Abstract

Healthcare institutions consume large amounts of energy, ranking the second highest energy-intensive buildings in the commercial sector. Within developed countries, the energy consumption of healthcare institutions may account for up to 18% of the overall energy usage in commercial sectors. Within developing countries, such as South Africa, the energy consumption of healthcare institutions is observed to be a close second to the food service sector. Energy consumption of healthcare institutions per bed typically range from 43–92 kWh per day. In this paper, the largest energy consumers in South African healthcare institutions are identified and appropriate energy-efficiency (EE) initiatives are proposed, in terms of performance, operation, equipment and technology efficiency (POET). Two main thermal energy consumers are identified as heating, ventilation and air conditioning (HVAC) and water-heating systems. These systems are critical to patient health and may be classified as non-deferrable loads. Therefore, several initiatives are suggested to improve the energy efficiency and demand-side management capability of these systems. These initiatives are subdivided into different levels: the conceptual level, active level, technical and further improvement level, as defined in the POET framework. At each level, energy-efficiency initiatives are introduced based on potential energy savings and the effort required to achieve these savings. In addition, model predictive control (MPC) approaches are discussed and reviewed as part of the further improvement section. Average possible energy savings ranged from 50%–70% at the conceptual level, while energy savings of 15%–30% may be expected for energy-efficiency initiatives at the active level. EE activities at the technical level and the further improvement level may result in savings of 50%–70% and 5%–10%, respectively.

1. Introduction

According to [1,2], the energy consumption of commercial buildings in developed countries (USA, UK, EU, Spain), ranges from 8%–18%, while the world average for these buildings account for up to 7% of the total energy consumed. Healthcare institutions are the fifth highest energy consumer in the commercial sector, in terms of energy consumption. However, when evaluating the energy-use intensity (EUI) of each building type, healthcare institutions rank the second highest in most developed countries; second only to the food service sector. A similar observation may be made for the South African case, where the EUI of healthcare institutions is approximately three times that of typical commercial buildings. Additionally, it was noted that the energy consumption of healthcare institutions ranges from approximately 43–92 kWh/bed/day [3]. The high energy intensity of these buildings may be attributable to energy-intensive systems that are required to operate at full scale, 24 h a day. Continuous operational requirements result in high energy costs. This is particularly true for systems subjected to time-based pricing structures, otherwise called time-of-use (TOU) tariffs implemented by the national electricity supplier in South Africa. However, in the case of health care institutions, loads may be seen as undeferrable, in order to satisfy sensitive load requirements. This results in substantial electricity costs due to equipment being operated through peak periods where electricity costs are highest. In hindsight, with the recent hikes in electricity tariffs in South Africa, exceedingly expensive healthcare is expected. This introduces a problem for the country’s citizens, many of whom are incapable of affording this basic necessity [4].

In order to reduce the impact that electricity costs have on healthcare expenses, energy-intensive systems need to be effectively managed in terms of energy efficiency. Energy-efficiency studies and initiatives may be applied to healthcare buildings, which could result in substantial energy and cost savings and in turn reduce the strain on the national energy grid. A large body of research with the explicit objective to improve energy efficiency of specific systems in buildings has been conducted, particularly in the past two decades [5,6]. However, a comprehensive review of scientific articles on energy-efficiency initiatives in healthcare institutions is currently lacking, substantiating the need for such a review. Therefore, the aim of this research is to conduct a review using a well-established energy-management framework. The foremost used method or framework for implementing energy-management activities, is the stepwise loop called the Plan, Do, Check and Act (PDCA) cycle. The PDCA cycle, also known as the Deming cycle is an iterative approach and forms the basis against which the ISO 50001 standard procedure is realized. The PDCA cycle consists of four sequential stages, defined as; Plan, Do, Check and Act (PDCA) [7].

The first stage incorporates energy policy and planning with the aim of obtaining an initial energy baseline, energy performance indicators, strategic and operative energy objectives and action plans. The evaluations and data obtained from this stage form the basis for the following improvement process, otherwise noted as the “Do” phase. In this second stage, action takes place in the form of implementing the planned energy-management practices. The “Check” phase is represented by monitoring and measurement of energy related performance of the systems that were implemented in the previous phase. The results obtained at this phase are evaluated and compared to objectives previously established in the planning period. As part of the last stage, the “Act” stage, the acquired results are broken down into reports, which forms the basis for further improvement studies. These phases are arranged in a circular cycle, which implies that after the last stage has been finalized, all stages will feature again in the same sequential manner as to ensure continuous improvement [8].

The PDCA model has the advantage of being a powerful, yet simple methodology to resolve new and recurring issues in any industry. This is largely due to the fact that its core commitment is continuous improvement. However, three major drawbacks relevant to energy management include: oversimplification of the improvement process, its reactive nature and the inability to encourage radical innovation. The oversimplified and reactive nature of the PDCA model have an overlapping problem. The problem introduces itself with the PDCA’s circular paradigm and the first stage of the model. It may be assumed that any energy-management program starts with planning. This may not always maximize the potential for energy-efficiency improvement in practice, as such, deviation from the rigid circular structure is often necessary [9].

Another major drawback, similarly as a consequence of the circular paradigm and the step-by-step process, is the limitation placed on radical innovation. The core philosophy of PDCA is planning and implementing an activity first and then evaluating the implications or resultant drawbacks of the activity after implementation. Therefore, the PDCA model has its focus on correcting mistakes rather than preventing it. Consequently, the time required to implement a program with the best possible outcome, in this case, maximized energy efficiency, is increased substantially [10].

In retrospect, an alternative approach is deemed necessary to effectively evaluate the maximum potential energy savings that the various existing energy-efficiency initiatives may offer. Energy efficiency may consist of several aspects, such as operational efficiency, performance efficiency, carrier efficiency, maintenance efficiency, conversion efficiency, fuel efficiency, etc. Literature based on these aspects applied to various cases are plentiful and widely available. However, it may be observed that these aspects are not clearly defined or classified and do not follow similar points of departure on the constituents of energy efficiency [11].

Therefore, an amalgamating classification of energy efficiency in terms of performance, operation, equipment, and technology (POET) was presented in 2010 by the authors; Xiaohua Xia and Jiangfeng Zhang in [12].

Energy efficiency, in general, is defined as the percentage of the total energy supplied to a process that is consumed as useful work and not wastefully expended as heat or other forms of energy [13]. This is the key principle that is taken into consideration in various energy management, renewable and sustainable energy developments. As stated in [12], multiple aspects exist in the broad category of energy efficiency. These aspects are not clearly defined or categorized and introduce a problem in the energy-management field. Addressing this problem entails the design of a framework or guideline, in order to provide clear cut boundaries between various energy-efficiency initiatives, for effective and sustainable energy management. Therefore, energy efficiency may be divided into four components: performance (P), operation (O), equipment (E), and technology (T) efficiency, or POET in short, as described in [12]. The POET framework has been successfully applied to various types of systems and buildings; these include: commercial buildings [14], heavy haul trains [12], conveyer belt systems [15], wastewater treatment processes [16], pumping systems [17], etc. As a result of applying the POET framework to these case studies, the most effective energy-efficiency initiatives could be identified to maximize energy and associated cost savings. As noted in [12,14,15,16,17], effective energy management is highly dependent on the energy efficiency of electrical equipment used in any building. Maximizing the potential energy cost savings in these buildings may, in some cases, be a formidable task. To this end, an energy-management program may be divided into four levels;

The initial level may incorporate simple energy-efficiency activities, while the subsequent levels increases with complexity. Therefore, the first level may be classified as the conceptual level, which entails a basic energy consumption analysis, in order to identify energy-efficiency problems within a particular building. The solutions to these problems within the conceptual level usually refer to the Pareto principle, also known as the 80/20 rule. This rule implies that if 20% effort is to be applied, an 80% return will be made [18].

The second level, the active level, entails a more complex approach. The active level requires more effort, compared to the previous level, resulting in a less than 80% return. Furthermore, the active level requires a validation of the problem, addressed at the first level using additional strategies and equipment, which may result in a further potential improvement in efficiency.

The third level, the technical level of the hierarchy, may involve a redesign in terms of retrofitting or introducing new technologies to replace inefficient existing systems. This level requires further verification of collected data, obtained at the second level for accurate payback period calculations and other relevant feasibility studies.

The last level focuses on optimization, also referred to as the engineering or further possible improvement level. This level often overlaps with the technical level in that validated data is required to apply optimization to existing energy efficient technologies and equipment. Therefore, the last level will provide the maximum possible savings if properly implemented [19].

The layout of this paper is as follows: Section 2 provides an overview of the sustainability of energy-efficiency initiatives based on the POET framework. Section 3 presents the methodology, aim and contribution of the paper. In Section 4, the literature based on the energy efficiency of thermal processes in healthcare institutions are summarized according to the levels of the POET hierarchy. Section 5 outlines the key findings on reviewed literature. Section 6 concludes the paper, while Section 7 offers recommendations for future work.

2. Sustainable Energy Efficiency Based on the Performance, Operation, Equipment and Technology Efficiency (POET) Framework

The sustainability of an energy-management program for the improvement of energy efficiency may be evaluated by considering the following three aspects; organizational structure, compatibility of performance indices and engineering support [14].

A well-designed organizational structure supports the sustainability of an energy-management program. In order to effectively stimulate the POET efficiency activities and in turn the sustainability of an energy-management program, certain external mechanisms such as energy policies, regulations, incentives and penalties are necessary. These mechanisms are usually enforced by the governing body of a country and often prove to be highly effective when appropriately planned and executed. Conversely, internal mechanisms include human sensitization, which involves procedural guidance of workflow, awareness campaigns, skill training, technology roadshows, appointment of energy managers, production exhibitions, etc. [20,21].

