Abstract

Agricultural waste poses significant environmental, economic, and social challenges globally, with estimates indicating that 10–50% of agricultural products are discarded annually as waste. This review explores strategies for managing agricultural waste to mitigate its adverse impacts and promote sustainable development. Agricultural residues, such as those from sugarcane, rice, and wheat, contribute to pollution when improperly disposed of through burning or burying, contaminating soil, water, and air. However, these residues also represent untapped resources for bioenergy production, composting, mulching, and the creation of value-added products like biochar, bioplastics, single-cell protein and biobased building blocks. The paper highlights various solutions, including integrating agricultural waste into livestock feed formulations to reduce competition for human food crops, producing biofuels like ethanol and biodiesel from lignocellulosic materials, and adopting circular economy practices to upcycle waste into high-value products. Technologies such as anaerobic digestion for biogas production and gasification for synthesis gas offer renewable energy alternatives and ample feedstocks for gas fermentation while addressing waste management issues. Composting and vermicomposting enhance soil fertility, while mulching improves moisture retention and reduces erosion. Moreover, the review emphasizes the importance of policy frameworks, public-private partnerships, and farmer education in promoting effective waste management practices. By implementing these strategies, agricultural waste can be transformed into a resource, contributing to food security, environmental conservation, and economic growth.

1. Introduction

The escalating issue of agricultural waste presents a significant challenge for numerous countries, particularly those in the developing world. A primary contributor to the increase in agricultural waste and residues, apart from simple mismanagement, is environmental degradation, which underscores the urgent need for environmental preservation and the optimal utilization of natural resources as integral components of development planning. The imperative to safeguard the environment and protect natural resources is essential for enhancing living conditions and livelihoods in rural areas, and in the long run even for the survival of human life. This necessity aligns with the broader goal of environmental protection and the conservation of a nation’s natural resources [1,2].

Increasing waste generation is a consequence of population growth, urbanization, and economic development [3]. It is projected that global waste production will reach approximately 2.6 billion tons by 2030, with an anticipated increase to 3.4 billion tons by 2050, effectively doubling the figures from 2016 and tripling them by the year 2100 [4]. The classification of waste can be approached from various perspectives, including material composition, physical state, or source of origin. This review distinguishes between three categories of waste streams based on their source: municipal solid waste (MSW), agricultural solid waste, and industrial solid waste. MSW represents a significant byproduct of urban living and is increasing at a rate that outpaces urbanization itself [5,6]. This category typically encompasses waste generated from households, commercial establishments, office buildings, institutions, and small enterprises [7]. It is estimated that by 2025, approximately 4.3 billion individuals will reside in urban areas, generating an average of 1.42 kg of MSW per person per day [8]. Improper disposal of domestic waste can lead to significant health and environmental challenges [9]. Urbanization is a megatrend, and effective and efficient MSW management is imperative. MSW, when contaminated with batteries and other non-intended streams, can also become hazardous waste.

In 1989, the Food and Agriculture Organization (FAO) articulated a definition of sustainable development within the food and agriculture sectors, characterizing it as the management and maintenance of natural resources alongside the governance of changes and administrative frameworks to ensure the continuous fulfillment of human needs and the satisfaction of both present and future generations. Environmental protection can be encapsulated in three fundamental elements: water, soil, and air, with all environmental discussions inherently linked to these spheres. The issue of agricultural waste poses a threat to all three compartments, as the decomposition of organic waste generates various gases that contribute to air pollution, amongst them CH4, which fuels climate change. Furthermore, agricultural waste and its byproducts, such as leachate, can lead to the contamination of surrounding soil and both surface- and groundwater [10].

The improper disposal methods of burying, burning, or simply neglecting agricultural waste also give rise to significant environmental and health concerns. Additionally, the proliferation of agricultural waste is associated with substantial economic losses, which include the misallocation of limited resources (such as water and soil), a decline in product quality, the squandering of subsidies, an increased reliance on imports, diminished income, and a threat to the livelihoods of producers. Consequently, the agricultural sector, which plays a pivotal role in the economies not only of developing nations, must pursue sustainable development through the preservation of natural resources for the benefit of present and future generations [11,12]. The disposal of waste biomass and agricultural residues through methods such as burial, open burning, and abandonment constitutes a significant environmental burden in many countries. The residue-to-crop ratio of common cultivated plants is 1:10 (sugarcane, sugarbeet) up to 3:1 (rapeseed, cotton) and more [13].

One effective approach to managing agricultural waste is sidestream valorization, including the reuse or recycling of such materials. An example is coconut fibers which are used for cushions or mats, or fertilizer made from sheep wool or ram horn. Byproducts offer an income potential for farmers and reduce the amount of waste. However, today a significant proportion of such byproducts is ultimately discarded, leading to additional expenditures in the collection and disposal. This cycle not only inflicts considerable harm on the environment but also represents a misallocation of resources and foregone opportunities. If a majority of these agricultural wastes could be effectively put to use, and if appropriate investments were made, it would be possible to mitigate environmental degradation and pollution. Furthermore, this approach would contribute to a reduction in the demand for raw materials and the extraction of natural and mineral resources, thereby ensuring their availability for future generations. Consequently, addressing agricultural waste is crucial for achieving sustainable development. This can be accomplished through the effective management of agricultural waste and the minimization of waste generation within this sector, thereby aligning with the objectives of sustainable development, bioenergy production, and environmental conservation [14,15,16].

Global agricultural waste production has been estimated to account for a significant portion of total waste generated annually. According to the World Bank’s “What a Waste 2.0” report [3], global waste production is projected to reach approximately 2.6 billion tons by 2030, with agricultural waste constituting a substantial fraction of this total. In developing countries, agricultural waste often represents up to 30–40% of total crop mass [17], while in developed nations, it ranges between 10–20% due to more efficient harvesting and processing techniques. Regionally, the FAO reports that in Sub-Saharan Africa, post-harvest losses amount to around 15–20% of total production [18], primarily due to inadequate storage and transportation infrastructure. Similarly, in South Asia, cereal losses alone are estimated at 8–16% [19], translating to millions of tons of lost resources annually. For instance, India alone generates over 580 million tons of crop residues annually, with only a fraction being utilized effectively [20]. Meanwhile, in Europe, studies indicate that agricultural waste accounts for roughly 15% of total food loss and waste, equating to about 88 million tons per year [15]. In terms of specific crops, sugarcane and rice contribute significantly to global agricultural waste. Sugarcane bagasse production globally exceeds 250 million tons annually, while rice husk waste amounts to approximately 120 million tons per year [21]. These figures underscore the vast potential for utilizing agricultural waste as a resource rather than discarding it.

2. Definition of Agricultural Waste and Its Types

According to the FAO, any alteration in quality that results in the unavailability and compromised safety of a product, ultimately rendering the agricultural product unsuitable for human consumption, is classified as agricultural waste. Some scholars argue that waste should be assessed from the planting phase throughout to the consumption phase, while others contend that waste should be evaluated starting from the harvesting phase and continuing through to consumption [17]. In middle and high-income nations, food waste predominantly occurs at the consumption stage, primarily attributable to consumer behavior. Conversely, in low-income countries, agricultural and food waste is mainly generated during the initial stages of the food supply chain, prior to reaching the consumer [17,18], which points to inefficiencies in harvesting, storing and transporting the produce to the consumer.

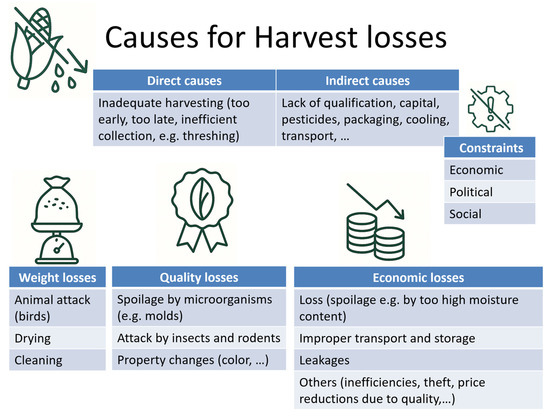

The wastage of agricultural products can be attributed to insufficient harvesting equipment for various types of agricultural and horticultural goods, as well as the absence of nearby processing, packaging and finishing industries. This inadequacy has resulted in significant losses for producers, even in instances where there is a strong domestic demand for these products. Disruptions in supply and subsequent waste have hindered the fulfillment of this demand [22,23].

According to the established definition of post-harvest agricultural waste, any products that remain unused and are deemed unsuitable for market consumption, regardless of the underlying reasons, are classified as waste. This definition underscores the critical importance of market regulation policies in mitigating agricultural product waste. By ensuring that these products are processed appropriately and made available in a timely manner, it is possible to satisfy domestic market needs while also creating opportunities for export, thereby reducing producer losses [17,24].

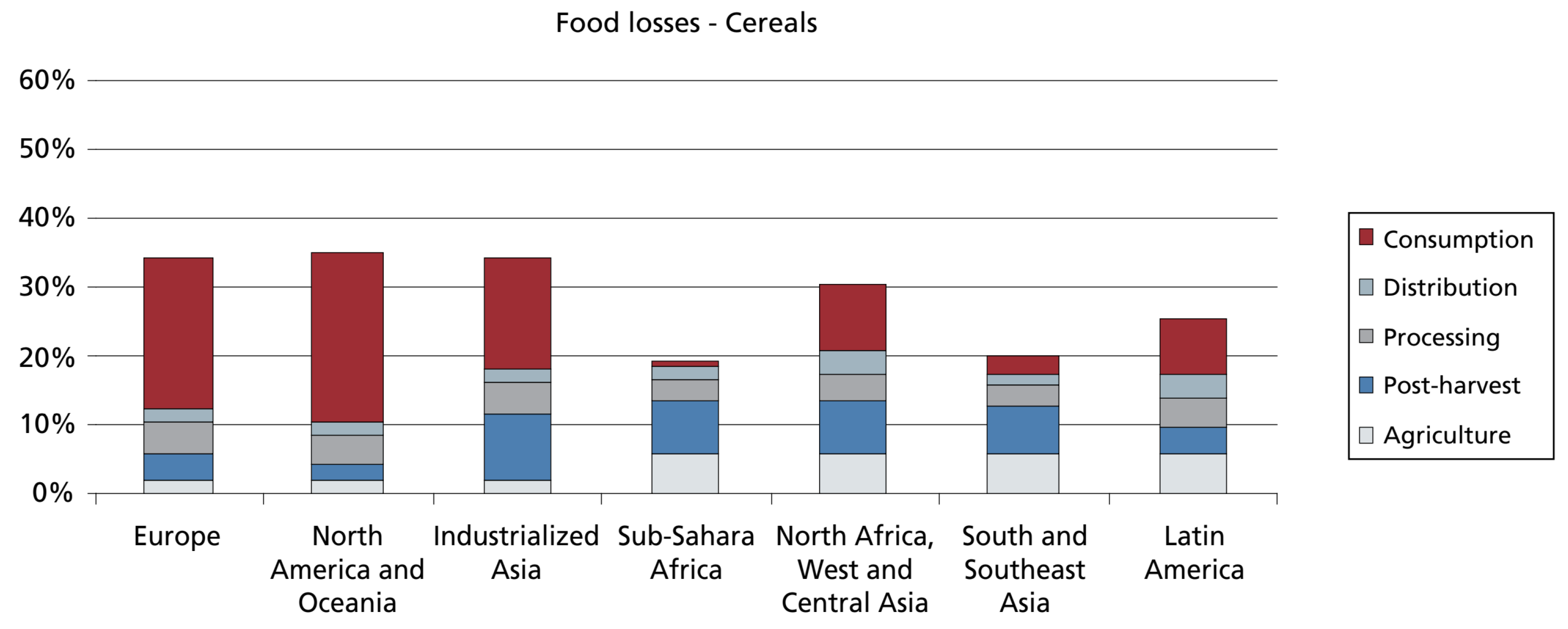

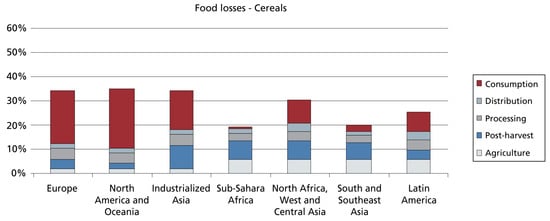

Agriwaste is typically classified into four distinct categories: (1) Direct losses, which refer to the outright loss of agricultural products resulting from factors such as seepage, bag leakage, or consumption by pests including insects, rodents, and birds; (2) Indirect losses, which pertain to a decline in the quality of agricultural products that leads consumers to either reject the items or accept them at a reduced price; (3) Quantitative losses, which involve measurable reductions in the weight or volume of agricultural products; (4) Qualitative waste, which signifies a deterioration in the quality of agricultural products, with its assessment method differing from that of quantitative waste [19]. Figure 1 [18] compares the losses “from field to fork” across different regions, from which one can see that roughly 1/5–1/3 of cereals is squandered.

