Modelling of Impact Falling Ball Test Response on Solid and Engineered Wood Flooring of Two Eucalyptus Species

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Species

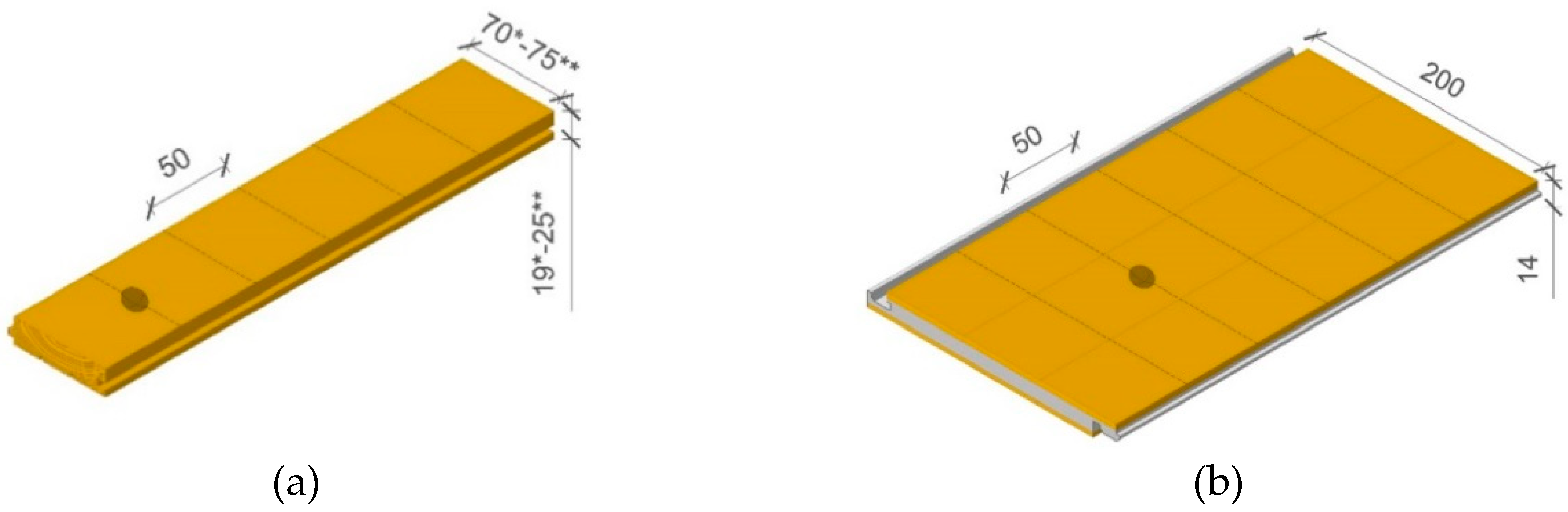

2.2. Wood Flooring Specimens

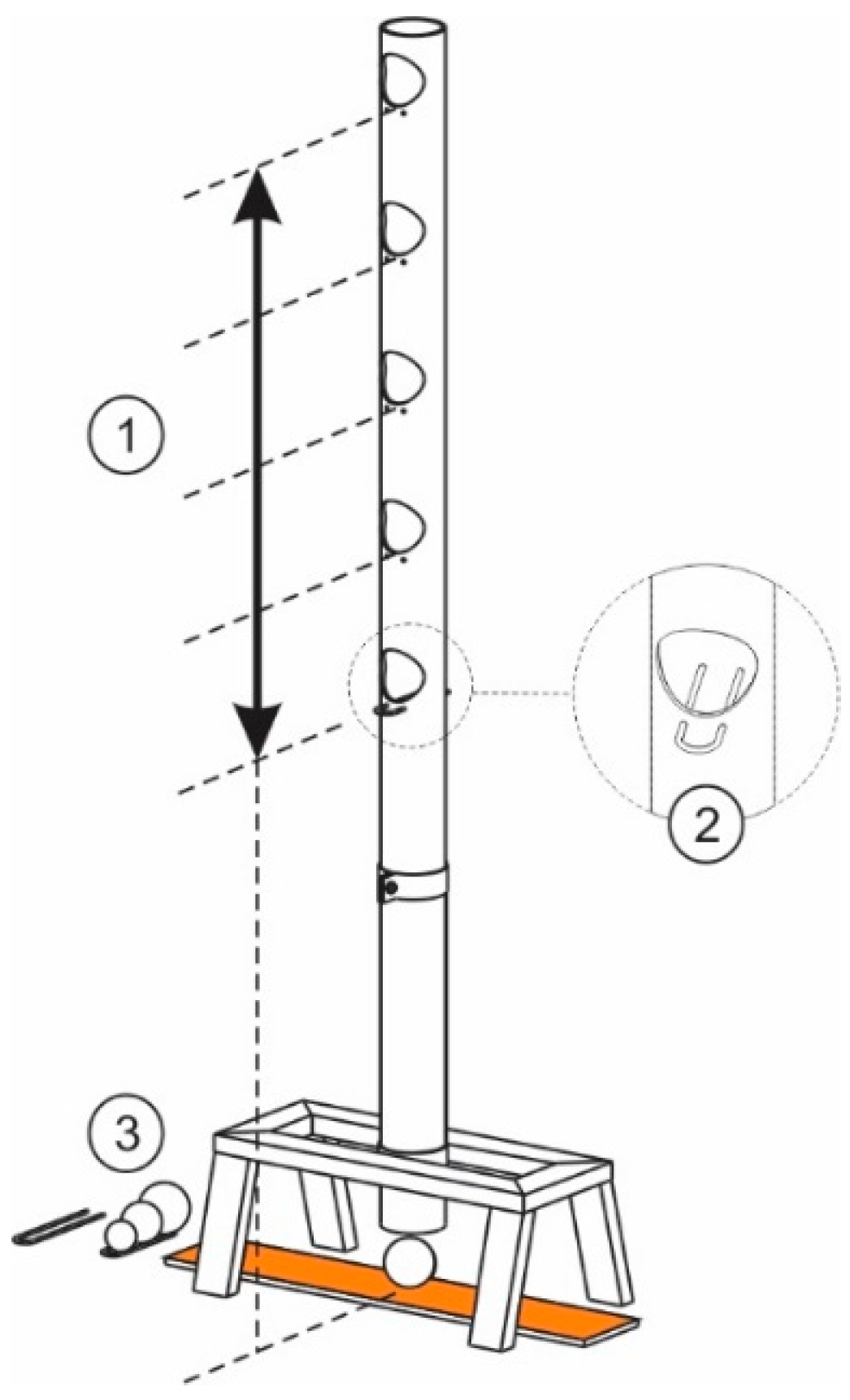

2.3. Impact Test

2.4. Statistical Analysis

2.5. Modelling of Impact Falling Ball Test

2.5.1. Model Development and Selection

2.5.2. Model Diagnostic

2.5.3. Prediction and Validation

3. Results and Discussion

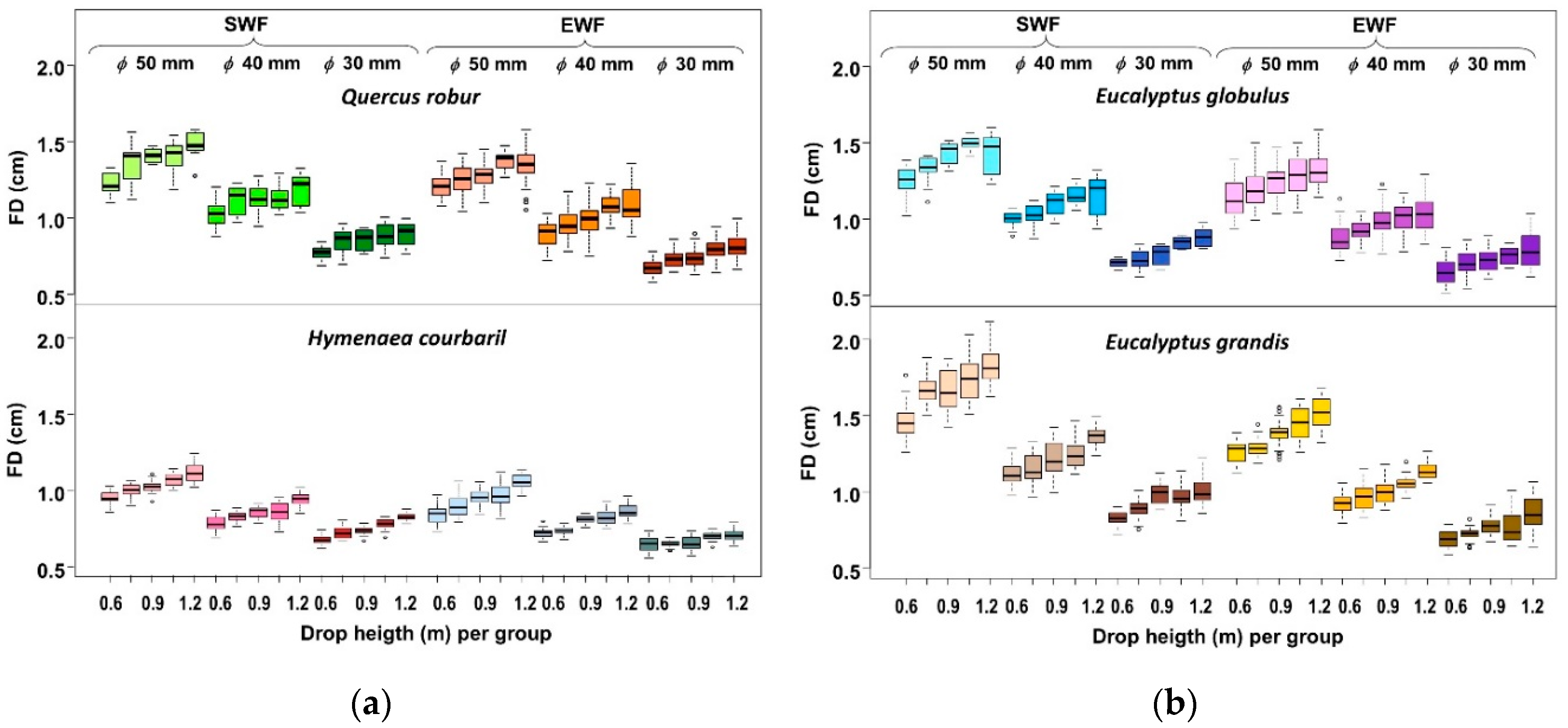

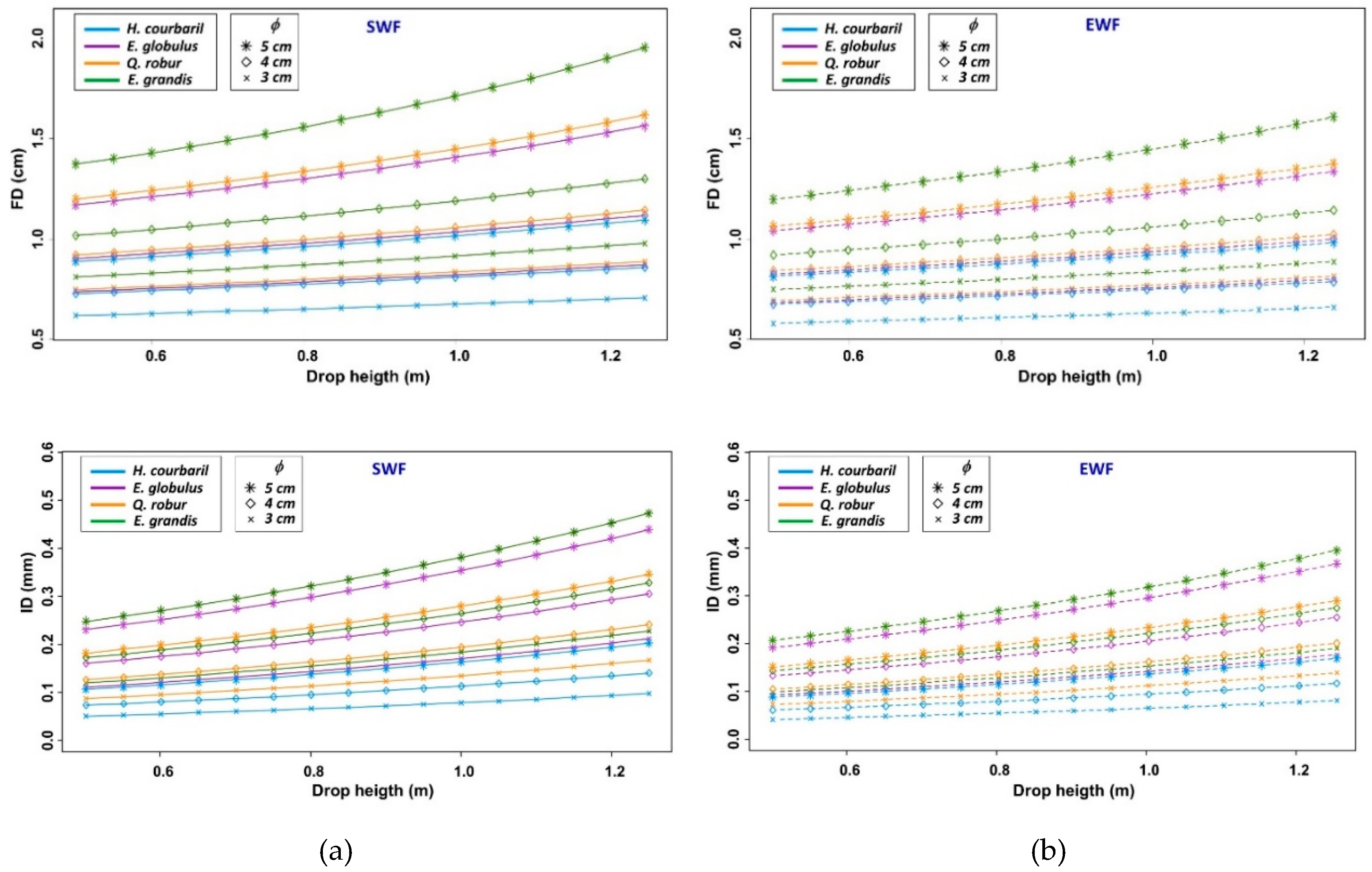

