The performance evaluation of an EMS oriented toward stationary applications, like houses or small buildings, requires the evaluation of the system for at least one full day. In this work, simulations are carried out in order to verify controller reliability through different RES generation and load demand scenarios. Once the EMS was tested through simulations, an experimental test was performed to validate the simulations results.

4.2. Simulation Results

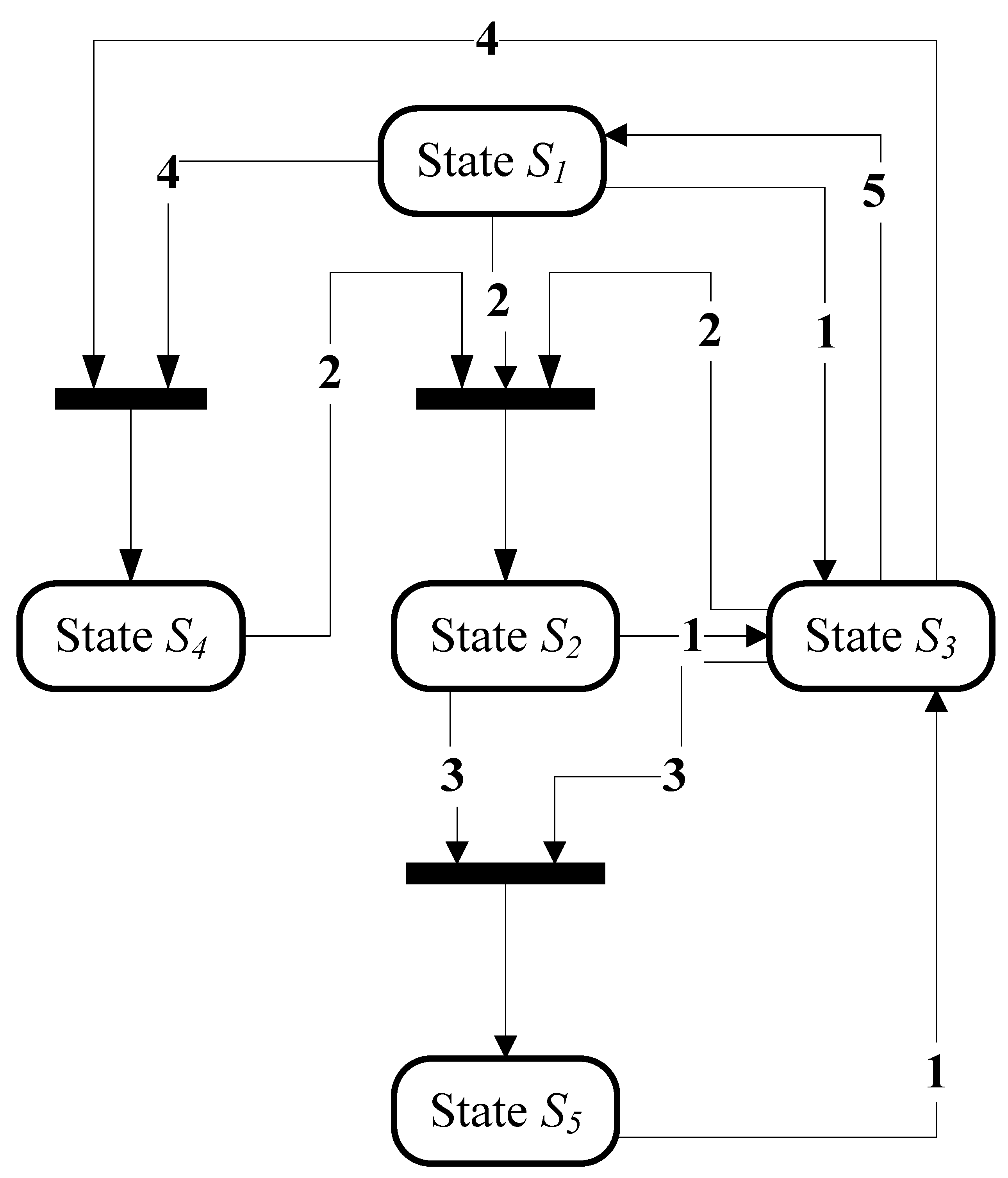

A complete model of the system was implemented in MATLAB/Simulink according to the description of the models of

Section 2. The system specifications,

levels, the constant battery charging power, as well as maximum power adopted are shown in