The compatibility of performance indices is evaluated in terms of engineering indices and socio-economic indices. Engineering indices may include energy consumption, energy security and other technical indicators. Socio-economic indicators, on the other hand, include energy costs, quality of production, environmental impact, etc. In retrospect, it may be observed that the energy efficiency of a certain system is improved when the engineering indices follow an upward trend, while the opposite is noted when evaluating the socio-economic indices. Therefore, both indices are to be taken into consideration in order to guarantee a positive growth in the performance efficiency of an energy system. This will ultimately provide additional support for the sustainability of an energy-management program [22].

Engineering support plays a crucial role in evaluating the technical feasibility of a system. In hindsight, support entails energy analysis, system modelling and the implementation of relevant optimization techniques. Suitable engineering support will improve the reliability of energy solutions, while ensuring sustainability [23].

3. Method

The POET perspective, originally developed by Xiaohua Xia and Jiangfeng Zhang, serves as a unifying classification of energy efficiency in terms of performance, operation, equipment, and technology efficiency (POET for short) [12].

In this paper a comprehensive review on energy efficiency in healthcare institutions is conducted from the POET perspective. The context to substantiate the need for such a review has been outlined in the introduction. The remainder of this section will provide an overview on how the review was conducted as well as the advantages and drawbacks of this approach.

A systemic review methodology was followed based on the POET perspective to assess the possible energy-efficiency improvements that may be applied to healthcare institutions. Systemic reviews are most often used in clinical practice to provide the highest level of reliable evidence [24]. The aim of such reviews is to provide a broad, exhaustive summary of current available research evidence. As a result, the researcher is forced to investigate all pertinent studies as to not be constrained by their own boundaries of experience [25]. In addition, the systemic review and by extension, the POET perspective, aims to answer predefined research questions. Therefore, the aim of this study may further be expanded to answer the following three research questions:

Research Question 1: What is the existing evidence base regarding potential energy and cost savings of current energy-efficiency initiatives applied to these buildings available in literature?

Research Question 2: Can healthcare institutions reach energy targets in order to align with trajectories developed by the Construction Industry Development Board (CIDB) and the Council for Scientific and Industrial Research (CSIR) through effective implementation of these initiatives?

Research Question 3: Based on the above research questions, what is the economic feasibility of implementing energy-efficiency initiatives to reach these energy targets.

With reference to the research questions stated above, the POET framework is used to conduct a comprehensive review taking into consideration all aspects of energy efficiency.

The search strategy consisted of identifying relevant studies (all aspects of energy efficiency) within research-based sources, represented by scientific papers available in peer-reviewed conference proceedings and journals. Online databases where consulted in order to retrieve all published articles on the topics related to improving the energy efficiency of thermal processes in healthcare institutions. The decision to evaluate only thermal processes is justified in Section 4 of this paper. All efforts have been made to obtain the most recent publications, whereas older studies were only consulted out of absolute necessity. The major sources used to identify relevant scientific literature were; Google Scholar, ScienceDirect, Institute of Electrical and Electronics Engineers (IEEE) Xplore digital library and PubMed Central.

The selection criteria for this study, besides the general criteria, were the following; only articles in English were considered, articles available in full-text, date of publication, relevance to the search topics were essential.

In hindsight, evaluating the available literature subjected to the above stated search strategy in conjunction with the POET perspective offers a clear advantage over the traditional PDCA method in that every avenue of the broad category of energy efficiency is consulted [26].

Therefore, the contribution of this study is a comprehensive assessment of the potential energy and associated cost savings that may result if appropriate sustainable energy-efficiency measures were to be implemented. Additionally, the presented data with respect to the ranged average payback periods or economic feasibility of the initiatives at each level may provide valuable insight to energy managers during the planning phase of energy-efficiency projects.

The drawback of the POET perspective presents itself when energy-efficiency initiatives are evaluated and categorized within the hierarchy of the framework [27]. It may be challenging to determine the exact amount of “effort” required compared to the potential “profit” of implementing each energy-efficiency initiative as described by the pareto principle in the introduction section. This means that at each level of the hierarchy, it is necessary to express the quantitative data obtained from literature in terms of energy savings and associated payback periods in averaged ranges rather than exact values.