Figure 1.

Production losses and waste at the FSC (food supply chain) stages, for cereals in a global comparison. Source: [18]. Europe and North America waste a lot in the consumption stage.

Research conducted by Kummu et al. [19] indicates that approximately 25% of global agricultural output is lost or wasted throughout the food supply chain. That level of waste corresponds to the utilization of around 23–24% of total freshwater resources, as well as significant amounts of land dedicated to cultivation, chemical fertilizers and other resources ultimately spent in vain. The findings suggest that if measures were implemented to effectively and efficiently reduce this waste by half, it could potentially provide sustenance for one billion individuals worldwide (Figure 2).

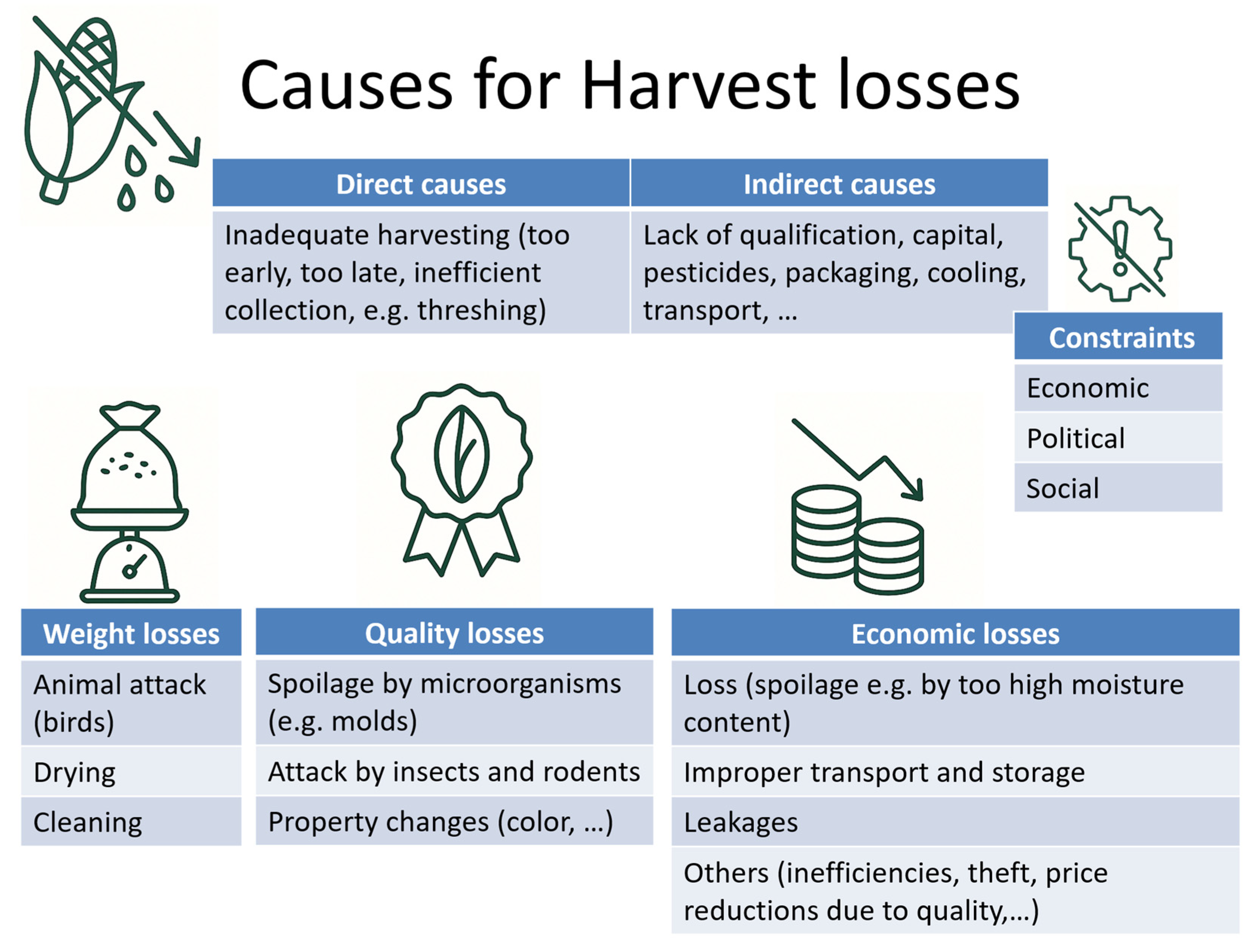

Figure 2.

Root causes of post-harvest losses are manifold. Modified from [25].

Agricultural waste in general and food waste in particular also has a strong impact on the climate, with agriculture contributing disproportionately to anthropogenic CH4 and N2O emissions [26,27].

The growing problem of food waste is a significant challenge faced by many nations, particularly those that are developing. Each year, a substantial quantity of agricultural and horticultural goods spoil at different stages, especially post-harvest, with waste levels in developing countries exceeding those in industrialized nations. Deficiencies in the storage, processing, and distribution systems lead to considerable losses of agricultural products (Table 1 and Table 2) [17,18,28,29].

The economic advantages of decreasing agricultural waste can be considered from two main perspectives. First, reducing agricultural waste has a direct positive impact on the earnings of farmers, enabling lower prices for consumers. This is especially crucial for numerous small-scale farmers who experience financial uncertainty, as less waste can significantly enhance their economic conditions. Lowering agricultural waste contributes to decreased production expenses, which subsequently leads to lower prices for goods [17,30]. To determine whether there is relatively more waste in developing or developed countries, it is essential to gather precise data on post-harvest waste. To estimate waste levels, the difference between total production and total consumption is analyzed [31,32]. Second, reducing agricultural waste can improve the overall efficiency of the food supply chain, leading to better resource utilization. This can result in more sustainable agricultural practices, preserving resources like water, land, and energy, while also minimizing environmental impacts such as greenhouse gas emissions, and ultimately allows to maintain end user prices at a lower level than “squandering” practices would force to charge.

Table 1.

Post-harvest losses occur at different levels of the supply chain and for different reasons.

Table 1.

Post-harvest losses occur at different levels of the supply chain and for different reasons.

| Supply Chain Stage | Post-Harvest Losses (%) | Corrupting Factors for Losses | Percentage of Losses (Total) |

|---|---|---|---|

| Harvesting | 20 | Physical factors | 29 |

| Handling and storage | 3 | Physiological factors | 4 |

| Processing and packaging | 1 | Pathological | 9 |

| Distribution and retail marketing | 12 | ||

| Consumer stages | 28 |

Source: [33].

Table 2.

Losses after the harvesting in some countriespostharvest.org, 2015. https://web.archive.org/web/20160402074336/https://www.postharvest.org/PEF_White_Paper_15-02_PHFVmeasurement.pdf (accessed on 1 June 2025).

Table 2.

Losses after the harvesting in some countriespostharvest.org, 2015. https://web.archive.org/web/20160402074336/https://www.postharvest.org/PEF_White_Paper_15-02_PHFVmeasurement.pdf (accessed on 1 June 2025).

| Country | Losses (%) | Reference |

|---|---|---|

| Benin | 17 (early April) 70 (mid-June) due to fruit flies | [34] |

| Brazil | 28 | [35] |

| Costa Rica | 14.1 (dry season) 84.4 (rainy season)—due to anthracnose (fungi-induced plant diseases) | [36] |

