Abstract

This study aimed to evaluate the effects of mechanical treatment through twin-screw extrusion for the enhancement of biomethane production. Four lignocellulosic biomasses (i.e., sweetcorn by-products, whole triticale, corn stover and wheat straw) were evaluated, and two different shear stress screw profiles were tested. Chemical composition, particle size reduction, tapped density and cellulose crystallinity were assessed to show the effect of extrusion pretreatment on substrate physico-chemical properties and their biochemical methane production (BMP) capacities. Both mechanical pretreatments allowed an increase in the proportion of particles with a diameter size less than 1 mm (from 3.7% to 72.7%). The most restrictive profile also allowed a significant solubilization of water soluble coumpounds, from 5.5% to 13%. This high-shear extrusion also revealed a reduction in cellulose crystallinity for corn stover (i.e., 8.6% reduction). Sweetcorn by-products revealed the highest BMP values (338–345 NmL/gVS), followed by corn stover (264–286 NmL/gVS), wheat straw (247–270 NmL/gVS) and whole triticale (233–247 NmL/gVS). However, no statistical improvement in maximal BMP production was provided by twin-screw extrusion. Nevertheless, BMP kinetic analysis proved that both extrusion pretreatments were able to increase the specific rate constant (from 13% to 56% for soft extrusion and from 66% to 107% for the high-shear one).

1. Introduction

The increase in the world’s population correlated with the increase in energy demand has raised concerns about the problem of the supply of fossil resources such as oil, gas or coal, and their harmful effects, contributing strongly to global warming. Renewable and alternative energy sources may be able to solve these problems, but they require major investments and innovative technologies to do so [1].

One of the most promising and profitable biotechnologies for replacing fossil energy with renewable energy, such as bioethanol or biodiesel production, is anaerobic digestion (AD) as methane produced by the bioconversion of numerous sources of organic materials can be used to generate heat, electricity and fuel, while the digestate generated in the process may be disposed of as an organic amendment for agricultural soils [2]. AD is a biological process characterized by four successive metabolic pathways, i.e., hydrolysis, acidogenesis, acetogenesis and methanogenesis, and involves the gradual conversion of high molecular weight compounds such as carbohydrates, proteins and lipids into biomethane [3].

Lignocellulosic biomass represents one of the most attractive sources of organic matter for biogas production since it is widely available through by-products or wastes generated by activities such as agriculture or agro-industry [4]. Lignocellulose consists of three main biopolymers, which are associated with each other to form a complex network. Cellulose, the most abundant natural polymer, is a polysaccharidic homopolymer made of glucose units linked by β-1,4 glycosidic bonds. Hemicelluloses are also polysaccharides, but these heteropolymers are made from different monomers such a pentoses (e.g., xylose and arabinose), hexoses (e.g., mannose, glucose and galactose) and uronic acids. Finally, lignin is, unlike the previous biopolymers, an amorphous polyphenolic heteropolymer composed of three different monolignols (i.e., coumaryl, coniferyl and sinapyl alcohols). [5].

Among lignocellulosic biomasses, agro-industrial or agricultural by-products are key carbon resources available in vast quantities since the four most farmed plants in the world, namely sugar cane, corn, rice and wheat, already generate more than 2.55 billion tons of plant fiber annually [6]. Catch crops such as grass, clover, hemp or triticale also represent an appealing answer to the competitive use of agricultural land, and they can be efficiently valorized through biogas production [7].

However, as the complex structure and physico-chemical properties of cell walls inside lignocellulosic substrates constitute a natural barrier against pests such as insects or microorganisms, they also limit the hydrolysis stage of AD, and therefore the substrate’s natural digestibility, which is the main limiting factor for their utilization [8].

Therefore, to break this complex structure of lignocellulose and access the monomeric sugars forming cellulose and hemicelluloses, which are consumed by microorganisms during AD, a pretreatment step is essential [9]. Biological, mechanical, physical and/or chemical pretreatments are the main pretreatments that can be applied [10,11,12]. For the mechanical pretreatments, such as grinding, milling or shredding, the main issue is their energy requirement, especially when coupled with thermal pretreatment [13]. However, these are able to efficiently disrupt the cell wall structure, thus improving the accessible contact surface area between anaerobic microorganisms and the substrate. Physical pretreatments, mainly ultrasound or microwave, or physico-chemical pretreatments such as steam explosion, are also able to disrupt the cell wall structure, and they are more cost-effective than mechanical pretreatments. However, the former lack their industrial maturity, whereas the latter may generate toxic compounds [10,14,15]. Chemical pretreatments, mainly alkaline and acid pretreatments, while often very efficient in increasing biogas production through the removal of either hemicelluloses or lignin, have the main disadvantages of being pretty expensive and not very environmentally friendly, and they can also generate AD inhibitors in the process such as furans and phenols compounds [16]. On the other hand, biological pretreatments, which mainly use enzymes or fungi, are environmentally friendly, and do not generate inhibitors, but they are expensive and constitute pretty slow processes [17].

Twin-screw extrusion is a continuous mechanical process allowing biomass disruption with strong mixing and shearing forces generated at least by the intermeshing of the two rotating screws [18] and, in most cases, by the use of specific shearing screw elements along the screw profile [19]. Twin-screw extrusion is considered a promising process to simultaneously apply mechanical and thermal pretreatments for lignocellulosic substrates, explaining why it was investigated since the 1990s [20]. This technology presents key parameters that can be set according to the required purposes, i.e., configuration parameters such as screw elements and module types, and operational parameters such as screw rotation speed, temperature profile, solid-to-liquid ratio and feeding rates [21]. Twin-screw extrusion processes can be implemented from ambient to hot temperatures, and they can adapt to many types of biomasses. Twin-screw extrusion also has the possibility of combining mechanical pretreatment with other categories of pretreatment, either thanks to the addition of chemicals in the case of reactive extrusion [22] or enzymes in the case of bioextrusion [23,24]. Finally, twin-screw extrusion is an easy scalable technology with excellent repeatability results when transferred from a laboratory scale to pilot and industrial ones [25,26].

Over the past decade, several studies have especially focused their efforts on assessing the effect of twin-screw extrusion pretreatment for AD. Several biomasses including rice, wheat or corn straw, grass, sprout stem, vine shoot or miscanthus were proven to generate better methane yields (from a 16% to 72% increase) after mechanical twin-screw extrusion pretreatment [27,28,29,30]. Triticale, when harvested fresh at the milky stage as a catch crop, is another biomass of interest for AD as it presents a lower lignin content than other cereal straws harvested at the fully ripe stage [31] and, to the best of our knowledge, has not yet been pretreated through twin-screw extrusion. Furthermore, for all the references listed above, a particle size reduction up to a 2–40 mm range has been conducted beforehand, which may minimize the real efficiency of mechanical pretreatment through twin-screw extrusion. Lastly, a 60–100 °C temperature range has also been set inside the extruder barrel, which could add thermal pretreatment in addition to the mechanical one.

The aim of this study was to assess the effect of twin-screw extrusion mechanical pretreatment on biomethane production from different agro-industrial, agricultural and catch crop biomasses. Two different screw profiles were tested on four biomasses (i.e., sweetcorn by-product, triticale, corn stover, wheat straw), and twin-screw extrusion treatment was conducted at ambient temperature while avoiding particle size reduction before extrusion. Then, the influence of twin-screw extrusion pretreatment on their physico-chemical properties and their performances in AD were evaluated.

