Fertigation of Maize with Digestate Using Drip Irrigation and Pivot Systems

Abstract

:1. Introduction

2. Materials and Methods

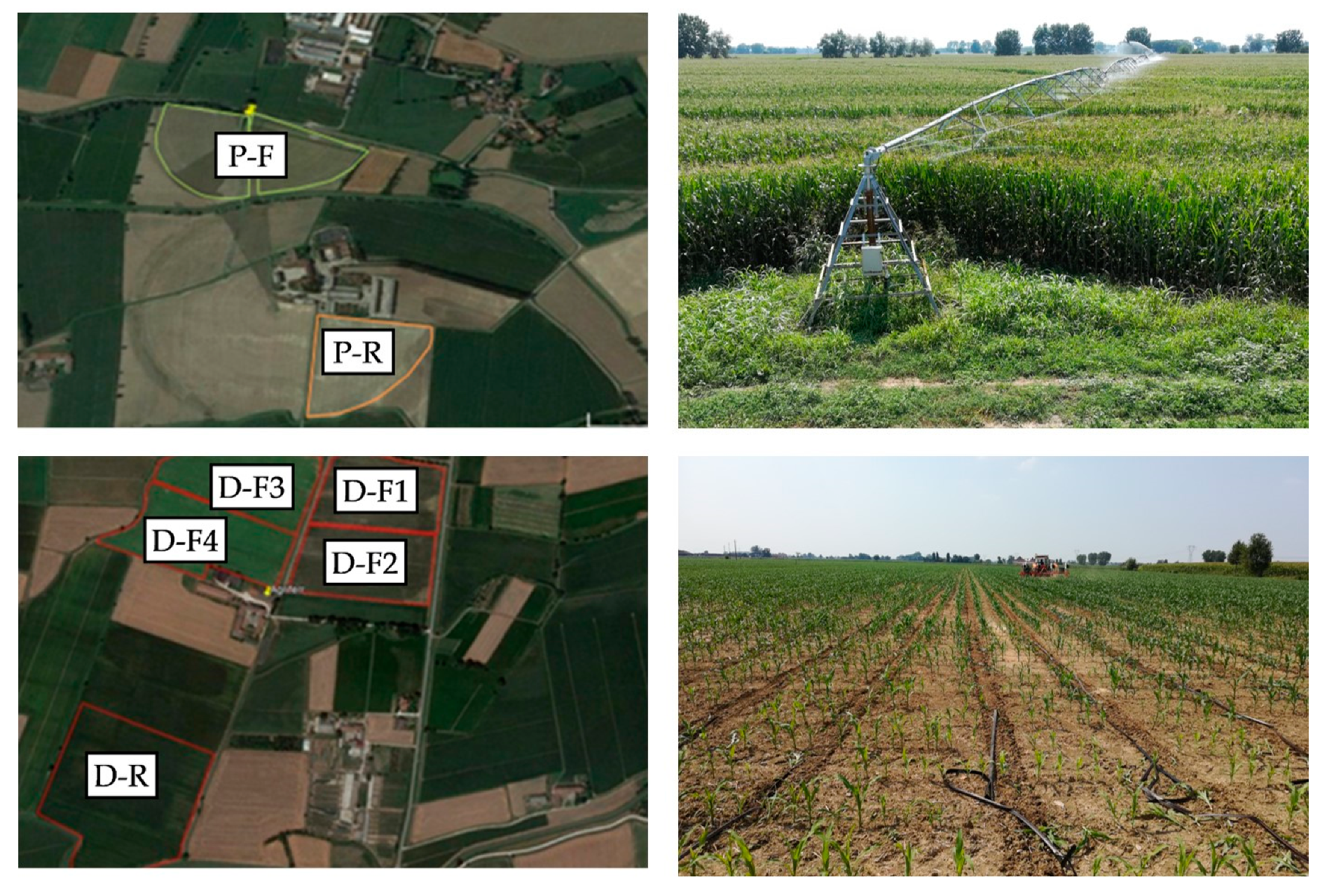

2.1. Study Area

2.2. Agronomic Management

2.3. Irrigation Techniques

2.4. Fertigation Requirements and Analysis

2.5. Nitrogen Use Efficiency

3. Results and Discussion

3.1. Agronomic Management

Field Management

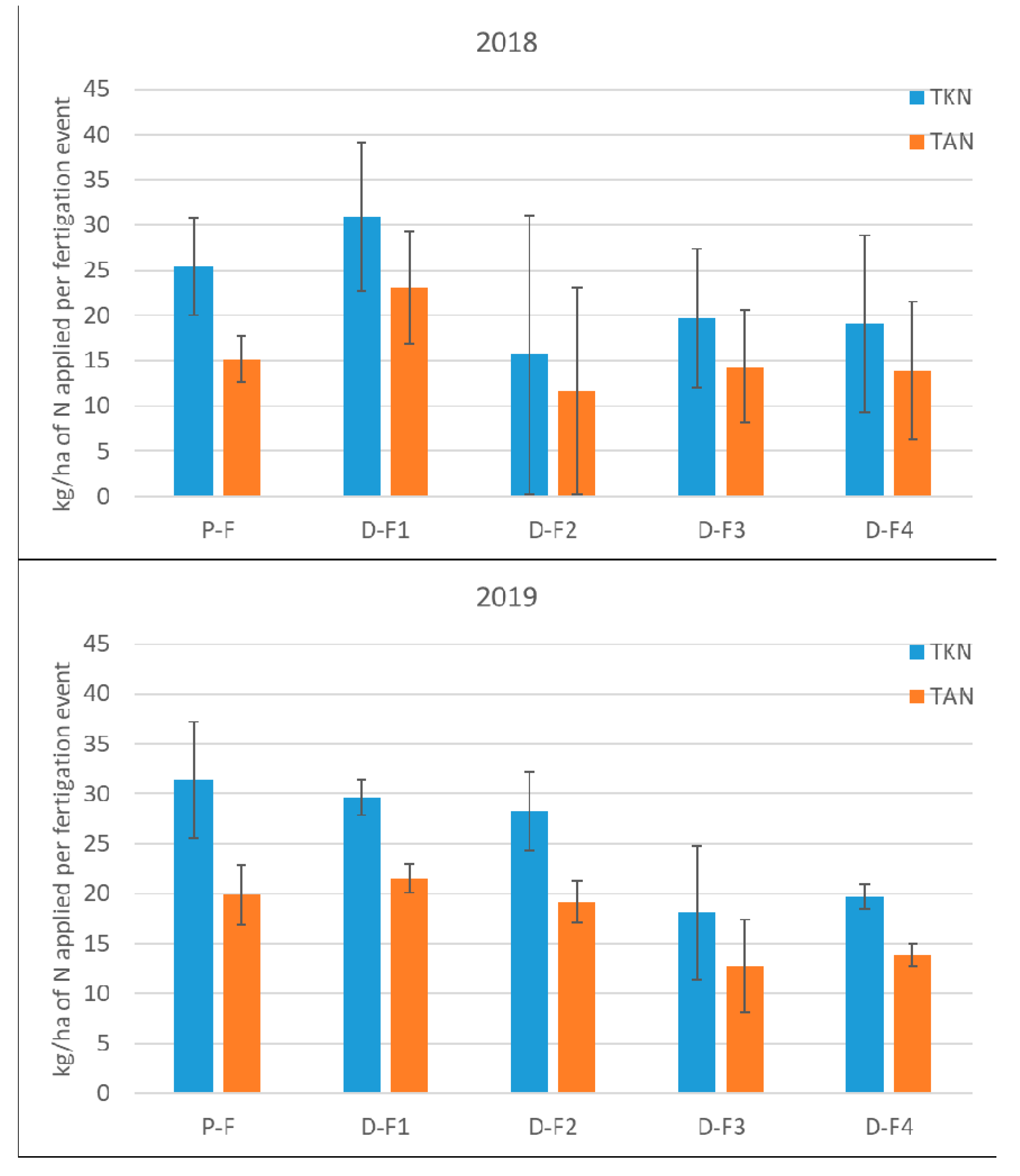

3.2. Fertigation Performance and Analysis

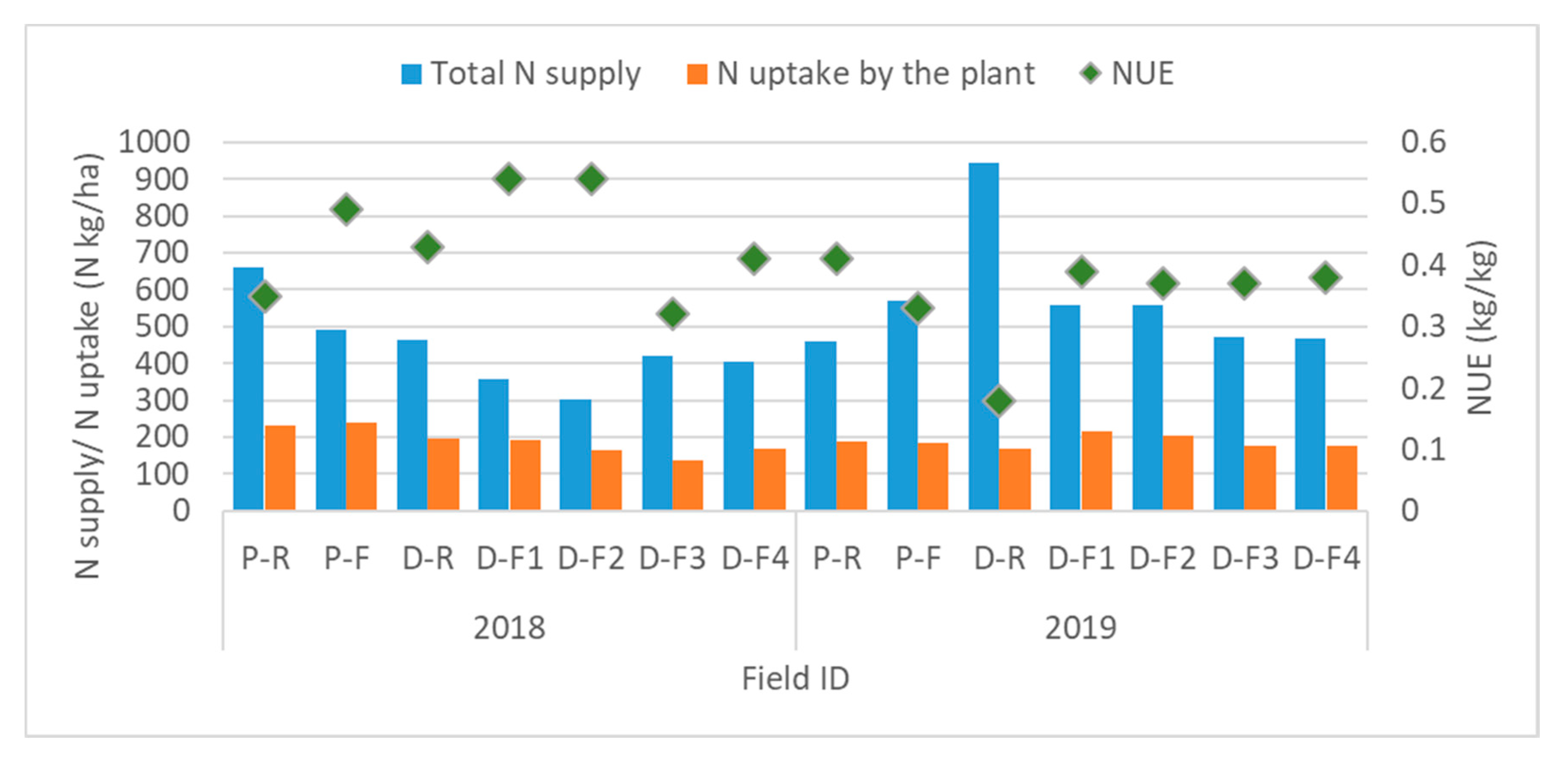

3.3. Nitrogen Use Efficiency

