 8 | --- | --- | --- |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F-Ratio | P-Value |

|---|---|---|---|---|---|

| Between groups | 124.3 | 2 | 62.2 | 447.8 | 0.0000 |

| Within groups | 0.8 | 6 | 0.1 | --- | --- |

| Total | 125.2 | 8 | --- | --- | --- |

References

- Caetano, B.F.R.; de Moura, N.A.; Almeida, A.P.S.; Dias, M.C.; Sivieri, K.; Barbisan, L.F. Yacon (Smallanthus sonchifolius) as a food supplement: Health-promoting benefits of fructooligosaccharides. Nutrients 2016, 8, 436. [Google Scholar] [CrossRef] [PubMed]

- Choque, D.G.T.; da Silva, C.T.W.M.; Maróstica, J.M.R.; Pastore, G.M. Yacon (Smallanthus sonchifolius): A Functional Food. Plant Foods Hum. Nutr. 2013, 68, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Sahnoun, M.; Bejar, S.; Daoud, L.; Ayadi, L.; Brini, F. Effect of Agave americana L. on the human, and Aspergillus oryzae S2 α -amylase inhibitions. Nat. Prod. Res. 2017, 6419, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Bouaziz, M.A.; Rassaoui, R.; Besbes, S. Chemical composition, functional properties, and effect of inulin from tunisian Agave americana L. Leaves on textural qualities of pectin gel. J. Chem. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- da Silva, M.D.F.G.; Dionísio, A.P.; Ferreira Carioca, A.A.; Silveira Adriano, L.; Pinto, C.O.; Pinto de Abreu, F.A.; Wurlitzer, N.J.; Araújo, I.M.; dos Santos Garruti, D.; Ferreira Pontes, D. Yacon syrup: Food applications and impact on satiety in healthy volunteers. Food Res. Int. 2017, 100, 460–467. [Google Scholar] [CrossRef]

- Salem, A.Z.M.; Valdez, N.T.; Olafadehan, O.A.; Elghandour, M.M.Y.; Barbabosa Pliego, A.; Coyote, R.L. Influence of aguamiel (Agave atrovirens) as a natural feed additive on cecal fermentation kinetics of some forage species in horse feeding. J. Equine Vet. Sci. 2017, 48, 103–112. [Google Scholar] [CrossRef]

- Pedreschi, R.; Campos, D.; Noratto, G.; Chirinos, R.; Cisneros-Zevallos, L. Andean yacon root (Smallanthus sonchifolius Poepp. Endl) fructooligosaccharides as a potential novel source of prebiotics. J. Agric. Food Chem. 2003, 51, 5278–5284. [Google Scholar] [CrossRef]

- Rajchl, A.; Fernández Cusimamani, E.; Prchalová, J.; Ševčík, R.; Čížková, H.; Žiarovská, J.; Hrdličková, M. Characterisation of yacon tuberous roots and leaves by DART-TOF/MS. Int. J. Mass Spectrom. 2018, 424, 27–34. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Kaur & Gupta Applications of inulin and oligofructose in health and nutrition. J. Biosci. 2002, 27, 703–714. [CrossRef]

- Korbelik, M.; Cooper, P.D. Potentiation of photodynamic therapy of cancer by complement: The effect of γ-inulin. Br. J. Cancer 2007, 96, 67–72. [Google Scholar] [CrossRef] [PubMed]

- Roberfroid, M.B. Introducing inulin-type fructans. Br. J. Nutr. 2005, 93, S13. [Google Scholar] [CrossRef] [PubMed]

- Taper, H.S.; Roberfroid, M.B. Possible adjuvant cancer therapy by two prebiotics—Inulin or oligofructose. In Vivo (Brooklyn) 2005, 19, 201–204. [Google Scholar]

- Leyva-porras, C.; López-pablos, A.L.; Alvarez-salas, C.; Pérez-urizar, J. Physical properties of inulin and technological applications. Polysaccharides 2014, 1–22. [Google Scholar] [CrossRef]

- Mensink, M.A.; Frijlink, H.W.; Van Der Voort Maarschalk, K.; Hinrichs, W.L.J. Inulin, a flexible oligosaccharide I: Review of its physicochemical characteristics. Carbohydr. Polym. 2015, 130, 405–419. [Google Scholar] [CrossRef]