| Mexico | <10 at home | [37] |

| USA | 6–12 due to improper handling, storage, and transportation | [38] |

| European Union | 5–15 | [39] |

| Pakistan | 31 36.1 | [40] [41] |

3. Burning Agricultural Residues as an Aggravating Factor of Global Warming

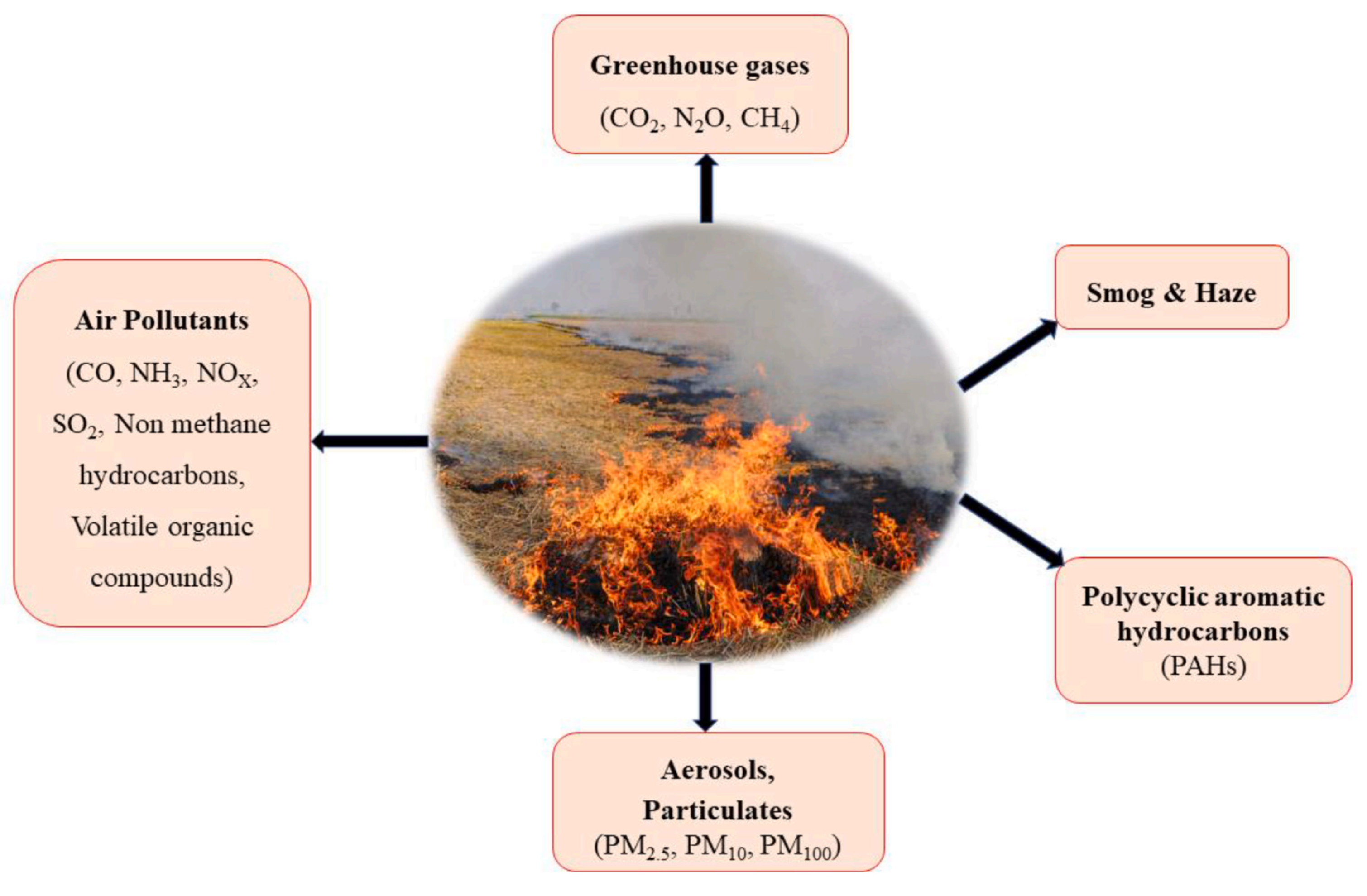

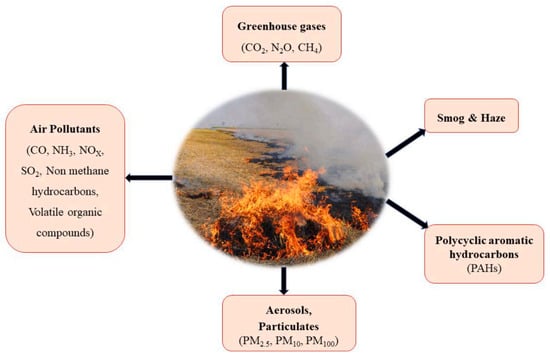

The practice of burning agricultural residues following harvest is a detrimental tradition that persists among certain farming communities. This practice not only results in the destruction of numerous farms at the conclusion of the harvest season, but it also adversely affects soil health and contributes to air pollution. Furthermore, it heightens the risk of fire spreading to adjacent areas, including pastures and forests. Farmers often resort to this method due to its expediency and low cost, as it facilitates the preparation for subsequent crops, eradicates weeds and pests, and addresses issues related to uneven greening in row crops [42,43,44], see (Figure 3).

Figure 3.

Crop residues burning and its pollutants. Source: [20].

The practice of open burning of rice straw is prevalent among farmers as a method for clearing fields post-harvest in preparation for subsequent crops [42,44,45]. This combustion process generates substantial quantities of air pollutants, including soot, polycyclic aromatic hydrocarbons, particulate matter, volatile organic compounds, sulfur dioxide, nitrogen oxides, and carbon monoxide. The release of these pollutants poses considerable risks to local air quality and public health [20,42,45,46]. Gaseous pollutants, specifically nitrogen oxides and sulfur dioxide, are significant contributors to environmental pollution resulting from rice straw burning, as they play a crucial role in the formation of nitrate and sulfate particulate matter [45] as well as smog and ground-level ozone.

The phenomenon of air pollution, particularly the inhalation of noxious gases and the development of various respiratory sensitivities following the practice of field burning, is increasingly pronounced in certain countries due to the proximity of agricultural land to urban and rural residential areas. When multiple fields are burned simultaneously, the resulting smoke often envelops entire communities, leading to widespread issues such as respiratory difficulties, and heightened air pollution. This situation has led to significant public discontent [42,45,46].

4. Agricultural Waste Management

Managing waste streams from agricultural operations encompasses a variety of strategies, including the utilization of burial and disposal sites, composting, recycling, waste reduction at the source, and the reuse of materials. The preservation of water and air quality is directly influenced by the effective handling of both organic and inorganic waste generated from agricultural practices. One traditional approach to managing agricultural waste involves recycling it for use as organic fertilizer in plant cultivation and agricultural activities. When implemented effectively and in accordance with scientific principles, this method serves as a viable strategy for environmental conservation [47].

A significant challenge faced by numerous nations, particularly those in the developing world, is the escalating issue of food waste. Consequently, policymakers and scholars in these countries are actively seeking strategies to mitigate the wastage of agricultural products throughout the various stages of production, including planting, harvesting, distribution, and consumption [48].

Since plastics items are used extensively in agriculture, plastics waste has become a big issue, too, also in the form of persistent micro- and nanoplastics, where timely collection of plastics items such as mulching films—and their replacement by suitable alternatives and substitutes e.g., for seed coatings and tree protection covers—is a viable strategy. Expired food packed in plastics is another problem, where disposal is problematic due to the mix of typically non-degradable plastics and foodstuff. Excessive amounts of plastics waste in organic waste collected for composting, for instance, can render the input material useless, resulting in high disposal costs and environmental burden.

5. Using Agricultural and Livestock Waste in Livestock Feeding

The indiscriminate and improper utilization of pastures—unless new ones are obtained at the expense of other land use such as natural ecosystems—leads to a recession in both the quantity and quality of livestock production, resulting in irreversible harm to these ecosystems. Conversely, the rising costs of livestock inputs, particularly feed for livestock and poultry, render production unprofitable for certain operations, as approximately 60 to 70% of the daily expenditures associated with livestock units are attributed to feed costs [49]. Pastures are not the most efficient method of feeding cattle; Owing to their significant nutritional benefits, ease of preparation, and widespread availability, various agricultural by-products are presently utilized in a conventional and systematic manner for the formulation of ruminant animal and poultry feed, but also aquaculture. Notable examples of these by-products include sugarcane molasses, sugar beet molasses, cotton seeds and their meal, as well as wheat straw. They can partly replace fish meal and soybean meal, when admixed to fodder “raw” or after fermentation. In addition to the aforementioned waste materials, the primary manufacturing and further processing of agricultural products generate a diverse array of plant residues, crop residues, and by-products that possess nutritional value and are suitable for livestock and poultry feed. However, these resources have not garnered substantial attention yet and are far from being exploited to their full potential, primarily due to the lack of adequate infrastructure and a deficiency of information available to farmers. This includes lignocellulosic waste, which encompasses agricultural by-products such as straw, corn stalks, and sunflower stalks, as well as waste from the wood industry, including sawdust and wood chips. Additionally, waste generated from wastewater recycling can also be categorized within this context [50,51]. Direct feeding or conversion via fermentative processes is feasible in principle, and detailed studies are needed for each side stream to determine advantageous and possible dosing ranges for targeted farmed animals.

The practice of utilizing by-products from the agricultural and food industries as feed for domesticated animals dates back to the inception of animal domestication. This approach offers two primary advantages: it diminishes the reliance of livestock on grains that are suitable for human consumption, and it alleviates the financial burden associated with waste disposal management systems [52]. Ruminants possess a distinctive capability to metabolize fibrous materials, facilitated by the presence of specialized microorganisms in their rumen. Consequently, agricultural by-products can effectively serve as substitutes for traditional grains. The economic implications of incorporating these by-products into animal diets are favorable, as they are typically less expensive than conventional feed options. Furthermore, agricultural by-products represent significant resources in terms of energy, protein, and fiber, often constituting a substantial portion of total agricultural output [53,54].

Agricultural products typically require a series of processing steps before they can be utilized for animal consumption, as they are not suitable for direct use in their raw form. The residual materials generated from these processes, with certain exceptions, are deemed unfit for human consumption and are referred to as by-products of agricultural industries [55]. Concurrently, the scarcity of high-quality fodder for farmed animals is recognized as a fundamental challenge facing animal husbandry sectors in developing nations. Contributing factors to this issue include the limited availability of arable land for forage production, the increasing competition for crop consumption from the expanding human population, the deficiency of enriched animal feed options such as various types of grains, and the rising societal demand for animal protein. These elements collectively heighten the necessity for alternative sources of animal feed. In this context, the exploration of unconventional food and feed sources has drawn significant attention in developed and developing countries, which often experience shortages in both the quality as well as the quantity of feed and food. Notably, the by-products of agricultural industries present a viable opportunity to bridge the gap between the supply and demand for animal feed in these regions [50], see Table 3.

Table 3.

Agro-Industrial By-Products (Processing Plant Residue) and their feed utilization, excerpt from [56].

The utilization of by-products from agricultural industries in animal feed is significant for three primary reasons [57]: (a) It diminishes the reliance of livestock on grains and other produce that are intended for human consumption. (b) It lowers the expenses associated with supplying essential nutrients to livestock. (c) It mitigates the need for costly initiatives aimed at disposing of residues from agricultural processing facilities, thereby preventing environmental pollution caused by these residues [58].

By-products are categorized into four classes based on their metabolizable energy content and nitrogen levels [59]: The first category comprises by-products characterized by low digestibility and nitrogen content. This group includes various types of straws, pods, and the outer shells of plant seeds. To enhance the nutritional value of these by-products, it is advisable to supplement them with nitrogen-rich nutritional additives that are fermentable in the stomach, such as urea, and essential minerals. These additives exhibit a slow digestion rate and prolonged retention time in the rumen; consequently, their excessive inclusion in the diet may lead to a decrease in voluntary feed intake. The second category contains by-products characterized by low digestibility and comparatively high nitrogen content. This group includes by-products from the food industries, such as coffee residues, grape pomace and cocoa flour. When these products are utilized in conjunction with those from the third category and cereals, they form an appropriate dietary combination for ruminants [60], but also for other species of farmed animals. The third category encompasses by-products characterized by high energy content and low nitrogen levels, including those from the sugar industry such as molasses or pulp from food processing, as well as waste generated from horticultural activities and inedible fats and oils. The effective utilization of these materials is feasible due to their high digestibility and energy content, coupled with their low nitrogen concentration, provided they are combined with easily digestible nitrogen sources. In monogastric diets, suitable nitrogen sources may include skimmed milk, blood meal, fish meal, soybean meal, or dried yeast, an example of single-cell protein (SCP). SCP can be produced by various microorganisms from a wide range of feedstocks, including waste and side streams. For instance, methanotrophic bacteria can convert CH4 (e.g., from biogas) into protein, and hydrogen-oxidizing bacteria HOB) as well as acetogenic bacteria are able to feed upon H2 and CO2 or CO, where biomass gasification can provide the raw material. Gas fermentation of H2 (e.g., from solar production) and CO2 (e.g., from an industrial point source) is a means of producing SCP with low environmental footprint. Bacteria have the fastest growth rates of all microorganisms, therefore bacterial SCP (bacterial meal) is poised to be most suitable for high-volume, low-cost SCP production [61].

Conversely, in ruminant nutrition, highly potent nitrogen sources such as urea can be employed [62]. It is important to note that the excessive incorporation of fats and oils into ruminant diets may lead to complications related to the digestion of cell walls. The fourth category encompasses by-products characterized by elevated energy and nitrogen content. This group includes remnants from slaughterhouse operations, such as blood, fish meal, and meals derived from oilseeds. These products may potentially harbor toxic substances or be susceptible to spoilage during storage. Consequently, it is imperative to implement preventive strategies to mitigate these risks [59,60].

It is essential to assess the nutritional value of those alternative ingredients on the level of the specific type of target animal and its production system, taking into account factors such as anti-nutritional compounds and physical limitations on consumption. Consequently, it is advisable to utilize lower-quality by-products (categories one and two) for animals with lower nutritional requirements, such as sheep or dairy cows, or during the winter months for beef cattle and lambs, as a means of reducing feed costs. Conversely, by-products classified as third and fourth groups as introduced above may be more appropriately employed in more intensive and advanced production systems, such as those involving pigs, poultry, and ruminants [59], (Table 4).

