An Intelligent Management Model for College-Level Reagent Repositories in Universities

Abstract

1. Introduction

2. College-Level Intelligent Management System for Reagent Repositories

2.1. The Necessity of Intelligent Management

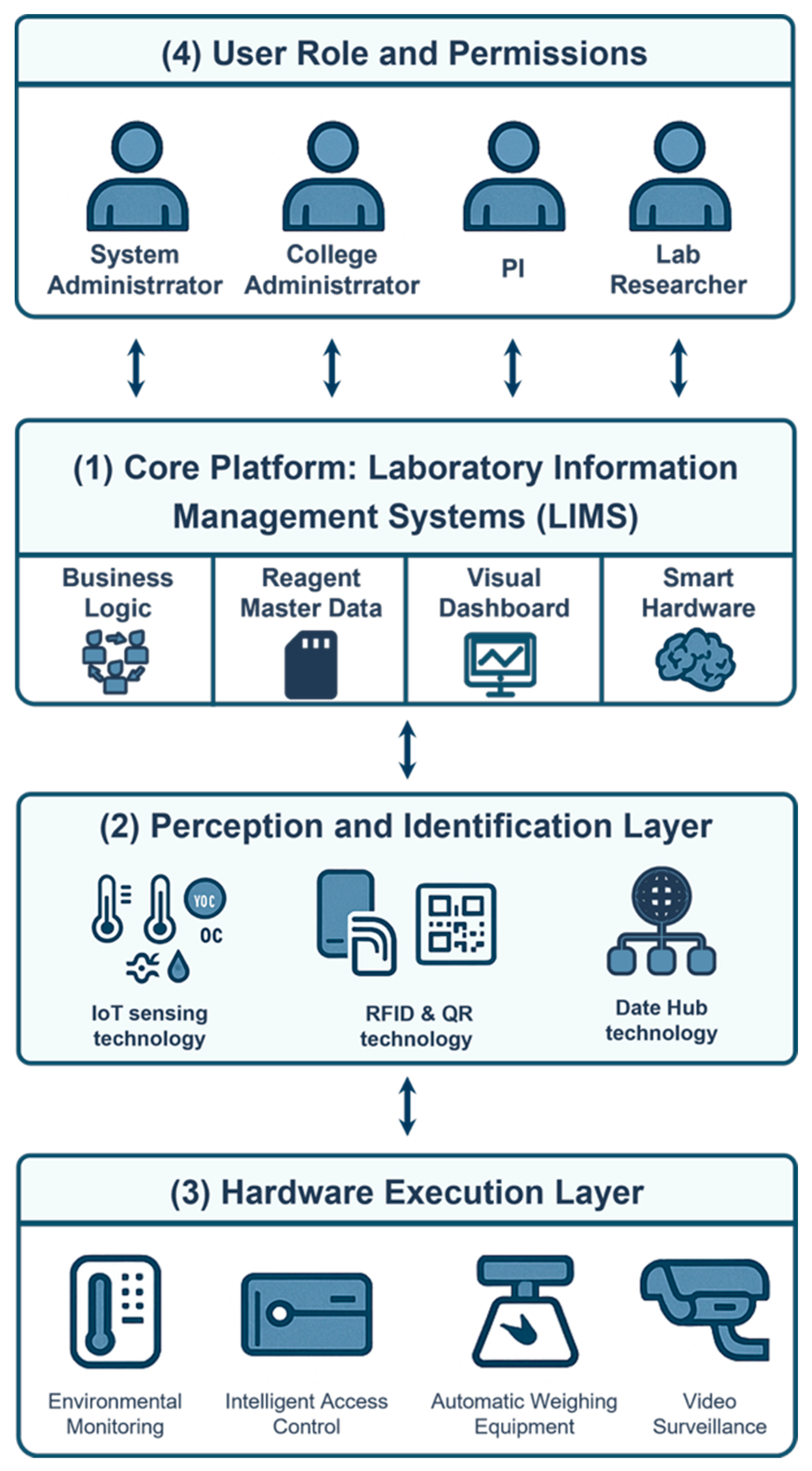

2.2. Overall System Architecture Design

- (1)

- Core Platform

- (2)

- Perception and Identification Layer

- (3)

- Hardware Execution Layer

- Environmental Monitoring Terminals: These comprise various IoT sensors, such as temperature/humidity sensors and gas leak detectors.

