Digitalization: An Opportunity for Contributing to Sustainability From Knowledge Creation

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

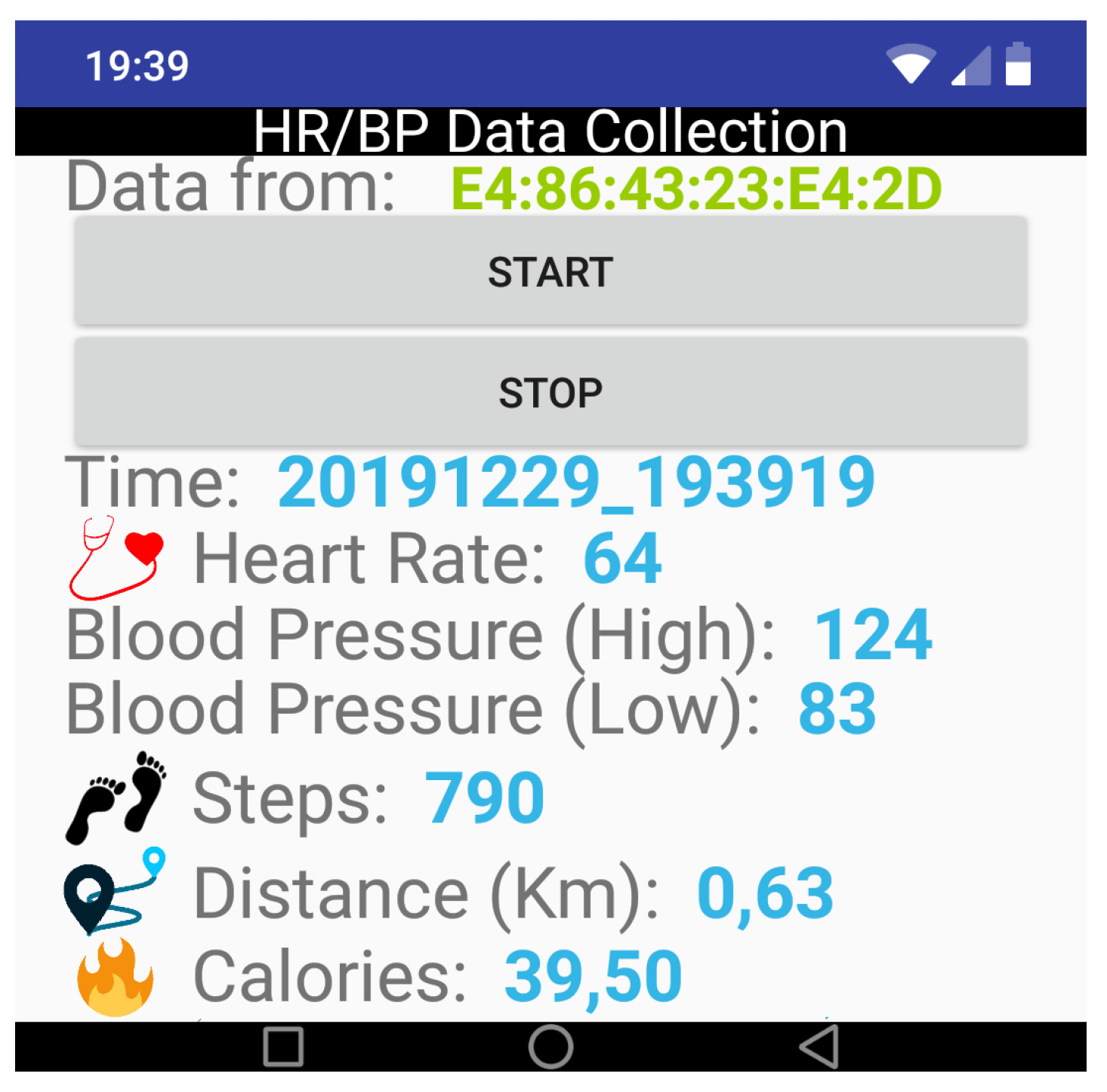

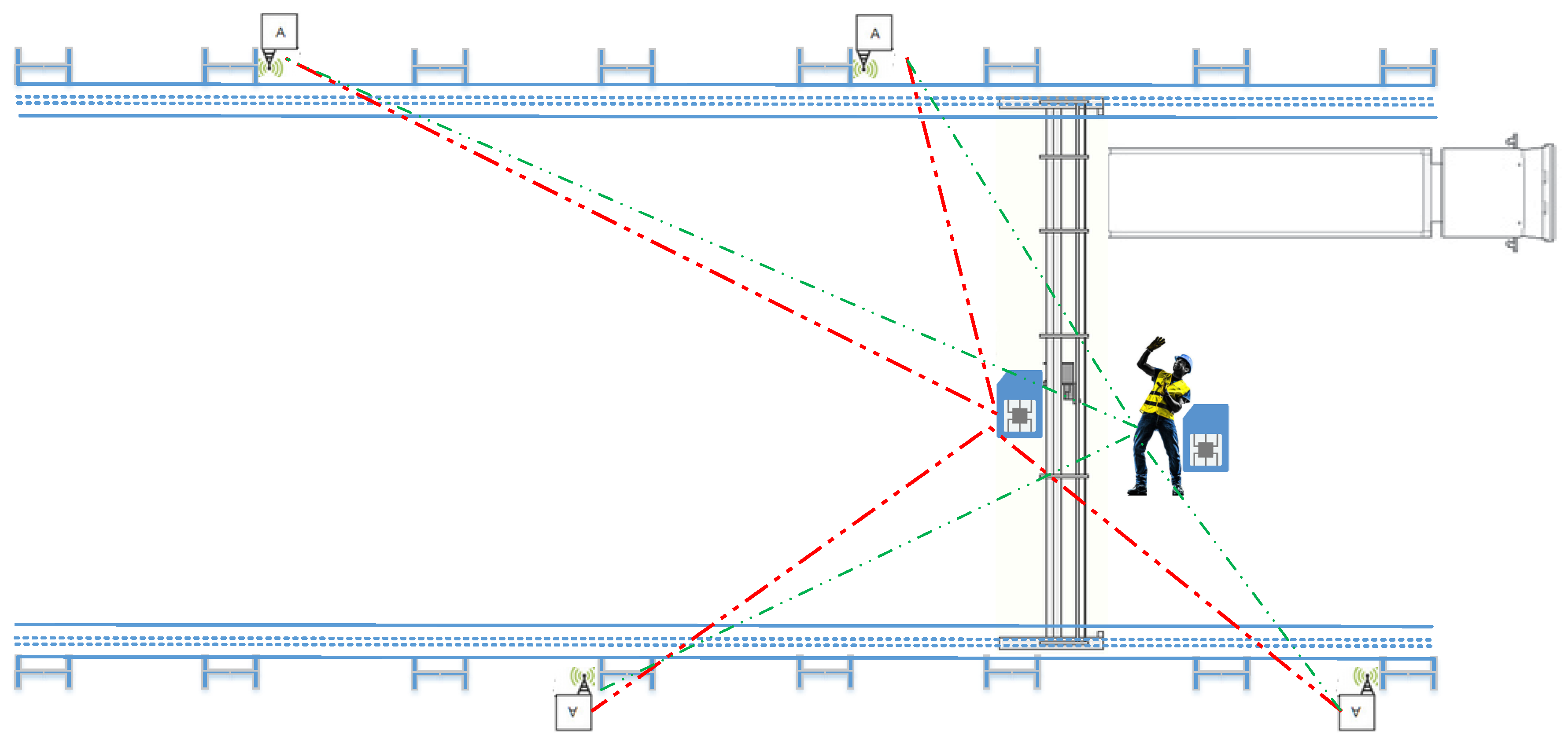

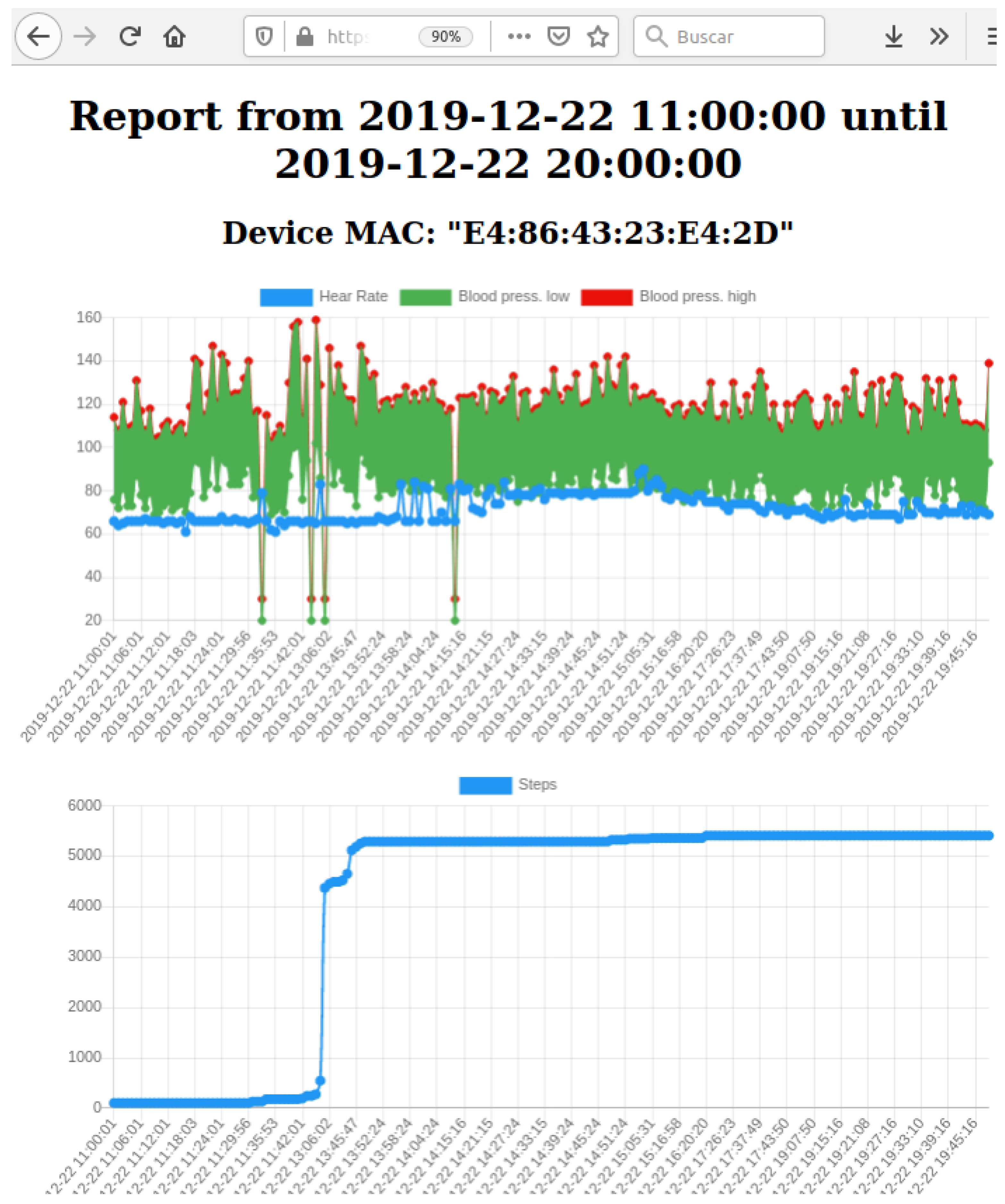

3.1. Manufacturing Case