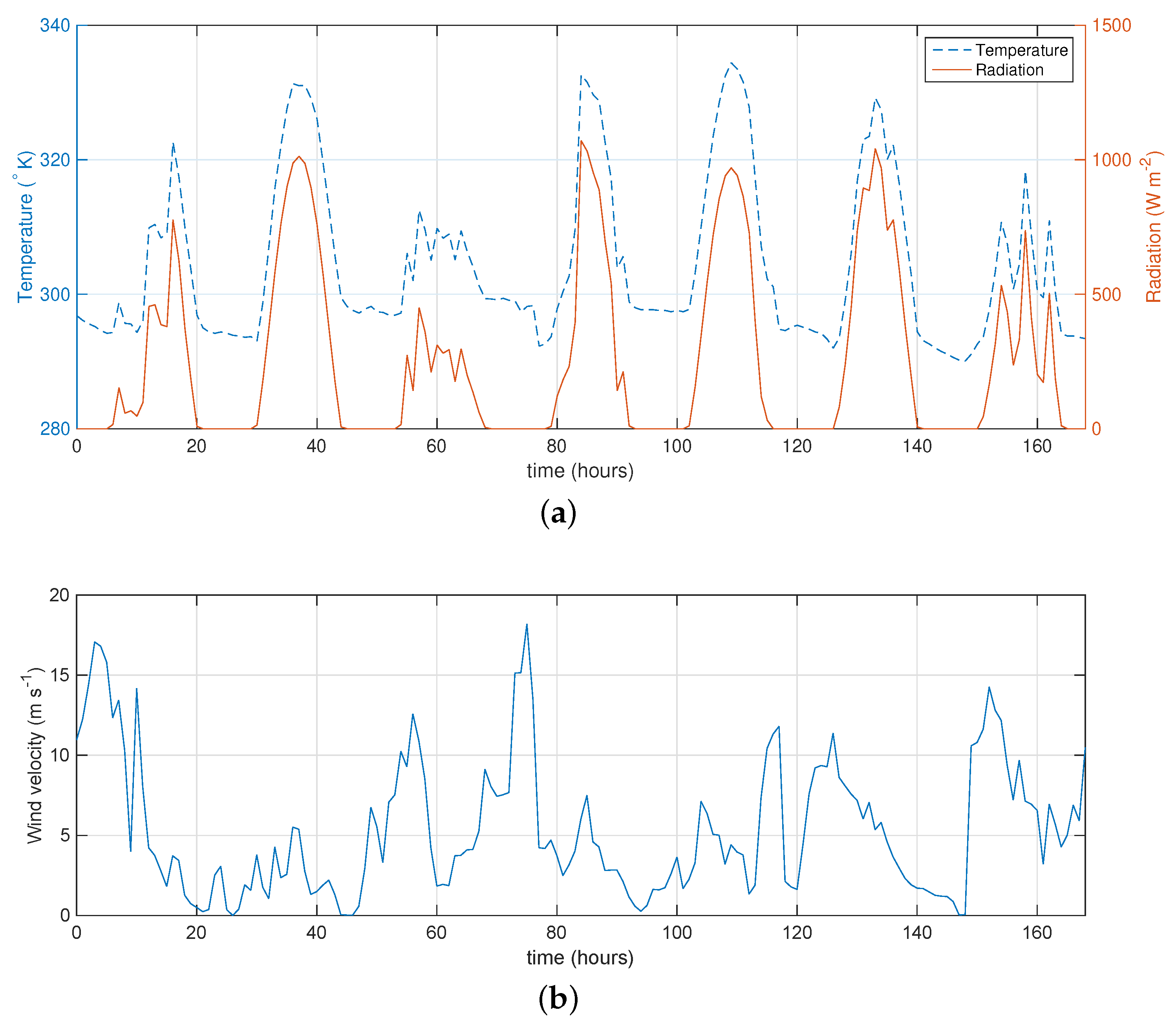

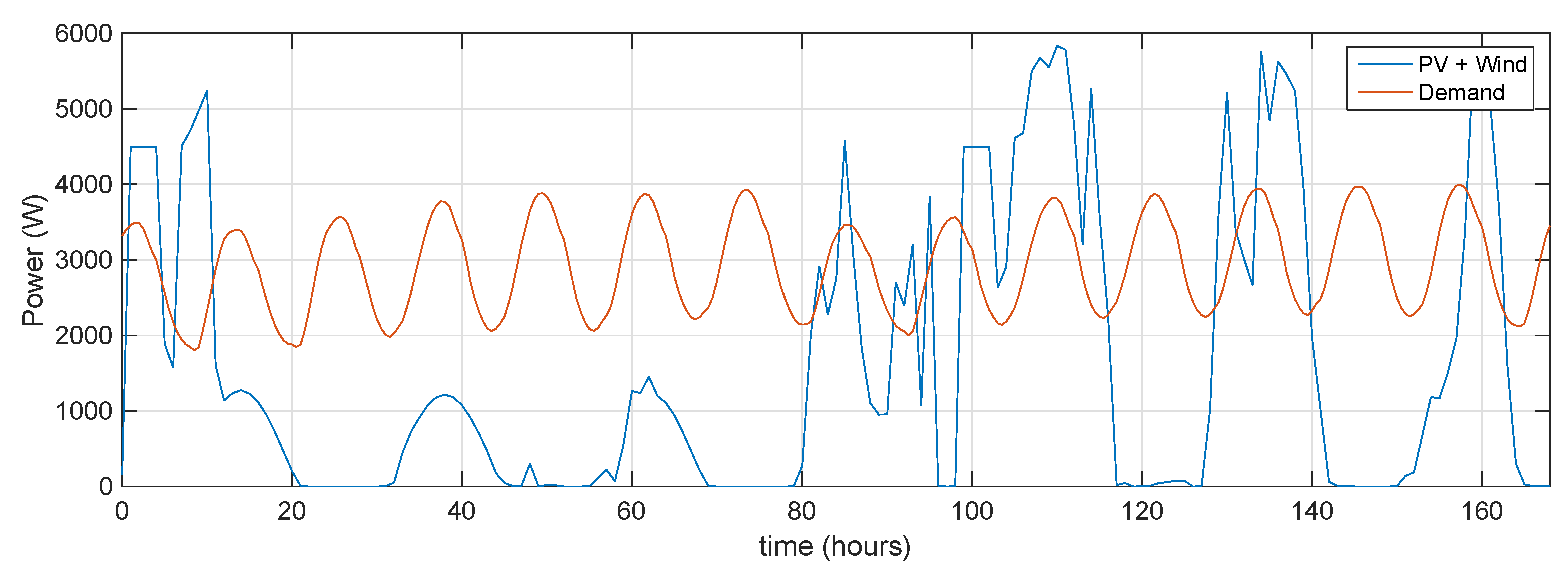

Table 6. The profiles corresponding to the generation from RESs and the load demand shown in

Figure 4 are used to carry out the simulation of the EMS performance.