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vaneeckhaute, C.; Meers, E.; Michels, E.; Ghekiere, G.; Accoe, F.; Tack, F.M.G. Closing the nutrient cycle by using bio-digestion waste derivatives as synthetic fertilizer substitutes: A field experiment. Biomass Bioenergy 2013, 55, 175–189. [Google Scholar] [CrossRef] [Green Version]

- Maucieri, C.; Barbera, A.C.; Borin, M. Effect of injection depth of digestate liquid fraction on soil carbon dioxide emission and maize biomass production. Ital. J. Agron. 2016, 11, 6–11. [Google Scholar] [CrossRef]

- Jensen, L.S. Animal Manure Fertiliser Value, Crop Utilisation and Soil Quality Impacts. In Animal Manure Recycling; Sommer, S.G., Christensen, M.L., Schmidt, T., Jensen, L.S., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2013; pp. 295–328. ISBN 9781118676677. [Google Scholar]

- Petersen, S.O.; Sommer, S.G.; Béline, F.; Burton, C.; Dach, J.; Dourmad, J.Y.; Leip, A.; Misselbrook, T.; Nicholson, F.; Poulsen, H.D.; et al. Recycling of livestock manure in a whole-farm perspective. Livest. Sci. 2007, 112, 180–191. [Google Scholar] [CrossRef]