- Intelligent Access Control System: This system enables automatic and precise identity verification for personnel entry and exit, logging records to replace traditional key management and enhance security.

- Automatic Weighing Equipment: Electronic balances connected to the system automatically record weight changes during checkout and return operations.

- Video Surveillance System: This system comprehensively monitors key areas within the repository, linking video streams with operation records (e.g., checkout and return) to form a traceable and complete evidence chain.

- (4)

- User Role and Permissions

2.3. Model Comparison and Innovative Analysis

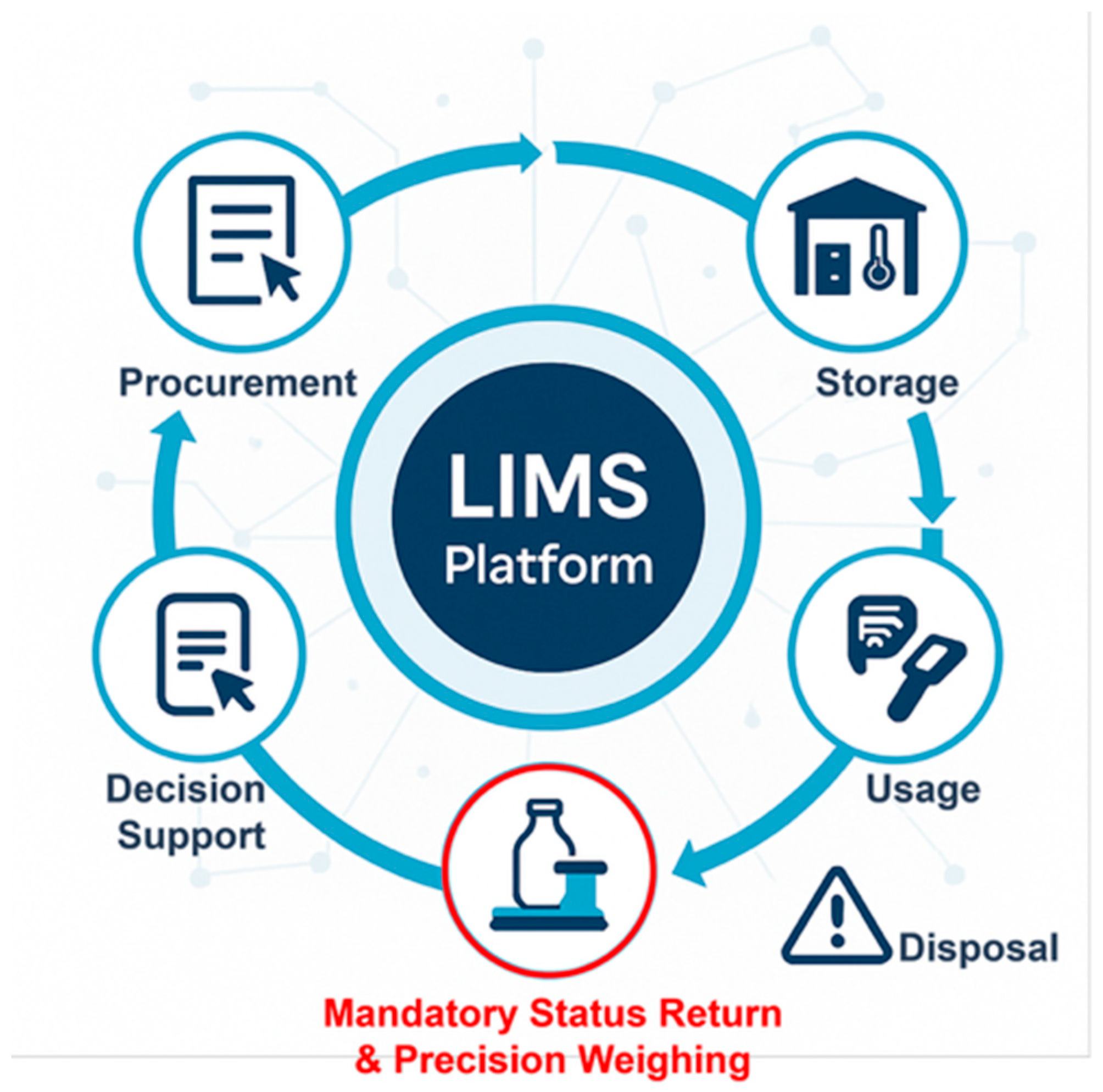

3. Implementation Pathway for the Intelligent Management Model

3.1. Intelligent Procurement and Multi-Level Approval

- General reagents only require approval from the PI;

- Non-controlled hazardous chemicals require collaboration between the PI and the college-level administrator;

- Controlled hazardous chemicals require a multi-level approval process, filing with the public security department, and final purchase authorization by the university.

3.2. Intelligent Storage, and Distribution

3.3. Mandatory Return and Precise Consumption Tracking

- For Partially Used Reagents: The system calculates the difference and updates the inventory to reflect the remaining quantity.

- For Empty Bottles (Fully Consumed): The system updates the item’s status to “empty” and adds the bottles to the disposal waiting list. It then prompts the administrator to record the type of bottle, its state of cleanliness (e.g., washed), and the type of residue by selecting from a menu.

4. Technical Implementation Challenges and Proposed Solutions

4.1. Challenges Regarding Heterogeneous System Integration and Data Interoperability

4.2. Challenges of Reliable Identification and Data Acquisition in Complex Environments

4.3. User Adoption Strategies, Compliance Assurance, and Behavioral Change Management