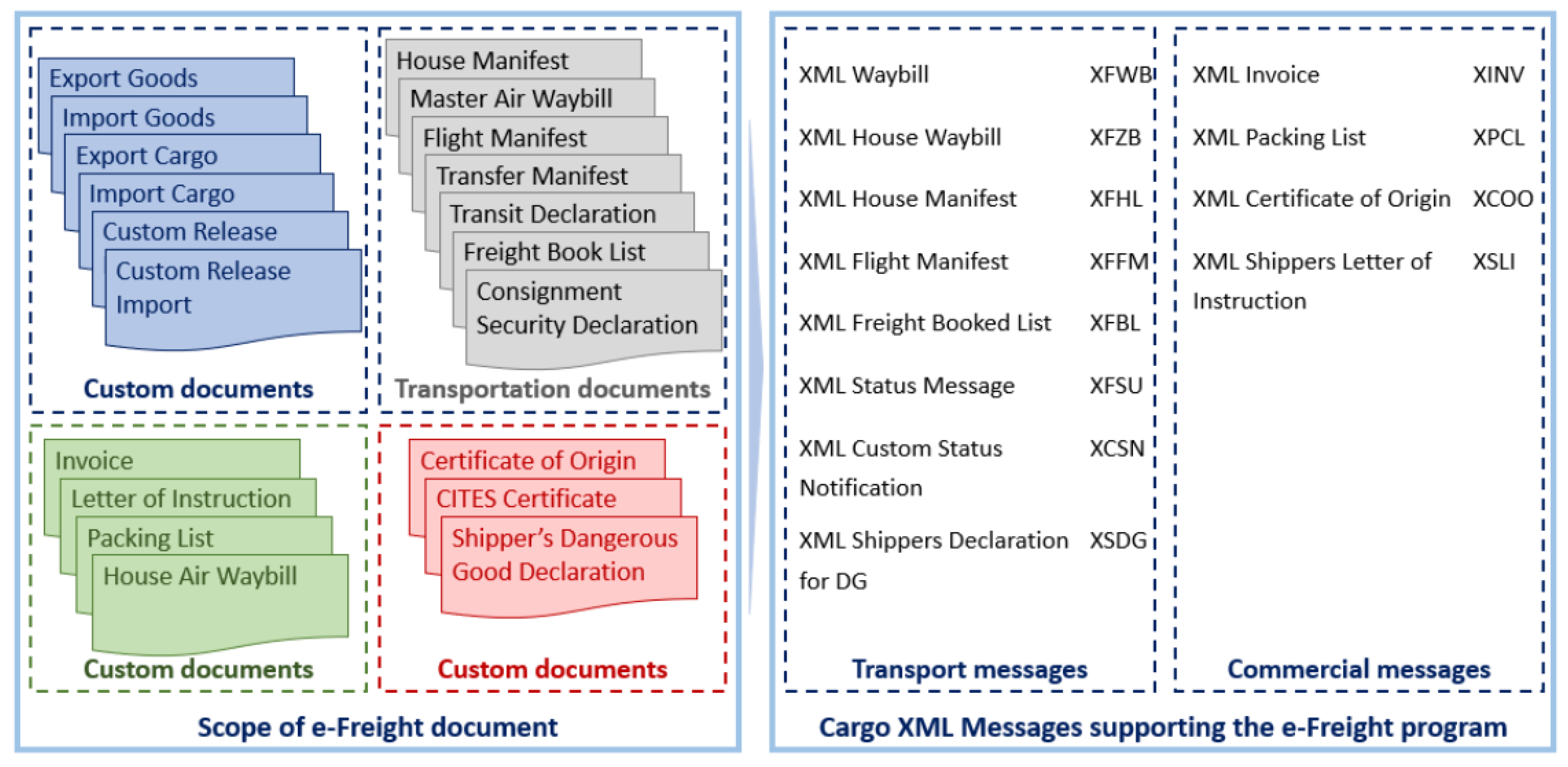

3.2. Air Transportation Case

- (a)

- FRED+ platform,

- (b)

- Trajectory Sharing Platform (TSP) and

- (c)

- e-Freight program.