- Cavalli, D.; Bechini, L.; Di Matteo, A.; Corti, M.; Ceccon, P.; Marino Gallina, P. Nitrogen availability after repeated additions of raw and anaerobically digested 15N-labelled pig slurry. Eur. J. Soil Sci. 2018, 69, 1044–1055. [Google Scholar] [CrossRef]

- Cavalli, D.; Cabassi, G.; Borrelli, L.; Geromel, G.; Bechini, L.; Degano, L.; Marino Gallina, P. Nitrogen fertilizer replacement value of undigested liquid cattle manure and digestates. Eur. J. Agron. 2016, 73, 34–41. [Google Scholar] [CrossRef]

- UNECE United Nations Economic Commission for Europe Framework Code for Good Agricultural Practice for Reducing Ammonia Emissions. Available online: http://www.unece.org/environmental-policy/ (accessed on 29 April 2020).

- Webb, J.; Sørensen, P.; Velthof, G.; Amon, B.; Pinto, M.; Rodhe, L.; Salomon, E.; Hutchings, N.; Burczyk, P.; Reid, J. Chapter Seven—An Assessment of the Variation of Manure Nitrogen Efficiency throughout Europe and an Appraisal of Means to Increase Manure-N Efficiency. Adv. Agron. 2013, 119, 371–442. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; de la Fuente, C.; Ferrer-Costa, A.; Carrasco, L.; Cegarra, J.; Abad, M.; Bernal, M.P. Assessment of the fertiliser potential of digestates from farm and agroindustrial residues. Biomass Bioenergy 2012, 40, 181–189. [Google Scholar] [CrossRef]

- Provenzano, M.R.; Iannuzzi, G.; Fabbri, C.; Senesi, N. Qualitative Characterization and Differentiation of Digestates from Different Biowastes Using FTIR and Fluorescence Spectroscopies. J. Environ. Prot. 2011, 2, 83–89. [Google Scholar] [CrossRef] [Green Version]

- Provolo, G.; Mattachini, G.; Finzi, A.; Cattaneo, M.; Guido, V.; Riva, E. Global warming and acidification potential assessment of a collective manure management system for bioenergy production and nitrogen removal in Northern Italy. Sustainability 2018, 10, 3653. [Google Scholar] [CrossRef] [Green Version]

- Provolo, G.; Perazzolo, F.; Mattachini, G.; Finzi, A.; Naldi, E.; Riva, E. Nitrogen removal from digested slurries using a simplified ammonia stripping technique. Waste Manag. 2017, 69, 154–161. [Google Scholar] [CrossRef]

- Perazzolo, F.; Mattachini, G.; Tambone, F.; Calcante, A.; Provolo, G. Nutrient losses from cattle co-digestate slurry during storage. J. Agric. Eng. 2016, 47, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Perazzolo, F.; Mattachini, G.; Tambone, F.; Misselbrook, T.; Provolo, G. Effect of mechanical separation on emissions during storage of two anaerobically codigested animal slurries. Agric. Ecosyst. Environ. 2015, 207, 1–9. [Google Scholar] [CrossRef]

- Cattaneo, M.; Finzi, A.; Guido, V.; Riva, E.; Provolo, G. Effect of ammonia stripping and use of additives on separation of solids, phosphorus, copper and zinc from liquid fractions of animal slurries. Sci. Total Environ. 2019, 672. [Google Scholar] [CrossRef] [PubMed]

- Plana, P.V.; Noche, B. A review of the current digestate distribution models: Storage and transport. Waste Manag. Environ. VIII 2016, 1, 345–357. [Google Scholar] [CrossRef] [Green Version]

- Sarteel, M.; Tostivint, C.; Landowski, A.; Basset, C.; Muehmel, K.; Lockwood, S.; Ding, H.; Oudet, N.; Mudgal, S.; Cherrier, V.; et al. Resource Efficiency in Practice: Closing Mineral Cycles: Final Report; European Commission, Directorate-General for the Environment: Luxembourg, 2016; Volume KH-01-16-4. [Google Scholar]

- Orzi, V.; Riva, C.; D’imporzano, S.B.; Tambone, F.; Adani, F. Anaerobic digestion coupled with digestate injection reduced odour emissions from soil during manure distribution. Sci. Total Environ. 2017, 621. [Google Scholar] [CrossRef]