5. Conclusions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, F. Research on Intelligent Management of Laboratory Information Technology. Procedia Comput. Sci. 2022, 208, 184–189. [Google Scholar] [CrossRef]

- Shaban, S.A. A Smart System for the University Chemical Laboratory Using IoT. J. Adv. Inform. Technol. 2024, 15, 104–117. [Google Scholar] [CrossRef]

- Menard, A.D.; Trant, J.F. A Review and Critique of Academic Lab Safety Research. Nat. Chem. 2020, 12, 17–25. [Google Scholar] [CrossRef]

- Sims, B. Safe science: Material and Social Order in Laboratory Work. SOC Stud. Sci. 2005, 35, 333–366. [Google Scholar] [CrossRef]

- Kinoshita, T.; Tonokura, K.; Shibata, I.; Yamada, E.; Murata, S.; Matsumoto, M.; Sawamura, M.; Nakagawa, H.; Morimoto, K.; Koyama, A. Management of Chemicals for Safety and Education in Laboratory. J. Environ. Saf. 2015, 6, 81–84. [Google Scholar]

- Sussman, V.; Dutta, S.; Foisel, J. Of People, Programs, and Priorities: The Impact of Organizational Culture in Industrial Research and Development Laboratories. ACS Chem. Health Saf. 2023, 30, 223–235. [Google Scholar] [CrossRef]

- Boustras, G.; Waring, A. Towards a Reconceptualization of Safety and Security, Their Interactions, and Policy Requirements in a 21st Century Context. Saf. Sci. 2020, 132, 104942. [Google Scholar] [CrossRef]

- Bai, M.; Liu, Y.; Qi, M.; Roy, N.; Shu, C.-M.; Khan, F.; Zhao, D. Current Status, Challenges, and Future Directions of University Laboratory Safety in China. J. Loss Prev. Process Ind. 2022, 74, 104671. [Google Scholar] [CrossRef]

- Walters, A.U.; Lawrence, W.; Jalsa, N.K. Chemical Laboratory Safety Awareness, Attitudes and Practices of Tertiary Students. Saf. Sci. 2017, 96, 161–171. [Google Scholar] [CrossRef]

- Huang, K. Exploration and Practice on Construction of Laboratory Safety Education System in Peking University. Exp. Technol. Manag. 2013, 30, 1–4. (In Chinese) [Google Scholar]