3.1. Footprint Diameter (FD)

3.1.1. Pairwise Comparison for FD between Wood Flooring Types (SWF and EWF)

3.1.2. Pairwise Comparison for FD between Wood Species (to Each Wood Flooring Types)

3.2. Indentation Depth (ID)

3.2.1. Behaviour Comparison of ID Values: SWF vs. EWF

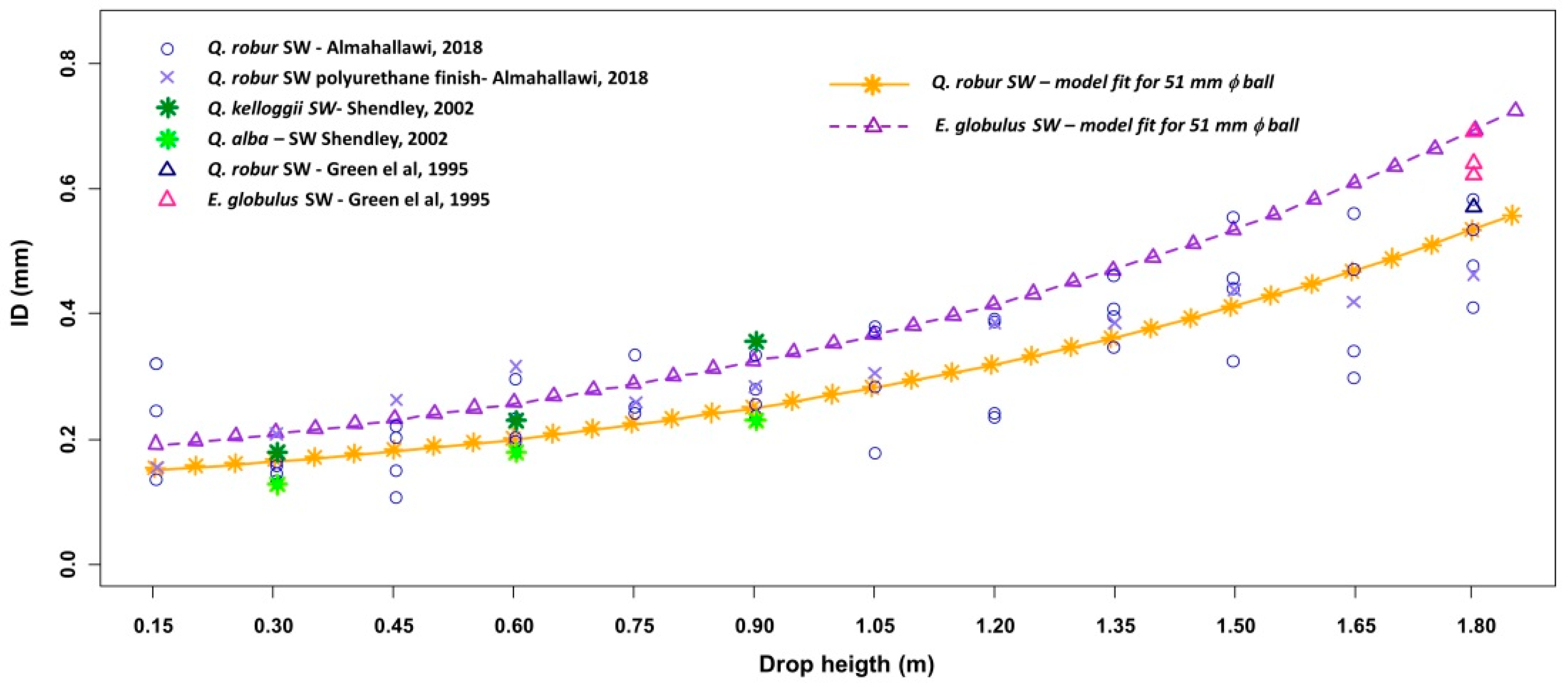

3.2.2. Pairwise Comparison for ID between Wood Species

3.3. Model Selection

- Residual analyses over models numbers 1, 2, 3, 4, 5, 6 for Y = FD and ID, presented an evident lack of normality, so they were discarded.

- Residual plot of model 9 was not suitable.

