Digital Twin Reference Model Development to Prevent Operators’ Risk in Process Plants

Abstract

1. Introduction

2. Literature Review: Digital Twin and Risk Assessment

3. Material and Methods: Current Technologies Deployed in Digital Twin

3.1. Industrial Internet of Things and Digital Twin

- (1)

- Firstly, Digital Twin pushes the boundary of sensing capabilities toward the physical world. Sensing methods that monitor physical metrics in an industrial context and which use less resources are more practical in industrial IoT. Wireless and battery-free sensors can support lightweight and robust monitoring. How to extend the capabilities of wireless signals [27,28,29,30] and how to increase the battery life have triggered numerous research motivations over the past few years [31,32,33];

- (2)

- Secondly, the processing of massive networked sensors requires the upgrade of computing architecture to reduce elaboration time, e.g., collaborative edge computing [34,35,36], and in order to reduce the effort of cloud architecture and save the bandwidth, it is important to enable a resource-constrained IoT device with modern analysis techniques, e.g., deep learning [37,38,39,40];

- (3)

3.2. Simulation Technology and Digital Twin

3.3. Machine Learning and Digital Twin

- Data availability. Machine learning works on information, and without the proper quantity and quality of data, it is impossible to develop and implement a proper machine learning model. It is important to analyze and to visualize the data to perform integrity checks, to validate data quality and to understand data meanings. Nowadays, industrial organizations commonly lack digitalized data, with several analogic PLCs (Programmable Logic Controllers) and few digital monitoring systems.

- Complex environment and the human factor. Several industrial contexts are a complex reality, with processes, resources and people that interact partly with linear cause-effect relationships and partly with nonlinear, complex and even unpredictable ones [50]. Industries are socio-technical systems difficult to simulate and predict, due to their variability and irregularity.

3.4. Augmented and Virtual Reality and Digital Twin

- (1)

- Calibration: in order to obtain a clear and intuitive data visualization using AR devices, all the processing of historical data is as important as the data. In order to better manage the AR device, the 3D or 2D models must be perfectly aligned with the physical part. This process is called calibration.

- (2)

- Control process: the control process is a very important aspect for AR systems as it allows the user to interact with both the physical and the virtual part of the Digital Twin. After viewing the data in the increased process, users can use this information to support decision-making and directly control the physical part through the AR device.

- (3)

- Augmented process: the augmented process, through the AR devices, must provide users with an intuitive and clear AR view of the information coming from the Digital Twin. In practice, the AR device receives data from the virtual part, and after the calibration phase, it correctly presents this to the user.

- (1)

- Real-time data: there is a huge amount of real-time data exchanged between the manufacturing process, cloud and VR device, and these have to be managed in order to support the users and operators in the correct way.

- (2)

- 3D and 2D modeling: recognizing, tracking and following the target object(s) is extremely important for the quality of AR utilization.

- (3)

- Reliability: the manufacturing environment is dangerous, noisy and dirty, so the AR device has to be reliable and robust enough to carry out the tasks.

- (4)

- User cooperation: the manufacturing task can be done with the cooperation of multiple users and operators at the same time, so the VR infrastructure must be flexible enough to permit the data exchange between multiple devices.

3.5. Cloud Technology and Digital Twin

- (1)

- IBM is a vendor that offers the most complete solution. It could build a Digital Twin on IBM Watson IoT [57];

- (2)

- Amazon refers to the Digital Twin as a device shadow which is a JavaScript Object Notation (JSON) file that contains information, metadata, timestamps, and other important information to unequivocally identify the connected device. The near real-time communication could be implemented using Representational State Transfer (REST) call or MQ Telemetry Transport or Message Queue Telemetry Transport (MQTT) architecture [58];

- (3)

- Microsoft proposes the Azure IoT solution which has the “Device Twin” model as part of device management. The Device Twin is represented by a JSON file that stores information on the status of the device and is updated in near real-time from the data coming from the real system [59].

- (1)

- Data privacy: the sharing of data regarding production is one of the major privacy issues.

- (2)

- Security: with the high amount of factory information gathered from the production plant and sent to the Cloud for Digital Twin elaboration, the risk to security becomes more important.

- (3)

- Connectivity: the virtual process and the real system are to connect with each other in a real-time mode. Granting data connectivity and full bandwidth are the principal elements for a correct Digital Twin implementation.