2. Materials and Methods

2.1. Feedstocks and Inoculum

Four feedstocks were selected among agro-industrial wastes, agricultural by-products or energy catch crops. These were chosen from among lignocellulosic biomasses available in the south-west part of France, and in sufficient quantities for potential large-scale exploitation through biogas plants. Sweetcorn by-product (i.e., husk and cob) recovered from Soleal–Bonduelle factory (Bordères-et-Lamensans, France) is referred to as “SB”. Whole fresh triticale harvested in a plot located in the city of Pavie (France) is referred to as “WT”. Corn stover harvested in the city of Cescau (France) is referred to as “CS”. Lastly, wheat straw, also harvested in the city of Cescau, is referred to as “WS”. All four biomasses were comb milled using a hammer mill (Goulu N, Electra, Poudenas, France). Then, the only WS was also processed through a crushing mill (Bro140, Electra, Poudenas, France) equipped with a 15 mm grid. Comb or crush milled samples before extrusion are referred to as “CM”. WT was then dried at 50 °C during 24 h for conservation purposes, and then rehydrated at initial humidity (i.e., 69% moisture content) by mixing it with water in a concrete mixer before extrusion.

Anaerobic digester inoculum was recovered from an industrial biogas plant from TotalEnergies located in the city of Bénesse-Maremne (France). Inoculum was maintained in a 5 L glass bioreactor at 38 °C under stirring and anaerobic conditions before performing Biochemical Methane Potential (BMP) tests. Main inoculum parameters were 3.9 ± 0.1 TS, 2.7 ± 0.1 VS, 7.8 ± 0.0 pH, 1.5 ± 0.0 gCH3COOH/L, 4.1 ± 1.4 gN-NH4+/L and 0.17 ± 0.0 FOS/TAC ratio.

2.2. Extrusion Pretreatment

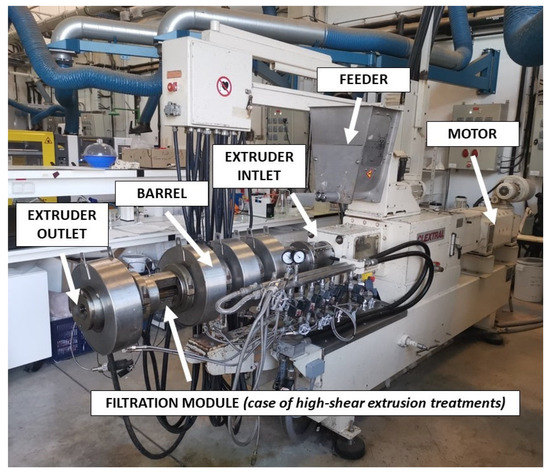

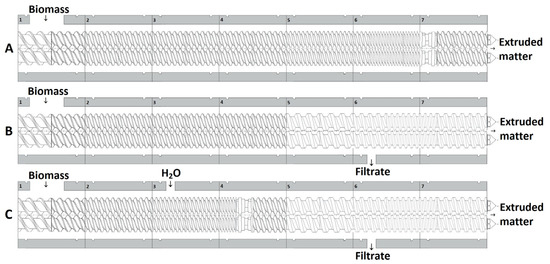

A BC 45 twin-screw extruder (Clextral, Firminy, France) was used for extrusion pretreatment (Figure 1). The machine is made of 7 consecutive modules, each 200 mm in length, and its screw elements have a diameter of 55 mm and lengths of either 50 or 100 mm. Three different screw profiles were investigated (Figure 2). The first screw profile (A) is referred to as soft extrusion (SE), and it was tested on all four biomasses. It consists of trapezoidal double-thread screw elements (T2F) on module 1, followed by conveying double-thread screw elements (C2F) on modules 2 to 6, and then 5 kneading (i.e., bilobal) elements (BL22) with a −45° angle at the early beginning of module 7, followed by C2F elements up to the extruder outlet. The second screw profile (B) is referred to as high-shear extrusion (HE), and it was only used on SB and WT. It also starts with T2F elements on module 1, followed by C2F elements on modules 2 to 4, then conveying single-thread screw elements (C1F) in modules 5 and 6, and lastly reverse single-thread screw elements with grooves (CF1C) and C1F elements on module 7. For this screw profile, a filter section was positioned at the level of module 6 to allow the collection of a liquid separately from the solid and thus avoid waterlogging the machine over time. It consisted of six semi-cylindrical grids with eight per square centimeter conical holes with 1 mm inside diameter and 2 mm outside diameter. The third and last screw profile (C), referred to as high-shear extrusion with rehydration (HER), is actually only a variation of the second one. It was needed as CS and WS required rehydration at the moment of high-shear extrusion to prevent the machine from blocking. It only differs from profile B by the addition of 5 BL22 elements with a +45° angle on module 4 to favor intimate mixing between the solid and water. The latter was injected thanks to a piston pump at the beginning of module 3. HE and HER screw profiles are expected to generate the same mechanical pretreatment as the intense mechanical shear zone in module 7, made of CF1C elements, and are perfectly identical.

Figure 1.

Photograph of the Clextral BC 45 twin-screw extruder that has been used in this study.

Figure 2.

Schematic representation of the three screw profiles tested in the Clextral BC 45 twin-screw machine. (A) Soft extrusion, (B) high-shear extrusion and (C) high-shear extrusion with rehydration.

During extrusion tests, neither heating nor temperature regulation were applied but material temperature was measured at the level of the stress zone (i.e., module 7). Screw rotation speed was set at 60 rpm. Biomass supply was fulfilled either manually in the case of SB, WT, CS and WS for SE, and in the case of SB and WT for HE, or with a volumetric twin-screw feeder in the specific case of CS and WS for HER. CS and WS were slightly rehydrated by mixing them with water in a concrete mixer up to a 70% total solid content (TS) and 75% TS, respectively, before SE as they were too dry to be extruded as such. Extrudate samples and filtrate ones for the HE and HER configurations were collected after reaching the extruder stability. For each test, three samplings were conducted during 4 min, and this enabled the calculation of mean outlet flow rates. The latter were then used through a material balance to calculate the raw material inlet flow rate, based on the dry matter contents of raw and extruded solid samples plus that of the filtrate for HE and HER.

2.3. Biochemical Methane Potential (BMP)

Extruded samples were dried at 40 °C for 24 h before BMP. Batch BMP values were assessed in 569 mL glass flask with a working volume 269 mL at 37 °C with a stirring speed of 75 RPM for a duration of 32 days corresponding to time needed to reach a daily biomethane production <1%. An 18 mL macro element solution (Na2HPO4 22.4 g/L; NH4Cl 10.6 g/L; KH2PO4 5.4 g/L; MgCl2 2 g/L; CaCl2 1.5 g/L; FeCl2 0.4 g/L), 0.3 mL oligoelement solution (CoCl2 0.1 g/L; MnCl2 0.05 g/L: NiCl2 0.01 g/L; ZnCl2 0.005 g/L; H3BO3 0.005 g/L; Na2SeO3 0.005 g/L; CuCl2 0.003 g/L; NaMoO4 0.001 g/L) and 15 mL bicarbonate buffer solution (NaHCO3 50 g/L) were added the medium to ensure good bacterial development. Carboxymethylcellulose was used as positive control and sole inoculum as negative control (BMP produced was then subtracted from results). Extrudate and filtrate samples from HE/HER were reassembled as one sample keeping the same proportions as at the extrusion outlet. A 0.5 gVS substrate/gVS inoculum ratio was set, and 7–8.5 pH range check were realized to avoid initial medium acidification. Flasks were flushed with nitrogen at the beginning of the trials to ensure anaerobic condition, then were sealed with impermeable red butyl rubber septum-type stoppers. BMP tests were performed in duplicate.

Biogas analyses were performed by using an Agilent 990 Micro GC with two columns: one at 80 °C and 200 kPa with argon as carrier phase for H2, O2, N2 and CO2, one at 60 °C and 150 kPa with helium as carrier phase CH4 and one for CO2 and H2S. Injector temperature was 80 °C. Biogas production was calculated from pressure increase measured with a manometer.