Figure 5a shows the resulting power distribution on the HRES. As can be seen, the specifications stated in

Section 3 are satisfied by applying the proposed EMS. The RESs work in MPPT most of the time, and the batteries are charged if the generation from RESs exceeds the load demand, until

is reached. At this point, the RES goes to work in LPT mode (e.g., between Hour 100 and 116). The PEMFC acts as a secondary source when the RESs produce less than the load demand, while the batteries ensure the power balance during transient periods.

Figure 5b shows the behavior of the

and the states in which the EMS works. It can be seen that the EMS ensures the power balance, trying to keep the

at the desired value (

). This value is between

and

, giving the battery the ability to absorb or deliver energy if there is an excess or lack of power in the DC bus, respectively. Finally, it can be mentioned that the simulation results obtained have demonstrated the ability of the EMS to manage the energy in the system.

It is necessary to evaluate the performance of the EMS and verify the compliance with the system specifications (autonomy time and recharge time) in a critical scenario.

Figure 6a shows the power distribution in the simulated scenario, while

Figure 6b shows the corresponding

evolution and states of the EMS. At time

, the generation from the renewable sources is set to zero, and the load demand is set to its rated value. As a result of this, the fuel cell and the battery feed the load demand, and the battery is discharged during the autonomy time from

to

. At this moment, the EMS changes from State 2 to State 5, where only the vital loads are fed. Then, batteries start to charge (recharge time) until the

is reached, and the EMS leaves State 5. At this point (

), the critical scenario is reset, and the normal conditions are restored. The simulations show an adequate fulfillment of the imposed specifications.

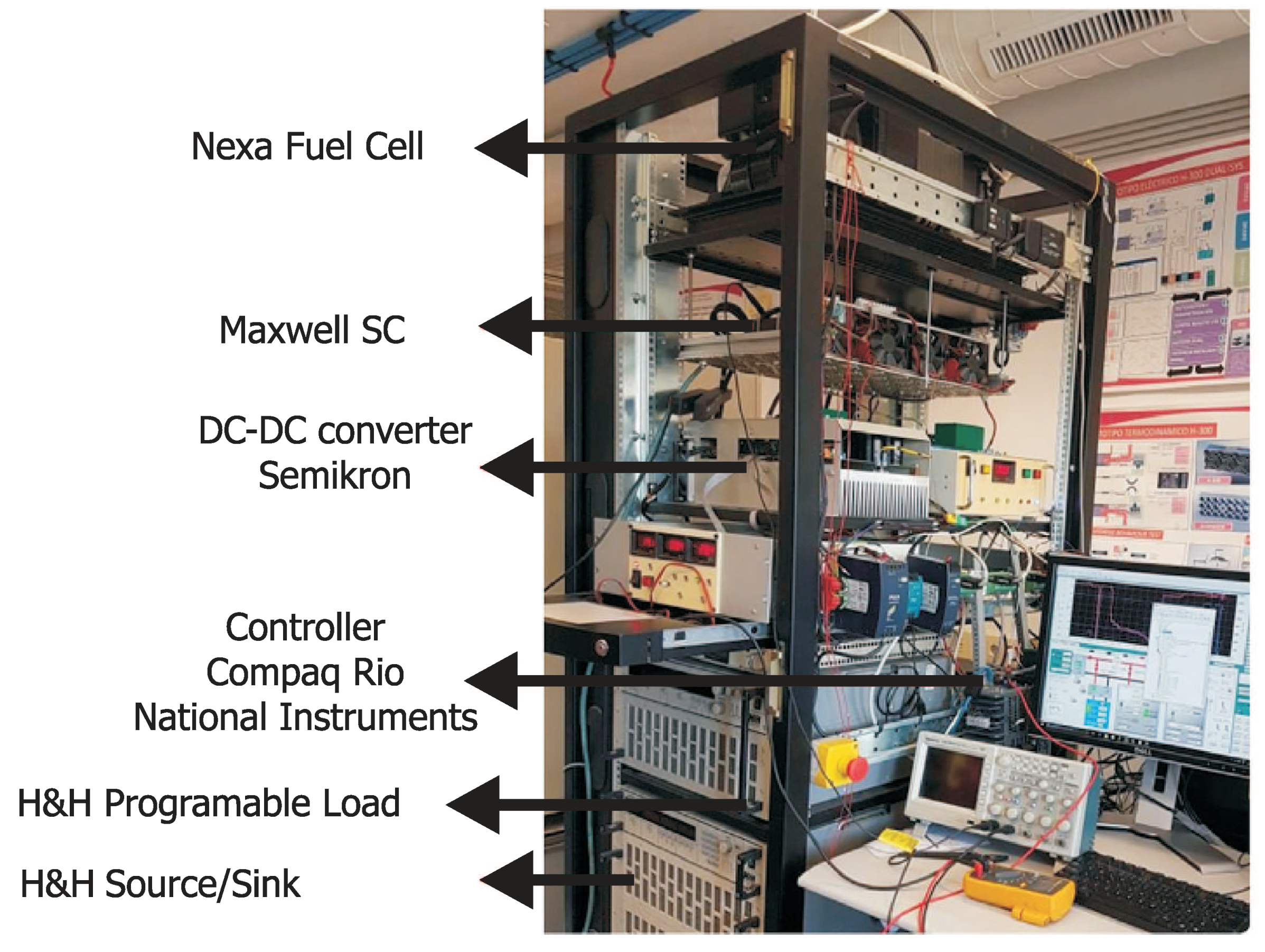

4.3. Laboratory Station Description

The experimental validation was performed in the Fuel Cell Laboratory of the Institut de Robòtica i Informàtica Industrial (IRI) of the Technical University of Catalonia (CSIC-UPC), in Barcelona, Spain. In this work, a fuel cell test station is used, which consists of a PEMFC stack and a supercapacitor (SC) bank. The SC is used in this experimental setup to replace the batteries as the energy storage. The demand profile is emulated by a programmable load, while the RESs generation is emulated with a programmable current source/sink. A picture of the laboratory station is shown in

Figure 7. This station has already been used successfully to validate an EMS applied to hybrid vehicle in [

30].

