Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage

Abstract

:1. Introduction

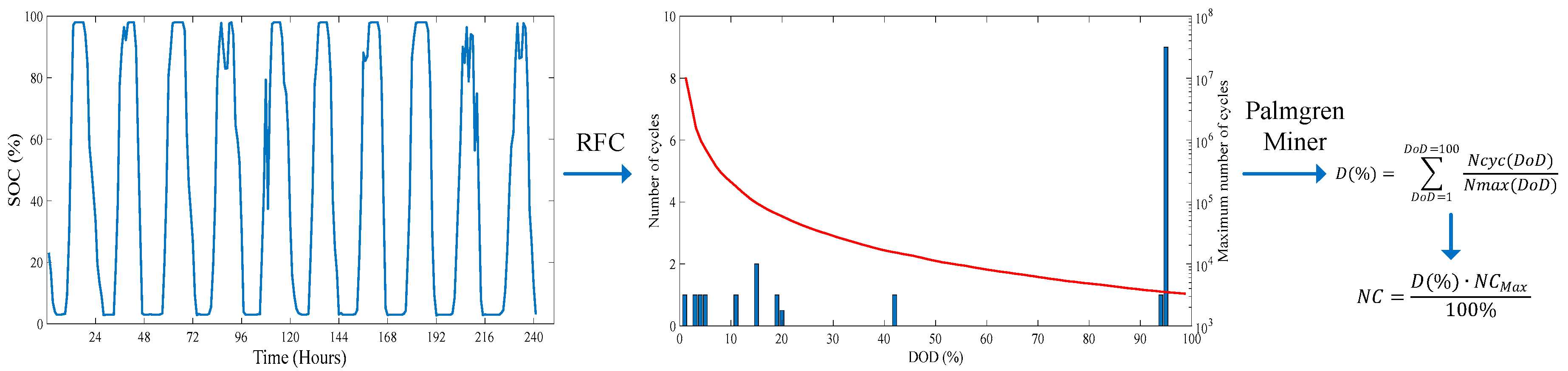

2. Methods

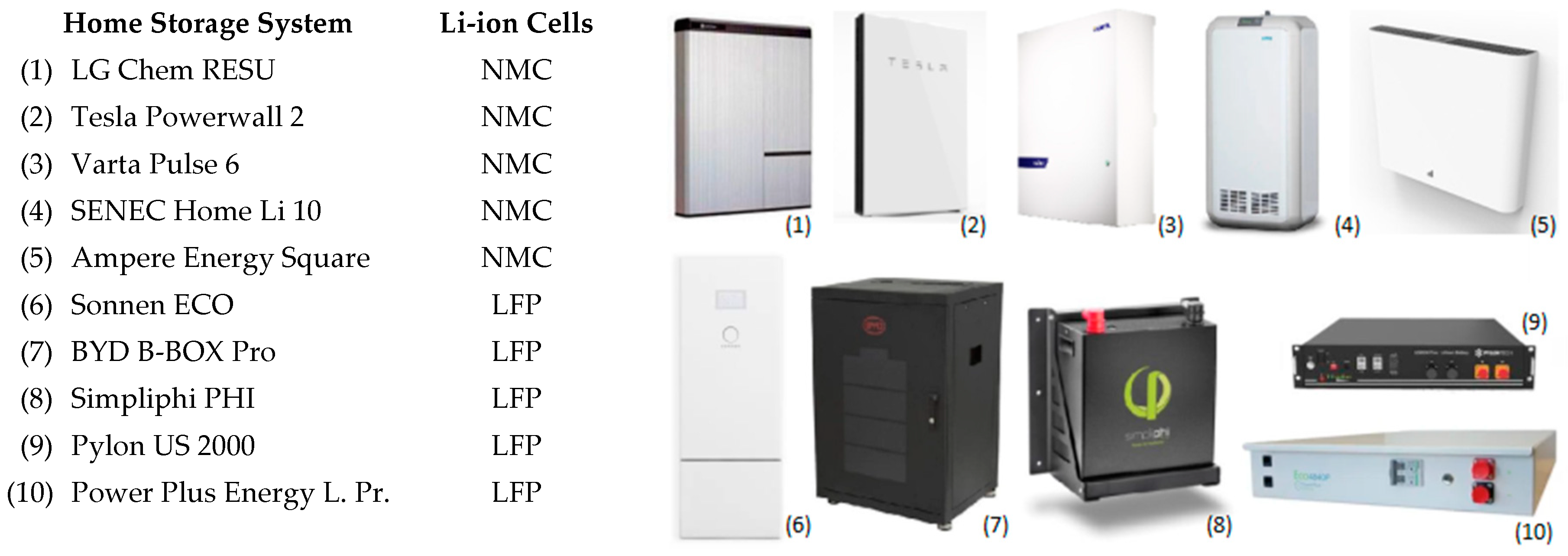

2.1. Li-ion Batteries and their Degradation Models

2.2. Reference Degradation Model for LiFePO4 Cells

2.3. Reference Degradation Model for Li(NiMnCo)O2 Cells

2.4. Degradation Models for State-of-the-Art Cells

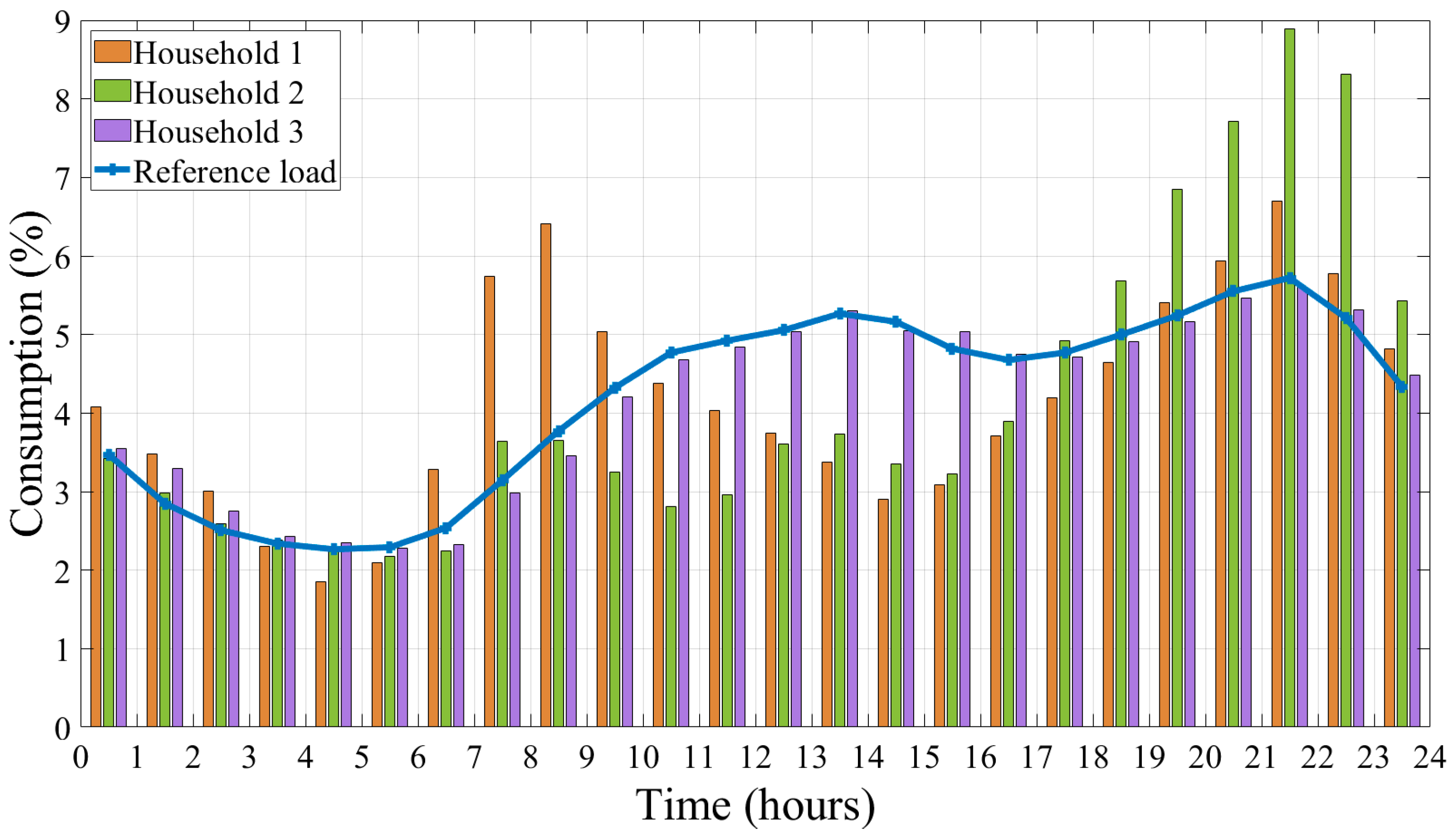

2.5. Operation of PV Systems with Batteries

- T is the sampling period.

- and are the predictions for and , respectively.

- is the power exchanged with the grid at instant , with when energy is purchased.

- is the power exchanged by the battery at instant , with when discharging.

- is the energy available in the battery at instant .

- and are the lower and upper bounds for the power exchanged with the ESS. These constraints are due to the limitations on the power converters and, therefore: .

- and are the lower and upper bounds for the power exchanged with the grid (). These can also represent limitations on a converter or can be used in order to implement peak shaving.

- and are the limits in between which the battery SOC must be kept.