- Fangueiro, D.; Surgy, S.; Fraga, I.; Cabral, F.; Coutinho, J. Band application of treated cattle slurry as an alternative to slurry injection: Implications for gaseous emissions, soil quality, and plant growth. Agric. Ecosyst. Environ. 2015, 211, 102–111. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Fiala, M. Mechanisation of organic fertiliser spreading, choice of fertiliser and crop residue management as solutions for maize environmental impact mitigation. Eur. J. Agron. 2016, 79, 107–118. [Google Scholar] [CrossRef]

- Mikkelsen, R.; Hartz, T.K.; Rusan, M.J.M. Challenges of increasing water and nutrient efficiency in irrigated agriculture. In Managing Water and Fertilizer for Sustainable Agricultural Intensification, 1st ed.; Drechsel, P., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA), International Water Management Institute (IWMI), International Plant Nutrition Institute (IPNI) and International Potash Institute (IPI): Paris, France, 2015; Chapter 8; pp. 168–186. ISBN 979-10-92366-02-0. [Google Scholar]

- Sharma, B.; Molden, D.; Cook, S. Water use efficiency in agriculture: Measurement, current situation and trends. In Managing Water and Fertilizer for Sustainable Agricultural Intensification; Pay, D., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA), International Water Management Institute (IWMI), International Plant Nutrition Institute (IPNI), and International Potash Institute (IPI): Paris, France, 2015; pp. 39–64. ISBN 979-10-92366-02-0. [Google Scholar]

- Reetz, H.F., Jr.; Heffer, P.; Bruulsema, T.W. 4R nutrient stewardship: A global framework for sustainable fertilizer management. In Managing Water and Fertilizer for Sustainable Agricultural Intensification; Drechsel, P., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA), International Water Management Institute (IWMI), International Plant Nutrition Institute (IPNI), and International Potash Institute (IPI): Paris, France, 2015; Chapter 4; pp. 65–86. ISBN 979-10-92366-02-0. [Google Scholar]

- Weih, M. A Calculation Tool for Analyzing Nitrogen Use Efficiency in Annual and Perennial Crops. Agronomy 2014, 4, 470–477. [Google Scholar] [CrossRef] [Green Version]

- Quemada, M.; Delgado, A.; Mateos, L.; Villalobos, F.J. Nitrogen Fertilization I: The Nitrogen Balance. In Principles of Agronomy for Sustainable Agriculture; Villalobos, F.F., Ed.; Springer: Cham, Switzerland, 2016; pp. 341–368. [Google Scholar]

- Yin, G.; Wang, X.; Du, H.; Shen, S.; Liu, C.; Zhang, K.; Li, W. N2O and CO2 emissions, nitrogen use efficiency under biogas slurry irrigation: A field study of two consecutive wheat-maize rotation cycles in the North China Plain. Agric. Water Manag. 2019, 212, 232–240. [Google Scholar] [CrossRef]

- Rasmussen, I.S.; Dresbøll, D.B.; Thorup-Kristensen, K. Winter wheat cultivars and nitrogen (N) fertilization—Effects on root growth, N uptake efficiency and N use efficiency. Eur. J. Agron. 2015, 68, 38–49. [Google Scholar] [CrossRef]

- Zavattaro, L.; Costamagna, C.; Grignani, C.; Bechini, L.; Spiegel, A.; Lehtinen, T.; Guzmán, G.; Krüger, J.; D’Pose, T.; Pecio, A.; et al. Long-term effects of best management practices on crop yield and nitrogen surplus. Ital. J. Agron. 2015, 10, 47–50. [Google Scholar] [CrossRef] [Green Version]

- Sandén, T.; Spiegel, H.; Stüger, H.-P.; Schlatter, N.; Haslmayr, H.-P.; Zavattaro, L.; Grignani, C.; Bechini, L.; D′Hose, T.; Molendijk, L.; et al. European long-term field experiments: Knowledge gained about alternative management practices. Soil Use Manag. 2018, 34, 167–176. [Google Scholar] [CrossRef]

- Jarosch, K.; Richner, W.; Mayer, J. Nitrogen-use efficiency of biogas digestate. Rech. Agron. Suisse 2018, 3, 76–81. [Google Scholar]

- Quemada, M.; Delgado, A.; Mateos, L.; Villalobos, F.J. Nitrogen Fertilization II: Fertilizer Requirements. In Principles of Agronomy for Sustainable Agriculture; Villalobos, F.F., Ed.; Springer: Cham, Switzerland, 2016; pp. 369–380. [Google Scholar]