4. Energy-Efficiency Initiatives Based on the POET Energy-Management Framework

4.1. Conceptual Level

4.1.1. Technology Efficiency

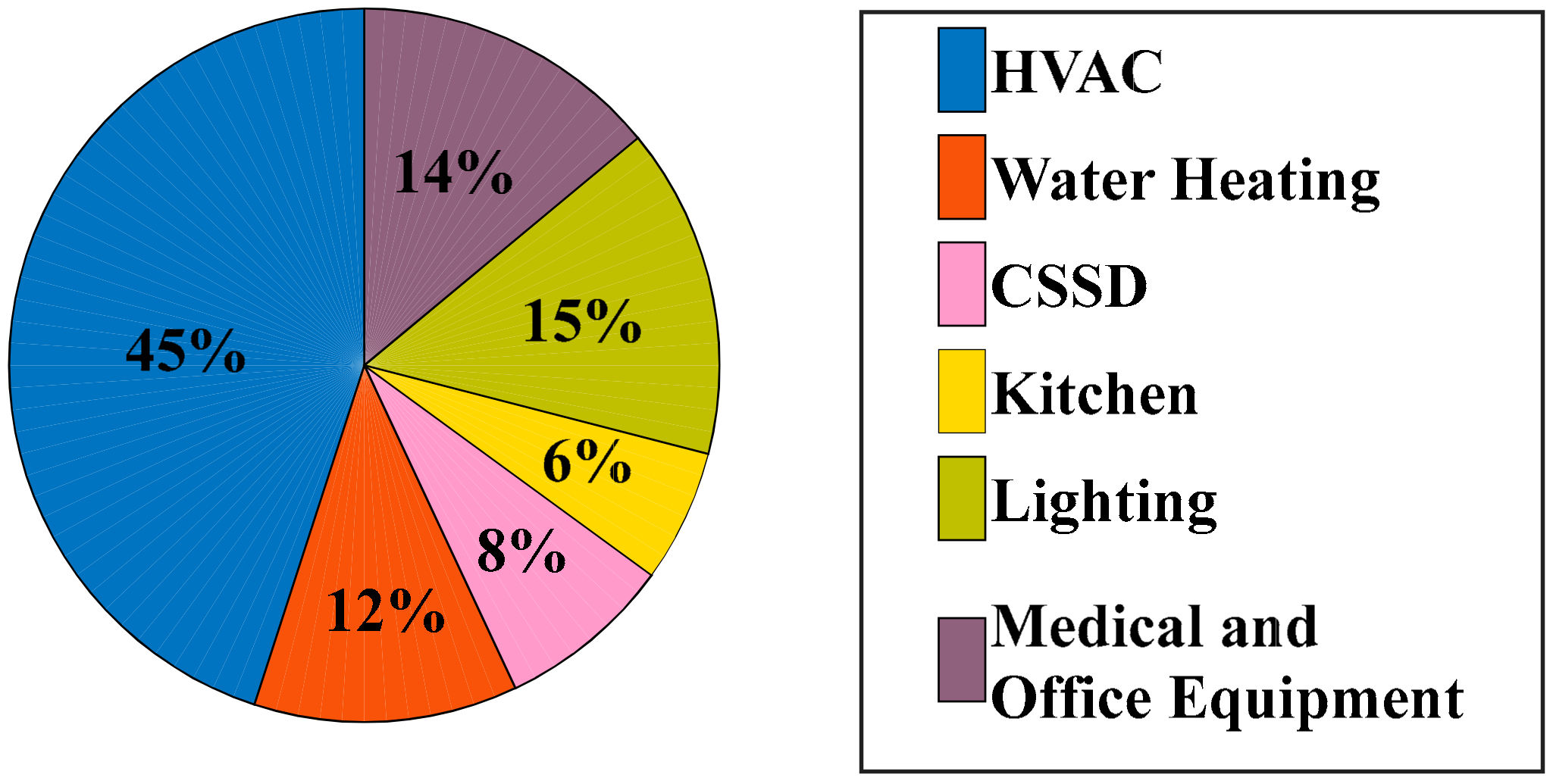

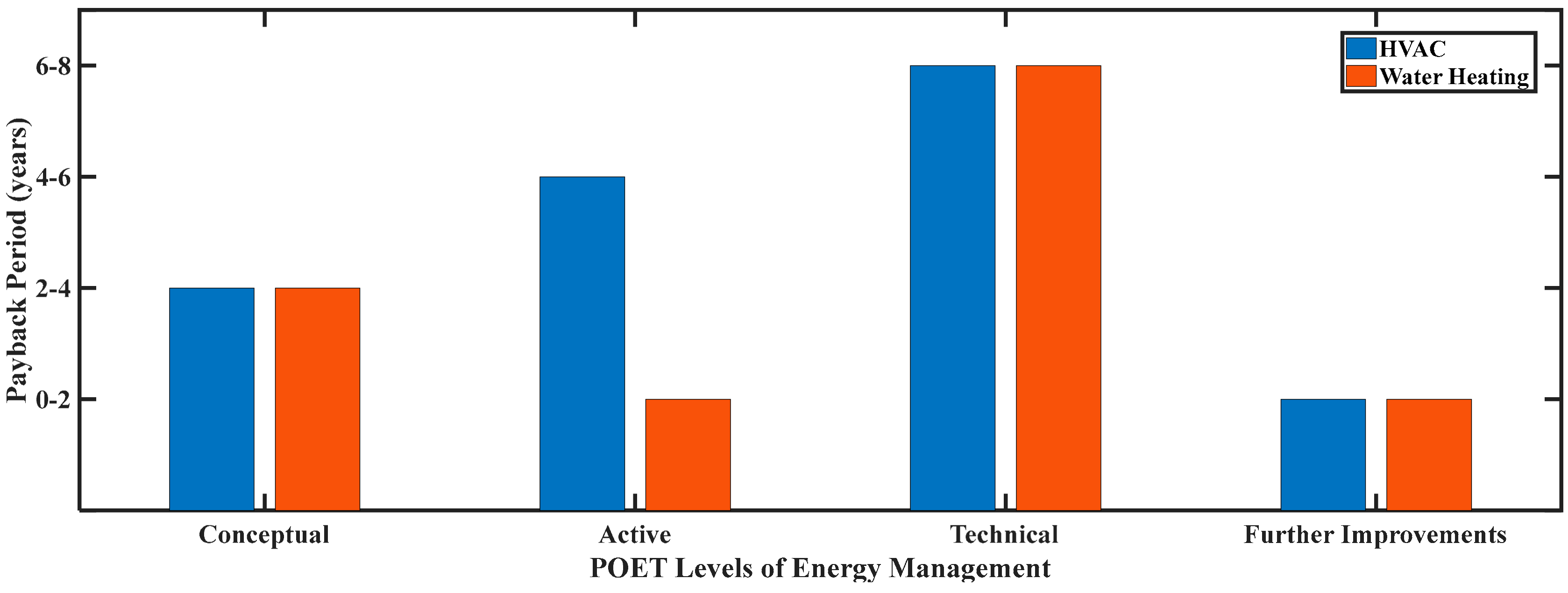

Energy consumption data of healthcare institutions may be analyzed, in order to obtain the typical energy usage spectrum. In Figure 1, the average energy usage of multiple healthcare institutions in South Africa is shown in the form of a pie chart [28]. From the chart, it is evident that heating, ventilation and air-conditioning (HVAC) systems are the single largest energy-intensive processes in healthcare institutions, contributing to 45% of the overall energy consumption. Lighting consumes approximately 15% of the total energy in healthcare institutions and is the second largest consumer of energy. Medical and office equipment may consume up to 14% of energy, while the processes involved in water heating are responsible for 12% of energy used. The central sterile services department (CSSD) consumes significantly less energy when compared to other processes, followed by the kitchen services department occupying 6% of the total energy usage spectrum.

Figure 1.

Energy usage spectrum of hospital buildings in South Africa [28].

In retrospect, the two major thermal energy-intensive processes, accounting for 59% of the overall energy consumption may be identified as HVAC and water-heating systems. In this case, the thermal processes are selected due to the large amounts of energy consumed and the potential for energy-efficiency improvement. The remaining categories account for approximately 41% of the total energy consumed, the largest of which are lighting, medical and office equipment followed by smaller loads, such as the kitchen and CSSD.

4.1.2. Equipment Efficiency

After identifying energy-intensive processes, in this case HVAC and water-heating systems, suitable decisions may be made to prioritize and justify equipment replacement. Improving energy efficiency at this level may entail replacement or retro fitment of existing equipment. In general, this improvement may further be referred to as building energy-efficiency retrofit (BEER).

Heating, Ventilation and Air-Conditioning (HVAC) Equipment

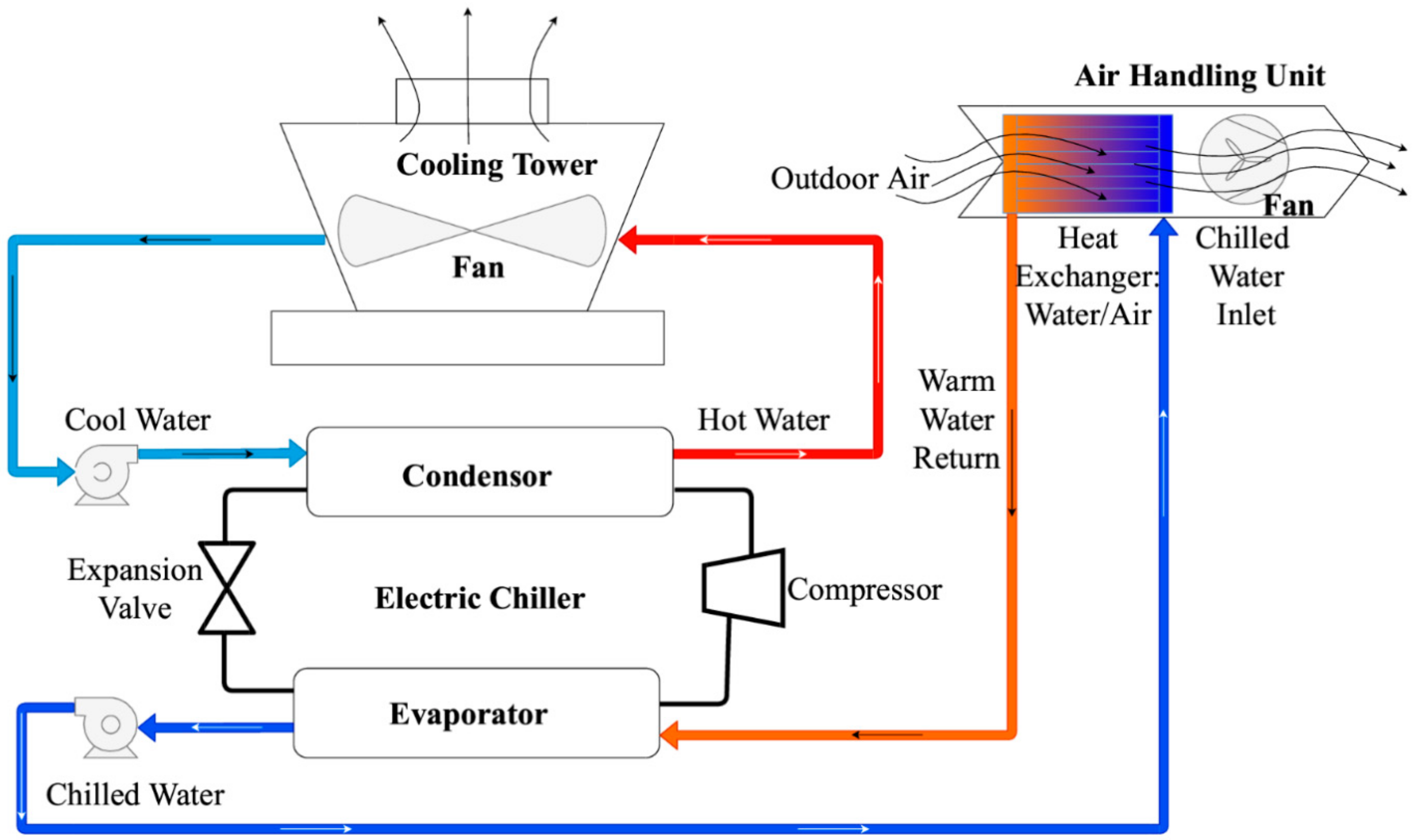

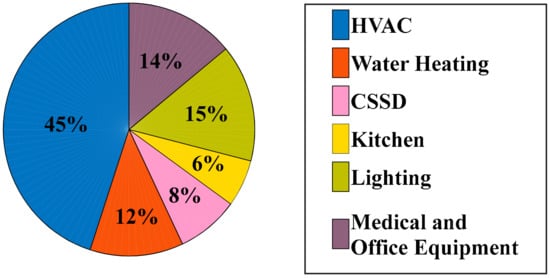

Considering HVAC processes, improved equipment components available on the market may be purchased and installed, replacing existing inefficient components. The typical layout of a large-scale HVAC system is illustrated in Figure 2. According to Ref [29], typical energy usage of HVAC components may be divided into five categories, these are; fans, cooling, heating, pumps and cooling towers. The energy usage of fans, cooling and heating account for 34%, 27% and 17%, respectively. Pumps and cooling towers are responsible for 16% and 6%, respectively. In hindsight, replacing existing equipment, responsible for these energy-intensive processes with higher efficiency equipment, may offer substantial savings. Furthermore, existing systems are usually outdated and subjected to poor performance, due to degradation over time. The main contributor to the degradation of these systems may be a result of continuous operation, poor maintenance and prolonged exposure to environmental conditions.

Figure 2.

Heating, ventilation and air-conditioning (HVAC) system layout.

Moreover, recently developed equipment may offer substantial improvements in terms of energy efficiency. For instance, the use of variable speed drives to control compressor systems in chillers, as opposed to standalone fixed speed compressors, may offer substantial savings. A demand response component is introduced, as opposed to the constant supply of compressed refrigerant being delivered by the conventional system. In addition, variable speed drives have similarly been introduced to water pumps and fans, to obtain further efficiency gains. Pumps are located in both the evaporator and condenser sections, while fans, responsible for heat extraction and airflow regulation, are located at the condenser section and the air-handling units, respectively.

Other improvements in HVAC design may incorporate permanent magnet synchronous motors, rather than induction motors, offering average energy-efficiency gains of up to 10.4% across the total speed range. To put this into perspective, the overall energy savings in HVAC systems may be as high as 8.58% as a result of replacing induction motors. Permanent magnet synchronous motors may replace all existing induction motors in the HVAC system, so that overall energy efficiency may be increased. Additionally, permanent magnet synchronous motors usually operate at a near constant efficiency of approximately 96%, at any given speed percentile.

Moreover, when considering the evaporator, significant advancements have been made in recent years to improve evaporator performance. The most commonly used evaporator design in the past was the flooded type, where refrigerant completely covered water conduits within the evaporator. Two other arrangements were introduced to decrease the amount of refrigerant required to deliver the same results as the most commonly utilized system i.e., the flooded type. A reduction in refrigerant may result in less energy spent in terms of work required to compress and pump refrigerant around the cooling loop. These improved evaporator systems comprise of the mixed falling (MF) film evaporator and the full falling (FF) film evaporator. The MF type evaporator was observed to use approximately 15% less refrigerant than the conventional flooded type, while the FF type may reduce the required refrigerant by up to 40%, as compared to the flooded type. Therefore, in choosing the FF type, the energy required through compression and pumping of the refrigerant may be reduced by approximately 40%. This roughly translates into energy savings of approximately 10.8%, considering the total energy consumption of HVAC equipment [30]. Additionally, the use of state-of-the-art variable refrigerant flow (VRF) systems may offer savings of 30%–40% on overall HVAC energy consumption [31].