Table 4.

Classification of agri-waste and examples, modified and expanded from [56].

6. Using Agricultural and Livestock Waste via Fermentation

Finally, agricultural byproducts can be fed to microorganisms to obtain products of interest, amongst them single-cell protein (SCP), bioplastics, biofuels or biobased building blocks. Different yeasts and bacteria can be deployed. Another production system is microalgae, where waste streams can provide P, N and other nutrients at low cost.

Agricultural residues present a viable substrate for the production of bioplastics via microbial fermentation processes. The bioeconomy today is mostly sugar-based, and alternative, non-food and non-feed sugar or other feedstocks are needed at scale. The selection of specific yeasts and bacteria is contingent upon the desired product and the type of feedstock utilized. For example:

Polylactic Acid (PLA) production: The bacteria Lactobacillus delbrueckii and Lactobacillus casei are frequently employed in lactic acid fermentation, which is a precursor for PLA synthesis. These microorganisms effectively convert sugars derived from agricultural waste into lactic acid under anaerobic conditions. PLA is a widely used bioplastics material, e.g., in food packaging or for additive manufacturing (filament).

Polyhydroxyalkanoates (PHA) production: Cupriavidus necator, previously known as Ralstonia eutropha, is extensively utilized for PHB (polyhydroxybutyrate, the simplest and most common PHA) production due to its capacity to accumulate significant quantities of that polymer when supplied with organic compounds such as volatile fatty acids sourced from waste biomass under P and N deficiency. Additionally, Pseudomonas putida has been investigated for the production of specialized PHAs with customized properties. The yeast Yarrowia lipolytica is recognized for its ability to synthesize PHB, from lignocellulosic hydrolysates. This strain thrives on carbon sources like xylose and glucose, which are prevalent in agricultural residues. PHA are versatile and fully biodegradable, also in the marine environment [63]. They are costly to produce, mainly because of the sugar required for fermentation; Waste streams have the potential to reduce PHA production costs.

Methanotrophic Bacterial Single-Cell Protein (SCP): Methanotrophic bacteria, including Methylococcus spp., Methylomonas spp. and Methylocystis spp., can convert methane-rich biogas into protein-rich biomass suitable for animal feed. These microorganisms utilize methane as their exclusive carbon and energy source, providing an environmentally sustainable method for SCP production.

Other bacteria in gas fermentation for SCP: Hydrogen-oxidizing bacteria, such as Ralstonia eutropha, and acetogenic bacteria, like Clostridium ljungdahlii, are capable of utilizing hydrogen (H2) and carbon dioxide (CO2) generated from biomass gasification to produce SCP with minimal environmental impact. These strains exhibit rapid growth rates, rendering them suitable candidates for large-scale bacterial meal production.

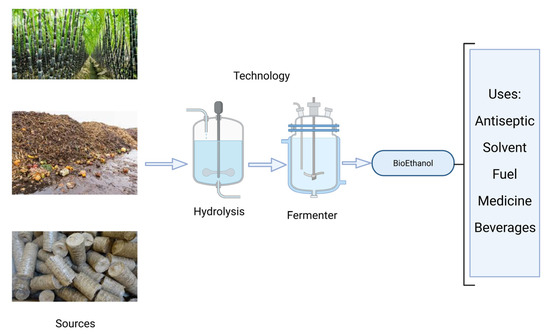

Ethanol Fermentation: The yeast Saccharomyces cerevisiae remains the predominant microorganism for ethanol production from sugars present in agricultural residues. Research has also highlighted the efficacy of Zymomonas mobilis in producing ethanol from lignocellulosic materials, for instance orange peels. Ethanol is needed in large quantities as biofuel, for instance, where 1st generation production has been discouraged due to environmental concerns. See Section 7 below for details.

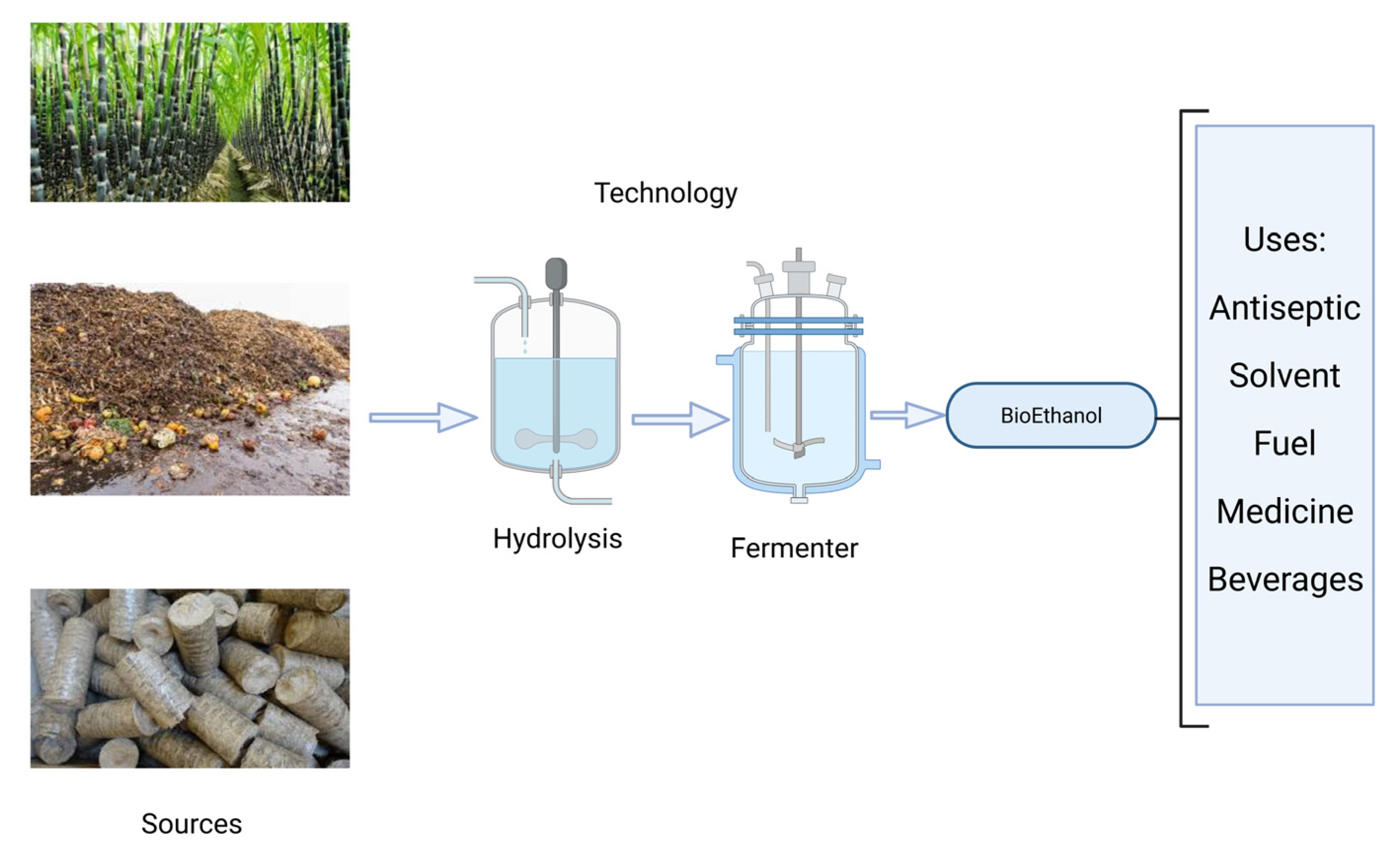

7. Production of Fuel Ethanol as an Energy Source

Energy sources are primarily divided into renewable (clean, “green”) and non-renewable types. Among these, biomass stands out as effective, readily and abundantly available, renewable energy source, demonstrating compatibility with environmental sustainability. Biomass energy can fulfill our energy requirements, serving as a primary energy source for electricity generation or as energy carrier in the form of gaseous and liquid fuels [64]. Biomass accounts for over 10% of the global energy supply and 13% of total energy consumption [65]. As stated above, significant volumes of agricultural waste are generated, which are often incinerated in rural regions of developing nations as a means of land clearance. This practice contributes to the escalation of greenhouse gas emissions and constitutes a waste of energy resources [66,67]. In several countries, amongst them the United States of America and Brazil, huge amounts of biofuels are manufactured. The use of biofuels reduces CO2 compared to fossil fuels [27]. While first generation biofuels (1G) use primary agricultural products such as starch, sugar or plant oils, second generation biofuels (2G) are made from waste biomass streams, typically through enzymatic degradation of lignocellulosic materials. 3G biofuels made from algae are on the horizon (Figure 4).

Figure 4.

Production of ethanol from biomass. Modified after [21].

Fossil fuels still serve as the primary energy sources for industrial and developing economies, on the order of ¾ of all primary energy globally, however, they are associated with detrimental environmental impacts. Furthermore, these resources are non-renewable.

Bioethanol (1G) is obtained from sugar- or starch-containing products such as corn and sugarcane. Ethanol can be used in its pure form as a fuel for vehicles with internal combustion engines or in a Direct Ethanol Fuel Cell (DEFC), but it is usually deployed as a supplement to gasoline to increase the octane number (ON) (ethanol has an ON of 113) and lower vehicle emissions. It can also be used as disinfectant, for instance.

A study with Saccharomyces cerevisiae to obtain bioethanol from sorghum stover as a substrate was carried out [68]. The fermentation process employed crude hydrolyzed enzymes derived from sorghum, and the researchers investigated the influence of pH, temperature, and inoculum concentration on ethanol yield. Their findings indicated that optimal ethanol production occurred at a pH of 6.5, a temperature of 35 °C, and an inoculum level of 10%. Also, the potential of utilizing dried and crushed banana peel biomass to produce bioethanol through a fermentation process conducted by Saccharomyces cerevisiae was evaluated [69].

The optimal method for hydrolyzing orange peels utilizing Zymomonas mobilis was investigated [70]. Bioethanol production from waste of fruits and vegetables through the use of Saccharomyces cerevisiae was explored. Agricultural residues, which are by-products, do not impose additional demands on land, water, or energy resources, and their application in bioethanol production does not compromise global food security [71].

Production of Biodiesel from Lipids as an Energy Source

Biodiesel is produced from plant (and animal) oils and fats (triglycerides of fatty acids) via a transesterification process, which involves the reaction of the triglycerides with methanol, yielding FAME (fatty acid methyl esters), which have a lower viscosity than pure plant oils, similar to diesel. The triglycerides utilized in this process can originate from both virgin and used edible and inedible oils, including soybean, oil palm, rapeseed, sunflower and others. Notably, vegetable oils that have been previously employed in cooking can also serve as viable feedstocks to make biodiesel. The benefits of biodiesel include its high lubricity, elevated flash point, low viscosity, biodegradability, and reduced greenhouse gas emissions [72]. The properties of biodiesel depend on the specific lipid and alcohol feedstocks utilized. Biodiesel can serve as a viable alternative to petroleum-based fuels, effectively addressing the increasing demand for transportation fuels [73]. With engine modifications, also pure plant oil (PPO) can be burnt.