4. Results

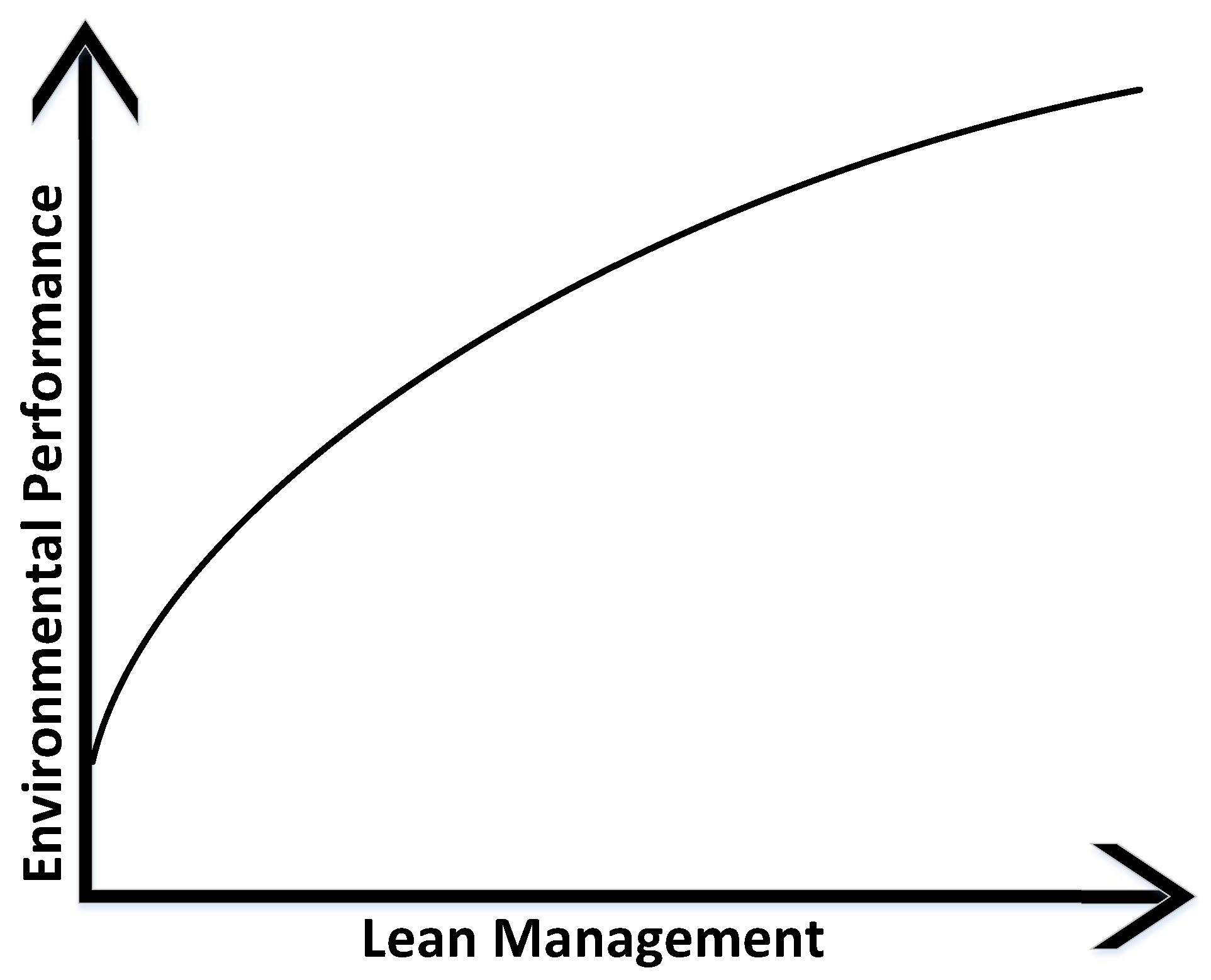

4.1. Manufacturing Case

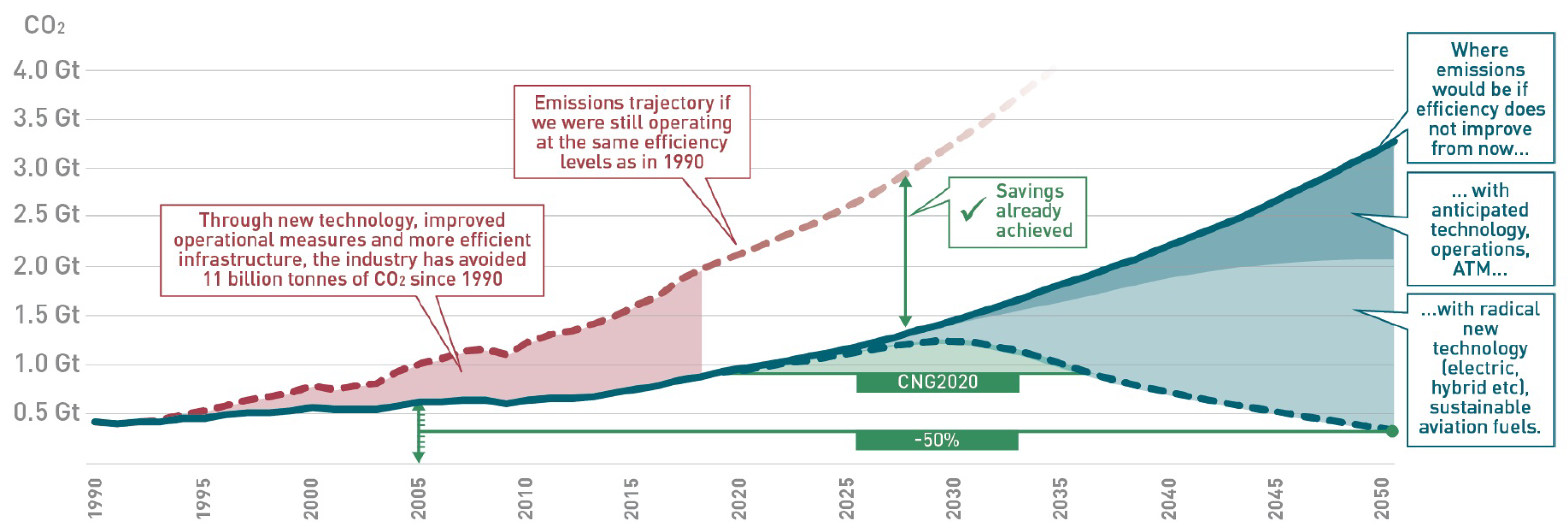

4.2. Air Transportation Case

- (a)

- Reduce CO by around 2.5 billion tonnes.

- (b)

- Generate above 40 billion in climate finance.

- (a)

- Technology, including the usage of alternative sustainable fuels. An example of the impact of this pillar on aviation is the evolution of aircraft fuel consumption. Since the beginning of jet travel, fuel efficiency improvement was between 15% and 20% compared with the previous aircraft generation. That is the main reason behind the reduction of 8% in US airline emissions between 2000 and 2014, while air traffic rose by 20% [65]. Nowadays, aircraft manufacturers are working on several fronts to enhance aircraft sustainability, gathering technical feedback from aircrafts during their lifetime [66], or assessing the feasibility of other energy sources for aircraft like solar or hydrogen, and new wing designs [67]. What is clear is that the next sustainable developments for aircrafts will rely on breakthrough technologies because current ones have already reached their ceiling [68].

- (b)

- Operations improvement. This pillar ranges from ground operations to flight trajectories. A very important point to take into account about this pillar is that operational improvements, in comparison with technology, could have an immediate impact on the entire air transport efficiency.In the operational field, the study of the optimal trajectory has been broadly researched [69,70,71], in most of the cases linked to FCO. The FCO in the air transport sector is an old topic [72], and aside from the obvious business interests, sustainability is making it again a trending topic [73,74,75,76].

- (c)

- Infrastructure. Concerning infrastructure, the air transport sector is already facing the digitalization challenges of the airports [77], and also the advantages of improving infrastructure efficiencies like ground operations [78] or even baggage handling [79].Regarding sustainability improvement, the IPCC estimated that only in the USA the introduction of the recommended changes on air traffic management would represent savings of around 6.1 million pounds of fuel, equivalent to 12.7 million pounds of CO emissions [80].All of the above only highlights the importance of this third pillar in improving the sustainability of air transport. Moreover, it is reinforced by the emergence of the models for assessing the sustainability of airports [81].

- (d)

- Global market-based measure. This last pillar is required to accomplish the explained objectives. Even relying on the first three pillars, a potential gap could occur. To close that gap, international CO emissions trading must be considered as a temporary solution, as suggested by Absi et al. [82], while solutions coming from the other three pillars are implemented.

- The IEnvA (IATA Environmental Assessment) oriented to support airlines achieving ISO14001:2015 compliance.

- The “Single European Sky” program of the EU, aiming to improve ATM in Europe to make air traffic growth sustainable and environmentally friendly [91].

- Or the models developed by Eurocontrol to analyze the air quality around the airports (Open-ALAQS) or IMPACT for the combined analysis of noise, fuel consumption, and emissions [92] and not only in Europe.