Water-Heating Systems

Hot-water availability in healthcare institutions are of utmost importance to maintain hygiene. While various water-heating systems are available on the market, careful consideration is required in selecting the appropriate water-heating device. Certain trade-offs exist between the various technologies, used for water heating. For instance, the implementation of a heat pump water heater may result in an energy savings of approximately 65%, compared to a traditional electric storage tank water heater (ESTWH) [32]. A major drawback of the heat pump water heater is the high failure rates and investment costs, as compared to the traditional ESTWH. These factors should be considered in the decision-making process, in terms of replacement.

An instantaneous tankless water-heating system, as opposed to the storage tank type water heater, may further be considered. The instantaneous water heater or demand type water heater has the advantage of not being subjected to standby losses, compared to the tank type water heater. A drawback of this type of system are the enormous amounts of energy required to achieve the temperature levels in a significantly short time [33].

Alternatively, the solar water heater may be considered as a standalone system at this level. However, this introduces the problem of renewable energy availability being inadequate, in terms of sufficiently supplying the demand [34]. Hybrid solar water-heating systems are discussed at the technical level, as it forms part of additional equipment retrofits.

4.1.3. Operational Efficiency

Addressing the operational efficiency of a building at this level, might entail basic energy-management activities. The major improvement in operational efficiency may be achieved by mitigating standby energy usage of equipment. The four major energy-consuming processes discussed in the technology and equipment efficiency section at a conceptual level may similarly be addressed in this section, in terms of operational efficiency.

HVAC Equipment

The improvement in operational efficiency in this case, generally entails switching HVAC equipment OFF when consumers are not present and adjusting the set temperature, in order to reduce energy usage.

Dettenkofer et al. [35] conducted an experimental study on the impact of shutting down air-conditioning systems in operating rooms (OR) on infection control and environmental aspects. In the study, the HVAC system was switched OFF for 10 h and particles suspended in the air and near the operating table were counted. The OR air temperature was measured and settle plates were exposed and incubated. Conclusions made from results arising from 13 investigations illustrated that switching HVAC equipment OFF when not in use resulted in no significant increase in microbial contamination. However, it is recommended to initiate ventilation systems at least 30 min before any surgical activity is scheduled to take place. In retrospect, switching air-conditioning systems OFF for 10 h, as opposed to leaving systems running continuously, may result in daily potential energy savings of up to 41%. Similar observations may be made for patient ward sections, provided that necessary hygienic procedures are followed.

In addition, an effective method of decreasing energy usage of HVAC systems entails set point temperature adjustment. This involves increasing the cooling set temperature and decreasing the heating set point temperature. Previous research conducted on this matter has proven that by increasing the cooling set point from 22.2 °C to 25 °C, an approximate average energy saving of 27% may be achieved. Similarly, lowering the heating set point from 21.1 °C to 20 °C, might result in savings of up to 34% [36]. Adapted for the South African climate and extrapolation, calculated annual potential savings may be in the order of 28.8%. This effectively translates into savings of 7.8%, in terms of the overall energy consumed by HVAC processes.

In addition, considering the implementation of variable speed drives at the equipment efficiency stage, basic motor speed matching with thermal loads may be applied, using variable speed drive (VSD) equipment at the operational level. This allows HVAC fans, pumps and compressors to operate in response to varying thermal load requirements, instead of simply operating in the “ON/OFF” mode.

Water-Heating Systems

During hot-water demand occurrences, thermostat set temperature levels may be lowered in order to shorten the ON time durations. According to [37], reducing the water heater thermostat temperature by 10 °C may result in savings of up to 5%.

4.1.4. Performance Efficiency

The performance efficiency is demarcated by the energy performance index (EPI) of the building or process. The energy security, energy consumption, energy cost and carbon emissions per service delivered may form part of a specific building’s EPI.

The energy security of any building may be enhanced by improving the reliability of supply. One method, entails the implementation of a back-up energy system to mitigate the interruption of critical system operations. Popular systems include electrical energy-storage systems, such as battery backups, in the form of uninterruptable power supplies (UPS) or generator sets. Healthcare institutions in particular may prioritize energy security, due to the sensitive nature of load demands, as compared to other commercial-type buildings. UPS systems may be implemented in conjunction with generator systems in order to increase the ride through capability of the power supply, in the event of power disruption. UPS systems may sustain the power supplied to the building for short periods to mitigate the interruption of supply while generator systems are primed. When the generator systems are operational, a supply change-over action will occur, drawing power from the generator, instead of the inactive grid system [38].

The energy consumption indicator, also considered at this level albeit basic, offers a tool for improving the performance efficiency. This is done by evaluating a baseline energy usage profile, taken over a year (monthly intervals) and setting reasonable energy-saving targets to be achieved in subsequent years. This would stimulate the implementation of “quick win” energy-efficiency initiatives [39].

The energy costs and carbon emissions per service delivered, depends on the energy consumption indicator. Assessing the trends of these indices may reveal a directly proportional relationship to the energy consumption indicator. In retrospect, if reduced energy costs and carbon emissions are desired, a decrease in energy consumption is necessary.

Therefore, improving the energy security and reducing the energy consumption of particular building or system will result in an improvement of the performance efficiency and in turn, an increase in the overall energy efficiency [40].

4.2. Active Level

The active level of energy-efficiency improvement may require the implementation of additional equipment and software. This level has its emphasis on validation of the energy usage data and energy-efficiency improvement methods, previously established at the conceptual level. Therefore, at this level, further effort is required to improve overall efficiency.

4.2.1. Technology Efficiency

At this stage, low-cost rudimentary energy-monitoring technologies are implemented and tested. Energy usage may be measured and logged, using web-based energy data acquisition and monitoring technologies.

Web-based energy-monitoring systems may be linked to energy metering devices, in order to transmit real time data to technical personnel for condition monitoring. Real-time data may be accessed on-line for increased convenience. These systems may be set to dispatch alerts to personnel in the event of abnormal energy usage or fault occurrences [41].

4.2.2. Equipment Efficiency

At this stage, obsolete equipment has been replaced with higher efficiency equipment available on the market. However, limited energy-management activities have been applied, increasing the equipment efficiency at the conceptual level. Therefore, in this section, basic energy management through the implementation of additional equipment is considered.

HVAC Equipment

Recently developed HVAC systems, operating at higher efficiencies, have been purchased and installed. Nevertheless, external HVAC equipment efficiency improvement activities have not been considered. Hence, the following may be considered at the active level to enhance HVAC equipment efficiency:

- Implementation of VSD motors may be considered in addition to previously replaced equipment at the conceptual level. This may include the implementation of VSDs to air-handling units to allow for energy efficient speed control, offering additional savings in energy [42].

- Reduce building air leakage by replacing existing insulation of building envelopes with dynamic insulating materials, may offer maximum potential heating and cooling energy savings, particularly in mild weather conditions. Additional insulation may be introduced in the form of double-glazed windows, roof and door insulation, compliant with sans 10400-xa building laws, reducing the total heat exchange through building envelopes [43]. Revolving doors may be installed at entrances if a pressure differential is unavoidable, implementation is subjected to practicality and building accessibility considerations. Addressing building air leakage issues could potentially reduce overall HVAC energy usage by approximately 40% [44].

Water-Heating Systems

Water-heating systems may be subjected to standing or standby losses, in that stored hot water may lose thermal energy to the surrounding ambient air over time. Large standing losses may be predominantly observed in electric storage tank water heaters (ESTWH) and hot-water conduits with poor or no insulation. It is evident that standing losses may not be avoided all together, rather a reduction is possible. This may be accomplished by implementing additional insulation to hot-water storage tanks (geyser blankets) and conduits leading to points of hot-water consumption (pipe lagging). Geyser blankets may be introduced to hot-water storage tanks to promote energy savings of up to 21.74% per day, while pipe lagging may result in energy savings of up to 13.04%. Combined savings, as a result of insulation may yield savings of up to 26.97% [45].

Standby losses may be prevented to a certain degree, by means of implementing low-cost timer systems to decrease the switching frequency of ESTWH. Timer systems may be set to relay power to the ESTWH system at a predetermined time prior to when large hot-water demands occur. These timer systems may work in conjunction with thermostats within ESTWH systems, to maintain the desired temperature, when required [46].

4.2.3. Operational Efficiency

The operational efficiency may be improved by applying effective control techniques in conjunction with the newly acquired equipment as described in Section 4.2.2. Therefore, in this section, human intervention will be discussed in terms of implementing effective control techniques to improve the operational efficiency.

HVAC Equipment

Operational efficiency of HVAC equipment is improved by reducing VSD operating speeds. In Dezfouli et al. [47] noted a maximum energy saving of 83% when motor speeds were reduced by 60%, while a minimum saving of 22% was obtained at a speed reduction of 10%, in terms of energy consumed by motors (fans) in air-handling units (AHUs).

However, these speeds might not satisfy the sensitive load requirements of healthcare institutions. Therefore, intervention by technical personnel may be required to monitor and adjust VSD settings, in order to effectively manage these systems, according to load requirements. In retrospect, the reported maximum savings of 83% may in fact not be possible to maintain sufficient air quality. Rather, the only sensible energy-saving projection may be located closer to the minimum possible savings of 22%. This translates into a minimum energy saving of 7.48% in terms of overall HVAC energy consumption [47].