The PEMFC stack is a

Nexa

TM model MAN5100078, manufactured by Ballard

TM. The output voltage can be operated safely in the linear range of voltages from

to

and currents from

to

. The ESS consists on a

Maxwell

TM Supercapacitor model BMOD0165. The nominal voltage is

with values up to a maximum of

. The SC supports a nominal current of 98 in continuous mode and shows a serial resistance of approximately

. The DC-DC boost converters are implemented with two branches of Semikron

TM IGBTs. The converters are controlled with a

PWM signal, whose switching duty cycle is set by the EMS. The maximum voltage allowed in each switch is

, and the nominal current is

. The inductances in the converters have a value of

. The DC bus voltage adopted is

, and the bus capacitance is

. The programmable source is an NL Source-Sink (SS) from Hocherl & Hackl GmbH

TM. The output voltage of this source can reach a maximum of

with a nominal power of

. The installed programmable load (PL) is a ZL Electronic DC Load from Hocherl & Hackl GmbH

TM, which can work with a maximum voltage of

and

. Finally, the control is implemented using a National Instruments

TM controller model Compaq Rio 9035, which has a CPU Dual-Core of

and an FPGA Xilinx Kintex-7 7K70T. The rated values of the fuel cell test station are summarized in

Table 7.

4.4. Scaling Methodology

In this work, a method is developed to scale a given scenario so that it can be reproduced in the test station. The scaling methodology preserves most of the relevant energy-flow characteristics. Henceforward, the term scaled (superscript

s) will be used to refer to the test station, while the term real (superscript

r) to the HRES described in

Section 2 together with the realistic scenario.

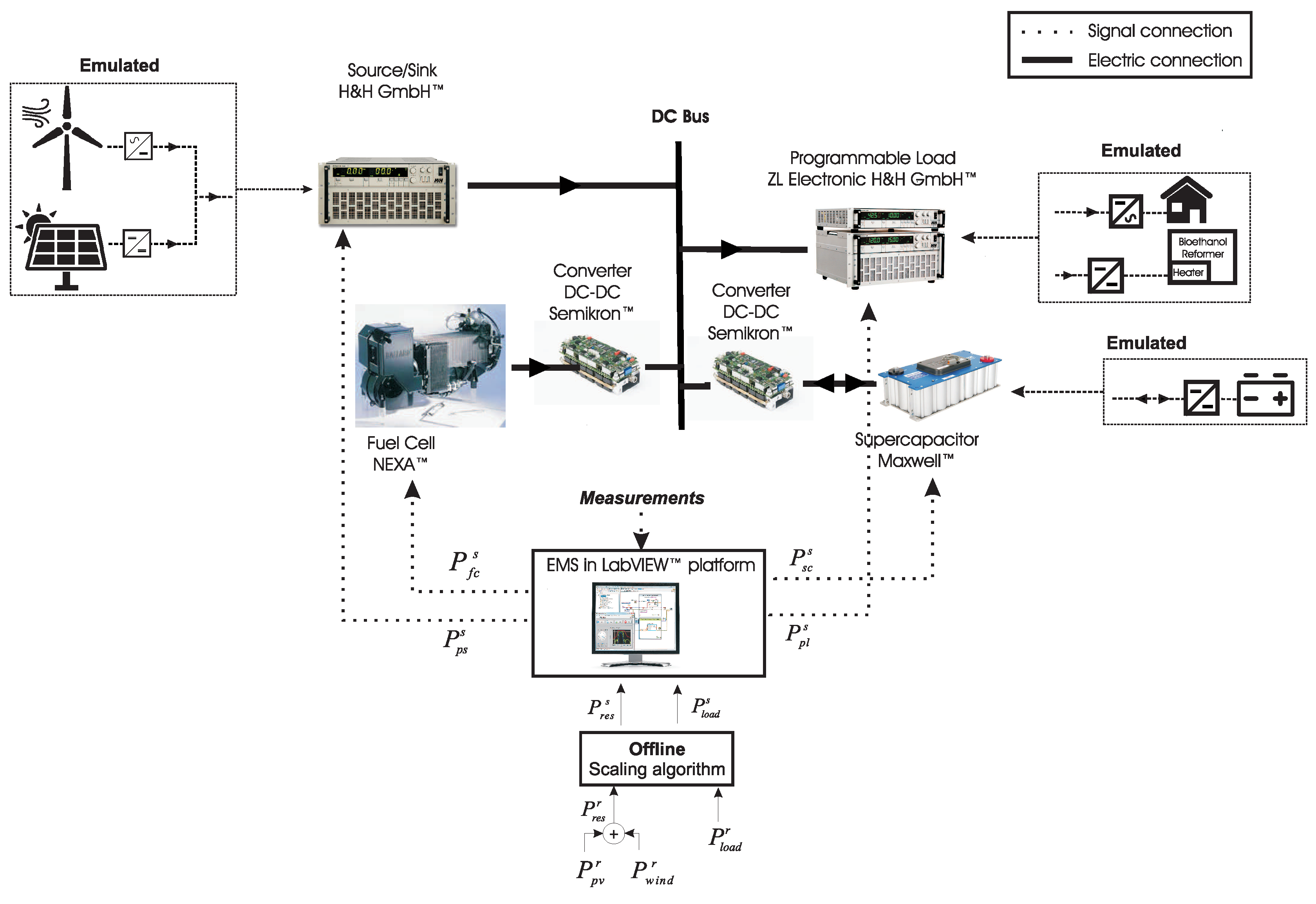

Figure 8 shows the experimental setup used. The EMS is executed in a host computer running a LABView