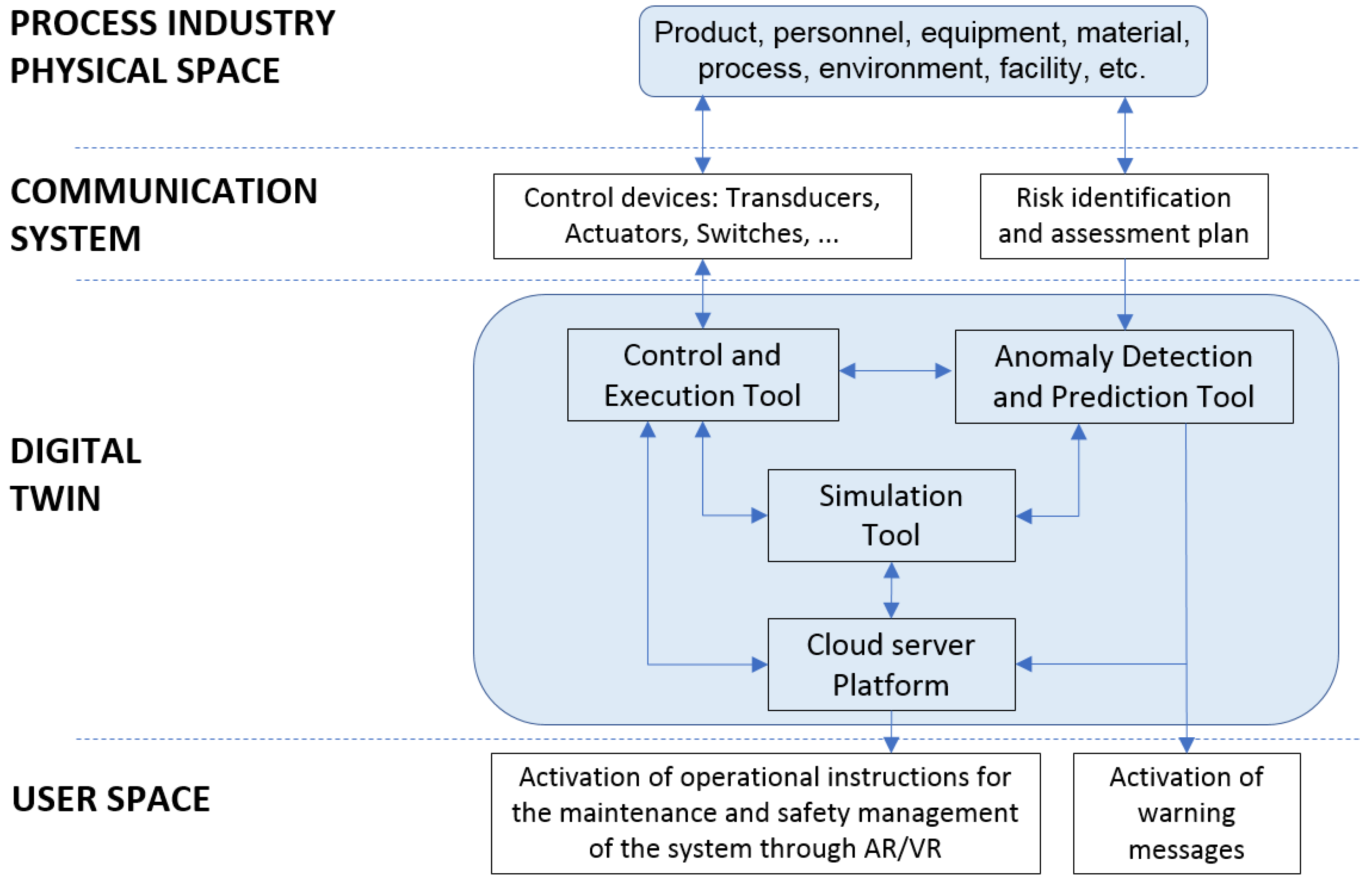

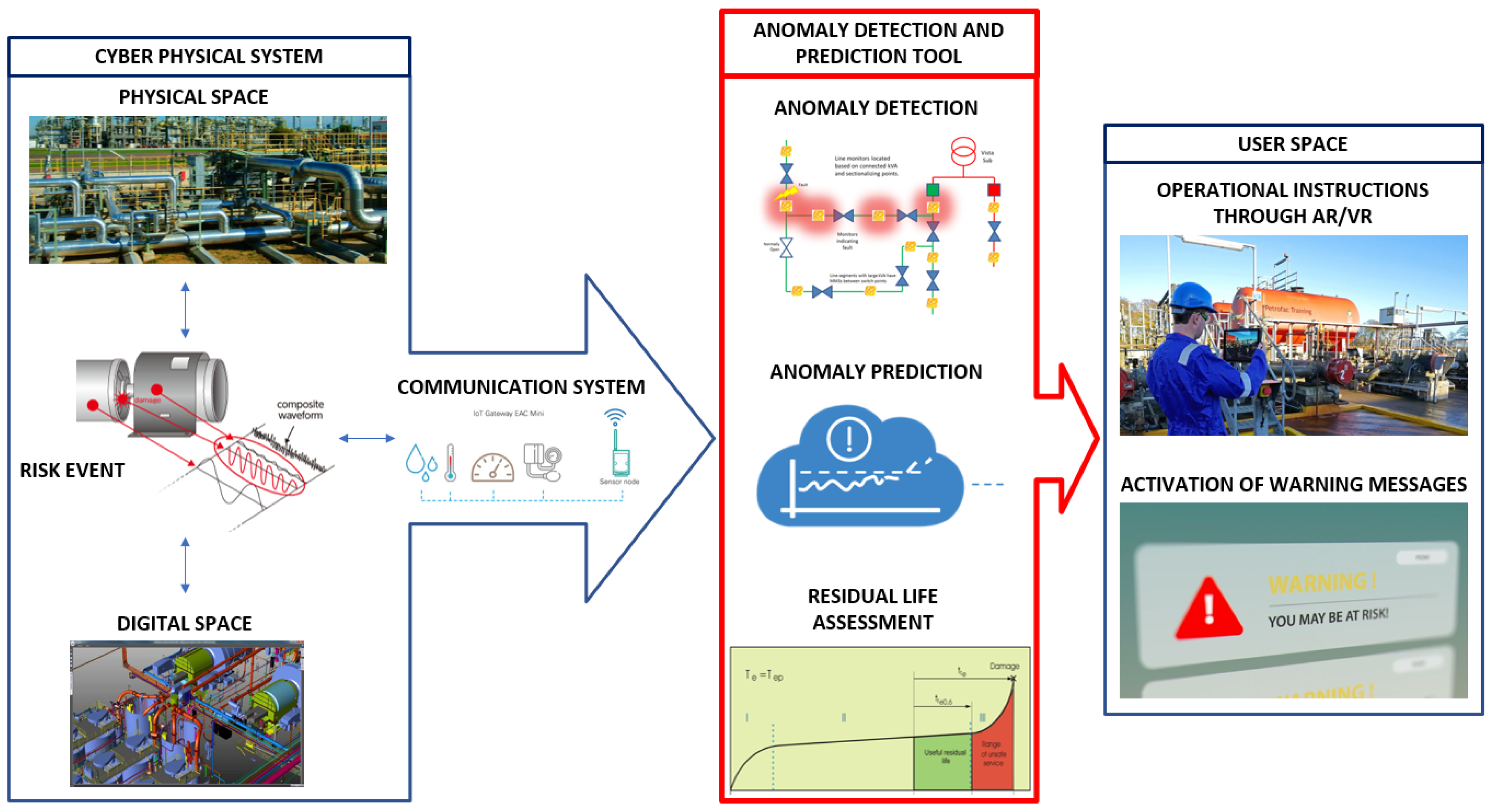

4. Digital Twin Reference Model

- (1)

- Process industry physical space: this layer consists of all physical industry resources such as product, personnel, equipment, material, process, environment, facility etc. This is the primary environment of the Digital Twin reference model that the company aims to control. With physical space, we refer to all observable plant elements in production that shall be monitored and sensed and may be actuated and controlled.

- (2)

- Communication system: the second layer is dedicated to transferring data or information between Digital Twin and plant elements. Physical elements are monitored and sensed from control devices and execution tools for data collecting and device controlling with various devices such as sensors, cameras, actuators and other composite devices. This system connects observable plant elements to digital entities, and vice versa, for their synchronization. To complete the second layer, a 3D Model Representation and a Risk Identification and Assessment Plan are needed in order to set up the simulation system and the Anomaly Prediction and Detection Tool.

