How Microanalysis Can Be Discriminant on Black Pompeian Wares

Abstract

1. Introduction

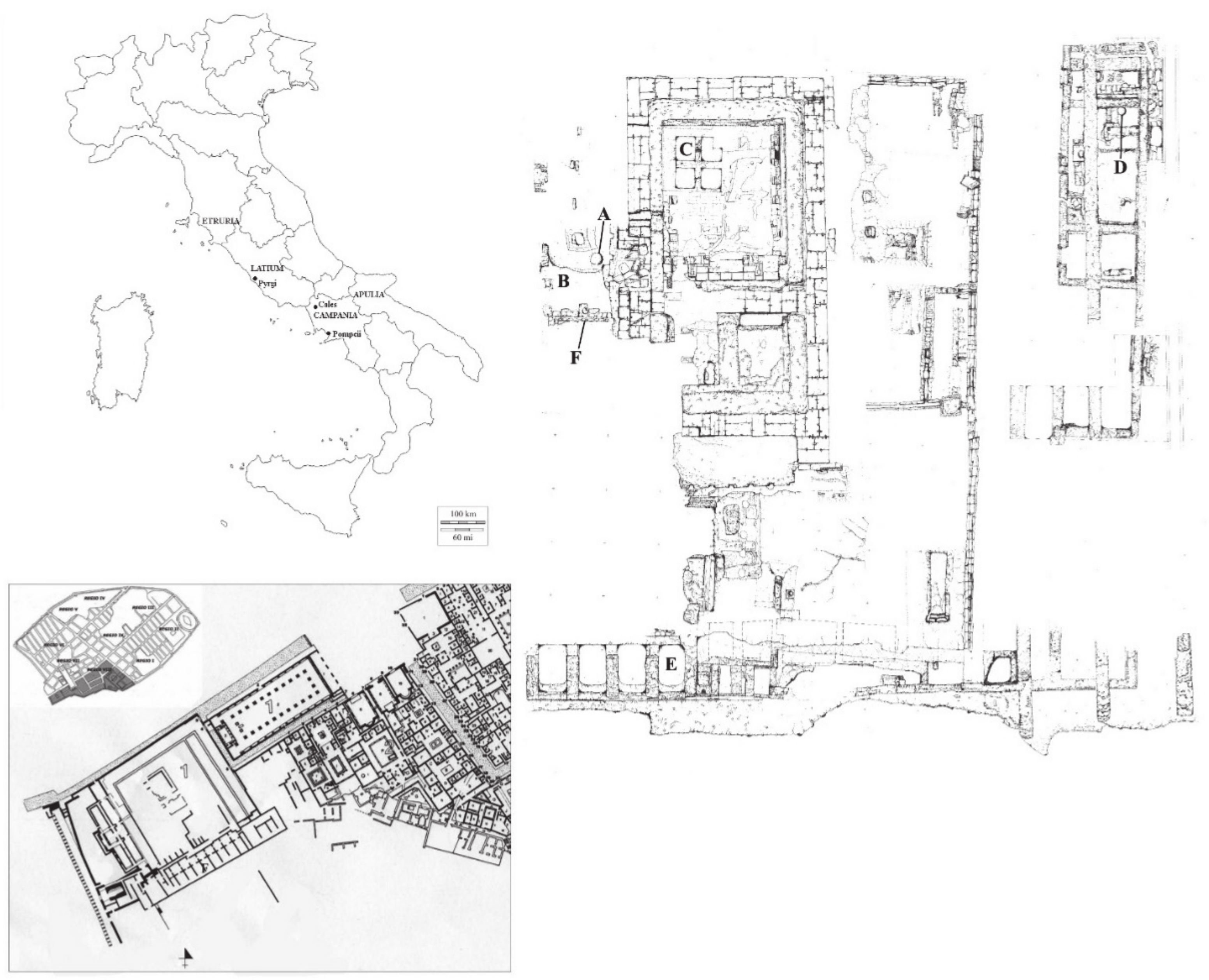

2. Geological and Archaeological Context

3. Materials and Methods

4. Results

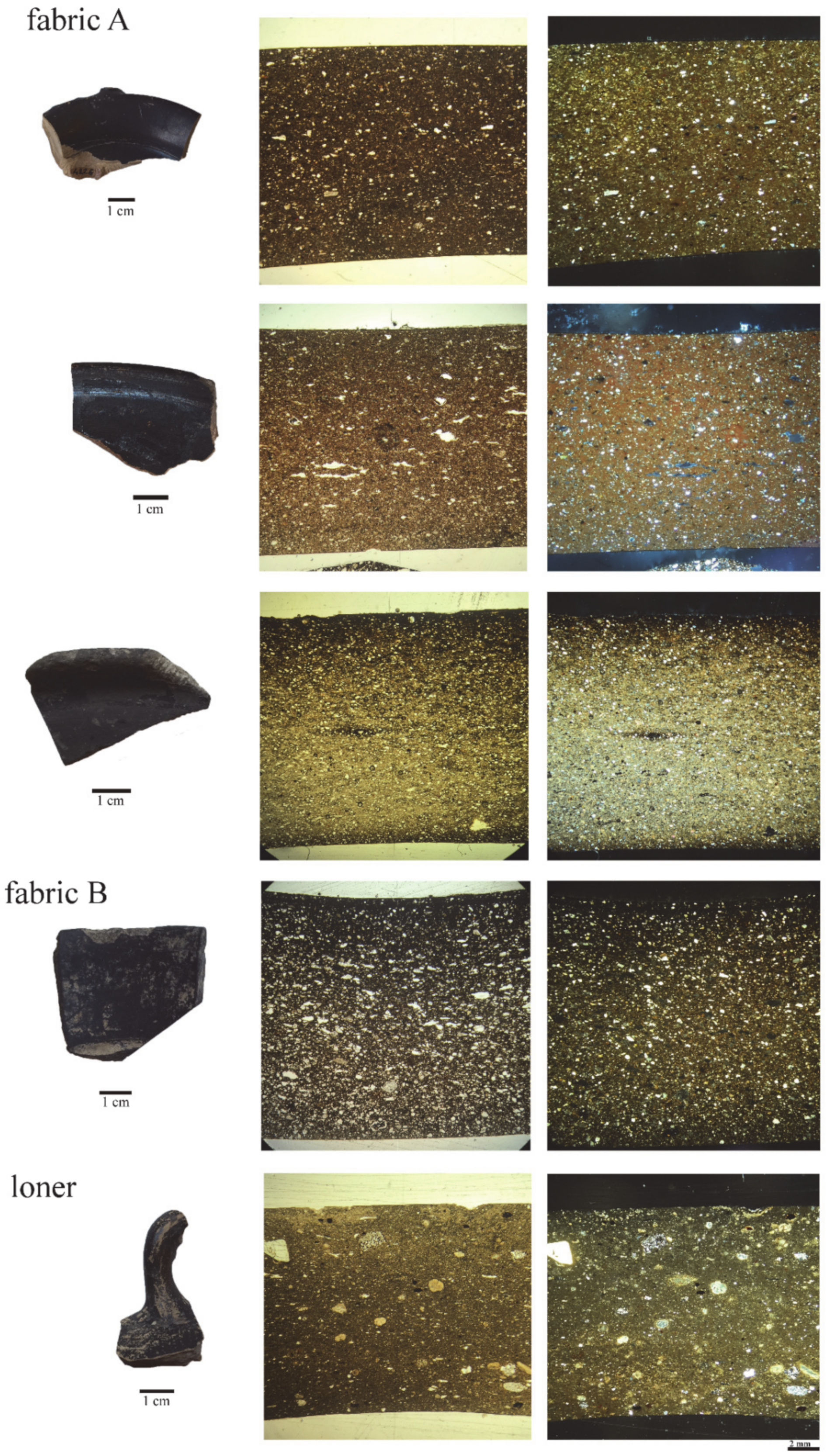

4.1. Ceramic Body

4.1.1. OM Analysis

4.1.2. XRPD Analysis

4.1.3. SEM-EDS Analysis

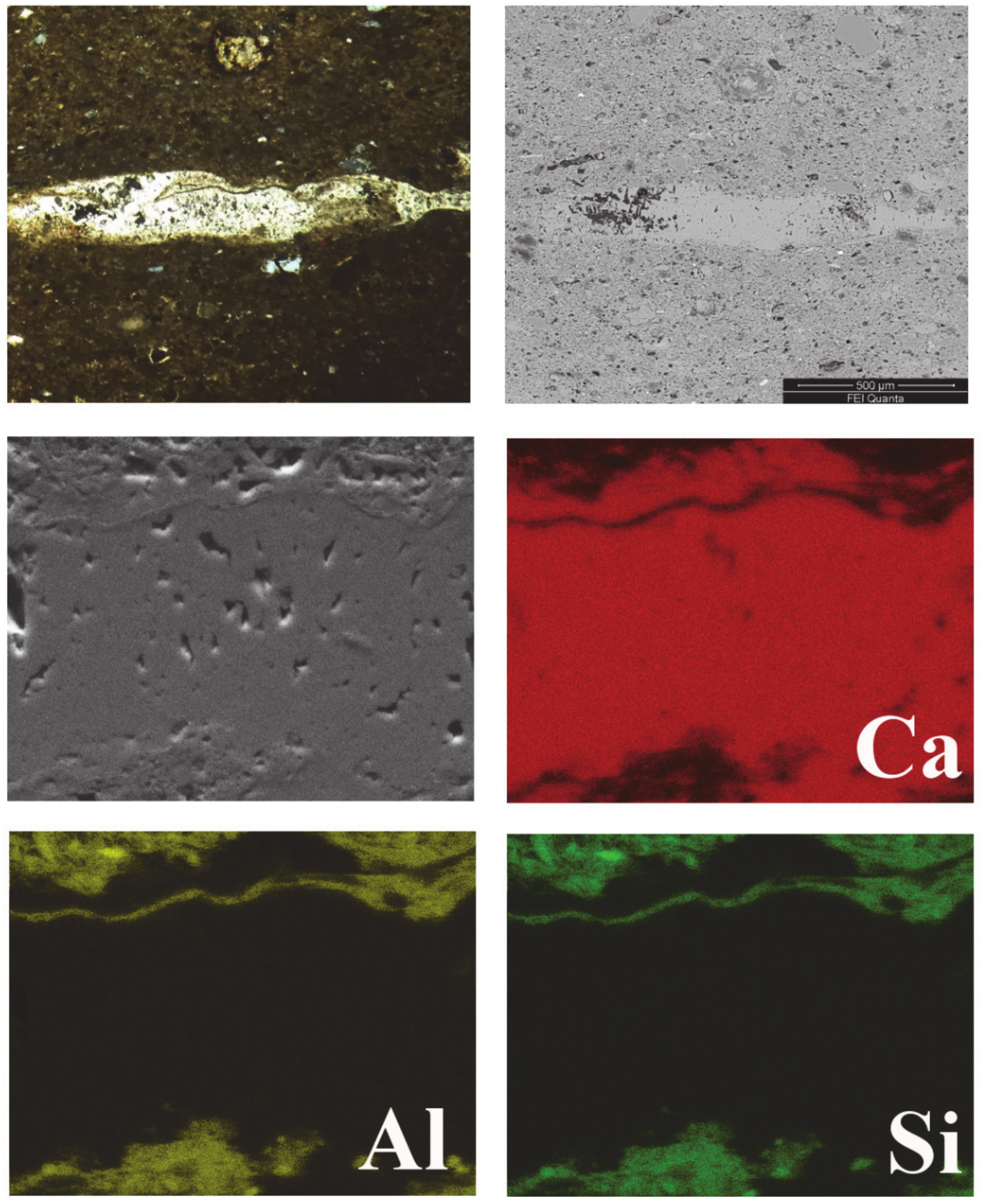

4.2. Slip

4.2.1. OM Analysis

4.2.2. SEM-EDS and EMP Analyses

5. Discussion

5.1. Production Technology

5.2. Provenance

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morel, J.P. La produzione della ceramica campana: Aspetti economici e sociali. In Società Romana e Produzione Schiavistica, II. Merci, Mercati e Scambi nel Mediterraneo; Giardina, A., Schiavone, A., Eds.; Laterza: Bari, Italy, 1981; pp. 81–97. [Google Scholar]

- Guerrini, C.; Mancini, L. La ceramica di età romana. In Introduzione Allo Studio Della Ceramica in Archeologia; Dipartimento di Archeologia e Storia delle Arti, Università di Siena, Centro Editoriale Toscano sas: Firenze, Italy, 2007; pp. 197–234. ISBN 88-86796-47-1. [Google Scholar]

- Lollini, D. Bucchero in Encicl. dell’Arte Antica Ebook. In Treccani; Treccani: Rome, Italy, 1959. [Google Scholar]