- The rest of the models were suitable, but, in accordance with the principle of parsimony, for FD, the 7 and 8 models and the Gamma model with reciprocal and log link were selected (green highlight). For ID, the Gamma log model was chosen (orange highlight).

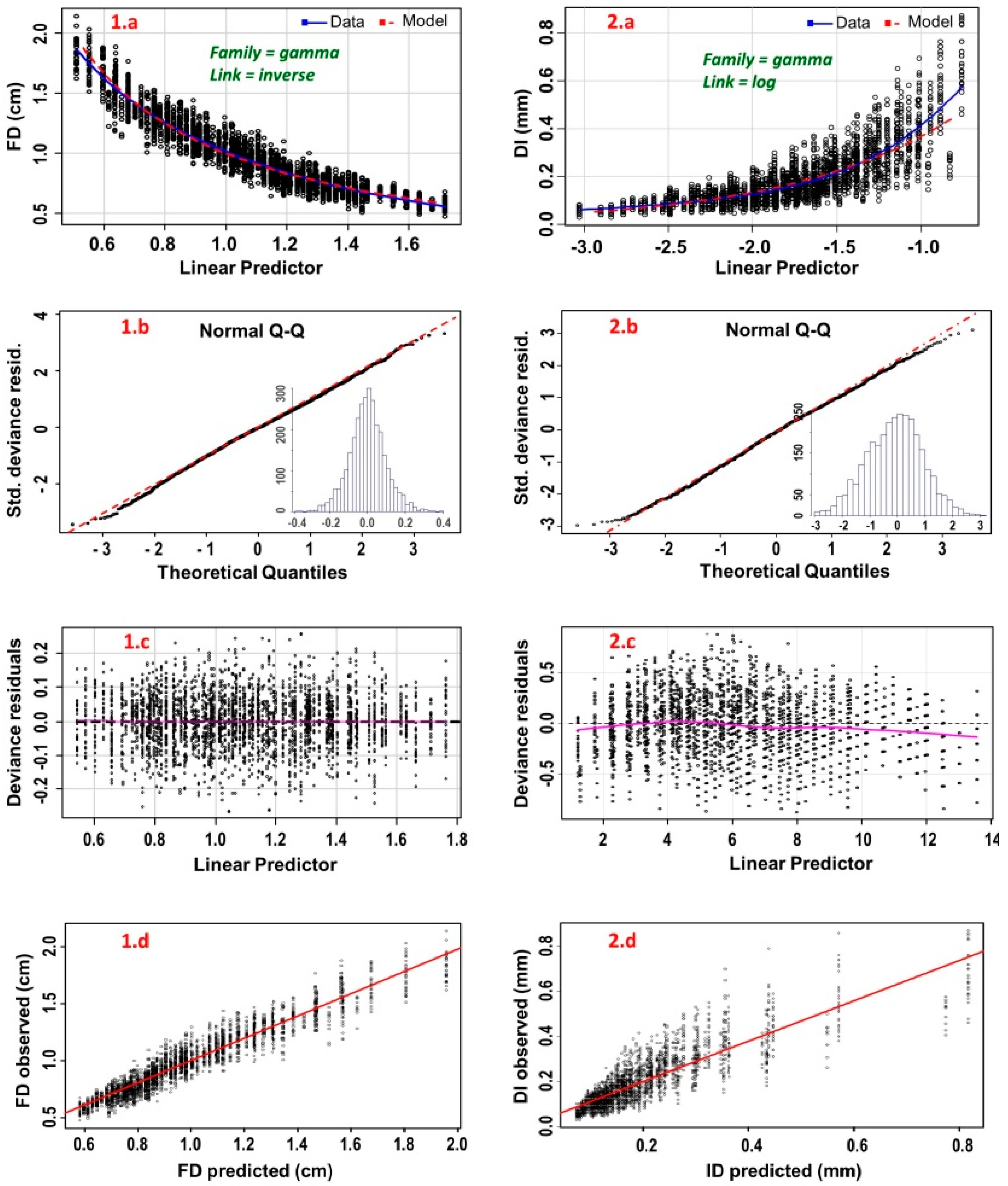

3.4. Model Diagnostic

3.5. Prediction and Validation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Andrade, A.; Jankowsky, I.P.; Takeshita, S.; Neto, P.R. Análise de qualidade em pisos de madeira. Rev. Madeira 2010, 125, 12–18. [Google Scholar]

