Abstract

The massive production of municipal solid waste presents a significant global challenge for sustainable urban development and maintaining citizens’ quality of life, requiring effective management and disposal strategies. Waste-to-energy incineration technology has become increasingly important as a solution that simultaneously addresses the growing volumes of municipal solid waste and rising energy needs worldwide. This comprehensive review examines the research findings on the effectiveness of incineration as a waste-to-energy conversion method. The primary goal was to conduct a thorough systematic review assessing WtE incineration effectiveness across several key areas: energy recovery efficiency, waste volume reduction capabilities, environmental impact, and economic feasibility. A comprehensive literature search was conducted across ScienceDirect and additional pertinent databases, utilizing appropriate search terms in accordance with the PRISMA framework. A total of 431 studies were systematically identified, published between 2015 and 2025, and only 25 relevant studies were included in this review. Researchers collected data focusing on energy recovery percentages, volume reduction rates, emission reductions, and economic performance metrics. The findings revealed that every study included in the analysis showed positive results for WtE incineration across various performance measures. This research discovered the feasibility of generating electrical power from garbage through WtE incineration processes. The projected energy yields, ranging from gigawatt-hours to kilowatt-hours, were quantified for several nations, including Mexico (11,681.64 GWh), Cambodia (1625.81 GWh), Bangladesh (187.04 GWh), South Africa (6944 GWh), Iran (17,678 GWh), Nigeria (10,000 GWh), Indonesia (2487 MWh), Algeria (11.6 MWh), China (2316.52 MWh), Iraq (203.917 MWh), Uganda (774 kWh), and Pakistan (675 kWh). Energy recovery efficiency demonstrated a wide range from 30% to 92.75%, with waste volume reduction consistently reaching 90–95% levels, significantly prolonging landfill operational lifespans. From an environmental perspective, technology achieved greenhouse gas emission reductions ranging from 30% to 87%. This dual-purpose approach makes it an attractive, sustainable solution for both waste management and renewable energy production. By adopting this approach, cities can address waste and energy issues while boosting economic growth and job creation. However, it also involves substantial costs, technical difficulties, and environmental hazards that necessitate meticulous oversight.

1. Introduction

Today’s world faces two major problems that are worsening and are closely connected, threatening our ability to develop sustainably: we continue to produce increasing amounts of waste, and we require more and more electricity [1]. Dealing with trash and waste is one of the biggest headaches that confronts environmental conservation agencies today [2].

Since 2007, the Dikeni region, under the Raymond Mhlaba municipality, has been experiencing a substantial rise in electricity consumption and waste accumulation across the city [3]. This notable surge in waste production is accompanied by a similarly remarkable increase in electricity consumption, driven by rapid urbanization, population growth, and economic development. To reduce waste piling up, residents burn waste openly, resulting in land pollution at 30% and aquatic pollution at 14%. These further release carbon dioxide (CO2) and generate toxic and carcinogenic fumes, thereby exacerbating climate change and public health risks [4,5]. This practice aligns with SDG number 11, which aims to make cities and human settlements inclusive, safe, resilient, and sustainable for everyone.

Raymond Mhlaba, characterized as a rural municipality, predominantly relies on its agricultural sector, which encompasses citrus cultivation, forestry, livestock husbandry, and crop farming. This encompasses all solid waste generated from water treatment plants, residential homes, commercial establishments, educational institutions, workplaces, construction sites, and building demolitions [2]. Inadequate waste management methodologies contribute to environmental deterioration, resource depletion, and threats to public health. Simultaneously, electrical energy demand across various nations continues its upward trend, with township populations demonstrating an increased dependence on electricity for virtually all aspects of modern life [2]. This dual pressure engenders a multifaceted sustainability crisis, wherein traditional linear economic paradigms, which essentially extract resources, produce goods, and discard them, no longer suffice [6].

Urban development serves as a critical driving force that intensifies both issues. When people crowd into cities, the demand for electricity increases due to heightened business activity, expanding industries, and improved lifestyles [1,2,7]. Recent data indicate that South Africa produces approximately 122 million tons of waste annually. Of this total, only about 10% is subjected to recycling or recovery for alternative uses, while at least 90% is disposed of in landfills or through illegal dumping [4]. Landfilling remains the most common and cost-effective method of waste disposal across the region. Yet, it is an imperfect solution due to groundwater contamination, soil degradation, and odor emissions [8,9].

However, these two problems actually create a unique chance for creative solutions. The combination of piling up waste and the need for more electricity has sparked significant interest in waste-to-energy technologies, which could address both issues simultaneously. These approaches convert different types of waste into energy that we can actually use, helping to generate electricity while reducing pressure on landfills [10,11]. Understanding how waste accumulates and electricity demand operates, especially in rapidly growing cities and developing economies, is crucial for developing policies and technologies that can deliver both environmental protection and energy reliability.

Conventional waste management practices, including landfill operations and uncontrolled dumping, constitute substantial contributors to environmental deterioration, the emission of greenhouse gases, and the depletion of natural resources. By tackling these twin issues of rising waste generation and the demand for sustainable energy sources, within this framework, waste-to-energy (WtE) through incineration technology has emerged as a prominent solution that concurrently addresses waste management problems while facilitating the production of renewable energy resources [4,9,12].

WtE incineration operates through the systematic burning of municipal solid waste at elevated temperatures, transforming the chemical energy contained within waste materials into thermal energy that can then be converted into electrical power, heating, or a combination of both using integrated heat and power systems [9,13].

The primary objective of this research is to examine how effectively WtE incineration transforms municipal solid waste into practical energy sources (electricity), while evaluating its capacity to reduce waste volumes and measuring its environmental effects, particularly regarding decreased greenhouse gas emissions and influences on air quality. Through the utilization of waste’s energy capabilities, these sustainable resources can foster economic development while addressing environmental challenges linked to inadequate waste management. This methodology enables municipal authorities to transition toward renewable energy frameworks by utilizing waste combustion for electricity production, thereby reducing waste accumulation and generating environmentally friendly, economically viable solutions [4,14].

1.1. Overview of Waste-to-Energy (WtE) Process

Waste-to-Energy (WtE) incineration serves as a technology with two key functions: tackling the challenges of managing municipal solid waste while meeting energy production requirements. This process utilizes controlled high-temperature burning of municipal solid waste, transforming the chemical energy contained within waste materials into thermal energy. This thermal energy can then be converted into electricity, heat, or both using combined heat and power systems [4,9,15]. Through controlled combustion at elevated temperatures, combustible waste materials are converted into electrical energy, while simultaneously achieving an 80–95% reduction in waste volume and approximately a 70–80% reduction in waste mass [4,16,17,18].

WtE plants are prevalent in densely populated regions with limited land availability, such as Japan and various European nations, including Denmark, Sweden, Germany, and France. In Western Europe, WtE is the predominant method for managing MSW, processing around 40 million tons [17]. WtE incineration facilities currently encompass around 512 operational plants across Europe. These installations include 251 facilities that generate both heat and power, 161 plants dedicated solely to electricity production, and 94 units focused exclusively on heat generation. Together, these European WtE operations deliver a combined incineration capacity totaling 93 million tons [19]. In the Middle East, Dubai hosts the world’s largest waste-to-energy facility. This power plant processes approximately 1.9 million metric tons of waste annually, accounting for around 45% of Dubai’s total waste. The initiative generates 200 megawatts of electricity daily, supplying power to 135,000 homes [17].

A significant environmental benefit of WtE programs lies in their ability to decrease both greenhouse gas emissions and air pollution that typically result from landfill disposal and conventional waste management practices [4]. Burning waste offers multiple environmental benefits compared to conventional disposal approaches. This method substantially decreases greenhouse gas emissions by preventing methane from being released into the atmosphere from landfills [20,21]. When operated correctly, contemporary waste-to-energy plants produce electricity while emitting fewer health-related air pollutants and greenhouse gases per unit than burning fossil fuels. These WtE initiatives offer an environmentally responsible method for expanding energy portfolio diversity while reducing reliance on finite fossil fuel resources [4].

A study by Tahiru et al. acknowledged that adopting waste-to-energy technologies has a significant positive impact on combating global warming by reducing greenhouse gas emissions, including CO2, compared to traditional waste disposal techniques such as open burning and unregulated landfilling. When municipal solid waste (MSW) is incinerated in a thermal waste-to-energy facility, it prevents approximately 1010 kg of CO2 per ton of waste from entering the atmosphere, excluding biogenic carbon emissions from methane gas in landfills. CO2 emissions from incinerators are recorded at 1.188 pounds of CO2 per kWh [22].

1.2. Benefits and Advantages of the Waste-to-Energy (WtE) Approach

The production of electrical power from waste incineration represents a thermal WtE approach that transforms discarded materials into electricity through combustion within specialized burning chambers. This process typically involves several essential phases: gathering and managing waste materials, preparing them for combustion, conducting the incineration process, capturing and converting the released energy, and handling the resulting ash residue [18]. This process decreases air and water pollution, creates jobs, and enables effective waste management through separation and recycling [23].