- (3)

- Digital Twin: this is the third layer. From a conceptual point of view, the Digital Twin infrastructure must be able to manage the following agents:

- Acquisition of data coming from sensors, actuators devices, etc. installed on the system;

- Visualization of the data coming from the field;

- Data analysis for anomaly detection purposes and related prediction;

- Integration of anomaly detection algorithm data to compare trends;

- Development of the Digital Twin that simulates the behavior of the plant (possibility of developing what-if scenarios);

- Integration of the Digital Twin and relative comparison with the physical space in order to determine anomalous behaviors;

- Identification of dangerous situations for the operator;

- Activation and management of alerts on the 3D model towards operators, plant managers and other systems;

- Support for maintenance following anomalies.

- During the operative phase of the plant, the operator closes by mistake a shut-off valve and the plant goes into overpressure, putting at risk the integrity of the piping and the personnel. Before the safety valve intervenes (which would lead to a partial emptying of the system with consequent stoppage of the system for a long time), the tool detects an increase in pressure at certain points, identifies the problem and warns the operator about the type of anomaly that is occurring;

- During a pump maintenance operation, the operator does not close the shut-off valve and floods the area;

- The control valve downstream of the tank is blocked and closed due to a fault and the system goes into overpressure;

- A pump vibrates abnormally due to bearing failure;

- A shut-off valve upstream of the pump closes by mistake and the pump goes into cavitation.

- -

- Data input from the PLC;

- -

- External engines for input data analysis (sensor readings);

- -

- Elaborations carried out by the data analysis engines, after which they are visualized for comparison;

- -

- Data coming from the sensors to the simulated model of the plant;

- -

- Data coming from the simulated model (what-if scenarios) and relative comparison with the real one;

- -

- Data coming from the sensors to the 3D model of the plant;

- -

- Data coming from the 3D model and its comparison with the real one.

User Space

- Activation of operational instructions for the maintenance and safety management of the system through AR/VR;

- Activation of warning messages.

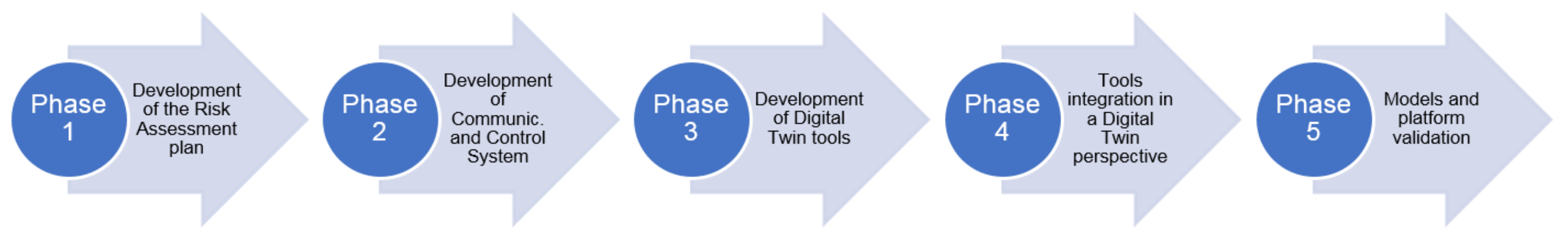

5. Implementation of Digital Twin Reference Model

- Analysis of the context of application. It is important to understand the environment, the boundaries and the dependencies of the analyzed processes. In fact, this step defines the structure of the machine learning model and its target. For example, the reduction of the operators’ risk requires the definition of the specific risks that can affect the operators.

- Monitoring of the process and data records. The data must be prepared to make them suitable for use by the machine learning model;

- Set up the parameters of the machine learning model;

- Training of the model with training data from the real production process;

- Testing the model on different data, for verifying its effectiveness. This is the conclusion of the real development of the machine learning model;

- Improvement of the capacities of the machine learning model using the Digital Twin, as explained above.

