1. Introduction

Cement production is one of the most energy-intensive industrial processes, accounting for approximately 8% of the global CO

2 emissions [

1,

2]. In West Africa, particularly in Togo, the cement industry plays a crucial role in economic development as urbanization and infrastructure construction are expanding rapidly [

3]. The West African cement corridor, spanning cities like Lomé, Accra, and Lagos, serves a mega-urban region with over 40 million people, creating substantial demand for cement production and consequently, significant environmental challenges [

4].

Traditional cement production relies heavily on fossil fuels, such as coal, fuel oil, petroleum coke, and natural gas, contributing to greenhouse gas emissions and operational costs [

5]. Alternative fuels (AF), derived from various waste streams, including industrial, municipal, and hazardous waste, have emerged as promising substitutes for reducing both environmental impact and production costs [

6]. These alternative fuels can achieve substitution rates of up to 100% in modern cement kilns, with the global AF utilization for cement production expected to increase by 1% annually [

7,

8].

Among these alternatives, tire-derived fuels (TDF) from end-of-life tires (ELT) are promising due to their high energy content (~7500 kcal/kg), low moisture levels, stable material properties, and favorable combustion characteristics, which make them especially suitable for cement kiln applications [

9].

In Togo, about 350,000 t of end-of-life tires are generated annually, and only a few are re-treaded or used for artisanal recycling. Most ELTs are either illegally openly burned [

10,

11] (

Figure 1) or simply dumped (25%). These practices pose serious environmental hazards, as the dumping of ELTs can increase the mosquito population carrying diseases and leaching toxic materials [

12]. Additionally, the risk of open burning of ELTs emitting uncontrolled emissions of hazardous substances is dangerous to human health [

13]. This substantial waste stream represents an untapped resource for sustainable energy recovery during cement production.

The economic potential of ELT utilization is significant, with varying sourcing costs depending on the tire type and size. Local market analysis revealed that commercial truck tires cost approximately 1.22 € per unit, while passenger car tires cost 0.8 € per unit, with different weight distributions affecting the overall economics of TDF production (

Table 1). While European cement plants successfully utilize up to 550,000 t per annum of TDF [

14], limited research exists on its implementation feasibility in African cement facilities. The research limitations are the local waste tire characteristics, heterogeneous waste streams, and regional operational conditions.

Previous studies have primarily focused on laboratory-scale analyses or European/North American contexts, with several key limitations: most research lacks full-scale industrial validation under African operational conditions and tropical climate considerations, and limited data on the heterogeneous nature of local waste tire streams and their impact on process stability and combustion efficiency are available. Economic analyses considering local waste tire sourcing costs, transportation logistics, and regional market conditions are insufficient, as comparable data have not yet been assessed. In addition, there is no comprehensive emission profiling specific to regional cement plant configurations. This article addresses these gaps by providing the first comprehensive full-scale evaluation of ELT utilization as an alternative fuel in a Togolese cement plant.

The research objectives of this article are to evaluate and compare the technical feasibility of partial coal substitution with shredded ELT and whole ELT in full-scale clinker production and to assess kiln stability and operating conditions. The aim is also to conduct a comprehensive environmental impact assessment through continuous emission monitoring during ELT co-processing, compare atmospheric emissions with conventional coal firing, and analyze clinker quality parameters, including chemical composition, physical properties, and performance characteristics under alternative fuel operation. Lastly, a detailed economic viability analysis of ELT utilization will be performed, considering local waste tire sourcing costs, processing requirements, transportation logistics, and operational modifications.

The findings of this study will provide critical insights for sustainable cement production in West Africa, contribute to circular economy development through waste tire valorization, and establish a framework for alternative fuel implementation in similar industrial contexts across developing regions. It also highlights a critical demonstration for decision-makers in Togo that establishing a tire re-cycling industry represents a viable economic opportunity, given the cement industry’s demand for TDF as an alternative fuel source.

2. Materials and Methods

Experimental tests were conducted at a clinker plant in Tabligbo, Togo. The plant has a clinker capacity of 210 t/h and uses a four-stage cyclone preheater and an in-line calciner. Raw material firing occurs in the cyclone tower, while clinkering occurs in the rotary kiln. The pre-calciner, a 50 m-long duct, uses tertiary air from the final clinker cooler for the calcination process. The methodology for the case study was similar to that described by Murray in 2008 [

15]. The following steps elaborate on the research activities carried out as part of the case study.