Elemental analyses (CaHbNcSdOe) of dried samples were performed to calculate their maximal theorical BMP (BMPth) using Buswell equation [32,33]:

Khongchamnan et al.’s [34] elemental analysis of lignin was also used to calculate lignin maximal theorical BMP (621 NmLCH4/gVS), which was then used to determine samples’ adjusted theorical maximal BMP (BMPth adjusted) using the following formula:

The biodegradability index (BI) was finally calculated using the following equation:

2.4. Analytical Methods

2.4.1. Sample Preparation for Analysis

Parts of raw and extruded samples were dried at 105 °C until constant weight for total solid content (TS) determination, and they were then mineralized at 550 °C during 8 h for ash and volatile solid content (VS) determination according to the National Renewable Energy Laboratory (NREL) procedures [35]. The rest of raw and extruded samples were dried at 40 °C during 24 h for further characterizations. Parts of dried samples were used as such for granulometry and tapped density measurements, and the remaining dried samples were milled with a 1 mm grid on a microfine grinder drive (MF 10 basic, IKA Werke, Staufen im Breisgau, Germany). Two mechanical sieves (aperture sizes of 0.8 and 0.18 mm, respectively) and a bottom plate were used on a vibratory sieve shaker (AS 200, Retsch, Hann, Germany) during 10 min at a 3 mm amplitude to recover sample fractions depending on their particle sizes. Sample fractions between 0.8 and 0.18 mm were used for lignocellulosic composition analysis, whereas fractions under 0.18 mm were used for cellulose crystallinity assessment.

2.4.2. Fiber Composition

Fiber composition of lignocellulosic samples was determined in triplicate according to an adapted protocol [36] from the National Renewable Energy Laboratory (NREL) procedures [37]. Water and then 96% (v/v) ethanol extractions were performed on an extraction system (Fibertec FT 122, Foss, Hillerød, Denmark) using 1 g of dry sample and 100 mL of boiled solvent at 100 °C and atmospheric pressure for 1 h. Cellulose, hemicelluloses and lignin contents were assessed with a two-step hydrolysis using a 72% (w/w) sulphuric acid at 30 °C for 1 h and then a 4% (w/w) solution after dilution during 1 h at 121 °C, followed by filtration. Acid-insoluble lignin in residues was determined by weight loss after calcination during 8 h at 450 °C. Part of the extracts was then used for acid-soluble lignin on UV spectrophotometer (UV-1800, Shimadzu, Kyoto, Japan) at 320 nm for CS samples and at 240 nm for the other ones, and the rest of the extracts were neutralized with calcium carbonate until reaching pH 5–7 and then filtered using a 0.2 µm cellulose acetate filter. Analysis of sugar monomers (i.e., arabinose, glucose, galactose, xylose and mannose) was performed on a Dionex (Sunnyvale, CA, USA) ICS-3000 type ion chromatography HPLIC system with a pumping device, an auto-injector, an electrochemical detector with a gold electrode and an Ag/AgCl reference electrode. A pre-column (4 × 50 mm, Dionex) connected to a Carbopac PA1 column (4 × 250 nm, Dionex) was used for the stationary phase with a 1 mM sodium hydroxide solution as an eluent. A total of 25 μL of samples were injected automatically with separation of sugars carried out at a flow rate of 1 mL/min at 25 °C. A range of standards was made from 1 to 100 mg/L to undertake external calibration for the quantification of sugar monomers. Chromeleon analysis was conducted with the 6.8 version of Dionex processing software.

2.4.3. Granulometry and Tapped Density

Seven mechanical sieves (aperture sizes of 4.0, 2.0, 1.0, 0.8, 0.5, 0.25 and 0.125 mm) and a bottom plate were used to measure, in triplicate, the particle size distribution using the Retsch AS 200 vibratory sieve shaker during 10 min at a 3 mm amplitude.

A bulk density tapping instrument (Densi-Tap, Ma.Tec, Novara, Italy), modified to support a 1000 mL graduated cylinder, with a cam shaft speed of 250 rpm and a stroke travel of 3.2 mm, was used to determine tapped density. A total of 1000 taps were repeated until the tapped volume did not change between two consecutive cycles. The final tapped volume was read on the graduated cylinder. All determinations were conducted in triplicate.

2.4.4. Cellulose Crystallinity

Cellulose crystallinity was determined using an X-ray diffraction (XRD) instrument (D8 Advance, Brucker, San Jose, CA, USA) with a 0.154 nm wavelength, Cu/Kα radiation at 40 kV and 40 mA tube current. Samples were implemented with a speed of 1°/min, in a range of 2θ varying from 6° to 30°, and a step size of 0.0303° at room temperature.

The crystallinity index (Cr) was determined using the following equation [38]:

where:

I002 is the intensity of the crystalline portion of the biomass (cellulose) at 2θ = 22°;

Iamorphous is the peak of the amorphous portion at 2θ = 16°.

Analyses were conducted in triplicate.

2.5. Data Analyses

Kinetic study of the biomethane production was assessed by applying a model based on the modified Gompertz equation [39]:

where:

B: cumulative biomethane production (NmL/gVS);

BMP∞: maximal biomethane production (NmL/gVS);

Rm: specific biomethane production rate (NmL/gVS.day);

λ: lag phase time (day).

Kinetic parameters were determined by minimizing the sum of the least squares between the observed and predicted values.

2.6. Statistical Analyses

For statistical analyses made on chemical composition, tapped density, cellulose crystallinity and experimental BMP, Student’s tests were conducted with statistical significance level of p < 0.05 on the Microsoft Office Excel software (Microsoft, Albuquerque, NM, USA). Data are expressed as means ± standard deviations (s.d.).

3. Results and Discussion

3.1. Description of the Twin-Screw Extrusion Pretreatments

Usually, when working on laboratory scale extruders, biomasses are first reduced to smaller particle sizes (within a 1 mm to 2 cm range) before extrusion to enable stable device feeding [25,40,41]. In this study, in order to be as close as possible to pilot or industrial reality, biomasses were extruded fresh and they were just comb milled to avoid any influence of additional mechanical pretreatment before extrusion [4]. Measured parameters during samplings and material balances are given in Table 1.

Table 1.

Measured parameters and material balances of the different twin-screw extrusion pretreatments.

Dry inlet flow rates were intended to be set to 5 kg/h. However, from a practical point of view, it was not possible to achieve precisely this 5 kg/h dry inlet flow rate as substrates were manually fed into the machine for the SE and HE configurations. In the case of SE, dry inlet flow rates were 5.3 kg/h, 5.6 kg/h and 5.1 kg/h, respectively, for SB, WT and WS. For CS, it was only 3.7 kg/h due to there being coarser and less flexible solid particles in the starting material. When using the HE configuration, trials conducted from SB and WT revealed rather different inlet flow rates, i.e., 7.2 kg/h and 3.7 kg/h, respectively. Regarding HER configuration, which was applied to CS and WS only, rehydration should have been set to a 75/25 water-to-dry matter ratio. However, this could not be performed as such because when this rehydration rate was applied, it generated non-homogeneous rehydration in the extruder and a too low moisture content, resulting in the blocking of the machine. CS and WS were instead rehydrated to higher water-to-dry matter ratios, which were respectively 85/15 and 82/18.

As no temperature regulation was applied during the extrusion pretreatment, the temperature in the stress zone (i.e., module 7) was probably too low to allow good rehydration according to the literature [42,43]. However, this solution has the advantage of being less energy-consuming and therefore less expensive. Extrudate-to-filtrate ratios expressed in terms of dry mass for the HE/HER configurations were 80/20 for SB, 84/16 for WT, 90/10 for CS and 92/8 for WS.

The decrease in the proportion of dry matter in the filtrate in the case of the HER configuration in need of rehydration at the moment of twin-screw extrusion seems to correlate with the hypothesis of superficial rehydration. SB, WT, CS and WS initial dry matter contents increased by 2.8%, 2.6%, 6.0% and 4.6%, respectively, using the SE configuration, and they increased much more, i.e., by 15.4%, 42.3%, 67.0% and 59.0%, respectively, using the HE/HER ones. It has to be noted here that for the HER configuration, water injected in the extruder at the moment of the pretreatment was taken into account for calculating the above-mentioned increases in dry matter content for the CS and WS solid materials.

