A New Approach to Micromachining: High-Precision and Innovative Additive Manufacturing Solutions Based on Photopolymerization Technology

Abstract

:1. Introduction

- Powder bed fusion: It works by melting powder to fuse particles together. It is ideal for most types of manufacturing [6].

- Sheet lamination: Ultra-thin layers of solid material are bonded by alternating layers of adhesive. It is best used for non-functional models [17].

- Photopolymerization of liquid resin:

- o

- SLA—stereolithography,

- o

- DLP—digital light processing,

- o

- MJP—multijet printing,

- o

- BJ—binder jetting,

- o

- CAL—computed axial lithography,

- o

- SGC—solid ground curing,

- o

- CLIP—continuous liquid interface production.

- Thermal processing of thermoplastic polymers:

- o

- FDM—fused deposition modeling,

- o

- BPM—ballistic particle manufacturing,

- o

- SLS—selective laser sintering.

- Metal structure fabrication:

- o

- DED—directed energy deposition,

- o

- DMLS/SLM—direct metal laser sintering,

- o

- EBM—electron-beam additive manufacturing,

- o

- MBJ—metal binder jetting.

- Other methods:

- o

- LAM—liquid additive manufacturing deposits a liquid or highly viscous material (e.g., liquid silicone rubber) onto a build surface to create an object, which is then vulcanized using heat to harden it,

- o

- LOM—laminated object manufacturing patented by Michael Feygin—printers that cut cross-sections out of special adhesive coated paper using a carbon dioxide laser and then laminate them together,

- o

- CFF—continuous filament fabrication.

