Abstract

Sustainable bioeconomy is a promising pathway towards the transition to a circular and climate-neutral economy. The valorization of biowaste is a key player in this direction. This paper presents the design and development of the AgriPLaCE Platform, which aims to promote synergies that enable the utilization of biowaste from the fruit and vegetable supply chain. The platform consists of the AgriPLaCE Waste Management Database, which provides users with an extended list of potential utilization methods for various types of fruit and vegetable biowaste streams, and the AgriPLaCE Synergies Tool, which facilitates synergies between different actors involved in the biowaste-to-resource value chain from agricultural waste production to waste treatment and new valuable products’ exploitation. Initially, the conceptual design of both tools took place based on analysis of user needs and services alongside the system architecture. Following this, the AgriPLaCE Platform was developed with the implementation of all the necessary subsystems. The results of the platform’s implementation demonstrated its potential to generate multiple collaborations and synergies while users can also deepen their knowledge about alternative and emerging treatment technologies and valuable products from a wide range of fruit and vegetable biowaste streams.

1. Introduction

In December 2019, the European Union (EU) announced its commitment to achieving climate neutrality by 2050. This commitment was outlined in the European Green Deal, in alignment with the goals and targets set under the Paris Agreement [1,2]. According to the position of the European Parliament [3], to protect, preserve, and improve the quality of the environment and public health, waste management should be improved and transformed into sustainable material management, promoting the principles of circular economy, enhancing the use of renewable energy, increasing energy efficiency, providing new economic opportunities and contributing to long-term competitiveness. To achieve a truly circular economy, additional measures on sustainable production must be taken, focusing on the entire life cycle of products in a way that preserves resources and closes the loops [4]. In this context, highlighting waste as a valuable material can provide greater independence in terms of raw material import needs and can create important opportunities for local economies and stakeholders to strengthen the circular economy’s alignment with various policy objectives, and deliver environmental benefits through reductions in greenhouse gas emissions. This is in line with the “industrial symbiosis” concept, which encourages collaboration and resource sharing among traditionally separate entities [5]. Originally, the concept of industrial symbiosis focused on the physical transfer of materials (such as waste, stock, or by-products), energy, and/or water between geographically proximate companies. This exchange entails one company utilizing another company’s residual flow as an input, resulting in mutual benefits and reduced environmental impact. Currently, industrial symbiosis encompasses various forms of intercompany cooperation, including resource exchange or sharing, underutilized resource utilization, utility sharing, infrastructure collaboration, and service cooperation [6,7].

Connecting industrial symbiosis and the bioeconomy can offer synergistic opportunities to enhance sustainability and resource efficiency. The European Parliament emphasizes the need to encourage investments in the development of a sustainable bioeconomy where fossil-intensive materials are replaced by renewable and bio-based ones since a switch to sustainable materials can play a significant role in the transition to a climate-neutral economy [8]. One of the most promising routes to a resource-efficient circular economy is toward bio-products and bio-based value chains. Industrial symbiosis can facilitate the exchange of bio-based resources, by-products, or waste streams between different companies within the bioeconomy. Several research studies have been carried out to explore the valorization of diverse biowaste streams, including agricultural waste [9] and industrial biowaste [10,11,12,13,14]. Additionally, there has been increasing attention towards plant-origin biowaste, specifically fruit and vegetable biowaste [12], as an area of interest for valorization efforts. Fruit and vegetable biowaste from the fruit and vegetable supply chain can originate from agriculture production, the food and beverage processing industry, retail, and the hotel, restaurant, and catering (HoReCa) sector.

Overall, while industrial symbiosis offers numerous benefits, several barriers can hinder its widespread adoption, depending on the specific context and stakeholders involved. Such barriers can be the lack of awareness and knowledge, regulatory and legal constraints, financial constraints, infrastructure limitations, and a lack of trust and data exchange between stakeholders [5,6,7]. Several tools have been created in recent years to overcome some of these obstacles. Existing tools have been categorized into different types depending on their facilitation approach in a recent literature review of information systems aiding the promotion of industrial symbiosis [15]. There are five of them: (1) open online waste markets, (2) facilitated synergy identification systems, (3) industry sector synergy identification, (4) social network platforms and communities, and (5) tools to identify potential waste-to-resource exchanges at the industry sector level [16]. They represent digital environments for businesses to find and establish partnerships for waste-to-resource exchanges.

Several recent studies [6,7,17,18,19] have explored the development of web platforms that address the utilization of various waste types as valuable resources; however, none of these platforms specifically emphasize the matchmaking of synergies for biowaste utilization. Additionally, the Sustainable Agriculture Initiative Platform (SAI Platform) [20] was established in 2002. The SAI Platform is a global membership organization dedicated to promoting sustainable agriculture on a global scale. It achieves this objective through capacity building and communication in the field of sustainable agriculture. The platform offers tools like the Sustainability Performance Assessment tool, which enables self-assessment or external assessment of sustainable agricultural practices. Nevertheless, a platform with a specialized focus on supporting the efficient utilization of fruit and vegetable biowaste through web-based matchmaking algorithms, eliminating intermediaries, is currently absent. Considering the substantial volume of fruit and vegetable biowaste generated, it is imperative to develop mechanisms for reutilizing them and fostering synergies among suppliers and demanders.

To cover this gap, an electronic platform, the AgriPLaCE Platform, focusing on fruit and vegetable biowaste valorization, was developed. In particular, this study presents the development of the AgriPLaCE Platform, which aims to promote synergies for the utilization of fruit and vegetable biowaste in the production of secondary materials. The platform consists of two (2) tools, i.e., the AgriPLaCE Waste Management Database and the AgriPLaCE Synergies Tool. Overall, the process involved formulating the concept of AgriPLaCE, conducting a literature review on fruit and vegetable biowaste valorization methods, implementing the platform, and validating its functionality and effectiveness.

2. Materials and Methods

2.1. The Concept behind the AgriPLaCE Platform

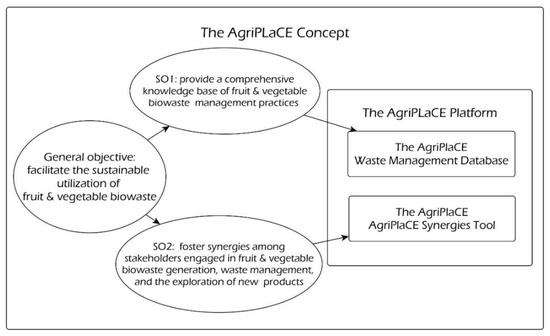

The general objective of this study was to facilitate the efficient and sustainable utilization of fruit and vegetable biowaste for resource recovery through a digital platform, the AgriPLaCE Platform. To this end, the first specific objective (SO1) was to provide a comprehensive knowledge base of fruit and vegetable biowaste management practices to various stakeholders, including agricultural producers, food processors, waste management companies, and potential end-users, and facilitate informed decision-making in this field. To achieve SO1, the AgriPLaCE Waste Management Database was designed and developed. This database serves as a centralized repository for fruit and vegetable biowaste management information. Moreover, the second specific objective (SO2) was to foster collaboration among various stakeholders from the supply chain of fruit and vegetable biowaste generation; the waste management industry, and the new valuable products industries. With this objective in mind, the AgriPLaCE Synergies Tool was created and implemented. This tool facilitates synergies between different actors involved in the biowaste-to-resource value chain. Figure 1 presents the AgriPLaCE concept and interconnections between the objectives and the AgriPLaCE tools.