This technology can power homes, businesses, and vehicles as a renewable energy source. WtE projects drive economic growth, enhance energy security by diversifying sources, and reduce fossil fuel dependence. Revenue from electricity sales and renewable energy credits can fund community development, social services, and infrastructure improvements, enhancing residents’ quality of life [4]. Modern waste incinerators achieve 20–30% electricity efficiency and 60–85% heat efficiency, depending on waste calorific value, with overall conversion efficiencies approaching 100% [24]. Waste materials with high calorific values, such as plastics, yield more heat and generate the most energy. WtE systems present numerous advantages over conventional waste management methods:

(i) Reduced waste volume

Annually, the global production of municipal solid waste (MSW) exceeds two billion tons, a figure anticipated to rise by 56% by 2025. The escalating volume of waste and its related pollution are intrinsically linked to climate change. When compared with alternative waste management approaches, WtE incineration provides numerous benefits. This method achieves the greatest volume reduction rates, with an 80–95% reduction among available thermal treatment technologies. The system can effectively process mixed waste types without requiring extensive preliminary sorting or preparation [9,17].

(ii) Resource recovery and Cleaner than landfills

Incineration reduces waste mass by 80% and volume by over 95%. WtE facilities produce fewer emissions than landfills due to strict regulations on pollutants like heavy metals and dioxins [16]. Pre-processing waste into refuse-derived fuel removes non-combustible materials, creating higher heating value fuel with better combustion properties. This requires less excess air (50% versus 100%) than mass burn methods, reducing exhaust gas volume and lowering air pollution, and potentially lower greenhouse gas emissions [17,25]. WtE incineration exhibits significantly better environmental outcomes than traditional landfill disposal. This approach reduces the global warming impact by approximately 30% by preventing methane release and reducing dependence on fossil fuels.

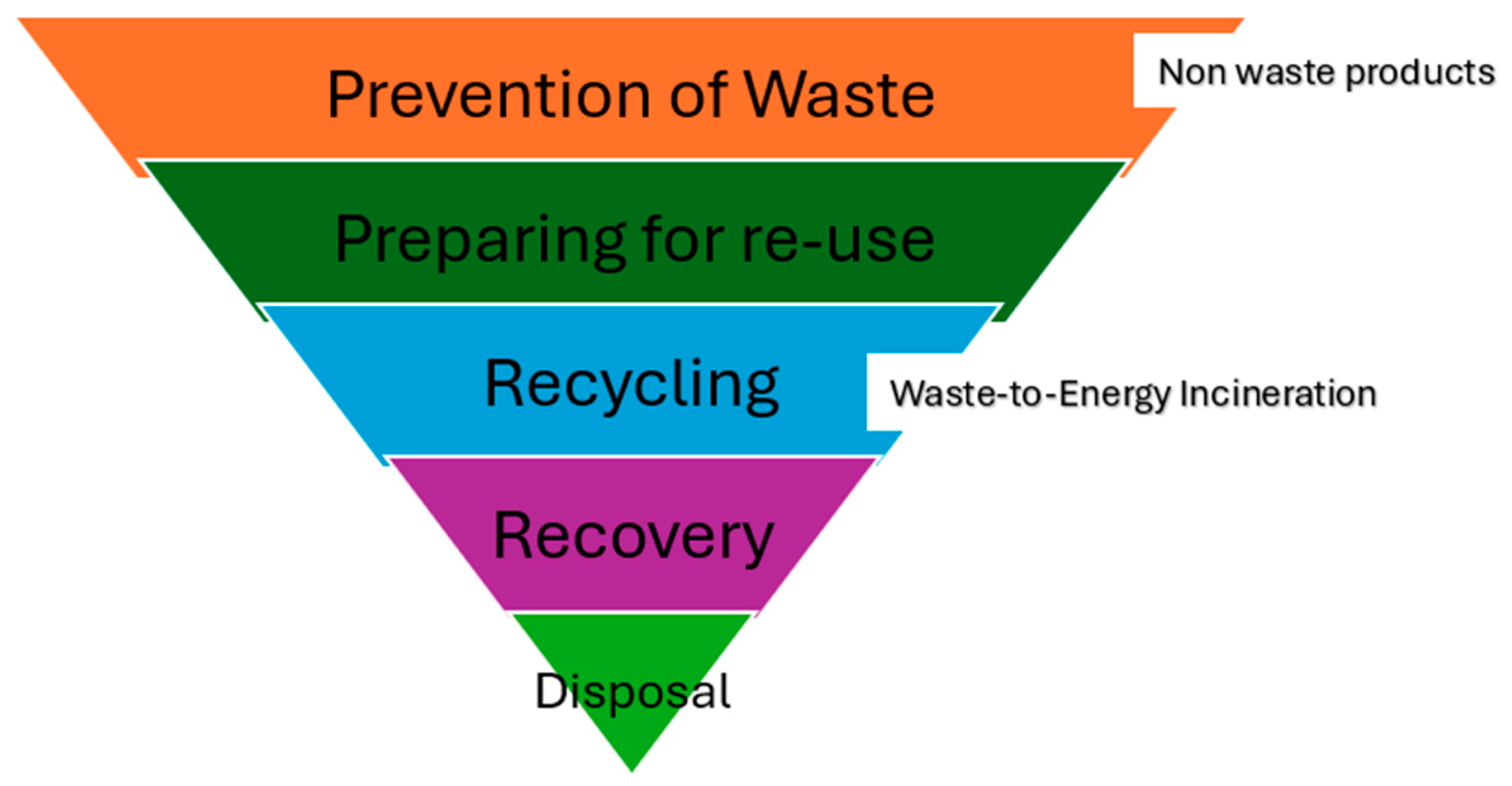

On the other hand, high-temperature incineration effectively eliminates pathogenic bacteria and toxic substances, reducing environmental harm and public health risks [16,25]. When used for energy generation, it can decrease fossil fuel dependence, although this depends on process efficiency [25]. Recycling garbage is advocated by the waste management hierarchy to increase revenue and reduce the impact of air pollution from incinerators (Figure 1). This is consistent with the tenets of the circular economy, which advocate for extending the useful life of resources [26].

Figure 1.

The waste management hierarchy [27].

(iii) Economic importance and application

The incineration of waste generates two primary categories of solid byproducts: bottom ash and fly ash. Bottom ash accounts for approximately 20–25% of the original waste material’s mass and comprises non-combustible substances that can serve as viable materials for construction purposes [28,29]. Significant metals and minerals are found in incineration bottom ashes, presenting numerous opportunities for recycling and reuse. Bottom ash (IBA) consists of inert, non-combustible materials that remain after combustion: sand, stones, and ash from the burned material, referred to as the mineral fraction, which constitutes 80–85% of IBA. This material can be utilized as a filling substance for construction applications (serving as sub-base material in road construction, replacing virgin gravel, or in concrete products, thereby reducing the demand for energy-intensive concrete production) [15,30].

Furthermore, there is a process involving high-temperature melting, where bottom ash is subjected to extreme heat, typically at temperatures of 1250 °C or higher in specialized furnaces such as coke bed, fuel-fired, or electric furnaces. This method not only helps reduce waste volume but also transforms the ash into a valuable material for various industrial applications [30].

The ash residue produced after waste treatment can serve as paving materials for roads and can also be transformed into building materials, effectively converting waste into valuable resources. The thermal energy generated during the waste incineration process can be harnessed for heating, cooling, and electricity generation [31].

Calorific value refers to the amount of heat produced when a certain amount of waste is burned. This means that if waste has a calorific value of 14.4 MJ/kg or more, it can be burned in an incinerator without the need for additional fuel, as the waste itself contains sufficient energy to sustain combustion. When you mix different types of waste in the incinerator, you can actually increase the energy output, resulting in more electricity being produced at the waste-to-energy facility [32]. Table 1 presents the various types of waste found and produced daily in the Dikeni region. What is interesting is that both PVC and cow dung manure have really high calorific values, which makes the energy they produce much cheaper compared to what you would obtain from fossil fuels.

Table 1.

The caloric value of waste in Dikeni.

Additionally, the potential economic benefits of the resulting residues enhance the attractiveness of this technology [22]. Modern WtE technology improvements have enhanced efficiency, reduced emissions since they utilize cutting-edge emission control systems, and increased economic viability. These developments demonstrate the ability of WtE technology to address conventional waste management limitations while meeting the growing demand for clean energy. Integrating WtE technology into waste management systems is crucial because it supports global sustainability goals by reducing solid waste’s environmental impact, preserving natural resources, and generating renewable energy. Moreover, WtE offers significant economic benefits, including job creation, lower waste management costs, and enhanced energy security through the use of diversified energy sources [33].

1.3. Conversion of Waste to Energy Procedure

Contemporary WtE plants utilize diverse combustion technologies, with moving grate incinerators representing the most widely adopted approach. The process comprises three main stages: incineration, energy recovery, and emission controlThe combustion process occurs within a sealed water-wall furnace chamber, where temperatures typically range between 850 °C and 1100 °C [34]. Heat from the combustion gases is transferred to water circulating through boiler tubes, which produce high-pressure steam. High-pressure steam drives turbine blades connected to generators, producing electrical power. Each ton of waste typically generates 500–600 kWh of electricity [17]. This steam subsequently powers turbines linked to electrical generators, generating electricity. Additionally, some plants incorporate combined heat and power systems to enhance energy efficiency by simultaneously generating electricity and providing district heating services. Waste materials with a higher energy content can sustain combustion independently, without requiring supplementary fuel sources [35].