- Rotroff, S.I. The Athenian Agora: Results of Excavations Conducted by the American School of Classical Studies at Athens. Volume XXXIII. Hellenistic Pottery: The Plain Wares; The American School of Classical Studies at Athens: Princeton, NJ, USA, 2006. [Google Scholar]

- Gliozzo, E.; Kirkman, I.W.; Pantos, E.; Turbanti, I.M. Black gloss pottery: Production sites and technology in northern Etruria, part II: Gloss technology. Archaeometry 2004, 46, 227–246. [Google Scholar] [CrossRef]

- Morsiani, S. Ceramica a vernice nera. In Pompei. Insula IX 8. Vecchi e Nuovi Scavi (1879-); Coralini, A., Ed.; Ante Quem: Bologna, Italy, 2017; pp. 569–586. ISBN 9788878491151. [Google Scholar]

- Lamboglia, N. Per una classificazione preliminare della Ceramica Campana; Istituto Internazionale di Studi Liguri: Bordighera, Imperia, Italy, 1952; pp. 1–68. [Google Scholar]

- Montana, G.; Tsantini, E.; Randazzo, L.; Burgio, A. SEM-EDS analysis as a rapid tool for distinguishing Campanian A ware and sicilian imitations. Archaeometry 2013, 55, 591–608. [Google Scholar] [CrossRef]