Among the various technologies available for the conversion of waste into biofuels, transesterification of waste cooking oil or animal fat into biodiesel is considered one of the most effective methods [74,75]. The investigation of the economic sustainability of biofuel production encompasses an analysis of various parameters, including the raw materials (origin and type), the technological methodologies employed, the quality of the final products, and their acceptance in the market. With regard to technological advancements, the production of liquid biofuels demonstrates a greater level of sophistication compared to the production of solid and gaseous biofuels, as it offers enhanced conversion potential, reduced waste generation, and low consumption of water and land resources [74,75,76]. The energy density of biodiesel is approximately 90% that of conventional diesel fuel. In contrast, the energy content of bioethanol is about 50% that of gasoline, whereas biobutanol possesses an energy content that is roughly 80% that of gasoline [77]. Furthermore, biodiesel is a fuel that adheres to the emission standards established by the Environmental Protection Agency’s Clean Air Act [78].

While biodiesel is typically made from oilseeds, it can also be obtained from waste and side streams, such as waste cooking oil or orange peel oil [79], always followed by transesterification. The resulting biodiesel exhibited a viscosity of 2.1 cm2/s (cST) and a density of 825 kg/m3 [79]. An investigation into the potential applications of algal biomass for the generation of biofuels and bio-based products was carried out in [80,81,82]; Algae-based fuels are considered 3rd generation biofuels (3G), with potentially highest productivities per hectare, on non-arable land. The study [82] delineates the various processes and methodologies available for the biological assessment of algal biomass. It emphasizes the biorefinery model and its integrative approach, which encompasses multiple processes aimed at producing environmentally sustainable, low-cost commodities such as biofuels and value-added compounds. Furthermore, the authors address the opportunities and challenges associated with the bioassessment of algal biomass, offering insights into the production processes and the feasibility of conducting research on algae for the sustainable production of biofuels and bio-based products [82]. Various waste streams from agriculture can be used as nutrients for algae.

8. Preparation of Compost from Waste and Agricultural Residues

Compost production is fundamentally a biological decomposition process through which organic and biodegradable waste materials are transformed into beneficial organic substances for plant growth, occurring under aerobic conditions. Agricultural waste, which is abundant in organic matter and has drawn trace elements from the soil, necessitates the return of these elements to the fields to sustain the production of healthy crops. A rudimentary and traditional method of compost production has been employed by farmers and gardeners globally for centuries. Plant residues and agricultural by-products have been systematically accumulated in piles or deposited in ponds to undergo decomposition facilitated by the natural activities of microorganisms, ultimately rendering them suitable for agricultural applications.

The utilization of diverse fertilizer sources can markedly influence both crop yield and product quality. In numerous sustainable agricultural practices, particularly within the realm of organic farming, compost and organic fertilizers, along with their extracts, are employed to enhance soil conditions and fertility, as well as to mitigate and manage plant diseases and pest infestations [83,84].

General goals of preparing compost and vermicompost [85,86] are:

- Increasing soil organic matter

- Increasing soil fertility and improving soil productivity

- Quantitative and qualitative increase of agricultural products and ultimately higher farmers’ income and increase in national production

- Lowering the need for chemical fertilizers

- Increasing the efficiency of water consumption

- Reduction of wind and water erosion

Composting and vermicomposting [84] are popular methods for recycling solid organic waste. The end products, compost and vermicompost, can serve as organic matter for improving soil, providing nutrients for fertilizing soil, or acting as components in growing media for soilless farming [87]. Composting is an aerobic process where bacteria, including both thermophiles and mesophiles, break down organic material to create compost. Vermicomposting is a biological oxidation process that involves earthworms alongside microorganisms. The microorganisms found in the digestive systems of earthworms and in the organic material break down the organic matter biochemically. Meanwhile, the earthworms help to break up the substrate, enhancing the surface area available for microorganisms to act on [88].

Another possibility is the production of biochar, to increase the water retention potential of soil and to store carbon, see below in Section 13.

9. Preparation of Mulch from Agricultural Waste to Prevent Soil Erosion

Mulch refers to a layer of organic or inorganic materials applied to the soil surface with the purpose of enhancing soil quality and protection. It serves to mitigate solar radiation effects, reduce water evaporation, and increase soil moisture retention. Additionally, mulch plays a critical role in preventing soil erosion, minimizing compaction, and safeguarding plant roots from extreme temperatures, drought, and heavy rainfall. It also optimizes tillage practices, enhances both the quantity and quality of crops, facilitates crop cleaning, controls weed growth, regulates soil temperature, and stabilizes areas prone to landslides. Furthermore, mulch contributes to the development of green spaces, improves water infiltration during periods of intense rainfall, and promotes overall soil health and yield [89].

In natural ecosystems, mulch is formed over extended periods through the accumulation of organic matter at the base of trees. It can be classified as either permanent or temporary and is typically applied to bare soil or around trees. Organic mulches, such as manure and compost, are integrated into the soil through the activities of soil organisms. The practice of mulching is advocated for both commercial agriculture and gardening, as it has been shown to enhance soil fertility when implemented correctly. Mulch provides thermal protection to the soil, maintaining cooler temperatures during prolonged summer afternoons, which in turn extends the vegetative growth period and reduces moisture loss [90]. In conditions of heavy rainfall, mulching is effective in preventing the washout of surface soil and mitigating wind erosion. Organic mulches not only contribute nutrients to the soil but also, through their gradual decomposition into compost and humus, further enrich the soil. Soil organisms, including earthworms, facilitate the incorporation of decomposed mulch into deeper soil layers, transforming it into plant-available nutrients. It is important to consider the carbon-to-nitrogen ratio when utilizing organic mulches [89,91]. Additionally, the reduced light intensity beneath the mulch layer inhibits weed growth [92].

A significant concern for nations globally is the phenomenon of desertification. Regrettably, the expansion of desert areas occurs annually, with deforestation and the degradation of grazing lands identified as contributing factors. To combat soil desertification, various strategies have been implemented, one of which is the application of mulching. Common mulches employed to mitigate soil erosion encompass materials such as straw, animal manure, and foliage from plants [93,94], thereby providing a valuable utilization of waste biomass.

A study on the impact of straw mulch, hydro-mulch, and polyacrylamide (PAM) on soil erosion control under simulated rainfall conditions was carried out [95]. The findings indicated that the combination of hydro-mulch and PAM as temporary ground covers yielded the most effective results. Nevertheless, the study also revealed that the incorporation of PAM into a more economical straw mulch achieved comparable or superior outcomes relative to the application of hydro-mulch without PAM. Plastics-based mulching films or ground covers, however, cause persistent microplastics pollution [96,97].

Another study examined the impact of utilizing plastic film in conjunction with straw mulch on soil moisture, temperature, grain yield, and water-use efficiency (WUE) in winter wheat cultivation within the arid regions of the Loess Plateau in China [98]. The findings revealed that the integration of plastic film and straw mulch resulted in a significant enhancement of grain yield (average increase of 35%) and water use efficiency (average increase of 25%), alongside a modest rise in evapotranspiration (average increase of 8%) when compared to traditional agricultural practices.

Common types of organic mulch include grass clippings, leaves, straw, wheat, rice and other grain husks, shredded tree bark, wood chips, sawdust, root rot, straw, palm leaves, compost, tree bark (especially conifers), animal manure, corn cobs, woody residues, shredded paper, cardboard, shells, moss, wool, or felt. Woven or synthetic materials such as mats, felt, carpets [99], as well as biodegradable plastics or crushed stone are also used.

The selection and utilization of mulch materials are influenced by various factors, including their intended function, the specific plant species being cultivated, availability, cost, durability, aesthetic considerations, and their impact on soil properties such as pH, fire risk, and decomposition rates. Additionally, the cleanliness of the materials with respect to weed seeds and pathogens is a significant consideration [91,100]. Weather conditions also play a critical role in determining the appropriate type of mulch, particularly in regulating soil temperature. For instance, winter mulches for woody plants are typically applied in late autumn to help maintain soil temperature. Commonly used materials such as straw and stubble from wheat, barley, rye, and rice are readily available and cost-effective, making them suitable for winter mulching around trees, shrubs, and in strawberry production. However, these materials present certain disadvantages, including high flammability, the presence of seeds from other plants, potential function as rodent habitats, a reduction in soil nitrogen levels, the necessity for annual replacement, and susceptibility to displacement by wind. The application of nitrogen fertilizers, particularly urea, can significantly mitigate nitrogen deficiencies in the carbon-to-nitrogen ratio. Conversely, summer mulches are employed during the spring and summer months to prevent soil overheating as temperatures rise. The primary function of summer mulch is to suppress weed growth and retain soil moisture [101]. Furthermore, plant materials and residues may harbor weeds and fungi, which can be effectively decomposed and transformed into compost through the addition of nitrogen. As the composting process advances, the conversion of inorganic nitrogen by soil microorganisms diminishes, resulting in reduced nitrogen deficiencies for plants [102]. The application of compost mulch, when incrementally incorporated into the soil, fosters a condition of particle adhesion that significantly mitigates the degradation of soil surface structure. This practice effectively reduces erosion resulting from precipitation, minimizes the formation of surface cracks, curtails water loss, and addresses salinity issues. Furthermore, compost mulch serves as an organic soil amendment that enhances the stability of soil aggregates, improves hydraulic conductivity, and promotes long-term water infiltration into the soil. Additionally, it can function as an appropriate alternative to organic fertilizers in situations where such fertilizers are not readily available [103].

Wang et al. [104] documented that the utilization of crop residues as fertilizers in Henan Province, China, encompasses various practices, including the retention of straw in the field, the return of straw to the field, straw chipping and mulching, rapid composting, fermentation of straw piles returned to the field, the production of organic fertilizers from straw, ammonization of straw, and the creation of silage from straw. Furthermore, it was reported that in 2009, China utilized approximately 15.4 million tons of wheat straw and 9.7 million tons of rice straw for fertilization purposes [105]. Batidzirai et al. [106] indicated that in South Africa, of the total maize stover production amounts to 16 million tons per year, and 6.3 million tons are located below ground level and contribute to the maintenance of soil organic carbon, while 4.2 million tons are necessary for soil erosion control. In a similar context, from a total of 1.8 million tons of wheat straw, 970,000 tons situated below ground level also play a role in maintaining soil organic carbon. In their investigation of residue biomass utilization patterns within the cereal-sheep production system in North Africa, Ameur et al. [107] found that 70.4% of farmers in Tunisia retain less than 200 kg of crop residue per hectare, 15.1% retain between 200 and 500 kg per hectare, and only 14.5% retain more than 500 kg per hectare as mulch. Furthermore, Baudron et al. [108] reported that merely 3% of farmers in the Ethiopian Rift Valley retain over 1 ton of crop residues per hectare.

10. Expansion of Agro–Industries to Reduce Agricultural Waste

Agro–Industries encompass sectors that utilize physical and chemical processes to modify agricultural and horticultural products. This transformation enhances the products’ shelf life, optimizes their consumption and distribution, and ultimately contributes to an increase in their economic value. Agricultural products often exhibit varying timelines for production and consumption; while their production or harvesting occurs within a limited and specific timeframe, consumption typically extends over a more prolonged period. Transformation industries possess the capability to modify and preserve these products, thereby enabling their availability for consumption throughout the entire year. The establishment and growth of transformation industries yield several economic benefits, including the generation of added value, the creation of employment opportunities, the generation of foreign exchange earnings, and the enhanced utilization of agricultural products, which collectively contribute to the reduction of product wastage [109].

Muehlfed et al. [110] conducted a study that investigated the impact of processing industries on the mitigation of agricultural product waste. The findings suggest that certain factors contribute to the loss of agricultural products, including the spoilage of specific items resulting from limited access to processing facilities and farmers’ insufficient knowledge of processing and transformation techniques.