- Stevens, C.V.; Meriggi, A.; Booten, K. Chemical modification of inulin, a valuable renewable resource, and its industrial applications. Biomacromolecules 2001, 2, 1–16. [Google Scholar] [CrossRef]

- Stevens, C.V.; Meriggi, A.; Peristeropoulou, M.; Christov, P.P.; Booten, K.; Levecke, B.; Vandamme, A.; Pittevils, N.; Tadros, T.F. Polymeric surfactants based on inulin, a polysaccharide extracted from chicory. 1. Synthesis and interfacial properties. Biomacromolecules 2001, 2, 1256–1259. [Google Scholar] [CrossRef]

- Anańina, N.A.; Andreeva, O.A.; Mycots, L.P.; Oganesyan, E.T. Standardization of inulin extracted from Dahlia single tubers and some physicochemical properties of inulin. Pharm. Chem. J. 2009, 43, 157–159. [Google Scholar] [CrossRef]

- Arango, O.; Cuarán, I.; Fajardo, J.C. Extraction, crystalization and characterization of inulin from yacon (Smallanthus sonchifolius (Poepp. & Endl.) for to be used in food and farmaceutic industry. Biotecnología en el Sector Agropecuario y Agroindustrial 2008, 6, 14–20. [Google Scholar]

- Kumar, V.P.; Prashanth, K.V.H.; Venkatesh, Y.P. Structural analyses and immunomodulatory properties of fructo-oligosaccharides from onion (Allium cepa). Carbohydr. Polym. 2015, 117, 115–122. [Google Scholar] [CrossRef]

- Milani, E.; Koocheki, A.; Golimovahhed, Q.A. Extraction of inulin from Burdock root (Arctium lappa) using high intensity ultrasound. Int. J. Food Sci. Technol. 2011, 46, 1699–1704. [Google Scholar] [CrossRef]

- Sánchez-Madrigal, M.Á.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Báez-González, J.G.; Núñez-González, M.A.; Ruiz-Gutiérrez, M.G.; Garzón-Tiznado, J.A. Ultrasound-assisted extraction of fructans from agave (Agave tequilana Weber var. azul) at different ultrasound powers and solid-liquid ratios. Food Sci. Technol. 2017, 37, 261–268. [Google Scholar] [CrossRef]

- Apolinário, A.C.; Martins de Carvalho, E.; Goulart de Lima Damasceno, B.P.; Dantas da Silva, P.C.; Converti, A.; Pessoa, A.; da Silva, J.A. Extraction, isolation and characterization of inulin from Agave sisalana boles. Ind. Crops Prod. 2017, 108, 355–362. [Google Scholar] [CrossRef]

- Olvera Carranza, C.; Ávila Fernandez, A.; Bustillo Armendáriz, G.R.; López-Munguía, A. Processing of fructans and oligosaccharides from agave plants. In Processing and Impact on Active Components in Food; Preddy, V., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 121–129. ISBN 9780124047099. [Google Scholar]

- Montañez-Soto, J.; Venegas-González, J.; Vivar-Vera, M.; Ramos-Ramirez, E. Extracción, caracterización y cuantificación de los fructanos contenidos en la cabeza y en las hojas del Agave tequilana Weber azul. Bioagro 2011, 23, 199–206. [Google Scholar]

- Narváez-Flores, M.; Sánchez-Madrigal, M.; Quintero-Ramos, A.; Paredes-Lizárraga, M.A.; González-Laredo, R.F.; Ruiz-Gutiérrez, M.G.; Piñón-Castillo, H.A.; Meléndez-Pizarro, C.O. Ultrasound assisted extraction modeling of fructans from agave (Agave tequilana Weber var. Azul) at different temperatures and ultrasound powers. Food Bioprod. Process. 2015, 96, 232–239. [Google Scholar] [CrossRef]

- Narváez-Zapata, J.A.; Sánchez-Teyer, L.F. Agaves as a raw material: Recent technologies and applications. Recent Pat. Biotechnol. 2009, 3, 185–191. [Google Scholar] [CrossRef]