TM platform. The PEMFC stack and the SCs are connected to the DC bus through DC-DC converters. The H&H Source/Sink is used to emulate the RES generation delivered to the bus (

). The scaled version of RES’s available power (

) is obtained using the off-line scaling methodology applied to the real RES generation profile (

), which is formed by the wind turbines’ (

) and PV array’s (

) available powers. The scaled version of the load demand (

) and the power consumed by the BRS heater (

) are emulated using the programmable load (

). Note that the energy required by the heater is obtained using the power delivered by the Nexa

TM.

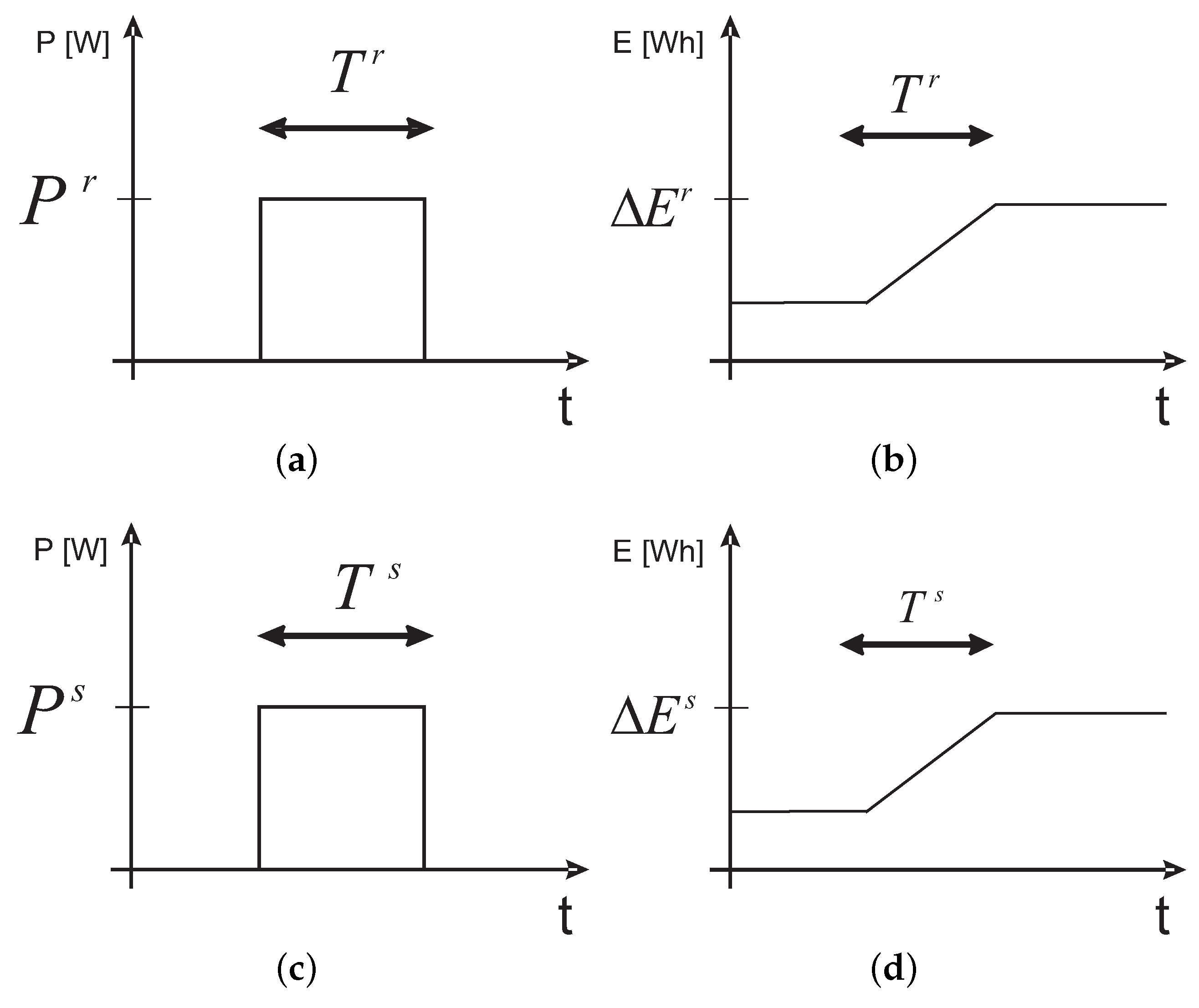

Given a real system with a net power

during a period

(

Figure 9a), the stored energy results

(

Figure 9b). In the same way, in the laboratory test station, there is an equivalent scenario with a power

and time

(

Figure 9c), resulting in a stored energy

(

Figure 9d). The relative change with respect to the maximum energy capacity

(with

) can be expressed as:

The relationship between the real scenario and the scaled scenario can be defined taking into account that the power step must produce the same relative change in the stored energy of both scenarios. From Equation (

38), it results:

The scaling coefficients can be defined by Equation (

39):

while the fundamental relationship can be rewritten as:

where

,

and

are the energy, power and time scaling coefficients, respectively. Then, the load and RES scaled profiles result:

Note that the power consumed by the heater in the scaled system (

) is not multiplied by

because it is calculated by Equation (

1) using the measure of the power delivered by the fuel cell (

).