Water-Heating Systems

Operational efficiency may be improved in water-heating systems by evaluating the hot-water consumption profiles of users and water temperature requirements throughout the year. The time required to reach the desired temperature and the variation of hot-water consumption is major factors that requires consideration [48].

The lower temperature is dependent on climatic conditions and will influence the time required to heat water to the desired temperature. For instance, the time required for water to reach the desired temperature in winter conditions will be higher than that of summer conditions. Moreover, the high probability of the presence of the bacteria known as Legionella pneumophila in stagnant water ranging from 20 °C to 45 °C may constrain the degrees of freedom in terms of operation. It may be recommended to allow water temperatures to reach at least 55 °C daily to guarantee sufficiently low levels of bacteria presence [48].

The amount of time required to heat water from approximately 25 °C to 55 °C, may be calculated to be 1 h and 45 min when using the power equation in [49].

4.2.4. Performance Efficiency

The energy security was improved at the conceptual level with the implementation of backup energy systems. Improving the reliability of these systems will in turn improve the performance efficiency at the active level. This may be accomplished by establishing a database of all backup systems, while also implementing monitoring devices.

Databases and monitoring systems may contain details of generator systems. These may include; load specifications, diesel storage levels and standby capacity [50,51]. The data pertaining to generator health, in terms of operating hours, temperatures and past maintenance, may be a valuable reliability of supply indicator. Similarly, vital UPS data may include state of charge, remaining charge cycles, voltage levels, temperatures and overall battery health [52].

Evaluation of this data might be useful in determining when the system should be serviced or replaced, maintaining overall energy security.

4.3. Technical Level

The technical level of energy-efficiency improvement features the implementation of further energy-saving initiatives, while verifying the claimed energy efficiency of the conceptual and active levels. At this level, new energy technologies, retro fitment, automation and control techniques may be introduced. This level may further introduce cyber-physical systems as a means to improve overall energy efficiency. Cyber-physical systems generally consist of physical, digital and biological elements operating in unison. Therefore, systems implemented at this level may enter the realm of the fourth industrial revolution, otherwise abbreviated as 4IR [53].

Additionally, at this level, basic energy-management techniques may be applied in terms of demand-side management. Large-scale commercial buildings, such as healthcare buildings, are often subjected to time-of-use tariffs. These tariffs were implemented in order to provide an incentive to reduce energy usage during peak demand periods. Effectively implemented demand-side management systems may offer substantial energy savings and, in turn, improve the overall energy-efficiency respective buildings [54].

4.3.1. Technology Efficiency

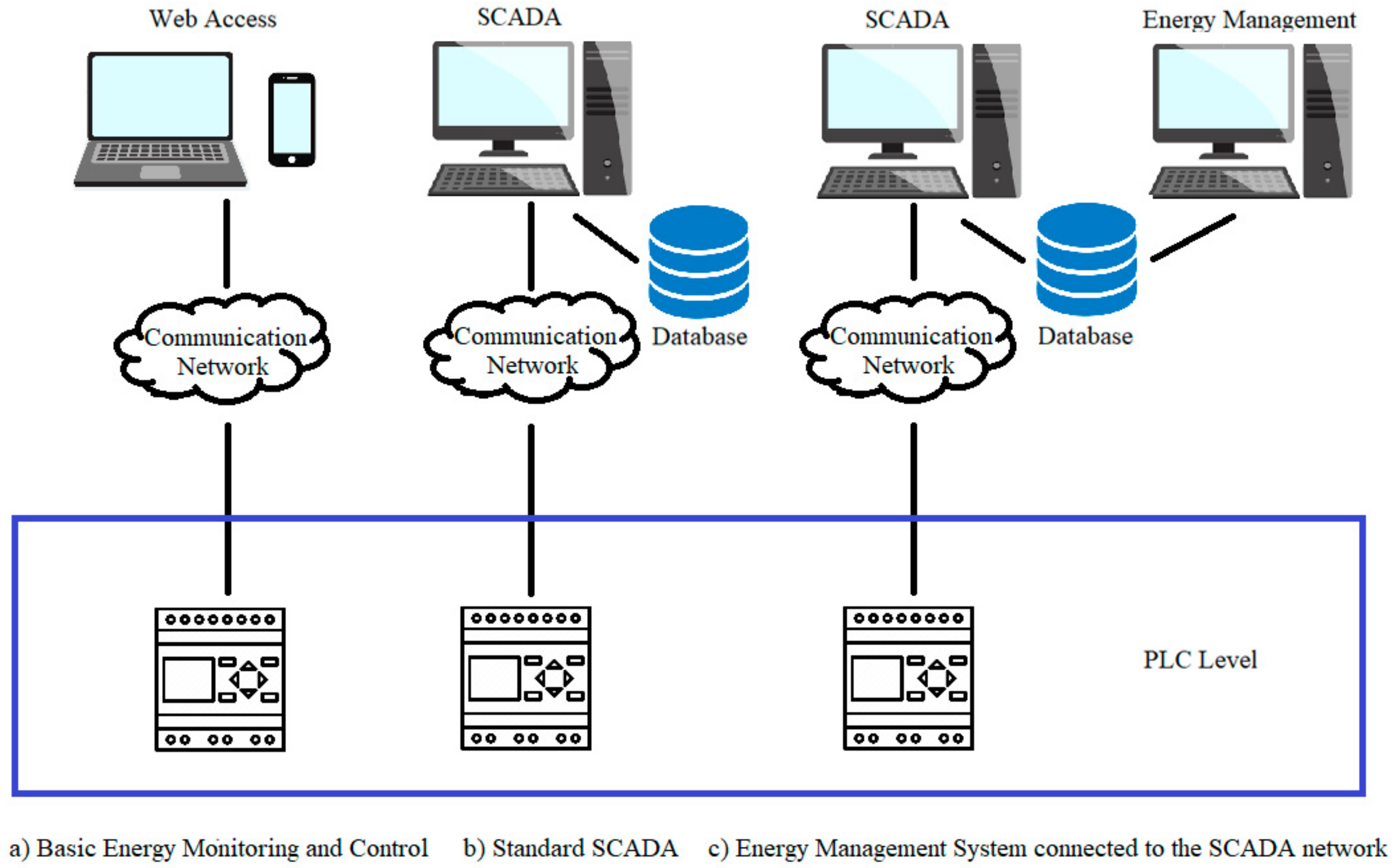

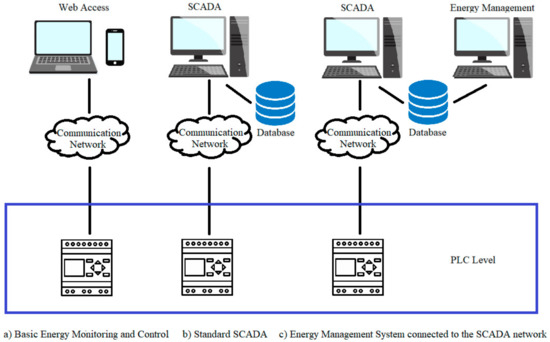

Advanced web-based energy-monitoring dashboards or supervisory control and data acquisition (SCADA) software may be implemented. The software is generally accompanied by measuring devices to provide an in-depth real time energy consumption analysis of all major components. Monitoring dashboards form part of SCADA systems and may provide process control functionalities, depending on the software package and application [55]. In order to enable these functionalities, some additional control devices i.e., programmable logic controllers (PLC) and relevant communication interfaces, such as remote telemetry units (RTUs) are required. This allows technical personnel to control processes either locally or remotely. Large networks of devices that allow for the control of processes remotely, while real-time data is monitored and logged through web-based systems, may form part of the Internet of Things (IoT). The presence of the IoT devices signals the arrival of the fourth industrial revolution and all the benefits associated with it. These benefits may include energy-efficiency improvements to the highest degree [56].

In Figure 3, the various energy-monitoring topologies is illustrated. Basic energy monitoring allows web access and limited control functionalities through PLC devices, as shown in Figure 3a. Figure 3b illustrates the basic SCADA system layout, while Figure 3c introduces a dedicated energy-management system to the SCADA network [57].

Figure 3.

Energy-monitoring topologies of web based and supervisory control and data acquisition (SCADA) systems [57].

4.3.2. Equipment Efficiency

In order to improve the equipment efficiency at the technical level, the implementation of renewable energy source systems is considered. These systems may operate in conjunction with relevant energy-storage systems to increase the demand-side management capability of processes. Systems designed to match the load requirements without storage, may offer electrical energy savings of up to 33% [58]. The implementation of hybrid renewable energy systems, depending on the design, may result in electrical energy savings in the range of 33% to 100% [59]. However, it may not be economically feasible to implement hybrid renewable energy systems for a 100% reduction in electric grid energy usage. Therefore, these systems are optimally designed, in order to attain the lowest possible payback period. In hindsight, for these systems, the objective is to minimize grid energy usage based on the TOU electricity tariff. The aim is to avoid the costly regions of the TOU tariff and use grid energy during the least costly periods. For instance, in the event that all grid energy usage is shifted to the least costly regions of the TOU tariff, an approximate energy cost saving of 52% may be obtained. This is mainly achieved through the use of hybrid energy systems with energy-storage capabilities [60].

HVAC Equipment

The equipment efficiency of HVAC systems may be improved by implementing supplementary equipment to these systems, and equipment retrofits relevant to healthcare institutions may include the following;

- The use of thermal energy-storage (TES) systems or electrical energy storage (EES) in conjunction with HVAC schemes has been popularized in recent years in that it increases the demand-side management capability of these systems. Thermal energy-storage systems may consist of either water, ice or phase change materials. These TES systems may shift a proportion of the electrical demand associated with cooling processes from peak to off-peak energy usage periods [61].

- Introducing solid–liquid phase change materials (PCM) to TES systems may result in energy savings of 6%–9% in water chiller systems [62].