- Morel, J.P.M. Céramique Campanienne: Les Formes; École Française de Rome: Rome, Italy, 1981. [Google Scholar]

- Brecciaroli Taborelli, L. Ceramiche a Vernice Nera. In La ceramica e i Materiali di Età Romana. Classi, Produzioni, Commerci e Consumi; Gandolfi, D., Ed.; Ist. Studi Liguri: Bordighera, Imperia, Italy, 2005; pp. 59–75. ISBN 978-8886796477. [Google Scholar]

- Maggetti, M.; Galetti, G.; Schwander, H.; Picon, M.; Wessicken, R. Campanian pottery: The nature of the black coating. Archaeometry 1981, 23, 199–207. [Google Scholar] [CrossRef]

- Maniatis, Y.; Aloupi, E.; Stalios, A.D. New evidence for the nature of the Attic Black Gloss. Archaeometry 1993, 35, 23–34. [Google Scholar] [CrossRef]

- Vendrell-Saz, M.; Pradell, T.; Molera, J.; Aliaga, S. Proto-Campanian and A-Campanian ceramics: Characterization of the differences between the black coatings. Archaeometry 1991, 33, 109–117. [Google Scholar] [CrossRef]

- Mirti, P.; Casoli, A.; Calzetti, L. Technology of production of fine pottery excavated on a western Greek site investigated by scanning electron microscopy coupled with energy-dispersive X-ray detection. X-Ray Spectrom. 1996, 25, 103–109. [Google Scholar] [CrossRef]