- Orozco-Cortés, A.D.; Álvarez-Manilla, G.; Gutiérrez-Sánchez, G.; Rutiaga-Quiñones, O.; López-Miranda, J.; Soto-Cruz, N.O. Characterization of fructans from Agave durangensis. African J. Plant Sci. 2015, 9, 360–367. [Google Scholar] [CrossRef]

- Salazar-Leyva, J.A.; Osuna-Ruiz, I.; Rodríguez-Tirado, V.A.; Zazueta-Patrón, I.E.; Brito-Rojas, H.D. Optimization study of fructans extraction from Agave tequilana Weber azul variety. Food Sci. Technol. 2016, 36, 631–637. [Google Scholar] [CrossRef][Green Version]

- Fogler, S. Elementos de Ingeniería de las Reacciones Químicas, 3rd ed.; Pearson Education: Mexico City, Mexico, 2001. [Google Scholar]

- Campos, D.; Mescua, L.; Aguilar-Galvez, A.; Chirinos, R.; Pedreschi, R. Effect of Yacon (Smallanthus sonchifolius) fructooligosaccharide purification technique using activated charcoal or ion exchange fixed bed column on recovery, purity and sugar content. Int. J. Food Sci. Technol. 2017, 1–10. [Google Scholar] [CrossRef]

- Loginova, K.V.; Shynkaryk, M.V.; Lebovka, N.I.; Vorobiev, E. Acceleration of soluble matter extraction from chicory with pulsed electric fields. J. Food Eng. 2010, 96, 374–379. [Google Scholar] [CrossRef]

- Geankoplis, C.J.; Hersel, A.; Lepek, D.H. Transport Processes and Separation Process Principles, 5th ed.; Pearson Education, Inc.: London, UK, 2018. [Google Scholar]

- Terkmane, N.; Krea, M.; Moulai-Mostefa, N. Optimisation of inulin extraction from globe artichoke (Cynara cardunculus L. subsp scolymus (L.) Hegi.) by electromagnetic induction heating process. Int. J. Food Sci. Technol. 2016, 51, 1997–2008. [Google Scholar] [CrossRef]

- Temkov, M.; Petkova, N.; Denev, P.; Krastanov, A. Characterization of inulin from Helianthus tuberosus L obtained by different extraction methods—Comparative study. In Proceedings of the food science, engineering and technology 2015, Plovdiv, Bulgaria, 8–10 October 2015. [Google Scholar]

- Larkin, P. Infrared and Raman Spectroscopy: Principles and Spectral Interpretation; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780123869845. [Google Scholar]

- Sun, L.; Simmons, B.A.; Singh, S. Understanding tissue specific compositions of bioenergy feedstocks through hyperspectral Raman imaging. Biotechnol. Bioeng. 2011, 108, 286–295. [Google Scholar] [CrossRef] [PubMed]

- Sederoff, R.R.; MacKay, J.J.; Ralph, J.; Hatfield, R.D. Unexpected variation in lignin. Curr. Opin. Plant Biol. 1999, 2, 145–152. [Google Scholar] [CrossRef]

- Boeriu, C.G.; Bravo, D.; Gosselink, R.J.A.; Van Dam, J.E.G. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind. Crops Prod. 2004, 20, 205–218. [Google Scholar] [CrossRef]

- Chaturvedula, V.S.P.; Mubarak, C.; Prakash, I. IR spectral analysis of diterpene glycosides isolated from Stevia rebaudiana. Food Nutr. Sci. 2012, 3, 1467–1471. [Google Scholar] [CrossRef]

- Vargas Jentzsch, P.; Torrico-Vallejos, S.; Mendieta-Brito, S.; Ramos, L.A.; Ciobotə, V. Detection of counterfeit stevia products using a handheld Raman spectrometer. Vib. Spectrosc. 2016, 83, 126–131. [Google Scholar] [CrossRef]

- Espinosa-Andrews, H.; Urias-Silvas, J.E. Thermal properties of agave fructans (Agave tequilana Weber var. Azul). Carbohydr. Polym. 2012, 87, 2671–2676. [Google Scholar] [CrossRef]