2. Photopolymerization-Based 3D Printing Methods

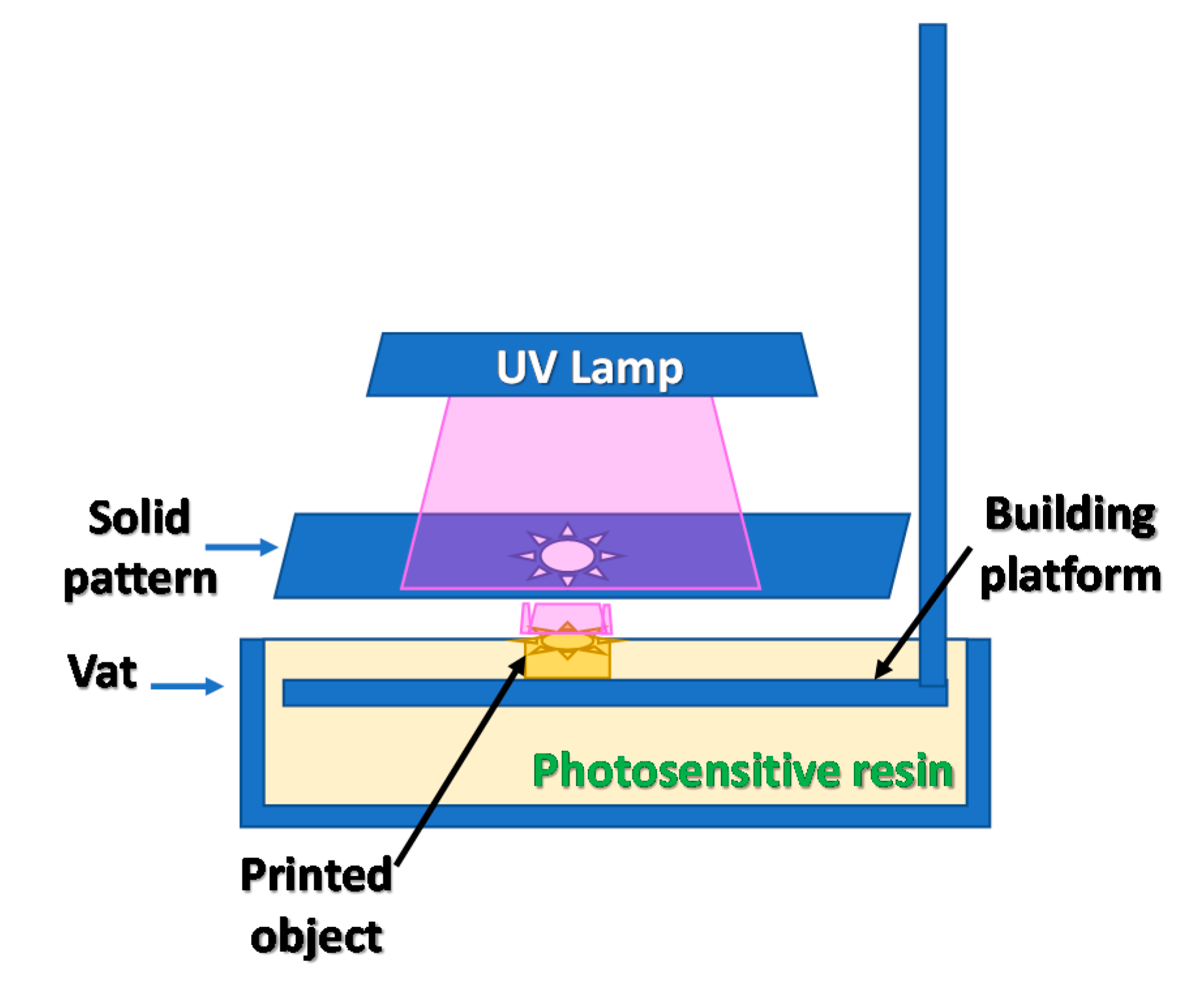

2.1. Stereolithography (SLA) Overview

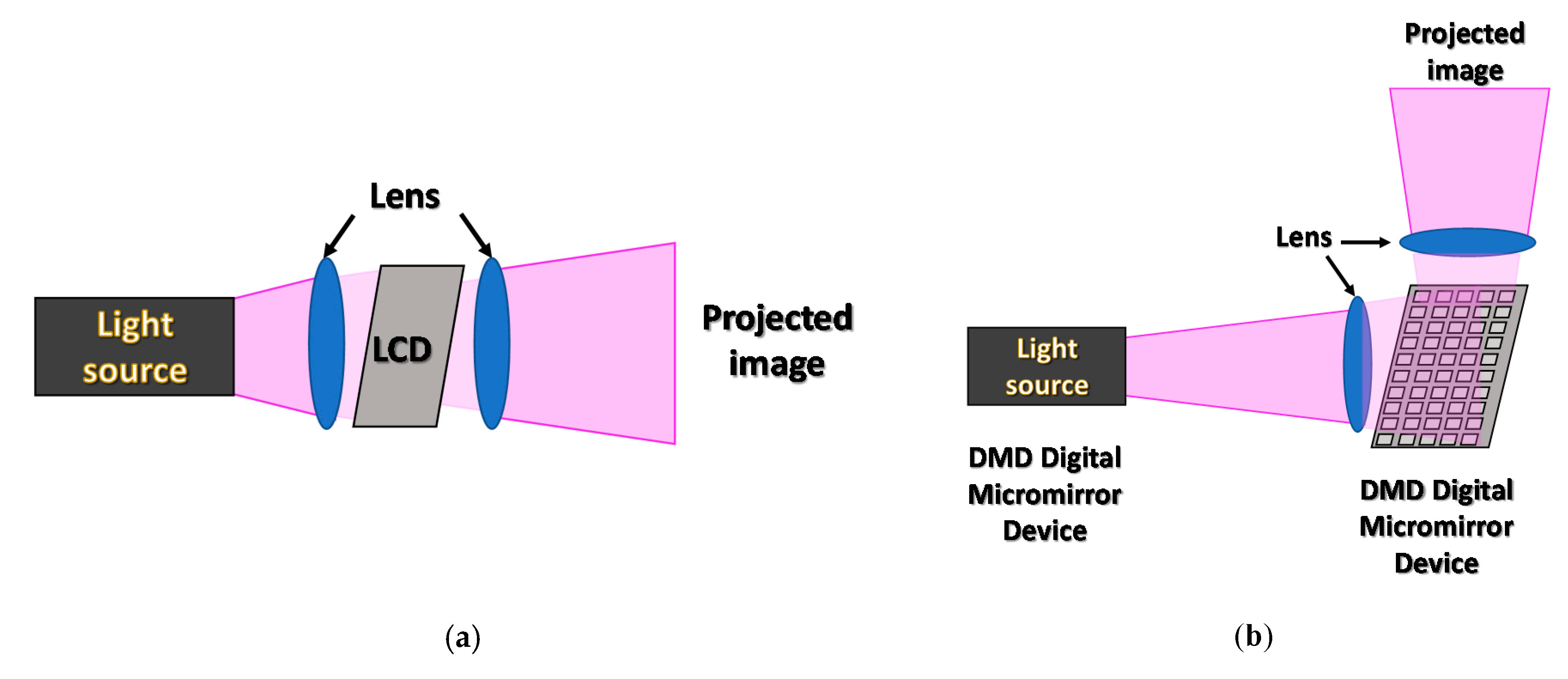

2.2. Digital Light Processing (DLP) Overview

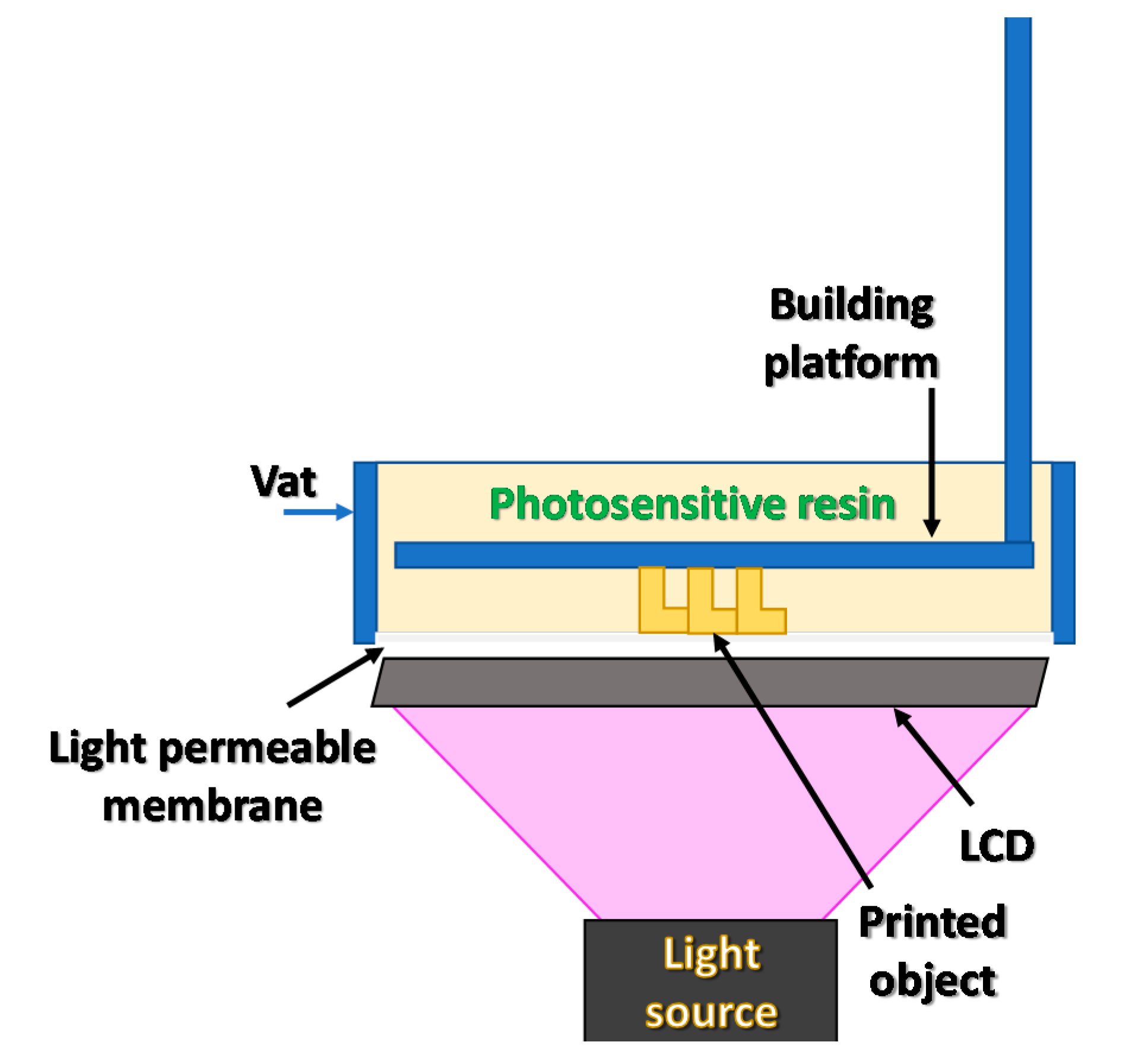

2.3. LCD 3D Printing Overview

2.4. Continuous 3D Printing Overview

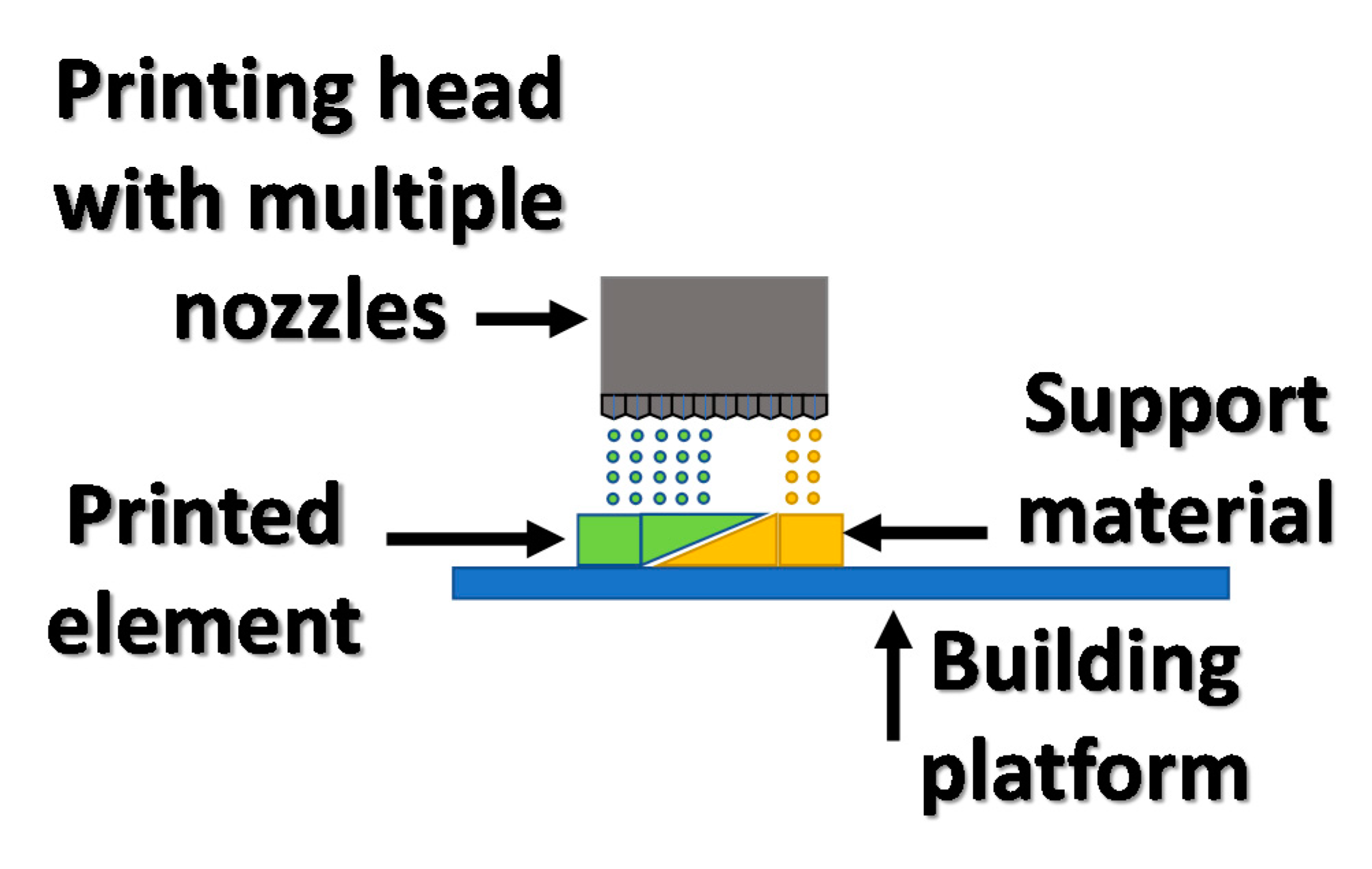

2.5. Inkjet Printing

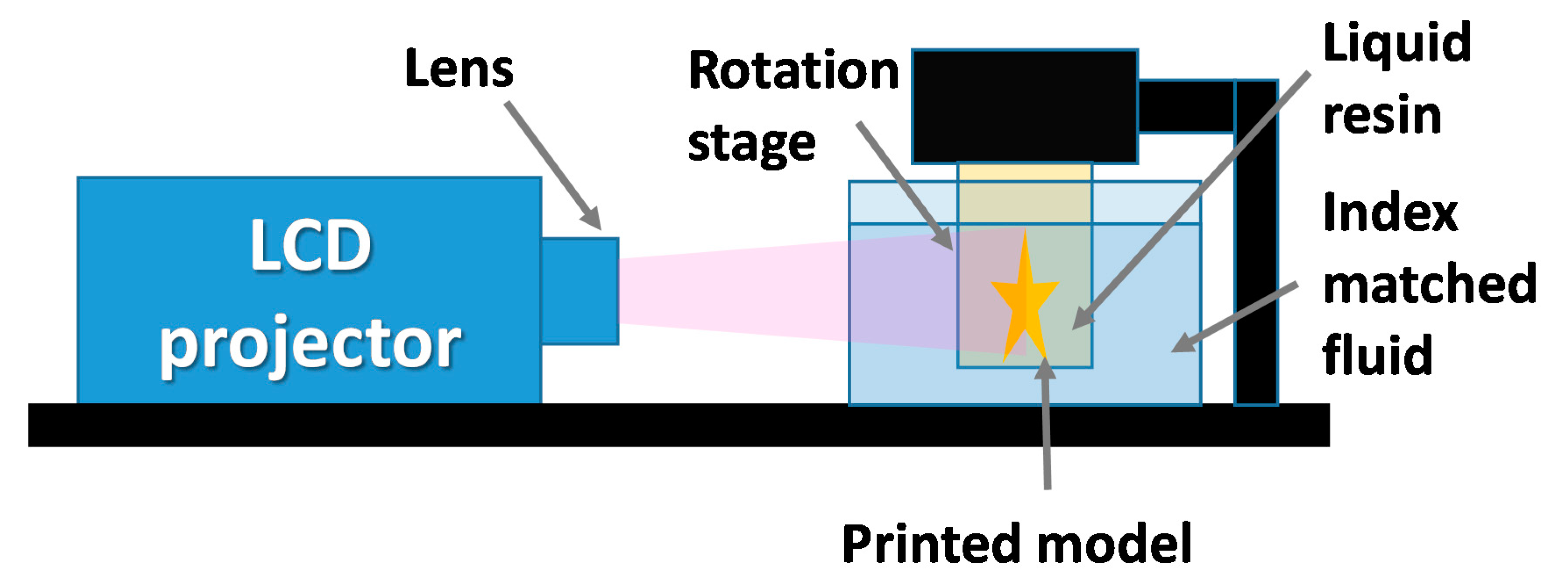