As described in

Section 2.5, the ESS in the real system is formed by a battery bank. Then, the maximum energy storing capacity (

) can be approximated by:

Since the ESS in the test station is composed of SCs, the maximum energy storing capacity (

) is calculated as:

where

is the capacity of the SC and

and

are the maximum and minimum voltage imposed on the SC in the emulation test, respectively. Note that the definition of a minimum and a maximum value in the SC voltage allows us to manipulate its energy capacity, which is one of the scaling process variables. The

level from the SC can be calculated as:

where

is the SC voltage.

Then, replacing (

40), (

45) and (

46) in (

43), the power scaling coefficient results:

To avoid exceeding the laboratory station capacities established in

Section 4.3 and taking into account the case study description, some constraints must be imposed on Equation (

48). The power scaling coefficient (

) must take into account the power range of the real system profiles (RESs, load demand and fuel cell) in such a way that the scaled powers do not exceed power equipment limitations. These constraints impose upper bounds on

:

where

is the rated power of the source/sink and

is the rated power of the programmable load.

is the maximum power peak of the RES generation profile;

is maximum load demand; and

is the power consumed by the electric heater with the fuel cell at its maximum power.

is the rated power of the fuel cell in the real scenario, while

is the rated power of the Nexa

TM fuel cell.

In addition, the maximum current of the SC (

) also imposes an upper bound on

. In charging mode, the maximum current occurs with the maximum charging power and the minimum voltage. With the proposed EMS, the maximum charging power matches the maximum RES generated power (

), while the minimum voltage is

:

In discharging mode, the maximum power is when the SC has to provide all the power required by the load:

It is expected that the maximum power rate allowed in the laboratory station fuel cell (

), once unscaled, would not exceed the real system constraints (

):

This constraint imposes a lower bound on

that depends on

:

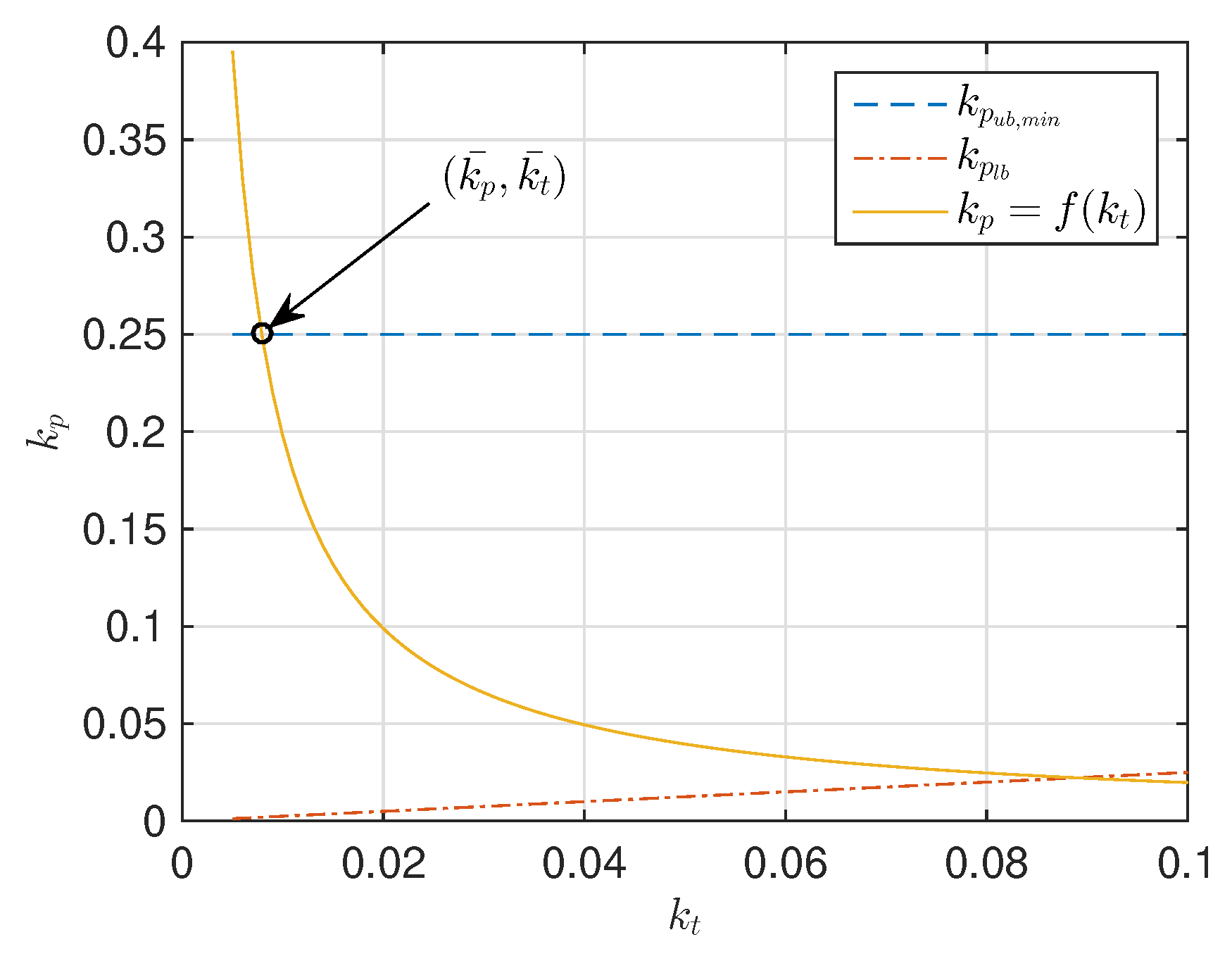

In

Figure 10 are summarized the feasible values of the scaling coefficients (

) and the constraints described before. As can be seen,

can take values in the dashed line (defined by Equation (

48)) between the lower bound (

) and the most restrictive upper bound (

). To obtain an experimental test duration as short as possible, a value of

as small as possible has to be chosen. Then, the adopted scaling coefficient pair

is in the intersection defined by Equation (

48) and

. Finally,

Table 8 summarizes the characteristic values of the real scenario, the adopted voltage values for the SCs in the emulation test and the resulting scaling coefficients. The values of the maximum RES generation and the maximum load demand were obtained from the real scenario taking into account a complete year.

4.5. Experimental Results

The experimental validation of the EMS was performed using a typical winter day from the annual profiles of the real scenario.

Figure 11 shows the evolution of power generation from renewable sources (blue line) and the load power demanded (red line) over the selected day. With regard to the power generated, this power is the sum of the powers corresponding to the two renewable sources: wind and photovoltaic. This power has a peak at 15 o’clockdue to the contribution of sun and wind and a valley during the night because there is no contribution from the Sun. With regard to the curve of the power demanded, it is a profile consistent with the power demand of a home where two peaks are observed, one in the morning near noon and another near dinner time, and two valleys, one in the morning and the other in the afternoon.

Then, the power profiles were scaled according to the methodology presented in

Section 4.4 to perform the experimental test. Note that, once scaled, the original length of 24 × 3600 = 86,400 s resulted in a duration of the experiment of 86,400

= 682.5 s. The reduction in experiment duration is an important advantage that results from applying the proposed scaling methodology.

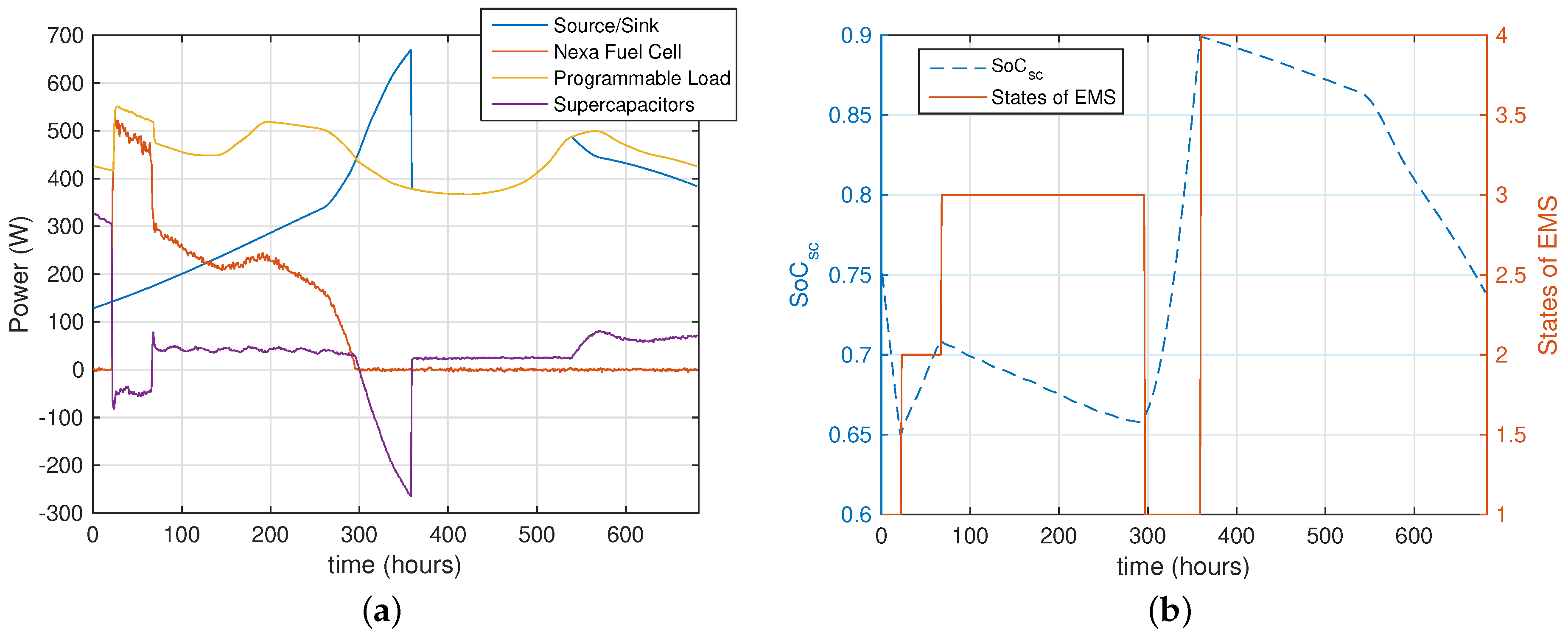

Figure 12a shows the power distribution resulting from the test. As explained in

Section 4.3, the RES generation is emulated with the source/sink, while the load demand and the power consumed by the heater are emulated with the programmable load. Note that, while the load demand is scaled from the load profile of

Figure 11, the power required by the heater is obtained from Equation (

1) using the measured power of the Nexa

TM fuel cell. The power delivered by the fuel cell is set by the EMS, and the power delivered/absorbed by the SC arises as a result of the two PI controllers in cascade that attempt to maintain the DC bus voltage at the desired level, while in the simulation, it is computed from a power balance. A constant power delivered by the SC can be seen that corresponds to the necessary power to maintain the DC bus at the desired value. Then,

Figure 12b shows the evolution of the state of charge of the batteries and the state in which the EMS works. The commutations between states according to the occurrence of events can be seen.