- are the electricity prices. changes its values with the hour of the day depending on the rate period (on-peak or off-peak), while is considered constant and for any given .

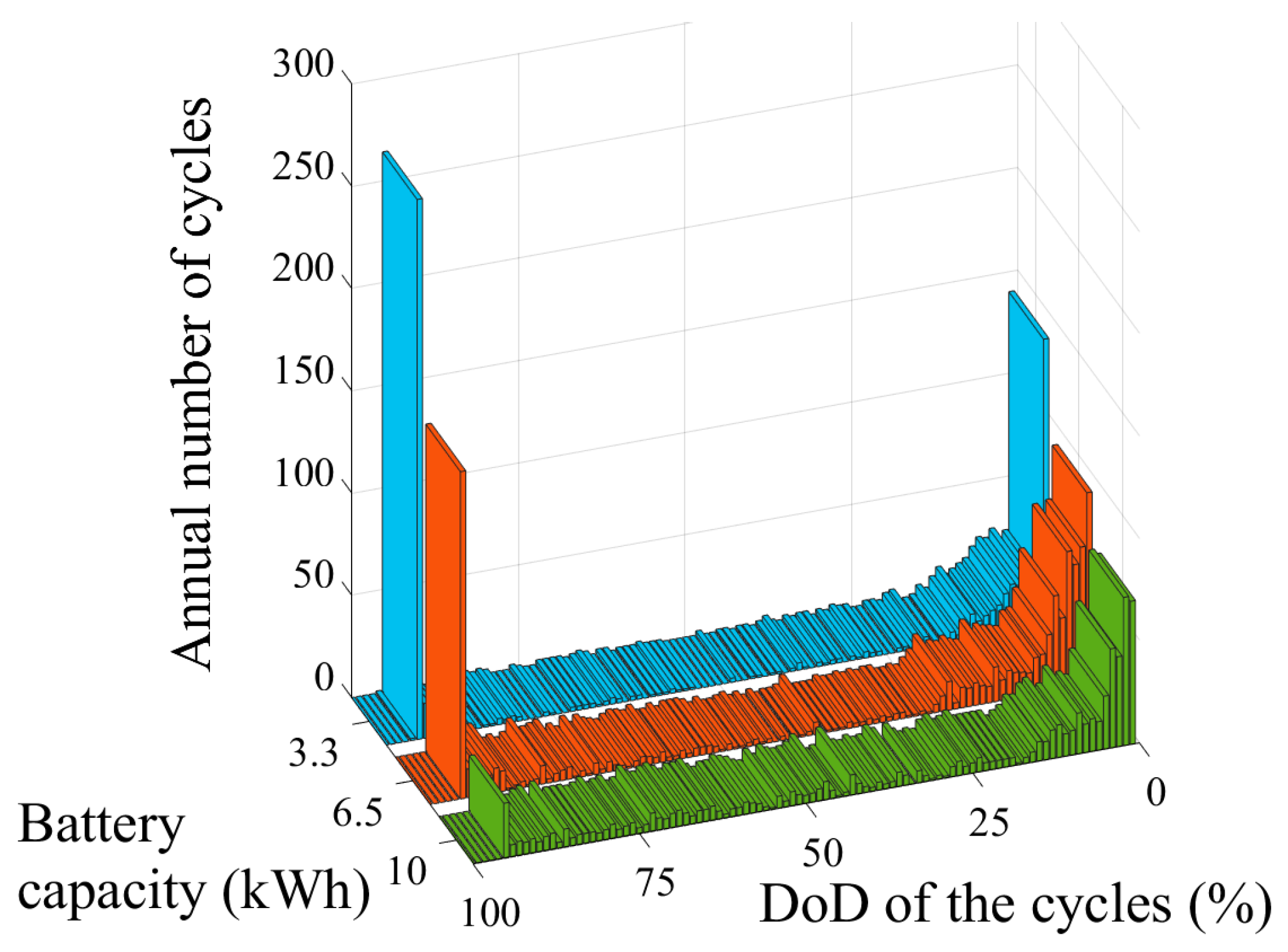

3. Results and Discussion

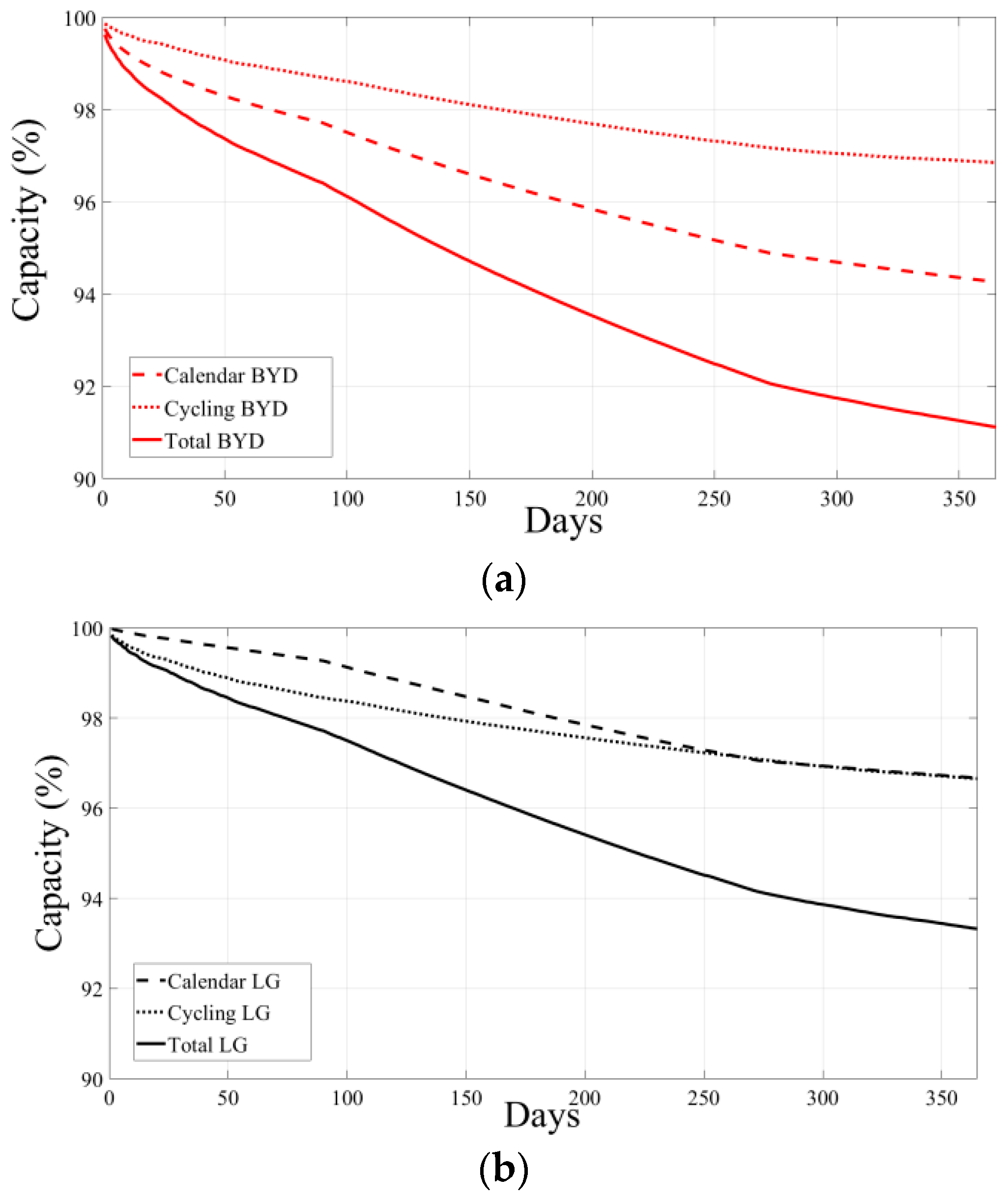

3.1. Annual Evolution of the Global Degradation

3.2. Comparative Discussion among Technologies.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- REN21. Renewables 2019 Global Status Report; REN21: Paris, France, 2019. [Google Scholar]

- International Energy Agency (IEA). Tracking Progress on PV. 2019. Available online: https://www.iea.org/tcep/power/renewables/solarpv/ (accessed on 15 January 2020).

- Joint Research Centre. European Comission. PV Status Report 2018; Publications Office of the European Union: Brussels, Belgium, 2018. [Google Scholar]

- Bermudez, V. Electricity storage supporting PV competitiveness in a reliable and sustainable electric network. J. Renew. Sustain. Energy 2017, 9, 12301. [Google Scholar] [CrossRef] [Green Version]

- Leadbetter, J.; Swan, L. Battery storage system for residential electricity peak demand shaving. Energy Build. 2012, 55, 685–692. [Google Scholar] [CrossRef]

- Teng, F.; Strbac, G. Business cases for energy storage with multiple service provision. J. Mod. Power Syst. Clean Energy 2016, 4, 615–625. [Google Scholar] [CrossRef] [Green Version]

- Hesse, H.C.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-ion battery storage for the grid—A review of stationary battery storage system design tailored for applications in modern power grids. Energies 2017, 10, 2107. [Google Scholar] [CrossRef] [Green Version]

- Wood Mackenzie. Global Energy Storage Outlook: Q3 2019; Wood Mackenzie: Edinburgh, UK, 2019. [Google Scholar]

- International Renewable Energy Agency. Innovation Landscape Brief: Behind-the-Meter Batteries; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019.

