Techno-Economics of Using Second Life BEV Traction Batteries as BESS in Domestic RES Installations

Abstract

1. Introduction

- Will every used battery (type A or B) removed from an EV be suitable for use as a BESS in a residential building, and how will its performance parameters compare to those of a commonly available PV BESS?

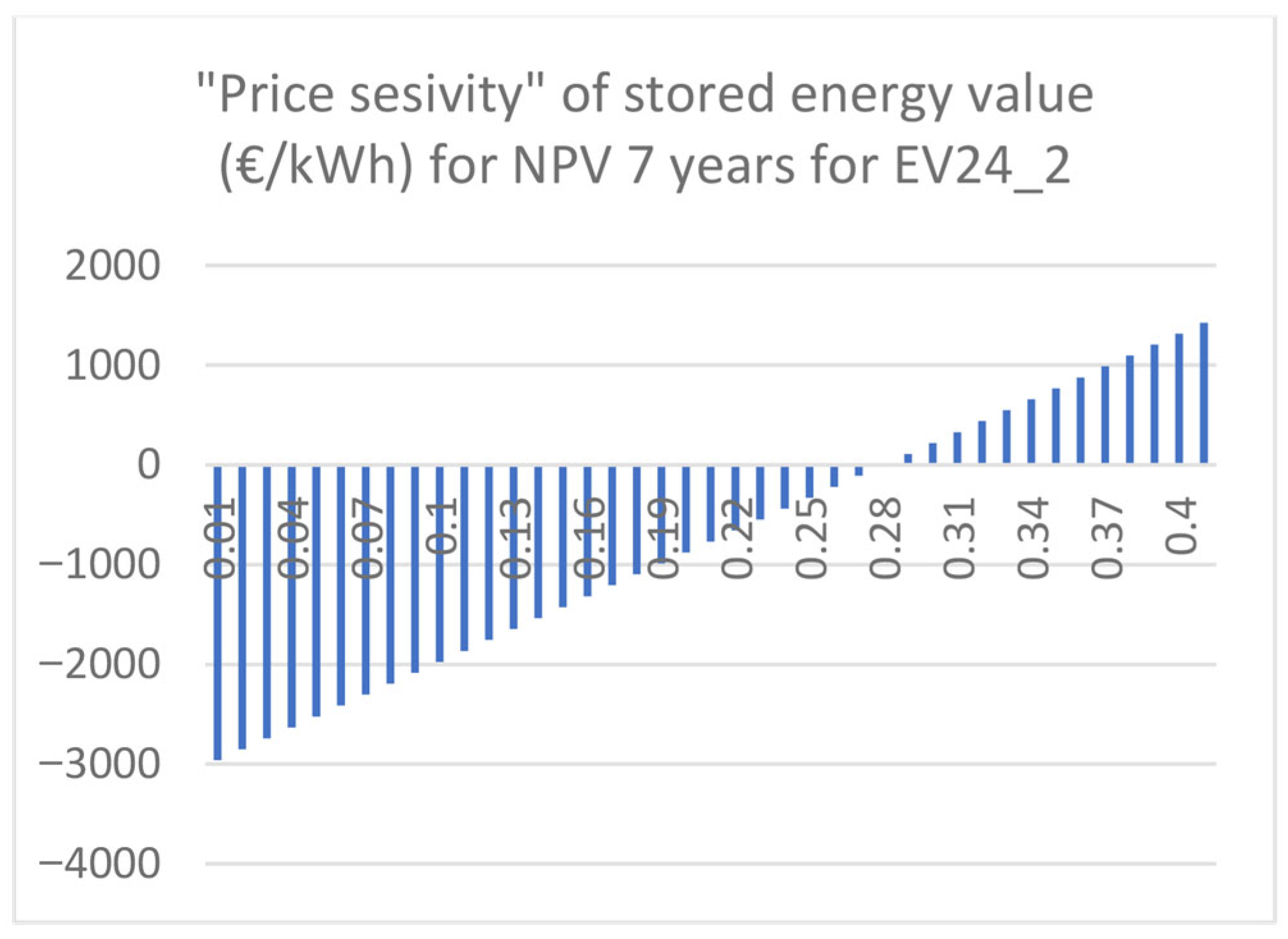

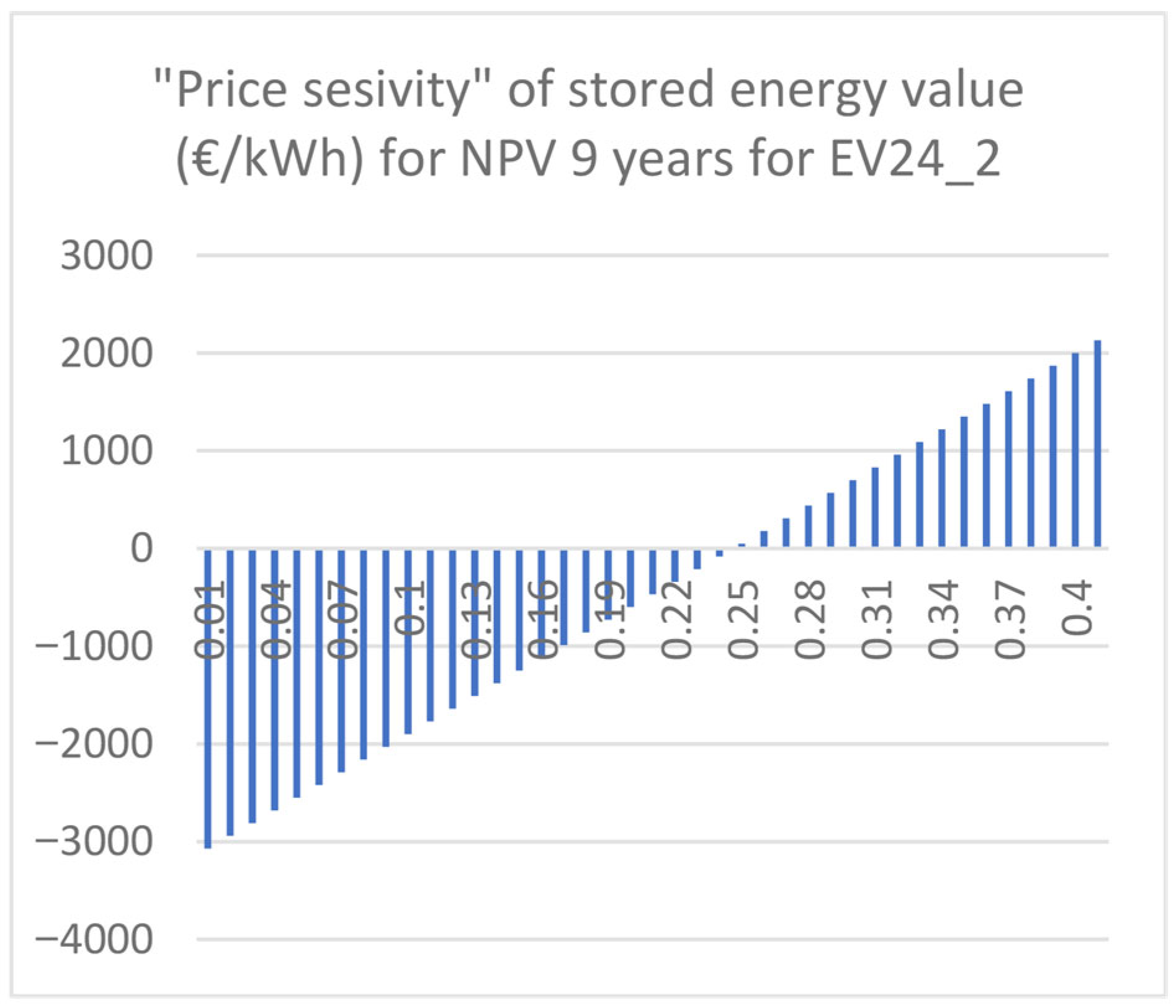

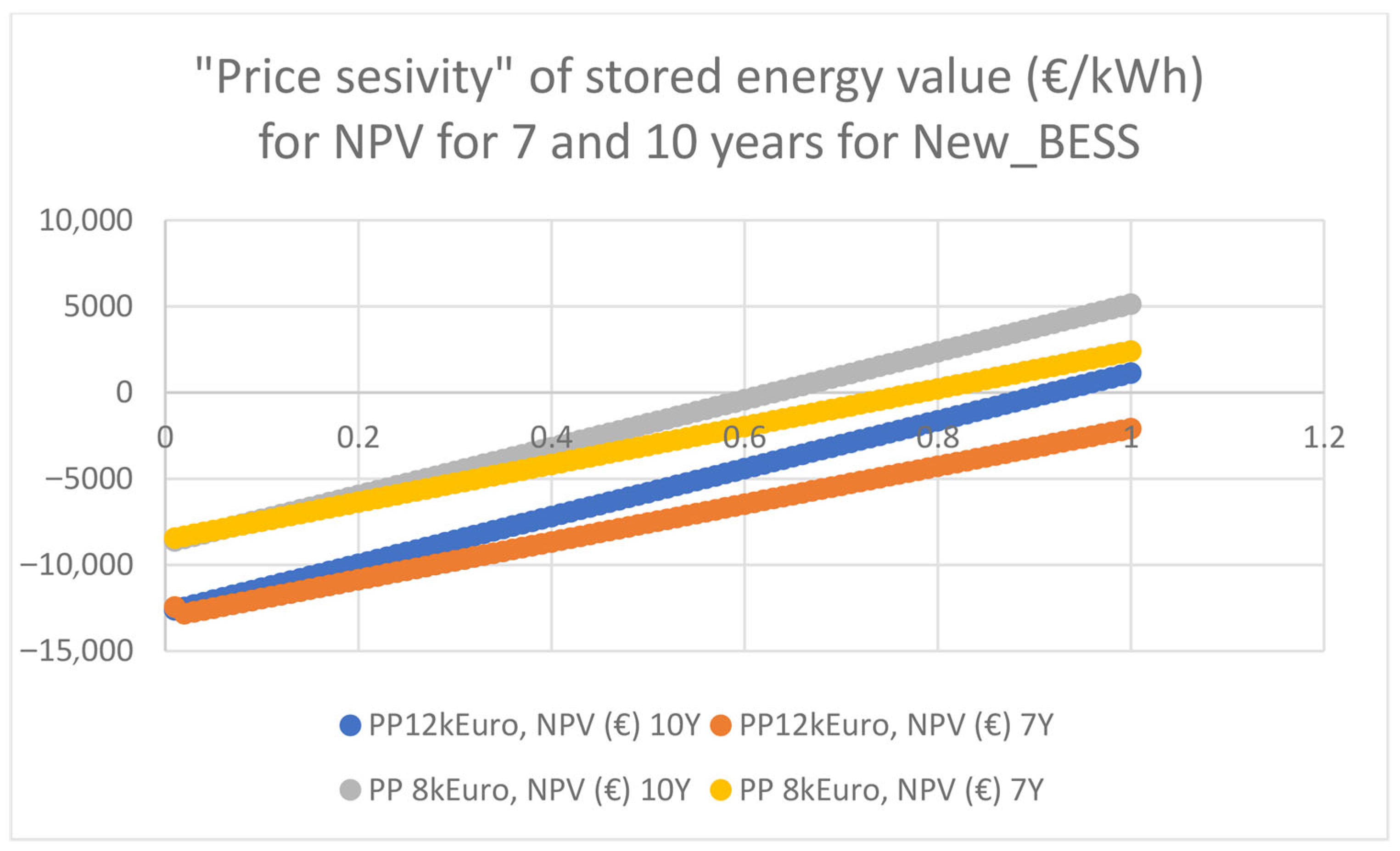

- What will the cost be of converting a BEV battery to a BESS battery? What will the real (not Simple Pay Back Time) payback period be? The payback calculation should take into account the cost of money, the degree of actual use of the BESS, and the degree of degradation of the SLBEV, i.e., an NPV calculation should be performed. How sensitive is NPV calculation to the market value of electricity (including that from renewable energy sources)?

- Are there any other factors to consider, such as safety or environmental impact, when comparing these two solutions (SLBEV vs. BESS)?