- Gibson, J.H.; Schröder, I.; Wayne, N.L. A Research University’s Rapid Response to a Fatal Chemistry Accident: Safety Changes and Utcomes. J. Chem. Health Saf. 2014, 21, 18–26. [Google Scholar] [CrossRef]

- Chen, M.; Wu, Y.; Wang, K.; Guo, H.; Ke, W. An Explosion Accident Analysis of the Laboratory in University. Process Saf. Prog. 2020, 39, e12150. [Google Scholar] [CrossRef]

- Global Times. Nanjing Lab Blast Kills 2, Hurts 9, Triggering Renewed Safety Concerns Over Research Institutes. Available online: https://www.globaltimes.cn/page/202110/1237165.shtml (accessed on 24 October 2021).

- Ye, Y.X.; Ma, J.; Zhao, Y.Z.; Shen, Y.L.; Ren, Z.C. Statistical Analysis of 150 Laboratory Accidents and Research on Safety Management Strategies. Exp. Technol. Manag. 2020, 37, 317–322. (In Chinese) [Google Scholar]

- Du, Y.; Feng, J.Y.; Zhang, X.X. Summary of Three-Year Laboratory Safety Inspections in Universities (II): Current Status of Laboratory Safety Management from Inspection Perspectives. Exp. Technol. Manag. 2018, 35, 5–11. (In Chinese) [Google Scholar]

- Galasso, A.; Luo, H.; Zhu, B. Laboratory Safety and Research Productivity. Res. Policy 2023, 52, 104827. [Google Scholar] [CrossRef]

- Li, Y.L.; Wang, W.F.; Zhang, X.H. Construction of Real-Time Chemical Management Systems in Colleges and Universities Based on Data Fusion. Exp. Technol. Manag. 2024, 41, 250–254. (In Chinese) [Google Scholar]

- Jiao, Z.; Hu, P.; Xu, H.; Wang, Q.S. Machine Learning and Deep Learning in Chemical Health and Safety: A Systematic Review of Techniques and Applications. J. Chem. Health Saf. 2020, 27, 316–334. [Google Scholar] [CrossRef]

- Subasinghe, S.S.; Gersib, S.G.; Frueh, T.M.; Mankad, N.P. Can Large Language Models (LLMs) Act as Virtual Safety Officers? ACS Chem. Health Saf. 2024, 32, 39–47. [Google Scholar] [CrossRef]

- Li, Y.T.; Han, B.J.; Zhao, X.J.; Li, E.J. Laboratory Chemical Safety Management Practices in Chinese Universities: A Case Study of Peking University. ACS Chem. Health Saf. 2025, 32, 572–581. [Google Scholar] [CrossRef]

- Yin, W.T.; Yin, W.D.; Huang, X.L.; Xie, Y.S. Design and Implementation of Intelligent Management System for University Lab Equipment Based on RFID Technology. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Belagavi, India, 24–26 November 2023; pp. 1–4. [Google Scholar]

- Blumenthal, J.; Diamond, M.L.; Hoffmann, M.; Wang, Z. Time to Break the “Lock-In” Impediments to Chemicals Management. Environ. Sci. Technol. 2022, 56, 3863–3870. [Google Scholar] [CrossRef]

- Cardoso Rial, R. AI in Analytical Chemistry: Advancements, Challenges, and Future Directions. Talanta 2024, 274, 125949. [Google Scholar] [CrossRef]

- Li, L.P.; Tian, H.; Yuan, X.P.; Du, G.Y.; Du, G.Y.; Huang, J.J.; Lu, Y.R.; Liu, Q.L. Design and Practice of Laboratory Information Management System based on WeChat Mini-Program. Lab. Sci. 2022, 25, 61–64. (In Chinese) [Google Scholar]

- Gu, W.Y.; Yang, F.F.; Li, W.B.; Wang, Z.F.; Zhu, Z. Intelligent Monitoring System for Hazardous Sources in University Laboratories based on IoT-enabled Smart Sensing. Exp. Technol. Manag. 2025, 1–11. Available online: https://link.cnki.net/urlid/11.2034.T.20251022.1628.010 (accessed on 23 October 2025). (In Chinese).