Figure 1.

The AgriPLaCE concept and interconnections of objectives and AgriPLaCE tools.

Both the AgriPLaCE Waste Management Database and the AgriPLaCE Synergies Tool cater to specific user categories, i.e., waste suppliers (WS) and waste demanders (WD). The waste suppliers (WS) category encompasses a range of entities involved in the generation of fruit and vegetable biowaste, including farmers, the food and beverage industry, retailers (grocery stores, supermarkets, farmers’ markets), and HoReCa representatives. On the other hand, the waste demanders (WD) category includes owners of waste treatment technologies and industrial partners that are interested in developing technologies to produce products from biowaste.

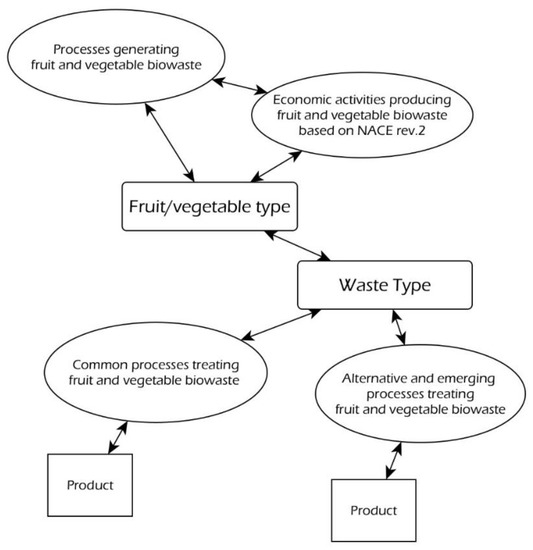

The conceptual design was based on the assumption that there is a mutual demand and that each user category (WS or WD) requires information from the other user category to cover their needs. In specific, the WS requires information from the WD to understand how their (WS) waste could be exploited, and the WD need information regarding which WS could provide them with waste that could be exploitable by them (WD). Consequently, the need for a common waste stream categorization vocabulary arose. Additionally, it was essential to define the processes generating fruit and vegetable biowaste streams as well as the processes to treat those waste streams both through conventional waste treatment methods and through alternative and emerging ones. Moreover, it was crucial to define the sectors that would act as end-users of tio-based products. Finally, establishing the interconnections between these elements was also essential. The interconnections are depicted in Figure 2, while further details for each element are given afterwards.

Figure 2.

Interconnections between the elements of the AgriPLaCE concept.

2.1.1. Waste Streams Categorization Vocabulary

To address the mutual demand between WS and WD, it was necessary to investigate the fruit and vegetable biowaste streams as generated by the WSs and also, to investigate the fruit and vegetable biowaste streams specifications as they are required by the WDs for being able to receive the waste. The findings showed that waste generated in agricultural fields could be categorized per type of fruit/vegetable and then further sub-categorized into leaves, stems, twigs, and fruits/vegetables unsuitable for human consumption due to factors, such as quality standards or aesthetic preferences. Regarding the fruit and vegetable biowaste generated by the food industry and the HoReCa sector, it encompasses various components of fruits and vegetables, including pits, kernels, seeds, and peels. Additionally, unsold fruits and vegetables are also included in this category of biowaste. The reasons for the generation of such biowaste from those sectors can be attributed to factors, such as quality standards, aesthetic preferences, shelf-life limitations, overstocking or excess inventory, fluctuations in market demand, and evolving consumer preferences, among others.

The waste streams that can be exploitable by the WD were the following:

- Waste stream category “a”: This category comprises waste streams that consist of only one part of one specific type of fruit/vegetable. Examples include kernels from apricots, peels from tomatoes, or seeds from lemons.

- Waste stream category “b”: In this category, waste streams are formed by one part of more than one or all types of fruit/vegetable plant/s. Examples include twigs from all types of fruit and vegetable plants, or fruits/vegetables unsuitable for human consumption derived from all categories of fruit/vegetable plants.

- Waste stream category “c”: This category includes waste streams that consist of different parts from more than one or all registered types of fruit/vegetable plants. Examples can include leaves, twigs, and seeds from all kinds of fruit/vegetable plants.

To ensure that the needs of both WS and WD would be met, it was essential to account for all possible waste streams. To achieve this, the adopted waste stream classification was defined as presented in Table 1.

Table 1.

Waste classification in AgriPLaCE Platform.

2.1.2. Processes Generating Fruit and Vegetable Biowaste Streams

As was already mentioned, the economic activity, the agro-industrial sector, and the processes generating different fruit and vegetable biowaste streams were investigated. As a result, information regarding the waste stream origin was provided per waste type (part of fruit/vegetable) for each type of fruit and vegetable. This was achieved by both indicating the relevant code(s) of the economic activity(ies) generating the different waste streams based on the Statistical Classification of Economic Activities in the European Community (NACE Rev. 2) and also by providing information about the process generating each waste stream (e.g., food processing).

2.1.3. Processes Treating Fruit and Vegetable Biowaste Streams for Bio-Based Products

Regarding the fruit and vegetable biowaste treatment methods for the generation of valuable bio-based products, two categories were taken into consideration:

- The established and frequently applied waste management methods;

- The alternative and emerging biowaste management methods.

While the project aimed to promote alternative biowaste management solutions and emerging management techniques, conventional waste management methods, such as processes producing biogas, pellets, animal food, etc., were also considered per waste type (part of a fruit/vegetable plant) for each type of fruit or vegetable, because a lot of biowaste streams are not exploited even with conventional methods and are just discarded; however, the main part of the study was focused on defining alternative biowaste management solutions and emerging management techniques. To this end, an extended literature review was conducted. As a result, a plethora of information was extracted regarding innovative existing and emerging technologies for the treatment of the fruit and vegetable biowaste stream categories “a”, “b” and “c”.

2.1.4. Sectors That Can Act as End-Users of the Bio-Based Products

The products derived from the methods described above have a wide range of applications in different industrial sectors, including the food, cosmetic and pharmaceutical industries, polymer production, energy, etc. To this end, those sectors were identified and matched with each specific bio-based product.

2.2. AgriPLaCE Platform Development

The AgriPLaCE Platform was implemented with the latest technologies in web development, through the use of open-source platforms, offering flexible access through mobile devices and personal computers to allow easy access and use by any user from any device connected to the internet. The AgriPLaCE Platform [21], available in the Greek language, was the output of the AgriPLaCE project: ‘Valorisation of Agricultural waste for the production of innovative Plastic materials in line with the Circular Economy’ co-financed by the ERDF of EU and Greek funds (project code: Τ6ΥΒΠ-00220, MIS 5048495).

During the implementation of the AgriPLaCE Platform, the subsequent methodological phases were followed:

- Preliminary conceptualization of the actual functionalities of the two tools.

- Preparation of draft documents with expected visuals of the platform.

- Enrichment of the draft documents and development of wireframes.

- Drafting of mock-ups.

- Mock-up revision and finalization.

- Development of the AgriPLaCE framework. The completion of the mock-ups was followed by the actual development of the AgriPLaCE Platform.