An air pollution control system captures contaminants from combustion gases before they are released through the smokestack. Secondary chambers operate at higher temperatures for complete combustion. Gases from both primary and secondary chambers are channeled through flutes into chimneys for release [17]. Additionally, ash produced from the incineration process is collected from both the boiler area and the air pollution control system for proper disposal or treatment [17,36]. Steam boilers exemplify auxiliary equipment that generates energy or heat in installations using waste heat [37].

2. Materials and Methods

2.1. Literature Search

A systematic and comprehensive literature review was employed in this study to evaluate the efficacy of generating electricity from incinerated waste via the WtE approach. This research adheres to the PRISMA-P (Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols) framework to ensure transparency, reproducibility, and methodological rigor throughout the systematic review process. This systematic review critically examines scholarly publications from 2015 to 2025 that concern the feasibility of utilizing municipal solid waste for electrical energy production, with a particular emphasis on thermal conversion technologies, notably incineration processes. A rigorous systematic literature search was undertaken across multiple academic databases, including ScienceDirect, Web of Science, Scopus, Google Scholar, Semantic Scholar, and PubMed. A comprehensive search strategy was created by combining a number of well-chosen keywords with Boolean operators (“and”, “or”) to guarantee a thorough and pertinent search. Among the keywords were “waste to energy,” “waste incineration,” “thermal electricity,” “waste management,” “MSW to energy recovery,” “renewable electricity generation,” “environmental impacts of WtE,” “sustainable remediation technologies,” and “soil remediation” [22].

2.2. Handling of Data

All relevant research articles identified through database searches were imported into EndNote. Duplicates were removed during quality control. The remaining articles underwent a multi-stage screening process: first, by title for preliminary relevance, then by abstract for potential contribution, and finally by full-text review against the inclusion criteria for final selection in the systematic review or meta-analysis.

2.3. Selection Criteria and Data Extraction

Following the inclusion and exclusion parameters outlined in Table 2, the retrieved literature from the databases was subjected to a dual-phase screening methodology. The initial phase involved examining titles, abstracts, and conclusions to assess adherence to fundamental inclusion criteria, followed by a comprehensive evaluation of full texts deemed pertinent to the study objectives. The key characteristics of integrated research on waste-to-energy (WtE) through combustion include the analysis of waste mass and volume reduction efficiency, potential for electrical power generation, management and reduction in gaseous emissions, and economic considerations.

Table 2.

Inclusion and exclusion criteria for the WtE approach.

2.4. PICO Framework

The eligibility parameters were formulated employing the (PECO) framework, which stands for population (P), intervention (I) comparison (C), and outcome (O) [22], as articulated in the following manner: Population (P): municipal solid waste or particular waste categories (e.g., organic waste, animal waste, paper waste, and industrial waste) designated for incineration with the purpose of energy recovery. Intervention (I): waste incineration technology employed for waste-to-energy conversion. Comparison (C): Alternative WtE technologies such as gasification, pyrolysis, anaerobic digestion, or conventional waste disposal approaches such as landfilling. Outcomes (O): the particular outcomes under evaluation include decreasing landfill waste, lowering greenhouse gas emissions, producing electrical energy, and assessing economic viability. All authors conducted a comprehensive analysis of every paper within the database to verify adherence to predetermined inclusion and exclusion parameters, achieving an inter-rater reliability coefficient of 78%. Disagreements among reviewers were addressed through a systematic discussion process until a unanimous agreement was reached. This methodology enhances research transparency by explicitly identifying data categories derived from individual studies, while acknowledging each study’s unique contribution to the comprehensive synthesis.

3. Results

3.1. Search Results

This study has focused on energy generation, specifically electricity from municipality solid waste through the incineration process as one effective approach of the WtE process.

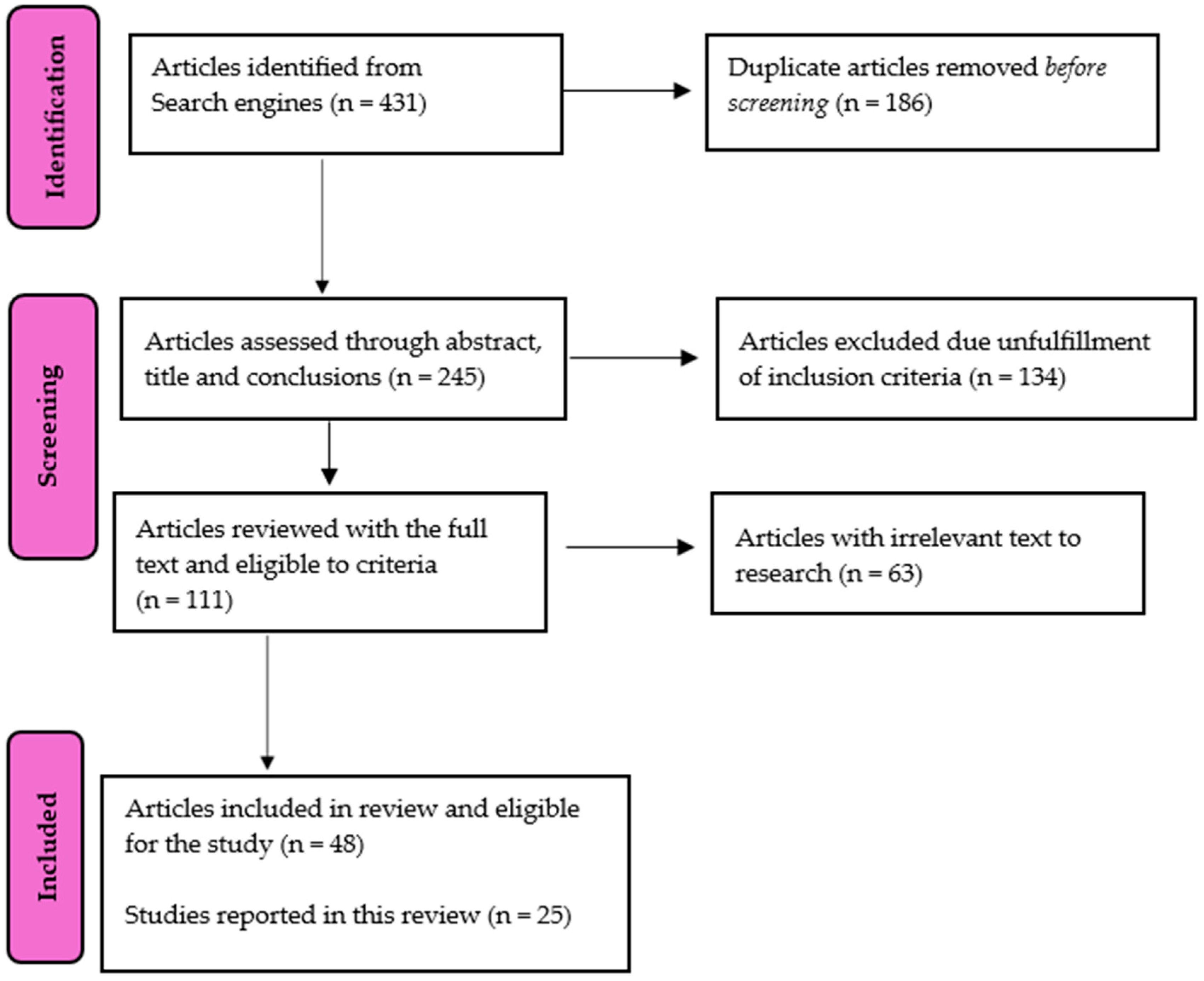

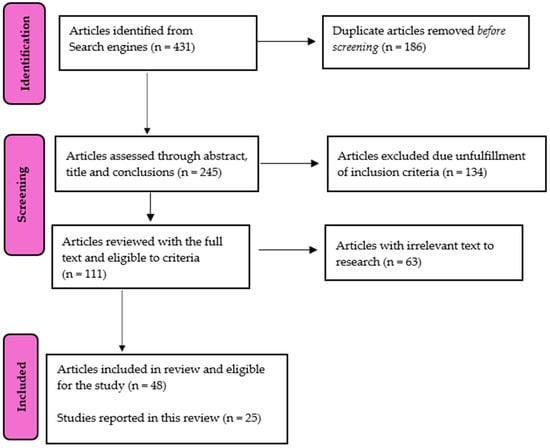

Based on the evaluation method, the systematic review employed a rigorous methodological approach encompassing identification, screening, and eligibility evaluation phases, as illustrated in Figure 2. A completed PRISMA 2020 checklist is provided in the Supplementary Materials. The comprehensive database search yielded 431 initial citations, which were systematically reduced to 186 after duplicate records were removed. Subsequently, the screening procedure resulted in 245 manuscripts being subjected to content relevance evaluation, whereby 16 studies satisfied the criteria for comprehensive full-text examination and in-depth analysis. Sixty-three (63) publications were excluded from consideration due to inadequate data provision or non-compliance with established study eligibility criteria. Therefore, the systematic review culminated in the selection of 48 studies that demonstrated alignment with the research objectives and furnished essential empirical evidence to address the specified research inquiries. However, only 25 articles presented data that align with this study’s objectives and assessment purposes.