- (1)

- Multimodal information: the platform has to be able to integrate multimodal information, such as sounds, videos, texts, 3D animations etc. into the platform;

- (2)

- Browsing and editing: the platform must enable the creation, modification and navigation of cyber-physical systems, which means modifying and creating environments that integrate the physical and virtual space;

- (3)

- Detection: through a grid of sensors, the platform must have the ability to monitor and store activities that occur in the work environment;

- (4)

- Heterogeneity: the platform should support different types of sensors and actuators;

- (5)

- Semantic abstraction and modularity: the platform should be able to provide a semantic abstraction, allowing easy communication between the elements of the environment;

- (6)

- Verification, validation and simulation: the platform must be able to simulate the behavior of the physical units present in the productive world. This will allow a company to predict and control the highest-risk events and to formulate alternative scenarios.

6. Discussion

6.1. Criticality in Reference Model Implementation

- IoT is not perfectly IIoT (Industrial IoT). The industrial version of devices requires resilient, robust and reliable solutions, which are subject to industry regulations and standards (e.g., watchdog systems, certified code). Today, the solutions on the market, in many cases, do not perfectly meet the needs, in terms of performance and flexibility, compared to the industrial reality.

- The need for deterministic transactions. Real-time implies determinism, i.e., the guarantee that an action by an actor is implemented, not necessarily at high speed. This means that processing must be based on suitable (operating) systems designed for real-time. The design of embedded systems, by definition, is aimed at applications with specific performance and guaranteed stability.

- For embedded systems, the usual concept that computing devices will soon be more powerful and less expensive is no longer valid. Programming paradigms must take into account a new dimension where resources are limited “by design”.

- When the number of pervasive devices is large, factors such as energy consumption and energy supply (energy scavenging/harvesting techniques), life cycle and maintenance of components (dispersion of pollutants, recovery at the end of life, maintenance, recycling and/or reuse) become critical. Rapid wake-up systems (e.g., non-volatile memories) after minimum consumption sleep cycles.

- Targeted design of human–machine interfaces (new, small but expressive interactive displays, low power consumption, e.g., Organic Light-Emitting Diode (OLED), e-paper), which are minimally invasive and disturbing (calm technology).

6.2. Practical Implications

- Enable maintenance technicians to make their repair decisions based on actual data and forecasting of future scenarios, as opposed to the traditional approach to maintenance based on predefined activities or just on conjecture, by knowing about upcoming problems;

- Provide a tool with high added value, allowing company managers to make increasingly reliable forecasts about the evolution of risk events. This functionality perfectly fits within the digital continuity required by modern industrial paradigms;

- Helping business leaders in decision-making activities not only from an economic but also from an organizational point of view: resources can, therefore, be managed at their optimum level to obtain maximum profits, rather than performing corrective and reactive maintenance in the event of a part failure.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IS0/TC184/SC4/WG15. ISO CD 23247-1: Digital Twin Manufacturing Framework—Part 1: Overview and General Principles. Under Development, ISO. 2019. Available online: https://www.iso.org/standard/75066.html (accessed on 2 February 2020).

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G. A Fuzzy, Cognitive Maps Tool for Developing a RBI & M Model. Qual. Reliab. Eng. Int. 2016, 32, 373–390. [Google Scholar]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.-A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- SIEMENS Digitalization in Industry: Twins with Potential. Available online: https://new.siemens.com/global/en/company/stories/industry/the-digital-twin.html (accessed on 26 November 2019).

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Patriarca, R.; Bergström, J.; Di Gravio, G.; Costantino, F. Resilience engineering: Current status of the research and future challenges. Saf. Sci. 2018, 102, 79–100. [Google Scholar] [CrossRef]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar]

- Patriarca, R.; Falegnami, A.; De Nicola, A.; Villani, M.L.; Paltrinieri, N. Serious games for industrial safety: An approach for developing resilience early warning indicators. Saf. Sci. 2019, 118, 316–331. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E. Human factor risk management in the process industry: A case study. Reliab. Eng. Syst. Saf. 2018, 169, 149–159. [Google Scholar] [CrossRef]

- Zhou, J. Intelligent manufacturing—Main direction of “Made in China 2025”. China Mech. Eng. 2015, 26, 2273–2284. [Google Scholar]

- Lee, J.; Cameron, I.; Hassall, M. Improving process safety: What roles for digitalization and industry 4.0? Process Saf. Environ. Prot. 2019, 132, 325–339. [Google Scholar] [CrossRef]

- Ma, X.; Tao, F.; Zhang, M.; Wang, T.; Zuo, Y. Digital twin enhanced human-machine interaction in product lifecycle. Procedia CIRP 2019, 83, 789–793. [Google Scholar] [CrossRef]