- Mirti, P.; Casoli, A.; Barra Bagnasco, M.; Preacco Ancona, M.C. Fine ware from Locri Epizephiri: A provenance study by Inductively Coupled Plasma Emission Spectroscopy. Archaeometry 1995, 37, 41–51. [Google Scholar] [CrossRef]

- Prag, A.J.N.W.; Schweizer, F.; Williams, J.L.W.; Schubiger, P.A. Hellenistic glazed wares from Athens and southern Italy: Analytical techniques and implications. Archaeometry 1974, 16, 153–187. [Google Scholar] [CrossRef]

- Mirti, P.; Davit, P. Technological characterization of Campanian pottery of type A, B and C and of regional products from ancient Calabria (Southern Italy). Archaeometry 2001, 43, 19–33. [Google Scholar] [CrossRef]

- Tang, C.C.; MacLean, E.J.; Roberts, M.A.; Clarke, D.T.; Pantos, E.; Prag, A.J.N.W. The study of Attic black gloss sherds using synchrotron X-ray diffraction. J. Archaeol. Sci. 2001, 28, 1015–1024. [Google Scholar] [CrossRef]

- Rasmussen, T.B. Bucchero Pottery from Southern Etruria; Cambridge University Press: Cambridge, UK, 1979; ISBN 9781107297944. [Google Scholar]

- Maiuri, A. Saggi nell’area del tempio di Apollo. Mem. dei Lincei 1943, IV, 123–149. [Google Scholar]

- Stefano, D.C. Saggi nell’area del Tempio di Apollo a Pompei Scavi Stratigrafici di A. Maiuri 1931-32, 1942–43; Istituto Universitario Orientale, Dipartimento Di Studi Del Mondo Classico E Del: Napoli, Italy, 1986. [Google Scholar]

- Francaviglia, V.; Minardi, M.E.; Palmieri, A. Comparative study of various samples of Etruscan Bucchero by X-ray Diffraction, X-ray Spectrometry and Thermoanalysis. Archaeometry 1975, 2, 223–231. [Google Scholar] [CrossRef]

- Tite, M.S. Pottery production, distribution, and consumption—The contribution of the physical sciences. J. Archaeol. Method Theory 1999, 6, 181–233. [Google Scholar] [CrossRef]

- Turbanti Memmi, I. Pottery production and distribution: The contribution of mineralogical and petrographical methodologies in Italy. State of the art and future developments. Period. Mineral. 2004, 73, 239–257. [Google Scholar]

- Patrick, S.Q. Ceramic Petrography: The Interpretation of Archaeological Pottery and Related Artefacts in Thin Section; Archaeopress Archaeology: Oxford, UK, 2013; ISBN 978-1905739592. [Google Scholar]

- Velde, B.; Druc, I.C. Archaeological Ceramic Materials: Origin and Utilization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Santacreu, D.A.; Vicens, G.M. Raw Materials and Pottery Production at the Late Bronze and Iron Age Site of Puig de Sa Morisca, M allorca, S pain. Geoarchaeology 2012, 27, 285–299. [Google Scholar] [CrossRef]

- Hunt, A.M. The Oxford Handbook of Archaeological Ceramic Analysis; Oxford University Press: Oxford, UK, 2017. [Google Scholar]

- De Vito, C.; Medeghini, L.; Mignardi, S.; Ballirano, P.; Peyronel, L. Technological fingerprints of the Early Bronze Age clay figurines from Tell Mardikh-Ebla (Syria). J. Eur. Ceram. Soc. 2015, 35, 3743–3754. [Google Scholar] [CrossRef]

- Ion, R.M.; Dumitriu, I.; Fierascu, R.C.; Ion, M.; Pop, S.F.; Radovici, C.; Bunghez, R.I.; Niculescu, V.I.R. Thermal and mineralogical investigations of historical ceramic: A case study. J. Therm. Anal. Calorim. 2011, 104, 487–493. [Google Scholar] [CrossRef]

- De Benedetto, G.E.; Laviano, R.; Sabbatini, L.; Zambonin, P.G. Infrared spectroscopy in the mineralogical characterization of ancient pottery. J. Cult. Herit. 2002. [Google Scholar] [CrossRef]

- Forte, V.; Medeghini, L. A preliminary study of ceramic pastes in the copper age pottery production of the Rome area. Archaeol. Anthropol. Sci. 2017, 9, 209–222. [Google Scholar] [CrossRef]

- Quinn, P.; Day, P.; Kilikoglou, V.; Faber, E.; Katsarou-Tzeveleki, S.; Sampson, A. Keeping an eye on your pots: The provenance of Neolithic ceramics from the Cave of the Cyclops, Youra, Greece. J. Archaeol. Sci. 2010, 37, 1042–1052. [Google Scholar] [CrossRef]

- Quinn, P.S.; Burton, M.M. Ceramic distribution, migration and cultural interaction among late prehistoric (ca. 1300–200 B.P.) hunter-gatherers in the San Diego region, Southern California. J. Archaeol. Sci. Reports 2016, 5, 285–295. [Google Scholar] [CrossRef]

- Tite, M.S.; Maniatis, Y. Examination of ancient pottery using the scanning electron microscope. Nat. Publ. Gr. 1975, 257, 122–123. [Google Scholar] [CrossRef]