- Deployment of the AgriPLaCE Platform release candidate version. A fully functional version was deployed and provided for testing and further contributions.

- Validation exercise: A validation exercise with the technical partners was organized. All comments were incorporated into the final release.

- Final release of the AgriPLaCE Platform.

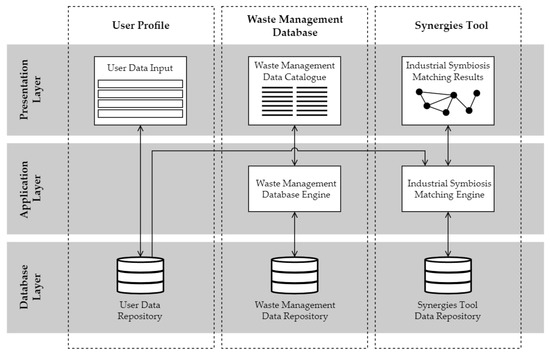

2.2.1. AgriPLaCE Platform System Architecture

The subsystems that form the AgriPLaCE platform stack followed a simple and intelligent architecture consisting of three layers, i.e., (i) the Presentation layer, (ii) the Application layer, and (iii) the Database layer [22], as depicted in Figure 3.

Figure 3.

The AgriPLaCE System Architecture.

The user interacts with the platform by way of the Presentation layer, which provides all necessary user interfaces for performing the tools’ functionalities. Every action in the system triggers an operation on the Application layer. Conversely, when the user requests information by performing the relevant actions in the Presentation layer, the Application layer retrieves any relevant data from the Database layer, transforms it to the appropriate format, and then sends it to the Presentation layer to present the data to the user.

The Presentation layer uses JavaScript with VueJS [23] as the primary framework and additionally Vuelidate [24] for model-based validation and Vuetify [25] framework for the components. Vuetify is a complete user interface framework built on top of VueJS. The goal of this approach was to provide the AgriPLaCE platform with all the necessary features needed to build a rich and engaging user experience. Additionally, Vuetify takes a “mobile first” approach to design, which means that the platform just works out of the box—whether it’s on a phone, tablet, or desktop computer.

The Application layer incorporates the Laravel Framework [26], a free and open-source PHP web framework intended for the development of web applications. In that manner, the web application dynamically interacts with the user providing faster and smoother transitions making the website feel more responsive [27].

The Database layer encompasses a PostgreSQL database [28] for computational operations [29]. PostgreSQL is a free and open-source relational database management system that operates as a data repository for the user input data, the waste management catalogue data, and the synergies tool data.

The server is the physical container that hosts the AgriPLaCE Platform and makes all its functionality available to the public. NGINX [30] and the Apache HTTP web server software [31] resides on the server hosting all the platform’s layers. NGINX was used as a reverse proxy server for handling static content requests and Apache as the backend to serve dynamic content, offering enhanced server performance for the web platform. Each web server software has Docker containers installed to provide all the software infrastructure to host the platform. The AgriPLaCE docker contained a standard unit of software that packages up the AgriPLaCE code and all its dependencies for the application to run quickly and reliably from one computing environment to another [32].

2.2.2. AgriPLaCE User Profile

To access the full functionality of the AgriPLaCE Platform, users are prompted to register on the website by submitting relevant information regarding their waste management needs. Apart from login details, users are requested to provide the enterprise type and geographical location, as well as information regarding their waste supply or needs. These data are stored in the User Data Repository and used in the Synergies Tool for calculation of the industrial symbiosis matching. Based on the information stored in their profile, the users can view a ranked catalogue of potential waste management partners and contact them through the Synergies Tool of the AgriPLaCE Platform.

2.2.3. AgriPLaCE Waste Management Database

The AgriPLaCE Waste Management Database provides an extended list of potential utilization methods for a variety of fruit and vegetable biowaste types and acts as a catalogue for waste management applications for its users. The AgriPLaCE Database is open to the public and users do not have to be registered to the platform to access it. The list provides detailed information related to the waste, specifically:

- Type of fruit or vegetable;

- Waste type;

- Processes generating waste;

- Economic activity from which the waste originates based on NACE Rev. 2;

- Conventional methods of waste management;

- Emerging technologies of waste management;

- Products derived from conventional and emerging waste management methods;

- Economic activity and industrial sectors valorize products derived from waste.

The database users can use filters and perform an advanced search for their waste type of interest by typing keywords in the search field. The algorithm then recategorizes the results based on the specific filtering provided. Finally, users can download their search results in .xls file format for further editing.

2.2.4. AgriPLaCE Synergies Tool

The successful implementation of industrial symbiosis relies heavily on stakeholders’ willingness to collaborate and share information. Consequently, stakeholders must have trust in the platform provider regarding matters of confidentiality [7]. Thus, the AgriPLaCE Synergies Tool is accessible only to registered users. This approach ensures that any sensitive information shared on the tool remains confidential and secure. In particular, upon registration, users are requested to provide information related to their waste supply or demand needs. This process occurs in the user profile subsystem, which stores the user data input in the User Data Repository. Once the registered user enters the AgriPLaCE Synergies Tool page, the Industrial Symbiosis Matching Engine calculates the priority of each user profile stored in the user data repository and sorts all users based on their assigned priority.

Upon calculation, the user is presented with a sorted list of potential industrial symbiosis matches. Results (other platform users) with the same priority value are shown alphabetically, and the user can further categorize them by performing an advanced search of the results with the use of filters and searching by keywords. The engine then recategorizes the results based on the specific filtering provided and presents the updated list to the user. It is also possible to download the industrial symbiosis matching list in .xls file format for further editing.

Finally, the AgriPLaCE Synergies Tool incorporates a communication feature within its contact module, enabling registered platform users to connect. Specifically, following the matchmaking process, the user can send a message through the platform that reaches the receiver via e-mail. Importantly, the receiver’s e-mail is shared only if a reply is initiated, ensuring compliance with the General Data Protection Regulation (GDPR) principles.

2.3. Industrial Symbiosis Matching Algorithm

The Industrial Symbiosis Matching Engine of the Synergies Tool encompasses the profile matching algorithm, which was based on weighted variables in a weighted sum model [33,34]. Specifically, there were five indexes used for ranking the potential matching of two users. Each index was assigned one variable, which receives the value 1 in case two users have a common index value and 0 in case the users have different index values.

The priority calculation formula is:

where K, W, R, U, and M are the index variables, and a, b, c, d, e are the weights of each variable, and P is the priority value.

a·K + b·W + c·R + d·U + e·M = P,

For each index variable, a unique weight was assigned based on the importance of each index to the matchmaking process. The five indexes and the respective variables and weights are presented in Table 2.

Table 2.

Synergies Tool indexes with respective variables and weights.

The most important indexes (core indexes) were the “Type of fruit or vegetable” (Κ, a = 0.35) and the “Waste type” (W, b = 0.35) since those were the necessary indexes to achieve an agreement for the material to create synergy. For this reason, each one of these core indexes (“Type of fruit or vegetable”, “Waste type”) receives a higher weight than the weight of indexes that are related to the location (“Region”, “Regional unit”, “Municipality”). Moreover, the total weight of the location indexes (0.1 + 0.1 + 0.1) is lower than the individual weight of each of the core indexes (“Type of fruit or vegetable”, “Waste type”) which each is equal to 0.35.