The high compression action of the CF1C reverse screw elements used in the HE and HER screw profiles reflects the increase in mechanical shear applied to biomasses in comparison with the less restrictive bilobal elements used during soft extrusion. This compression action appeared to be more intense for CS and WS as illustrated by the higher values of the extrudate’s dry matter contents.

Moreover, when comparing the SE and HE/HER configurations with each other, temperature ranges in the stress zone increased from 18–22 °C to 31–36 °C for SB, from 26–27 °C to 30–34 °C for WT, from 32–34 °C to 28–42 °C for CS and from 27–32 °C up to 58–63 °C for WS, which illustrates once again the mechanical stress increase using the high-shear extrusion conditions, especially with WS and, to a lesser extent, with CS. In the same way, the motor current range increased between SE and HE/HER from 14–15 A to 16–25 A for SB, from 27–35 A to 41–47 A for WT, from 11–19 A to 27–37 A for CS and from 12–21 A to 27–30 A for WS. These amperage increases were further proof of the increase in mechanical shear applied to the biomass using CF1C reverse screws instead of BL22 kneading elements.

These results are consistent with those found in the literature where the reverse screw elements used in HE/HER are presented as stronger flow-restricting elements than the kneading elements mounted with reverse pitch used in SE [19,44].

3.2. Effect of the Twin-Screw Extrusion Mechanical Pretreatment on the Chemical Composition of Biomasses

The chemical compositions of biomasses before and after extrusion are shown in Table 2. SB is characterized by 30%TS of cellulose, 17%TS of hemicelluloses and 15.5%TS of Klason lignin, which is perfectly in accordance with the literature data as Lallement et al. [45] showed 27–30% content for cellulose, 16–21% for hemicelluloses and 13–16% for Klason lignin for maize residues. WT is characterized by 27%TS of cellulose, 24.5%TS of hemicelluloses and 18%TS of Klason lignin, which is similar to the already published data for lignin and hemicelluloses but a bit lower for cellulose: e.g., 36%TS, 25%TS and 16%TS for cellulose, hemicelluloses and lignin, respectively, in Pronyk et al. [46], and 35%TS, 23%TS and 17.5%TS in Tamaki and Mazza [47].

Table 2.

Chemical compositions of solid samples before and after twin-screw extrusion pretreatment.

As triticale was harvested fresh, its lignocellulosic composition may differ from the literature data in which it was harvested at a late stage [48]. In addition, triticale is not a species that is as documented as others such as wheat or maize. Thus, its composition could also differ from those of other varieties as triticale includes over 320 species in the European catalogue [49]. CS contained 32%TS of cellulose, 19%TS of hemicelluloses and 17%TS of Klason lignin, which is similar to the already published data, i.e., 28–44% TS, 13–25%TS and 14–26%TS, respectively, for cellulose, hemicelluloses and lignin [50]. WS contained 34%TS of cellulose, 19%TS of hemicelluloses and 22.5%TS of Klason lignin, which is also quite similar to the already published data, i.e., 23–36%, 11–31% and 10–23%, respectively, for cellulose, hemicelluloses and lignin [51], although presenting high cellulose and Klason lignin contents.

Overall, there are slight variations regarding SB before and after extrusion even if a small but statistically significant reduction in the content of extractables was observed, especially after HE, due to their partial solubilization and then their removal by filtration in the case of HE. Regarding WT, for all families of molecules quantified, the differences in composition between CM, SE and HE are systematically significant from a statistical point of view. Only a small solubilization of extractables (5%), leading to an increase in cellulose (5%) and in lignin (1.5%), simultaneously with a small decrease in hemicelluloses (3%), is observed after SE. However, a much more significant solubilization of extractables (15%) is observed after HE, also leading to the increases in both cellulose (8%) and lignin (6%) and a very small decrease in hemicelluloses (1%).

As shown earlier with the motor’s amperage, HE was more intense for WT than for SB, which led to a much higher proportion of extractables removed by filtration and thus to a much more significant reduction in the content of extractables inside the WT-based extrudate. For CS, there is a moderate difference in the biomass chemical composition after SE. However, there is again an important solubilization of extractables (13.5%) after HER, leading as well to statistically significant increases in cellulose (9%), hemicelluloses (3.5%) and lignin (3%). Finally, WS shows similar trend as CS with no drastic modification in chemical composition after SE but a solubilization of extractables (5.5%), leading, at the same time, to the increases in cellulose (2%), hemicelluloses (1.5%) and lignin (2%) after HER. Moreover, for each biomass, the lower extractable content measured after HE/HER was always statistically different compared to SE.

Even if Menardo et al. [26] used a mixture of rice straw silage, maize silage and triticale silage in their study, no literature was found about whole triticale or triticale straw extrusion. However, as a rye and wheat hybrid [52], it might be approximated as such. Vandenbossche et al. [53] reported slight composition variations as well when extruding wheat straw with reverse single-thread screw elements despite an internal heating temperature of 80 °C. Moreover, Zheng et al. [54] showed no difference in corn cob composition after using conveying, kneading or reverse elements through twin-screw extrusion. Finally, in the case of rehydrated corn stover, which was mechanically treated with a twin-screw extruder, Wang et al. [55] showed a slight increase for cellulose (1%), and slight decreases for hemicelluloses (1%) and, especially, lignin (0.2%) contents. Lastly, in their very recent study, Elalami et al. [56] showed no statistical difference in the chemical composition of corn stover before and after extrusion.

In conclusion, although HE/HER configuration allowed partial solubilization of extractables, which significantly impacted the extrudate’s composition in lignocellulosic compounds from a statistical point of view, mechanical extrusion only slightly altered the biomass lignocellulosic composition.

3.3. Effect of the Twin-Screw Extrusion Mechanical Pretreatment on Granulometry

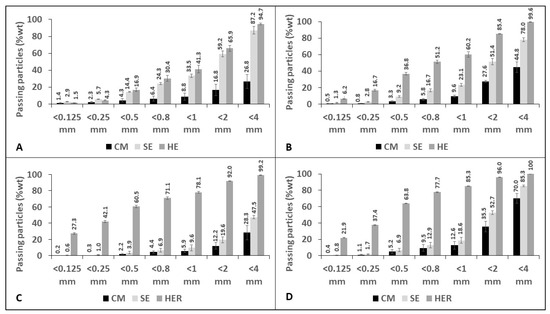

The samples’ cumulated granulometries before and after extrusion treatments are shown in Figure 3 and expressed in % of total particle weight (%wt). Overall, SE and HE had quite similar effects regarding SB: only 2.3%wt of particles were smaller than 0.25 mm before extrusion instead of 5.7%wt after SE and 4.3%wt after HE. In the same way, for bigger particles, 6.4% of them were smaller than 0.8 mm before extrusion instead of 24.3% after SE and 30.4%wt after HE, and 16.8%wt of particles were smaller than 2 mm before extrusion instead of 59.3%wt after SE and 65.9%wt after HE.

Figure 3.

Cumulated granulometries of solid samples before and after twin-screw extrusion pretreatment: (A) SB, (B) WT, (C) CS and (D) WS.

For WT, the results obtained are really different: only 0.8%wt of particles were smaller than 0.25 mm before extrusion instead of 2.8%wt after SE and 16.7%wt after HE. In the same way, 5.8%wt of particles were smaller than 0.8 mm before extrusion instead of 16.7%wt after SE and 51.2%wt after HE, and 27.6% of particles were smaller than 2 mm before extrusion instead of 51.4%wt after SE and 85.4%wt after HE. In the case of WT, the SE effect in particle size reduction was less important than for SB. However, the HE one was much more important, with the high-shear extrusion process contributing to a significant additional reduction in particle size in comparison with the soft one.