Figure 2.

Schematic diagram of the PRISMA framework showing the results of the reviewed data.

Although there is a growing interest in the WtE technology approach for safely managing waste from municipalities. The research database published over 5000 journal articles with keywords related to waste-to-energy and incineration. The majority of those studies present different procedures for converting waste to energy, which are outside the scope of this review. This includes the WtE approach through conventional methods such as hybrid systems, anaerobic digestion, gasification, and pyrolysis.

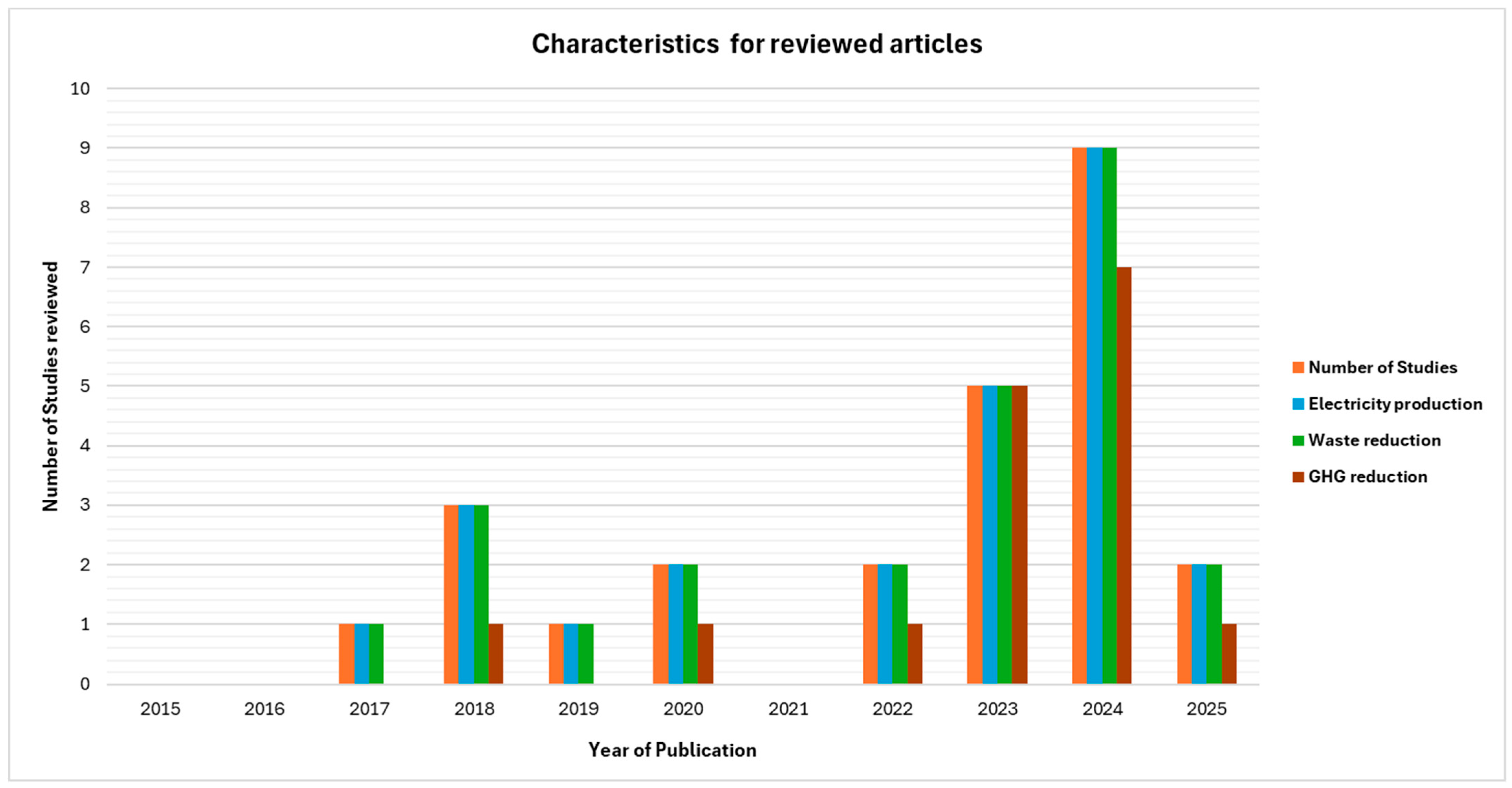

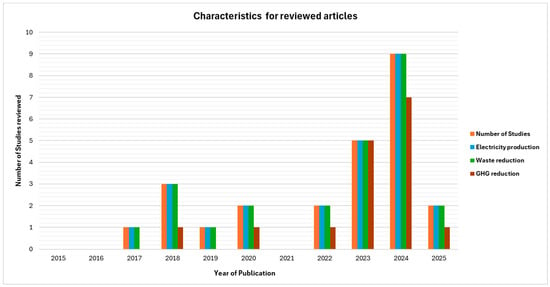

This research study examined three essential aspects of converting waste into energy through incineration methods. These core aspects included the efficiency of waste-to-energy conversion for electricity production, the management of municipal solid waste through volume reduction, and environmental sustainability by reducing greenhouse gas emissions. Every study examined in this research showed favorable results (100%) for WtE incineration when evaluated against various performance measures (as illustrated in Figure 3). A review of existing research suggests that significant electrical energy can be harnessed through the complete incineration of combustible waste across various geographical areas. The generation of electricity via incineration is considered a remarkably efficient method for power production, particularly in developing nations, with estimated outputs varying from gigawatt-hours to kilowatt-hours: Mexico (11,681.64 GWh), Cambodia (1625.81 GWh), Bangladesh (187.04 GWh), South Africa (6944 GWh), Iran (17,678 GWh), Nigeria (10,000 GWh), Indonesia (2487 MWh), Algeria (11.6 MWh), China (2316.52 MWh), Iraq (203.917 MWh), Uganda (774 kWh), and Pakistan (675 kWh), respectively [26,38,39,40,41,42,43,44,45,46,47,48,49].

Figure 3.

The schematic diagram of the evaluated articles of WtE electricity generation through incineration.

The reduction in waste volume reliably reached between 90% and 95%, accompanied by substantial environmental benefits, including decreases in greenhouse gas emissions ranging from 30% to 87%. Volumetric waste reduction was consistently observed across all examined WtE installations. However, empirical evidence suggests that approximately 10% of the surveyed facilities encountered significant difficulties in mitigating gaseous emissions generated throughout the incineration process.

3.2. Electrical Energy Generation Potential from Waste

The incineration of municipal solid waste shows significant potential for generating electricity through various operational sizes and technological setups. The data obtained demonstrates that within implemented waste-to-energy initiatives, electrical power is produced from refuse materials. Mujalge et al. (2020) documented that the incineration model for municipal solid waste in Palghar district demonstrated the facility’s capacity to process approximately 686,750 MT of total waste annually, whilst generating 121.53 GWh of electricity for commercial distribution [50].

The empirical study revealed that the incineration process efficiently produces electricity through the conversion of roughly 15,451.35 tons of municipal solid waste into high-temperature steam, which generates 956.04 MWh of electrical power. This process simultaneously achieves substantial waste reduction, decreasing waste mass by 81.52–96.50% while adhering to established environmental standards. The integrated pollution control systems effectively treat both wastewater and flue gas emissions, ensuring compliance with national environmental regulations [38]. The heating value of waste plays a vital role in incineration processes, as it directly impacts combustion temperatures, process efficiency, energy generation capabilities, and the management of toxic emissions. The operational capacity of incineration technology within the Northwest province demonstrated that paper-based waste materials generated approximately 6897 GWh, whilst plastic waste materials produced between 5171 GWh and 5207 GWh of electrical energy [51].

Furthermore, Akinshilo (2019) emphasizes that an energy recovery potential exceeding 1300 GW/day, with a substantial power generation capacity of over 10,000 MW, was achieved from municipal solid waste, comprising primary constituents such as food waste, metallic materials, and plastic waste [39]. Chaerul and Ridho (2025) emphasize the importance of optimizing waste segregation and recycling processes to improve the efficiency and sustainability of incineration operations [26]. Comparable results were observed in research conducted in Phnom Penh, Cambodia, which demonstrated that incineration achieved the greatest energy generation, producing between 793.13 and 1625.81 GWh annually throughout a 20-year forecast timeframe. These figures substantially exceeded the performance of alternative methods, including landfill gas recovery systems that generated between 115.44 and 271.81 GWh annually. Consequently, incineration emerged as the most effective technology for optimizing energy extraction from municipal solid waste materials [40].

Their findings revealed that, over five months, electricity generation totaled 2487 MWh, equivalent to 280 kWh per ton of incinerated waste. The processed waste composition comprised 54.82% organic materials, 18.22% non-PET plastics, 6.72% paper products, and 3.71% PET plastic materials, respectively [26].

Punjab’s urban centers demonstrate optimal electrical energy output from municipal solid waste (MSW) processing, achieving generation rates between 514 and 675 kilowatt-hours per ton of MSW, which represents the maximum net energy yield documented in the literature [41].