- Oyebiyi, F.B.; Aula, L.; Omara, P.; Nambi, E.; Dhillon, J.S.; Raun, W.R. Maize (Zea mays L.) Grain Yield Response to Methods of Nitrogen Fertilization. Commun. Soil Sci. Plant Anal. 2019, 50, 2694–2700. [Google Scholar] [CrossRef]

- Lazcano, C.; Tsang, A.; Doane, T.A.; Pettygrove, G.S.; Horwath, W.R.; Burger, M. Soil nitrous oxide emissions in forage systems fertilized with liquid dairy manure and inorganic fertilizers. Agric. Ecosyst. Environ. 2016, 225, 160–172. [Google Scholar] [CrossRef]

- Panison, F.; Sangoi, L.; Durli, M.M.; Leolato, L.S.; Coelho, A.E.; Kuneski, H.F.; de Liz, V.O. Timing and splitting of nitrogen side-dress fertilization of early maize hybrids for high grain yield. Rev. Bras. Cienc. Solo 2019, 43. [Google Scholar] [CrossRef] [Green Version]

- Sandhu, O.S.; Gupta, R.K.; Thind, H.S.; Jat, M.L.; Sidhu, H.S. Yadvinder-Singh Drip irrigation and nitrogen management for improving crop yields, nitrogen use efficiency and water productivity of maize-wheat system on permanent beds in north-west India. Agric. Water Manag. 2019, 219, 19–26. [Google Scholar] [CrossRef]

- Bortolini, L. A low environmental impact system for fertirrigation of maize with cattle slurry. Contemp. Eng. Sci. 2016, 9, 201–213. [Google Scholar] [CrossRef]

- Demurtas, C.E.; Seddaiu, G.; Ledda, L.; Cappai, C.; Doro, L.; Carletti, A.; Roggero, P.P. Replacing organic with mineral N fertilization does not reduce nitrate leaching in double crop forage systems under Mediterranean conditions. Agric. Ecosyst. Environ. 2016, 219, 83–92. [Google Scholar] [CrossRef]

- Oker, T.E.; Kisekka, I.; Sheshukov, A.Y.; Aguilar, J.; Rogers, D.H. Evaluation of maize production under mobile drip irrigation. Agric. Water Manag. 2018, 210, 11–21. [Google Scholar] [CrossRef]

- Kranz, L.W.; Koelsch, K.R.; Shapiro, A.C. Application of Liquid Animal Manures Using Center Pivot Irrigation Systems. Ext. Div. Circ. 2007, 1, 1–13. Available online: https://extensionpubs.unl.edu/publication/9000016364607/application-of-liquid-animal-manures-using-center-pivot-irrigation-systems/ (accessed on 23 April 2020).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019; Volume 53, p. 24. [Google Scholar]

- Rubel, F.; Brugger, K.; Haslinger, K.; Auer, I. The climate of the European Alps: Shift of very high resolution Köppen-Geiger climate zones 1800-2100. Meteorol. Z. 2017, 26, 115–125. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2014, Update 2015; World Soil Resources Reports No. 106; International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; FAO: Rome, Italy, 2015; p. 192. [Google Scholar]

- APHA; AWWA; WEF. Standard Methods for Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA, 2012; p. 1360. ISBN 978-087553-013-0. Available online: http://www.standardmethods.org/ (accessed on 29 July 2020).

- Yagüe, M.R.; Quílez, D. Response of Maize Yield, Nitrate Leaching, and Soil Nitrogen to Pig Slurry Combined with Mineral Nitrogen. J. Environ. Qual. 2010, 39, 686–696. [Google Scholar] [CrossRef] [PubMed]

- Arbat, G.; Roselló, A.; Olivé, F.D.; Puig-Bargués, J.; Llinàs, E.G.; Duran-Ros, M.; Pujol, J.; de Cartagena, F.R. Soil water and nitrate distribution under drip irrigated maize receiving pig slurry. Agric. Water Manag. 2013, 120, 11–22. [Google Scholar] [CrossRef]

- Finzi, A.; Oberti, R.; Negri, A.S.; Perazzolo, F.; Cocolo, G.; Tambone, F.; Cabassi, G.; Provolo, G. Effects of measurement technique and sample preparation on NIR spectroscopy analysis of livestock slurry and digestates. Biosyst. Eng. 2015, 134, 42–54. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, G.; Li, H.; Wang, L.; Wu, S.; Wu, W.; Meng, F. Mitigation of greenhouse gas emissions through optimized irrigation and nitrogen fertilization in intensively managed wheat–maize production. Sci. Rep. 2020, 10, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lovarelli, D.; Ingrao, C.; Fiala, M.; Bacenetti, J. Beyond the Water Footprint: A new framework proposal to assess freshwater environmental impact and consumption. J. Clean. Prod. 2018, 172, 4189–4199. [Google Scholar] [CrossRef]