- Retrofitting conventional air-conditioning systems with evaporative cooling systems may offer a saving of 12.05% in overall building energy consumption. Studies suggest that coupling existing systems with regenerative evaporative cooling systems provides potential energy savings of up to 15.69% [63]

- The implementation of renewable energy systems may be considered, these might include photovoltaic (PV) or wind turbine systems to reduce the peak energy consumption from the electrical grid. These systems coupled to TES or EES may offer further improvements in equipment efficiencies [64].

- Additional PLC systems may be introduced to provide a wider range of control of the various processes that exists in HVAC systems. For instance, PLC devices may be implemented to control AHU units, VSD systems connected to multiple motor-driven processes, and set point temperatures [65].

- Heat-recovery systems may be implemented additional to existing HVAC systems. However, the efficiency of HVAC systems may not be improved in that heat is transferred to another process. Other processes, such as water-heating systems may use recovered waste heat to increase the thermal level of water supplied to water-heating units. This essentially means that the equipment efficiency of water-heating systems is increased in that water should be preheated prior to being supplied to water heaters in order to decrease the temperature differential. The decrease in temperature differential should, in turn, reduce the energy required to raise thermal levels to desired levels [66].

- Implementation of multifunctional chiller systems, or replacement of existing chiller systems with multifunctional chiller systems. Multifunctional chiller systems supply cooling loads, while waste heat is transferred to water-heating schemes. Similarly, these systems may increase the equipment efficiencies of other equipment in healthcare institutions, such as water-heating units [67].

Water-Heating Systems

- Renewable energy source systems, particularly solar water heaters, may be introduced to existing water-heating systems. Solar irradiance levels in South Africa are amongst the highest in the world, making the solar water heater a viable option for water-heating applications of any regions in the country. According to Hohne et al. [68], an average grid energy saving of 55% may be achieved when adequately sized solar water heaters with an electrical backup-element is installed.

- Solar assisted heat pump water heaters with state-of-the-art phase change materials for thermal energy storage may be introduced to minimize grid energy usage [69].

- The implementation of hybrid water-heating systems, consisting of heat pump water heaters and inline gas boosters warrants consideration. However, the economic feasibility of these systems might be called into question, considering the poor life expectancy and high initial implementation costs associated with heat pump water heaters.

- Implementation of large preheated water storage tanks, in conjunction with solar water heater systems or hybrid water heater systems, to improve demand-side management capabilities.

- Coupling waste heat recovery systems from multifunctional chillers systems have proven to be an efficient method of increasing thermal levels of preheated water storage systems. Preheated storage systems supply ESTWH to improve energy efficiencies.

- State-of-the-art phase change materials (PCM) may be incorporated in solar collector storage systems coupled to ESTWH systems to overcome thermal losses during night/overcast sky conditions and maximize hot-water availability [70].

4.3.3. Operational Efficiency

The operational efficiency at the technical level is featured by effectively managed energy-efficiency initiatives at previous levels. This involves control techniques for demand-side management applied by suitably trained personnel, as well as necessary maintenance.

HVAC Equipment

- Basic demand-side management based on time-of-use tariff structure is exercised on systems with TES. HVAC systems charge TES systems during off-peak periods and discharge during peak periods, while load requirements are satisfied. Implementing basic demand-side management may not reduce cooling energy consumption, in most cases, rather a reduction in energy cost may be observed if the energy consumer is subjected to TOU tariffs. However, if effectively implemented, a maximum energy saving of 5% may be observed, while cost savings may reach up to 55% in terms of cooling demand, as noted in [71]. In the case of renewable energy systems with energy storage, grid energy savings of up to 52% may be obtained.

- Implementation of proportional integral (PI) controllers to regulate temperatures of each zone individually/separately in a multi-zone building, without communicating any information to the neighboring controllers [72].

- Relevant staff is trained to effectively operate and maintain HVAC equipment given the new control parameters attained from newly implemented PLC devices, as discussed in the equipment efficiency section.

Water-Heating Systems

Water-heating systems employed in commercial buildings usually consist of tank type systems rather than demand-type (tankless) systems. These include heat pump water heaters, boiler systems, and the electric resistive storage tank water heater. Due to the presence of thermal storage in these systems, the demand-side management potential is increased. This means that water may be preheated during less costly regions of time-based pricing structures. In addition, a large proportion of standby losses may be avoided by scheduling water-heating systems to switch on a predetermined time, prior to when hot water is drawn [73]. This reduces the energy usage of these systems, while maintaining load requirements, as a result energy efficiency is increased. In retrospect, this may only be accomplished when the majority of hot water is drawn near the least costly regions of time-based pricing regions, or energy requirements may increase [74]. This may be achieved through the following;

- Demand-side management is applied to water-heating systems by adjusting timer controls to limit power usage during peak and standard periods of the TOU tariff. However, in most cases energy savings may not be attainable, rather energy cost savings may be substantial [75].

- Energy usage is frequently monitored in order to identify any potential problems.

- Basic load forecasting is conducted and timer control settings are adjusted accordingly [76].

4.3.4. Performance Efficiency

The energy dashboard in SCADA or web-based systems is an effective tool to monitor the performance efficiency of systems connected to the network. Energy targets may be set in terms of energy and cost savings.

The Department of Energy of South Africa [77], released a post-2015 National Energy Efficiency Strategy (NEES), Targets, Measures and implementation Plan. The plan was compiled by the Danish Energy Management division of the Danish Management Group, in April 2016. The plan presents specific goals for accelerating the current rate of improvement in energy efficiency per square meter of lettable/inhabited floor space in the case of the commercial sector. Additionally, the draft plan provides a review on the status of current energy-efficiency improvements, how goals may be achieved and indicators of successful energy-efficiency improvement.

Under the current status section, the draft document elaborates on the maximum energy-efficiency standards by building type according to SANS 204:2011. Furthermore, the technical specifications to reduce the consumption of energy in new buildings was defined in the SANS 10400-XA in 2014 [78]. While it was noted that the construction industry has already met these targets in most cases, a further reduction in energy consumption is required in order to align with trajectories developed by the Construction Industry Development Board (CIDB) and Council for Scientific and Industrial Research (CSIR).

A major barrier in improving energy efficiency, is the practical and financial challenges faced when considering the retro fitment of the existing building stock. Healthcare institutions may face considerable challenges in terms of practical implementation, due to the unique load requirements as opposed to other commercial buildings.

In order to achieve the goal of improving energy efficiency according to the NEES document, the following measures were proposed:

- Introduction of mandatory Energy Performance Certificates (ECPs) under the SANS 1544. ECPs will be produced by an accredited body and enforced by legislation.

- Revision of the existing 12 L tax incentive. The tax incentive, according to the Income Tax Act, 1962 (Act No. 58 of 1962), allows incentive for businesses to implement energy-efficiency activities. The current 12 L incentive offers a tax deduction of 95 cents per verified kWh saved, as compared to a baseline profile taken throughout one year. A review of the 12L incentive structure is required to accommodate the specific case of healthcare institutions, among other commercial energy consumers. As a result, the feasibility of improving energy efficiency may be increased substantially.

- Develop further tax incentives for deep energy-efficiency retrofits. These energy-efficiency retrofits entail the implementation of systems with high initial investment costs, resulting in higher payback periods, as compared to systems with relatively low investment costs which, in most cases, subsequently leads to lower payback periods. Tax rebates may be provided to encourage deep retrofits, which would in turn reduce payback periods of these systems to within acceptable timeframes.

In addition to improving energy efficiency, all the proposed measures promote job creation. Several other measures were proposed in the NEES document, and the remaining measures not discussed in this section have either been addressed in previous sections in this paper, or do not hold definite relevance to healthcare institutions in South Africa and may not provide desired/anticipated impact.

The NEES document further states that a potential reduction of 37% in specific energy consumption may be achieved by 2030, compared to the 2015 baseline, if current energy-efficiency improvement trends continue, while all of the proposed measures are implemented. Estimations, based on current trends, amount to an 11% reduction in specific energy consumption by 2030. This prediction, however, considers the effect of the current SANS 10400XA standards and not the proposed measures. Setting a precise target may prove difficult for the case of healthcare institutions. The target may depend on decisions to implement all or some of the proposed measures. If all proposed energy-efficiency measures were to be implemented up to the technical level, energy targets of 37% may easily be attainable. Therefore, in the case of healthcare institutions, a target range may be provided, which would be subjected to changes according to government decisions to provide suitable incentives. Therefore, proposed energy targets for healthcare institutions, aligned with commercial building sector targets, is a 37% reduction in specific energy consumption relative to the 2015 baseline by 2030 [79].

4.4. Further Improvement

The further improvement level, otherwise known as the engineering level, involves the implementation of specialized energy-efficiency initiatives. This level may be featured by various optimization techniques applied to each POET component. This may entail a comprehensive energy-monitoring dashboard, optimal maintenance plans and optimal operational control to maximize the energy efficiency of the building in order to ensure that energy-saving targets are reached timeously [80].

4.4.1. Technology Efficiency

Improve energy dashboard to include additional information, which may comprise of simple maintenance schedule based on training, data analysis and historic efficiency indicators. Additionally, an economic analysis functionality may be incorporated to provide information, which includes cumulative costs, predicted costs and time remaining on the payback period.

The implementation of advanced building automation systems, which provide optimal control functionalities applied to energy-intensive processes, in this case, HVAC and water-heating systems. Therefore, at this level, dynamic optimization strategies are applied to achieve the maximum possible energy savings.

4.4.2. Equipment Efficiency

At this stage, equipment retrofitment or replacement is no longer possible, as these activities were considered at previous levels. Therefore, at this level, improved or optimal equipment maintenance is considered to maximize equipment efficiency. In order to establish a well-planned maintenance schedule, relevant staff will be trained to compile appropriate maintenance timetables based on equipment specifications and requirements.