The ELT trial burn tests were conducted for over 100 h of continuous plant operation over four months. Waste material was used in the form of shredded chips (TDF) injected at the entrance of the pre-calciner and whole tires (ELT) at the kiln inlet. The particle characteristics are listed in

Table 2.

The size characteristics, feeding location, and injection modes of tire chips were selected after careful evaluation of process requirements, such as the optimal recovery of fuel heat content, minimization of fuel heat combustion time, accuracy of material proportioning, and eventual utilization of different alternative fuels.

2.1. Feed Rate Control and Quality Assurance

An alternative fuel feeding system was designed to maintain precise control over the substitution rates. TDF was fed at rates ranging from 2.5 to 4.2 t/h through a controlled dosing system as the pre-calciner entrance. This was a 14–25% thermal substitution of conventional coals. ELT feeding at the kiln inlet was controlled at 0.8 to 1.5 t/h. This corresponds to an 8–15% thermal substitution. The combined AF substitution rate was maintained at 28% throughout the test period, with daily feed rates monitored and recorded every two hours.

2.2. Material Quality Control and Specifications

The material examined in this study was obtained from a supplier in Togo. The specific tolerable specifications for the AF were communicated to the supplier as part of the contract to ensure consistently high quality; deliveries failing to meet these criteria were subject to rejection. Upon arrival at the plant site, the delivery truck was weighed on a bridge scale to determine the exact quantity of AF received, with an average daily intake of 195 t. Each delivery underwent mandatory quality inspection, including visual assessment for contamination, random sampling for laboratory verification, and documentation of source traceability. Contractual specifications regarding the feedstock included a minimum lower heating value (LHV) of 28 MJ/kg, a maximum 3% (weight) moisture content, and size consistency. TDF particles were within a 50–100 mm range, with less than 5% oversized materials.

Incoming material inspection was performed as a quality control procedure. Visual inspection was systematically performed to assess contamination with foreign materials (stones, sand, etc.) and size distribution compliance.

The plant operates continuously throughout the year, except for scheduled maintenance or emergency shutdowns. During the case study period, no instances of prolonged plant shutdowns exceeding six hours were observed. Consequently, the supplier was requested to deliver AF over five weekdays, with an additional two days of supply provided prior to the weekends. Sufficient storage capacity was allocated, including a one-day backup supply, to account for unforeseen delays. This arrangement ensured a continuous and reliable supply of AF to meet the plant’s operational requirements.

2.3. Characterization of the ELT and TDF

The AF was sampled in order to perform laboratory investigations. In the laboratory, the following parameters were investigated: lower heating value (LHV), moisture content, and density. In addition, an analysis of the optimum substitution ratio (between AF and coal) was carried out to determine the optimum ratio at which the specific AF from this supplier would provide maximum plant performance and energy efficiency. This was done by measuring O

2 and CO% at the kiln inlet and cooler efficiency [

16,

17,

18].

2.4. Sample Collection Points and Frequency

Sampling was performed at the standard operational positions of the kiln operation (

Figure 2). Samples were collected every two hours during the trial period.

2.5. Change of the Raw Meal Design

The raw meal was redesigned to accommodate the new co-processing systems. In the new design, the lime saturation factor was decreased to fit the ash content in the AF.

2.6. Operation and Technical Performance

The plant has accumulated extensive performance data over several years of operation using 100% conventional fuels (primarily coal). During the test phase, this was reduced to a coal usage of 72%. To evaluate the technical viability of co-processing with a high proportion (28%) of alternative fuels (AF), a direct comparison of the plant’s performance was conducted, focusing on kiln inlet oxygen levels. During the test phase, either ELT plus coal or TDF plus coal was used in order to determine the optimal co-feeding material. To reduce the possibility of buildup and ring formation in cement kilns, a good sulfur and alkali balance must be maintained. This was accomplished by maintaining consistent operation and avoiding analyses caused by excessive or insufficient burning, uneven kiln feed rates, and irregular fuel feed combinations.

Continuous process monitoring and control instruments were employed, focusing on clinker quality and TDF replacement tests. Flue gas stack measurements were conducted to determine the levels of CO, SO

2, NO

x, total particulates, and trace metals. Full TDF and ELT operation data are provided in Annexes 1 and 2. The resulting data were used in a kinetic model to optimize the injection and shredding modes, with the goal of improving combustion conditions. Combustion tests were also performed to assess the burnout times and weight loss of typical TDF chips.