The priority calculation matrix, based on the index variable values, is presented in Table 3.

Table 3.

User matching priority matrix based on index variable value.

Users receiving a higher priority value are then classified as more suitable candidates for waste transactions and appear higher on the AgriPLaCE Synergies Tool matching list. Users receiving the same priority value are then listed alphabetically.

At this point, it should be noted that when K = 0 and W = 1, the type of fruit or vegetable (K) is determined by only one of the matched users (WS or WD), while the waste type (W) is defined by both of them. For instance, this applies in situations where a WS indicates that they offer “seeds” (waste type) from “tomato”, and the WD expresses the desire to receive “seeds” without specifying the fruit’s specific type.

Users can be waste suppliers, demanders, or both based on the information stored on their profile. The AgriPLaCE Synergies tool provides two independent lists:

- Suppliers list, presenting waste suppliers matching the user’s waste demands;

- Demanders list, presenting waste demanders matching the user’s waste supplies.

In case the user falls under only one category, e.g., is a waste supplier, the waste supplier list performs the same algorithm showcasing the user’s competition based on the same criteria.

3. Results

3.1. Results Related to AgriPLaCE Waste Management Database

The extended literature review on processes generating fruit and vegetable biowaste resulted in the identification of a diverse range of alternative and emerging biowaste treatment technologies with the potential to produce valuable materials that have applications across a wide spectrum of industrial sectors. These emerging biowaste treatment technologies descriptions are provided to the users through the AgriPLaCE Waste Management Database. The user can access information about waste treatment technologies for waste streams of interest (waste stream categories “a”, “b” and “c”) or obtain insights into which stream categories (“a”, “b” and “c”) can be effectively treated using the waste treatment technologies that align with their interests. This inclusive approach ensures that both user categories (WS and WD) can obtain specific and pertinent information.

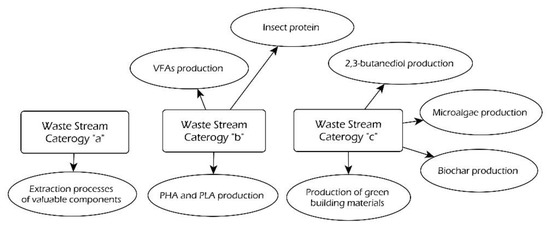

Following is a summary of the identified fruit and vegetable biowaste treatment methods applicable to different waste stream categories (“a”, “b” and “c”):

- Valuable components’ extraction processes (relevant to waste stream category “a”). For instance, these processes may include the extraction of various types of oils from the peels and kernels of fruits such as lemons, oranges, or from vegetables. Additionally, extraction methods have been applied to obtain lycopene from tomato peels, extract pectin from watermelon peels, and isolate valuable compounds, such as chlorogenic acid, vanillic acid, and ferulic acid, from pear peels. Numerous other valuable ingredients have also been extracted from various waste streams using similar processes [12,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66].

- Volatile fatty acid (VFA) production (relevant to waste stream category “b”). Fruit and vegetable waste (flesh) have been used as raw materials for the production of VFAs. VFAs are chemical building blocks, which are globally demanded by the chemical industry. Due to their functional groups, they are suitable precursors necessary for the production of chemicals, such as biopolymers, polyhydroxyalkanoates (PHAs), polylactic acids (PLAs), ketones, esters, alcohols, aldehydes, alkanes and biofuels, such as CH4 and H2 [67,68,69,70,71].

- PHA and PLA production (relevant to waste stream category “b”). Traditionally, bioplastics have been primarily produced from food crops, such as corn starch, tapioca roots, or sugar cane; however, in recent years, there has been a growing focus on utilizing bio-waste, including the flesh of fruit and vegetable waste as a raw material for bioplastic production [72].

- Insect protein production for animal feed (relevant to waste stream category “b”). Many varieties of insects are used for animal feed, so mass production of edible insects for animal feed appears to be a viable method to meet the growing demand for animal protein. Regarding the feed provided to farmed animals, restrictions have been established at EU level. In this context, insects intended for farmed animals’ feed must be fed exclusively with materials of plant origin. Therefore, fruit and vegetable waste (flesh) has been used as a suitable raw material for insect farming [73,74].

- Production of “green” building materials (relevant to waste stream category “c”). Certain types of biowaste, such as leaves, stems, and branches, can be effectively used as a valuable source of fibers to reinforce building materials, such as panels or for the production of biocomposites.

- 2,3-butanediol production (relevant to waste stream category “c”). 2,3-butanediol is a valuable chemical building block with a wide variety of applications in areas, such as chemical, energy, food, and polymer production. The industrial production of this compound is carried out by chemical methods from fossil sources and requires high energy intensity and the use of expensive catalysts. 2,3-butanediol is an alcohol that has been produced by fermentation of sugars derived from a wide range of plant raw materials: garden waste, vegetable and fruit waste (fruits, stems, leaves, and branches) [75].

- Microalgae production for animal feed (relevant to waste stream category “c”). The use of fruit and vegetable waste (flesh) could be applied to the production of microalgae. Fruit and vegetable flesh is a rich source of nutrients necessary for the growth of algae [76,77,78,79].

- Biochar production (relevant to “c” waste stream). Biochar is produced by a process called carbonization. This process involves pyrolysis in the absence of oxygen. The pyrolysis process has been employed on both the small and industrial scale to generate biochar from residual forest and agricultural biomass; hence, fruit and vegetable waste can be utilized for biochar production [80,81].

Figure 4 presents a summary representation of fruit and vegetable biowaste treatment methods for all waste stream categories.

Figure 4.

Fruit and vegetable biowaste treatment methods for all waste stream categories.

3.2. Results Related to the AgriPLaCE Synergies Tool

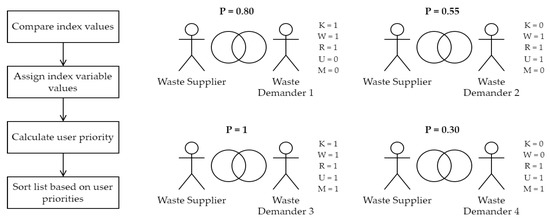

To illustrate the functionality of the AgriPLaCE Synergies Tool, a hypothetical use case of five potential users (one waste supplier and four waste demanders) was presumed, where the main user is a waste supplier (WS) seeking potential partners (waste demanders) in need of the supplied waste (WD 1, 2, 3 and 4). Each user has provided information on their profile upon registration, where they have selected their needs from a given list of items. For the Synergies Tool, the functionality was based on five indexes, where the users selected the values presented in Table 4.

Table 4.

Use case of a waste supplier (WS) and four waste demanders (WD) index values.

These data were extracted from the User Data Repository and fed to the Industrial Symbiosis Matching Engine as inputs to perform calculations. Based on the common index values between the waste supplier and each waste demander, each potential collaboration pair received a binary value for each index variable. The index variable matrix for each potential pair is presented in Table 5.

Table 5.

Use Case of a waste supplier (WS) and four waste demanders (WD) index variable values.

Then, the engine calculated each demander’s priority for the given supplier profile and sorted the synergies tool list based on the users with the highest priority ranking. The flow diagram of the use cases for the user priority calculation and Synergies Tool list sorting is depicted in Figure 5.