- Wood Mackenzie. Europe Residential Energy Storage Outlook 2019–2024; Wood Mackenzie: Edinburgh, UK, 2019. [Google Scholar]

- Weniger, J.; Tjaden, T.; Quaschning, V. Sizing of residential PV battery systems. Energy Procedia 2014, 46, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Tant, J.; Geth, F.; Six, D.; Tant, P.; Driesen, J. Multiobjective battery storage to improve PV integration in residential distribution grids. IEEE Trans. Sustain. Energy 2013, 4, 182–191. [Google Scholar] [CrossRef] [Green Version]

- Hafiz, F.; de Queiroz, A.R.; Husain, I. Multi-stage stochastic optimization for a PV-storage hybrid unit in a household. In Proceedings of the 2017 IEEE Industry Applications Society Annual Meeting, Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar]

- Naumann, M.; Karl, R.C.; Truong, C.N.; Jossen, A.; Hesse, H.C. Lithium-ion battery cost analysis in PV-household application. Energy Procedia 2015, 73, 37–47. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Sun, F.; Moura, S.J. Nonlinear predictive energy management of residential buildings with photovoltaics & batteries. J. Power Sources 2016, 325, 723–731. [Google Scholar]

- Segarra-Tamarit, J.; Perez, E.; Alfonso-Gil, J.C.; Arino, C.; Aparicio, N.; Beltran, H. Optimized management of a residential microgrid using a solar power estimation database. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics, Edinburgh, UK, 19–21 June 2017. [Google Scholar]

- Barcellona, S.; Piegari, L.; Musolino, V.; Ballif, C. Economic viability for residential battery storage systems in grid-connected PV plants. IET Renew. Power Gener. 2018, 12, 135–142. [Google Scholar] [CrossRef]

- Munzke, N.; Schwarz, B.; Barry, J. The Impact of Control Strategies on the Performance and Profitability of Li-Ion Home Storage Systems. Energy Procedia 2017, 135, 472–481. [Google Scholar] [CrossRef]

- Beltran, H.; Garcia, I.T.; Alfonso-Gil, J.C.; Perez, E. Levelized Cost of Storage for Li-Ion Batteries Used in PV Power Plants for Ramp-Rate Control. IEEE Trans. Energy Convers. 2019, 34, 554–561. [Google Scholar] [CrossRef]

- Kakimoto, N.; Satoh, H.; Takayama, S.; Nakamura, K. Ramp-Rate Control of Photovoltaic Generator With Electric Double-Layer Capacitor. IEEE Trans. Energy Convers. 2009, 24, 465–473. [Google Scholar] [CrossRef]

- Du, Y.; Jain, R.; Lukic, S.M. A novel approach towards energy storage system sizing considering battery degradation. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition, Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Swierczynski, M.; Stroe, D.I.; Stan, A.I.; Teodorescu, R.; Sauer, D.U. Selection and performance-degradation modeling of LiMo2/Li4Ti5O12 and LiFePO4/C battery cells as suitable energy storage systems for grid integration with wind power plants: An example for the primary frequency regulation service. IEEE Trans. Sustain. Energy 2014, 5, 90–101. [Google Scholar] [CrossRef]

- Wankmüller, F.; Thimmapuram, P.R.; Gallagher, K.G.; Botterud, A. Impact of battery degradation on energy arbitrage revenue of grid-level energy storage. J. Energy Storage 2017, 10, 56–66. [Google Scholar] [CrossRef] [Green Version]

- Berglund, F.; Zaferanlouei, S.; Korpas, M.; Uhlen, K. Optimal operation of battery storage for a subscribed capacity-based power tariff prosumer—A Norwegian case study. Energies 2019, 12, 4450. [Google Scholar] [CrossRef] [Green Version]

- Hoke, A.; Brissette, A.; Smith, K.; Pratt, A.; Maksimovic, D. Accounting for lithium-ion battery degradation in electric vehicle charging optimization. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 691–700. [Google Scholar] [CrossRef]

- Grün, T.; Stella, K.; Wollersheim, O. Impacts on load distribution and ageing in Lithium-ion home storage systems. Energy Procedia 2017, 135, 236–248. [Google Scholar] [CrossRef]

- Angenendt, G.; Zurmühlen, S.; Mir-Montazeri, R.; Magnor, D.; Sauer, D.U. Enhancing Battery Lifetime in PV Battery Home Storage System Using Forecast Based Operating Strategies. Energy Procedia 2016, 99, 80–88. [Google Scholar] [CrossRef] [Green Version]

- Abdulla, K.; De Hoog, J.; Muenzel, V.; Suits, F.; Steer, K.; Wirth, A.; Halgamuge, S. Optimal Operation of Energy Storage Systems Considering Forecasts and Battery Degradation. IEEE Trans. Smart Grid 2018, 9, 2086–2096. [Google Scholar] [CrossRef]