- Piccini, C.; Di Bene, C.; Farina, R.; Pennelli, B.; Napoli, R. Assessing nitrogen use efficiency and nitrogen loss in a forage-based system using a modeling approach. Agronomy 2016, 6, 23. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Meng, F.; Li, H.; Wang, L.; Wu, S.; Xiao, G.; Wu, W. Optimized fertigation maintains high yield and mitigates N2O and NO emissions in an intensified wheat–maize cropping system. Agric. Water Manag. 2019, 211, 26–36. [Google Scholar] [CrossRef]

- Berenguer, P.; Santiveri, F.; Boixadera, J.; Lloveras, J. Fertilisation of irrigated maize with pig slurry combined with mineral nitrogen. Eur. J. Agron. 2008, 28, 635–645. [Google Scholar] [CrossRef]

- Wu, D.; Xu, X.; Chen, Y.; Shao, H.; Sokolowski, E.; Mi, G. Effect of different drip fertigation methods on maize yield, nutrient and water productivity in two-soils in Northeast China. Agric. Water Manag. 2019, 213, 200–211. [Google Scholar] [CrossRef]

| Site | Field | Area (ha) | Sand (%) * | Loam (%) * | Clay (%) * | Total N (g/kg) * | Organic Carbon (g/kg) * | Organic Matter (%) * | pH in Water * |

|---|---|---|---|---|---|---|---|---|---|

| 1 | P-R | 7.0 | 23.3 | 71.8 | 5.0 | 3.3 | 23.1 | 4.0 | 7.5 |

| 1 | P-F | 10.6 | 14.0 | 77.4 | 8.6 | 3.0 | 19.0 | 3.3 | 7.8 |

| 2 | D-R | 7.0 | 11.3 | 59.2 | 29.5 | 2.5 | 13.7 | 2.4 | 7.0 |

| 2 | D-F1 | 4.2 | 33.9 | 40.3 | 25.8 | 2.2 | 11.4 | 2.0 | 6.7 |

| 2 | D-F2 | 4.5 | 22.0 | 51.7 | 26.3 | 2.4 | 14.5 | 2.5 | 6.6 |

| 2 | D-F3 | 5.1 | 17.1 | 49.9 | 33.0 | 2.4 | 13.4 | 2.3 | 6.8 |

| 2 | D-F4 | 5.3 | 13.0 | 53.9 | 33.2 | 2.5 | 12.1 | 2.1 | 6.9 |

| Base Dressing in 2018 | Base Dressing in 2019 | ||||||

|---|---|---|---|---|---|---|---|

| Site | Field id | (m3/ha) | (kg N/ha) | (kg N-NH4/ha) | (m3/ha) | (kg N/ha) | (kg N-NH4/ha) |

| 1 | P-R | 85.2 | 659 | 378 | 73.6 | 461 | 297 |

| 1 | P-F | 43.5 | 337 | 193 | 63.0 | 444 | 278 |

| 2 | D-R | 112.5 | 464 | 344 | 229.9 | 942 | 680 |

| 2 | D-F1 | 51.5 | 297 | 202 | 81.3 | 500 | 335 |

| 2 | D-F2 | 47.3 | 273 | 185 | 81.3 | 500 | 335 |

| 2 | D-F3 | 65.8 | 380 | 258 | 71.8 | 436 | 300 |

| 2 | D-F4 | 63.8 | 368 | 250 | 71.8 | 429 | 297 |

| 2018 | 2019 | ||||

|---|---|---|---|---|---|

| Site | Field id | Yield (t/ha DM) | Maize Growing Days | Yield (t/ha DM) | Maize Growing Days |

| 1 | P-R | 19.2 | 104 | 14.9 | 101 |

| 1 | P-F | 20.5 | 105 | 15.2 | 102 |

| 2 | D-R | 14.8 | 113 | 13.9 | 118 |

| 2 | D-F1 | 14.7 | 93 | 16.5 | 125 |

| 2 | D-F2 | 12.9 | 95 | 15.6 | 125 |

| 2 | D-F3 | 10.5 | 92 | 13.4 | 124 |

| 2 | D-F4 | 13.3 | 93 | 14.5 | 124 |

| Site | Year | TAN (g/kg) | TKN (g/kg) | Percentage of TAN in TKN (%) | pH | TS (% wb) | Percentage of VS in TS (%) | SS (% wb) |