Figure 5.

Synergies Tool functionality flow for the use case scenario.

On the left side of Figure 5, the flow diagram of the Industrial Symbiosis Matching Engine algorithm is depicted, while on the right side, the user profile data are compared, and index variables take the value 1 when the respective index values are the same and the value 0 when the respective index values are different. In these cases, the priority equations are calculated as follows:

0.35 · 1 + 0.35 · 1 + 0.10 · 1 + 0.10 · 0 + 0.10 · 0 = 0.80

0.35 · 0 + 0.35 · 1 + 0.10 · 1 + 0.10 · 1 + 0.10 · 0 = 0.55

0.35 · 1 + 0.35 · 1 + 0.10 · 1 + 0.10 · 1 + 0.10 · 1 = 1

0.35 · 0 + 0.35 · 0 + 0.10 · 1 + 0.10 · 1 + 0.10 · 1 = 0.30

Based on these calculations, the system presented the list to the waste supplier, sorted by the highest priority:

- Waste Demander 3

- Waste Demander 1

- Waste Demander 2

- Waste Demander 4

Apart from the use case presented above, the Synergies Tool was tested with over 20 different user profiles (both waste suppliers and demanders,) showcasing multiple potential users and successful collaborations that arise through the use of the AgriPLaCE Platform.

4. Discussion

Numerous efforts have been undertaken to foster industrial symbiosis synergies via a digital platform, targeting the valorization of diverse waste and wastewaters. In the subsequent paragraphs, the most pertinent initiatives will be presented and compared with the AgriPLaCE Platform for comparative analysis.

Akrivou et al. [6] presented a conceptual framework for industrial symbiosis matchmaking, specifically designed for a waste valorization marketplace. This framework aimed to provide users with a comprehensive evaluation that incorporates both quantitative and qualitative information, thereby contributing to the decision-making process. The total relevance score was calculated taking into consideration the sub-scores derived from three different level scoring systems: (i) level A: stakeholders’ compatibility regarding industrial symbiosis compliance level assessed via a questionnaire, expressed as sub-score A; (ii) level B: flow analysis, expressed as sub-score B; and (iii) level C: environmental impact of a potential synergy through Life Cycle Assessment; however, it is important to note that the research did not encompass the development of a matchmaking algorithm, similar to the case of the AgriPLaCE platform. Nevertheless, it is worth mentioning that, akin to the AgriPLaCE Platform, the study conducted by Akrivou et al. [6] also considered compatibility based on flow characteristics (both quality and quantity) as a fundamental aspect of their matching concept. This research also proposes quantifying the impact assessments for the synergies created, aiming to provide potential users with information regarding the most environmentally friendly synergies. This aspect, which is not currently included in the AgriPLaCE matching algorithm, could be seen as a potential area for future improvement of the AgriPLaCE Platform.

The e-Symbiosis platform [19] was a web-based platform that enabled users to participate in industrial symbiosis activities to improve resource efficiency across the economy. The creation of synergies on the e-Symbiosis platform between users was achieved through a matchmaking algorithm. The three different user categories were waste providers, solution providers, and waste demanders. The users were matched based on the resources’ categorization, the availability and quantity of the resources, the location, and the supply pattern. While there are certain similarities between the AgriPLaCE Synergies Tool and the e-Symbiosis Synergies Tool, a key difference lies in the scope of their coverage. The e-Symbiosis platform aimed to encompass all types of waste that may arise within a given region. In contrast, AgriPLaCE specifically focused on biowaste originating from the fruit and vegetable value chain. Moreover, in the e-Symbiosis tool, biowaste types were classified into broader categories, whereas AgriPLaCE offered a precise classification specifically for fruit and vegetable biowaste. This meticulous classification system in AgriPLaCE facilitated the identification of highly specific utilization opportunities, enabling the application of a wide range of valorization techniques.

On the other hand, the main objective of the first Industrial Symbiosis Platform in Italy [18] was to launch industrial symbiosis through a geo-referenced information system. It served as a tool to support businesses and the local community. It incorporated a taxonomy designed for capturing input–output data from companies, encompassing resources, such as “materials, energy, services, and skills,” while utilizing official national codes for numerous inventories; however, it should be noted that the waste classification in this platform is not as comprehensive as in AgriPLaCE, as it primarily focuses on broader categories.

The Online Brine Platform (OBP) [17], which is focused on industrial saline wastewater, aimed to create direct synergies between its users. While both the AgriPLaCE Synergies Tool and the Online Brine Platform considered the quantity, quality characteristics, and location of flows in the matchmaking process between users, there is a notable distinction. In the case of the OBP, the roles are not limited to waste receivers and waste providers but also include waste providers (and heat providers), technology providers, recovered material demanders and recovered material providers. It is important to highlight that the OBP’s primary focus of interest lies in saline wastewater, which is entirely different from the focus of the AgriPLaCE Platform.

Finally, the SAI Platform [20] is a tool designed to assess outcomes and track progress in four impact areas of agricultural activities related to soil, biodiversity, water, and climate. The SAI Platform is a portal where registered users can use the Farm Sustainability Assessment (FSA) and Sustainable Dairy Partnership (SDP) online training, technical documents, and guidance materials exclusively for members. The FSA enables food and beverage businesses to assess, improve, and validate on-farm sustainability in their supply chains. In addition, this platform provides a space for knowledge-sharing, networking, and collaboration among stakeholders in the agro-industrial sector. It facilitates discussions on sustainable practices, promotes research findings and technological developments, and creates opportunities for partnerships and projects related to the valorization of agro-industrial waste. While the platform indirectly contributes to addressing the issue of waste management and utilization of biological origin, its primary focus is on broader aspects of sustainable agriculture rather than directly connecting waste producers with waste demanders from the fruit and vegetable supply chain.

The implementation of the AgriPLaCE Digital Platform has demonstrated promising results in terms of its potential contribution to the sustainable bioeconomy and circular economy, specifically through the effective utilization of fruit and vegetable biowaste. By facilitating the exchange of resources, the platform plays a crucial role in waste reduction. Additionally, it can enhance economic performance by lowering costs and fostering the emergence of novel business opportunities and circular business models.

Furthermore, an important characteristic of the AgriPLaCE Platform is its scalability, which allows for potential expansion to encompass additional industries and resources. This scalability offers the opportunity for even greater environmental and economic benefits. As the platform continues to grow and evolve, new synergies and opportunities for resource exchange are likely to arise, further bolstering sustainability efforts and diminishing the environmental impact within the fruit and vegetable supply chain and the biowaste-to-resource value chain.

While the results of the evaluation were positive, there were certain challenges and limitations to the implementation of the AgriPLaCE Platform. One notable challenge is ensuring the active participation and engagement of all relevant industries within the region. While some users may readily embrace the platform and recognize its potential benefits, others may exhibit reluctance in terms of sharing information or engaging in resource exchange. This emphasizes the significance of ongoing outreach and education efforts to effectively communicate the advantages of industrial symbiosis and the digital platform.