2.6. Computer Axial Lithography

2.7. High Area Rapid Printing

2.8. Hot Lithography

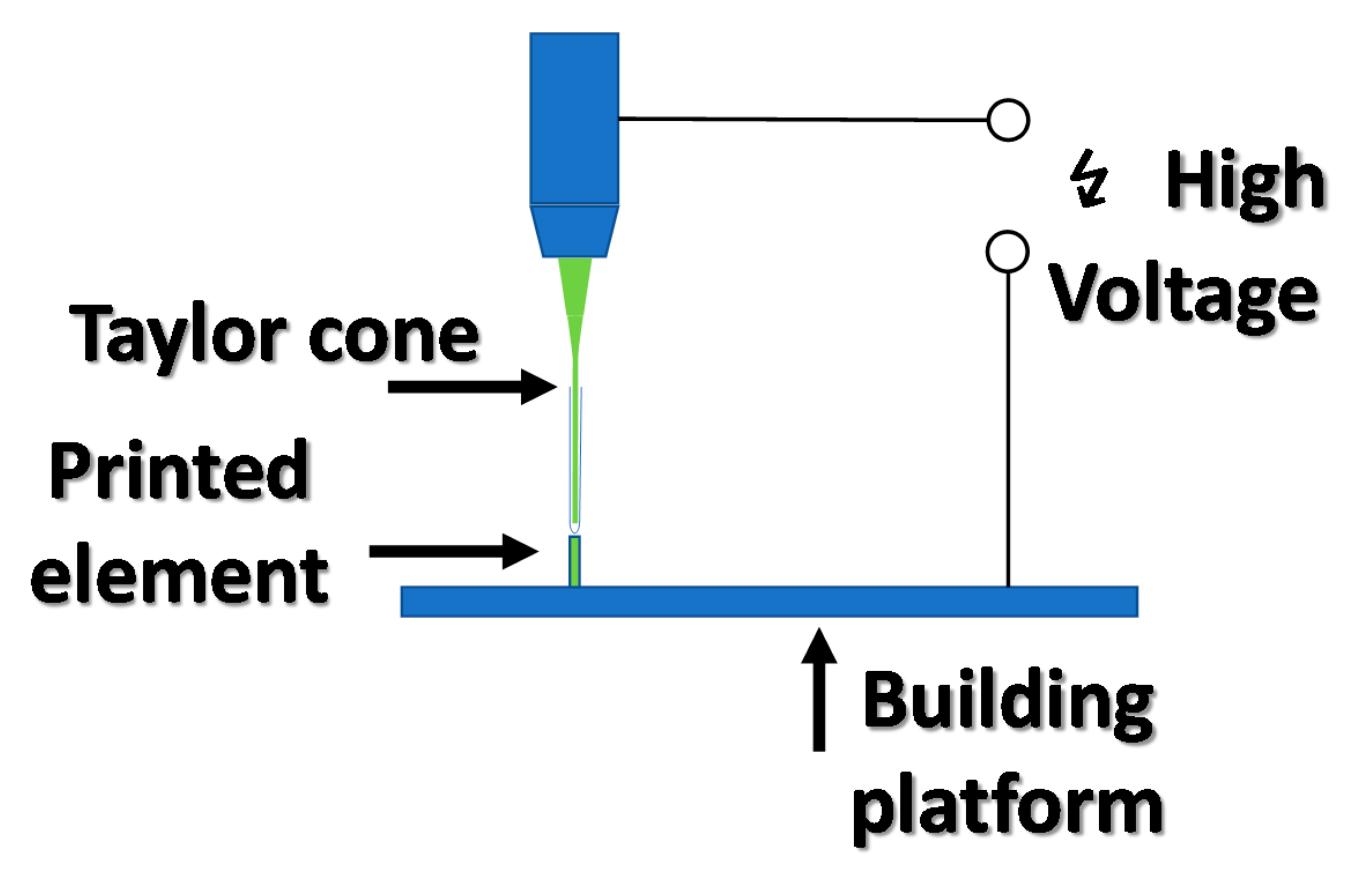

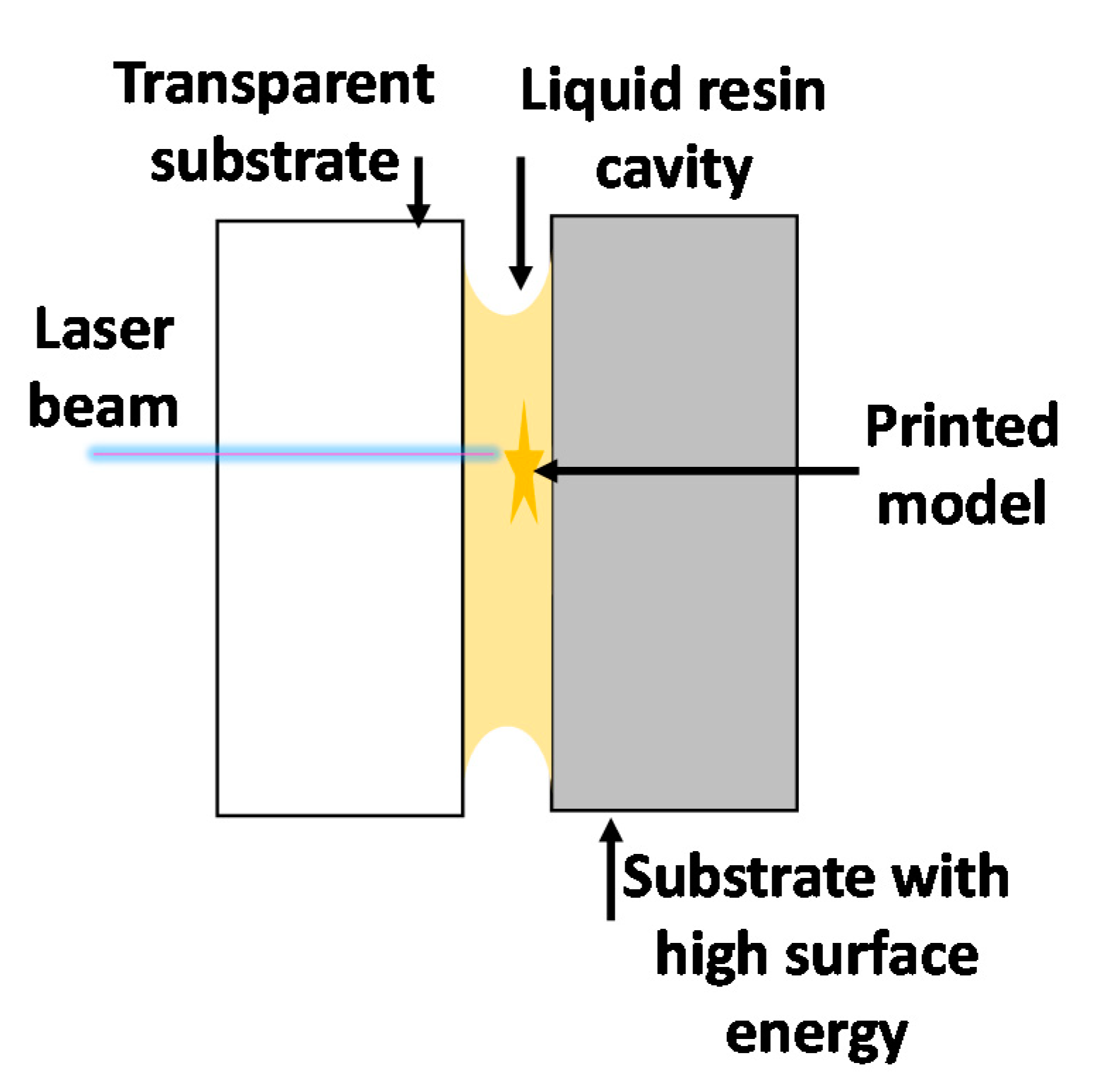

2.9. Liquid Bridge Microstereolithography

2.10. Direct Ink Writing

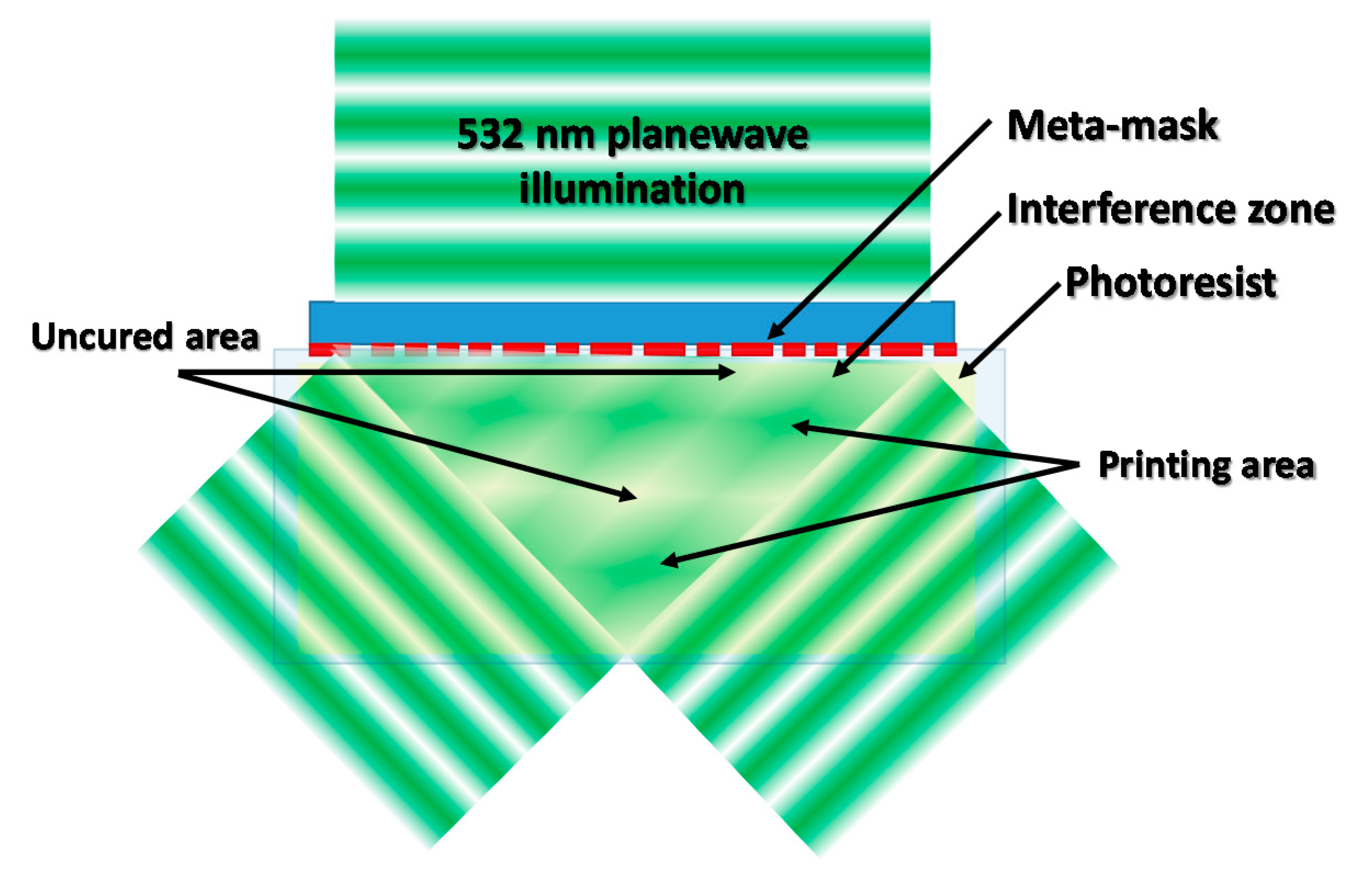

2.11. Large-Scale Metamask-Assisted 3D Fabrication

3. High Accuracy Photopolymerization-Based 3D Printing Processes

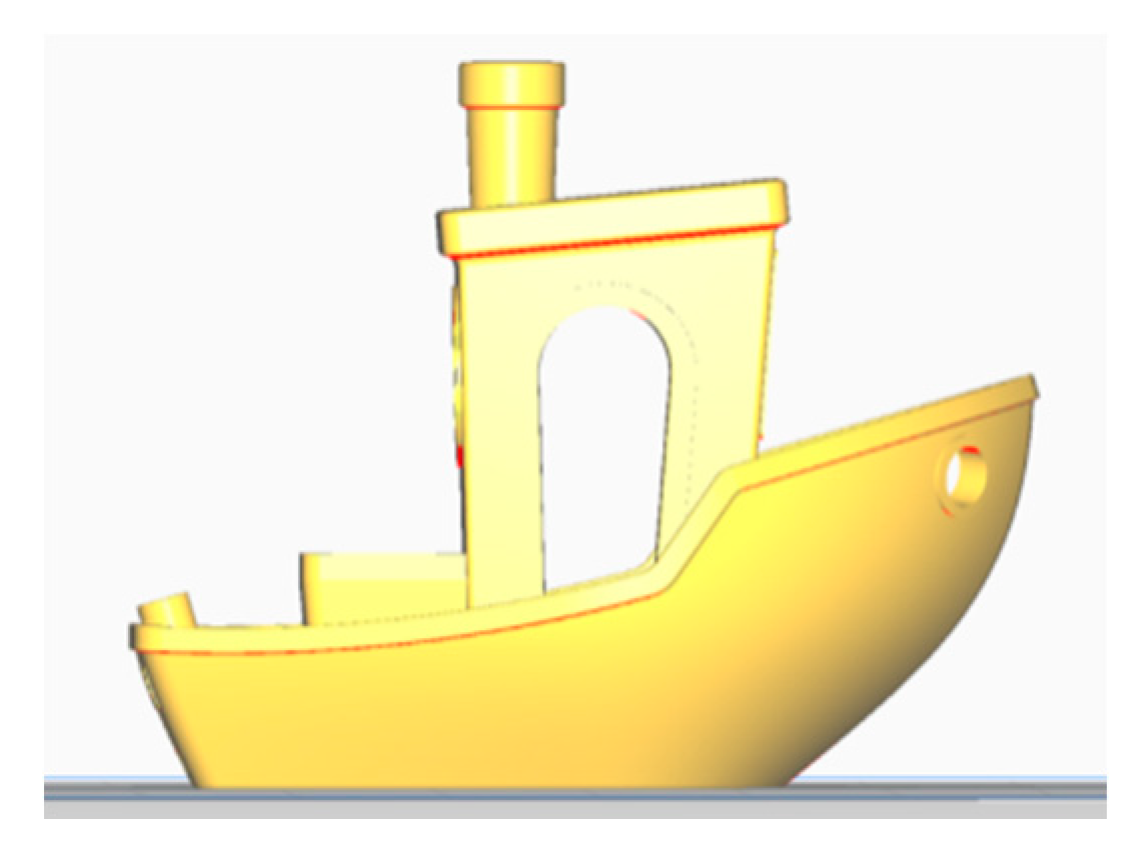