In terms of designing ideal equipment maintenance plans, the selection of the most suitable maintenance policy is required. The appropriate policy should cover detailed maintenance actions and schedules. As defined in MIL-STD-721C [81], maintenance actions refer to restoring or retaining equipment to a specified condition. Furthermore, the actions may be categorized as corrective maintenance (CM) and preventive maintenance (PM). CM signifies actions performed as a result of failure (restoration), while PM refers to actions required to retain equipment conditions (prevention of failure).

Energy dashboards may also be used to plan and compile schedules based on historic equipment performance. The frequency at which maintenance should occur would increase over time, as equipment ages. This should further be considered along with the environmental conditions that these systems might be subjected to. In the case of healthcare institutions, where uninterrupted operation is required, schedules should be planned carefully, as to not disrupt processes.

HVAC Equipment

Regular maintenance of HVAC systems may increase energy efficiency, a number of studies quantified the potential energy savings as a result of effective maintenance. These studies are categorized in terms of: HVAC component failures and prospective energy savings for correcting failures in question and interviews with HVAC maintenance specialists. According to these studies the following energy savings are possible, in terms of HVAC component maintenance [82]:

- Repairing or adjusting economizer actuators or dampers may offer savings of 14% to 40%.

- Repairing failed sensors may provide savings of up to 40% if these sensors are required for optimal economizer operation.

- Maintaining adequate refrigerant charges/levels may introduce savings of 5%–11%.

In retrospect, best practices in HVAC equipment maintenance may reduce energy usage in the range of 10% to 20%, while poor or inadequate maintenance may be responsible for increased energy usage on the order of up to 60% [83].

Water-Heating Systems

- In terms of water-heating systems maintenance, the following may be considered [84,85];

- Hot-water conduits inspection (pipe lagging and leaks) leading to points of consumption;

- Self-sacrificing anodes inspection and replacement on ESTWH;

- Drip tray outlet inspection (blockage removal).

4.4.3. Operational Efficiency

The operational efficiency may be improved by implementing various dynamic optimization techniques. These techniques may be applied to individual processes and to hybrid renewable-energy systems with storage capability. Hybrid renewable-energy systems may be optimized, in terms of dispatched power, to achieve additional savings. This may be realized by optimally dispatching energy from renewable sources and storage systems to loads during costly regions of the TOU tariff. The storage systems are again charged during the low-cost regions of the TOU tariff. Excess energy may also be sold back to the grid subjected to a feed-in-tariff (FIT). However, grid energy savings may be small compared to the associated energy cost savings. Energy savings in the order of 5%–10% may be expected, in terms of optimal power dispatch control [86].

Decreased costs of data processing, storage and communication over recent years have encouraged the design and implementation of more complex optimization control techniques to commercial building processes. In particular, the implementation of model predictive control (MPC) techniques has gained popularity in recent years, due to the several advantages they offer, as opposed to other control techniques, which may include [87]:

- Implementation or use of a system model for anticipatory control instead of corrective control;

- Incorporation of disturbance rejection through the use of disturbance models;

- Ability to operate closer to constraints and adjust for uncertainties;

- Ability to incorporate a wide range of operating conditions and time-varying system dynamics;

- Ability to effectively control slow-moving processes, while subjected to time delays;

- Allow for multiple objectives through the use of a cost function;

- Superior control for processes with multiple control variables;

- Capable of controlling systems at the supervisory as well as local loop levels.

The MPC method uses a system model to predict future states of the dynamic system process. The MPC controller generates a control vector, in order to minimize a predefined cost function subjected to disturbances and constraints over a certain prediction horizon. Control vector elements are computed for all sampling intervals in the prediction horizon. However, only the first control vector element is applied at the initial sampling interval, while the remaining vectors are discarded. This process repeats itself for every subsequent sampling interval in the prediction horizon, so that an optimized control vector is generated for each sampling interval in the prediction horizon [88]. The cost function is formulated to achieve an objective.

In the case of improving energy efficiency, the objective will be to minimize the energy usage or the costs associated with energy consumption, while maintaining load requirements. A reduction in the overall energy consumption may result in reduced energy costs. Therefore, an optimization algorithm using MPC methods is usually required to improve the operation of a certain process. The algorithm is developed to minimize energy usage, while considering time-based pricing so that unnecessary energy usage may be mitigated. The ability of the MPC method to achieve multiple objectives may prove highly useful in this regard [89].

HVAC Equipment

A large body of research has been conducted on controlling HVAC processes, particularly in terms of energy and cost savings. Serale et al. [90] identified a total of 161 papers linked to MPC methods applied to HVAC processes in buildings. From the reviewed papers, it was observed that the MPC approach is an effective method to improve HVAC efficiency. Reviewed papers included thermal storage systems, ventilation systems, window control and ground-coupled heat pumps among others. The identified papers were published between 2008 and 2017. Additionally, in the same paper, it was noted that these algorithms result in typical energy savings of approximately 15%–20%, as compared to conventional control methods. While a review of the most recently published literature (January 2018 to December 2019), revealed similar findings in terms of energy savings in commercial buildings, a lack of papers was noted, concerning healthcare institutions in South Africa. It should be noted that past research on the subject may align with the specific case of South Africa, due to some similarities in the variation of system disturbances. However, the unique variability in the combination of disturbances, generally identified as weather, occupancy, cost of energy and loads, particularly in the case of healthcare institutions in South Africa, has not been considered. Therefore, further research in this regard is required, so that accurate approximation ranges could be presented, as opposed to the 15%–20% average potential energy savings that MPC could offer in commercial buildings. In retrospect, a preliminary approximation of potential savings achievable may be noted to be approximately 15%.

The accuracy of data pertaining to potential cost savings may further be improved by simulating processes and control in real-time. This may be achieved through real-time simulation hardware and software. Moreover, valuable information in terms of model validation, with regards to real-time dynamic process representation may be obtained.

Water-Heating Systems

Improving the operational efficiency of water-heating systems, particularly systems with thermal storage capability, merits attentive consideration. As discussed in previous sections, the set temperature levels, regulated by the thermostat, may be decreased, in order to save substantial amounts of energy. However, thermostat temperature levels may not be set below 55 °C, as to avoid infection from Legionella bacteria. Furthermore, when effectively applied, the implementation of demand-side management (DSM) activities has shown promising results in reducing the energy consumption of water-heating systems with thermal storage. In hindsight, the cost saving benefits of DSM activities may far exceed that of specific energy reduction. Several studies concerning the control of water-heating systems for DSM have been conducted. Kepplinger et al. [91] established that when an autonomous optimal control approach was applied to resistive domestic hot-water heaters for a particular case study, energy savings of 4% were noted, while energy cost savings of 12% was observed. Moreover, Hohne et al. [92], determined that when an optimal control technique is applied to a resistive water-heating system coupled to a solar water heater, annual energy savings of 8.32% were noted, while cost savings of 32.86% were obtained, compared to timer-based demand-side management applied to the same setup.

Furthermore, Rankin et al. [93] found that DSM activities applied to commercial buildings, using an inline heat pump water-heating system, reduced the peak demand of water-heating energy consumption by 86%. As a result, a reduction of 36% were observed in the peak demand of the entire building. In hindsight, buildings subjected to maximum demand charges may benefit financially from peak demand reduction, otherwise known as peak clipping.

Other studies focused on the optimal control of water-heating systems with hybrid renewable energy sources, to reduce grid energy consumption and associated costs, as in Refs. [94,95,96,97,98,99]. These studies applied open loop optimal control approaches to control various hybrid renewable systems connected to heat pump water heaters, energy savings ranged from 23.4%–51.23%, while cost savings ranged from 33.8%–70.74%.

Additional opportunities for energy and cost savings exist in water pressure management. At this level, optimal water pressure management may be applied to further reduce energy usage and associated costs. Energy savings may be attained by implementing optimal control techniques to water pressure systems, which could reduce the energy consumed by pressure pumps and the amount of water lost in cases where leaks are prevalent. Reducing the water lost through leaks, particularly in hot-water conduits may lead to a reduction in hot-water consumption, which in turn, reduces the energy consumption of water-heating systems. In Refs. [100,101], an optimal control model has been implemented on water pressure management systems to reduce water leakage.

An MPC (closed-loop) approach was applied to a hybrid resistive/heat pump water heater system, coupled to hybrid renewable energy systems subjected to TOU and FI tariffs in [102], energy and associated cost savings of 33.80% and 66.10% were achieved, respectively. From these studies, it may be evident that to attain maximum energy and cost savings, the implementation of hybrid renewable energy systems and hybrid water-heating systems should be considered. Furthermore, in terms of controlling these large multivariable systems, the closed-loop MPC strategy seemed to be the most fitting. Although the MPC approach may generally be computationally expensive, it delivers the only real platform for addressing control problems involving the state in the presence of constraints and the ability to account for constraint violations [103].