- Castro, G.; Zanuttini, R. Multilaminar wood: Manufacturing process and main physical-mechanical properties. Forest Prod. J. 2004, 54, 61–67. [Google Scholar]

- Bergman, R.D.; Bowe, S.A. Life cycle inventory of manufacturing prefinished engineered wood flooring in Eastern us with comparsion to solid strip wood flooring. Wood Fiber Sci. 2011, 43, 421–441. [Google Scholar]

- Li, N.; Tsushima, E.; Tsushima, H. Comparison of impact force attenuation by various combinations of hip protector and flooring material using a simplified fall-impact simulation device. J. Biomech. 2013, 46, 1140–1146. [Google Scholar] [CrossRef]

- Buckley, D.S.; Clatterbuck, W.K. Proceedings of the 15th Central Hardwood Forest Conference; e-Gen. Tech. Rep. SRS–101; US Department of Agriculture, Forest Service, Southern Research Station: Knoxville, TN, USA, 2007.

- Padilha, C.; Lima, J.T.; Silva, J.R.M.; Trugilho, P.F.; Andrade, H.B. Avaliação da qualidade da madeira de Eucalyptus urophylla para utilização em pisos. Sci. For. 2006, 71, 141–147. [Google Scholar]

- Mania, P.; Wróblewski, M.; Wójciak, A.; Roszyk, E.; Moliński, W. Hardness of densified wood in relation to changed chemical composition. Forests 2020, 11, 506. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Impregnation of wood with microencapsulated bio-based phase change materials for high thermal mass engineered wood flooring. Appl. Sci. 2018, 8, 2696. [Google Scholar] [CrossRef]

- Hague, J. Utilisation of Plantation Eucalypts in Engineered Wood Products; Forest and Wood Products Australia: Melbourne, Australia, 2013. [Google Scholar]

- Nogueira, M.C.D.J.A.; de Araujo, V.A.; Vasconcelos, J.S.; Christoforo, A.L.; Lahr, F.A.R. Sixteen properties of Eucalyptus Tereticornis wood for structural uses. Biosci. J. 2020, 36, 449–457. [Google Scholar] [CrossRef]

- Crespo, J.; Majano-Majano, A.; Lara-Bocanegra, A.J.; Guaita, M. Mechanical properties of small clear specimens of eucalyptus globulus Labill. Materials 2020, 13, 906. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of physical and mechanical properties of unthinned and unpruned plantation-grown eucalyptus nitens H. Deane & Maiden Lumber. Forests 2019, 10, 194. [Google Scholar] [CrossRef]

- Jeon, J.Y.; Ryu, J.K.; Jeong, J.H.; Tachibana, H. Review of the impact ball in evaluating floor impact sound. Acta Acust. United Acust. 2006, 92, 777–786. [Google Scholar]

- Todaro, L. Effect of steaming treatment on resistance to footprints in Turkey oak wood for flooring. Eur. J. Wood Prod. 2012, 70, 209–214. [Google Scholar] [CrossRef]

- Németh, R.; Molnar, S.; Bak, M. Performance evaluation of strip parquet flooring panels after long-term, in-service exposure. Drewno 2014, 57, 1–16. [Google Scholar] [CrossRef]

- Sepliarsky, F.; Tapias-Martin, R.; Acuña-Rello, L. Parquet multicapa de Eucalyptus globulus y Quercus robur. resistencia al impacto para diversas tipologías de fabricación. Maderas Cienc. Tecnol. 2018, 20, 103–116. [Google Scholar] [CrossRef]

- Oliveira, M.B.D.; Silva, J.R.M.D.; Hein, P.R.G.; Lima, J.T. Establishment of quality classes for hardwood floorings by simulated use. CERNE 2019, 25, 105–109. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C.; Welzbacher, C.R. Dynamic and static hardness of wood: Method development and comparative studies. Int. Wood Prod. J. 2011, 2, 5–11. [Google Scholar] [CrossRef]

- Hirata, S.; Ohta, M.; Honma, Y. Hardness distribution on wood surface. J. Wood Sci. 2001, 47, 1–7. [Google Scholar] [CrossRef]

- Kollmann, F. Technologie des Holzes und der Holzwerkstoffe; Springer: Berlin, Germany, 1951. [Google Scholar]

- Rautkari, L.; Kamke, F.A.; Hughes, M. Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci. Technol. 2001, 45, 693–705. [Google Scholar] [CrossRef]

- Doyle, J.; Walker, J.C.F. Indentation of wood by wedges. Wood Sci. Technol. 1985, 19, 47–55. [Google Scholar] [CrossRef]

- UNE-EN 1534:2020. Wood Flooring and Parquet. Detrmination of Resistance to Indentation. Test Method; Asociación Española de Normalización: Madrid, Spain, 2020. [Google Scholar]

- ASTM D 143-14. Standard Test Methods for Small Clear Specimens of Timber; ASTM International: West Conshohocke, PA, USA, 2014. [Google Scholar]

- Bektas, I.; Alma, M.H.; As, N. Determination of the relationships between Brinell and Janka hardness of eastern beech (Fagus orientalis Lipsky). Forest Prod. J. 2001, 51, 84. [Google Scholar]

- Niemz, P.; Stübi, T. Investigations of hardness measurements on wood based materials using a new universal measurement system. In Proceedings of the Symposium on Wood Machining Properties of Wood and Wood Composites Related to Wood Machining, BOKU–University of Natural Resources and Applied Life Sciences, Vienna, Austria, 27–29 August 2000; pp. 51–61. [Google Scholar]

- Heräjärvi, H. Variation of basic density and Brinell hardness within mature Finnish Betula pendula and B. pubescens stems. Wood Fiber Sci. 2004, 36, 216–227. [Google Scholar]

- Doyle, J.; Walker, J.C.F. Indentation hardness of wood. Wood Fiber Sci. 1985, 17, 369–376. [Google Scholar]

- Holmberg, H. Influence of grain angle on Brinell hardness of Scots pine (Pinus sylvestris L.). Holz Als Roh-Und Werkst. 2000, 58, 91–95. [Google Scholar] [CrossRef]

- Grekin, M.I.K.A.; Verkasalo, E. Variations in and models for Brinell hardness of Scots pine wood from Finland and Sweden. Balt. For. 2013, 19, 128–136. [Google Scholar]

- Helińska-Raczkowska, L.; Moliński, W. The effect of the Janka ball indentation depth on the hardness number determined for selected wood species. Folia For. Pol. 2003, 34, 27–36. [Google Scholar]

- De Assis, A.A.; Alexandre, R.P.; Ballarin, A.W. Dynamic hardness of wood–measurements with an automated portable hardness tester. Holzforschung 2017, 71, 383–389. [Google Scholar] [CrossRef]

- Ballarin, A.; Almeida, P.; Palma, H.L.; Colenci, R. Portable hardness tester for timber classification. In Proceedings of the WCTE 2010-World Conference on Timber Engineering, Riva del Garda, Italy, 20–24 June 2010; pp. 20–24. [Google Scholar]

- UNE-408: 2011+A1:2012. Timber Structures–Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties; Asociación Española de Normalización: Madrid, Spain, 2012. [Google Scholar]

- EN 13183-1:2002. Moisture Content of a Piece of Sawn Timber. Part 1: Determination by Oven Dry Method; European Committee of Standardization (CEN): Brussels, Belgium, 2002. [Google Scholar]

- ASTM D1037-99. Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials; ASTM International: West Conshohocke, PA, USA, 1999. [Google Scholar]

- AITIM. Reglamento Del Sello de Calidad Aitim Para Pavimentos de Madera, Parquet Industrial, Parquet Mosaico, Lamparquet y Tarima. 2012. Available online: http://infomadera.net/uploads/sellos_calidad/reglamento_23_Sello%204.1,%204.3%20y%204.4%20Pmosytarim_19%2007%2012.pdf (accessed on 5 December 2016).