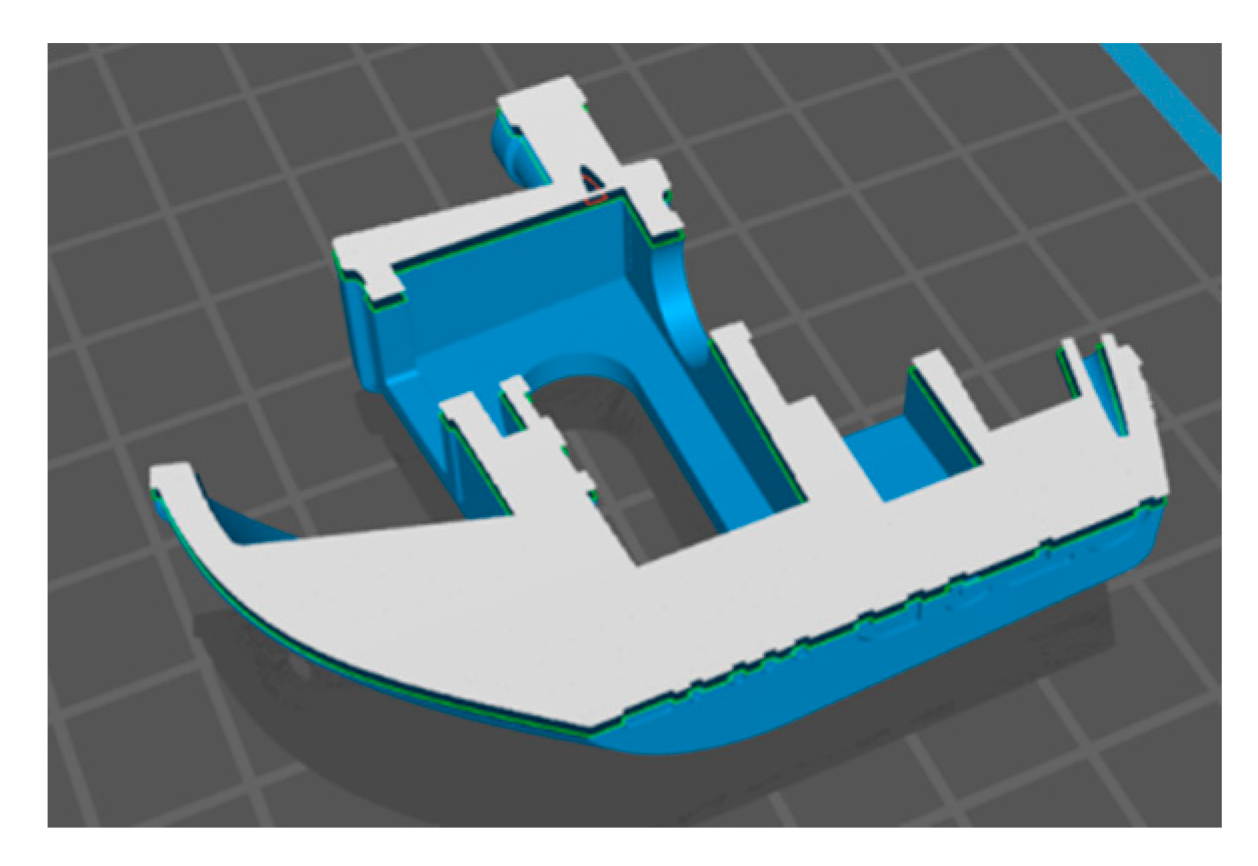

3.1. Preparation of Projects for the 3D Printing Process

3.2. Future Fabricated with Photopolymerization

- Monomers and prepolymers with appropriate reactivity,

- Initiating system consisting of a photoinitiator or a complex system of photoinitiators and photosensitizers,

- A UV blocker: a highly absorbing agent blocking unwanted excessive radiation of resin.