- Patriarca, R.; Di Gravio, G.; Cioponea, R.; Licu, A. Safety intelligence: Incremental proactive risk management for holistic aviation safety performance. Saf. Sci. 2019, 118, 551–567. [Google Scholar] [CrossRef]

- Liu, Z.; Meyendorf, N.; Mrad, N. The role of data fusion in predictive maintenance using digital twin. In Proceedings of the AIP Conference Proceedings, Provo, UT, USA, 16–21 July 2017; Volume 1949. [Google Scholar]

- Milazzo, M.F.; Bragatto, P.; Ancione, G.; Scionti, G. Ageing assessment and management at major-hazard industries. Chem. Eng. Trans. 2018, 67, 73–78. [Google Scholar]

- Marsh. The 100 Largest Losses 1978–2017. 2018. Available online: http://www.marshmercamexico.com/Reportes%20energy/18-0101_100%20largest%20losses_v8_print.pdf (accessed on 2 Fubruary 2020).

- Cameron, I.; Mannan, S.; Németh, E.; Park, S.; Pasman, H.; Rogers, W.; Seligmann, B. Process hazard analysis, hazard identification and scenario definition: Are the conventional tools sufficient, or should and can we do much better? Process Saf. Environ. Prot. 2017, 110, 53–70. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Shinohara, S.; Shimada, Y.; Suzuki, K. Experiment on distributed dynamic simulation for safety design of chemical plants. Simul. Model. Pract. Theory 2003, 11, 109–123. [Google Scholar] [CrossRef]

- Ramzan, N.; Compart, F.; Witt, W. Application of extended Hazop and event-tree analysis for investigating operational failures and safety optimization of distillation column unit. Process Saf. Prog. 2007, 26, 248–257. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, L.; Hu, J.; Lind, M.; Zhang, X.; Jørgensen, S.B.; Sin, G.; Jensen, N. An integrated qualitative and quantitative modeling framework for computer-assisted HAZOP studies. AIChE J. 2014, 60, 4150–4173. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Reniers, G. Dynamic risk analysis for Seveso sites. J. Loss Prev. Process Ind. 2017, 49, 111–119. [Google Scholar] [CrossRef]

- Kummer, A.; Varga, T. Process simulator assisted framework to support process safety analysis. J. Loss Prev. Process Ind. 2019, 58, 22–29. [Google Scholar] [CrossRef]

- Moskowitz, I.; Seider, W.; Soroush, M.; Oktem, U.; Arbogast, J. Chemical processsimulation for dynamic risk analysis: A steam-methane reformer case study. Ind. Eng. Chem. Res. 2015, 54, 4347–4359. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Lin, Q.; Li, X.-Y.; Liu, Y. Making sense of mechanical vibration period with sub-millisecond accuracy using backscatter signals. In Proceedings of the 22nd Annual International Conference on Mobile Computing and Networking, New York, NY, USA, 3–7 October 2016; pp. 16–28. [Google Scholar]

- Wang, J.; Xiong, J.; Chen, X.; Jiang, H.; Balan, R.K.; Fang, D. TagScan: Simultaneous target imaging and material identification with commodity RFID devices. In Proceedings of the 23rd Annual International Conference on Mobile Computing and Networking, Snowbird, UT, USA, 16–20 October 2017; pp. 288–300. [Google Scholar]

- Khutsoane, O.; Isong, B.; Abu-Mahfouz, A.M. IoT devices and applications based on LoRa/LoRaWAN. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 6107–6112. [Google Scholar]

- Habib, G.; Haddad, N.; Khoury, R.E. Case study: WIRELESSHART vs ZIGBEE network. In Proceedings of the 2015 Third International Conference on Technological Advances in Electrical, Electronics and Computer Engineering (TAEECE), Beirut, Lebanon, 29 April–1 May 2015; pp. 135–138. [Google Scholar]

- Decuir, J. Bluetooth Smart Support for 6LoBTLE: Applications and connection questions. IEEE Consum. Electron. Mag. 2015, 4, 67–70. [Google Scholar] [CrossRef]