- Wilcox, R. Introduction to Robust Estimation and Hypothesis Testing; Academic Press: New York, NY, USA, 2016. [Google Scholar]

- Welch, B.L. On the comparison of several mean values—An alternative approach. Biometrika 1951, 38, 330–336. [Google Scholar] [CrossRef]

- Nelder, J.A.; Wedderburn, R.W.M. Generalized linear models. J. R. Stat. Soc. 1972, 135, 370–384. [Google Scholar]

- Dobson, A.J. An Introduction to Generalized Linear Models; Chapman & Hall/CRC: London, UK, 2002. [Google Scholar] [CrossRef]

- Faraway, J.J. Extending the Linear Model with R, Generalized Linear, Mixed Effects and Non-Parametric Regression Models; Chapman and Hall/CRC: New York, NY, USA, 2006. [Google Scholar]

- Krzanowski, W.J. An Introduction to Statistical Modelling; John Wiley & Sons Inc.: London, UK, 2010. [Google Scholar]

- Burnham, K.P.; Anderson, D.R. Model Selection and Inference: A Practical Information—Theoretic Approach; Springer: New York, NY, USA, 1998. [Google Scholar]

- Anderson, D.R.; Burnham, K.P.; Thompson, W.L. Null hypothesis testing: Problems, prevalence, and an alternative. J. Wildl. Manag. 2000, 64, 912–923. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, T.; Friedman, J. The Elements of Statistical Learning: Data Mining, Inference, and Prediction; Springer: New York, NY, USA, 2001. [Google Scholar]

- Wackerly, D.D.; Mendenhall, W., III; Scheaffer, R.L. Mathematical Statistics with Applications; Pacific Grove, Wad worth Group, Duxbury and Brooks/Cole: London, UK, 2002. [Google Scholar]

- Schwarz, G. Estimation the Dimension of a Model. Ann. Stat. 1978, 6, 461–464. [Google Scholar] [CrossRef]

- Chen, J.; Chen, Z. Extended bayesian information criteria for model selection with large model space. Biometrika 2008, 95, 759–771. [Google Scholar] [CrossRef]

- Almahallawi, T.M. Flooring Systems from Locally Grown Casuarina Wood: Performance Evaluation Based on Simulated in-Service Testing. Master’s Thesis, The American University in Cairo, Cairo, Egypt, 2018. [Google Scholar]

- Shedley, P.N. The Cost Benefits of Small Log Processing Laminated Three-Ply Flooring: A Case Study in WA: A Report for the RIRDC/Land and Water Australia/FWPRDC Joint Venture Agroforestry Program and the Wood and Paper Industry Strategy-Industry Development Program; Rural Industries Research and Development Corporation: Melbourne, Australia, 2002. [Google Scholar]

- Green, D.; von Segen, W.; Willits, S. Western Hardwoods Value-Added Research and Demonstration Program. Forest Products Laboratory; General Technical Report FPL-GTR-85; Oregon State University: Washington, DC, USA, 1995. [Google Scholar] [CrossRef]

- Cook, R.D.; Weisberg, S. Graphics for assessing the adequacy of regression models. J. Am. Stat. Assoc. 1997, 92, 490–499. [Google Scholar] [CrossRef]

- Fox, J.; Monette, G. Generalized collinearity diagnostics. J. Am. Stat. Assoc. 1992, 87, 178–183. [Google Scholar] [CrossRef]

- Gareth, J.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning: With Applications in R; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Aitkin, M. A general maximum likelihood analysis of overdispersion in generalized linear models. Stat. Comput. 1996, 6, 251–262. [Google Scholar] [CrossRef]

- Adewale, A.J.; Xu, X. Robust designs for generalized linear models with possible overdispersion and misspecified link functions. Comput. Stat. Data Anal. 2010, 54, 875–890. [Google Scholar] [CrossRef]

| Solid Wood Flooring | Engineered Wood Flooring | ||||

|---|---|---|---|---|---|

| Species | Nº of Pieces/Impacts | Nominal Size (l × w × t *) (mm) | Density (kg·m−3) | Nº of Pieces/Impacts | Nominal Size (l × w × t) * (mm) |

| Oak (Q. robur L.) | 30/150 | 300 × 70 × 25 | 686.1 (9.1 **) | 30/450 | 1000 × 200 × 14 |

| Jatoba (H. courbaril L) | 30/450 | 300 × 70 × 25 | 954.6 (10.4 **) | 30/450 | 1000 × 200 × 14 |

| Blue gum (E. globulus Labill) | 30/150 | 300 × 75 × 16 | 854.8 (11.3 **) | 30/450 | 1000 × 200 × 14 |

| Rose gum (E. grandis W. Hill) | 30/450 | 300 × 75 × 16 | 488.3 (9.8 **) | 30/450 | 1000 × 200 × 14 |

| Nominal Diameter (mm) | Weight (g) | Impact Energy (J) * | ||||

|---|---|---|---|---|---|---|

| h = 0.60 m | h = 0.75 m | h = 0.90 m | h = 1.05 m | h = 1.20 m | ||

| 50 | 508.8 | 2.99 | 3.74 | 4.49 | 5.24 | 5.99 |

| 40 | 260.5 | 1.53 | 1.92 | 2.30 | 2.68 | 3.07 |

| 30 | 109.9 | 0.65 | 0.81 | 0.97 | 1.13 | 1.29 |

| Solid Wood Flooring (SWF) | Engineered Wood Flooring (EWF) | |||||

|---|---|---|---|---|---|---|

| Height | Φ 50 mm | Φ 40 mm | Φ 30 mm | Φ 50 mm | Φ 40 mm | Φ 30 mm |

| E. globulus | ||||||

| 1.20 m | 13.74 | 11.05 | 8.59 | 12.78 | 10.05 | 7.72 |

| (9.57) 0.1827 * | (12.45) 0.1274 * | (6.89) 0.1525 * | (8.57) 0.0681 * | (10.66) 0.2018 * | (14.23) 0.6422 * | |

| 1.05 m | 14.38 | 11.14 | 8.24 | 12.48 | 9.79 | 7.48 |

| (2.72) 0.8420 * | (5.75) 0.7633 * | (3.91) 0.4223 * | (9.14) 0.4584 * | (10.46) 0.1361 * | (6.46) 0.0520 * | |

| 0.90 m | 13.77 | 10.73 | 7.52 | 12.05 | 9.67 | 7.13 |

| (5.11) 0.0836 * | (7.01) 0.7221 * | (7.42) 0.1009 * | (8.17) 0.9492 * | (10.38) 0.4191 * | (9.77) 0.5336 * | |