4.4.4. Performance Efficiency

As discussed at the technical level, the proposed target for the commercial sector is a 37% reduction in the overall specific energy consumption by 2030 relative to a 2015 baseline. Sub-targets may be established in accordance with the various energy-efficiency initiatives applied to energy-intensive equipment. These sub-targets may align with potential energy savings, as a result of implementing these initiatives. Furthermore, the assigned sub-targets may be enhanced by including financial budget constraints, payback periods and the time allocated to equipment retrofits. In order to improve the accuracy of the aforementioned feasibility measures, savings from tax incentives and rebates should be taken into account. Additional expansions to energy dashboards may be considered, these may include major performance efficiency indicators, as described in Section 2. These indicators, comprising energy cost, carbon emissions, energy losses, skill and knowledge levels of staff, equipment life cycle costs, cost to benefit ratios among others, may provide valuable insight to energy managers for further efficiency improvements. In addition, energy dashboards may be linked to other healthcare institutions or branch facilities, in order to compare and evaluate the impact of energy-efficiency initiatives in various scenarios. In hindsight, increasing the data measurement and model verification ability of institutions may ultimately improve evidence-based policy making [104]. Moreover, when considering the specific case of healthcare institutions, the security and reliability of the energy supply is of utmost importance. This introduces a problem when implementing unproven optimization techniques, where a risk of disrupting crucial processes may exist. Therefore, system models and optimization techniques should be validated before implementation. This may be possible using real-time simulation hardware and software. In recent years, the cost of real-time simulation technologies decreased significantly, and as a result validating models and control techniques have been less costly and time consuming [105]. Any given process may be modelled and simulated using real time technologies, while a physical controller may be tested offline before implementation [106,107]. In this case, a real-time simulator with analog and digital input-output (I/O) channels may represent the operation of an existing process and emulate the behavior of the process, so that a pre-programmed controller may respond accordingly [108]. This will allow the programmer/engineer to detect any errors before implementation. In addition, control loops and tuning factors of various control devices may be adjusted, in order to satisfy system constraints without compromising the actual system. Major systems may require the use of fast, scalable and flexible real-time simulators to improve model validation and data verification. This will, in turn, play a key role in improving the performance efficiency of a system and ultimately the overall energy efficiency [109].

5. Key Findings of Reviewed Literature

The POET energy-management framework is an effective tool for evaluating and improving a building or large-scale system’s energy efficiency. Potential energy-efficiency improvements were proposed, based on the four POET energy-management levels. These levels were discussed throughout the previous sections of this paper, and are: the conceptual, active, technical and further improvement level.

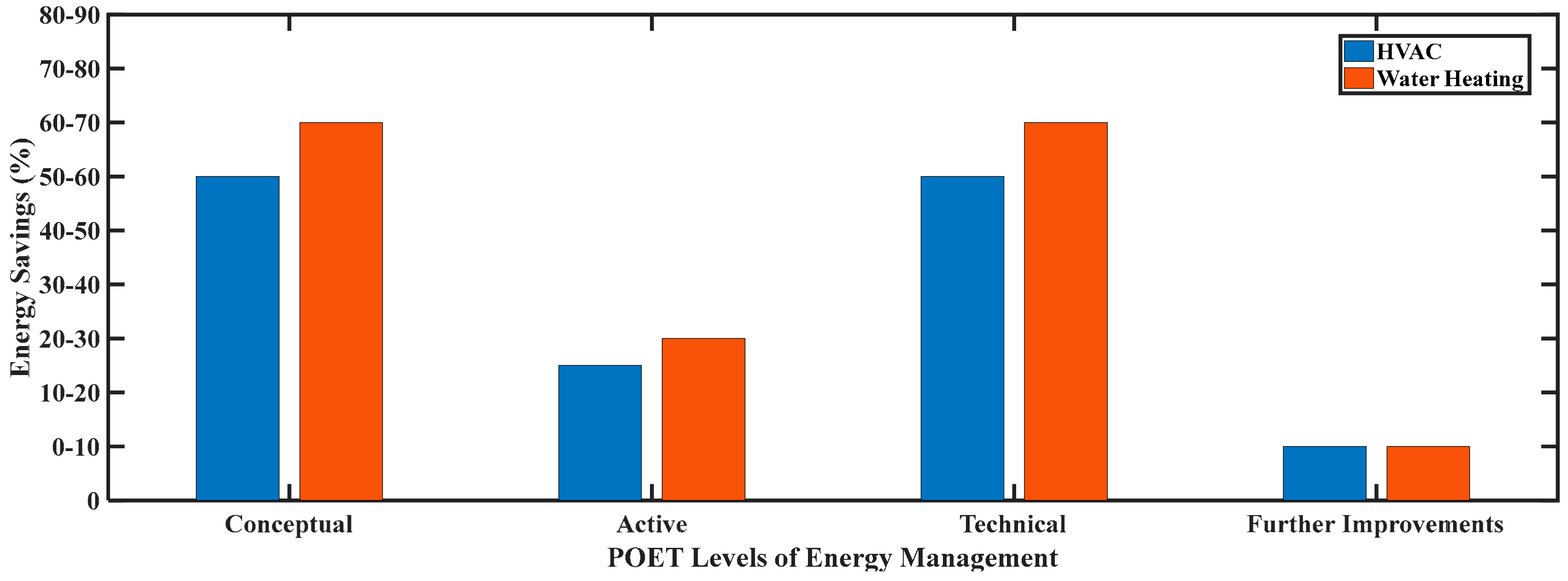

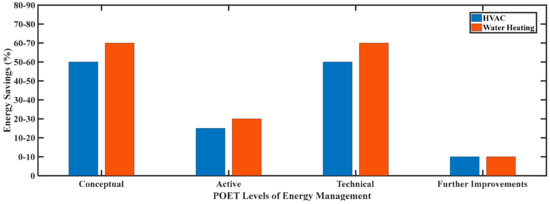

A systematic review was conducted, from a POET perspective, to which three research questions were raised. The research questions and the motivation behind the questions are presented in the method section of this paper. The first research question was introduced to evaluate the existing evidence base regarding potential energy and cost savings of energy-efficiency initiatives applied to healthcare institutions. This prompted an extensive search of available literature. A large body of scholarly articles was available on energy-efficiency initiatives with regard to HVAC and water-heating systems. However, studies were limited for the specific cases of healthcare institutions. It was further necessary to obtain regional data to assess the environmental influence on particular case studies. For these instances, research was similarly lacking. Therefore, with the available data from scholarly articles, approximations were made to attain average energy savings for each energy-efficiency initiative. These energy savings are presented throughout the previous sections of this paper, while averaged savings at each level is depicted by Figure 4.

Figure 4.

Maximum potential energy savings attainable for each performance, operation, equipment and technology efficiency (POET) energy-management level.

The second research question was; “Can healthcare institutions reach energy targets in order to align with trajectories developed by CIDB and CSIR through effective implementation of these initiatives?”. In Section 4.3.4, it was determined that healthcare institutions may reach energy targets if proposed measures at the technical level were to be implemented. However, this depends on the economic feasibility of implementing these measures and external stimulus from government. Therefore, the third research question considers the feasibility of each initiative at each corresponding level of the POET framework.

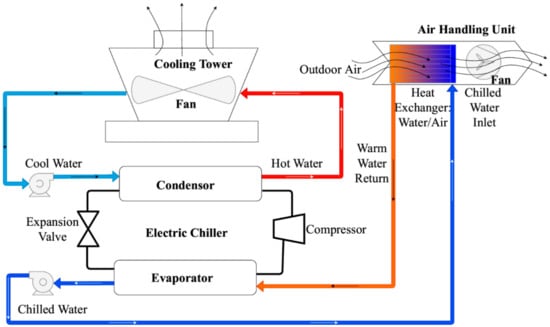

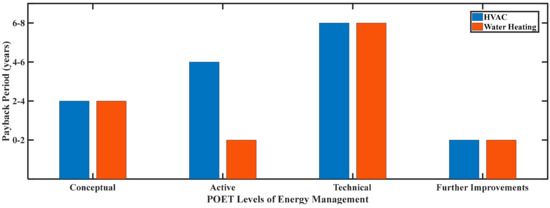

As previously described, the conceptual level may be analogized by the pareto principle, which denotes that a profit (energy saving in this case) of 80% will be attained for an effort of 20%. In retrospect, the subsequent levels may require increasing amounts of effort, in order to achieve significant savings. Comparatively, this means that the rule may roughly change to “60/40” for the active level, “40/60” for the technical level and “20/80” for the further improvement level. This rule may be partially substantiated by comparing the energy savings and payback periods for each of the POET levels in Figure 4 and Figure 5, respectively.

Figure 5.

Expected payback period for each performance, operation, equipment and technology efficiency (POET) energy-management level.

Figure 4 illustrates the maximum potential energy savings attainable at each level. These savings do not account for renewable energy savings, the savings illustrated, is based on electrical energy supplied from the national electricity supplier. It should further be noted that these energy savings were extrapolated, based on findings from available research as discussed in the previous sections. Therefore, the savings illustrated in this paper may only serve as the best-case scenario. Furthermore, the corresponding payback periods have been calculated and extrapolated based on previous research conducted at each energy-management level of POET and is illustrated in Figure 5.

In Figure 4 and Figure 5, it may be observed that the required effort at the active level is higher, compared to the conceptual level, while it was observed that the resulting energy savings decreased. Only at the technical level may a substantial improvement of energy savings be observed, as compared to the active level. However, this may be accredited to the implementation of external energy sources, such as renewable-energy supplies.

In Figure 5, it may be noted that at the conceptual level, relatively low payback periods for energy-efficiency initiatives are to be expected for comparatively high returns. The energy savings drop in Figure 4 during the active level, while a similar trend is observed for the payback period in Figure 5. Further investigation shows that the amount of effort required to attain significant energy savings at the technical level, in terms of cost, is exceedingly high compared to previous levels. In most commercial buildings, a system may be deemed economically feasible if the payback period does not exceed 2–4 years [110]. In the case of implementing renewable-energy systems, payback periods generally range from 6–8 years. This introduces a predicament with regards to the justification required for implementing these systems. As a result, additional energy-efficiency initiatives may be employed, in order to reduce payback levels and in turn the feasibility of these systems. These initiatives were discussed in the further improvements section. This section is mainly characterised by the optimal operation and maintenance of systems. It may be noted that the energy-efficiency improvement potential dropped significantly, as compared to the technical level. However, an average saving of approximately 10% may be attained for relatively low effort, as noted by the comparatively shorter payback periods. In retrospect, the further improvement section may provide further incentive for the implementation of efficiency measures at the technical level. This implies that the implementation of proposed initiatives up to the further improvement level may offer the maximum return on investment.

6. Conclusions