Concerning CS, only 0.3%wt of particles were smaller than 0.25 mm before extrusion, and this mass content increased to 1%wt after SE and to 42.1%wt after HER. Identically, 4.4%wt of particles were smaller than 0.8 mm before extrusion instead of 6.9%wt after SE and 71.1%wt after HER. For particles smaller than 2 mm, their mass content was 12.2%wt before extrusion, 19.6%wt after SE and 92%wt after HER. The important reduction in the particle size after HER in comparison with SE is therefore even more pronounced for CS than for WT. Oppositely, the SE effect in particle size reduction was less important than for SB and WT.

Quite the same conclusions can be made for WS. Only 1.1%wt of particles were smaller than 0.25 mm before extrusion instead of 1.7%wt after SE and 37.4%wt after HER. In the same way, 9.5%wt of particles were smaller than 0.8 mm before extrusion instead of 12.9%wt after SE and 77.7%wt after HER, and 35.5%wt of particles were smaller than 2 mm before extrusion instead of 52.7%wt after SE and 96%wt after HE. SE and HER effects in particle size reduction are thus similar for WS and CS samples. However, in contrast to the other substrates, one should be aware that WS had to be ground once more through a 15 mm grid before extrusion, which must have already reduced its particle size.

In their study, Duque et al. [57] showed a small (i.e., 20%) reduction of particles with a size that was more important than the 3.14 mm on extruded barley straw processed with reverse screws as samples were crush milled with a 5 mm mesh before extrusion, while Zheng et al. [54] showed a clear reduction in particle size after extrusion in the case of corn cob but no difference depending on the type of screws used along the profile (i.e., conveying, kneading or reverse elements). However, in that study, corn cob particles were already ground to particle sizes between 0.6 and 0.76 cm before extrusion, meaning that the effect of reducing the size of large particles more or less at the moment of the extrusion pretreatment depending on the screw elements used may probably not have been illustrated properly. In contrast, Garuti et al. [58] showed a net reduction of 7.1% of particles with a size of more than 5 mm, simultaneously with a 19.6% increase in particles less than 0.3 mm in diameter after extrusion conducted on an agricultural waste mix.

In the present study, the absence of fine milling before extrusion, although being more restrictive for the application of the mechanical pretreatment in the extruder as shown earlier, showed more realistic particle size reduction at the moment of the only pretreatment. This reduction in particle size was evidenced for the four biomasses treated, and, even if both SE and HE pretreatments resulted in the same size reduction for SB, the high-shear extrusion pretreatment was much more restrictive for WT, and especially for CS and WS. This important reduction in size with the HER configuration (i.e., CS and WS feedstocks) is probably the consequence of superficial rehydration inside the extruder. With cell walls within the particles being less moist and therefore more rigid, a reduction in size was probably favored.

3.4. Effect of the Twin-Screw Extrusion Mechanical Pretreatment on Tapped Density

The evolutions of tapped densities before and after extrusion are shown in Table 3, and the results are in general agreement with those of particle size distribution presented previously (Figure 3). After SE, the tapped densities of all substrates increased significantly, with increases of 2.7, 4.8, 2.4 and 2.6 times for SB, WT, CS and WS, respectively, indicating particle refining even with soft extrusion. After HE/HER, tapped densities increased even more with increases of 5.3, 5.4, 7.0 and 8.5 times, respectively, for SB, WT, CS and WS. This increase in tapped densities was thus consistent with the particle size reduction discussed earlier, as smaller particle sizes led to a better stacking of the particles between them after compaction, and therefore a reduction in the inter-particle voids and, as a result, higher densities. This was also confirmed by Chen et al. [27] who showed that the bulk density of rice straw increased by 2.2-fold after extrusion. However, when looking at SB results, and taking into account that particle sizes were quite similar after SE and HE pretreatments (Figure 3), it would have been expected for values of tapped densities to be closer to each other. Likewise, WT tapped density after HE would have been expected to be much higher than that after SE. In this case, one possible explanation would be the formation of aggregates during sample drying after extrusion that would have been separated after particle size distribution measurements but not in the case of the tapped density ones.

Table 3.

Tapped densities and cellulose crystallinities of solid samples before and after twin-screw extrusion pretreatment.

3.5. Effect of the Twin-Screw Extrusion Mechanical Pretreatment on Cellulose Crystallinity

As shown in Table 3, no cellulose crystallinity change was observed after extrusion for SB, WT and WS. In contrast, the 8.6% decrease in cellulose crystallinity of CS after HER pretreatment was statistically significant. Regarding the results for CS, the most logical explanation would be that HER pretreatment was more impactful on it than on the other biomasses as it was previously illustrated by its high decrease in particle size (Figure 3) and its much higher tapped density value (Table 3). In the literature, mechanical pretreatments are generally known to be efficient in the decrystallization of cellulose [59]. However, it is not always the case with extrusion pretreatments. While Zhang et al. [60] achieved an impressive 48.4% cellulose crystallinity reduction on rice straw with only extrusion, Zhang et al. [22] instead did not observe a decrease in cellulose crystallinity for corn stover after reactive alkali extrusion. Here, the most likely reason for the cellulose crystallinity reduction of CS after HER is that its more rigid morphological structure compared to other biomasses was more affected by the high-shear twin-screw extrusion mechanical pretreatment.

3.6. Effect of the Twin-Screw Extrusion Mechanical Pretreatment on BMP Results

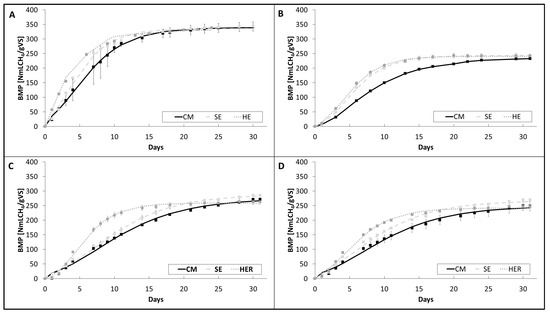

Figure 4 shows experimental BMP and the BMP kinetics using the modified Gompertz equation model, while their parameters are gathered in Table 4. The experimental BMP tests showed methane production ranges of 338–345 NmL/gVS for SB, 233–247 NmL/gVS for WT, 264–286 NmL/gVS for CS and 247–270 NmL/gVS for WS, which is in accordance with standard values for lignocellulosic biomasses [61,62]. SB shows the highest methanogenic potential with a 40–48% increase compared to WT, a 20–28% increase compared to CS and a 27–37% increase compared to WS, which definitely makes it the best candidate for biomethane production followed by CS.

Figure 4.

Experimental BMP (square symbols) and BMP kinetics using the modified Gompertz equation model (lines) before and after twin-screw extrusion pretreatment: (A) SB, (B) WT, (C) CS and (D) WS. BMPs from HE/HER samples were assessed after mixing extrudate and filtrate samples in the same proportions as at the extrusion outlet.

Table 4.

Experimental BMP, maximal and adjusted maximal theorical BMP and kinetics parameters of modified Gompertz equation model before and after twin-screw extrusion pretreatment.

However, no BMP increase or BMP decrease provided by SE or HE/HER pretreatments was observed from a statistical point of view, and this for all the biomasses tested. Therefore, extrusion had no impact on the experimental maximal BMP. Wahid et al. [63] and Victorin et al. [64] also reported no statistical increase or statistical decrease in final BMP after the extrusion of wheat straw. Hjorth et al. [18] also reported no statistical increase in BMP after 90 days on extruded barley straw. This confirms that the mechanical treatment provided by extrusion does not generate or allow a better degradation of the compounds usually non-valorized during AD, which also correlates with the lack of cellulose crystallinity variation shown earlier.