| 0.75 m | 12.69 | 9.82 | 7.19 | 11.56 | 8.98 | 7.00 |

| (7.14) 0.0495 * | (8.31) 0.2154 * | (8.40) 0.9949 * | (10.47) 0.2484 * | (7.80) 0.4405 * | (10.96) 0.9294 * | |

| 0.60 m | 11.94 | 9.66 | 6.99 | 11.03 | 8.52 | 6.39 |

| (9.06) 0.3414 * | (5.65) 0.2543 * | (3.62) 0.8008 * | (11.09) 0.2563 * | (10.95) 0.1576 * | (12.60) 0.4577 * | |

| E. grandis | ||||||

| 1.20 m | 18.27 | 13.65 | 10.15 | 15.17 | 11.39 | 8.63 |

| (6.62) 0.3259 * | (4.35) 0.6817 * | (9.21) 0.3950 * | (6.62) 0.6440 * | (4.33) 0.4621 * | (12.57) 0.3904 * | |

| 1.05 m | 17.46 | 12.56 | 9.76 | 14.56 | 10.60 | 7.70 |

| (8.17) 0.3886 * | (7.41) 0.3204 * | (7.23) 0.1444 * | (8.17) 0.0525 * | (4.16) 0.1673 * | (12.56) 0.2805 * | |

| 0.90 m | 16.64 | 12.26 | 9.89 | 13.88 | 10.05 | 7.84 |

| (7.97) 0.1838 * | (9.88) 0.4595 * | (6.74) 0.2404 * | (7.97) 0.1599 * | (7.46) 0.5368 * | (7.31) 0.9575 * | |

| 0.75 m | 16.69 | 11.51 | 8.93 | 12.92 | 9.72 | 7.26 |

| (5.25) 0.9129 * | (8.55) 0.6479 * | (6.26) 0.5137 * | (5.25) 0.5169 * | (8.21) 0.4977 * | (5.66) 0.3510 * | |

| 0.60 m | 14.65 | 11.18 | 8.28 | 12.66 | 9.29 | 6.93 |

| (8.42) 0.5391 * | (6.47) 0.9554 * | (5.76) 0.3923 * | (6.06) 0.1106 * | (6.82) 0.9821 * | (8.27) 0.3850 * | |

| H. courbaril | ||||||

| 1.20 m | 10.80 | 8.94 | 7.69 | 10.18 | 8.12 | 6.40 |

| (5.90) 0.5247 * | (4.94) 0.7940 * | (3.22) 0.5049 * | (5.27) 0.5041 * | (6.11) 0.2670 * | (6.62) 0.4060 * | |

| 1.05 m | 10.33 | 8.01 | 7.20 | 9.28 | 7.68 | 6.34 |

| (4.18) 0.5157 * | (8.84) 0.2151 * | (4.50) 0.2345 * | (8.57) 0.5574 * | (6.44) 0.3707 * | (4.39) 0.4979 * | |

| 0.90 m | 9.82 | 8.05 | 6.72 | 9.06 | 7.50 | 5.83 |

| (4.00) 0.4358 * | (4.80) 0.1256 * | (3.98) 0.6787 * | (5.53) 0.9318 * | (3.53) 0.6316 * | (8.09) 0.4809 * | |

| 0.75 m | 9.57 | 7.71 | 6.57 | 8.41 | 6.74 | 5.78 |

| (4.85) 0.3640 * | (4.09) 0.5652 * | (6.51) 0.1398 * | (8.79) 0.2842 * | (3.72) 0.9730 * | (4.12) 0.2709 * | |

| 0.60 m | 9.06 | 7.26 | 6.07 | 7.85 | 6.55 | 5.77 |

| (5.34) 0.3627 * | (6.61) 0.5163 * | (4.56) 0.7879 * | (7.71) 0.4798 * | (4.56) 0.6901 * | (8.43) 0.4758 * | |

| Q. robur | ||||||

| 1.20 m | 14.10 | 11.45 | 8.66 | 12.89 | 10.38 | 7.83 |

| (5.93) 0.1593 * | (8.05) 0.1486 * | (8.55) 0.4531 * | (9.68) 0.3466 * | (11.12) 0.4838 * | (9.32) 0.6585 * | |

| 1.05 m | 13.32 | 10.77 | 8.46 | 13.14 | 10.31 | 7.61 |

| (8.35) 0.2208 * | (7.12) 0.5532 * | (9.25) 0.9602 * | (3.88) 0.1747 * | (7.00) 0.8050 * | (8.69) 0.9895 * | |

| 0.90 m | 13.48 | 10.80 | 8.26 | 12.24 | 9.55 | 7.16 |

| (3.05) 0.4346 * | (8.64) 0.9505 * | (7.36) 0.2211 * | (5.99) 0.7939 * | (10.02) 0.9541 * | (8.39) 0.2331 * | |

| 0.75 m | 13.06 | 10.71 | 8.13 | 11.95 | 9.18 | 7.09 |

| (9.71) 0.7198 * | (8.44) 0.1935 * | (9.69) 0.6854 * | (7.82) 0.7497 * | (9.54) 0.8067 * | (7.90) 0.3736 * | |

| 0.60 m | 11.71 | 9.88 | 7.44 | 11.56 | 8.65 | 6.50 |

| (6.14) 0.7400 * | (9.02) 0.9974 * | (6.45) 0.7442 * | (6.73) 0.2864 * | (9.16) 0.4378 * | (7.43) 0.8355 * | |

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | = | x | x | = | x | x | x | x | = | x | x | x | x | x | x |

| E. globulus | x | x | x | x | = | x | x | x | x | x | x | = | = | x | x |

| E. grandis | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| H. courbaril | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| Solid Wood Flooring (SWF) | |||||||||||||||

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | b | b | b | c | b | b | a b | b | b | b | c | c | c | b | b |

| E. globulus | b | b | b | b | b | b | b | b | b | b | b | b | b | b | b |

| E. grandis | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a |

| H. courbaril | c | c | c | d | c | c | c | c | c | c | d | d | d | c | c |

| Engineered Wood Flooring (EWF) | |||||||||||||||

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | c | b | b | c | b | b | b | a | a b | b | b | a b | b | a b | b |

| E. globulus | b | b | b | b | b | b | b | a | b | b | b | b | b | b | b |

| E. grandis | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a |

| H. courbaril | d | c | c | d | c | c | c | b | c | c | c | c | c | c | c |

| Solid Wood Flooring | Engineered Wood Flooring | |||||

|---|---|---|---|---|---|---|

| Height | Φ 50 mm | Φ 40 mm | Φ 30 mm | Φ 50 mm | Φ 40 mm | Φ 30 mm |

| E. globulus | ||||||

| 1.20 m | 0.252 | 0.200 | 0.138 | 0.331 | 0.263 | 0.206 |

| (14.03) 0.2978 * | (16.67) 0.5647 * | (25.92) 0.2509 * | (27.65) 0.06104 * | (33.64) 0.0080 * | (25.92) 0.6793 * | |

| 1.05 m | 0.223 | 0.180 | 0.139 | 0.313 | 0.247 | 0.184 |

| (19.00) 0.6451 * | (19.91) 0.2026 * | (29.68) 0.3278 * | (28.70) 0.4577 * | (23.16) 0.7085 * | (29.68) 0.7952 * | |