3.3. Photocuring 3D Printing Speed

3.4. Resolving Power in the 3D Printing Processes

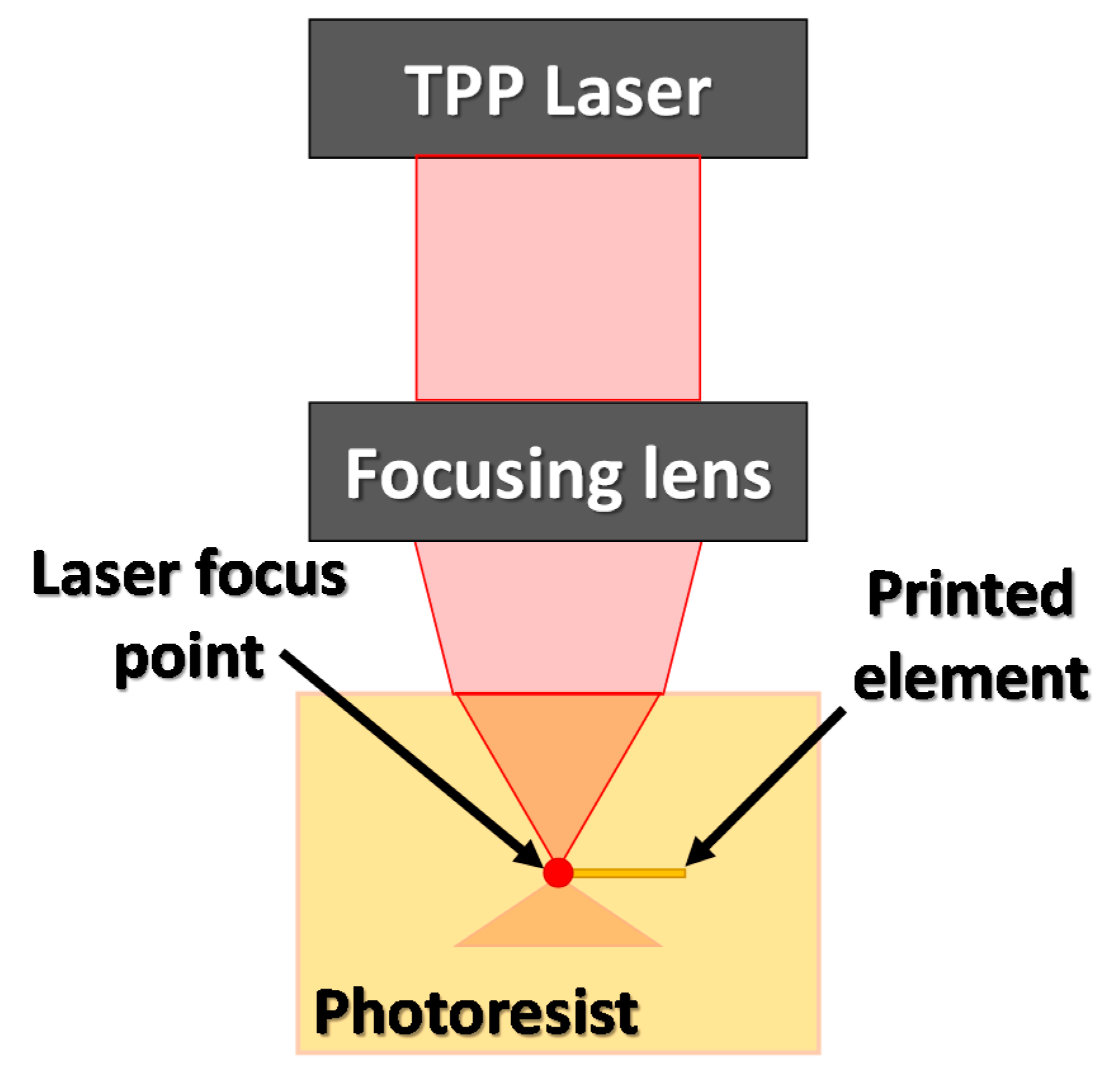

3.4.1. Two-Photon Polymerization (TPP) as a High-Resolution 3D Printing Process

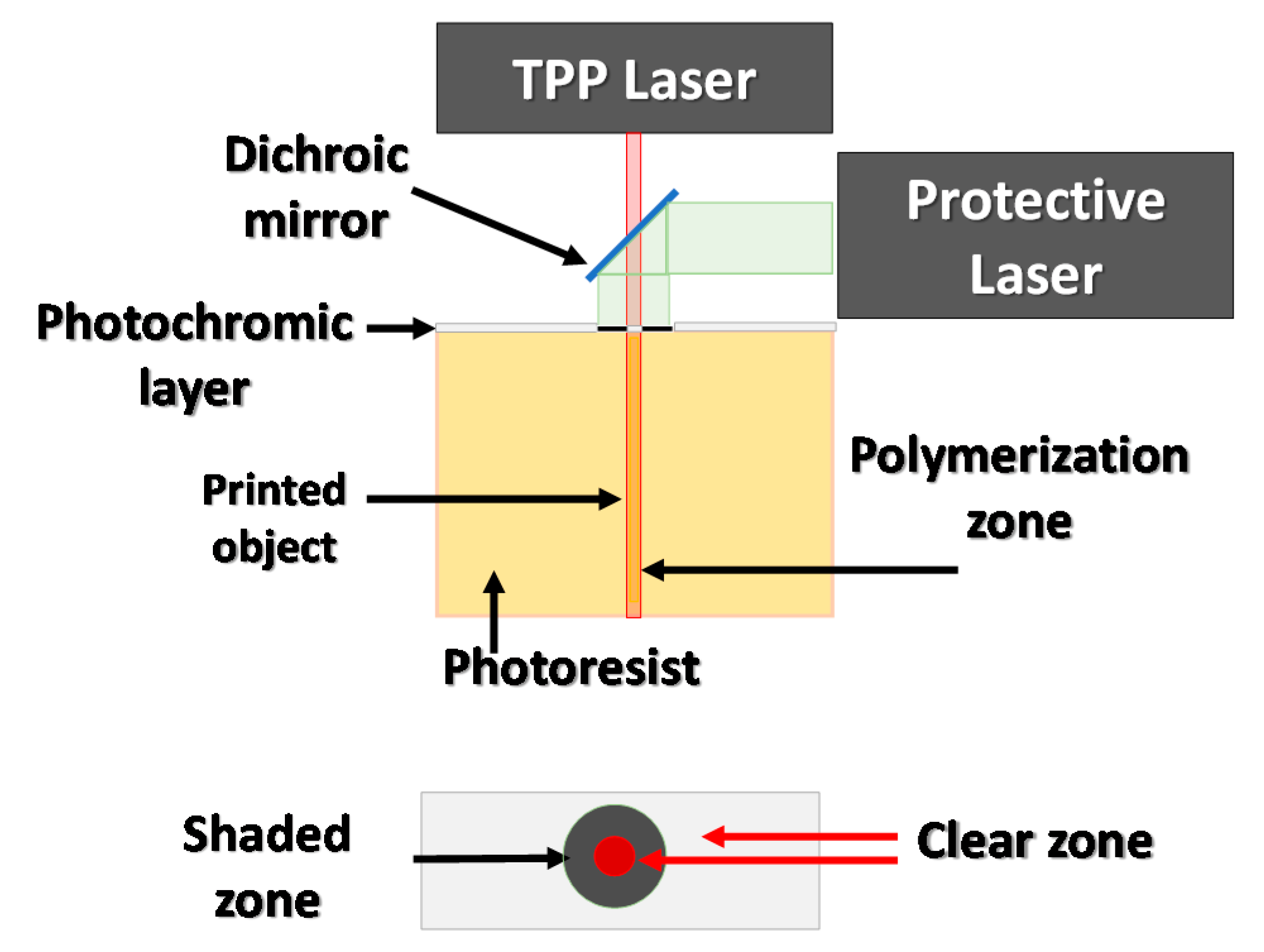

3.4.2. Increasing Spatial Resolution of Two-Photon Polymerization (TPP) by the Application of a Photochromic Layer

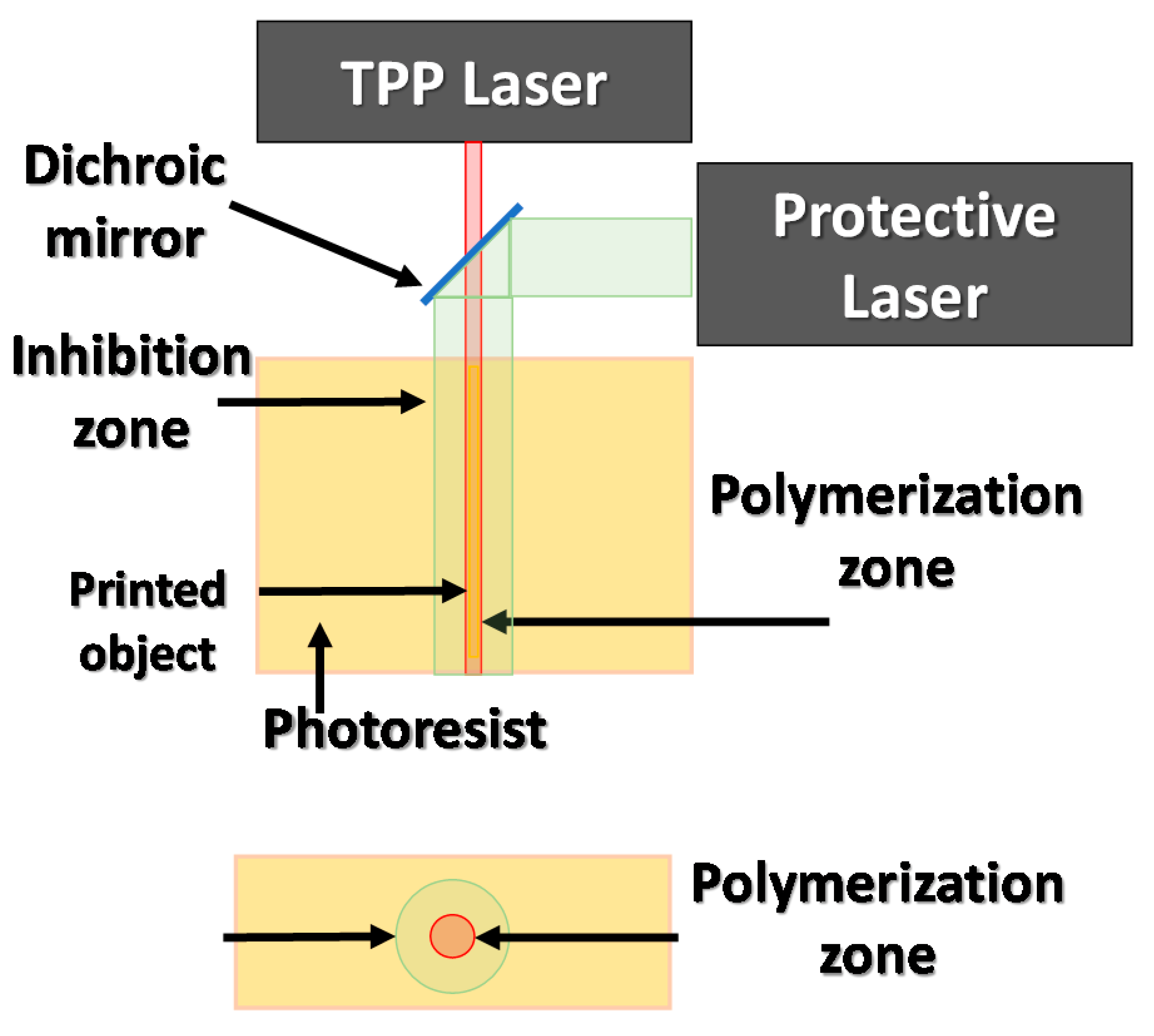

3.4.3. Increasing Spatial Resolution of the TPP by the Stimulated Emission Induced Depletion (STED) Method

3.4.4. A Novel Solution for High Speed and Accuracy of TPP Printing

3.5. Functional Materials for High-Precision and Innovative Additive Manufacturing Solutions

3.5.1. Mechanical and Electrical Properties of 3D Printed Composites

3.5.2. Magnetic 3D Printing Nanocomposites

3.5.3. 3D Printing Advanced Optical Materials

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Huang, W.; Li, Y. Survey on artificial intelligence for additive manufacturing. In Proceedings of the 2017 23rd International Conference on Automation and Computing (ICAC), Huddersfield, UK, 7–8 September 2017; pp. 1–6. [Google Scholar]

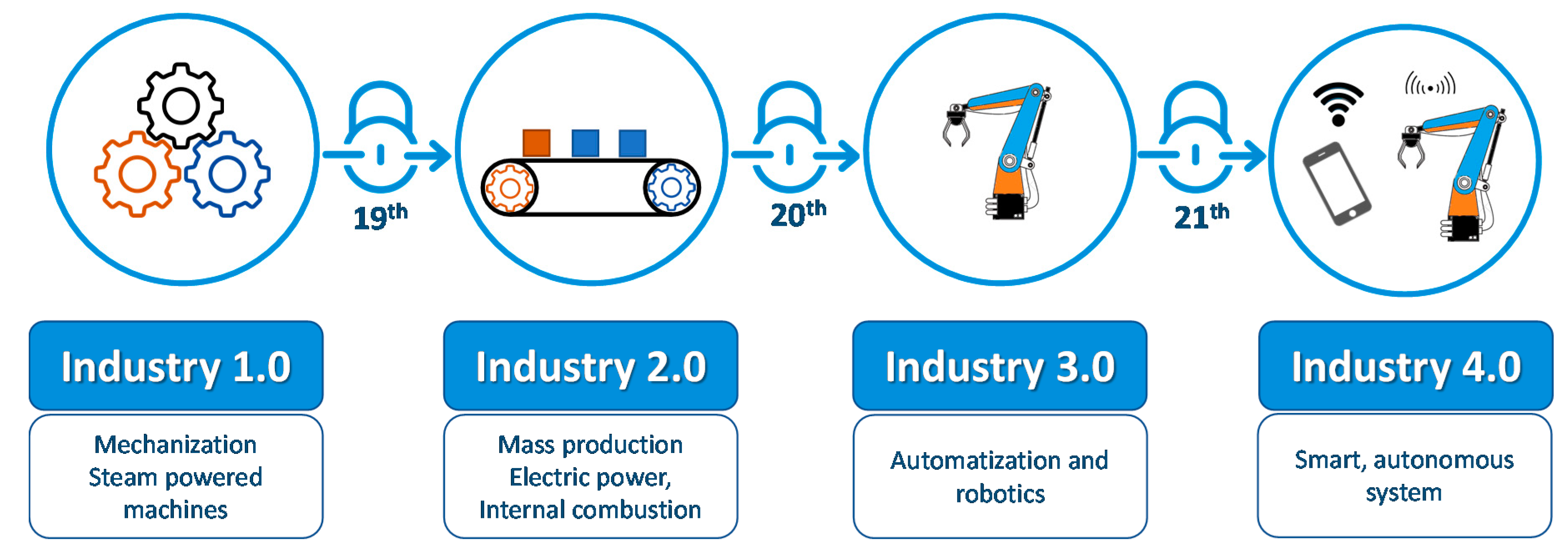

- Varghese, A.; Tandur, D. Wireless requirements and challenges in Industry 4.0. In Proceedings of the 2014 International Conference on Contemporary Computing and Informatics (IC3I), Mysore, India, 27–29 November 2014; pp. 634–638. [Google Scholar]

- Ford, S.; Minshall, T. Invited review article: Where and how 3D printing is used in teaching and education. Addit. Manuf. 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Wang, X. Advanced polymers for three-dimensional (3D) organ bioprinting. Micromachines 2019, 10, 814. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Aduba, D.C.; Margaretta, E.D.; Marnot, A.E.C.; Heifferon, K.V.; Surbey, W.R.; Chartrain, N.A.; Whittington, A.R.; Long, T.E.; Williams, C.B. Vat photopolymerization 3D printing of acid-cleavable PEG-methacrylate networks for biomaterial applications. Mater. Today Commun. 2019, 19, 204–211. [Google Scholar] [CrossRef]

- Salmi, M.; Ituarte, I.F.; Chekurov, S.; Huotilainen, E. Effect of build orientation in 3D printing production for material extrusion, material jetting, binder jetting, sheet object lamination, vat photopolymerisation, and powder bed fusion. Int. J. Collab. Enterp. 2016, 5, 218. [Google Scholar] [CrossRef]

- Heigel, J.C.; Michaleris, P.; Reutzel, E.W. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2019, 4, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Bass, L.; Meisel, N.A.; Williams, C.B. Exploring variability of orientation and aging effects in material properties of multi-material jetting parts. Rapid Prototyp. J. 2016, 22, 826–834. [Google Scholar] [CrossRef]