- Enea-Giurgiu, A.; Ionescu, C.; Hoeck, V.; Tudor, T.; Roman, C. An archaeometric study of early Copper Age pottery from a cave in Romania. Clays Clay Miner. 2019, 54, 255–268. [Google Scholar] [CrossRef]

- Ferreira, L.F.V.; Gonzalez, A.; Pereira, M.F.C.; Santos, L.F.; Casimiro, T.M.; Ferreira, D.P. Spectroscopy of 16th century Portuguese tin-glazed earthenware produced in the region of Lisbon. Ceram. Int. 2015, 41, 13433–13446. [Google Scholar] [CrossRef]

- Barilaro, D.; Barone, G.; Crupi, V.; Donato, M.G.; Majolino, D.; Messina, G.; Ponterio, R. Spectroscopic techniques applied to the characterization of decorated potteries from Caltagirone (Sicily, Italy). J. Mol. Struct. 2005, 744, 827–831. [Google Scholar] [CrossRef]

- Medeghini, L.; Fayek, M.; Mignardi, S.; Coletti, F.; Contino, A.; De Vito, C. A provenance study of Roman lead-glazed ceramics using lead isotopes and secondary ion mass spectrometry (SIMS). Microchem. J. 2020, 154, 104519. [Google Scholar] [CrossRef]

- Dorais, M.J.; Lindblom, M.; Shriner, M. Evidence for a single clay/temper source for the manufacture of Middle and Late Helladic Aeginetan pottery from Asine, Greece. Geoarchaeology 2004, 19, 657–684. [Google Scholar] [CrossRef]

- Barone, G.; Belfiore, C.M.; Mazzoleni, P.; Pezzino, A.; Viccaro, M. A volcanic inclusions based approach for provenance studies of archaeological ceramics: Application to pottery from southern Italy. J. Archaeol. Sci. 2010, 37, 713–726. [Google Scholar] [CrossRef]

- Belfiore, C.M.; La Russa, M.F.; Barca, D.; Galli, G.; Pezzino, A.; Ruffolo, S.A.; Viccaro, M.; Fichera, G. V A trace element study for the provenance attribution of ceramic artefacts: The case of Dressel 1 amphorae from a late-Republican ship. J. Archaeol. Sci. 2014, 43, 91–104. [Google Scholar] [CrossRef]

- Fabrizi, L.; Nigro, L.; Ballirano, P.; Guirguis, M.; Spagnoli, F.; Medeghini, L.; De Vito, C. The Phoenician Red Slip Ware from Sulky (Sardinia-Italy): Microstructure and quantitative phase analysis. Appl. Clay Sci. 2020, 197, 105795. [Google Scholar] [CrossRef]

- De Vito, C.; Medeghini, L.; Mignardi, S.; Coletti, F.; Contino, A. Roman glazed inkwells from the “Nuovo Mercato di Testaccio” (Rome, Italy): Production technology. J. Eur. Ceram. Soc. 2017, 37, 1779–1788. [Google Scholar] [CrossRef]

- De Vito, C.; Medeghini, L.; Garruto, S.; Coletti, F.; De Luca, I.; Mignardi, S. Medieval glazed ceramic from Caesar’s Forum (Rome, Italy): Production technology. Ceram. Int. 2018, 44, 5055–5062. [Google Scholar] [CrossRef]

- Curti, E. Le aree portuali di Pompei: Ipotesi di lavoro. In Suburbio ‘portuale’ di Pompei; Scarano Ussani, V., Ed.; Loffredo Editore: Napoli, Italy, 2005; pp. 51–76. ISBN 8875641048. [Google Scholar]

- Curti, E. Il tempio di Venere Fisica e il Porto di Pompei. In Proceedings of the Atti del Convegno Internazionale “Nuove ricerche archeologiche nell’area vesuviana (scavi 2003–2006)”, Roma, Italy, 11–3 February 2007; Guzzo, P.G., Guidobaldi, M.P., Eds.; “L’Erma” di Bretschneider: Rome, Italy, 2008; pp. 47–59. [Google Scholar]

- Seiler, F.; Märker, M.; Kastenmeier, P.; Vogel, S.; Esposito, D.; Heussner, U.; Boni, M.; Balassone, G.; Maio, G.D.; Joachimski, M. Interdisciplinary approach on the reconstruction of the ancient cultural landscape of the Sarno River Plain before the eruption of Somma-Vesuvius A.D. 79. Tag Landesmus Vor. Halle 2011, 6, 1–10. [Google Scholar]

- ISPRA. Carta Geologica d’Italia. Dai Rilevamenti Geologici 1:10000. Available online: https://www.isprambiente.gov.it/Media/carg/466_485_SORRENTO_TERMINI/Foglio.html (accessed on 20 September 2020).