| 0.90 m | 0.208 | 0.169 | 0.134 | 0.275 | 0.221 | 0.155 |

| (14.40) 0.5809 * | (15.76) 0.9935 * | (23.32) 0.7721 * | (23.85) 0.7111 * | (28.77) 0.5392 * | (23.32) 0.1498 * | |

| 0.75 m | 0.194 | 0.167 | 0.118 | 0.278 | 0.194 | 0.143 |

| (18.63) 0.6777 * | (24.54) 0.7542 * | (21.34) 0.5954 * | (20.31) 0.4314 * | (24.70) 0.2987 * | (21.34) 0.9729 * | |

| 0.60 m | 0.137 | 0.143 | 0.100 | 0.262 | 0.169 | 0.122 |

| (23.86) 0.2260 * | (20.56) 0.3949 * | (28.64) 0.3010 * | (19.24) 0.0603 * | (27.77) 0.2489 * | (28.64) 0.6362 * | |

| E. grandis | ||||||

| 1.20 m | 0.674 | 0.393 | 0.144 | 0.445 | 0.331 | 0.137 |

| (13.66) 0.3177 * | (21.02) 0.3252 * | (33.68) 0.0223 | (15.99) 0.6821 * | (17.12) 0.8061 * | (24.41) 0.0705 * | |

| 1.05 m | 0.558 | 0.369 | 0.135 | 0.370 | 0.243 | 0.116 |

| (22.32) 0.1250 * | (19.56) 0.1708 * | (25.33) 0.3171 * | (26.88) 0.0940 * | (26.28) 0.2100 * | (29.47) 0.0153 | |

| 0.90 m | 0.481 | 0.274 | 0.138 | 0.370 | 0.233 | 0.100 |

| (23.10) 0.4694 * | (22.00) 0.4704 * | (22.95) 0.6653 * | (20.83) 0.5546 * | (28.02) 0.4308 * | (21.18) 0.0153 | |

| 0.75 m | 0.441 | 0.206 | 0.103 | 0.282 | 0.200 | 0.101 |

| (21.50) 0.1049 * | (24.20) 0.7412 * | (22.25) 0.5623 * | (22.30) 0.7861 * | (30.46) 0.0499 * | (19.17) 0.0412 | |

| 0.60 m | 0.324 | 0.143 | 0.091 | 0.230 | 0.180 | 0.091 |

| (28.78) 0.0306 | (29.56) 0.4790 * | (16.67) 0.1248 * | (18.73) 0.7997 * | (16.70) 0.1770 * | (27.73) 0.0478 | |

| H. courbaril | ||||||

| 1.20 m | 0.188 | 0.145 | 0.136 | 0.140 | 0.107 | 0.090 |

| (19.92) 0.1972 * | (14.96) 0.0229 | (20.87) 0.0205 | (22.48) 0.2284 * | (21.92) 0.2459 * | (25.12) 0.0785 * | |

| 1.05 m | 0.148 | 0.127 | 0.113 | 0.106 | 0.095 | 0.082 |

| (16.90) 0.8213 * | (11.87) 0.4255 * | (19.42) 0.0416 * | (24.92) 0.0685 * | (15.05) 0.4364 * | (17.05) 0.0812 * | |

| 0.90 m | 0.124 | 0.121 | 0.090 | 0.094 | 0.083 | 0.066 |

| (22.96) 0.5623 * | (15.68) 0.1132 * | (17.80) 0.1366 * | (15.70) 0.0257 * | (15.86) 0.0877 * | (26.90) 0.0072 * | |

| 0.75 m | 0.116 | 0.114 | 0.084 | 0.086 | 0.065 | 0.055 |

| (14.83) 0.0794 * | (19.45) 0.0918 * | (11.16) 0.0186 * | (26.85) 0.1989 * | (20.19) 0.0046 * | (19.58) 0.0028 * | |

| 0.60 m | 0.110 | 0.097 | 0.060 | 0.082 | 0.065 | 0.063 |

| (19.10) 0.0795 * | (20.32) 0.1033 * | (12.04) 0.0102 * | (17.87) 0.2330 * | (19.41) 0.0011 * | (14.09) 0.2429 * | |

| Q. robur | ||||||

| 1.20 m | 0.323 | 0.226 | 0.198 | 0.244 | 0.177 | 0.132 |

| (15.66) 0.0894 * | (18.59) 0.7587 * | (8.00) 0.1759 * | (34.37) 0.0777 * | (34.47) 0.1052 * | (0.323) 0.0809 * | |

| 1.05 m | 0.311 | 0.223 | 0.170 | 0.231 | 0.159 | 0.122 |

| (7.90) 0.9437 * | (14.46) 0.4078 * | (11.25) 0.1149 * | (29.99) 0.6467 * | (34.85) 0.1068 * | (0.311) 0.7232 * | |

| 0.90 m | 0.276 | 0.204 | 0.138 | 0.227 | 0.155 | 0.101 |

| (20.42) 0.1422 * | (16.00) 0.6060 * | (16.49) 0.3931 * | (28.25) 0.3705 * | (28.40) 0.0531 * | (0.276) 0.0674 * | |

| 0.75 m | 0.238 | 0.169 | 0.127 | 0.195 | 0.129 | 0.101 |

| (22.79) 0.6361 * | (16.55) 0.1654 * | (22.13) 0.5434 * | (37.66) 0.0081 * | (29.11) 0.5753 * | (0.238) 0.4062 * | |

| 0.60 m | 0.192 | 0.164 | 0.107 | 0.187 | 0.125 | 0.091 |

| (22.50) 0.2240 * | (16.31) 0.9113 * | (12.13) 0.8374 * | (32.40) 0.0954 * | (38.64) 0.4118 * | (0.192) 0.0832 * | |

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | = | = | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | = | ∗ | ∗ | ∗ | ∗ |

| E. globulus | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | = | ∗ | ∗ | ∗ | = | = | = | = | ∗ |

| E. grandis | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | = | ∗ | ∗ | ∗ | = | = | ∗ | ∗ | = |

| H. courbaril | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | ∗ | = | ∗ | ∗ | ∗ | ∗ |

| Solid Wood Flooring (SWF) | |||||||||||||||

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | c | b | b | b | b | a | b | c | b | b | b | a | a | b | b |

| E. globulus | b | b | c | c | c | a | b | b | c | b | ab | a | a | abc | a |

| E. grandis | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a |

| H. courbaril | d | c | d | d | d | b | d | d | d | c | c | b | b | c | c |

| Engineered Wood Flooring (EWF) | |||||||||||||||

| Φ 50 mm | Φ 40 mm | Φ 30 mm | |||||||||||||

| Height (m) | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 | 0.60 | 0.75 | 0.90 | 1.05 | 1.20 |

| Q. robur | b | b | b | b | b | b | b | b | b | b | a | a | a | a | a |

| E. globulus | c | b | c | c | c | a | a | a | a | c | b | b | b | b | b |

| E. grandis | a | a | a | a | a | a | a | a | a | a | a | a | a | a | a |

| H. courbaril | d | c | d | d | d | c | c | c | c | d | c | c | c | c | c |

| Model | Family (Link) | AIC (Akaike Information Criteria) | BIC (Bayesian Information Criteria) | Log— Likelihood | D2 MacFadden | Pseudo R2 CoxSnell | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FD | DI | FD | DI | FD | DI | FD | DI | FD | DI | |||

| Y* = V1 + V2 + V3 + V4 | 1 | Gaussian (identity) | −4934 | −7000 | −4880 | −6952 | 2475.9 | 2475.9 | 86.35 | 63.88 | 0.86 | 0.64 |