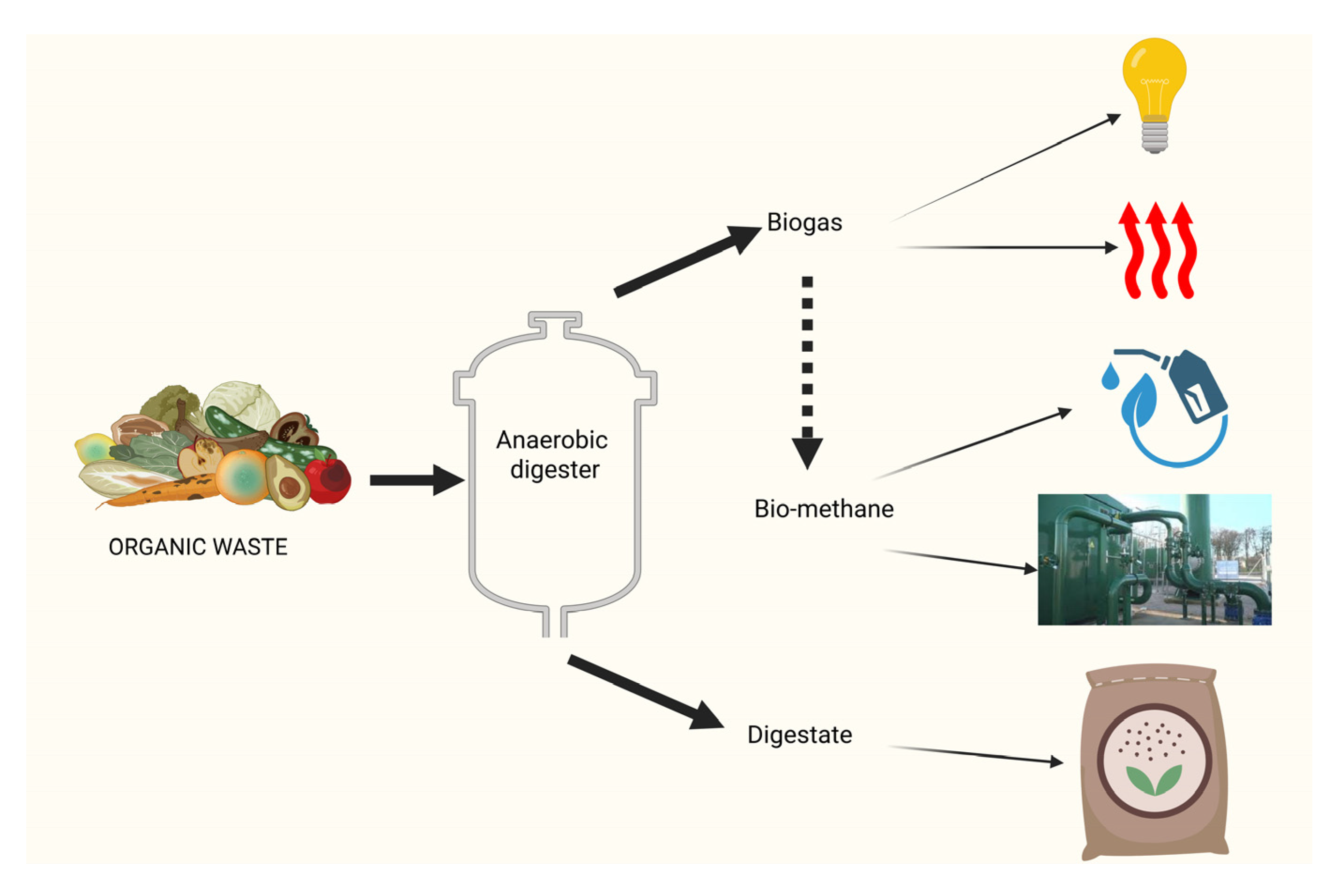

11. Biogas Production from Waste and Agricultural Residues

Biomass represents a viable source of renewable energy, with potential applications in the production of power and heat, as green electricity and thermal energy [111], preferably in combined heat and power (CHP), or to feed the methane from biogas into the gas grid as synthetic natural gas (SNG).

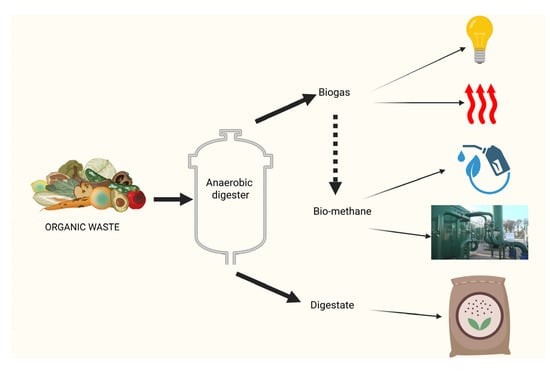

Biomass is estimated to have accounted for approximately 10–14% of global energy production in the year 2021, positioning it as a significant contributor to renewable energy sources [65,112]. An effective approach to harnessing the significant potential of biomass is through the utilization of energy derived thereof, e.g., as syngas or biogas. In relation to the greenhouse effect, a significant global concern, approximately 465 million tons of methane are generated each year from the agricultural sector in Europe alone [113,114] and subsequently released into the Earth’s atmosphere. The collection of agro-waste materials presents an opportunity for controlled methane gas production through the utilization of biogas systems. In biogas production units, the microorganisms decompose organic matter through the process of anaerobic digestion, which leads to the formation of methane. Biogas consists to about 60–70% of methane, the rest being carbon dioxide, with traces of hydrogen sulfide and hydrogen [115]. Biogas technology in rural communities, in addition to providing part of the required energy and solving environmental problems, has important social and economic benefits. The methane generated during this process can be utilized for the production of electricity or as a fuel source, in addition to its on-site applications in cooking, heating, and lighting [116] (Figure 5). The leftover (digestate) is a good fertilizer.

Figure 5.

Principles of anaerobic digestion. Source: [117].

Currently, there is a growing interest among scientists and governmental bodies regarding the generation of biogas from renewable resources from within the food industry and beyond. Anaerobic digestion harnesses only a small portion of the total energy potential that could be derived from the available organic waste. A significant constraint associated with utilizing anaerobic digestion for energy or chemical production is the lignocellulosic composition of various organic waste types, such as agricultural residues [118]. Lignocellulosic biomass exhibits a slow biodegradation rate, which has thus far prevented its application as a substrate for biogas. Numerous investigations into the utilization of lignocellulosic biomass for fermentation processes have involved the pretreatment of the raw materials prior to the fermentation phase [119,120,121].

Biomass is widely utilized worldwide for the generation of methane as an energy source. In recent years, advancements in anaerobic digestion have enabled the production of biological products, including organic acids [122,123], which constitutes a higher valorization.

In a study examining the potential for biogas production from livestock waste in Malaysia, among the various feedstocks, organic materials derived from livestock waste are identified as the principal contributors to biogas production [124].

The Canadian economic and emission model for agriculture was employed to assess the potential for renewable energy generation from biomass [112]. The study examined two distinct scenarios. The first scenario incorporates a combination of market incentives and policy directives, while the second scenario focuses solely on the incentives provided by the carbon compensation market, which was valued at 50 dollars per megagram of carbon dioxide (it is subject to strong fluctuations). Next to the compulsory carbon market, where the European EU-ETS is the largest scheme, there is a growing voluntary carbon market, where consumers can compensate their emissions. Agriculture is (not yet) part of compulsory emissions trading schemes, but carbon credits (carbon certificates) can be generated for the voluntary carbon market, which offers interesting business opportunities. The findings indicate that the scenario integrating market incentives and policy guidelines is likely to result in a substantial increase in biomass-derived ethanol and electricity production, potentially leading to significant transformations in land use practices. Overall, agriculture possesses considerable potential for biomass energy production and for mitigating greenhouse gas emissions. Nevertheless, the effectiveness of bioenergy production will be heavily contingent upon the strategic combination of policies and market incentives implemented [112].

In 2019, Melnyk conducted a study on the potential for generating renewable energy and biofuels from agricultural raw materials in Ukraine [125]. The findings of the study indicate that renewable energy sources derived from agricultural materials could serve as a catalyst for the advancement of bioenergy in Ukraine. Furthermore, the research demonstrates that the annual increase in the prices of natural gas and other fossil fuels may incentivize the development and utilization of bioenergy fuels. Additionally, it has been established that Ukraine possesses considerable potential for biomass cultivation and the application of bioenergy fuels [125].

The leading energy-from-biomass producers in Europe are Germany, Sweden, and the United Kingdom, collectively boasting an installed capacity of approximately 2 gigawatts [65]. Notably, in 2018, Germany was responsible for 22.6% of the total 224.7 billion kWh of electricity from renewable energy from biomass in Europe [65]. Additionally, research conducted in Sudan indicates that agricultural waste presents a viable option for domestic energy and for decreasing reliance on imports [126], as another example of the potential of biogas. Biomass-derived CH4 can be a more sustainable option than natural gas or LNG (liquefied natural gas), also allowing for local value creation.

12. Synthesis Gas Production from Waste Biomass

An alternative to biogas is offered by synthesis gas (syngas), which is obtained by thermochemical conversion of carbonaceous materials—where dry biomass can be used. As the population and energy needs grow, the reliance on finite fossil fuel resources has increased significantly. This has raised concerns about the depletion and rising costs of these fuels, as well as associated global warming, leading to greater public interest in clean energy sources and technologies. Gaseous fuels, like synthesis gas, can be more efficient and cleaner than solid fuels. Utilizing gasifier technology to produce synthesis gas is a viable option for power generation and heating, as it can be integrated into existing gas-burning equipment like furnaces and burners, allowing synthesis gas from agri-waste to replace fossil fuels. Additionally, with appropriate design, it is possible to use raw materials like biomass, to address waste disposal issues in some cases [127,128] [Table 5].

Waste can be transformed into energy through various methods, including thermochemical and biochemical conversion processes. Biochemical methods can be employed to convert humid waste biomass, such as animal manure, into gaseous fuels (biogas by anaerobic digestion), while thermochemical processes are applicable to materials such as plastics, textiles, sludge, wood, and garden waste—or a wide variety of agricultural waste and side streams-which have a lower water content. Among these methods, gasification can be a more efficient means of converting biomass and waste into (electrical) energy compared to traditional combustion techniques [129,130]. For instance, the soybean harvest and processing sectors generate various waste products, including straws, hulls, and fibers, which are all suitable for gasification. Similarly, the harvesting of flax plants for their seeds results in a significant quantity of flax straw which could also be gasified. Despite being a valuable resource, agricultural straw by-products are often underutilized. A portion of the collected straw is repurposed as livestock feed or bedding, while the remainder is processed into products such as briquettes, biocomposites [131], and fuel pellets [132]. In several developing countries, the prevalent use of agricultural straw as fuel contributes to greenhouse gas emissions [133] and air pollution through particulate matter. Rather than being disposed of, straw has the potential to be harnessed for renewable energy production. Straw can also be used for insulation purposes in buildings [134] or to reinforce concrete [135]. Furthermore, numerous valuable constituents within agricultural straw waste can be transformed into biofuels and biochemicals. These constituents include lignin, cellulose, hemicellulose, carbohydrates, proteins, and lipids. Specifically, the chemical composition of soybean straw consists of 34.1% cellulose, 16.1% hemicellulose, and 21.6% lignin [136,137]. Like other waste streams, straw can readily be gasified.

Table 5.

Some published research works on biomass used for syngas production.

Table 5.