3.3. Environmental Sustainability (Waste Reduction and GHG Combating)

Reducing waste volume stands as one of the most essential measures of how effectively incineration technology performs, with direct consequences for landfill space availability and the long-term viability of waste management systems. A contemporary study reported that a WtE facility demonstrates environmental performance that complies with national standards, successfully achieving mass waste reductions of 81.52–96.50% [38].

The projected yearly energy generation reaches 187.04 GWh while simultaneously achieving a decrease of 17,400 tCO2-eq in carbon emissions. Furthermore, waste-to-energy incineration proves to be an effective approach for municipal solid waste processing, generating an excess of 102.36 GWh of electrical energy beyond what is required to meet the yearly electricity needs of electric vehicles [45].

The environmental benefits of WtE incineration become most evident through significant reductions in greenhouse gas emissions when compared to other waste management methods. At the same time, environmental sustainability is maintained through the reduction in greenhouse gas emissions, and climate change mitigation is achieved, thereby establishing an environmentally sound and sustainable ecosystem [38]. The reduction of carbon footprints may be achieved through waste incineration rather than disposal via environmentally detrimental local methodologies, including open burning practices, which consequently result in decreased greenhouse gas (GHG) emissions [41,51]. WtE systems have demonstrated efficacy in mitigating environmental contamination to a considerable degree, while simultaneously reducing the emission levels of deleterious greenhouse gases, including methane, carbon monoxide, and carbon dioxide, as well as numerous other potentially harmful atmospheric compounds [4,39,43,52]. Despite the production of 774 kWh of electricity per ton of municipal solid waste, which possessed the capacity to supply electrical power to approximately 1062 households within Kampala, Uganda, Amulen et al. (2022) identified several adverse consequences associated with the waste-to-energy facility, encompassing environmental pollution, methane emissions that contribute to climate change, and employment-related complications [49].

Dlamini et al. (2018) support these findings and contend that incineration technologies possess the capability to diminish the volume of waste directed to landfills. This is achieved by diverting both biodegradable and non-recyclable waste from landfills, thereby enhancing the landfill airspace until 2030, with a projected 93% waste diversion rate. This diversion could potentially yield carbon credits, create employment opportunities, and generate renewable electricity, in addition to revenue from the sale of byproducts [3].

The research team found that the facility is expected to decrease yearly carbon dioxide (CO2) emissions by 0.045 million tons, thereby supporting environmental sustainability efforts. The results demonstrate that WtE technology offers an effective solution for addressing urban waste management issues, while simultaneously enhancing energy security, paving the way for sustainable development, and serving as an exemplary model for comparable urban environments [50,53].

WtE technology facilitates the recovery of valuable materials, such as metals, from incineration residues, thereby promoting reuse and recycling, which aligns with the principles of a circular economy. The studies published indicate that WtE generates economic, social, and environmental co-benefits through the efficient utilization of natural resources, reduction in emissions, job creation, and the promotion of innovation in raw materials in a sustainable manner. This thermal treatment via incineration offers communities dual economic benefits, including cost savings and job creation [3,4]. This technology advances carbon reduction goals by reducing land requirements and greenhouse gas emissions, which supports circular economic objectives. The successful implementation and long-term financial viability of incineration facilities depend significantly on policy initiatives, economic incentives, and regulatory structures that encourage widespread adoption.

This underscores the ability of municipalities to lessen their reliance on external energy sources, which in turn will reduce utility bills for residents, as the power is generated locally. Moreover, the construction and operation of WtE facilities create numerous job opportunities within communities, ranging from skilled engineers and technicians to administrative and support positions. The jobs created tend to invigorate the local economy. These facilities can also market WtE byproducts, such as metals and aggregates, thereby establishing an additional revenue stream through the sale of energy. This strategy further contributes to the creation of new jobs in the market, encompassing roles in waste collection and transportation, research, engineering, and environmental compliance. These economic advantages play a significant role in fostering sustainable local development and lowering waste management costs.

In the realm of social relations, the implementation of WtE systems significantly enhances community resilience by providing a reliable and sustainable energy source, diversifying energy options, improving energy security, and creating opportunities for revenue generation. Most importantly, the educational programs linked to these initiatives promote environmental stewardship, fostering a sense of community pride and shared responsibility. Moreover, WtE technology not only addresses waste management issues but also catalyzes positive socio-economic transformations in communities.

4. Discussion

The presented results confirm the importance of adopting the perspective of the WtE approach as a dual method for electricity generation and waste volume reduction. Utilizing energy derived from municipal solid waste serves a dual purpose: resolving waste management challenges while simultaneously creating opportunities for electrical power generation, diminishing reliance on fossil fuel resources, and reducing greenhouse gas emissions. Hossain et al. highlighted that converting Waste to Electrical Energy (WTEE) represents a compelling alternative for power generation, specifically through the transformation of Municipal Solid Waste (MSW), which holds substantial energy potential and demonstrates its effectiveness as a solution to overcome conventional power generation limitations. This approach highlights how transforming waste into electrical power can enhance waste management practices while contributing to meeting yearly energy demands [53].

It has been reported that the combustion of 1 metric ton of MSW in a modern incineration facility can recover approximately 80% of the embedded energy as heat, which can be utilized to generate steam in a steam turbine, producing between 500 and 600 kWh of electricity and 1000 kWh of thermal energy. The total electricity output from waste incineration plants is estimated to be between 70.18 and 84.21 TWh, while the heat output is around 140.35 TWh. This waste heat can provide process heat for industrial applications and district heating systems [36,46]. The yearly electrical generation is projected to be 187.04 GWh, accompanied by a decrease of 17,400 tCO2-eq in carbon emissions. Furthermore, waste-to-energy incineration proves to be an effective approach for handling municipal solid waste, potentially generating an excess of 102.36 GWh of power beyond what is required to satisfy annual electric vehicle energy needs [45].

Research conducted by Hadi et al. in 2024 indicates that municipal solid waste has a high heating value of 12.789 MJ/kg, which enables the generation of electrical energy of 119.287 MW and 203.917 MW across different sectors, demonstrating the viability of steam-powered facilities [47]. The total energy generation capacity through incineration processes is anticipated to achieve 2,316,523 MWh annually by 2025, with a projected growth of 14.3% by 2050, representing a 3.72% contribution toward Indonesia’s renewable energy objectives within the electrical grid composition [48].

Research by Straka et al. in 2017 employed computational simulation techniques to examine and subsequently optimize the waste incineration procedure. The simulation findings indicate that incineration over a twelve-month timeframe process approximately 15,266 tons of plastic and electronic materials, generating roughly 590,000 GJ of energy along with approximately 199,000 tons of steam [54].

Wollongong was selected for this research due to its annual production of approximately 121,000 tons of municipal waste, with roughly 48,400 tons being recycled. The simulation model results demonstrate that incineration technology produces electricity at approximately 1700 kW, significantly surpassing the landfill approach, which generates only around 100 kW, thereby showcasing its superior potential for waste-to-energy transformation [55].

Furthermore, the incineration of 27.36 million tons of organic waste each year, utilizing appropriate technology for energy recovery, has the potential to produce between 14.52 and 23.08 TWh of electricity annually. When paper and textiles are included, the potential output increases to 18.69 and 29.71 TWh per year. The estimated power generation from agricultural residues is 80.3 GW [8]. By 2014, the UK had incinerated 35% (6.72 million tons) of its total MSW stream, generating 3.94 TWh of electricity, which accounted for 1.1% of the UK’s total energy supply [22].

Denmark, Sweden, Estonia, and Finland appear to be at the forefront of the waste-to-energy (WtE) sector, incinerating as much as 50% of their municipal solid waste (MSW). As a result, they have managed to decrease landfilling to below 10% of the total MSW generated, except for Finland, which still landfills 17% of its overall MSW throughput. Japan also plays a significant role in East Asia, treating 67% of the 65 million tons of MSW produced through thermal methods [22].

China is at the forefront among developing nations in terms of installed waste-to-energy (WtE) plant capacity, boasting over 510 WtE Municipal Solid Waste (MSW) plants that collectively generate 13.41 GW [8].

Although WtE technology remains in its early stages of development in countries like South Africa, the achievements observed in nations with diverse economic and waste management profiles offer critical insights [49]. South Africa has made notable progress using MSW feedstock, anaerobic digestion, landfill gas, and incineration technologies to generate between 900 kWh and 9 MWh of energy daily [8].

While waste-to-energy incineration proves effective for waste reduction, the authors identified a primary concern and limitation: the release of carbon dioxide emissions that may contribute to global warming. However, these CO2 concentrations pose less environmental harm than other gaseous emissions such as methane, sulfur oxides, and nitrogen oxides. This highlights the importance of implementing controlled waste incineration techniques to reduce the impact on global warming [47]. On a different note, research conducted by Zeng et al. demonstrated that incineration processes can achieve an average reduction of 41% in CO2 emissions, emphasizing the environmental advantages of this approach [48]. In a similar vein, Joshi and their team contended that waste-to-energy technologies play a crucial role in diminishing dependence on landfills and lowering greenhouse gas emissions through the replacement of fossil fuels with renewable energy alternatives [56].