2. Materials and Methods

| Description | PylontechH1 Set. BESS_1 (Figure 2) | DIY EVB_1 24 kWh Y2012 Version | DIY EVB_2 24 kWh Y2016 Version |

|---|---|---|---|

| Chemistry | LFP | LMN + NMC | NMC |

| Nominal {real} capacity (kWh) | 23.6 {20} | 24 {15–22} | 24 {24} |

| Voltage (V) | 336 Vdc | 350–410 Vdc | 350–410 Vdc |

| Capacitance | 70 Ah | 37–54 * Ah | 59 Ah |

| Communication | RS485, CAN | CAN | CAN |

| Working temperature | 0–50 °C | −20–50 °C | −20–50 °C |

| Placement | Indoor only | Outdoor only | Outdoor only |

| Effectiveness | 96% | 65–80% * | 90–95% |

| Weight [kg] | ~286 | ~294 | ~280 |

| Dimensions [mm] | 1380 × 600 × 380 | 1600 × 1170 × 270 | 1600 × 1170 × 270 |

| Cost [Euro] | k€8–12 | 2500 | 2500 |

| Set | Set ** | Set ** | |

| Guarantee Estimated lifespan | 6000 cycles @25 °C | No | No |

| 6 years *** | 0–6 years **** | 8–10 years **** |

| Name | BESS | Nominal Capacity (kWh) | Initial Cost (Euro) | Set Description |

|---|---|---|---|---|

| 1. | BESS-NEW Pylontech H1 | 24 | k€8–12 1 | Set of BES module, rack, 7 battery modules, cables |

| 2. | DIY EV 24_1 | 24 | 2500 2 | Set of EV battery incl. BMS, modules replacement, CAN emulator, cables |

| 3. | DIY EV 24_2 | 25 | 2500 | Set of EV battery incl. BMS, CAN BYD HVM emulator, cables |

| Number | Parameter | NPV1 | NPV2 | Set Description |

|---|---|---|---|---|

| 1. | Daily Energy Used | 8 kWh | 8 kWh | 24 h energy stored and used from BESS |

| 2. | Efficiency (η) | 0.765 | 0.765 | Charging (0.95)–discharging (0.8) efficiency |

| 3. | Annual degradation (d) | 4% | 4% | Estimated battery capacity degradation (capacity) |

| 4. | Annual maintenance (M) | €100 | €100 | Annual cost of maintenance (test and care) |

| 5. | Discount Rate (r) | 5.35% | 5.35% | Current discount rate in Poland [13] |

| 6. | Lifetime (N) | 7 | 7 | Based on a new BESS guarantee time and expected life time of SLBEVs or BESSs |

| 7. | Initial Cost (€) | k€2.5 | k€8–12 | Calculation of DIY BESS based on used BEV battery compared to new BESSs |

3. Results

3.1. Batteries Tests Results

3.2. Price Sensitivity Simulation Results

4. Discussion

5. Conclusions

- BEV battery packs, when combined with small interfaces (CAN Bridge), offer an interesting price alternative to the ‘ready-made’ BESS kits available on the market. They offer significantly higher capacities at a lower purchase price, providing a much shorter payback time than ready-made home BESS kits. LIB technology is definitely better for energy storage than lead-acid batteries [17]. In order to ensure the safe use of LIBs, however, it is necessary to ensure a safer location for such a battery facility (preferably in a separate fire zone) [14,18].

- The increasing popularity of BEVs, coupled with the statistical withdrawal of vehicles from circulation, provides a natural supply of batteries to the secondary market. This encourages independent companies to establish a market for battery repair and reintroduction into the circular economy, as recommended in EU Directive 2023/1542 [1]. Reusing LIB EV batteries as home BESSs has the potential to significantly increase the self-consumption of RES energy in households, as well as using EBEV cars as mobile storage V2G (vehicle-to-grid) and V2H (vehicle-to-home) as described in the author’s latest publication [19].

- Due to dynamic progress in automotive battery solutions, even traction batteries from the same car model but with different years of manufacture can be a useful or completely useless source of DIY BESSs for domestic applications depending on the production chemistry. However, for marketing reasons, car manufacturers do not publish this data.

- Advantages of BEV battery packs over domestic BESSs include:

- A significantly wider operating temperature range, meaning they can be used without heating or cooling systems, making them attractive for outdoor BESSs (safety considerations);

- A sealed construction;

- Resistance to environmental factors;

- Flame-retardant housing.

- Significantly higher capacity compared to regular domestic BESSs.

- A purchase price several times lower, especially in relation to EUR/kWh

- Another important technical advantage is that BEV batteries have been designed to operate with significantly higher currents in vehicles, meaning that powering buildings is exceptionally easy and non-destructive for them.