- Wang, J. Construction of A New Management Mode of Hazardous Chemicals in University Laboratories Supported by QR Code Technology. Chem. Eng. Manag. 2025, 22, 71–74. (In Chinese) [Google Scholar]

- Hu, W.C.; Chen, T.B.; Zhuang, X.J.; Cheng, X.D. An Exploration of Green and Safe Management Practices for Hazardous Chemicals in Agricultural University Laboratories under the “Internet +” Paradigm. China Edu. Technol. Equip. 2025, 12, 31–33. (In Chinese) [Google Scholar]

- Thermo Fisher Scientific. Sample Manager LIMS in Academic and Research Laboratories: Deployment Case Studies. Thermo Fisher Scientific White Paper. 2024. Available online: https://www.thermofisher.com/us/en/home/digital-solutions/lab-informatics.html (accessed on 14 April 2024).

- Duke, R.; Bhat, V.; Risko, C. Data Storage Architectures to Accelerate Chemical Discovery: Data Accessibility for Individual Laboratories and the Community. Chem. Sci. 2022, 13, 13646–13656. [Google Scholar] [CrossRef] [PubMed]

- Cui, Q.; Gan, S.; Zhong, Y.; Yang, H.; Wan, Y.; Zuo, Y.; Yang, H.; Li, M.; Zhang, S.; Negahdary, M.; et al. High-throughput and Specific Detection of Microorganisms by Intelligent Modular Fluorescent Photoelectric Microbe Detector. Anal. Chim. Acta 2023, 1265, 341282. [Google Scholar] [CrossRef]

- Wilbraham, L.; Mehr, S.H.M.; Cronin, L. Digitizing Chemistry Using the Chemical Processing Unit: From Synthesis to Discovery. Acc. Chem. Res. 2021, 54, 253–262. [Google Scholar] [CrossRef]

- Tamura, M.; Kawamoto, T.; Ishifuro, M.; Tamura, T.; Masumoto, Y.; Kenjo, M.; Kiguchi, M.; Awai, K.; Nagata, Y. Radio Frequency Identification Gate System to Identify Misused Personal Dosimeters. J. Med. Syst. 2023, 47, 107. [Google Scholar] [CrossRef] [PubMed]

| System (Year) | Full-Lifecycle Closed-Loop Management | Mandatory Status Return | Two-Way Sync with University Platform | Anti-Metal RFID + QR Backup | Dual-Person Dual-Lock | Real Deployment with Results Reported |

|---|---|---|---|---|---|---|

| WeChat mini-program (2022) [23] | Partial | No | No | Yes | No | No |

| IoT platform for hazardous chemicals (2025) [24] | Yes | No | No | Partial (IoT only) | No | No |

| QR Code for hazardous chemicals (2025) [25] | Yes | No | No | Partial (QR card only) | No | No |

| RFID intelligent cabinet (2024) [21] | Storage & distribution only | No | No | Yes | Partial (single lock) | No |

| “Internet+” safety management (2025) [26] | Partial | No | No | No | No | No |

| IoT university chemical laboratory (2024) [2] | Yes | No | No | Partial | No | No |

| Peking University case (2025) [20] | Yes | No | No | No | No | Yes |

| Thermo Fisher Sample Manager LIMS (2024) [27] | Yes | No | Partial | Optional add-on | Optional add-on | Yes (enterprise level) |

| Proposed Model (2025) | Yes | Yes | Yes | Yes | Yes | Will be deployed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C. An Intelligent Management Model for College-Level Reagent Repositories in Universities. Laboratories 2025, 2, 23. https://doi.org/10.3390/laboratories2040023

Ma C. An Intelligent Management Model for College-Level Reagent Repositories in Universities. Laboratories. 2025; 2(4):23. https://doi.org/10.3390/laboratories2040023

Chicago/Turabian StyleMa, Chao. 2025. "An Intelligent Management Model for College-Level Reagent Repositories in Universities" Laboratories 2, no. 4: 23. https://doi.org/10.3390/laboratories2040023

APA StyleMa, C. (2025). An Intelligent Management Model for College-Level Reagent Repositories in Universities. Laboratories, 2(4), 23. https://doi.org/10.3390/laboratories2040023