- Hesse, H.C.; Martins, R.; Musilek, P.; Naumann, M.; Truong, C.N.; Jossen, A. Economic optimization of component sizing for residential battery storage systems. Energies 2017, 10, 835. [Google Scholar] [CrossRef]

- Vieira, F.M.; Moura, P.S.; de Almeida, A.T. Energy storage system for self-consumption of photovoltaic energy in residential zero energy buildings. Renew. Energy 2017, 103, 308–320. [Google Scholar] [CrossRef]

- Castillo-Cagigal, M.; Caamano-Martín, E.; Matallanas, E.; Masa-Bote, D.; Gutiérrez, A.; Monasterio-Huelin, F.; Jiménez-Leube, J. PV self-consumption optimization with storage and Active DSM for the residential sector. Sol. Energy 2011, 85, 2338–2348. [Google Scholar] [CrossRef] [Green Version]

- Telaretti, E.; Ippolito, M.; Dusonchet, L. A simple operating strategy of small-scale battery energy storages for energy arbitrage under dynamic pricing tariffs. Energies 2016, 9, 12. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Wei, Y.L.; Cao, P.F.; Lin, M.C. Energy storage system: Current studies on batteries and power condition system. Renew. Sustain. Energy Rev. 2018, 82, 3091–3106. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Baghdadi, I.; Briat, O.; Delétage, J.Y.; Gyan, P.; Vinassa, J.M. Lithium battery aging model based on Dakin’s degradation approach. J. Power Sources 2016, 325, 273–285. [Google Scholar] [CrossRef]

- Cordoba-Arenas, A.; Onori, S.; Guezennec, Y.; Rizzoni, G. Capacity and power fade cycle-life model for plug-in hybrid electric vehicle lithium-ion battery cells containing blended spinel and layered-oxide positive electrodes. J. Power Sources 2015, 278, 473–483. [Google Scholar] [CrossRef] [Green Version]

- Tang, L.; Rizzoni, G.; Onori, S. Energy management strategy for HEVs including battery life optimization. IEEE Trans. Transp. Electrif. 2015, 1, 211–222. [Google Scholar] [CrossRef]

- Ecker, M.; Nieto, N.; Käbitz, S.; Schmalstieg, J.; Blanke, H.; Warnecke, A.; Sauer, D.U. Calendar and cycle life study of Li(NiMnCo)O2 -based 18650 lithium- ion batteries. J. Power Sources 2013, 248, 839–851. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Delaille, A.; Grolleau, S.; Duclaud, F. SIMCAL Project: Calendar Aging Results Obtained on a Panel of 6 Commercial Li-Ion Cells. In Proceedings of the 224ème Electrochemical Energy Summit de l’Electrochemical Society, San Fransisco, CA, USA, October 2013. [Google Scholar]

- Nishi, Y. Lithium-Ion Batteries. In Lithium-Ion Batteries, Science and Technologies; Masaki, Y.A., Brodd, R.J., Kozawa, A., Eds.; Springer: New York, NY, USA, 2014; pp. 21–39. [Google Scholar]

- Li, J.; Wang, D.; Pecht, M. An electrochemical model for high C-rate conditions in lithium-ion batteries. J. Power Sources 2019, 436, 226885. [Google Scholar] [CrossRef]

- Wu, Y.; Keil, P.; Schuster, S.F.; Jossen, A. Impact of Temperature and Discharge Rate on the Aging of a LiCoO2/LiNi0.8 Co0.15Al0.05O2 Lithium-Ion Pouch Cell. J. Electrochem. Soc. 2017, 164, A1438–A1445. [Google Scholar] [CrossRef]

- Stroe, D.; Swierczynski, M.; Stan, A.; Teodorescu, R. Accelerated Lifetime Testing Methodology for Lifetime Estimation of Lithium-ion Batteries used in Augmented Wind Power Plants. IEEE Trans. Ind. Appl. 2014, 50, 690–698. [Google Scholar] [CrossRef]

- SAFT Batteries. L41M Cell Datasheet. Available online: http://www.houseofbatteries.com/documents/VL41M.pdf (accessed on 21 November 2019).

- Beltran, H.; Barahona, J.; Vidal, R.; Alfonso, J.C.; Ariño, C.; Pérez, E. Ageing of different types of batteries when enabling a PV power plant to enter electricity markets. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1986–1991. [Google Scholar]

- Schmalstieg, J.; Käbitz, S.; Ecker, M.; Sauer, D.U. A holistic aging model for Li(NiMnCo)O2 based 18650 lithium-ion batteries. J. Power Sources 2014, 257, 325–334. [Google Scholar] [CrossRef]

- Sanyo. UR18650E Cell Datasheet. Available online: https://www.master-instruments.com.au/products/62415/UR18650E.html (accessed on 21 November 2019).