Another limitation pertains to the necessity for continuous maintenance and updates of the AgriPLaCE Platform. As new industries and resources are integrated, it becomes crucial to ensure that the database remains up-to-date and accurate. Furthermore, continuous user feedback and evaluation are essential in identifying areas for improvement and ensuring that the platform effectively caters to the needs of its users. By addressing these challenges and limitations, the platform can further enhance its functionality and maximize its potential impact.

Author Contributions

Conceptualization, E.S. and K.V.; methodology, I.V. and E.S.; software, I.V., G.L., E.R. and E.M.; validation, I.V., G.L., E.R. and E.M.; formal analysis, I.V., E.S., M.P. and S.P.; investigation, I.V., E.S., M.P. and S.P.; resources, I.V., E.S., M.P. and S.P.; data curation, I.V.; writing—original draft preparation, I.V., E.S., M.P. and S.P.; writing—review and editing, I.V., E.S., K.V., M.P. and S.P.; visualization I.V.; supervision, K.V.; project administration, K.V. and E.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been co-financed by the ERDF of EU and Greek national funds through the Operational Program Competitiveness, Entrepreneurship, and Innovation, under the special actions “Aquaculture”—“Industrial Materials”—“Open Innovation in Culture” (project code: Τ6ΥΒΠ-00220, MIS 5048495).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Dimitrov, R.S. The Paris Agreement on Climate Change: Behind Closed Doors. Glob. Environ. Politics 2016, 16, 1–11. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. Communication from the Commission. COM (2019) 640 Final; European Commission: Brussels, Belgium, 2019.

- European Parliament and Council (2018b) Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32018L0851 (accessed on 28 March 2023).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A new Circular Economy Action Plan For a cleaner and more competitive Europe. COM (2020) 98 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0098 (accessed on 20 May 2023).

- Papathanasoglou, A.; Panagiotidou, M.; Valta, K.; Loizidou, M. Institutional Barriers and Opportunities for the Implementation of Industrial Symbiosis in Greece. Environ. Pract. 2016, 18, 253–259. [Google Scholar] [CrossRef]

- Akrivou, C.; Lekawska-Andrinopoulou, L.; Manousiadis, C.; Tsimiklis, G.; Papadaki, S.; Oikonomopoulou, V.; Krokida, M.; Amditis, A. Industrial symbiosis marketplace concept for waste valorization pathways. E3S Web Conf. 2022, 349, 11005. [Google Scholar] [CrossRef]

- Akrivou, C.; Lekawska-Andrinopoulou, L.; Tsimiklis, G.; Amditis, A. Industrial symbiosis platforms for synergy identification and their most important data points: A systematic review. Open Res. Eur. 2021, 1, 101. [Google Scholar] [CrossRef]

- Gaffey, J.; McMahon, H.; Marsh, E.; Vos, J. Switching to Biobased Products—The Brand Owner Perspective. Ind. Biotechnol. 2021, 17, 109–116. [Google Scholar] [CrossRef]

- Toop, T.A.; Ward, S.; Oldfield, T.; Hull, M.; Kirby, M.E.; Theodorou, M.K. AgroCycle—Developing a circular economy in agriculture. Energy Procedia 2017, 123, 76–80. [Google Scholar] [CrossRef]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-industrial wastes and their utilization using solid state fermentation: A review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Valta, K.; Damala, P.; Orli, E.; Papadaskalopoulou, C.; Moustakas, K.; Malamis, D.; Loizidou, M. Valorisation Opportunities Related to Wastewater and Animal By-Products Exploitation by the Greek Slaughtering Industry: Current Status and Future Potentials. Waste Biomass Valorization 2015, 6, 927–945. [Google Scholar] [CrossRef]

- Valta, K.; Damala, P.; Panaretou, V.; Orli, E.; Moustakas, K.; Loizidou, M. Review and assessment of waste and wastewater treatment from fruits and vegetables processing industries in Greece. Waste Biomass Valorization 2017, 8, 1629–1648. [Google Scholar] [CrossRef]

- Valta, K.; Aggeli, E.; Papadaskalopoulou, C.; Panaretou, V.; Sotiropoulos, A.; Malamis, D.; Moustakas, K.; Haralambous, K.J. Adding value to olive oil production through waste and wastewater treatment and valorisation: The case of Greece. Waste Biomass Valorization 2015, 6, 913–925. [Google Scholar] [CrossRef]

- Valta, K.; Damala, P.; Angeli, E.; Antonopoulou, G.; Malamis, D.; Haralambous, K.J. Current treatment technologies of cheese whey and wastewater by Greek cheese manufacturing units and potential valorisation opportunities. Waste Biomass Valorization 2017, 8, 1649–1663. [Google Scholar] [CrossRef]

- van Capelleveen, G.; Amrit, C.; Yazan, D.M. A Literature Survey of Information Systems Facilitating the Identification of Industrial Symbiosis. In From Science to Society; Otjacques, B., Hitzelberger, P., Naumann, S., Wohlgemuth, V., Eds.; Progress in IS; Springer: Cham, Switzerland, 2017; pp. 155–169. [Google Scholar]

- Low, J.S.C.; Tjandra, T.B.; Yunus, F.; Chung, S.Y.; Tan, D.Z.L.; Raabe, B.; Ting, N.Y.; Yeo, Z.; Bressan, S.; Ramakrishna, S.; et al. A Collaboration Platform for Enabling Industrial Symbiosis: Application of the Database Engine for Waste-to-Resource Matching. Procedia CIRP 2018, 69, 849–854. [Google Scholar] [CrossRef]

- Bakogianni, D.; Skourtanioti, E.; Meimaris, D.; Xevgenos, D.; Loizidou, M. Online Brine Platform: A Tool for Enabling Industrial Symbiosis in Saline Wastewater Management Domain. In Proceedings of the 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini, Greece, 29–31 May 2019. [Google Scholar]

- Cutaia, L.; Luciano, A.; Barberio, G.; Sbaffoni, S.; Mancuso, E.; Scagliarino, C.; La Monica, M. The experience of the first industrial symbiosis platform in Italy. Environ. Eng. Manag. J. 2015, 14, 1521–1533. [Google Scholar] [CrossRef]

- Cecelja, F.; Raafat, T.; Trokanas, N.; Innes, S.; Smith, M.; Yang, A.; Zorgios, Y.; Korkofygas, A.; Kokossis, A. e-Symbiosis: Technology-enabled support for Industrial Symbiosis targeting Small and Medium Enterprises and innovation. J. Clean. Prod. 2015, 98, 336–352. [Google Scholar] [CrossRef]

- SAI Platform. Available online: https://saiplatform.org/ (accessed on 20 May 2023).

- AgriPLaCE Platform. Available online: https://www.agriplace.gr/ (accessed on 20 May 2023).

- Liu, X.; Heo, J.; Sha, L. Modeling 3-tiered Web applications. In Proceedings of the 13th IEEE International Symposium on Modeling, Analysis, and Simulation of Computer and Telecommunication Systems, Atlanta, GA, USA, 27–29 September 2005. [Google Scholar]

- Vue.js—The Progressive JavaScript Framework|Vue.js. Available online: https://vuejs.org/ (accessed on 20 May 2023).

- Vuelidate|A Vue.js Model Validation Library. Available online: https://vuelidate.js.org/ (accessed on 22 May 2023).

- Vuetify—A Vue Component Framework. Available online: https://vuetifyjs.com/en/ (accessed on 22 May 2023).