Some published research works on biomass used for syngas production.

| Substrate | Gas Yield (wt.%) | Reference |

|---|---|---|

| Sewage sludge | 21.77 | Trabelsi et al. [138,139,140] |

| Olive pomace waste | 37 | Aissaoui et al. [141] |

| Date palm leaves | 46 | Bensidhom et al. [142] |

| Date palm rachis | 39 | Bensidhom et al. [142] |

| Empty fruit bunch | 40 | Bensidhom et al. [142] |

| Date palm glaich | 43 | Bensidhom et al. [142] |

| Walnut shells | 15 | David [143] |

| Walnut shells | 8.9 | David [143] |

| Pinus radiata (Monterey pine) | 35.6 | Solar et al. [144] |

| Pinus radiata | 26.4 | Solar et al. [144] |

| Cotton stalk | 28.2 | Xie et al. [145] |

| wheat straw | 20.16 | Sedmihradská et al. [146] |

| wheat straw | 18.91 | Sedmihradská et al. [146] |

| barley straw | 19.1 | Sedmihradská et al. [146] |

| barley straw | 20.26 | Sedmihradská et al. [146] |

| Medical waste | 37.3 | Ullah et al. [147] |

| Waste cooking oil | 15.9 | Trabelsi et al. [148] |

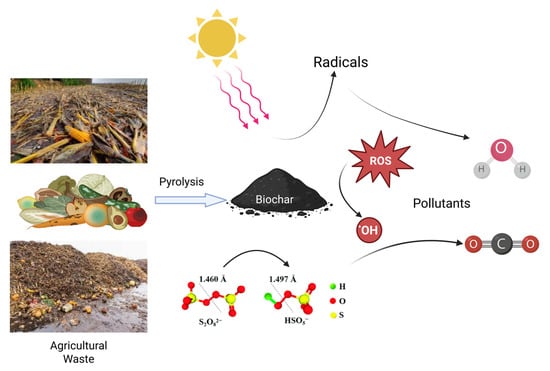

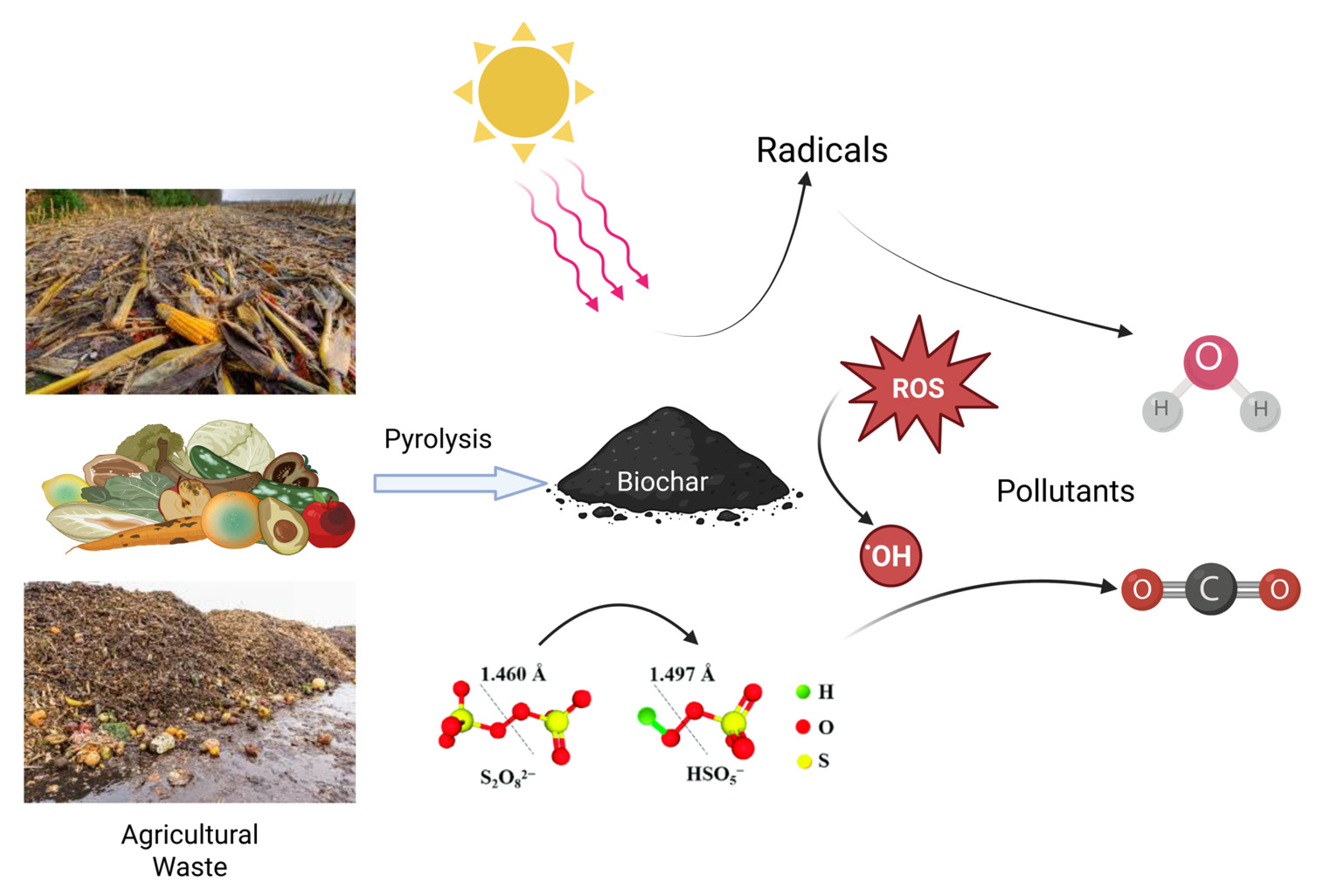

13. Converting Agro-Waste to Biochar

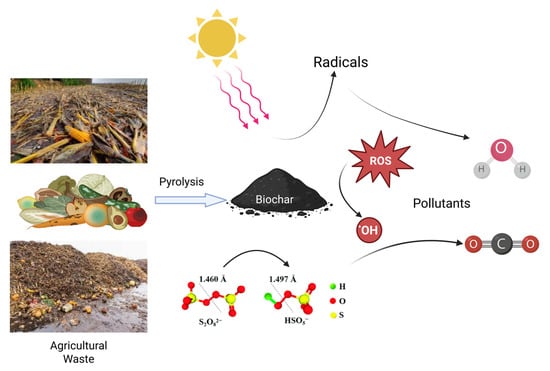

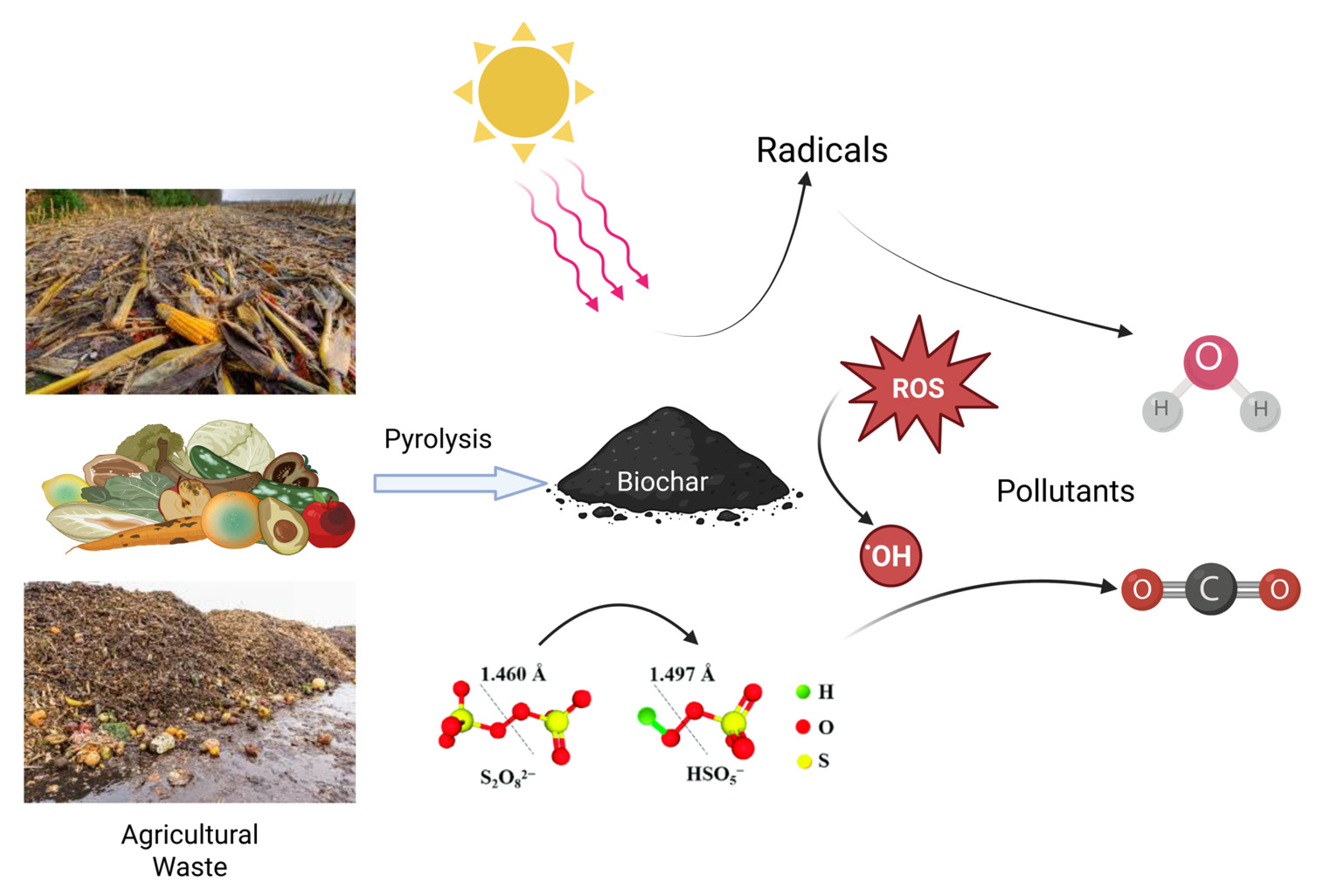

In recent decades, human activities have adversely impacted many ecosystems, amongst others by burning agro-waste. These emissions are strong contributors to smog formation, global warming, and respiratory problems. To mitigate atmospheric carbon dioxide levels, various solutions have been proposed, one of which involves the carbon stabilization of organic materials through the production of biochar. Biochar is a carbon-rich compound generated through the process of pyrolysis, which entails heating organic material in an environment with limited or no oxygen [149]. Nearly fifty percent of the dry biomass weight of plants consists of pure carbon. When this biomass undergoes decomposition in the open atmosphere, a significant portion of its carbon is released into the air within a short period of time. In contrast, during the process of pyrolysis, approximately 50% of the carbon contained in biomass is transformed into biochar. Wood waste, animal manure, crop residues and other sources can be used to make biochar (Figure 6). The versatility of biochar, derived from diverse biomass sources, along with its multifaceted applications, positions it as an environmentally advantageous and cost-effective material for environmental management [150]. Furthermore, contemporary research has introduced hydrochar, a solid product generated under conditions of high pressure and elevated temperatures in water, as an additional focus in environmental studies [151].