- BYD. BYD B-Box Limited Warranty Letter. 2018. Available online: https://solar-distribution.baywa-re.com.au/fileadmin/Solar_Distribution_AU/04_Products/03_Media/BYD/BYD_Battery-Box_LV_Warranty_Letter_Australia_.pdf (accessed on 21 November 2019).

- LG Chem, RESU Battery Storage Systems Limited Warranty. 2018. Available online: https://www.sharp.es/cps/rde/xbcr/documents/documents/Service_Information/Warranty/RESU3.3-6.5-10-Limited-Warranty-EU-Standard-EN-v1.1-191030.pdf (accessed on 21 November 2019).

- Camacho, E.F.; Bordons, C. Model Predictive Control; Springer: Berlin, Germany, 2004. [Google Scholar]

- Perez, E.; Beltran, H.; Aparicio, N.; Rodriguez, P. Predictive power control for PV plants with energy storage. IEEE Trans. Sustain. Energy 2013, 4, 482–490. [Google Scholar] [CrossRef] [Green Version]

- Molteni, F.; Buizza, R.; Palmer, T.N.; Petroliagis, T. The ECMWF Ensemble Prediction System: Methodology and validation. Q. J. R. Meteorol. Soc. 1996, 122, 73–119. [Google Scholar] [CrossRef]

- Dirección General de Política Energética y Minas—Ministerio para la Transición Ecológica. In Resolución de 21 de Diciembre de 2018, por la que se Aprueba el Perfil de Consumo y el Método de Cálculo a Efectos de Liquidación de Energía; Boletín Oficial del Estado Español (BOE): Madrid, Spain, 2018; pp. 536–713.

| Battery Model | ||||||

|---|---|---|---|---|---|---|

| Ref. LFP (Saft VL41M) | 3.087 × 10−7 | 6.87 × 10−5 | 0.05176 | 0.02715 | - | - |

| SoA LFP (BYD B-BOX) | 1.985 × 10−7 | 4.42 × 10−5 | 0.0510 | 0.02676 | - | - |

| Ref. NMC (Sanyo UR18650E) | - | - | - | - | 7.54 × 106 | 4.081 × 10−3 |

| SoA NMC (LG Chem RESU6.5) | - | - | - | - | 3.02 × 106 | 1.632 × 10−3 |

| Period | On-Peak | Off-Peak |

|---|---|---|

| Purchase price (c€/kWh) | 22 | 11 |

| Sale price (c€/kWh) | 5 | 5 |

| Model of Battery | PV Power (kW) | Battery Capacity (kWh) | Calendar Ageing EOL 70% | Cycling Ageing EOL 70% | Lifetime Expect. (years) | Calendar Ageing EOL 60% | Cycling Ageing EOL 60% | Lifetime Expect. (years) |