- 5.

- The attractiveness of BESSs in a given market depends heavily on the current relationship between the price of electricity purchased from and fed into the grid. Research has revealed that, if the energy price in a given market is too low, ready-made BESS kits will be too expensive in relation to the stored energy’s value. Consequently, the energy storage market will not develop. One solution is to use high-quality vehicle batteries, which, when properly selected, can be given a second life (SLBEV).

- 6.

- As a result, Author provides answers to the following research questions:

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EV/BEV | Electric vehicle/Battery Electric Vehicle |

| BESS | Battery Energy Storage System |

| SOH | State of Health–parameter describing battery wear out level |

| PHEV | Plug-in Electricity Vehicle, a Vehicle with ICE engine and electric engine |

Appendix A

Appendix A.1. Quotes from EU Directive [1]

- Author believes that, to stimulate the circular economy in Europe, this information should be clearly stated on every battery electric vehicle (BEV) battery, as encouraged by the EU Directive [1]. This Directive stats (Preface) “… electric vehicle batteries that are incorporated in motor vehicles should be removable and replaceable by independent professionals. It is appropriate to consider revising Directive 2000/53/EC to ensure that those batteries can be removed, replaced and disassembled, including as regards joining, fastening and sealing elements. For the purposes of the design, manufacturing and the repair of … electric vehicle batteries, manufacturers should provide the relevant vehicle on-board diagnostic information and vehicle repair and maintenance information on a non-discriminatory basis to any interested manufacturer, installer or repairer of equipment for vehicles…, as provided for in Regulation (EU) 2018/858/”

- Definitions (31) ‘Repurposing’ means any operation that results in a battery, that is not a waste battery, or parts thereof being used for a purpose or application other than that for which the battery was originally designed;

- Definitions (32) “Remanufacturing” means any technical operation on a used battery that includes the disassembly and evaluation of all its battery cells and modules and the use of a certain number of battery cells and modules that are new, used or recovered from waste, or other battery components, to restore the battery capacity to at least 90% of the original rated capacity, and where the state of health of all individual battery cells does not differ more than 3% between cells, and results in the battery being used for the same purpose or application as the one for which the battery was originally designed.

References

- Regulation (EU) 2023/1542 of the European Parliament and of the Council of 12 July 2023 Concerning Batteries and Waste Batteries, Amending Directive 2008/98/EC and Regulation (EU) 2019/1020 and Repealing Directive 2006/66/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023R1542 (accessed on 8 May 2025).

- Maćków, P.; Guzdek, P.; Grzesiak, W. Wybrane procedury procesu recyklingu częściowo wyeksploatowanych baterii trakcyjnych pojazdów elektrycznych. Przegląd Elektrotechniczny 2012, 98, 140. [Google Scholar]

- Sangwongwanich, A.; Zurmühlen, S.; Angenendt, G.; Yang, Y.; Séra, D.; Sauer, D.U.; Blåbjerg, F. Reliability Assessment of PV Inverters with Battery Systems Considering PV Self-Consumption and Battery Sizing. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE 2018), Portland, OR, USA, 23–27 September 2018; IEEE Press: Piscataway, NJ, USA; Volume 2018, pp. 7284–7291. [Google Scholar]

- Sarker, T.; Hussein, M.; Haram, S.M.; Shern, S.J.; Gobbi, R. Second life for electric car batteries for use in photovoltaic installations. Energies 2024, 17, 2345. [Google Scholar]

- Campana, P.E.; Cioccolanti, L.; François, B.; Jurasz, J.; Zhang, Y.; Varini, M.; Stridh, B.; Yan, J. Li-ion batteries for peak shaving, price arbitrage, and photovoltaic self-consumption in commercial buildings: A Monte Carlo Analysis. Energy Convers. Manag. 2021, 234, 113889. [Google Scholar] [CrossRef]

- Safarian, S. Environmental and energy impacts of battery electric and conventional vehicles: A study in Sweden under recycling scenarios. Fuel Commun. 2023, 14, 100083. [Google Scholar] [CrossRef]

- Oster, D. Leaf Battery as BESS Research. Available online: https://github.com/dalathegreat/Battery-Emulator (accessed on 10 March 2024).