Figure 2 illustrates the different areas and positions where the measurements were taken.

3. Results & Discussion

The study conducted trial burn evaluations using TDF as a fuel replacement in a furnace with ELT at the kiln inlet (

Table 1). The results showed that the furnace was insensitive to TDF (tire chips) even with a higher fuel replacement percentage (28%). The fuel substitution percentage was not limited by CO emissions, and the use of alternative fuels did not impact the main operating parameters [

19,

20]. The addition of TDF did not affect the quality of the clinker produced. The pneumatic conveyor system for feeding shredded tires to the furnace provides high precision in material proportioning and flexibility for different operating conditions [

19].

3.1. Comparative Analysis of TDF vs. ELT Feed Regimes

Two distinct operational regimes were investigated to determine the impact of alternative tire-based fuels on clinker plant productivity and the associated operational parameters. The TDF scenario used tire chips at higher feed rates (3.68–4.15 t/h), while the ELT scenario used whole tires at lower feed rates (1.24–2.24 t/h). The complete TDF and ELT operation data can be accessed in

Appendix A.1 and

Appendix A.2.

3.2. Productivity Impact

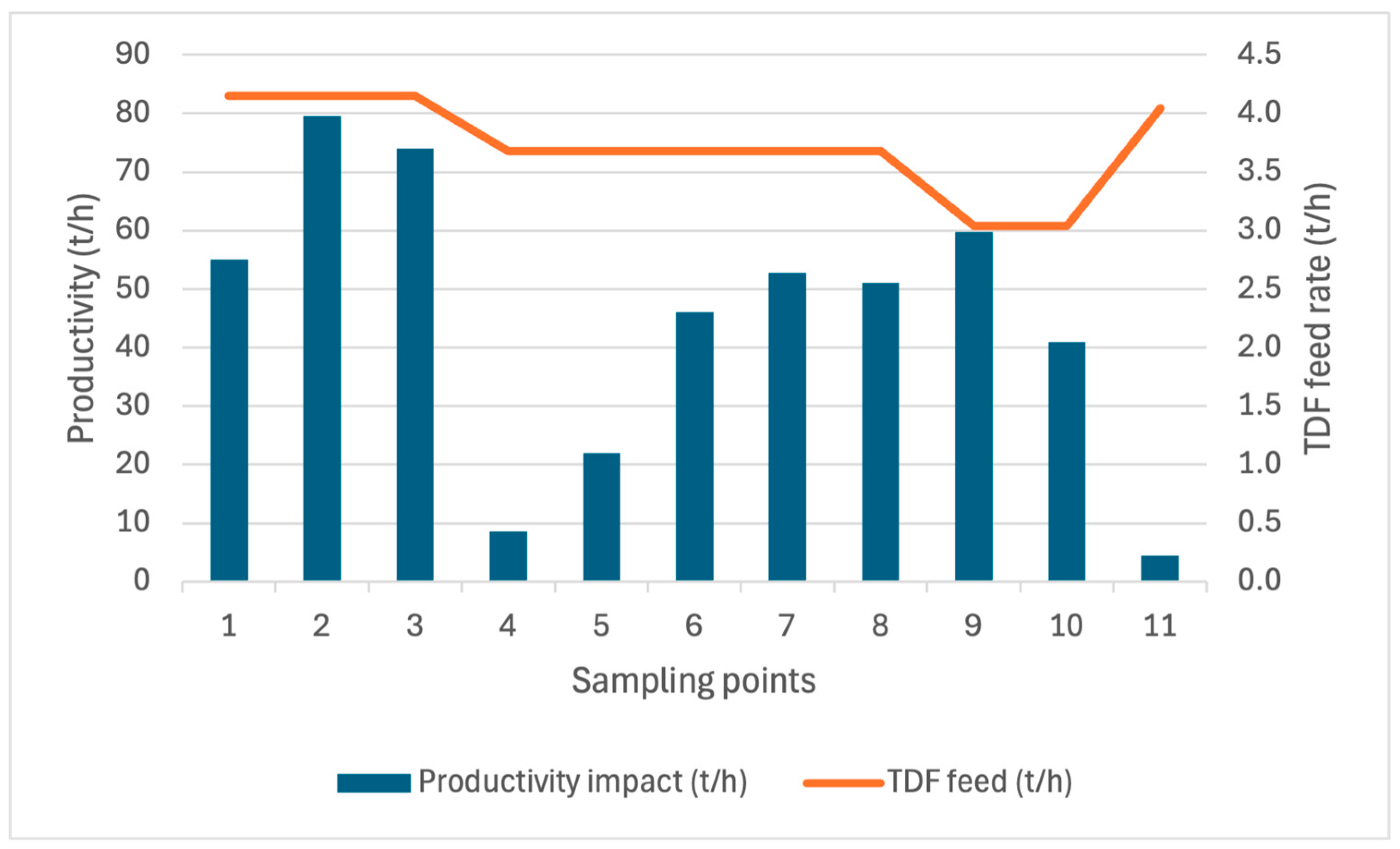

A contradiction was observed in the productivity impact (t/h) between the two operational regimes. The TDF scenario using tire chips demonstrated predominantly positive productivity impacts, with values reaching 79.6 t/h, 74 t/h, and 59.8 t/h during periods 2, 3, and 9, respectively (