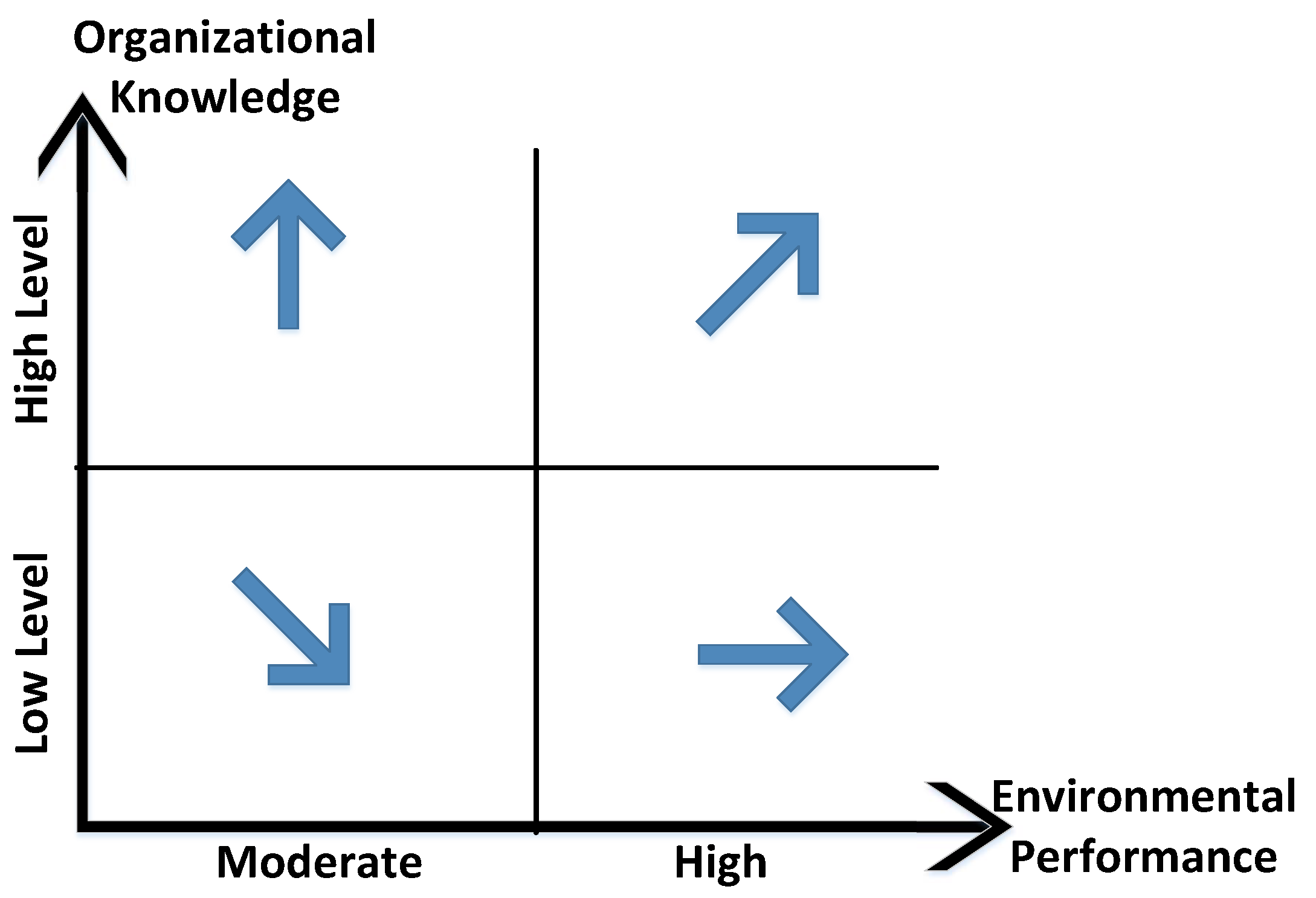

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DESI | Digital Economy and Society Index |

| ERP | Enterprise Resource Planning |

| MES | Manufacturing Execution System |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| UWB | Ultra Wide Band technology |

| ICAO | International Civil Aviation Organization |

| CORSIA | Carbon Offsetting and Reduction Scheme for International Aviation |

| FCO | Fuel Consumption Optimization |

| IPPC | Intergovernmental Panel on Climate Change |

| TSP | Trajectory Sharing Platform |

| ATC | Air Traffic Control |

| AWB | Air WayBill |

| TBL | Triple Bottom Line |

| CE | Circular Economy |

| GE | Green Economy |

| OHS | Occupational Health and Safety |

| ICT | Information and Communication Technologies |

| GDPR | General Data Protection Regulation |

References

- Bilge, P.; Seliger, G.; Badurdeen, F.; Jawahir, I. A novel framework for achieving sustainable value creation through industrial engineering principles. Procedia CIRP 2016, 40, 516–523. [Google Scholar] [CrossRef]

- Mateus, A. DESI 2015 Digital Economy and Society Index Methodological note. EU Comm. Bruxelles. 2015, 1, 8–9. [Google Scholar]

- Jovanović, M.; Dlačić, J.; Okanović, M. How Does the Digitalization Impact Society’s Sustainable Development? Measures and Implications. Available online: https://www.researchgate.net/profile/Milica_Jovanovic2/publication/325106114_How_does_the_digitalization_impact_society’s_sustainable_development_Measures_and_implications/links/5af6e648a6fdcc0c030d263e/How-does-the-digitalization-impact-societys-sustainable-development-Measures-and-implications.pdf (accessed on 30 November 2019).

- Shrouf, F.; Gong, B.; Ordieres-Meré, J. Multi-level awareness of energy used in production processes. J. Clean. Product. 2017, 142, 2570–2585. [Google Scholar] [CrossRef]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2019, 30, 79–95. [Google Scholar] [CrossRef]

- Pelletier, N.; Ustaoglu, E.; Benoit, C.; Norris, G.; Rosenbaum, E.; Vasta, A.; Sala, S. Social sustainability in trade and development policy. Int. J. Life Cycle Assess. 2018, 23, 629–639. [Google Scholar] [CrossRef]

- Vié, A.; Colapinto, C.; La Torre, D.; Liuzzi, D. The long run sustainability of the European Union countries: Assessing the Europe 2020 strategy through a fuzzy goal programming model. Manag. Decis. 2019, 57, 523–542. [Google Scholar] [CrossRef]

- Richter, C.; Kraus, S.; Brem, A.; Durst, S.; Giselbrecht, C. Digital entrepreneurship: Innovative business models for the sharing economy. Creat. Innov. Manag. 2017, 26, 300–310. [Google Scholar] [CrossRef]

- Sullivan, K.; Thomas, S.; Rosano, M. Using industrial ecology and strategic management concepts to pursue the Sustainable Development Goals. J. Clean. Product. 2018, 174, 237–246. [Google Scholar] [CrossRef]

- Brown, B.J.; Hanson, M.E.; Liverman, D.M.; Merideth, R.W. Global sustainability: Toward definition. Environ. Manag. 1987, 11, 713–719. [Google Scholar] [CrossRef]

- Peter Glavič, R.L. Review of sustainability terms and their definitions. J. Clean. Product. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Colbert, B.A.; Kurucz, E.C. Three conceptions of triple bottom line business sustainability and the role for HRM. People Strategy 2007, 30, 21. [Google Scholar]

- Alhaddi, H. Triple bottom line and sustainability: A literature review. Bus. Manag. Stud. 2015, 1, 6–10. [Google Scholar] [CrossRef]