- Laravel—The PHP Framework for Web Artisans. Available online: https://laravel.com/ (accessed on 22 May 2023).

- Tang, L. Building Websites with Laravel and VueJS; Centria University of Applied Sciences: Kokkola, Finland, 2019; Available online: https://www.theseus.fi/bitstream/handle/10024/261248/linh_tang.pdf?sequence=2&isAllowed=y (accessed on 22 May 2023).

- PostgreSQL: The World’s Most Advanced Open-Source Database. Available online: https://www.postgresql.org/ (accessed on 22 May 2023).

- Worsley, J.C.; Drake, J.D. Practical PostgreSQL, 1st ed.; O’Reilly & Associates, Inc.: Sebastopol, CA, USA, 2001. [Google Scholar]

- NGINX: Advanced Load Balancer, Web Server, & Reverse Proxy. Available online: https://www.nginx.com/ (accessed on 22 May 2023).

- Apache HTTP Server—The Apache Software Foundation! Available online: https://httpd.apache.org/ (accessed on 22 May 2023).

- Xu, Q.; Awasthi, M.; Malladi, K.; Bhimani, J.; Yang, J.; Annavaram, M.; Hsieh, M. Performance Analysis of Containerized Applications on Local and Remote Storage. In Proceedings of the 33rd International Conference on Massive Storage Systems and Technology (MSST 2017), Santa Clara, CA, USA, 12–15 May 2017. [Google Scholar]

- Kaddani, S.; Vanderpooten, D.; Vanpeperstraete, J.-M.; Aissi, H. Weighted sum model with partial preference information: Application to multi-objective optimization. Eur. J. Oper. Res. 2017, 260, 665–679. [Google Scholar] [CrossRef]

- Song, B.; Kang, S. A Method of Assigning Weights Using a Ranking and Nonhierarchy Comparison. Adv. Decis. Sci. 2016, 2016, 8963214. [Google Scholar] [CrossRef]

- Al-Sayed, H.M.A.; Ahmed, A.R. Utilization of watermelon rinds and sharlyn melon peels as a natural source of dietary fiber and antioxidants in cake. Ann. Agric. Sci. 2013, 58, 83–95. [Google Scholar] [CrossRef]

- Jiang, L.; Shang, J.; He, L.; Qian, W. Comparisons of Microwave-Assisted and Conventional Heating Extraction of Pectin from Seed Watermelon Peel. Adv. Mat. Res. 2012, 550–553, 1801–1806. [Google Scholar] [CrossRef]

- Prakash Maran, J.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Microwave assisted extraction of pectin from waste Citrullus lanatus fruit rinds. Carbohydr. Polym. 2014, 101, 786–791. [Google Scholar] [CrossRef]

- Persia, M.E.; Parsons, C.M.; Schang, M.; Azcona, J. Nutritional evaluation of dried tomato seeds. Poult. Sci. 2003, 82, 141–146. [Google Scholar] [CrossRef]

- Silva-Beltrán, N.P.; Ruiz-Cruz, S.; Chaidez, C.; Ornelas-Paz, J.d.J.; López-Mata, M.A.; Márquez-Ríos, E.; Estrada, M.I. Chemical constitution and effect of extracts of tomato plants byproducts on the enteric viral surrogates. Int. J. Environ. Health Res. 2015, 25, 299–311. [Google Scholar] [CrossRef] [PubMed]

- Taveira, M.; Ferreres, F.; Oliveira, L.; Valentão, P.; Andrade, P. Fast determination of bioactive compounds from Lycopersicon esculentum Mill. leaves. Food Chem. 2012, 135, 748–755. [Google Scholar] [CrossRef] [PubMed]

- Strati, I.F.; Oreopoulou, V. Recovery of carotenoids from tomato processing by-products—A review. Food Res. Int. 2014, 65, 311–321. [Google Scholar] [CrossRef]

- Khan, A.S.; Singh, Z.; Abbasi, N.; Swinny, E. Pre- or post-harvest applications of putrescine and low temperature storage affect fruit ripening and quality of ‘Angelino’ plum. J. Sci. Food Agric. 2008, 88, 1686–1695. [Google Scholar] [CrossRef]

- Wang, T.; Li, X.; Zhou, B.; Li, H.; Zeng, J.; Gao, W. Anti-diabetic activity in type 2 diabetic mice and α-glucosidase inhibitory, antioxidant and anti-inflammatory potential of chemically profiled pear peel and pulp extracts (Pyrus spp.). J. Funct. Foods 2015, 13, 276–288. [Google Scholar] [CrossRef]

- Dincel Kasapoglu, E.; Kahraman, S.; Tornuk, F. Apricot juice processing byproducts as sources of value-added compounds for food industry. Eur. Food Sci. Eng. 2020, 1, 18–23. [Google Scholar]

- Paraskevopoulou, C.; Vlachos, D.; Bechtsis, D.; Tsolakis, N. An assessment of circular economy interventions in the peach canning industry. Int. J. Prod. Econ. 2022, 249, 108533. [Google Scholar] [CrossRef]

- Wu, H.; Shi, J.; Xue, S.; Kakuda, Y.; Wang, D.; Jiang, Y.; Ye, X.; Li, Y.; Subramanian, J. Essential oil extracted from peach (Prunus persica) kernel and its physicochemical and antioxidant properties. LWT Food Sci. Technol. 2011, 44, 2032–2039. [Google Scholar] [CrossRef]

- Nowicka, P.; Wojdyło, A. Content of bioactive compounds in the peach kernels and their antioxidant, anti-hyperglycemic, anti-aging properties. Eur. Food Res. Technol. 2019, 245, 1123–1136. [Google Scholar] [CrossRef]

- Doğantürk, M.; Seçilmiş Canbay, H. Oil Ratio and Fatty Acid Composition of Cherry Seed Oil. Turk. J. Health Sci. Life 2019, 2, 21–24. [Google Scholar]

- Poguberović, S.S.; Krčmar, D.M.; Maletić, S.P.; Kónya, Z.; Pilipović, D.D.T.; Kerkez, D.V.; Rončević, S.D. Removal of As(III) and Cr(VI) from aqueous solutions using “green” zero-valent iron nanoparticles produced by oak, mulberry and cherry leaf extracts. Ecol. Eng. 2016, 90, 42–49. [Google Scholar] [CrossRef]

- Yukui, R.; Wenya, W.; Rashid, F.; Qing, L. Fatty Acids Composition of Apple and Pear Seed Oils. Int. J. Food Prop. 2009, 12, 774–779. [Google Scholar] [CrossRef]

- Barreira, J.C.M.; Arraibi, A.A.; Ferreira, I.C.F.R. Bioactive and functional compounds in apple pomace from juice and cider manufacturing: Potential use in dermal formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Bonarska-Kujawa, D.; Cyboran, S.; Oszmiański, J.; Kleszczyńska, H. Extracts from apple leaves and fruits as effective antioxidants. J. Med. Plant Res. 2011, 5, 2339–2347. [Google Scholar]

- Guneser, B.A.; Yilmaz, E. Bioactives, Aromatics and Sensory Properties of Cold-Pressed and Hexane-Extracted Lemon (Citrus limon L.) Seed Oils. J. Am. Oil Chem. Soc. 2017, 94, 723–731. [Google Scholar] [CrossRef]