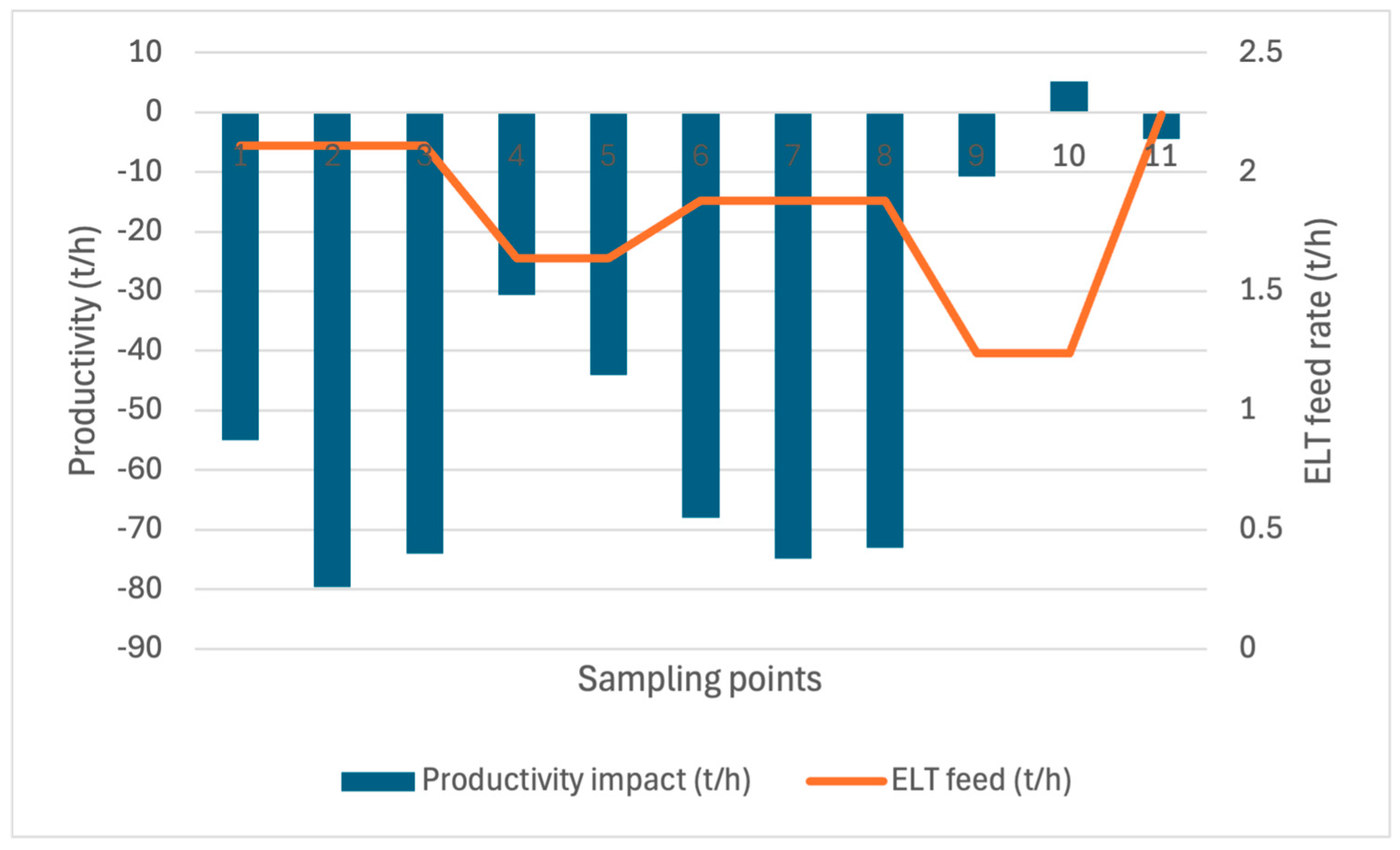

Figure 3). The ELT scenario using whole tires exhibited consistently negative productivity impacts across all measurement periods, with substantial decreases of −79.6 t/h, −74 t/h, and −74.8 t/h during periods 2, 3, and 7 (

Figure 4).

The correlation coefficient between the tire feed rate and productivity impact was calculated as r = 0.83 (p < 0.01), indicating a strong positive relationship between these variables. However, the physical form of the tire material (shredded vs. whole) appears to be a more significant factor than the feed rate alone, suggesting fundamental differences in the combustion dynamics between TDF and ELT processing.

3.3. Kiln Atmospheric Particulate Matter (APM)

Kiln APM measurements displayed similar patterns in both scenarios, with values ranging from 48 to 162 mg/Nm3 across both operational scenarios. Notable peaks in APM levels were observed during periods 7–10 under both operational regimes. However, the TDF scenario maintained more consistent APM levels when the productivity impacts were positive, suggesting more stable combustion conditions. This is likely attributable to the shredded form of TDF providing more homogeneous combustion characteristics than the heterogeneous burning patterns of whole tires in the ELT scenario.

Stack measurement campaigns [

21] were used to evaluate the impact of AF on atmospheric emissions. The results showed a significant reduction in NOx emissions with TDF utilization, which was confirmed by the NOx flue gas concentrations monitored across the pre-calciner, up- and downstream of the tire feeding section. The reductions during ELT utilization appeared regular, with a range between 150 and 300 ppm at 0% O

2. This study suggests that TDF utilization can potentially reduce emissions and improve the efficiency of reutilization practices.

TDF has also shown potential for reducing nitrogen emissions in re-burning applications. Its lower nitrogen content and higher volatile carbon content make it more effective as a reburn fuel in pre-calciners [

22]. The addition of significant amounts of AF with a higher volatile carbon content can enhance NO reduction in exhaust gas streams. TDF also reduces SO

2 concentrations, with over 30% reduction in input for 36% heat replacement.

There were no significant variations in the total particulates and VOCs outside the normal range of values found for the plant’s operating conditions, while CO emissions were negligible [

22,

23]. Metal emissions were not related to fuel substitution practices, confirming the potential of cement plants to develop significant trapping capacities during clinker formation. The high removal efficiencies developed by the AF over the particle size range were significant for volatile elements in TDF [

23].