- Bai, Y.; Williams, C.B. An exploration of binder jetting of copper. Rapid Prototyp. J. 2015, 21, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Gaytan, S.M.; Cadena, M.A.; Karim, H.; Delfin, D.; Lin, Y.; Espalin, D.; MacDonald, E.; Wicker, R.B. Fabrication of barium titanate by binder jetting additive manufacturing technology. Ceram. Int. 2015, 41, 6610–6619. [Google Scholar] [CrossRef] [Green Version]

- Park, S.I.; Rosen, D.W.; Choi, S.K.; Duty, C.E. Effective mechanical properties of lattice material fabricated by material extrusion additive manufacturing. Addit. Manuf. 2014, 1, 12–23. [Google Scholar]

- Peng, F.; Vogt, B.D.; Cakmak, M. Complex flow and temperature history during melt extrusion in material extrusion additive manufacturing. Addit. Manuf. 2018, 22, 197–206. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F.; Simchi, A. Evaluation of a polymer-steel laminated sheet composite structure produced by friction stir additive manufacturing (FSAM) technology. Polym. Test. 2020, 90, 106690. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Horvath, J. Mastering 3D Printing: Modeling, Printing and Prototyping with Reprap-Style 3D Printers; Lowman, M., Ed.; Heinz Weinheimer Lead: New York, NY, USA, 2014; ISBN 978-1-4842-0025-4. [Google Scholar]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A review of the fatigue behavior of 3D printed polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-dmensonal Objects by Stereolithography. U.S. Patent US4575330A, 11 March 1986. [Google Scholar]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Tsien, R.Y. Fluorescent probes of cell signaling. Annu. Rev. Neurosci. 1989, 12, 227–253. [Google Scholar] [CrossRef]

- Roscoe, L. StereoLithography Interface Specification; 3D System Inc.: Rock Hill, SC, USA, 1988; Volume 27, p. 10. [Google Scholar]

- Bhushan, B.; Caspers, M. An overview of additive manufacturing (3D printing) for microfabrication. Microsyst. Technol. 2017, 23, 1117–1124. [Google Scholar] [CrossRef]

- Barone, S.; Neri, P.; Paoli, A.; Razionale, A.V.; Tamburrino, F. Development of a DLP 3D printer for orthodontic applications. Procedia Manuf. 2019, 38, 1017–1025. [Google Scholar] [CrossRef]

- Klikovits, N.; Sinawehl, L.; Knaack, P.; Koch, T.; Stampfl, J.; Gorsche, C.; Liska, R. UV-Induced Cationic Ring-Opening Polymerization of 2-Oxazolines for Hot Lithography. ACS Macro Lett. 2020, 9, 546–551. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Yi, R.; Liu, Y.J.; He, Y.; Wang, C.C.L. Delta DLP 3D printing with large size. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 2155–2160. [Google Scholar]

- Hornbeck, L.J. Digital Light Processing for high-brightness high-resolution applications. Proj. Displays III 1997, 3013, 27–40. [Google Scholar]

- Li, Z.; Wang, C.; Qiu, W.; Liu, R. Antimicrobial Thiol–ene–acrylate Photosensitive Resins for DLP 3D Printing. Photochem. Photobiol. 2019, 95, 1219–1229. [Google Scholar] [CrossRef] [PubMed]