- Svensson, G.; Padin, C. Industry note: Sustainable development requires economic, social and environmental sustainability: A business perspective. Int. J. Agric. Innov. Technol. Glob. 2019, 1. [Google Scholar]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y.; Oliveira, M.A.Y.; Ferreira, J.J.P. Business Model Generation: A handbook for visionaries, game changers and challengers. Afr. J. Bus. Manag. 2011, 5, 22–30. [Google Scholar]

- Guiltinan, J. Creative destruction and destructive creations: environmental ethics and planned obsolescence. J. Bus. Eth. 2009, 89, 19–28. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy: A new sustainability paradigm? J. Clean. Product. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Michela Piccarozzi, B.A.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review, identifying the current trends and future perspectives. Process Saf. Environ. Protect. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in Industry4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Filho, M.G. When titans meet: Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Tesavrita, C.; Suryadi, K.; Wiratmadja, I.I.; Govindaraju, R. Intra-Organizational and Inter-Organizational Knowledge Sharing in Collaborative Learning Process: A Conceptual Framework for SME. In Proceedings of the 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 21–23 April 2017. [Google Scholar]

- Wu, K.J.; Gao, S.; Xia, L.; Tseng, M.L.; Chiu, A.S.; Zhang, Z. Enhancing corporate knowledge management and sustainable development: An inter-dependent hierarchical structure under linguistic preferences. Resour. Conserv. Recycl. 2019, 146, 560–579. [Google Scholar] [CrossRef]

- Linneberg, M.S.; Madsen, M.T.; Nielsen, J.A. Micro-level translation of corporate sustainability: When strategy meets practice in the Danish hospitality sector. J. Clean. Product. 2017, 240, 118159. [Google Scholar] [CrossRef]

- Tosic, B.; Zivkovic, N. Knowledge Management and Innovation in the Digital Era: Providing a Sustainable Solution. Adv. Econ. Bus. Manag. Res. 2019, 108. [Google Scholar]

- Usman, M.; Ahmad, M.I.; Burgoyne, J. Individual and organizational learning from inter-firm knowledge sharing: A framework integrating inter-firm and intra-firm knowledge sharing and learning. Can. J. Adm. Sci. 2019, 36, 484–497. [Google Scholar] [CrossRef]

- Sayyadi, M. How effective leadership of knowledge management impacts organizational performance. Can. J. Adm. Sci. 2019, 36, 30–38. [Google Scholar] [CrossRef]

- Sukhorukov, A.; Koryagin, N.; Sulyagina, J.; Ulitskaya, N.; Eroshkin, S. Digital Transformation of Airline Management as the Basis of Innovative Development. Adv. Intell. Syst. Comput. 2020, 1115, 845–854. [Google Scholar]

- Li, D.; Landström, A.; Fast-Berglund, Å.; Almström, P. Human-Centred Dissemination of Data, Information and Knowledge in Industry 4.0. Procedia CIRP 2019, 84, 380–386. [Google Scholar] [CrossRef]

- Li, D.; Fast-Berglund, Å.; Paulin, D. Current and future Industry 4.0 capabilities for information and knowledge sharing. Int. J. Adv. Manuf. Technol. 2019, 105, 3951–3963. [Google Scholar] [CrossRef]

- Aromaa, S.; Liinasuo, M.; Kaasinen, E.; Bojko, M.; Schmalfuß, F.; Apostolakis, K.C.; Zarpalas, D.; Daras, P.; Özturk, C.; Boubekeuer, M. User Evaluation of Industry 4.0: Concepts for Worker Engagement. Adv. Intell. Syst. Comput. 2019, 876, 34–40. [Google Scholar]

- Kikkawa, Y.; Mavin, T.J. Integrated Digitised Video Recordings in Postflight-Simulator Training: A Matter of Reflection. Prof. Pract.-Based Learn. 2018, 21, 103–121. [Google Scholar]

- Kikkawa, Y.; Mavin, T.J. Gamification Concepts for Leveraging Knowledge Sharing in Industry 4.0. Int. J. Serious Games 2019, 6, 75–87. [Google Scholar]

- Adams, G.L.; Lamont, B.T. Knowledge management systems and developing sustainable competitive advantage. J. Know. Manag. 2003, 7, 142–154. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Indoor Air-Quality Data-Monitoring System: Long-Term Monitoring Benefits. Sensors 2019, 19, 4157. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Agency theory: An assessment and review. Acad. Manag. Rev. 1989, 14, 57–74. [Google Scholar] [CrossRef]

- Robert, Y. Case Study Research: Design and Methods; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2003; Volume 761, p. 8. [Google Scholar]

- Schwandt, T.A.; Lincoln, Y.S.; Guba, E.G. Judging interpretations: However, is it rigorous? Trustworthiness and authenticity in naturalistic evaluation. New Dir. Eval. 2007, 2007, 11–25. [Google Scholar] [CrossRef]

- Marsden, T.; Murdoch, J. Introduction between the Local and the Global: Confronting Complexity in the Contemporary Food Sector. In Between the Local and the Global (Research in Rural Sociology and Development); Emerald Group Publishing Limited: Bingley, UK, 2006; pp. 1–8. [Google Scholar]

- Rachinger, M.; Rauter, R.; Müller, C.; Vorraber, W.; Schirgi, E. Digitalization and its influence on business model innovation. J. Manuf. Technol. Manag. 2018, 30, 1143–1160. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, Q.H.; Ślusarczyk, B. Sustainability and Digitalization of Corporate Management Based on Augmented/Virtual Reality Tools Usage: China and Other World IT Companies’ Experience. Sustainability 2019, 11, 4717. [Google Scholar] [CrossRef]

- Kwon, S.; Jeong, J.; Shon, T. Toward Security Enhanced Provisioning in Industrial IoT Systems. Sensors 2018, 18, 4372. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Caramés, T.; Fraga-Lamas, P.; Suárez-Albela, M.; Díaz-Bouza, M. A fog computing based cyber-physical system for the automation of pipe-related tasks in the Industry 4.0 shipyard. Sensors 2018, 18, 1961. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Product. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Kabugo, J.C.; Jamsa-Jounela, S.L.; Schiemann, R.; Binder, C. Industry 4.0 based process data analytics platform: A waste-to-energy plant case study. Int. J. Electr. Power Energy Syst. 2020, 115. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, R.H.; Zheng, D.; Li, J.; Wu, P.; Cao, J. Efficient and Robust Certificateless Signature for Data Crowdsensing in Cloud-Assisted Industrial IoT. IEEE Trans. Indu. Inf. 2019, 15, 5099–5108. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented reality in support of Industry 4.0-Implementation challenges and success factors. Robot. Comput.-Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Heberle, A.; Lowe, W.; Gustafsson, A.; Vorrei, O. Digitalization Canvas—Towards Identifying Digitalization Use Cases and Projects. J. Univers. Comput. Sci. 2017, 23, 1070–1097. [Google Scholar]