3.4. Oxygen and Carbon Monoxide Levels

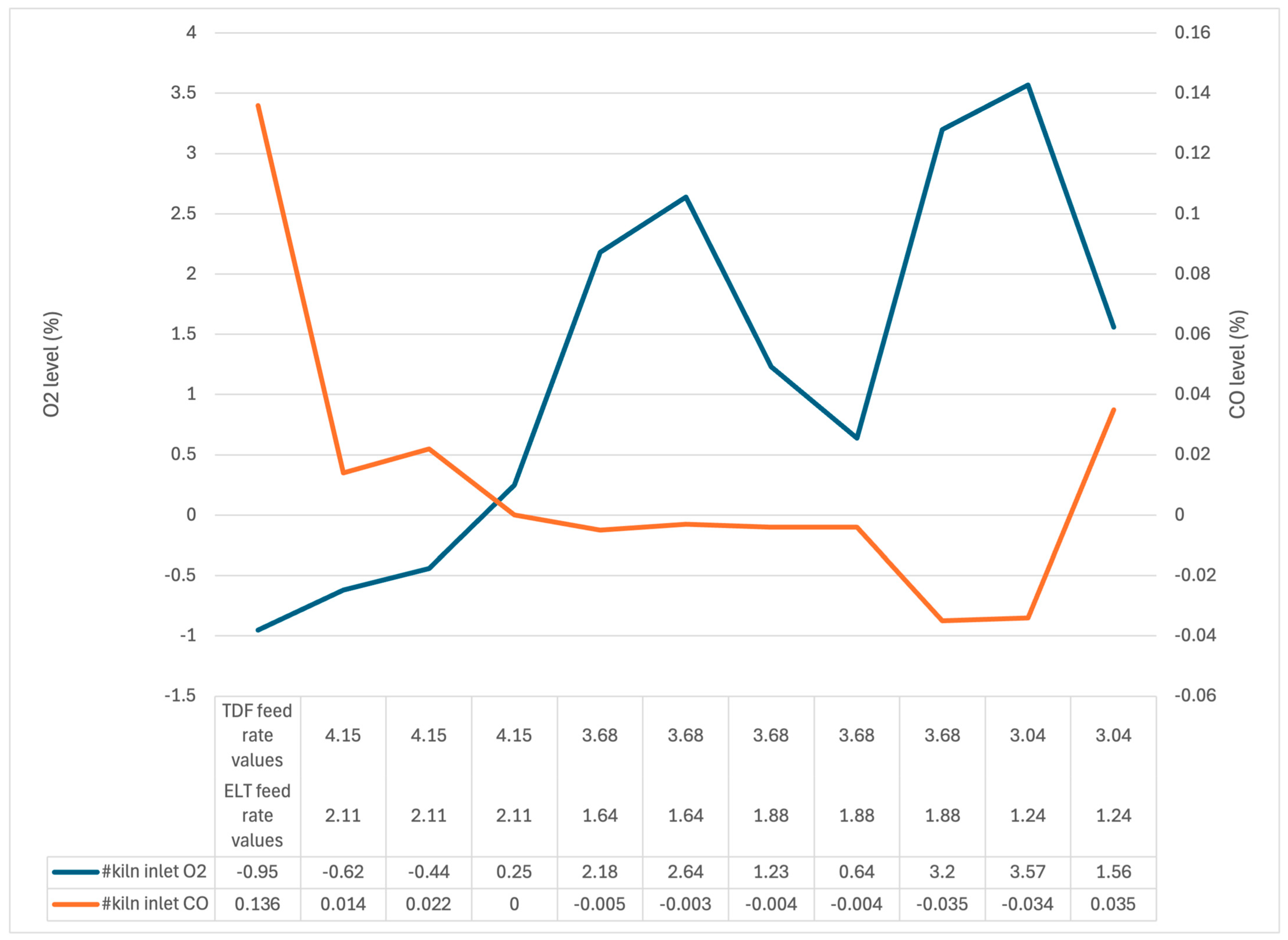

Figure 5 illustrates the oxygen (O

2) and carbon monoxide (CO) concentrations at the kiln inlet during the co-processing operations. Different feed rates of TDF and ELT were employed throughout the sampling period. Both fuels were used simultaneously as co-feeds with coal.

An inverse relationship between the O2 and CO levels was clearly observed in the data. When the O2 readings were negative or minimal, correspondingly higher CO concentrations were recorded. At the initial sampling points, where the TDF feed rates were highest (4.15) and the ELT rates were 2.11, oxygen levels were measured at −0.95% with elevated CO readings of 0.136. This suggests oxygen-deficient combustion conditions.

Notable changes in the kiln atmosphere were observed as the feed rates were adjusted. Progressive reductions in both TDF and ELT feed rates corresponded with improved oxygen availability in the kiln atmosphere. The negative O2 readings observed at higher feed rates transitioned to positive values, reaching up to 3.57% at the ninth sampling point.

Carbon monoxide levels decreased markedly after the initial sampling point. The values stabilized near zero or became slightly negative in the middle sampling range. A small increase to 0.035 was noted at the final sampling point despite the relatively high oxygen availability.

The most favorable combustion conditions appear to be achieved when the TDF feed rates are reduced to 3.04 and ELT to 1.24. Under these conditions, adequate oxygen levels were maintained without significant CO production. This suggests a more complete combustion of the co-processed materials.

The total ash was less than 0.5 kg/t clinker. Booster fuels, such as waste oils/solvents or fossil fuels, were used to stabilize the flame, thereby boosting the overall AF substitution rate.

Maintaining a consistent fuel mix package (ELTs + Coal and TDF + coal) reduced the quantity of fuel transport air at the main burner.