| 2 | Gaussian (log) | −6077 | −8295 | −6023 | −8247 | 3047.6 | 4155.7 | 90.68 | 76,55 | 0.91 | 0.77 | |

| 3 | Gaussian (inverse) | −6278 | −8377 | −6224 | −8329 | 3147.8 | 4196.6 | 91.28 | 77.18 | 0.91 | 0.77 | |

| Y* = V1 ∗ V2 ∗ V3 ∗ V4 | 4 | Gaussian (identity) | −6687 | −9130 | −6392 | −8932 | 3392.4 | 4597.9 | 92.59 | 82.53 | 0.93 | 0.83 |

| 5 | Gaussian (log) | −6681 | −9046 | −6387 | −8848 | 3389.6 | 4556.0 | 92.58 | 82.04 | 0.93 | 0.82 | |

| 6 | Gaussian (inverse) | −6673 | −8799 | −6379 | −8601 | 3385.6 | 4432.3 | 92.56 | 80.50 | 0.93 | 0.80 | |

| Y* = V1 + V2 + V3 + V4 | 7 | Gamma (inverse) | −6561 | −9699 | −6590 | −9633 | 3330.8 | 4848.4 | 91.12 | 73.11 | 0.91 | 0.72 |

| 8 | Gamma (log) | −6402 | −9654 | −6348 | −9606 | 3209.9 | 4835.0 | 90.38 | 73.97 | 0.90 | 0.74 | |

| Y* = V1 ∗ V2 ∗ V3 ∗ V4 | 9 | Gamma (inverse) | −7080 | −10,390 | −6786 | −10,192 | 3589.0 | 5227.9 | 92.53 | 76.87 | 0.93 | 0.76 |

| 10 | Gamma (log) | −7087 | −10,659 | −6793 | −10,461 | 3592.6 | 5362.4 | 92.54 | 77.49 | 0.93 | 0.77 | |

| Model | Estimate | SE | bootBias | bootSE | t Value | Pr (>|t|) | |

|---|---|---|---|---|---|---|---|

| FD | β0 (Intercept) | 2.3522 | 0.0109 | −5.04 × 104 | 0.0117 | 194.185 | <2 × 10−16 *** |

| β1 (V1) | −0.0255 | 0.0002 | −1.27 × 10−6 | 0.0002 | −128.029 | <2 × 10−16 *** | |

| β2 (V2 Q.robur) | −0.0311 | 0.0030 | −1.92 × 10−4 | 0.0047 | −10.433 | 1.4 × 10−5 *** | |

| β2 (V2 E.grandis) | −0.1580 | 0.0024 | −4.55 × 10−5 | 0.0050 | −66.437 | <2 × 10−16 *** | |

| β2 (V2 H.courbaril) | 0.2417 | 0.0030 | 1.37 × 10−4 | 0.0055 | 79.572 | <2 × 10−16 *** | |

| β3 (V3 EWF) | −0.0633 | 0.0031 | −5.25 × 10−5 | 0.0031 | 39.704 | <2 × 10−16 *** | |

| β4 (V4) | −0.2860 | 0.0073 | 3.73 × 10−4 | 0.0078 | −39.344 | <2 × 10−16 *** | |

| ID | β0 (Intercept) | −4.0007 | 0.0362 | −1.1 × 10−4 | 0.0376 | −110.22 | <2 × 10−16 *** |

| β1 (V1) | 0.0363 | 0.0007 | −2.8 × 10−5 | 0.0007 | 53.70 | <2 × 10−16 *** | |

| β2 (V2 Q.robur) | 0.2334 | 0.0101 | 3.2 × 10−4 | 0.0119 | 22.22 | <2 × 10−16 *** | |

| β2 (V2 E.grandis) | 0.3068 | 0.0092 | −1.1 × 10−4 | 0.0098 | 33.30 | <2 × 10−16 *** | |

| β2 (V2 H.courbaril) | −0.5379 | 0.0092 | −7.6 × 10−5 | 0.0089 | −58.38 | <2 × 10−16 *** | |

| β3 (V3 EWF) | 0.0937 | 0.0058 | 3.3 × 10−4 | 0.0059 | 16.08 | <2 × 10−16 *** | |

| β4 (V4) | 0.8568 | 0.0261 | 1.1 × 10−3 | 0.0264 | 32.88 | <2 × 10−16 *** |

| Model | Df | Deviance | AIC | Scaled Deviance | Pr (>Chi sq) | Withheld Deviance | Explained Deviance | GVIF | |

|---|---|---|---|---|---|---|---|---|---|

| FD | Model null | 6 | 22.097 | −6561.4 | - | - | 219.913 | 0.909 | - |

| V1 (Φ ball) | 1 | 146.829 | 10,429.2 | 16,992.6 | <2.2 × 10−16 *** | 124.731 | 0.515 | 1.004 | |

| V2 (specie) | 3 | 91.077 | 2829.9 | 9397.3 | <2.2 × 10−16 *** | 68.980 | 0.285 | 1.077 | |

| V3 (floor type) | 1 | 33.564 | −5001.2 | 1562.2 | <2.2 × 10−16 *** | 11.467 | 0.047 | 1.074 | |

| V4 (height) | 1 | 33.486 | −5011.9 | 1551.4 | <2.2 × 10−16 *** | 11.388 | 0.047 | 1.001 | |

| ID | Model null | 6 | 286.83 | −9654.0 | - | - | 782.11 | 0.732 | - |

| V1 (Φ ball) | 1 | 540.90 | −6885.0 | 2771.0 | <2.2 × 10−16 *** | 254.07 | 0.238 | 1.000 | |

| V2 (specie) | 3 | 624.50 | −5977.2 | 3682.8 | <2.2 × 10−16 *** | 337.67 | 0.316 | 1.011 | |

| V3 (floor type) | 1 | 309.87 | −9404.7 | 251.3 | <2.2 × 10−16 *** | 23.05 | 0.022 | 1.033 | |

| V4 (height) | 1 | 385.38 | −8581.1 | 1074.9 | <2.2 × 10−16 *** | 98.56 | 0.092 | 1.000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acuña, L.; Sepliarsky, F.; Spavento, E.; Martínez, R.D.; Balmori, J.-A. Modelling of Impact Falling Ball Test Response on Solid and Engineered Wood Flooring of Two Eucalyptus Species. Forests 2020, 11, 933. https://doi.org/10.3390/f11090933

Acuña L, Sepliarsky F, Spavento E, Martínez RD, Balmori J-A. Modelling of Impact Falling Ball Test Response on Solid and Engineered Wood Flooring of Two Eucalyptus Species. Forests. 2020; 11(9):933. https://doi.org/10.3390/f11090933

Chicago/Turabian StyleAcuña, Luis, Fernando Sepliarsky, Eleana Spavento, Roberto D. Martínez, and José-Antonio Balmori. 2020. "Modelling of Impact Falling Ball Test Response on Solid and Engineered Wood Flooring of Two Eucalyptus Species" Forests 11, no. 9: 933. https://doi.org/10.3390/f11090933

APA StyleAcuña, L., Sepliarsky, F., Spavento, E., Martínez, R. D., & Balmori, J.-A. (2020). Modelling of Impact Falling Ball Test Response on Solid and Engineered Wood Flooring of Two Eucalyptus Species. Forests, 11(9), 933. https://doi.org/10.3390/f11090933