- Kuang, X.; Wu, J.; Chen, K.; Zhao, Z.; Ding, Z.; Hu, F.; Fang, D.; Qi, H.J. Grayscale digital light processing 3D printing for highly functionally graded materials. Sci. Adv. 2019, 5, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Douglass, M. DMD reliability: A MEMS success story. In Proceedings of the Reliability, Testing, and Characterization of Mems/Moems II, San Jose, CA, USA, 27–29 January 2003; Volume 4980. [Google Scholar]

- Martin, P. Analysing LCD Display Colour Masks Using Transmission Microspectroscopy. Craic Technol. 2008, 1, 1–8. [Google Scholar]

- Hola, E.; Ortyl, J.; Jankowska, M.; Pilch, M.; Galek, M.; Morlet-Savary, F.; Graff, B.; Dietlin, C.; Lalevée, J. New bimolecular photoinitiating systems based on terphenyl derivatives as highly efficient photosensitizers for 3D printing application. Polym. Chem. 2020, 11, 922–935. [Google Scholar] [CrossRef]

- DeSimone, J.M.; Mpshkin, A.; Ermoshkin, N.; Samulski, E.T. Continuous Liquid Interphase Printing. International Patent Application WO2014126837A2, 21 August 2014. [Google Scholar]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Diegel, O.; Nordin, A.; Motte, D. Additive Manufacturing Technologies; Springer Science+Business Media: Berlin/Heidelberg, Germany, 2019; ISBN 9781493921126. [Google Scholar]

- Madla, C.M.; Trenfield, S.J.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D printing technologies, implementation and regulation: An overview. AAPS Adv. Pharm. Sci. Ser. 2018, 31, 21–40. [Google Scholar]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, and challenges. Prog. Mater. Sci. 2020, 100707. [Google Scholar] [CrossRef]

- Miyanaji, H.; Zhang, S.; Lassell, A.; Zandinejad, A.; Yang, L. Process Development of Porcelain Ceramic Material with Binder Jetting Process for Dental Applications. JOM 2016, 68, 831–841. [Google Scholar] [CrossRef]

- Walczak, R. Inkjet 3D printing—Towards new micromachining tool for MEMS fabrication. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 179–186. [Google Scholar]

- Check, C.; Chartoff, R.; Chang, S. Inkjet printing of 3D nano-composites formed by photopolymerization of an acrylate monomer. React. Funct. Polym. 2015, 97, 116–122. [Google Scholar] [CrossRef] [Green Version]

- Fritzler, K.B.; Prinz, V.Y. 3D printing methods for micro- and nanostructures. Uspekhi Fiz. Nauk 2019, 189, 55–71. [Google Scholar] [CrossRef]

- Ferraro, P.; Coppola, S.; Grilli, S.; Paturzo, M.; Vespini, V. Dispensing nano-pico droplets and liquid patterning by pyroelectrodynamic shooting. Nat. Nanotechnol. 2010, 5, 429–435. [Google Scholar] [CrossRef]

- Onses, M.S.; Sutanto, E.; Ferreira, P.M.; Alleyne, A.G.; Rogers, J.A. Mechanisms, Capabilities, and Applications of High-Resolution Electrohydrodynamic Jet Printing. Small 2015, 11, 4237–4266. [Google Scholar] [CrossRef]

- Mott, E.J.; Busso, M.; Luo, X.; Dolder, C.; Wang, M.O.; Fisher, J.P.; Dean, D. Digital micromirror device (DMD)-based 3D printing of poly(propylene fumarate) scaffolds. Mater. Sci. Eng. C 2016, 61, 301–311. [Google Scholar] [CrossRef] [Green Version]

- Walker, D.A.; Hedrick, J.L.; Mirkin, C.A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science 2019, 366, 360–364. [Google Scholar] [CrossRef]

- Kelly, B.; Panas, R.; Shusteff, M.; Spadaccini, C.; Taylor, H.; Tacharya, I. System and Method for Computed Axial Lithography (cal) for 3D Additive Manufacturing. International Patent Application No. PCT/US2018/024475, 27 March 2018. [Google Scholar]

- Pfaffinger, M. Hot Lithography - New Possibilities in Polymer 3D Printing. Laser Tech. J. 2018, 15, 45–47. [Google Scholar] [CrossRef] [Green Version]

- Song, S.Y.; Park, M.S.; Lee, D.; Lee, J.W.; Yun, J.S. Optimization and characterization of high-viscosity ZrO2 ceramic nanocomposite resins for supportless stereolithography. Mater. Des. 2019, 180, 107960. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, P. 3D printing of photopolymers. Polym. Chem. 2018, 9, 1530–1540. [Google Scholar] [CrossRef]

- Steyrer, B.; Busetti, B.; Harakály, G.; Liska, R.; Stampfl, J. Hot Lithography vs. room temperature DLP 3D-printing of a dimethacrylate. Addit. Manuf. 2018, 21, 209–214. [Google Scholar] [CrossRef]

- Tomal, W.; Pilch, M.; Chachaj-Brekiesz, A.; Galek, M.; Morlet-Savary, F.; Graff, B.; Dietlin, C.; Lalevée, J.; Ortyl, J. Photoinitiator-Catalyst Systems Based on Meta-Terphenyl Derivatives as Photosensitisers of Iodonium and Thianthrenium Salts for Visible Photopolymerization in 3D Printing Processes. Polym. Chem. 2020, 547–563. [Google Scholar] [CrossRef]

- Fiedor, P.; Pilch, M.; Szymaszek, P.; Chachaj-Brekiesz, A.; Galek, M.; Ortyl, J. Photochemical study of a new bimolecular photoinitiating system for vat photopolymerization 3D printing techniques under visible light. Catalysts 2020, 10, 284. [Google Scholar] [CrossRef] [Green Version]

- Tomal, W.; Pilch, M.; Chachaj-Brekiesz, A.; Ortyl, J. Development of new high-performance biphenyl and terphenyl derivatives as versatile photoredox photoinitiating systems and their applications in 3D printing photopolymerization processes. Catalysts 2019, 9, 827. [Google Scholar] [CrossRef] [Green Version]

- Ortyl, J.; Wilamowski, J.; Milart, P.; Galek, M.; Popielarz, R. Relative sensitization efficiency of fluorescent probes/sensitizers for monitoring and acceleration of cationic photopolymerization of monomers. Polym. Test. 2015, 48, 151–159. [Google Scholar] [CrossRef]

- Ortyl, J.; Milart, P.; Popielarz, R. Applicability of aminophthalimide probes for monitoring and acceleration of cationic photopolymerization of epoxides. Polym. Test. 2013, 32, 708–715. [Google Scholar] [CrossRef]

- Patel, D.K.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly Stretchable and UV Curable Elastomers for Digital Light Processing Based 3D Printing. Adv. Mater. 2017, 29, 1–7. [Google Scholar] [CrossRef]

- Kovalenko, I.; Garan, M. Effect of UV radiation by projectors on 3D printing. MATEC Web Conf. 2016, 88, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Little, S.H.; Vukicevic, M.; Avenatti, E.; Ramchandani, M.; Barker, C.M. 3D Printed Modeling for Patient-Specific Mitral Valve Intervention Repair with a Clip and a Plug. JACC Cardiovasc. Interv. 2016, 9, 973–975. [Google Scholar] [CrossRef]

- Bloomquist, C.J.; Mecham, M.B.; Paradzinsky, M.D.; Janusziewicz, R.; Warner, S.B.; Luft, J.C.; Mecham, S.J.; Wang, A.Z.; DeSimone, J.M. Controlling release from 3D printed medical devices using CLIP and drug-loaded liquid resins. J. Control. Release 2018, 278, 9–23. [Google Scholar] [CrossRef]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization Shoji. Opt. Lett. 1997, 22, 132–134. [Google Scholar] [CrossRef] [Green Version]

- Ortyl, J.; Fiedor, P.; Chachaj-Brekiesz, A.; Pilch, M.; Hola, E.; Galek, M. The applicability of 2-amino-4,6-diphenyl-pyridine-3-carbonitrile sensors for monitoring different types of photopolymerization processes and acceleration of cationic and free-radical photopolymerization under near UV light. Sensors 2019, 19, 1668. [Google Scholar] [CrossRef] [Green Version]

- Soifer, V.A. Diffractive Optics and Nanophotonics; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9783319242514. [Google Scholar]

- Tommaso, E. (Ed.) Three-Dimensional Microfabrication Using Two-photon Polymerization; William Andrew, Elsevier: Waltham, USA, USA, 2016; ISBN 9780323353212. [Google Scholar]

- Serbin, J.; Egbert, A.; Ostendorf, A.; Chichkov, B.N.; Houbertz, R.; Domann, G.; Schulz, J.; Cronauer, C.; Fröhlich, L.; Popall, M. Femtosecond laser-induced two-photon polymerization of inorganic–organic hybrid materials for applications in photonics. Opt. Lett. 2003, 28, 301. [Google Scholar] [CrossRef]

- Andrew, T.L.; Tsai, H.Y.; Menon, R. Confining light to deep subwavelength dimensions to enable optical nanopatterning. Science 2009, 324, 917–921. [Google Scholar] [CrossRef]

- Richner, P.; Galliker, P.; Lendenmann, T.; Kress, S.J.P.; Kim, D.K.; Norris, D.J.; Poulikakos, D. Full-Spectrum Flexible Color Printing at the Diffraction Limit. ACS Photonics 2016, 3, 754–757. [Google Scholar] [CrossRef] [Green Version]

- Fischer, J.; Wegener, M. Three-dimensional optical laser lithography beyond the diffraction limit. Laser Photonics Rev. 2013, 7, 22–44. [Google Scholar] [CrossRef]