- Coletti, F.; Sterpa, G. Resti pavimentali in cementizio, mosaico e sectile dall’area del tempio di Venere a Pompei: Dati di scavo. In Proceedings of the Atti del XIII Colloquio Internazionale dell’AISCOM, Canosa di Puglia, Italy, 21–24 February 2007; Angelelli, C., Massara, D., Sposito, F., Eds.; Scripta Manent: Rome, Italy, 2008; pp. 129–136. [Google Scholar]

- Coletti, F.; Prascina, C.; Sterpa, G.; Witte, N. Venus Pompeiana. Scelte progettuali e procedimenti tecnici per la realizzazione di un grande edificio sacro tra tarda Repubblica e primo Impero. In Proceedings of the Atti del workshop “Arqueología del la Costrucciòn, II. Los procesos constructivos en el mundo romano: Italia y Provincias Orientales”, Certosa di Pontignano-Siena, Italy, 13–15 November 2008; Camporeale, S., Dessales, H., Pizzo, A., Eds.; Consejo Superior de Investigaciones: Taravilla, Madrid, Spain, 2010; pp. 189–211. [Google Scholar]

- Coletti, F. Ceramica a vernice nera a Pompei. Il caso dei depositi votivi del santuario di Venere Fisica: Produzione, circolazione, mercati. Un primo bilancio. In Fecisti Cretaria: Dal Frammento al Contesto Studi Sul Vasellame Ceramico del Territorio Vesuviano; Osanna, M., Toniolo, L., Eds.; “L’Erma” di Bretschneider: Rome, Italy, 2020; pp. 77–95. [Google Scholar]

- Whitbread, I.K. Greek Transport Amphorae: A Petrological and Archaeological Study; British School at Athens: Athina, Greece, 1995; ISBN 0904887138. [Google Scholar]

- Pouchou, J.L.; Pichoir, F. “PAP” procedure for improved quantitative microanalysis. In Microbeam Analysis; Armstrong, J.T., Ed.; San Francisco Press: San Francisco, CA, USA, 1985; pp. 104–106. [Google Scholar]

- Maniatis, Y.; Tite, M. Technological studies of Neolithic-Bronze Age Pottery from Central and Southeast Europe and from the Near East. J. Archaeol. Sci. 1981, 8, 59–76. [Google Scholar] [CrossRef]

- Musthafa, A.M.; Janaki, K.; Velraj, G. Microscopy, porosimetry and chemical analysis to estimate the fi ring temperature of some archaeological pottery shreds from India. Microchem. J. 2010, 95, 311–314. [Google Scholar] [CrossRef]

- Aras, A. The change of phase composition in kaolinite- and illite-rich clay-based ceramic bodies. Appl. Clay Sci. 2004, 24, 257–269. [Google Scholar] [CrossRef]

- Rathossi, C.; Pontikes, Y. Effect of firing temperature and atmosphere on ceramics made of NW Peloponnese clay sediments. Part I: Reaction paths, crystalline phases, microstructure and colour. J. Eur. Ceram. Soc. 2010, 30, 1853–1866. [Google Scholar] [CrossRef]

- Medeghini, L.; Mignardi, S.; De Vito, C.; Macro, N.; D’Andrea, M.; Richard, S. New insights on Early Bronze Age IV pottery production and consumption in the southern Levant: The case of Khirbat Iskandar, Jordan. Ceram. Int. 2016, 42, 18991–19005. [Google Scholar] [CrossRef]

- Karunadasa, K.S.P.; Manoratne, C.H.; Pitawala, H.M.T.G.A.; Rajapakse, R.M.G. Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in-situ high-temperature X-ray powder diffraction. J. Phys. Chem. Solids 2019, 134, 21–28. [Google Scholar] [CrossRef]

- Privitera, A.; Guido, A.; Mastandrea, A.; Rao, A.; Russo, F. Morphological and mineralogical evolution of microfossils during the heating process: A contribution to the archaeometric study of ceramics. Rend. Fis. Acc. Lincei 2015, 26, 499–512. [Google Scholar] [CrossRef]

- Tenconi, M.; Maritan, L.; Donadel, V.; Angelini, A.; Leonardi, G.; Mazzoli, C. Evolution of the ceramic production at the Alpine site of Castel de Pedena: Technology and innovation between the Recent Bronze Age and the early Iron Age. Archaeol. Anthropol. Sci. 2017, 9, 965–984. [Google Scholar] [CrossRef]

- Maritan, L.; Mazzoli, C.; Freestone, I. Modelling changes in mollusc shell internal microstructure during firing: Implications for temperature estimation in shell-bearing pottery. Archaeometry 2007, 49, 529–541. [Google Scholar] [CrossRef]

- Maritan, L.; Zamparo, L.; Mazzoli, C.; Bonetto, J. Punic black-gloss ware in Nora (south-western Sardinia, Italy): Production and provenance. J. Archaeol. Sci. Reports 2019, 23, 1–11. [Google Scholar] [CrossRef]

- Gianoncelli, A.; Raneri, S.; Schoeder, S.; Okbinoglu, T.; Barone, G.; Santostefano, A.; Mazzoleni, P. Synchrotron µ-XRF imaging and µ-XANES of black-glazed wares at the PUMA beamline: Insights on technological markers for colonial productions. Microchem. J. 2020, 154, 104629. [Google Scholar] [CrossRef]

- Laurora, A.; Brigatti, M.F.; Mottana, A.; Malferrari, D.; Caprilli, E. Crystal chemistry of trioctahedral micas in alkaline and subalkaline volcanic rocks: A case study from Mt. Sassetto ( Tolfa district, Latium, central Italy ). 2020, 92, 468–480. [Google Scholar] [CrossRef]