Adjusted maximal theorical BMPs are proposed in this study as a way to calculate a more realistic estimation of the real biodegradability of the substrates as the monolignols constituting the native lignin are not consumed during AD [65]. SB, WT, CS and WS achieved around 89%, 66%, 76% and 74%, respectively, of adjusted theoretical biodegradability after CM, SE and HE/HER pretreatments. Therefore, a BMP improvement from 11% to 34% is still accessible for these biomasses according to the adjusted theorical biodegradability. The higher biodegradability shown by SB compared to the other biomass is in agreement with the 132 AD feedstock database established by Lallement et al. [45], who reported maximal theoretical biodegradabilities of 72% for agro-industrial residues and 56% for lignocellulosic matter, and this correlates with its higher experimental CH4 production.

BMP kinetics showed that most of the biomethane was produced within the first 10–20 days of BMP tests for all biomasses, which is usual according to the literature data [63,64]. A modified Gompertz model was used to model BMP kinetics as it is one of the most accurate models for anaerobic digestion processes [66]. The predicted BMP showed methane production ranges of 330–339 NmL/gVS for SB, 229–244 NmL/gVS for WT, 259–284 NmL/gVS for CS and 242–265 NmL/gVS for WS. These results are slightly lower to the experimental ones but nonetheless are very close as proven by an R2 correlation coefficient of more than 0.99 for all kinetics, and, this is expected when using a modified Gompertz model [67,68,69].

Lag phases were very short with an initial 0.2–1.3 day range, and they varied slightly with a 0.2–1.3 day range after SE and with a 0.01–1.4 day range after HE while retaining their short durations, which shows excellent adequacy between used inocula and substrates, and illustrates the easily digested biomass. This result is also correlated with the higher biodegradability of SB compared to WT, which, respectively, had the shortest and longest initial lag phases. The impact of pretreatment seems more impactful in the case of a longer initial lag phase as demonstrated by Tsapekos et al. [70] who managed to reduce the grass lag phase from 3.4 to 2.7 days thanks to a mechanical pretreatment.

The specific rate constant increased for all biomasses after SE and even more after HE or HER. For SB, it increased by 26% after SE and by 81% after HE. For WT, it increased by 56% after SE and by 67% after HE. For CS, it increased by 13% after SE and by 107% after HER. Lastly, for WS, it increased by 21% after SE and by 72% after HER. This demonstrates that the morphological modifications of the biomasses induced by the twin-screw extrusion mechanical pretreatments, especially the high-shear one, allowed better accessibility and degradability of methanizable compounds during digestion by the anaerobic microorganisms, which correlates with the particle size reduction and increase in tapped densities discussed earlier. Chen et al. [27] also reported a decrease in anaerobic digestion time after rice straw extrusion as well as Pérez-Rodrígez et al. [71] after the extrusion of corn cob. This improvement in the specific rate constant is a great indicator of how a substrate would react in the case of continuous biogas production [26], and the impact of SE and especially HE/HER pretreatments on the four biomasses evidenced in this study indicates promising perspectives in reducing their hydraulic residence times [72]. As a direct consequence, a smaller sizing of new biogas plant bioreactors could be considered, thus allowing a diminution in their capital expenditures (CAPEX) and their operating expenditures (OPEX) [73].

4. Conclusions

The effect of the mechanical pretreatment induced through twin-screw extrusion was able to greatly impact the physico-chemical properties of all four biomasses tested, at different levels depending on the selected screw profile as illustrated by the increase in the proportion of smaller size particles correlated with the impressive increase in tapped densities. The more intense mechanical shear effect of the high-shear extrusion pretreatments also allowed a significant solubilization of water-soluble compounds just as the reduction in the corn stover cellulose crystallinity by 8.6% showed, without affecting those of other biomasses. With soft extrusion, no modification of chemical composition and cellulose crystallinity was observed. Sweetcorn by-products revealed the highest BMP values (i.e., 338–345 NmL/gVS), followed by corn stover (264–286 NmL/gVS), wheat straw (247–270 NmL/gVS), and lastly, whole triticale (233–247 NmL/gVS), thereby illustrating their great potential as inputs for biogas production. Even if none of the physico-chemical modifications induced by the two applied extrusion pretreatments were proven to statistically improve the maximal BMP production, kinetic analysis revealed that both extrusion pretreatments, and especially the high-shear one, were able to increase the specific rate constant by up to 56% for soft extrusion and even 106% for high-shear extrusion. Further studies on either bioextrusion (i.e., addition of enzymes) and/or reactive extrusion (i.e., addition of chemicals) as additional pretreatments, known to improve biomethane production, are recommended to attain a synergistic effect with the only mechanical pretreatment.

Author Contributions

Conceptualization, A.C., P.E., F.M., V.V. and C.S.; methodology, A.C., P.E., F.M., V.V. and C.S.; validation, P.E., F.M., V.V. and C.S.; formal analysis, A.C.; investigation, A.C.; resources, P.E. and F.M.; writing—original draft preparation, A.C.; writing—review and editing, P.E., F.M., V.V. and C.S.; supervision, P.E., F.M., V.V. and C.S.; project administration, P.E. and C.S.; funding acquisition, P.E. and C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by ANRT (National Association for Research and Technology in France) under grant number 2021/0737.

Data Availability Statement

All the data are described in the Figures and Tables.

Acknowledgments

The authors would like to express their sincere gratitude to Ovalie Innovation (Auch, France) for supplying the batch of whole triticale used for the purpose of this study. They would also like to deeply thank the PERL and CIRIMAT laboratory teams for their respective help with BMP and cellulose crystallinity assessments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abas, N.; Kalair, A.; Khan, N. Review of fossil fuels and future energy technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, J. Enhancement of methane production in anaerobic digestion process: A review. Appl. Energy 2019, 240, 120–137. [Google Scholar] [CrossRef]

- Ampese, L.C.; Sganzerla, W.G.; Di Domenico Ziero, H.; Mudhoo, A.; Martins, G.; Forster-Carneiro, T. Research progress, trends, and updates on anaerobic digestion technology: A bibliometric analysis. J. Clean. Prod. 2022, 331, 130004. [Google Scholar] [CrossRef]

- Konan, D.; Koffi, E.; Ndao, A.; Peterson, E.C.; Rodrigue, D.; Adjallé, K. An Overview of Extrusion as a Pretreatment Method of Lignocellulosic Biomass. Energies 2022, 15, 3002. [Google Scholar] [CrossRef]

- Hendriks, A.T.W.M.; Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef]

- Tye, Y.Y.; Lee, K.T.; Wan Abdullah, W.N.; Leh, C.P. The world availability of non-wood lignocellulosic biomass for the production of cellulosic ethanol and potential pretreatments for the enhancement of enzymatic saccharification. Renew. Sustain. Energy Rev. 2016, 60, 155–172. [Google Scholar] [CrossRef]

- Gissén, C.; Prade, T.; Kreuger, E.; Nges, I.A.; Rosenqvist, H.; Svensson, S.-E.; Lantz, M.; Mattsson, J.E.; Börjesson, P.; Björnsson, L. Comparing energy crops for biogas production—Yields, energy input and costs in cultivation using digestate and mineral fertilisation. Biomass Bioenergy 2014, 64, 199–210. [Google Scholar] [CrossRef]

- Xu, N.; Liu, S.; Xin, F.; Zhou, J.; Jia, H.; Xu, J.; Jiang, M.; Dong, W. Biomethane Production from Lignocellulose: Biomass Recalcitrance and Its Impacts on Anaerobic Digestion. Front. Bioeng. Biotechnol. 2019, 7, 191. [Google Scholar] [CrossRef]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.Ş.; Unalan, S.; et al. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef]

- Carrere, H.; Antonopoulou, G.; Affes, R.; Passos, F.; Battimelli, A.; Lyberatos, G.; Ferrer, I. Review of feedstock pretreatment strategies for improved anaerobic digestion: From lab-scale research to full-scale application. Bioresour. Technol. 2016, 199, 386–397. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of lignocellulosic biomass: A review on recent advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar] [CrossRef]