- Simons, S. The AutFab smart factory—A learning factory for Industry 4.0. Atp Ed. 2018, 9, 46–61. [Google Scholar] [CrossRef]

- Golan, M.; Cohen, Y.; Singer, G. A framework for operator—Workstation interaction in Industry 4.0. Int. J. Product. Res. 2019. [Google Scholar] [CrossRef]

- Safeea, M.; Neto, P.; Bearee, R. On-line collision avoidance for collaborative robot manipulators by adjusting off-line generated paths: An industrial use case. Robot. Auton. Syst. 2019, 119, 278–288. [Google Scholar] [CrossRef]

- Jesus Roldan, J.; Crespo, E.; Martin-Barrio, A.; Pena-Tapia, E.; Barrientos, A. A training system for Industry 4.0 operators in complex assemblies based on virtual reality and process mining. Robot. Comput.-Integr. Manuf. 2019, 59, 305–316. [Google Scholar] [CrossRef]

- Graitec, G. Solutions for the Construction; Steel & Concrete Industry. Available online: https://www.armaplus.com/ (accessed on 20 October 2019).

- ATAG. Fact & Figures. Available online: http://www.atag.org/facts-figures.html (accessed on 18 October 2019).

- IATA. Carbon Offsetting for International Aviation. Available online: https://www.iata.org/policy/environment/Documents/paper-offsetting-for-aviation.pdf (accessed on 18 October 2019).

- Hillman, D.R.; Werner, T.K. Capturing Generation-Based Institutional Knowledge Utilizing Design Thinking. Perform. Improv. 2017, 56, 28–36. [Google Scholar] [CrossRef]

- Dehghan, H.; Mobinyzadeh, V.; Habibi, P. The Effects of Heat Stress on Job Satisfaction, Job Performance and Occupational Stress in Casting Workers. Jundishapur J. Health Sci. 2016, 8, 1–6. [Google Scholar] [CrossRef]

- Macoir, N.; Bauwens, J.; Jooris, B.; Van Herbruggen, B.; Rossey, J.; Hoebeke, J.; De Poorter, E. Uwb localization with battery-powered wireless backbone for drone-based inventory management. Sensors 2019, 19, 467. [Google Scholar] [CrossRef]

- IATA. IATA FRED+ General Presentation. Available online: https://www.iata.org/whatwedo/environment/Documents/fred+_general_presentation.pdf (accessed on 30 November 2019).

- Migdadi, Y.K.A.A. Identifying the best practices of airlines’ green operations strategy: A cross-regional worldwide survey. Environ. Q. Manag. 2018, 28, 21–32. [Google Scholar] [CrossRef]

- IATA. Carbon Offsetting Scheme for International Aviation (CORSIA). Available online: https://www.iata.org/policy/environment/Pages/corsia.aspx (accessed on 15 November 2019).

- IATA. Climate Change. Available online: https://www.iata.org/policy/environment/Pages/climate-change.aspx (accessed on 1 December 2019).

- ATAG. Aviation Climate Solutions. Available online: https://aviationbenefits.org/media/125796/Aviation-Climate-Solutions_WEB.pdf (accessed on 30 November 2019).

- Husain, W.W.; Shah, S.A. Potential Aircraft Design Improvement and Sustainability Through Feedback Information. Int. J. Eng. Technol. 2018, 7, 221–224. [Google Scholar]

- Ahmed, T.; Kurtulus, D.F. Technology Review of Sustainable Aircraft Design. In Sustainable Aviation; Springer: Cham, Switzerland, 2019; pp. 137–152. [Google Scholar]

- Iemma, U.; Pisi Vitagliano, F.; Centracchio, F. Multi-objective design optimization of sustainable commercial a-ircraft: Performance and costs. Int. J. Sustain. Eng. 2016, 10, 147–157. [Google Scholar] [CrossRef]

- García-Heras, J.; Soler, M.; Sáez, F.J. A comparison of optimal control methods for minimum fuel cruise at constant altitude and course with fixed arrival time. Procedia Eng. 2014, 80, 231–244. [Google Scholar] [CrossRef]

- Lee, K.C.; Tsai, W.H.; Yang, C.H.; Lin, Y.Z. An MCDM approach for selecting green aviation fleet program management strategies under multi-resource limitations. J. Air Transp. Manag. 2018, 68, 76–85. [Google Scholar] [CrossRef]

- Cavcar, A.; Cavcar, M. Impact of aircraft performance differences on fuel consumption of aircraft in air traffic management environment. Aircr. Eng. Aerosp. Technol. 2004, 6, 502–515. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, S.K. Fuel consumption optimization in air transport: A review, classification, critique, simple meta-analysis, and future research implications. Eur. Transp. Res. Rev. 2015, 7, 12. [Google Scholar] [CrossRef]

- Hammad, A.W.; Rey, D.; Bu-Qammaz, A.; Grzybowska, H.; Akbarnezhad, A. Mathematical optimization in enhancing the sustainability of aircraft trajectory: A review. Int. J. Sustain. Transp. 2019. [Google Scholar] [CrossRef]

- Matthes, S.; Team, A. Multi-criteria Environmental Impact Assessment and Optimisation of Aircraft Trajectories. 7th SESAR Innov. Days 2017, 4, 1–42. [Google Scholar]

- Matthes, S.; Grewe, V.; Dahlmann, K.; Frömming, C.; Irvine, E.; Lim, L.; Linke, F.; Lührs, B.; Owen, B.; Shine, K. A Concept for Multi-Criteria Environmental Assessment of Aircraft Trajectories. Aerospace 2017, 4, 42. [Google Scholar] [CrossRef]

- Lim, Y.; Gardi, A.; Sabatini, R. Optimal aircraft trajectories to minimize the radiactive impact of contrails and CO2. Energy Procedia 2017, 110, 446–452. [Google Scholar] [CrossRef]

- Zaharia, S.E.; Pietreanu, C.V. Challenges in airport digital transformation. Transp. Res. Procedia 2018, 35, 90–99. [Google Scholar] [CrossRef]

- Kovynyov, I.; Mikut, R. Digital technologies in airport ground operations. Netnomics 2019, 20, 1–30. [Google Scholar] [CrossRef]

- Koenig, F.; Found, P.A.; Kumar, M. Condition monitoring for airport baggage handling in the era of industry 4.0. J. Q. Maint. Eng. 2019, 25, 435–451. [Google Scholar] [CrossRef]

- IPCC. Aviation and the Global Atmosphere. Available online: https://archive.ipcc.ch/ipccreports/sres/aviation/index.php?idp=0 (accessed on 1 December 2019).