- Kastenmeier, P.; Di Maio, G.; Balassone, G.; Boni, M.; Joachimski, M.; Mondillo, N. The source of stone building materials from the Pompeii archaeological area and its surroundings. Period. Mineral. 2010, 79, 39–58. [Google Scholar] [CrossRef]

- Schneider, G.; Daszkiewicz, M.; Cottica, D. Pompeii as a pottery production centre. An archaeometric approach. Rei Cretariae Rom. Fautorum Acta 2010, 41, 313–318. [Google Scholar]

| Samples. | Shape | Production | Macroscopic Analysis of Gloss |

|---|---|---|---|

| 4026-102 | Kylix | Central Italy | Very thin layer of black paint with iridescent reflections and shades of green |

| 4032-101 | plate | Southern Etruria, Pyrgi | Very thin layer of black paint that, in direct light, shows a strong iridescence with green tones |

| 4032-158 | plate | Southern Latium | Very thin layer of black paint, with a slight blue-green iridescence |

| 4226-106 | plate | Cales | Black gloss with reflections in shades of green |

| 4032-103 | Kylix | Apulia | Altered black gloss |

| 4032-105 | Skyphos | Pompeii | Cup with black paint with a weak iridescence of the blue-green paint. The foot shows traces of a reddish coating |

| 4032-104 | plate | Pompeii | Very fine black paint, well preserved, with iridescent reflections tending to blue |

| 4226-108 | Stemmed bowl | Pompeii | Bucchero |

| 4226-109 | Rasmussen 1979—3a | Pompeii | Bucchero |

| 4226-110 | cup | Pompeii | Bucchero |

| 4020-107 | Rasmussen 1979—2 | Pompeii | Bucchero |

| Samples | Porosity | Matrix | Inclusions |

|---|---|---|---|

| FABRIC A 4026-102 | 10% micro-vesicles micro-/meso-vughs | 70% optically inactive | 20% Dominant: quartz (0.02–0.2 mm), plagioclase (0.02–0.1 mm) Common: mica (0.02–0.2 mm), nodules of iron oxides (0.02–0.15 mm) Rare: calcareous inclusions (0.02–0.8 mm) |

| 4226-106 | 5% micro-vesicles micro-/meso-vughs | 80% optically inactive | 15% Dominant: quartz (0.01–0.15 mm), plagioclase (0.01–0.1 mm) Rare: nodules of iron oxides (0.02–0.15 mm) Very rare: destabilized calcite (1 mm) |

| 4032-101 | 10% micro-/meso-vesicles meso-/macro-vughs | 70% optically inactive | 20% Dominant: quartz (0.02–0.2 mm), plagioclase (0.02–0.1 mm) Common: mica (0.02–0.2 mm), nodules of iron oxides (0.02–0.15 mm) Rare: calcareous inclusions (0.02–0.8 mm) |

| 4032-158 | 20% micro-/meso-vesicles micro-/macro-vughs | 60% optically inactive | 20% Dominant: quartz (0.1–0.15 mm), plagioclase (0.15–0.01 mm) Common: mica (0.01–0.08 mm), nodules of iron oxides (0.01–0.04 mm) |

| 4032-105 | 10% micro-/meso-vesicles micro-/macro-vughs | 70% optically inactive | 20% Dominant: quartz (0.02–0.1 mm), plagioclase (0.02–0.05 mm) Common: pyroxene (0.5–0.12 mm), mica (0.02–0.1 mm) Rare: nodules of iron oxides (0.02–0.2 mm) |

| 4032-104 | 10% micro-vesicles micro-/macro-vughs | 70% optically inactive | 20% Dominant: quartz (0.02–0.2 mm), plagioclase (0.05–0.15 mm) Common: mica (0.02–0.5 mm) Rare: fragments of rocks (0.01 mm) |

| 4226-108 | 10% micro-/meso-vesicles micro-/macro-vughs | 60% optically inactive | 20% Dominant: quartz (0.01–0.25 mm), plagioclase (0.05–0.1 mm) Common: mica (0.03–0.1 mm) |

| 4020-107 | 10% micro-vesicles micro-/mega-vughs | 60% optically active | 30% Dominant: quartz (0.01–0.08 mm), plagioclase (0.05–0.2 mm) Common: mica (0.01–0.2 mm), Rare: nodules of iron oxides (0.02–0.1 mm) |

| FABRIC B 4226-109 | 20% micro-/meso-vesicles micro-/meso-vughs | 50% optically active | 30% Dominant: quartz (0.02–0.15 mm) Common: plagioclase (0.05–0.1 mm), K-feldspar (0.02–0.4 mm), mica (0.01–0.2 mm) Rare: fragments of calcareous rocks (0.07–0.2 mm) |

| 4226-110 | 30% micro-/macro-vesicles micro-/meso-vughs | 30% optically active | 40% Dominant: quartz (0.01–0.2 mm), plagioclase (0.05–0.2 mm) Common: mica (0.03–0.1 mm) Rare: fragments of rocks (0.1–0.2 mm), fragments of calcareous rocks (0.07–0.2 mm) |