However, incinerators represent the most carbon-intensive method of electricity generation. For each unit of power produced, these facilities release 1.7 times more greenhouse gases and 4.8 times more nitrogen oxides compared to coal, which ranks as the second most polluting energy source. However, they generate only 0.4 times the sulfur dioxide emissions of coal. Among the facilities studied, 46 out of 69 incinerators (representing 67%) utilize selective catalytic or non-catalytic reduction systems to control nitrogen oxide emissions, while 61 facilities (88%) employ scrubber technology for sulfur dioxide management. The research reveals that incinerators produce higher greenhouse gas emissions per electricity unit generated (1707 g CO2e/kWh) than all other power generation methods, which range from 2.4 to 991.1 g CO2e/kWh. This positions incinerators as the most emission-heavy approach to electricity production [57].

Moreover, this study is found to align with and support three significant Sustainable Development Goals (SDGs), namely 7, 11, and 13. By converting municipal solid waste into power and heat, WtE technology helps achieve SDG 7 by increasing the percentage of renewable energy sources and improving energy efficiency while granting access to affordable, dependable, and sustainable energy. WtE helps cities become more sustainable in relation to SDG 11, which enhances resilience and urban living conditions. Lastly, WtE contributes to critical climate action objectives by reducing greenhouse gas emissions from landfills, which emit methane, and substituting cleaner energy sources for fossil fuels in order to combat climate change and meet SDG 13. Waste-to-energy technologies present an innovative approach to addressing two critical contemporary challenges: the escalating production of waste materials and the imperative for environmentally sustainable energy alternatives. These technologies offer a transformative approach to both waste management and power generation, thereby establishing a comprehensive solution to these interconnected environmental and energy challenges.

4.1. Feasibility of WtE in Dikeni Context

To bring fresh perspectives to the current discussion, this research has explored various ideas about the animal waste that enters the system. Cow manure proves to be particularly valuable for generating electricity because it contains a substantial amount of energy. When we treat these animal byproducts as waste materials and use what is called a ‘zero burden’ method, it means the material goes into the waste-to-energy system without carrying any of the environmental costs associated with raising livestock or processing animals, as well as the power produced. Raymond Mhlaba operates as a rural municipality where the agricultural sector serves as the primary economic driver, encompassing citrus farming, forestry operations, livestock management, and various crop cultivation activities. Waste incineration presents a superior alternative to other thermal electricity generation methods, as waste materials are continuously produced on a daily basis in homes, agricultural facilities, medical institutions, businesses, and various industrial sectors. This ensures a consistent supply of feedstock for the incineration process each day. This methodology surpasses conventional thermal electricity generation systems because incineration technology involves combusting solid waste materials, effectively reducing waste mass by 70% and volume by 90%, while simultaneously generating steam for electrical power production and cogeneration purposes [39].

Incorporating animal manure into this feedstock system significantly enhances energy output, as cow-dung cakes possess a calorific value of 6800 kJ/kg, capable of generating 54,400 kJ of thermal energy. Biomass derived from cow dung demonstrates excellent energetic characteristics, establishing it as a viable alternative energy source for successful implementation in waste-to-energy power facilities. Testing has validated its effectiveness for such applications [58].

Using a blend consisting of 30% cow dung combined with 70% agricultural waste creates a sustainable waste-to-energy solution for this region, as animal manure, food waste, and agricultural byproducts represent abundant and accessible raw materials, providing an effective response to energy shortages [59]. Additionally, the renewable nature of these materials is ensured through the continuous growth cycles of trees and crops, while animal dung remains consistently available locally as an alternative energy resource. Research findings indicate that animal dung has significant potential for energy production, warranting increased promotion of its utilization [60].

4.2. Economic Feasibility of WtE Incineration

This approach to generating electrical power from available waste is said to offer an economical and eco-friendly solution for energy production [53]. The concurrent need for renewable energy sources and effective waste management solutions has positioned waste-to-energy incineration as an appealing option for governmental authorities. When examining the economic feasibility of municipal solid waste incineration for power generation in developing nations, a multifaceted scenario emerges that depends heavily on regional circumstances, technological capabilities, and regulatory environments [48,59]. Multiple research efforts demonstrate that although incineration offers both sustainable waste management and energy production benefits, its financial success differs considerably depending on specific local conditions [40,61,62,63]. Research by Hossain et al. demonstrated that a 10 MW facility operating at 22.5% efficiency yielded promising results. The financial analysis yielded encouraging results, with a Net Present Value of $4.99 million and an Internal Rate of Return exceeding 10%, demonstrating the project’s economic soundness [53].

Additionally, valuable materials can be extracted from the remaining solid waste after the incineration process. Financial assessments indicate that incineration typically offers the most competitive levelized energy costs across various regions, establishing it as an economically efficient method of power generation. This approach also creates employment opportunities through the proposed WtE systems, supporting regional economic growth. The incineration procedure produces secondary materials, including bottom ash and fly ash, which can be reused for other purposes, thereby reducing the overall environmental impact [64].

4.3. Policies Governing WtE Strategies

The WtE technologies are demonstrably a promising avenue for addressing the dual challenges of waste management and energy shortages confronting South Africa’s urban centers. A significant catalyst for this is the 2009 national policy on the thermal treatment of General and Hazardous Waste. This policy, along with its implementation strategy, signifies the South African government’s strong endorsement of WtE as a novel waste management approach, aiming to overcome existing developmental hurdles for WtE plants. Consequently, substantial advancements have been made in Waste-to-Energy policies within South Africa. This includes efforts to promote WtE, notably through the National Waste Management Strategy (2020).

This strategy emphasizes sustainable, long-term waste management practices, thereby charting a clear course for advancing waste-to-energy technologies in the country. This research aligns with the objectives of the National Environmental Management: Waste Act (NEM:WA), particularly its waste management hierarchy, which encompasses the principles of reducing, reusing, recycling, recovering, treating, and disposing, while also regulating waste handling from collection to disposal. Furthermore, the National Environmental Management: Air Quality Act (NEM: AQA) complements this approach, as waste-to-energy facilities utilize incinerators that manage air emissions and comply with stringent standards to safeguard the environment from excessive greenhouse gas accumulation [65,66].

4.4. Limitations

Community support for the facility serves as the foundation for the project’s long-term viability, making it essential to engage residents throughout the development process of the plant. Transforming municipal waste into an energy source addresses the critical challenge of converting this material into a renewable resource. Utilizing municipal waste for energy production enables a reduction in fossil fuel dependency for power generation, thereby decreasing greenhouse gas emissions and mitigating the effects of global warming. Effective waste segregation remains necessary, creating implementation challenges for waste-to-energy technologies. The infrastructure requirements needed to support these technologies present obstacles to their broader adoption [55]. Proper garbage sorting systems are essential, yet they create difficulties in the successful deployment of waste-to-energy solutions. The substantial infrastructure investments required for these technologies can limit their widespread implementation. Collectively, these constraints hinder the ability of waste-to-energy technologies to be fully integrated into comprehensive, sustainable waste management and energy production frameworks [67].

5. Conclusions

Undoubtedly, embracing WtE technology has a profoundly beneficial impact on communities. The findings of this study significantly enhance the ongoing discussion regarding waste management in South Africa by outlining novel strategies needed to overcome and achieve sustainable waste management practices. Implementing WtE technology brings substantial benefits to local communities, as it helps reduce pressure on nearby landfills, which extends their operational life while minimizing residents’ concerns about unpleasant odors and pest problems, ultimately enhancing community well-being. This technology offers an alternative and more eco-friendly energy source (electricity production), while decreasing the amount of waste sent to landfills, enhancing revenue generation, decreasing reliance on fossil fuels, and alleviating greenhouse gas (GHG) emissions. Furthermore, WtE plants play a crucial role in addressing public health challenges that stem from poor waste management practices, including groundwater pollution, reduced atmospheric pollutants, and lower greenhouse gas (GHG) emissions, as well as better protection of natural habitats, and wildlife diversity.

This study recommends that the authorities design a legislative framework for WtE facilities, incorporating maintenance, monitoring, and evaluation strategies; establish guidelines for the safe disposal of hazardous byproducts; and expand waste collection services to support the development of WtE facilities. By promoting collaboration among government agencies, private sector entities, and community groups, this dissertation aims to enhance the implementation of these strategies and drive progress towards a more sustainable future for waste management in South Africa. Although, WtE process involves significant expenses, technical difficulties, and environmental hazards that necessitate meticulous oversight. WtE projects will promote sustainable waste management, enhance energy security, create employment opportunities, and foster environmental stewardship. Municipalities must adopt these systems since they have proven to be effective globally, providing sustainable solutions by diverting waste from landfills, reducing environmental pollution and GHG emissions, whilst generating clean energy.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/waste3040039/s1, PRISMA 2020 Checklist.