- Burnett, C.L.; Bergfeld, W.F.; Belsito, D.V.; Hill, R.A.; Klaassen, C.D.; Liebler, D.C.; Marks, J.G.; Shank, R.C.; Slaga, T.J.; Snyder, P.W.; et al. Safety Assessment of Citrus Fruit-Derived Ingredients as Used in Cosmetics. Int. J. Toxicol. 2021, 40, 5S–38S. [Google Scholar] [CrossRef]

- Giwa, S.; Muhammad, M.; Giwa, A. Utilizing orange peels for essential oil production. J. Eng. Appl. Sci. 2018, 13, 17–27. [Google Scholar]

- Willner, I.; Baron, R.; Willner, B. Growing Metal Nanoparticles by Enzymes. Adv. Mater. 2006, 18, 1109–1120. [Google Scholar] [CrossRef]

- Shankar, S.S.; Rai, A.; Ankamwar, B.; Singh, A.; Ahmad, A.; Sastry, M. Biological synthesis of triangular gold nanoprisms. Nat. Mater. 2004, 3, 482–488. [Google Scholar] [CrossRef]

- Basavegowda, N.; Rok Lee, Y. Synthesis of silver nanoparticles using Satsuma mandarin (Citrus unshiu) peel extract: A novel approach towards waste utilization. Mater. Lett. 2013, 109, 31–33. [Google Scholar] [CrossRef]

- Roselló-Soto, E.; Barba, F.J.; Parniakov, O.; Galanakis, C.M.; Lebovka, N.; Grimi, N.; Vorobiev, E. High Voltage Electrical Discharges, Pulsed Electric Field, and Ultrasound Assisted Extraction of Protein and Phenolic Compounds from Olive Kernel. Food Bioproc. Tech. 2015, 8, 885–894. [Google Scholar] [CrossRef]

- Difonzo, G.; Squeo, G.; Pasqualone, A.; Summo, C.; Paradiso, V.M.; Caponio, F. The challenge of exploiting polyphenols from olive leaves: Addition to foods to improve their shelf-life and nutritional value. J. Sci. Food Agric. 2021, 101, 3099–3116. [Google Scholar] [CrossRef] [PubMed]

- Perumalla, A.; Hettiarachchy, N. Green tea and grape seed extracts—Potential applications in food safety and quality. Food Res. Int. 2011, 44, 827–839. [Google Scholar] [CrossRef]

- Ferhi, S.; Santaniello, S.; Zerizer, S.; Cruciani, S.; Fadda, A.; Sanna, D.; Dore, A.; Maioli, M.; D’hallewin, G. Total Phenols from Grape Leaves Counteract Cell Proliferation and Modulate Apoptosis-Related Gene Expression in MCF-7 and HepG2 Human Cancer Cell Lines. Molecules 2019, 24, 612. [Google Scholar] [CrossRef]

- Pinela, J.; Carvalho, A.M.; Ferreira, I.C.F.R. Wild edible plants: Nutritional and toxicological characteristics, retrieval strategies and importance for today’s society. Food Chem. Toxicol. 2017, 110, 165–188. [Google Scholar] [CrossRef] [PubMed]

- Chiellini, E.; Cinelli, P.; Chiellini, F.; Imam, S.H. Environmentally Degradable Bio-Based Polymeric Blends and Composites. Macromol. Biosci. 2004, 4, 218–231. [Google Scholar] [CrossRef]

- Liang, S.; McDonald, A.G. Chemical and Thermal Characterization of Potato Peel Waste and Its Fermentation Residue as Potential Resources for Biofuel and Bioproducts Production. J. Agric. Food Chem. 2014, 62, 8421–8429. [Google Scholar] [CrossRef]

- Mitrus, M.; Moscicki, L. Physical properties of thermoplastic starches. Int. Agrophysics 2009, 23, 305–308. [Google Scholar]

- Wang, K.; Yin, J.; Shen, D.; Li, N. Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: Effect of pH. Bioresour. Technol. 2014, 161, 395–401. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Yang, Y.H. Microbial production of volatile fatty acids: Current status and future perspectives. Rev. Environ. Sci. 2017, 16, 327–345. [Google Scholar] [CrossRef]

- Agler, M.T.; Wrenn, B.A.; Zinder, S.H.; Angenent, L.T. Waste to bioproduct conversion with undefined mixed cultures: The carboxylate platform. Trends Biotechnol. 2011, 29, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Baumann, I.; Westermann, P. Microbial Production of Short Chain Fatty Acids from Lignocellulosic Biomass: Current Processes and Market. Biomed Res. Int. 2016, 2016, 8469357. [Google Scholar] [CrossRef] [PubMed]

- Zacharof, M.-P.; Lovitt, R.W. Complex Effluent Streams as a Potential Source of Volatile Fatty Acids. Waste Biomass Valorization 2013, 4, 557–581. [Google Scholar] [CrossRef]

- Bioplastics Market Data. European Bioplastics. Available online: https://www.european-bioplastics.org/market/ (accessed on 20 May 2023).

- Insect Protein Market by Insect Type, Form & Region for 2021–2029|Global Sales Analysis and Opportunity—2029|FMI futuremarketinsights.com), Insect Protein Market Size, Share & Covid analysis. Available online: https://www.fortunebusinessinsights.com/industry-reports/insect-based-protein-market-100780 (accessed on 21 May 2023).

- International Platform of Insects for Food and Feed—IPIFF, Insects as Feed EU Legislation—Aquaculture, Poultry & Pig Species. Available online: https://ipiff.org/insects-eu-legislation/ (accessed on 21 May 2023).

- Białkowska, A. Strategies for efficient and economical 2,3-butanediol production: New trends in this field. World J. Microbiol. Biotechnol. 2016, 32, 200. [Google Scholar] [CrossRef]

- Markou, G.; Georgakakis, D. Cultivation of filamentous cyanobacteria (blue-green algae) in agro-industrial wastes and wastewaters: A review. Appl. Energy 2011, 88, 3389–3401. [Google Scholar] [CrossRef]

- Lundquist, T.; Woertz, I.; Quinn, N.; Benemann, J. A Realistic Technology and Engineering Assessment of Algae Biofuel Production. Energy 2010, 1. [Google Scholar]

- Sirakov, I.; Velichkova, K.; Stoyanova, S.; Staykov, Y. The importance of microalgae for aquaculture industry. Review. Int. J. Fish. Aquat. Sci. 2015, 2, 81–84. [Google Scholar]

- Brown, M.R. Nutritional value of microalgae for aquaculture. Advances in Aquaculture nutrition. In Proceedings of the VI International Symposium on Nutrition Aquaculture, Cancun, Quintana Roo, Mexico, 3–6 September 2002. [Google Scholar]

- European Biochar Certificate—Guidelines for a Sustainable Production of Biochar EBC (2012–2022). European Biochar Foundation (EBC), Arbaz, Switzerland. Version 10.1 from 10 January 2022. Available online: http://european-biochar.org (accessed on 20 May 2023).

- Europe Biochar Market Trends, Size, Share, Analysis, Forecast 2022–2030. Available online: https://inkwoodresearch.com/reports/europe-biochar-market/ (accessed on 20 May 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).