- Chadly, A.; Azar, E.; Maalouf, M.; Mayyas, A. Techno-economic analysis of energy storage systems using reversible fuel cells and rechargeable batteries in green buildings. Energy 2022, 247, 123466. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Maćków, P.; Guzdek, P.; Biskupski, J.A.; Grzesiak, W. Innowacyjne magazyny energii wyposażone w funkcję monitorowania i nadzoru. Wybrane zagadnienia. Przegląd Elektrotechniczny 2022, 98, 194. [Google Scholar] [CrossRef]

- Reschiglian, T.; Sevdari, K.; Marinelli, M. Repurposing Second Life EV Battery for Stationary Energy Storage Applications. In Proceedings of the 2024 IEEE PES Innovative Smart Grid Technologies Europe (ISGT EUROPE), Dubrovnik, Croatia, 14–17 October 2024. [Google Scholar] [CrossRef]

- Pimm, J.A.; Cockerilla, T.T.; Taylor, P.G. The potential for peak shaving on low voltage distribution networks using electricity storage. J. Energy Storage 2018, 16, 231–242. [Google Scholar] [CrossRef]

- Discount Rate Source in Poland, National Bank of Poland. Available online: https://nbp.pl/podstawowe-stopy-procentowe-archiwum/ (accessed on 8 May 2025).

- Rafal, K.; Biskupski, J.A.; Chaja, P.; Kużminski, M. Budowa hybrydowych magazynów energii—Aspekty techniczne i bezpieczeństwo (ang. “Construction of Hybrid Energy Storage Systems—Technical and safety aspects”). Mater. Bud. 2023, 1, 49–51. [Google Scholar] [CrossRef]

- Ohnemüller, G.; Beller, M.; Rosemann, B.; Döppe, F. Disassembly and Its Obstacles: Challenges Facing Remanufacturers of Lithium-Ion Traction Batteries. Processes 2025, 13, 123. [Google Scholar] [CrossRef]

- Mia, Y.; Hynan, P.; von Jouanne, A.; Yokochi, A. Current Li-Ion Battery Technologies in Electric Vehicles and Opportunities for Advancements. Energies 2019, 12, 1074. [Google Scholar] [CrossRef]

- Keshan, H.; Thornburg, J.; Ustun, T.S. Comparison of Lead-Acid and Lithium Ion Batteries for Stationary Storage in Off-Grid Energy Systems. In Proceedings of the 4th IET Clean Energy and Technology Conference (CEAT 2016), Kuala Lumpur, Malaysia, 14–15 November 2016; Institution of Engineering and Technology (IET): Stevenage, UK, 2016; pp. 1–7. [Google Scholar]

- Mazza, A.; Mirtaheri, H.; Chicco, G.; Russo, A.; Fantino, M. Location and Sizing of Battery Energy Storage Units in Low Voltage Distribution Networks. Energies 2020, 13, 52. [Google Scholar] [CrossRef]

- Biskupski, J.A. Practical Validation of nearZEB Residential Power Supply Model with Renewable Electricity Brought into the Building Using Electric Vehicles (via V2G) Instead of the Distribution Network. Energies 2025, 18, 2786. [Google Scholar] [CrossRef]

- Kim, D.; Jang, Y.; Choi, Y. Improved metrics for evaluating self-consumption and self-sufficiency rates in ESS-integrated renewable energy systems. Renew. Energy 2025, 247, 123059. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biskupski, J.A. Techno-Economics of Using Second Life BEV Traction Batteries as BESS in Domestic RES Installations. Energy Storage Appl. 2025, 2, 13. https://doi.org/10.3390/esa2030013

Biskupski JA. Techno-Economics of Using Second Life BEV Traction Batteries as BESS in Domestic RES Installations. Energy Storage and Applications. 2025; 2(3):13. https://doi.org/10.3390/esa2030013

Chicago/Turabian StyleBiskupski, Jacek A. 2025. "Techno-Economics of Using Second Life BEV Traction Batteries as BESS in Domestic RES Installations" Energy Storage and Applications 2, no. 3: 13. https://doi.org/10.3390/esa2030013

APA StyleBiskupski, J. A. (2025). Techno-Economics of Using Second Life BEV Traction Batteries as BESS in Domestic RES Installations. Energy Storage and Applications, 2(3), 13. https://doi.org/10.3390/esa2030013