|---|---|---|---|---|---|---|---|---|

| 1 | 2018 | 3.6 (±0.5) | 6.1 (±1.0) | 59.0 (±3.6) | 8.0 (±0.1) | 5.8 (±1.2) | 68.0% (±1.0) | 2.3 (±0.7) |

| 2019 | 3.5 (±0.1) | 5.5 (±0.4) | 63.6 (±2.7) | 8.2 (±0.1) | 4.8 (±0.2) | 61.3% (±0.4) | 2.5 (±0.3) | |

| 2 | 2018 | 3.3 (±0.1) | 4.5 (±0.1) | 73.3 (±2.2) | 7.8 (±0.2) | 3.9 (±0.2) | 52.3% (±0.8) | 2.1 (±0.1) |

| 2019 | 3.4 (±0.1) | 4.9 (±0.2) | 69.3 (±2.1) | 8.0 (±0.1) | 4.3 (±0.2) | 54.0% (±0.9) | 2.3 (±0.2) |

| Fertigation 2018 | Fertigation 2019 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Site | Field | Dose (m3/ha) | TKN (kg/ha) | TAN (kg/ha) | n° Fertigation | Dose (m3/ha) | TKN (kg/ha) | TAN (kg/ha) | n° Fertigation |

| 1 | P-F | 25.2 | 152.6 | 91.0 | 6 | 22.7 | 125.5 | 79.6 | 4 |

| 2 | D-F1 | 13.9 | 61.8 | 46.2 | 2 | 12.6 | 59.3 | 43.1 | 2 |

| 2 | D-F2 | 7.0 | 31.3 | 23.3 | 2 | 11.3 | 56.6 | 38.3 | 2 |

| 2 | D-F3 | 8.8 | 39.3 | 28.7 | 2 | 7.2 | 36.2 | 25.5 | 2 |

| 2 | D-F4 | 8.6 | 38.2 | 27.8 | 2 | 8.1 | 39.4 | 27.8 | 2 |

| Site 1 | Site 2 | |||||

|---|---|---|---|---|---|---|

| Digestate (m3/ha Event) | Water (m3/ha Event) | Dilution (%) | Digestate (m3/ha Event) | Water (m3/ha Event) | Dilution (%) | |

| Fertigation 2018 | 4.2 (±0.68) | 128.8 (±16.57) | 3.2% (±0.43) | 4.8 (±2.28) | 137.0 (±61.40) | 3.4% (±0.9) |

| Fertigation 2019 | 5.7 (±0.76) | 126.5 (±12.32) | 4.3% (±0.2) | 4.9 (±1.36) | 117.0 (±30.4) | 4.0% (±0.6) |

| Fertigation 2018 | Fertigation 2019 | ||

|---|---|---|---|

| Site | Field | (m3/h) | (m3/h) |

| 1 | P-F | 3.0 (±0.34) | 4.1 (±0.23) |

| 2 | D-F1 | 2.3 (±0.04) | 2.5 (±0.36) |

| 2 | D-F2 | 2.3 (±0.98) | 2.6 (±0.43) |

| 2 | D-F3 | 2.2 (±0.98) | 2.4 (±0.66) |

| 2 | D-F4 | 2.2 (±0.84) | 2.8 (±0.18) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guido, V.; Finzi, A.; Ferrari, O.; Riva, E.; Quílez, D.; Herrero, E.; Provolo, G. Fertigation of Maize with Digestate Using Drip Irrigation and Pivot Systems. Agronomy 2020, 10, 1453. https://doi.org/10.3390/agronomy10101453

Guido V, Finzi A, Ferrari O, Riva E, Quílez D, Herrero E, Provolo G. Fertigation of Maize with Digestate Using Drip Irrigation and Pivot Systems. Agronomy. 2020; 10(10):1453. https://doi.org/10.3390/agronomy10101453

Chicago/Turabian StyleGuido, Viviana, Alberto Finzi, Omar Ferrari, Elisabetta Riva, Dolores Quílez, Eva Herrero, and Giorgio Provolo. 2020. "Fertigation of Maize with Digestate Using Drip Irrigation and Pivot Systems" Agronomy 10, no. 10: 1453. https://doi.org/10.3390/agronomy10101453