- Blecker, C.; Chevalier, J.-P.; Fougnies, C.; Van Herck, J.-C.; Deroanne, C.; Paquot, M. Characterisation of different inulin samples by DSC: Influence of polymerisation degree on melting temperature. J. Therm. Anal. Calorim. 2003, 71, 215–224. [Google Scholar] [CrossRef]

- Dan, A.; Ghosh, S.; Moulik, S.P. Physicochemical studies on the biopolymer inulin: A critical evaluation of its self-aggregation, aggregate-morphology, interaction with water, and thermal stability. Biopolymers 2009, 91, 687–699. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Rockville, MD, USA, 2005. [Google Scholar]

- Alvarez- Borroto, R.; Ruano- Nieto, A.L.; Calle- Miñaca, M.R.; Lara- Fiallos, M.V. Extracción y determinación de inulina del ajo común autóctono (Allium sativum) Extraction. Rev. Cuba. Quim. 2015, 27, 131–146. [Google Scholar]

- Saengkanuk, A.; Nuchadomrong, S.; Jogloy, S.; Patanothai, A.; Srijaranai, S. A simplified spectrophotometric method for the determination of inulin in Jerusalem artichoke (Helianthus tuberosus L.) tubers. Eur. Food Res. Technol. 2011, 233, 609–616. [Google Scholar] [CrossRef]

- Roberts, J.S.; Kidd, D.R.; Padilla-Zakour, O. Drying kinetics of grape seeds. J. Food Eng. 2008, 89, 460–465. [Google Scholar] [CrossRef]

- Fuentes Campos, M.E.; Cotrina Pedraza, L.; Romero Guzmán, B. Extracción y caracterización de la inulina presente en los tubérculos de la Dahlia spp. Revista del Instituto de Investigación de la Facultad de Ingeniería Geológica, Minera, Metalúrgica y Geográfica 2013, 16, 81–85. [Google Scholar]

- Calhoun, A. Polypropylene. In Multilayer Flexible Packaging: Second Edition; Wagner, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 35–45. ISBN 9780323371001. [Google Scholar]

| Plant | Fraction (% EtOH/H2O v/v) | Mw (g/mol) | DP |

|---|---|---|---|

| Jicama | Fraction 4 (60–80) 1 | 5799.9 ± 358.8 | 36 |

| Cabuya 2 | Fraction 1 (0–20) | 9489.6 ± 684.5 | 59 |

| Fraction 2 (20–40) | 6144.1 ± 237.6 | 38 | |

| Fraction 3 (40–60) | 3718.0 ± 486.4 | 23 |

Sample Availability: Samples of the inulins are not available from the authors. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escobar-Ledesma, F.R.; Sánchez-Moreno, V.E.; Vera, E.; Ciobotă, V.; Jentzsch, P.V.; Jaramillo, L.I. Extraction of Inulin from Andean Plants: An Approach to Non-Traditional Crops of Ecuador. Molecules 2020, 25, 5067. https://doi.org/10.3390/molecules25215067

Escobar-Ledesma FR, Sánchez-Moreno VE, Vera E, Ciobotă V, Jentzsch PV, Jaramillo LI. Extraction of Inulin from Andean Plants: An Approach to Non-Traditional Crops of Ecuador. Molecules. 2020; 25(21):5067. https://doi.org/10.3390/molecules25215067

Chicago/Turabian StyleEscobar-Ledesma, Freddy R., Vanessa E. Sánchez-Moreno, Edwin Vera, Valerian Ciobotă, Paul Vargas Jentzsch, and Lorena I. Jaramillo. 2020. "Extraction of Inulin from Andean Plants: An Approach to Non-Traditional Crops of Ecuador" Molecules 25, no. 21: 5067. https://doi.org/10.3390/molecules25215067

APA StyleEscobar-Ledesma, F. R., Sánchez-Moreno, V. E., Vera, E., Ciobotă, V., Jentzsch, P. V., & Jaramillo, L. I. (2020). Extraction of Inulin from Andean Plants: An Approach to Non-Traditional Crops of Ecuador. Molecules, 25(21), 5067. https://doi.org/10.3390/molecules25215067