Author Contributions

Conceptualization, N.G.M. and O.O.O.; methodology, N.G.M.; software, N.G.M.; writing and editing, N.G.M.; investigation, N.G.M.; data curation, N.G.M.; data analysis and interpretation, N.G.M.; data verification, N.G.M.; proofreading, O.O.O.; supervision, O.O.O.; funding acquisition, N.G.M. and O.O.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Department of Research and Innovation under the University of Fort Hare Institute.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Department of Research and Innovation, the University of Fort Hare Directorate of Research and Development, and the University of Fort Hare Chemical and Earth Sciences department.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Chen, D.M.C.; Bodirsky, B.L.; Krueger, T.; Mishra, A.; Popp, A. The world’s growing municipal solid waste: Trends and impacts. Environ. Res. Lett. 2020, 15, 074021. [Google Scholar] [CrossRef]

- Florence, O.O.; Sunday, O.O.; Saheed, A.A.; Omotayo, A.O.; Adesope, O.P.; John, A.K. Assessing the environmental impact of municipal solid waste. J. Environ. Sci. Sustain. Dev. 2024, 7, 618–639. [Google Scholar] [CrossRef]

- Dlamini, S.; Simatele, M.D.; Serge Kubanza, N. Municipal solid waste management in South Africa: From waste to energy recovery through waste-to-energy technologies in Johannesburg. Local Environ. 2019, 24, 249–257. [Google Scholar] [CrossRef]

- SALGA. Municipal Waste-to-Energy Projects: Innovative Approaches to Convert Waste into a Renewable Energy Source. Available online: https://salga.org.za/Documents/Knowledge%20Hub/Catalogue%20Products-July/Municipal%20Waste-to-Energy%20Projects%20-%20Case%20study.pdf (accessed on 12 May 2025).

- Venter, J. 1 December 2022. Burning Uncollected Waste, the Top Cause of Plastic Pollution in SA, Says the Report. Available online: https://www.dailymaverick.co.za/article/2022-12-01-burning-uncollected-waste-the-top-cause-of-plastic-pollution-in-sa-says-report/ (accessed on 8 July 2025).

- Vashishth, R.; Goel, M. Impact of circular economy in the construction sector: Review of current trends and future research direction. Sustain. Agri Food Environ. Res. Discontin. 2023, 11, 2978. [Google Scholar] [CrossRef]

- Ali, H.S.; Nathaniel, S.P.; Uzuner, G.; Bekun, F.V.; Sarkodie, S.A. Trivariate modelling of the nexus between electricity consumption, urbanization and economic growth in Nigeria: Fresh insights from Maki Cointegration and causality tests. Heliyon 2020, 6, e03400. [Google Scholar] [CrossRef]

- Umar, Y.; Yakubu, R.O.; Abdulazeez, A.A.; Ijeoma, M.W. Exploring Nigeria’s waste-to-energy potential: A sustainable solution for electricity generation. Clean. Energy 2024, 8, 82–95. [Google Scholar] [CrossRef]

- Khan, M.S.; Mubeen, I.; Caimeng, Y.; Zhu, G.; Khalid, A.; Yan, M. Waste to energy incineration technology: Recent development under climate change scenarios. Waste Manag. Res. 2022, 40, 1708–1729. [Google Scholar] [CrossRef]

- Oguntade, K.I.; Manczarski, P. Design of Waste-to-Electricity Model: Estimating the Potential of Electricity Recovery in Nigerian Geopolitical Zones. Gaz. Woda I Tech. Sanit. 2024, 98, 19–25. [Google Scholar] [CrossRef]

- Jamilatun, S.; Pitoyo, J.; Setyawan, M. Technical, economic, and environmental review of waste-to-energy technologies from municipal solid waste. J. Ilmu Lingkung. 2023, 21, 581–593. [Google Scholar] [CrossRef]

- Kasiński, S.; Dębowski, M. Municipal solid waste as a renewable energy source: Advances in thermochemical conversion technologies and environmental impacts. Energies 2024, 17, 4704. [Google Scholar] [CrossRef]

- Misganaw, A.; Teffera, B. An assessment of the waste-to-energy potential of municipal solid wastes in Ethiopia. Bioresour. Technol. Rep. 2022, 19, 101180. [Google Scholar] [CrossRef]

- Edwards, N. Waste-to-Energy an Innovative Solution to South Africa’s Energy Crisis. Available online: https://blog.interwaste.co.za/know-waste/waste-to-energy-an-innovative-solution-to-south-africas-energy-crisis (accessed on 12 May 2025).

- ESWET. Giving Ash a New Life: Waste-to-Energy and Material Recovery (12 May 2022). Available online: https://eswet.eu/giving-ash-a-new-life-waste-to-energy-and-material-recovery/ (accessed on 29 April 2025).

- Wang, A.; Dong, W. Discussion on waste incineration power generation and its process calculation. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Beijing, China, 19–20 April 2019; IOP Publishing: Bristol, UK, 2019; Volume 490, p. 072047. [Google Scholar] [CrossRef]

- Gomstyn, A.; Jonker, A. What Is Waste-to-Energy? 19 June 2024. Available online: https://www.ibm.com/think/topics/waste-to-energy#:~:text=Subscribe%20today-,How%20does%20waste%2Dto%2Denergy%20work?,C%20(2%2C642%C2%B0F).&text=The%20resulting%20heat%20converts%20water,generator%2C%20and%20it%20produces%20electricity (accessed on 5 June 2025).

- Jamadar, P.; Talwar, H.; Yadav, S.; Gupta, P.; Pathan, P.; Sawant, R. Electricity Generation by Waste Materials. Int. J. Res. Appl. Sci. Eng. Technol. 2025, 13, 81–84. [Google Scholar] [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.F. Status and opportunities for energy recovery from municipal solid waste in Europe. Waste Biomass Valorization 2019, 10, 2425–2444. [Google Scholar] [CrossRef]

- Lair, A.; Mansuy, M.; Romand, C.; Oberti, O.; Pradels, C.; Barina, G.; Denoun, T.; Venturini, M.; Trommsdorff, C. Enhancing landfill efficiency to drive greenhouse gas reduction: A comprehensive study on best practices and policy recommendations. Waste Manag. Res. 2024, 42, 889–900. [Google Scholar] [CrossRef] [PubMed]

- Lakhouit, A. Mitigating landfill emissions strategies for effective waste management in Tabuk. Clean. Waste Syst. 2024, 9, 100187. [Google Scholar] [CrossRef]

- Tahiru, A.W.; Cobbina, S.J.; Asare, W.; Takal, S.U. Unlocking energy from waste: A comprehensive analysis of municipal solid waste recovery potential in Ghana. World 2024, 5, 192–218. [Google Scholar] [CrossRef]

- Junttila, J. Waste-to-Energy: Turning Trash into Power. Available online: https://winnoenergy.com/waste-to-energy-turning-trash-into-power/#:~:text=There%20are%20different%20ways%20to,can%20be%20used%20as%20fuel (accessed on 27 May 2025).

- Hasan, M.R.; Anzar, N.; Sharma, P.; Malode, S.J.; Shetti, N.P.; Narang, J.; Kakarla, R.R. Converting biowaste into sustainable bioenergy through various processes. Bioresour. Technol. Rep. 2023, 23, 101542. [Google Scholar] [CrossRef]

- ACTenviro. A Complete Guide to Solid Waste Incineration. 11 July 2024. Available online: https://www.actenviro.com/solid-waste-incineration/#:~:text=Waste%20Destruction%3A%20Incineration%20can%20effectively,health%20risks%20and%20environmental%20contamination (accessed on 27 May 2025).

- Chaerul, M.; Ridho, M. Evaluation of Municipal Solid Waste Incineration in Jakarta for Electricity Generation. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Trondheim, Norway, 6 June 2025; IOP Publishing: Bristol, UK, 2025; Volume 1448, p. 012020. [Google Scholar] [CrossRef]

- Khawaja, M.K.; Alkayyali, K.; Almanasreh, M.; Alkhalidi, A. Waste-to-energy barriers and solutions for developing countries with limited water and energy resources. Sci. Total Environ. 2024, 926, 172096. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, A. Current developments in biotechnology and bioengineering and waste treatment processes for energy generation: An introduction. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K.; Heng, O.E. Recent advances and applications of municipal solid wastes bottom and fly ashes: Insights into sustainable management and conservation of resources. Environ. Technol. Innov. 2021, 21, 101267. [Google Scholar] [CrossRef]

- Liu, C. Waste-to-Energy Incineration-CCET Guideline Series on Intermediate Municipal Solid Waste Treatment Technologies. 2020. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/32795/WtEI.pdf?sequence=1&isAllowed=y (accessed on 6 April 2025).