Oxygen enrichment improved combustion in oxygen-rich primary air, minimizing flame and fuel burnout times and eliminating reducing circumstances. Stability is required for the high-volume use of alternative fuels (AF), as is consistent feeding and weighing.

3.5. Coal Consumption

Both scenarios showed negative values for pre-calciner feeding coal, highlighting the reduction in coal usage when alternative tire fuels were incorporated. This effect was more pronounced in the TDF scenario, with values reaching −0.97 during period 4, compared to the minimum of −0.62 in period 2 for the ELT scenario.

Kiln-feeding coal similarly showed reduction patterns in both scenarios, though with distinct profiles. The TDF scenario demonstrated more consistent coal replacement, with values averaging −0.34, while the ELT scenario showed greater variability, with values ranging from −0.42 to 0.76. This suggests that tire chips provide more reliable thermal substitution than whole tires, likely due to their more consistent combustion properties and improved surface area-to-volume ratio.

3.6. Material Preparation and Feed Rate Analysis

Statistical analysis of the data revealed fundamental differences between the TDF and ELT operational regimes. The TDF approach using tire chips at higher feed rates (3.68–4.15 t/h) consistently yielded positive productivity impacts, with an average increase of 54.9 t/h. In contrast, the ELT approach using whole tires at lower feed rates (1.24–2.24 t/h) resulted in uniformly negative productivity impacts, with an average decrease of 59.4 t/h.

These contrasting outcomes can be attributed to two principal factors: (1) physical preparation of the tire material and (2) feed rate. Tire chips provide a greater surface area for combustion, more homogeneous burning characteristics, and improved mixing with traditional fuels. Higher feed rates of TDF further contribute to achieving optimal thermal conditions within the kiln system, whereas whole tires in the ELT scenario appear to disrupt normal operations despite their lower feed rates.

The results strongly suggest that shredding end-of-life tires before feeding them into the clinker production process is critical for achieving productivity benefits, even though it requires additional pre-processing. This pre-processing cost appears to be offset by the substantial productivity gains observed in the TDF scenario. The ELT and TDF substitution percentages and clinker quality can be accessed in

Appendix A.3 and

Appendix A.4.

3.7. Economic Considerations

The use of waste as AF in the cement industry offers both economic and ecological benefits. It reduces the use of non-renewable fossil fuels like coal and the environmental impacts of coal mining. Additionally, it lowers emissions by replacing fossil fuels with materials that would otherwise have to be incinerated, potentially without energy recovery. The use of waste in cement furnaces also contributes to environmental protection, as it can reduce waste tire disposal by up to 99% [

19]. The cement industry also uses AF to reduce energy costs in clinker production. In this case, the use of AF reduced energy consumption by 28% of the total costs. Waste incineration in cement plants reduces waste disposal in landfills in Togo, limiting expansion and avoiding illegal waste management activities. Implementing ELT collection in rural areas contributes to overall development employment and generates additional revenue for economically backward farmers, aiding rural upliftment and improving their economic status [

24].

In Togo, the economic analysis of the two alternative fuel approaches revealed insights into the cost-effectiveness of TDF versus ELT utilization (

Figure 6).

The production chain in Togo begins with society generating approximately 350,000 t of ELT annually [

10] with no tipping fee, followed by collection and transport costs of €50/t (including payment for ELT acquisition). At this stage, two distinct processing pathways can be identified for the use of AF in cement plants:

- (a)

Direct ELT co-processing pathway: Whole tires are fed directly into the cement plant at a substitution fuel cost of €70/t (€0.5/GJ). However, this pathway incurs a productivity penalty of 45 t/h at a 28% ELT substitution rate, as evidenced by the consistently negative productivity impacts shown in

Figure 3.

- (b)

TDF pre-processing pathway: Alternatively, ELTs undergo additional processing at a recycling plant, adding pre-processing costs of €20/t. The resulting TDF is then fed into the cement plant at a higher substitution fuel cost of €90/t (€2.5/GJ). It is important to highlight that this pathway demonstrates no productivity loss at a 28% TDF substitution rate, confirming the positive productivity impacts observed in

Figure 4.