Biochar possesses the capacity to mitigate atmospheric carbon dioxide levels, and its incorporation into soil enhances soil fertility and water retention. Additionally, biochar has demonstrated significant potential in various environmental applications, such as carbon sequestration, soil enhancement, water purification, and environmental remediation [152]. Conversely, the escalating pollution of urban and industrial wastewater with toxic substances, a consequence of industrial development, presents a significant concern. Heavy metals, characterized by their non-biodegradable, highly toxic, accumulative, and carcinogenic properties, pose a threat not only to aquatic ecosystems but also render receiving water bodies unsuitable for multiple uses, including potable water supply [153].

Biochar possesses a carbon-rich composition characterized by a high surface area, rendering it an effective adsorbent. Its properties bear resemblance to those of activated carbon. The enhanced adsorption capacity of biochar can be attributed to three primary factors. Low-cost waste materials, such as the peels of various tree species (e.g., coconut, date, eucalyptus, pistachio, hazelnut, apple, and persimmon) and the skins of both oily and non-oily seeds (e.g., peanut, pistachio, walnut, hazelnut, soybean), are readily available in substantial quantities. Additionally, agricultural residues such as corn stalks, sugarcane, rice straw and bran, barley straw and bran, and sawdust have demonstrated effectiveness as biochar in absorbing pollutants, including heavy metals [154,155,156]. This process allows for the utilization of a diverse array of materials, and biochar can subsequently be employed for environmental remediation purposes [155].

Figure 6.

Converting agricultural waste to biochar and its use as catalyst to activate persulfate (PS) for degrading organic pollutants. Modified from [157].

Figure 6.

Converting agricultural waste to biochar and its use as catalyst to activate persulfate (PS) for degrading organic pollutants. Modified from [157].

It needs to be ensured that the biochar does not contain adsorbed toxins such as heavy metals or PHA (polycyclic aromatic hydrocarbons).

14. Manure, Sewage Sludge and Industrial Organic Waste to Bioplastics and Other Uses

Sewage sludge is a combination of solid materials that is extracted from the liquid portion of sewage during its processing. The sludge properties, including its color and odor, typically reflect its age and the extent of treatment it has undergone. This material is high in nitrogen and phosphorus, making it potentially advantageous for plants [158,159]. However, it has to be considered that sewage sludge can also contain significant levels of toxic substances like lead and cadmium, which can restrict its widespread application in agriculture, but also persistent organic pollutants which might stem from medication and its metabolites. The levels of heavy metals, nitrogen, and phosphorus are commonly used as key indicators to assess the suitability of sewage sludge for use on agricultural land [160]. Amongst the emerging pollutants in sewage sludge are micro- and nanoplastics particles.

The large-scale generation of organic waste from industrial activities and urban living has led to both immediate and long-term negative effects on environmental health [161]. These organic materials are typically high in essential nutrients for plants, particularly nitrogen and phosphorus [162], and they enhance the soil’s physical, chemical, and biological properties, including porosity, soil grain stability, fertility, and water retention [162]. Organic waste has been utilized globally and in various studies as a soil amendment. A key benefit of applying it to agricultural land is the enhancement of plant nutrients, a reduction in the need for fertilizers and pesticides, improvements in soil characteristics, a decrease in soil acidity, and ultimately, an increase in nutrient availability [163,164]. The organic freight in sewage from the dairy industry, or POME (palm oil mill effluent), to name two examples, can also be used as feedstock for biorefineries, e.g., to make bioplastics materials.

Bioplastics serve as a novel approach to transforming agricultural waste into products with added value, thereby aligning with the principles of the circular economy [165]. These materials are sourced from renewable biomass, including corn starch, sugarcane, potato starch, and various agricultural by-products, providing a sustainable alternative to traditional petroleum-derived plastics [166]. The production of bioplastics encompasses a range of methodologies, such as chemical synthesis, microbial fermentation, and thermal processing, which are selected based on the type of feedstock and the specific properties required. The global bioplastics market has witnessed substantial expansion in recent years, largely attributable to heightened environmental consciousness and supportive regulatory frameworks for sustainable materials. Industry analyses indicate that the market was valued at approximately USD 9.4 billion in 2022, with projections suggesting it will reach USD 26.9 billion by 2030, reflecting a compound annual growth rate (CAGR) of 12.8% throughout the forecast period [165]. Notable regions spearheading bioplastic production include Europe, North America, and Asia-Pacific, with countries such as Germany, Italy, and Thailand emerging as significant contributors to both research and commercialization initiatives in this sector [166]. Notwithstanding their promising attributes, bioplastics encounter several obstacles pertaining to cost, scalability, and performance. The production expenses associated with bioplastics continue to exceed those of conventional fossil-based plastics, primarily due to the relatively immature nature of the technology and the absence of significant economies of scale [165]. Additionally, the mechanical properties of certain bioplastics may not be comparable to those of traditional plastics, thereby constraining their applicability across various industries. Current research endeavors are directed towards addressing these challenges through improvements in feedstock utilization, process optimization, and material enhancement.

15. Other Solutions to Reduce Agricultural Waste

Without being complete, here are a few additional levers that can be deployed to reduce agro-waste formation and agricultural losses, where the applicability depends on the crop, locality and circumstances such as field size and available infrastructure:

- Advanced Harvesting Technologies: Utilizing GPS technology, drones, and internet of things (IoT) devices to optimize harvesting times, minimizing crop losses due to over-ripeness or spoilage [167], “Precision Agriculture” is a current trend. Also, Automated Harvesting Equipment is an important innovation, developing and adopting advanced robotic systems for more efficient and timely harvesting, reducing waste from manual harvesting errors [168].

- Post-Harvest Handling and Storage Innovations: Improved Storage Solutions can be created by implementing advanced storage technologies such as controlled atmosphere storage, hermetic storage bags, and smart silos that monitor and adjust conditions to prolong the products’ shelf life [169].Cooling Chain Development by expanding and optimizing cold chain logistics, particularly in developing regions, can be a good means to reduce spoilage of perishable goods during transport and storage [170].

- Circular Economy Practices: Upcycling Agricultural Waste [171]: Converting agricultural by-products into value-added products such as bioplastics [165], dye removal [172], natural dyes [173], and fibers for textile production [174]. For example, banana peels [174] and pineapple leaves [175] can be processed into sustainable textiles.

- Policy and Regulatory Frameworks: Incentives for Waste Reduction can be created by introducing subsidies and tax incentives for farmers and agribusinesses that adopt waste-reducing technologies and practices [176]. Waste Management Regulations can be enforced; Strengthening regulations that require proper disposal and management of agricultural waste, particularly for large-scale farming operations [177], see also the Farm to Fork Strategy of the EU [178].

- Educational and Extension Services: Farmer Education Programs: Expanding outreach programs that educate farmers on best practices for minimizing waste [179]. Extension Services for Waste Management: Providing dedicated extension services that focus on helping farmers implement effective waste management strategies tailored to their specific crops and environments [180].

- Innovative Food Processing Techniques: Zero-Waste Food Processing: Developing and adopting food processing techniques that utilize every part of the crop, such as extracting oils, fibers, and nutrients from traditionally discarded parts of fruits and vegetables [181].Secondary Product Development: Encouraging the creation of secondary products from waste materials, such as jams from overripe fruits [182] or animal feed from crop residues.

- Public-Private Partnerships: Collaboration between Farmers and Tech Companies: Encouraging partnerships between agricultural producers and technology firms to develop and implement innovative waste reduction solutions, such as mobile apps that help farmers connect with food banks or secondary markets. Government and NGO Collaboration: Facilitating partnerships between governments, NGOs, and the private sector to fund and support large-scale waste reduction projects, particularly in regions where waste management infrastructure is lacking [183].

- Sustainable Packaging Solutions: Biodegradable and Edible Packaging: Promoting the use of biodegradable and edible packaging materials made from agro-waste, to reduce plastic waste in the supply chain [166]. Reusable Packaging Systems: Encouraging the adoption of reusable packaging systems that can be returned, sanitized, and reused, reducing the need for single-use packaging [184].

- Consumer Awareness and Behavioral Change: Public Awareness Campaigns: Launching campaigns of how to avoid food waste by consumers [185], such as proper food storage techniques and the benefits of buying imperfect produce. Food Waste Reduction Programs: Implementing programs that encourage consumers to reduce waste, such as “ugly” produce boxes or apps that connect surplus food with those in need.

- Agroforestry and Diversified Farming Systems: Agroforestry Practices [186]: Integrating trees into agricultural systems to enhance biodiversity, improve soil health, and reduce waste by providing additional products such as fruits, nuts, and timber. Diversified Crop Systems: Promoting polyculture [187] and intercropping [188] systems that reduce the risk of total crop failure, ensuring that more produce is harvested and utilized.

- Reducing red meat production: Reducing red meat production represents a critical strategy for increasing land efficiency and mitigating environmental impacts. Compared to other livestock, such as poultry or fish, red meat production—particularly beef—requires significantly more resources, including land, water, and feed [189]. For instance, producing one kilogram of beef consumes approximately 15,415 L of water, while chicken requires only 4325 L [190]. Additionally, cattle farming contributes disproportionately to greenhouse gas emissions, primarily through methane released during enteric fermentation and manure management [26].

- Consumer food waste reduction: Reducing consumer-level food waste is essential for addressing inefficiencies in the food supply chain and ensuring resource conservation. Several strategies can be implemented at the household and retail levels to minimize waste, including adjustments in packaging size, optimization of shelf life, and innovative packaging technologies [191].

- R&D in biorefineries: Biorefineries represent an innovative approach to transforming agricultural waste into valuable products, aligning with the principles of the circular economy. These facilities integrate multiple processes to produce biofuels, biochemicals, and biomaterials from biomass feedstocks, mimicking the efficiency of petrochemical refineries. Advanced biorefinery technologies focus on maximizing resource utilization while minimizing waste generation, offering significant environmental and economic benefits [130], e.g., through feedstock flexibilization and cascaded bi

- Highly-efficient unconventional food sources, particularly for protein: In response to growing global demand for protein and concerns over land-use inefficiency in traditional livestock farming, unconventional food sources offer promising alternatives. These innovations focus on producing protein-rich materials with minimal environmental impact, leveraging diverse feedstocks, including agricultural waste.

Single-cell protein (bacteria, fungi, microalgae): Single-cell protein refers to microbial biomass produced through fermentation processes using substrates like sugars, gases, or organic acids. Methanotrophic bacteria, for example, can utilize methane from biogas to generate high-quality protein for animal feed. Similarly, hydrogen-oxidizing bacteria (HOB) and acetogenic bacteria can convert hydrogen and carbon dioxide into SCP, demonstrating low environmental footprints [190]. Bacterial meal, derived from these microorganisms, represents a cost-effective and scalable solution for addressing protein shortages.

Insects: Entomophagy, or the consumption of insects, has gained attention as a sustainable alternative to conventional animal proteins. Insects like crickets, mealworms, and black soldier flies require significantly less water, feed, and land compared to livestock, making them environmentally friendly options [192]. Additionally, insect farming can utilize organic waste streams, reducing disposal challenges while generating valuable protein-rich by-products.

Seaweed: Seaweeds possess remarkable nutritional profiles, rich in proteins, vitamins, minerals, and omega-3 fatty acids. Their cultivation does not compete with terrestrial agriculture for arable land or freshwater resources, making them ideal candidates for large-scale protein production [189]. Furthermore, seaweed farming contributes to marine ecosystem restoration by absorbing excess nutrients and mitigating ocean acidification.

Duckweed: Duckweed, a fast-growing aquatic plant, offers exceptional protein content (up to 45% dry weight) and can thrive on wastewater, simultaneously purifying water bodies and producing biomass [193]. Its rapid growth cycle and adaptability to various climatic conditions make it a viable candidate for sustainable protein production.