- Honggang, Z.; Chen, S.; Leyu, Z. Design and Implementation of Lightweight 6LoWPAN Gateway Based on Contiki. In Proceedings of the 2018 IEEE International Conference on Signal Processing, Communications and Computing (ICSPCC), Qingdao, China, 14–16 September 2018; pp. 1–5. [Google Scholar]

- Hancke, P.; Allen, B. Ultrawideband as an Industrial Wireless Solution. IEEE Pervasive Comput. 2006, 5, 78–85. [Google Scholar] [CrossRef]

- Ananthanarayanan, G.; Bahl, P.; Bodik, P.; Chintalapudi, K.; Philipose, M.; Ravindranath, L.; Sinha, S. Real-Time Video Analytics: The Killer App for Edge Computing. Computer 2017, 50, 58–67. [Google Scholar] [CrossRef]

- Long, C.; Cao, Y.; Jiang, T.; Zhang, Q. Edge Computing Framework for Cooperative Video Processing in Multimedia IoT Systems. IEEE Trans. Multimed. 2018, 20, 1126–1139. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, J. ViTrack: Efficient Tracking on the Edge for Commodity Video Surveillance Systems. In Proceedings of the IEEE INFOCOM 2018—IEEE Conference on Computer Communications, Honolulu, HI, USA, 16–19 April 2018; pp. 1052–1060. [Google Scholar]

- Guo, Y.; Yao, A.; Chen, Y. Dynamic network surgery for efficient DNNs. In Proceedings of the Advances in Neural Information Processing Systems, Barcelona, Spain, 5–10 December 2016; pp. 1387–1395. [Google Scholar]

- Yao, S.; Zhao, Y.; Zhang, A.; Su, L.; Abdelzaher, T. DeepIoT: Compressing Deep Neural Network Structures for Sensing Systems with a Compressor-Critic Framework. In Proceedings of the 15th ACM Conference on Embedded Networked Sensor Systems, Delft, The Netherlands, 6–8 November 2017; pp. 1–14. [Google Scholar]

- Lane, N.D.; Bhattacharya, S.; Georgiev, P.; Forlivesi, C.; Jiao, L.; Qendro, L.; Kawsar, F. DeepX: A Software Accelerator for Low-Power Deep Learning Inference on Mobile Devices. In Proceedings of the 2016 15th ACM/IEEE International Conference on Information Processing in Sensor Networks (IPSN), Vienna, Austria, 11–14 April 2016. [Google Scholar]

- Mathurz, A.; Lanezy, N.D.; Bhattacharyaz, S.; Boranz, A.; Forlivesiz, C.; Kawsarz, F. DeepEye: Resource efficient local execution of multiple deep vision models using wearable commodity hardware. In Proceedings of the 15th Annual International Conference on Mobile Systems, Applications, and Services, Niagara Falls, NY, USA, 19–23 June 2017; pp. 68–81. [Google Scholar]

- Huawei. What Is NB-IoT? Available online: https://support.huaweicloud.com/iot_faq/iot_faq_00200.html (accessed on 26 November 2019).

- Jin, M.; He, Y.; Meng, X.; Zheng, Y.; Fang, D.; Chen, X. FlipTracer: Practical Parallel Decoding for Backscatter Communication. IEEE/ACM Trans. Netw. 2019, 27, 330–343. [Google Scholar] [CrossRef]

- Guo, J.; He, Y.; Zheng, X. Pangu: Towards a software-defined architecture for multi-function wireless sensor networks. In Proceedings of the 2017 IEEE 23rd International Conference on Parallel and Distributed Systems (ICPADS), Shenzhen, China, 15–17 December 2018; pp. 730–737. [Google Scholar]

- Schluse, M.; Rossmann, J. From simulation to experimentable digital twins: Simulation-based development and operation of complex technical systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016. [Google Scholar]

- Boschert, S.; Rosen, R. Digital Twin-The Simulation Aspect. In Mechatronic Futures: Challenges and Solutions for Mechatronic Systems and Their Designers; Springer International Publishing: Cham, Switzerland, 2016; ISBN 9783319321561. [Google Scholar]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable Digital Twins-Streamlining Simulation-Based Systems Engineering for Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Cimino, C.; Macchi, M. FMU-supported simulation for CPS digital twin. In Proceedings of the International Conference on Changeable, Agile, Reconfigurable and Virtual Production, Nantes, France, 8–10 October 2018. [Google Scholar]