Cost-benefit analysis shows that despite the additional €20/t pre-processing cost and resulting higher fuel cost (€90/t vs. €70/t), the TDF pathway is significantly more economical when accounting for productivity impacts than the ELT pathway. With an average productivity increase of 54.9 t/h for TDF versus an average productivity decrease of 59.4 t/h for ELT, the net economic advantage of the TDF pathway is substantial (example calculation, see

Table 3).

This economic analysis demonstrates that the additional pre-processing cost of €20/t for converting ELT to TDF is more than offset by avoiding productivity losses. The return on investment for implementing TDF pre-processing was estimated at approximately 540%, calculated by comparing the avoided productivity losses to the additional pre-processing investment.

The cement industry is increasingly aware of its role in global carbon dioxide emissions and the need to reduce emissions and contribute more to mitigating global warming. The Kyoto Protocol and clean development mechanisms have impacted the industry globally, with the potential to support the replacement of fossil fuels with waste-derived ones. The Kyoto Protocol introduced three market-based instruments:

- -

Clean development mechanism (CDM),

- -

Joint implementation (JI), and

- -

Emissions trading (ET).

These instruments allow countries to reduce emissions or enhance carbon sinks at lower costs, with the potential value of these transactions reaching tens of billions of dollars annually [

25].

The Clean Development Mechanism (CDM) is a mechanism under the Kyoto Protocol that allows countries with emission targets to invest in emission control projects in developing countries without targets and earn credits for reductions in GHG emissions. This mechanism benefits both investors and host countries, with investor countries benefiting from follow-up exports and host countries benefiting from inward investment and technology transfer [

26].

The cement industry is particularly promising under the CDM, as developing countries like Togo in West Africa and its neighboring countries are major regional producers of cement and have significant potential for emission credits through alternative and waste-derived fuels.

4. Conclusions

A comparative evaluation of tire-derived fuel (TDF) and whole end-of-life tire (ELT) co-processing regimes in cement clinker production in Togo revealed significant operational and economic differences between these alternative fuel approaches. The experimental results demonstrated that the physical preparation of tire materials is a crucial factor in determining operational efficiency and productivity outcomes.

The TDF scenario, which utilized shredded tire chips at higher feed rates (3.68–4.15 t/h), consistently yielded positive productivity impacts with an average increase of 54.9 t/h, while the ELT scenario, which used whole tires at lower feed rates (1.24–2.24 t/h), resulting in uniformly negative productivity impacts. A strong positive correlation was established between the tire feed rate and productivity impact, although the physical form of the material was identified as the more decisive factor influencing combustion dynamics.

Environmental benefits were observed in both scenarios, with TDF demonstrating particular advantages in terms of emissions reduction. Nitrogen oxide emissions were significantly reduced across the pre-calciner system, with reductions ranging between 150 and 300 ppm at 0% O2. Additionally, sulfur dioxide concentrations were reduced by over 30% with 36% heat replacement while maintaining total particulates and volatile organic compounds within normal operational ranges. The inherent metal-trapping capacity of cement plants during clinker formation was confirmed, with no correlation observed between metal emissions and fuel substitution practices.

The economic analysis showed that despite the additional pre-processing costs of €20/t for TDF production, the overall economic benefit was substantially higher than that of direct ELT utilization. The return on investment for TDF pre-processing was calculated at approximately 540%, primarily attributed to avoiding productivity losses associated with whole tire combustion. The cost-benefit evaluation demonstrated that the additional pre-processing expenditure was more than compensated for by operational efficiency gains.

Combustion analysis indicated that optimal conditions were achieved when the TDF feed rate was maintained at 3.04 t/h and ELT at 1.24 t/h, resulting in adequate oxygen levels without significant carbon monoxide production. The inverse relationship between oxygen and carbon monoxide concentrations confirmed the importance of maintaining appropriate feed rates for the complete combustion of co-processed materials.

This study confirms that while both TDF and ELT represent viable pathways for alternative fuel utilization in cement production, the pre-processing of end-of-life tires into tire-derived fuel offers superior operational, environmental, and economic outcomes. These findings support the implementation of TDF pre-processing systems in cement plants, particularly in developing regions where waste tire management presents both environmental challenges and economic opportunities. This investigation was carried out to demonstrate to cement plants in Togo the advantages of TDF as an effective replacement for fossil fuels and to provide decision-makers in Togo with evidence that establishing a tire recycling industry represents a viable economic opportunity, given the cement industry’s demonstrated demand for TDF as an alternative fuel source.