- Lonati, G.; Cernuschi, S.; Giani, P. Air quality impact assessment of a Waste-to-Energy plant: Modelling results vs. monitored data. Atmosphere 2022, 13, 516. [Google Scholar] [CrossRef]

- Shaibur, M.R.; Husain, H.; Arpon, S.H. Utilization of cow dung residues of biogas plant for sustainable development of a rural community. Curr. Res. Environ. Sustain. 2021, 3, 100026. [Google Scholar] [CrossRef]

- Rahman, I.U.; Mohammed, H.J.; Bamasag, A. An exploration of recent waste-to-energy advancements for optimal solid waste management. Discov. Chem. Eng. 2025, 5, 7. [Google Scholar] [CrossRef]

- Kaneesamkandi, Z.; Sayeed, A. Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions. Energies 2023, 16, 5696. [Google Scholar] [CrossRef]

- De Greef, J.; Verbinnen, B.; Van Caneghem, J. Waste-to-energy: Coupling waste treatment to highly efficient CHP. Int. J. Chem. React. Eng. 2018, 16, 20170248. [Google Scholar] [CrossRef]

- Alao, M.A.; Popoola, O.M.; Ayodele, T.R. Waste-to-energy nexus: An overview of technologies and implementation for sustainable development. Clean. Energy Syst. 2022, 3, 100034. [Google Scholar] [CrossRef]

- Mabalane, P.N.; Oboirien, B.O.; Sadiku, E.R.; Masukume, M. A techno-economic analysis of anaerobic digestion and gasification hybrid system: Energy recovery from municipal solid waste in South Africa. Waste Biomass Valorization 2021, 12, 1167–1184. [Google Scholar] [CrossRef]

- Febijanto, I.; Steven, S.; Nadirah, N.; Bahua, H.; Shoiful, A.; Dian, P.D.; IP, A.K.; Khalda, A.H.; Yuliani, M.; Hanif, M.; et al. Municipal solid waste (MSW) reduction through incineration for electricity purposes and its environmental performance: A case study in Bantargebang, West Java, Indonesia. Evergreen 2024, 11, 32–45. [Google Scholar] [CrossRef]

- Akinshilo, A. Energy potential from municipal solid waste (MSW) for a developing metropolis. J. Therm. Eng. 2019, 5, 196–204. [Google Scholar] [CrossRef]

- Pheakdey, D.V.; Quan, N.V.; Xuan, T.D. Economic and environmental benefits of energy recovery from municipal solid waste in Phnom Penh Municipality, Cambodia. Energies 2023, 16, 3234. [Google Scholar] [CrossRef]

- Mondal, S.; Rafizul, I.M. Evaluating energy generation potential from municipal solid waste in an open dumping site of Khulna. City Environ. Interact. 2024, 24, 100172. [Google Scholar] [CrossRef]

- Djellad, A. Real Large-Scale Waste Management and Electricity Generation by Incineration and Methanation Routes: Methodologies and Comparative Investigation on Local Municipal Waste Landfills. Iran. J. Chem. Chem. Eng. (IJCCE) Res. Artic. 2024, 43, 3427–3437. [Google Scholar]

- Escamilla-García, P.E.; Camarillo-López, R.H.; Carrasco-Hernández, R.; Fernández-Rodríguez, E.; Legal-Hernández, J.M. Technical and economic analysis of energy generation from waste incineration in Mexico. Energy Strategy Rev. 2020, 31, 100542. [Google Scholar] [CrossRef]

- Safieddin Ardebili, S.M.; Asakereh, A.; Soleymani, M. An analysis of renewable electricity generation potential from municipal solid waste: A case study (Khuzestan Province, Iran). Biomass Convers. Biorefin. 2023, 13, 89–97. [Google Scholar] [CrossRef]

- Zafar, A.M.; Shahid, S.; Nawaz, M.I.; Mustafa, J.; Iftekhar, S.; Ahmed, I.; Tabraiz, S.; Bontempi, E.; Assad, M.; Ghafoor, F.; et al. Waste to energy feasibility, challenges, and perspective in municipal solid waste incineration and implementation: A case study for Pakistan. Chem. Eng. J. Adv. 2024, 18, 100595. [Google Scholar] [CrossRef]

- Chagunda, M.F.; Ruhiiga, T.M.; Palamuleni, L.G. Evaluation of energy generation potential from municipal solid waste in the Northwest province, South Africa. Int. J. Renew. Energy Dev. 2023, 12, 832. [Google Scholar] [CrossRef]

- Hadi, A.H.; Hussain, B.A.; Khalaf, A.A.; Abdurazak, A.F. A theoretical calculation of electrical energy production from the incineration of Baghdad municipal solid wastes. J. Eng. 2024, 30, 86–97. [Google Scholar] [CrossRef]

- Zeng, J.; Mustafa, A.B.; Liu, M.; Huang, G.; Shang, N.; Liu, X.; Wei, K.; Wang, P.; Dong, H. Environmental, energy, and techno-economic assessment of waste-to-energy incineration. Sustainability 2024, 16, 4140. [Google Scholar] [CrossRef]

- Amulen, J.; Kasedde, H.; Serugunda, J.; Lwanyaga, J.D. The potential of energy recovery from municipal solid waste in Kampala City, Uganda, by incineration. Energy Convers. Manag. X 2022, 14, 100204. [Google Scholar] [CrossRef]

- Mujalge, A.; Rodrigues, E.; Patil, N.; Shirke, S.; Heggond, S.B. Incineration Process for Municipal Solid Waste In Palghar District. Int. J. Innov. Eng. Sci. 2020, 5, 41–45. [Google Scholar] [CrossRef]

- Demissie, D.B.; Fetensa, G.; Desta, T.; Tiyare, F.T. Effectiveness and efficacy of long-lasting insecticidal nets for malaria control in Africa: Systematic review and meta-analysis of randomized controlled trials. Int. J. Environ. Res. Public Health 2025, 22, 1045. [Google Scholar] [CrossRef]

- Rimon, S.T.A.; Mohtasim, M.S.; Kibria, M.G.; Ahmed, M.M.; Das, B.K. Techno-economic and eco-friendly MSW-based strategy to reduce the impact of Rajshahi City’s electric vehicle power outage in Bangladesh. Clean Technol. Environ. Policy 2025, 1–14. [Google Scholar] [CrossRef]

- Hossain, M.M.; Shahriar, T.; Inan, M.N.; Habib, M.A.; Hasanuzzaman, M.; Hossain, M.M. Techno-economic Impact of Incineration-Based Waste to Energy Generation Technology in Bangladesh: A Short Review and A Case Study. ChemRxiv 2025. [Google Scholar] [CrossRef]

- Straka, M.; Rosova, A.; Malindzakova, M.; Khouri, S.; Culkova, K. Evaluating the Waste Incineration Process for Sustainable Development through Modelling, Logistics, and Simulation. Pol. J. Environ. Stud. 2018, 27, 6. [Google Scholar] [CrossRef]

- Akter, S.; Mohandas, Y.; Muttaqi, K.M.; Sutanto, D.; Al-Shetwi, A.Q.; Hannan, M.A. Municipal Solid Waste Fueled Power Generation: A Case Study of Waste-to-Energy. In Proceedings of the 2023 IEEE Industry Applications Society Annual Meeting (IAS), Nashville, TN, USA, 29 October–2 November 2023; IEEE: New York, NY, USA, 2023; pp. 1–8. [Google Scholar]

- Joshi, P.; Sharma, S. Sustainable Technologies: Waste to Energy Solutions. ShodhKosh J. Vis. Perform. Arts 2024, 5, 2158–2168. [Google Scholar] [CrossRef]

- Tangri, N. Waste incinerators undermine clean energy goals. PLoS Clim. 2023, 2, e0000100. [Google Scholar] [CrossRef]

- Szymajda, A.; Łaska, G. The effect of moisture and ash on the calorific value of cow dung biomass. Proceedings 2019, 16, 4. [Google Scholar] [CrossRef]

- Anwar, M.T.; Ullah, N.; Khalid, S.; Ahmad, N.; Shahzeb Khan, M. Fuel Composites Development Using Cow Dung and Agricultural Biomass. Mater. Proc. 2024, 17, 23. [Google Scholar]

- Phatak, A.; Pandey, A.; Mishra, K.P. Characterization and performance analysis of cow dung-based fuels for rural masses. Neuroquantology 2022, 20, 9721–9740. [Google Scholar]

- Aliabadi, Y.; Hajinezhad, A.; Fattahi, R.; Moosavian, S.F. Analysis of energy generation from MSW with auxiliary feed in the north of Iran. Results Eng. 2023, 18, 101185. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Hossan, M.N.; Masud, M.H. Prospect of waste-to-energy technologies in selected regions of lower- and lower-middle-income countries of the world. J. Clean. Prod. 2024, 450, 142006. [Google Scholar] [CrossRef]

- Yakah, N.; Kwarteng, A.A.; Addy, C.; Yirenkyi, M.; Martin, A.; Simons, A. Techno-Economic Assessment of Municipal Solid Waste (MSW) Incineration in Ghana. Processes 2024, 12, 1286. [Google Scholar] [CrossRef]

- Youcai, Z. Municipal solid waste incineration process and generation of bottom ash and fly ash. In Pollution Control and Resource Recovery: Municipal Solid Wastes Incineration; Butterworth-Heinemann: Oxford, UK, 2017; pp. 1–59. [Google Scholar] [CrossRef]

- Bioenergy, I.E.A. Review of Waste to Energy Policies in South Africa and International Comparisons; IEA Bioenergy: Paris, France, 2023. [Google Scholar]

- Department of Forestry, Fisheries and the Environment. National Environmental Management: Waste Act, 2008 (Act No. 59 Of 2008) National Policy for the Management of Waste Electrical and Electronic Equipment (WEEE), Government Gazette. Available online: https://www.gov.za/sites/default/files/gcis_document/202508/53243gon6554.pdf (accessed on 29 August 2025).

- Panya, K.O.; Abuya, J. Carbon pricing policies and global supply chain decisions: Africa’s perspective. Strateg. J. Bus. Change Manag. 2025, 12, 32–57. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).