- Gałązka, A.; Szadkowski, J. Enzymatic hydrolysis of fast-growing poplar wood after pretreatment by steam explosion. Cellul. Chem. Technol. 2021, 55, 637–647. [Google Scholar] [CrossRef]

- Thamizhakaran Stanley, J.; Thanarasu, A.; Senthil Kumar, P.; Periyasamy, K.; Raghunandhakumar, S.; Periyaraman, P.; Devaraj, K.; Dhanasekaran, A.; Subramanian, S. Potential pre-treatment of lignocellulosic biomass for the enhancement of biomethane production through anaerobic digestion—A review. Fuel 2022, 318, 123593. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Barakat, A.; Quéméneur, M.; Trably, E.; Steyer, J.-P.; Carrère, H. Do furanic and phenolic compounds of lignocellulosic and algae biomass hydrolyzate inhibit anaerobic mixed cultures? A comprehensive review. Biotechnol. Adv. 2014, 32, 934–951. [Google Scholar] [CrossRef]

- Naik, G.P.; Poonia, A.K.; Chaudhari, P.K. Pretreatment of lignocellulosic agricultural waste for delignification, rapid hydrolysis, and enhanced biogas production: A review. J. Indian Chem. Soc. 2021, 98, 100147. [Google Scholar] [CrossRef]

- Hjorth, M.; Gränitz, K.; Adamsen, A.P.S.; Møller, H.B. Extrusion as a pretreatment to increase biogas production. Bioresour. Technol. 2011, 102, 4989–4994. [Google Scholar] [CrossRef]

- Evon, P.; Vandenbossche, V.; Candy, L.; Pontalier, P.-Y.; Rouilly, A. Twin-Screw Extrusion: A Key Technology for the Biorefinery. In Biomass Extrusion and Reaction Technologies: Principles to Practices and Future Potential; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2018; Volume 1304, pp. 17–33. ISBN 978/0/8412/3371/3. [Google Scholar]

- Turick, C.; Peck, M.; Chynoweth, D.; Jerger, D.; White, E.; Zsuffa, L.; Kenney, W. Methane fermentation of woody biomass. Bioresour. Technol. 1991, 37, 141–147. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion pretreatment of lignocellulosic biomass: A review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef]

- Zhang, S.; Keshwani, D.R.; Xu, Y.; Hanna, M.A. Alkali combined extrusion pretreatment of corn stover to enhance enzyme saccharification. Ind. Crop. Prod. 2012, 37, 352–357. [Google Scholar] [CrossRef]

- Vandenbossche, V.; Brault, J.; Hernandez-Melendez, O.; Evon, P.; Barzana, E.; Vilarem, G.; Rigal, L. Suitability assessment of a continuous process combining thermo-mechano-chemical and bio-catalytic action in a single pilot-scale twin-screw extruder for six different biomass sources. Bioresour. Technol. 2016, 211, 146–153. [Google Scholar] [CrossRef]

- Gatt, E.; Rigal, L.; Vandenbossche, V. Biomass pretreatment with reactive extrusion using enzymes: A review. Ind. Crop. Prod. 2018, 122, 329–339. [Google Scholar] [CrossRef]

- Cha, Y.-L.; Yang, J.; Park, Y.; An, G.H.; Ahn, J.-W.; Moon, Y.-H.; Yoon, Y.-M.; Yu, G.-D.; Choi, I.-H. Continuous alkaline pretreatment of Miscanthus sacchariflorus using a bench-scale single screw reactor. Bioresour. Technol. 2015, 181, 338–344. [Google Scholar] [CrossRef]

- Menardo, S.; Cacciatore, V.; Balsari, P. Batch and continuous biogas production arising from feed varying in rice straw volumes following pre-treatment with extrusion. Bioresour. Technol. 2015, 180, 154–161. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, Y.; Gu, Y.; Liu, Z.; Shen, Z.; Chu, H.; Zhou, X. Enhancing methane production from rice straw by extrusion pretreatment. Appl. Energy 2014, 122, 34–41. [Google Scholar] [CrossRef]

- Khor, W.C.; Rabaey, K.; Vervaeren, H. Low temperature calcium hydroxide treatment enhances anaerobic methane production from (extruded) biomass. Bioresour. Technol. 2015, 176, 181–188. [Google Scholar] [CrossRef] [PubMed]

- Frydendal-Nielsen, S.; Hjorth, M.; Baby, S.; Felby, C.; Jørgensen, U.; Gislum, R. The effect of harvest time, dry matter content and mechanical pretreatments on anaerobic digestion and enzymatic hydrolysis of miscanthus. Bioresour. Technol. 2016, 218, 1008–1015. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Rodríguez, N.; García-Bernet, D.; Domínguez, J.M. Faster methane production after sequential extrusion and enzymatic hydrolysis of vine trimming shoots. Environ. Chem. Lett. 2018, 16, 295–299. [Google Scholar] [CrossRef]

- Niu, W.; Huang, G.; Liu, X.; Chen, L.; Han, L. Chemical Composition and Calorific Value Prediction of Wheat Straw at Different Maturity Stages Using Near-Infrared Reflectance Spectroscopy. Energy Fuels 2014, 28, 7474–7482. [Google Scholar] [CrossRef]

- Buswell, A.M.; Mueller, H.F. Mechanism of Methane Fermentation. Ind. Eng. Chem. 1952, 44, 550–552. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Theoretical analysis of biogas potential prediction from agricultural waste. Resour. Effic. Technol. 2016, 2, 143–147. [Google Scholar] [CrossRef]

- Khongchamnan, P.; Wanmolee, W.; Laosiripojana, N.; Champreda, V.; Suriyachai, N.; Kreetachat, T.; Sakulthaew, C.; Chokejaroenrat, C.; Imman, S. Solvothermal-Based Lignin Fractionation from Corn Stover: Process Optimization and Product Characteristics. Front. Chem. 2021, 9, 697237. [Google Scholar] [CrossRef]

- Sluiter, A. Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples: Laboratory Analytical Procedure (LAP). Tech. Rep. 2008, 9. Available online: https://www.nrel.gov/docs/gen/fy08/42621.pdf (accessed on 2 May 2022).

- Beaufils, N.; Boucher, J.; Peydecastaing, J.; Rigal, L.; Vilarem, G.; Villette, M.-J.; Candy, L.; Pontalier, P.-Y. The effect of time and temperature on the extraction of xylose and total phenolic compounds with pressurized hot water from hardwood species used for pulp and paper production in the South of France. Bioresour. Technol. Rep. 2021, 16, 100832. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass, in: Laboratory Analytical Procedure (LAP). Natl. Renew. Energy Lab. 2008, 1617. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 2 May 2022).