| loner 4032-103 | 20% micro-/meso-vesicles micro-/macro-vughs | 60% optically inactive | 20% Dominant: quartz (0.02–0.1 mm), plagioclase (0.05–0.2 mm) Microfossils Common: pyroxene (0.15–0.6 mm), fragments of basic rocks (0.05–0.4 mm) Rare: fragments of basic rocks (0.1–0.6 mm), fragments of calcareous rocks (0.02–0.15 mm) |

| Sample | Fabric | Qtz | Pl | Px | Cal | Mca | Hem | Kfs | Gh | |

|---|---|---|---|---|---|---|---|---|---|---|

| 4026-102 | BGW | A | ++++ | +++ | + | + | tr | + | + | tr |

| 4032-158 | BGW | ++++ | ++ | ++ | tr | + | tr | |||

| 4032-105 | BGW | ++++ | +++ | ++ | ++ | tr | tr | + | ||

| 4032-104 | BGW | +++ | +++ | ++ | tr | + | ++ | |||

| 4226-108 | Bucchero | ++++ | +++ | +++ | +++ | |||||

| 4226-109 | Bucchero | B | ++++ | ++ | ++ | + | + | |||

| 4226-110 | Bucchero | ++++ | + | tr | ++ | + | ||||

| 4032-103 | BGW | ++++ | +++ | ++ | ++ | + | + |

| Sample. | 4026-102 | 4032-158 | 4226-106 | 4032-103 | 4032-104 | 4032-105 | 4032-101 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Slip | Body | Slip | Body | Slip | Body | Slip | Body | Slip | Body | Slip | Body | Slip | Body | |

| SiO2 | 48.50 | 53.50 | 46.23 | 55.56 | 46.56 | 57.18 | 46.09 | 56.47 | 46.70 | 59.98 | 44.97 | 58.43 | 47.23 | 48.33 |

| TiO2 | 0.452 | 0.55 | 0.54 | 0.78 | 0.42 | 0.68 | 0.39 | 0.76 | 0.67 | 0.64 | 0.60 | 0.32 | 0.40 | 0.74 |

| Al2O3 | 28.63 | 19.72 | 27.81 | 20.05 | 28.32 | 17.12 | 30.72 | 16.98 | 27.83 | 18.92 | 27.57 | 19.17 | 27.84 | 17.58 |

| MgO | 2.75 | 4.21 | 2.28 | 2.59 | 2.17 | 2.73 | 1.56 | 3.58 | 2.41 | 1.57 | 2.02 | 2.35 | 2.44 | 5.75 |

| CaO | 0.69 | 7.79 | 0.56 | 7.90 | 0.83 | 12.98 | 1.70 | 10.22 | 0.98 | 5.75 | 0.97 | 4.74 | 0.94 | 6.53 |

| MnO | 0.17 | 0.04 | 0.12 | 0.09 | 0.09 | 0.14 | 0.31 | 0.31 | 0.29 | 0.27 | 0.99 | 0.09 | 0.09 | 1.48 |

| FeO | 13.15 | 8.55 | 13.11 | 3.53 | 12.32 | 5.73 | 12.58 | 7.44 | 14.54 | 5.31 | 13.87 | 6.94 | 11.91 | 16.48 |

| CuO | 0.03 | 0.10 | 0 | 0.02 | 0.03 | 0 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0 | 0.02 | 0.03 |

| ZnO | 0.06 | 0.12 | 0.10 | 0.07 | 0.10 | 0.07 | 0.04 | 0.02 | 0.04 | 0.11 | 0.04 | 0.01 | 0.12 | 0.04 |

| Na2O | 0.50 | 1.45 | 1.73 | 0.99 | 0.86 | 0.79 | 0.43 | 0.66 | 1.71 | 2.42 | 0.80 | 1.68 | 0.65 | 0.18 |

| K2O | 5.07 | 3.98 | 7.52 | 8.42 | 8.30 | 2.58 | 6.17 | 3.56 | 4.83 | 5.05 | 8.15 | 5.28 | 8.37 | 2.87 |

| Total: | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Al/Si | 0.6 | 0.4 | 0.6 | 0.4 | 0.6 | 0.3 | 0.7 | 0.3 | 0.6 | 0.3 | 0.6 | 0.3 | 0.6 | 0.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medeghini, L.; Mignardi, S.; Di Fusco, G.; Botticelli, M.; Coletti, F.; De Vito, C. How Microanalysis Can Be Discriminant on Black Pompeian Wares. Crystals 2020, 10, 879. https://doi.org/10.3390/cryst10100879

Medeghini L, Mignardi S, Di Fusco G, Botticelli M, Coletti F, De Vito C. How Microanalysis Can Be Discriminant on Black Pompeian Wares. Crystals. 2020; 10(10):879. https://doi.org/10.3390/cryst10100879

Chicago/Turabian StyleMedeghini, Laura, Silvano Mignardi, Giorgia Di Fusco, Michela Botticelli, Fulvio Coletti, and Caterina De Vito. 2020. "How Microanalysis Can Be Discriminant on Black Pompeian Wares" Crystals 10, no. 10: 879. https://doi.org/10.3390/cryst10100879

APA StyleMedeghini, L., Mignardi, S., Di Fusco, G., Botticelli, M., Coletti, F., & De Vito, C. (2020). How Microanalysis Can Be Discriminant on Black Pompeian Wares. Crystals, 10(10), 879. https://doi.org/10.3390/cryst10100879