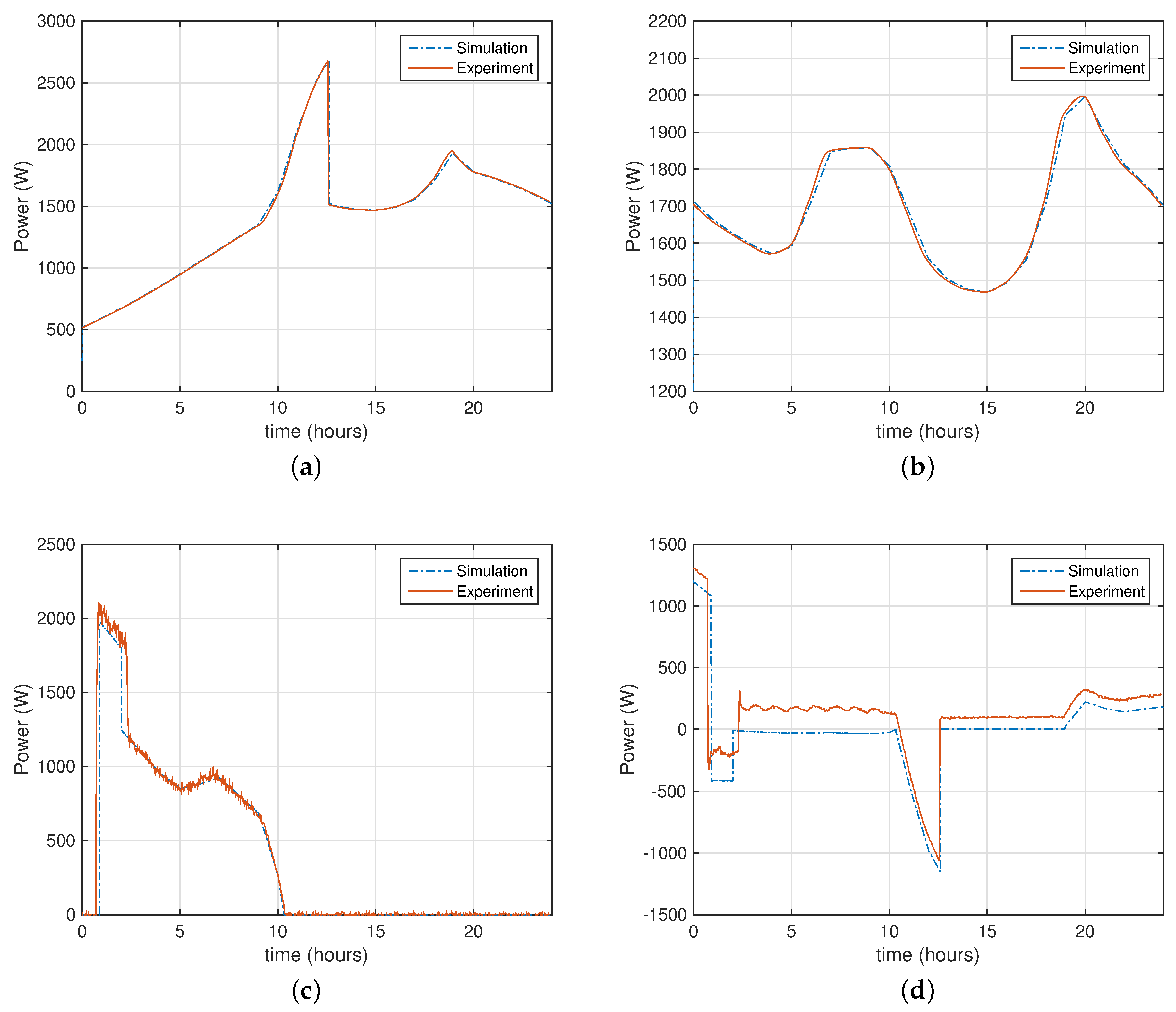

The HRES behavior is simulated using the profiles of

Figure 11 and compared with the experiment results. The inverse scaling process is carried out over the profiles presented in

Figure 12a. The evolutions of the main variables, both in simulation and in the experimental test, are shown in

Figure 13. The RES generation and the load power demand, which are emulated with the source/sink, and the programmable load are shown in

Figure 13a,b. In

Figure 13c is shown the Nexa

TM fuel cell, where the main difference of the experiment evolution with respect to the simulation is a small noise. The major differences observed between experimental and simulation results are found in the SC power of

Figure 13d and are due to the low efficiency in the bidirectional DC-DC converter, especially at low powers. This could be solved by incorporating the models of the converters with their efficiency curves. This improvement will be addressed in future works.

In summary, the experimental results presented in this section have demonstrated the feasibility of implementing the proposed EMS for the HRES under study. In the same way, the proposed scaling methodology provides a useful tool to evaluate the qualitative behavior of the main HRES variables in a real scenario.