- Abramovici, M.; Göbel, J.C.; Dang, H.B. Semantic data management for the development and continuous reconfiguration of smart products and systems. CIRP Ann. 2016, 65, 185–188. [Google Scholar] [CrossRef]

- Weyer, S.; Meyer, T.; Ohmer, M.; Gorecky, D.; Zühlke, D. Future Modeling and Simulation of CPS-based Factories: An Example from the Automotive Industry. IFAC-PapersOnLine 2016, 49, 97–102. [Google Scholar] [CrossRef]

- Abreu Saurin, T.; Patriarca, R. A taxonomy of interactions in socio-technical systems: A functional perspective. Appl. Ergon. 2020, 82, 102980. [Google Scholar] [CrossRef] [PubMed]

- Kuts, V.; Modoni, G.E.; Terkaj, W.; Tähemaa, T.; Sacco, M.; Otto, T. Exploiting Factory Telemetry to Support Virtual Reality Simulation in Robotics Cell. In Proceedings of the 4th International Conference on Augmented Reality, Virtual Reality, and Computer Graphics, Ugento, Italy, 12–15 June 2017; Springer International Publishing: Cham, Switzerland, 2017. ISBN 9783319609218. [Google Scholar]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the digital twin data in manufacturing by using augmented reality. Procedia CIRP 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 2015, 28, 567–572. [Google Scholar] [CrossRef]

- Korambath, P.; Wang, J.; Kumar, A.; Davis, J.; Graybill, R.; Schott, B.; Baldea, M. A smart manufacturing use case: Furnace temperature balancing in steam methane reforming process via kepler workflows. Procedia Comput. Sci. 2016, 80, 680–689. [Google Scholar] [CrossRef][Green Version]

- Boettiger, C. An introduction to Docker for reproducible research. ACM SIGOPS Oper. Syst. Rev. 2015, 49, 71–79. [Google Scholar] [CrossRef]

- Cecil, R.; Soares, J. IBM Watson Studio: A Platform to Transform Data to Intelligence. In Pharmaceutical Supply Chains-Medicines Shortages; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-15397-7. [Google Scholar]

- Brecher, C.; Buchsbaum, M.; Storms, S. Control from the cloud: Edge computing, services and digital shadow for automation technologies. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 9327–9333. [Google Scholar]

- Stackowiak, R. Azure IoT Solutions Overview BT—Azure Internet of Things Revealed: Architecture and Fundamentals; Stackowiak, R., Ed.; Apress: Berkeley, CA, USA, 2019; pp. 29–54. ISBN 978-1-4842-5470-7. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bevilacqua, M.; Bottani, E.; Ciarapica, F.E.; Costantino, F.; Di Donato, L.; Ferraro, A.; Mazzuto, G.; Monteriù, A.; Nardini, G.; Ortenzi, M.; et al. Digital Twin Reference Model Development to Prevent Operators’ Risk in Process Plants. Sustainability 2020, 12, 1088. https://doi.org/10.3390/su12031088

Bevilacqua M, Bottani E, Ciarapica FE, Costantino F, Di Donato L, Ferraro A, Mazzuto G, Monteriù A, Nardini G, Ortenzi M, et al. Digital Twin Reference Model Development to Prevent Operators’ Risk in Process Plants. Sustainability. 2020; 12(3):1088. https://doi.org/10.3390/su12031088

Chicago/Turabian StyleBevilacqua, Maurizio, Eleonora Bottani, Filippo Emanuele Ciarapica, Francesco Costantino, Luciano Di Donato, Alessandra Ferraro, Giovanni Mazzuto, Andrea Monteriù, Giorgia Nardini, Marco Ortenzi, and et al. 2020. "Digital Twin Reference Model Development to Prevent Operators’ Risk in Process Plants" Sustainability 12, no. 3: 1088. https://doi.org/10.3390/su12031088

APA StyleBevilacqua, M., Bottani, E., Ciarapica, F. E., Costantino, F., Di Donato, L., Ferraro, A., Mazzuto, G., Monteriù, A., Nardini, G., Ortenzi, M., Paroncini, M., Pirozzi, M., Prist, M., Quatrini, E., Tronci, M., & Vignali, G. (2020). Digital Twin Reference Model Development to Prevent Operators’ Risk in Process Plants. Sustainability, 12(3), 1088. https://doi.org/10.3390/su12031088