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; van’t Riet, K. Modeling of the Bacterial Growth Curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef]

- Evon, P.; Vandenbossche, V.; Pontalier, P.-Y.; Rigal, L. New thermal insulation fiberboards from cake generated during biorefinery of sunflower whole plant in a twin-screw extruder. Ind. Crop. Prod. 2014, 52, 354–362. [Google Scholar] [CrossRef]

- Heredia-Olea, E.; Pérez-Carrillo, E.; Montoya-Chiw, M.; Serna-Saldívar, S.O. Effects of Extrusion Pretreatment Parameters on Sweet Sorghum Bagasse Enzymatic Hydrolysis and Its Subsequent Conversion into Bioethanol. BioMed Res. Int. 2015, 2015, 325905. [Google Scholar] [CrossRef]

- Mazaheri Tehrani, M.; Ehtiati, A.; Sharifi Azghandi, S. Application of genetic algorithm to optimize extrusion condition for soy-based meat analogue texturization. J. Food Sci. Technol. 2017, 54, 1119–1125. [Google Scholar] [CrossRef] [PubMed]

- Brishti, F.H.; Chay, S.Y.; Muhammad, K.; Ismail-Fitry, M.R.; Zarei, M.; Saari, N. Texturized mung bean protein as a sustainable food source: Effects of extrusion on its physical, textural and protein quality. Innov. Food Sci. Emerg. Technol. 2021, 67, 102591. [Google Scholar] [CrossRef]

- Choudhury, G.S.; Gautam, A. Comparative study of mixing elements during twin-screw extrusion of rice flour. Food Res. Int. 1998, 31, 7–17. [Google Scholar] [CrossRef]

- Lallement, A.; Peyrelasse, C.; Lagnet, C.; Barakat, A.; Schraauwers, B.; Maunas, S.; Monlau, F. A Detailed Database of the Chemical Properties and Methane Potential of Biomasses Covering a Large Range of Common Agricultural Biogas Plant Feedstocks. Waste 2023, 1, 195–227. [Google Scholar] [CrossRef]

- Pronyk, C.; Mazza, G.; Tamaki, Y. Production of Carbohydrates, Lignins, and Minor Components from Triticale Straw by Hydrothermal Treatment. J. Agric. Food Chem. 2011, 59, 3788–3796. [Google Scholar] [CrossRef]

- Tamaki, Y.; Mazza, G. Measurement of structural carbohydrates, lignins, and micro-components of straw and shives: Effects of extractives, particle size and crop species. Ind. Crop. Prod. 2010, 31, 534–541. [Google Scholar] [CrossRef]

- Armstrong, D.G.; Cook, H.; Thomas, B. The lignin and cellulose contents of certain grassland species at different stages of growth. J. Agric. Sci. 1950, 40, 93–99. [Google Scholar] [CrossRef]

- Plant Variety Catalogues, Databases & Information Systems. Available online: https://food.ec.europa.eu/plants/plant-reproductive-material/plant-variety-catalogues-databases-information-systems_en (accessed on 5 March 2023).

- Pordesimo, L.O.; Hames, B.R.; Sokhansanj, S.; Edens, W.C. Variation in corn stover composition and energy content with crop maturity. Biomass Bioenergy 2005, 28, 366–374. [Google Scholar] [CrossRef]

- Collins, S.R.; Wellner, N.; Martinez Bordonado, I.; Harper, A.L.; Miller, C.N.; Bancroft, I.; Waldron, K.W. Variation in the chemical composition of wheat straw: The role of tissue ratio and composition. Biotechnol. Biofuels 2014, 7, 121. [Google Scholar] [CrossRef]

- Zillinsky, F.J. The Development of Triticale. In Advances in Agronomy; Brady, N.C., Ed.; Academic Press: Cambridge, MA, USA, 1974; Volume 26, pp. 315–348. [Google Scholar]

- Vandenbossche, V.; Doumeng, C.; Rigal, L. Thermomechanical and Thermo-mechano-chemical Pretreatment of Wheat Straw using a Twin-screw Extruder. BioResources 2014, 9, 1519–1538. [Google Scholar] [CrossRef]

- Zheng, J.; Choo, K.; Rehmann, L. The effects of screw elements on enzymatic digestibility of corncobs after pretreatment in a twin-screw extruder. Biomass Bioenergy 2015, 74, 224–232. [Google Scholar] [CrossRef]

- Wang, Z.; He, X.; Yan, L.; Wang, J.; Hu, X.; Sun, Q.; Zhang, H. Enhancing enzymatic hydrolysis of corn stover by twin-screw extrusion pretreatment. Ind. Crop. Prod. 2020, 143, 111960. [Google Scholar] [CrossRef]

- Elalami, D.; Aouine, M.; Monlau, F.; Guillon, F.; Dumon, C.; Hernandez Raquet, G.; Barakat, A. Enhanced enzymatic hydrolysis of corn stover using twin-screw extrusion under mild conditions. Biofuels Bioprod. Biorefining 2022, 16, 1642–1654. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, I.; Negro, M.J.; Oliva, J.M.; González, A.; Ballesteros, M. Sugar production from barley straw biomass pretreated by combined alkali and enzymatic extrusion. Bioresour. Technol. 2014, 158, 262–268. [Google Scholar] [CrossRef]

- Garuti, M.; Sinisgalli, E.; Soldano, M.; Fermoso, F.G.; Rodriguez, A.J.; Carnevale, M.; Gallucci, F. Mechanical pretreatments of different agri-based feedstock in full-scale biogas plants under real operational conditions. Biomass Bioenergy 2022, 158, 106352. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Gu, Y.; Zhou, X. A physicochemical method for increasing methane production from rice straw: Extrusion combined with alkali pretreatment. Appl. Energy 2015, 160, 39–48. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Barakat, A.; Guo, X.M.; Latrille, E.; Trably, E.; Steyer, J.-P.; Carrere, H. Predictive Models of Biohydrogen and Biomethane Production Based on the Compositional and Structural Features of Lignocellulosic Materials. Environ. Sci. Technol. 2012, 46, 12217–12225. [Google Scholar] [CrossRef]

- Thomsen, S.T.; Spliid, H.; Østergård, H. Statistical prediction of biomethane potentials based on the composition of lignocellulosic biomass. Bioresour. Technol. 2014, 154, 80–86. [Google Scholar] [CrossRef]

- Wahid, R.; Hjorth, M.; Kristensen, S.; Møller, H.B. Extrusion as Pretreatment for Boosting Methane Production: Effect of Screw Configurations. Energy Fuels 2015, 29, 4030–4037. [Google Scholar] [CrossRef]

- Victorin, M.; Davidsson, Å.; Wallberg, O. Characterization of Mechanically Pretreated Wheat Straw for Biogas Production. BioEnergy Res. 2020, 13, 833–844. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahring, B.K. Lignin degradation under anaerobic digestion: Influence of lignin modifications—A review. Biomass Bioenergy 2019, 128, 105325. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Meneses Quelal, O.; Gaibor, J.; Niño, Z. Review of Mathematical Models for the Anaerobic Digestion Process. In Anaerobic Digestion; IntechOpen: London, UK, 2018; ISBN 978/1/83881/849/4. [Google Scholar]

- Mancini, G.; Papirio, S.; Lens, P.N.L.; Esposito, G. Increased biogas production from wheat straw by chemical pretreatments. Renew. Energy 2018, 119, 608–614. [Google Scholar] [CrossRef]

- Lee, J.; Park, K.Y. Impact of hydrothermal pretreatment on anaerobic digestion efficiency for lignocellulosic biomass: Influence of pretreatment temperature on the formation of biomass-degrading byproducts. Chemosphere 2020, 256, 127116. [Google Scholar] [CrossRef]

- Sieborg, M.U.; Jønson, B.D.; Larsen, S.U.; Vazifehkhoran, A.H.; Triolo, J.M. Co-Ensiling of Wheat Straw as an Alternative Pre-Treatment to Chemical, Hydrothermal and Mechanical Methods for Methane Production. Energies 2020, 13, 4047. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Mechanical pretreatment for increased biogas production from lignocellulosic biomass; predicting the methane yield from structural plant components. Waste Manag. 2018, 78, 903–910. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, N.; García-Bernet, D.; Domínguez, J.M. Extrusion and enzymatic hydrolysis as pretreatments on corn cob for biogas production. Renew. Energy 2017, 107, 597–603. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Li, B.; Patel, K.; Wang, L.B. A Review of the Processes, Parameters, and Optimization of Anaerobic Digestion. Int. J. Environ. Res. Public. Health 2018, 15, 2224. [Google Scholar] [CrossRef]

- Janke, L.; Weinrich, S.; Leite, A.F.; Terzariol, F.K.; Nikolausz, M.; Nelles, M.; Stinner, W. Improving anaerobic digestion of sugarcane straw for methane production: Combined benefits of mechanical and sodium hydroxide pretreatment for process designing. Energy Convers. Manag. 2017, 141, 378–389. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).