- Ritschdorff, E.T.; Nielson, R.; Shear, J.B. Multi-focal multiphoton lithography. Lab Chip 2012, 12, 867–871. [Google Scholar] [CrossRef]

- Obata, K.; Koch, J.; Hinze, U.; Chichkov, B.N. Multi-focus two-photon polymerization technique based on individually controlled phase modulation. Opt. Express 2010, 18, 17193. [Google Scholar] [CrossRef]

- Trautmann, A.; Götzendorfer, B.; Walther, T.; Hellmann, R. Scaffolds in a shell–a new approach combining one-photon and two-photon polymerization. Opt. Express 2018, 26, 29659. [Google Scholar] [CrossRef]

- Abel, T.; Dörr, R.; Krüger, W.; Horstmann, R.; Schaumann, G.; Roth, M.; Schlaak, H.F. Combining two-photon-polymerization with UV-lithography for laser particle acceleration targets. J. Phys. Conf. Ser. 2018, 1079, 012012. [Google Scholar] [CrossRef]

- Tomal, W.; Ortyl, J. Water-soluble photoinitiators in biomedical applications. Polymers 2020, 12, 73. [Google Scholar] [CrossRef]

- Mei, J.; Lovell, M.R.; Mickle, M.H. Formulation and processing of novel conductive solution inks in continuous inkjet printing of 3-D electric circuits. IEEE Trans. Electron. Packag. Manuf. 2005, 28, 265–273. [Google Scholar]

- Nowak, D.; Ortyl, J.; Kamińska-Borek, I.; Kukuła, K.; Topa, M.; Popielarz, R. Photopolymerization of hybrid monomers, Part II: Determination of relative quantum efficiency of selected photoinitiators in cationic and free-radical polymerization of hybrid monomers. Polym. Test. 2018, 67, 144–150. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Yu, W.; Zhou, H.; Li, B.Q.; Ding, S. 3D Printing of Carbon Nanotubes-Based Microsupercapacitors. ACS Appl. Mater. Interfaces 2017, 9, 4597–4604. [Google Scholar] [CrossRef]

- Xiong, W.; Liu, Y.; Jiang, L.J.; Zhou, Y.S.; Li, D.W.; Jiang, L.; Silvain, J.F.; Lu, Y.F. Laser-Directed Assembly of Aligned Carbon Nanotubes in Three Dimensions for Multifunctional Device Fabrication. Adv. Mater. 2016, 28, 2002–2009. [Google Scholar] [CrossRef]

- Carlotti, M.; Mattoli, V. Functional Materials for Two-Photon Polymerization in Microfabrication. Small 2019, 15, 1–22. [Google Scholar] [CrossRef]

- Ushiba, S.; Shoji, S.; Masui, K.; Kuray, P.; Kono, J.; Kawata, S. 3D microfabrication of single-wall carbon nanotube/polymer composites by two-photon polymerization lithography. Carbon N. Y. 2013, 59, 283–288. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Schuschnigg, S.; Teliban, I.; Vogler, C.; Wautischer, G.; Windl, R.; Suess, D. 3D Printing of Polymer-Bonded Rare-Earth Magnets with a Variable Magnetic Compound Fraction for a Predefined Stray Field. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suter, M.; Zhang, L.; Siringil, E.C.; Peters, C.; Luehmann, T.; Ergeneman, O.; Peyer, K.E.; Nelson, B.J.; Hierold, C. Superparamagnetic microrobots: Fabrication by two-photon polymerization and biocompatibility. Biomed. Microdevices 2013, 15, 997–1003. [Google Scholar] [CrossRef]

- Xiong, Z.; Zheng, C.; Jin, F.; Wei, R.; Zhao, Y.; Gao, X.; Xia, Y.; Dong, X.; Zheng, M.; Duan, X. Magnetic-field-driven ultra-small 3D hydrogel microstructures: Preparation of gel photoresist and two-photon polymerization microfabrication. Sens. Actuators B Chem. 2018, 274, 541–550. [Google Scholar] [CrossRef]

- Willis, K.D.D.; Brockmeyer, E.; Hudson, S.E.; Poupyrev, I. Printed Optics: 3D Printing of Embedded Optical Elements for Interactive Devices. UIST 2012, 1, 589–598. [Google Scholar]

- Li, J.; Fejes, P.; Lorenser, D.; Quirk, B.C.; Noble, P.B.; Kirk, R.W.; Orth, A.; Wood, F.M.; Gibson, B.C.; Sampson, D.D.; et al. Two-photon polymerisation 3D printed freeform micro-optics for optical coherence tomography fibre probes. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef]

- Weibel, M.; Caseri, W.; Suter, U.W.; Kiess, H.; Wehrli, E. Preparation of polymer nanocomposites with “ultrahigh” refractive index. Polym. Adv. Technol. 1991, 2, 75–80. [Google Scholar] [CrossRef]

- Duan, X.M.; Sun, H.B.; Kaneko, K.; Kawata, S. Two-photon polymerization of metal ions doped acrylate monomers and oligomers for three-dimensional structure fabrication. Thin Solid Films 2004, 453, 518–521. [Google Scholar] [CrossRef]

- Guo, Q.; Ghadiri, R.; Weigel, T.; Aumann, A.; Gurevich, E.L.; Esen, C.; Medenbach, O.; Cheng, W.; Chichkov, B.; Ostendorf, A. Correction to Comparison of in Situ and ex Situ methods for synthesis of two-photon polymerization polymer nanocomposites. Polymers 2014, 6, 2037–2050. [Google Scholar] [CrossRef] [Green Version]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Thrimurthulu, K.; Pandey, P.M.; Reddy, N.V. Optimum part deposition orientation in fused deposition modeling. Int. J. Mach. Tools Manuf. 2004, 44, 585–594. [Google Scholar] [CrossRef]

- Kadry, H.; Wadnap, S.; Xu, C.; Ahsan, F. Digital light processing (DLP) 3D-printing technology and photoreactive polymers in fabrication of modified-release tablets. Eur. J. Pharm. Sci. 2019, 135, 60–67. [Google Scholar] [CrossRef]

- Hong, D.; Chou, D.T.; Velikokhatnyi, O.I.; Roy, A.; Lee, B.; Swink, I.; Issaev, I.; Kuhn, H.A.; Kumta, P.N. Binder-jetting 3D printing and alloy development of new biodegradable Fe-Mn-Ca/Mg alloys. Acta Biomater. 2016, 45, 375–386. [Google Scholar] [CrossRef] [Green Version]

| Family | Method (Light Source) | Advantages | Disadvantages |

|---|---|---|---|

| Stereolithography | Direct SLA (laser 365 to 405 nm) [26] | Oldest and well-developed method with multiple materials available. Fair resolution. | Low printing rate, resolution limited by the size of the laser beam and further with Abby diffraction limit |

| SLA–TPP (laser 532–1064 nm) [66,67] | Great resolution. The rising availability of materials. | Slow process—even the smallest models created in days. | |

| SLA–TPP with a dichromic layer (laser 532–1064 nm) [68] | Outstanding resolution of prints (a few nm). | Slow process—even the smallest models created in days. The necessity for the application of an additional photochromic layer on top of the photoresist. | |

| SLA–STED (laser 532–1064 nm) [69,70] | Outstanding resolution of prints (few nm). | Slow process—even the smallest models created in days. Tailoring of initiating–inhibiting systems needed for all materials. | |

| SLA–TPP–DMD (laser 532–1064 nm) [71] | Great resolution. Possible fabrication of multiple objects at the same time. | Underdeveloped method. | |

| SLA–TPP–Liquid crystal devices (laser 532–1064 nm) [72] | Outstanding resolution. Possible fabrication of multiple objects at the same time. Faster than SLA–TPP–DMD | Underdeveloped method. | |

| Fused deposition modeling | FDM (-) [93] | Great availability of filaments, moderate mechanical properties of printouts. | Low-resolution method. Can cause deformation of printouts during the process. |

| Digital Light Processing | DLP–DMD projector (HID lamp/LED lamp) [94] | High resolution for small models. High precision for small models. | Bigger models decrease resolution. |

| LCD–DLP (405–450 nm LED lamp) [21] | High resolution. Resolution independent on model size | Low light intensity reaching resin vat, only highly reactive resins can be used. | |

| Inkjet | Binder Jetting (HID lamp/LED lamp) [38,42,95] | Numerous materials available, relatively quick printing process. | Low resolution. Poor mechanical properties of green printouts. |

| Inkjet(HID lamp/LED lamp) [38] | High resolution, multiple materials available. Smooth surface finish. | The high cost of printer and materials. Only low viscous materials can be printed. | |

| Multijet (HID lamp/LED lamp) [44,45,46] | High resolution, multiple materials available. Possibility of printing with multiple materials at the same time. Possible creation of colorful printouts. Smooth surface finish. | The high cost of printer and materials. Only low viscous materials can be printed. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiedor, P.; Ortyl, J. A New Approach to Micromachining: High-Precision and Innovative Additive Manufacturing Solutions Based on Photopolymerization Technology. Materials 2020, 13, 2951. https://doi.org/10.3390/ma13132951

Fiedor P, Ortyl J. A New Approach to Micromachining: High-Precision and Innovative Additive Manufacturing Solutions Based on Photopolymerization Technology. Materials. 2020; 13(13):2951. https://doi.org/10.3390/ma13132951

Chicago/Turabian StyleFiedor, Paweł, and Joanna Ortyl. 2020. "A New Approach to Micromachining: High-Precision and Innovative Additive Manufacturing Solutions Based on Photopolymerization Technology" Materials 13, no. 13: 2951. https://doi.org/10.3390/ma13132951

APA StyleFiedor, P., & Ortyl, J. (2020). A New Approach to Micromachining: High-Precision and Innovative Additive Manufacturing Solutions Based on Photopolymerization Technology. Materials, 13(13), 2951. https://doi.org/10.3390/ma13132951