|---|---|---|---|---|---|---|---|---|

| LFP Ref | 2 | 3.3 | 22.07 | 7.94 | 3.56 | 29.43 | 10.57 | 6.30 |

| LFP Ref | 2 | 6.5 | 22.82 | 7.19 | 3.76 | 30.41 | 9.59 | 6.63 |

| LFP Ref | 2 | 10 | 24.40 | 5.61 | 4.38 | 32.57 | 7.44 | 7.59 |

| LFP Ref | 4 | 3.3 | 22.09 | 7.92 | 3.57 | 29.47 | 10.53 | 6.32 |

| LFP Ref | 4 | 6.5 | 22.39 | 7.62 | 3.65 | 29.89 | 10.12 | 6.45 |

| LFP Ref | 4 | 10 | 23.40 | 6.60 | 4.01 | 31.22 | 8.78 | 7.02 |

| LFP SoA | 2 | 3.3 | 19.12 | 10.88 | 10.16 | 25.53 | 14.47 | 17,80 |

| LFP SoA | 2 | 6,5 | 20.00 | 10.01 | 11.06 | 26.69 | 13.32 | 19.48 |

| LFP SoA | 2 | 10 | 22.02 | 7.98 | 13.38 | 29.38 | 10.62 | 23.53 |

| LFP SoA | 4 | 3.3 | 19.15 | 10.85 | 10.20 | 25.56 | 14.45 | 17.85 |

| LFP SoA | 4 | 6.5 | 19.52 | 10.48 | 10.53 | 26.04 | 13.96 | 18.55 |

| LFP SoA | 4 | 10 | 20.73 | 9.27 | 11.81 | 27.67 | 12.33 | 20.88 |

| NMC Ref | 2 | 3.3 | 15.01 | 15.00 | 2.05 | 21.65 | 18.37 | 3.34 |

| NMC Ref | 2 | 6.5 | 17.55 | 12.45 | 2.87 | 24.86 | 15.15 | 4.57 |

| NMC Ref | 2 | 10 | 20.26 | 9.74 | 4.19 | 28.40 | 11.61 | 6.47 |

| NMC Ref | 4 | 3.3 | 15.60 | 14.40 | 2.07 | 22.37 | 17.64 | 3.33 |

| NMC Ref | 4 | 6.5 | 17.47 | 12.54 | 2.57 | 24.63 | 15.38 | 4.18 |

| NMC Ref | 4 | 10 | 19.76 | 10.25 | 3.08 | 27.73 | 12.28 | 4.65 |

| NMC SoA | 2 | 3.3 | 17.78 | 12.22 | 8.49 | 25.20 | 14.80 | 13.48 |

| NMC SoA | 2 | 6.5 | 19.98 | 10.02 | 11.58 | 27.93 | 12.07 | 18.18 |

| NMC SoA | 2 | 10 | 22.43 | 7.57 | 16.02 | 30.98 | 9.02 | 24.58 |

| NMC SoA | 4 | 3.3 | 18.27 | 11.73 | 8.41 | 25.80 | 14.20 | 13.31 |

| NMC SoA | 4 | 6.5 | 19.80 | 10.20 | 10.37 | 27.71 | 12.29 | 16.19 |

| NMC SoA | 4 | 10 | 21.85 | 8.15 | 11.57 | 30.23 | 9.77 | 17.75 |

| Model of Battery | PV Power (kW) | Battery Capacity (kWh) | Lifetime Exp. Irradiance’16 (Years) | Lifetime Exp. Irradiance’17 (Years) | Lifetime Exp. Irradiance’18 (Years) |

|---|---|---|---|---|---|

| LFP SoA | 2 | 3.3 | 18.96 | 18.99 | 18.64 |

| LFP SoA | 2 | 6.5 | 21.91 | 21.80 | 21.49 |

| LFP SoA | 2 | 10 | 25.90 | 25.82 | 25.52 |

| LFP SoA | 4 | 3.3 | 18.15 | 18.21 | 18.07 |

| LFP SoA | 4 | 6.5 | 19.26 | 19.14 | 19.01 |

| LFP SoA | 4 | 10 | 22.48 | 22.57 | 22.42 |

| Model of Battery | PV Power (kW) | Battery Capacity (kWh) | Lifetime Exp. Location A (years) | Lifetime Exp. Location B (Years) | Lifetime Exp. Location C (Years) |

|---|---|---|---|---|---|

| NMC SoA | 2 | 3.3 | 13.50 | 13.12 | 12.93 |

| NMC SoA | 2 | 6.5 | 18.58 | 16.59 | 15.71 |

| NMC SoA | 2 | 10 | 25.43 | 21.45 | 19.81 |

| NMC SoA | 4 | 3.3 | 13.15 | 12.47 | 12.33 |

| NMC SoA | 4 | 6.5 | 16.09 | 14.98 | 14.35 |

| NMC SoA | 4 | 10 | 18.23 | 16.67 | 15.68 |

| Model of Battery | PV Power (kW) | Battery Capacity (kWh) | Lifetime Exp. Household 1 (years) | Lifetime Exp. Household 2 (years) | Lifetime Exp. Household 3 (years) |

|---|---|---|---|---|---|

| LFP SoA | 2 | 3.3 | 17.64 | 17.68 | 17.95 |

| LFP SoA | 2 | 6.5 | 18.67 | 18.79 | 20.13 |

| LFP SoA | 2 | 10 | 21.99 | 22.45 | 23.96 |

| LFP SoA | 4 | 3.3 | 17.62 | 17.61 | 17.66 |

| LFP SoA | 4 | 6.5 | 18.28 | 18.29 | 18.65 |

| LFP SoA | 4 | 10 | 20.72 | 21.16 | 22.27 |

| NMC SoA | 2 | 3.3 | 13.11 | 13.12 | 13.66 |

| NMC SoA | 2 | 6.5 | 16.44 | 16.59 | 18.60 |

| NMC SoA | 2 | 10 | 20.92 | 21.45 | 24.28 |

| NMC SoA | 4 | 3.3 | 12.55 | 12.47 | 12.77 |

| NMC SoA | 4 | 6.5 | 14.98 | 14.98 | 15.62 |

| NMC SoA | 4 | 10 | 16.55 | 16.67 | 17.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beltran, H.; Ayuso, P.; Pérez, E. Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage. Energies 2020, 13, 568. https://doi.org/10.3390/en13030568

Beltran H, Ayuso P, Pérez E. Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage. Energies. 2020; 13(3):568. https://doi.org/10.3390/en13030568

Chicago/Turabian StyleBeltran, Hector, Pablo Ayuso, and Emilio Pérez. 2020. "Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage" Energies 13, no. 3: 568. https://doi.org/10.3390/en13030568

APA StyleBeltran, H., Ayuso, P., & Pérez, E. (2020). Lifetime Expectancy of Li-Ion Batteries used for Residential Solar Storage. Energies, 13(3), 568. https://doi.org/10.3390/en13030568