- Kumar, A.; Aswin, A.; Gupta, H. Evaluating green performance of the airports using hybrid BWM and VIKOR methodology. Tourism Manag. 2020, 76, 103941. [Google Scholar] [CrossRef]

- Absi, N.; Dauzère-Pérès, S.; Kedad-Sidhoum, S.; Penz, B.; Rapine, C. Lot sizing with carbon emission constraints. Eur. J. Op. Res. 2013, 227, 55–61. [Google Scholar] [CrossRef]

- ICAO. Flight & Flow Information for a Collaborative Environment. Available online: https://www.icao.int/airnavigation/FFICE/Pages/default.aspx (accessed on 12 January 2019).

- Stephen, A.; Daniel Ferro, A.N.; Chapelle, J.P. Large scale validations of enhanced Conflict Management functions. The key contribution of accurate ADS-C ATN B2 trajectory data. In Air Traffic Management Requirements and Performance Panel (Atmrpp). Thirty-Seventh Working Group Meeting; ICAO (International Civil Aviation Organization): Montreal, QC, Canada, 2019. [Google Scholar]

- Suhang, C. The First Initial Four-dimensional Trajectory (I4D) Flight Trial in China. In Air Traffic Management Requirements and Performance Panel (Atmrpp). Thirty Seventh Working Group Meeting; ICAO (International Civil Aviation Organization): Montreal, QC, Canada, 2019. [Google Scholar]

- Sauv, M. eAWB Implementation Playbook. Available online: https://www.iata.org/contentassets/6c6b8373246b4b2db532ff9c89bee5a7/e-awb-implementation-playbook.pdf (accessed on 18 October 2019).

- Sauv, M. eAWB Implementation Playbook. Available online: https://www.iata.org/contentassets/6c6b8373246b4b2db532ff9c89bee5a7/e-awb-monthly-report-r17.pdf (accessed on 10 January 2020).

- Ramon, A.; Jean Mere, D.D.; Miquel, T. Flight Management System Pathfinding Algorithm for Automatic Vertical Trajectory Generation. In Proceedings of the 2018 IEEE/AIAA 37th Digital Avionics Systems Conference (DASC), London, UK, 23–27 September 2018. [Google Scholar] [CrossRef]

- Dalmau, R.; Prats, X. How much fuel and time can be saved in a perfect flight trajectory? In Proceedings of the 6th International Congress on Research in Air Transportation (ICRAT), Istanbul, Turkey, 26–30 May 2014. [Google Scholar]

- IATA. e-Freight. Available online: https://www.iata.org/whatwedo/cargo/e/efreight/Pages/index.aspx (accessed on 18 October 2019).

- EU. Single European Sky. Available online: https://ec.europa.eu/transport/modes/air/ses_en (accessed on 18 October 2019).

- Eurocontrol. Environment. Available online: https://www.eurocontrol.int/environment (accessed on 18 October 2019).

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Serenko, A.; Bontis, N. Understanding counterproductive knowledge behavior: Antecedents and consequences of intra-organizational knowledge hiding. J. Know. Manag. 2016, 20, 1199–1224. [Google Scholar] [CrossRef]

- Vuori, V.; Okkonen, J. Knowledge sharing motivational factors of using an intra-organizational social media platform. J. Know. Manag. 2012, 16, 592–603. [Google Scholar] [CrossRef]

- Indre Maurer, V.B.; Ebers, M. The Value of Intra-organizational Social Capital: How it Fosters Knowledge Transfer, Innovation Performance, and Growth. Organ. Stud. 2011, 32, 157–185. [Google Scholar] [CrossRef]

- Loebbecke, C.; van Fenema, P.C.; Powell, P. Managing inter-organizational knowledge sharing. J. Strateg. Inf. Syst. 2015, 25, 4–14. [Google Scholar] [CrossRef]

- Birou, L.M.; Green, K.W.; Inman, R.A. Sustainability knowledge and training: Outcomes and firm performance. J. Manuf. Technol. Manag. 2019, 30, 294–311. [Google Scholar] [CrossRef]

- Payán-Sánchez, B.; Plaza-Úbeda, J.A.; Pérez-Valls, M.; Carmona-Moreno, E. Social Embeddedness for Sustainability in the Aviation Sector. Corp. Soc. Resp. Environ. Manag. 2018, 25, 537–553. [Google Scholar] [CrossRef]

- Fang, S.Y.C.; Hsu, W. Inter-organizational knowledge transfer: The perspective of knowledge governance. J. Know. Manag. 2013, 17, 943–957. [Google Scholar] [CrossRef]

- Rothenberg, S. Knowledge content and worker participation in environmental management at NUMMI. J. Manag. Stud. 2003, 40, 1783–1802. [Google Scholar] [CrossRef]

- IATA. BSP Definition. Available online: https://www.iata.org/en/services/finance/bsp (accessed on 21 January 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ordieres-Meré, J.; Prieto Remón, T.; Rubio, J. Digitalization: An Opportunity for Contributing to Sustainability From Knowledge Creation. Sustainability 2020, 12, 1460. https://doi.org/10.3390/su12041460

Ordieres-Meré J, Prieto Remón T, Rubio J. Digitalization: An Opportunity for Contributing to Sustainability From Knowledge Creation. Sustainability. 2020; 12(4):1460. https://doi.org/10.3390/su12041460

Chicago/Turabian StyleOrdieres-Meré, Joaquín, Tomás Prieto Remón, and Jesús Rubio. 2020. "Digitalization: An Opportunity for Contributing to Sustainability From Knowledge Creation" Sustainability 12, no. 4: 1460. https://doi.org/10.3390/su12041460

APA StyleOrdieres-Meré, J., Prieto Remón, T., & Rubio, J. (2020). Digitalization: An Opportunity for Contributing to Sustainability From Knowledge Creation. Sustainability, 12(4), 1460. https://doi.org/10.3390/su12041460