A Review of Glass Substrate Technologies

Abstract

1. Introduction

- Tailorable mechanical properties by tuning composition;

- Superior dimensional stability due to its homogeneous structure;

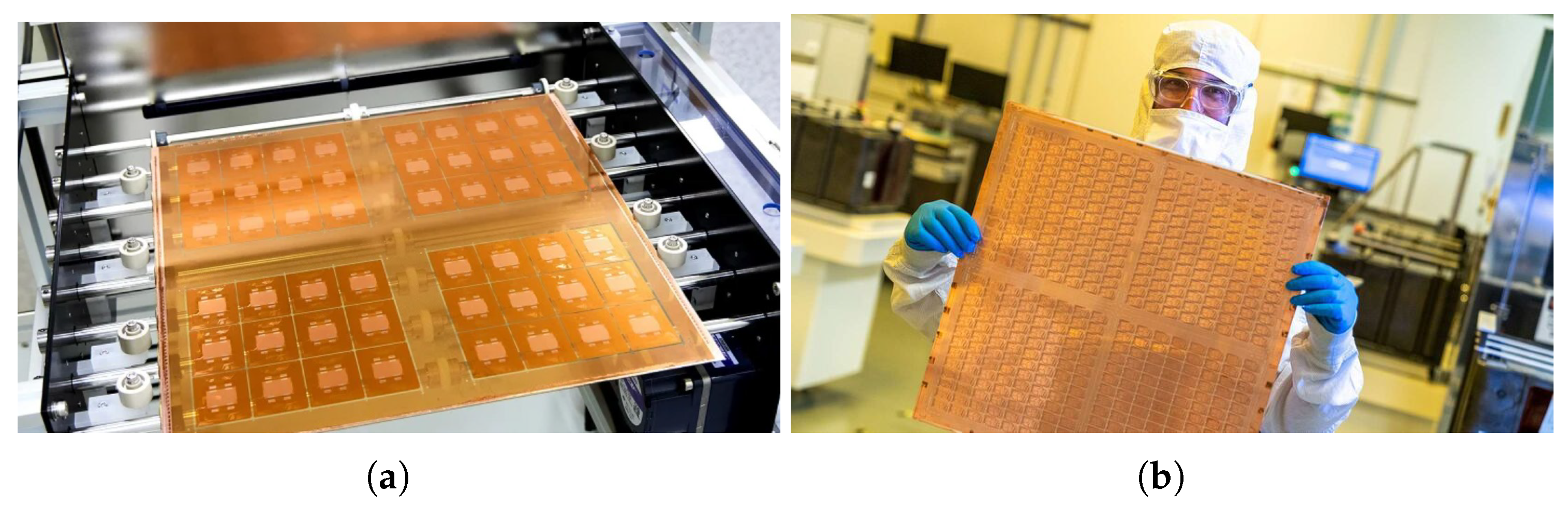

- Compatibility with large-panel manufacturing, leveraging existing infrastructure;

- Enhanced integration capability through microstructuring features like through vias and cavities.

2. Current State of the Art

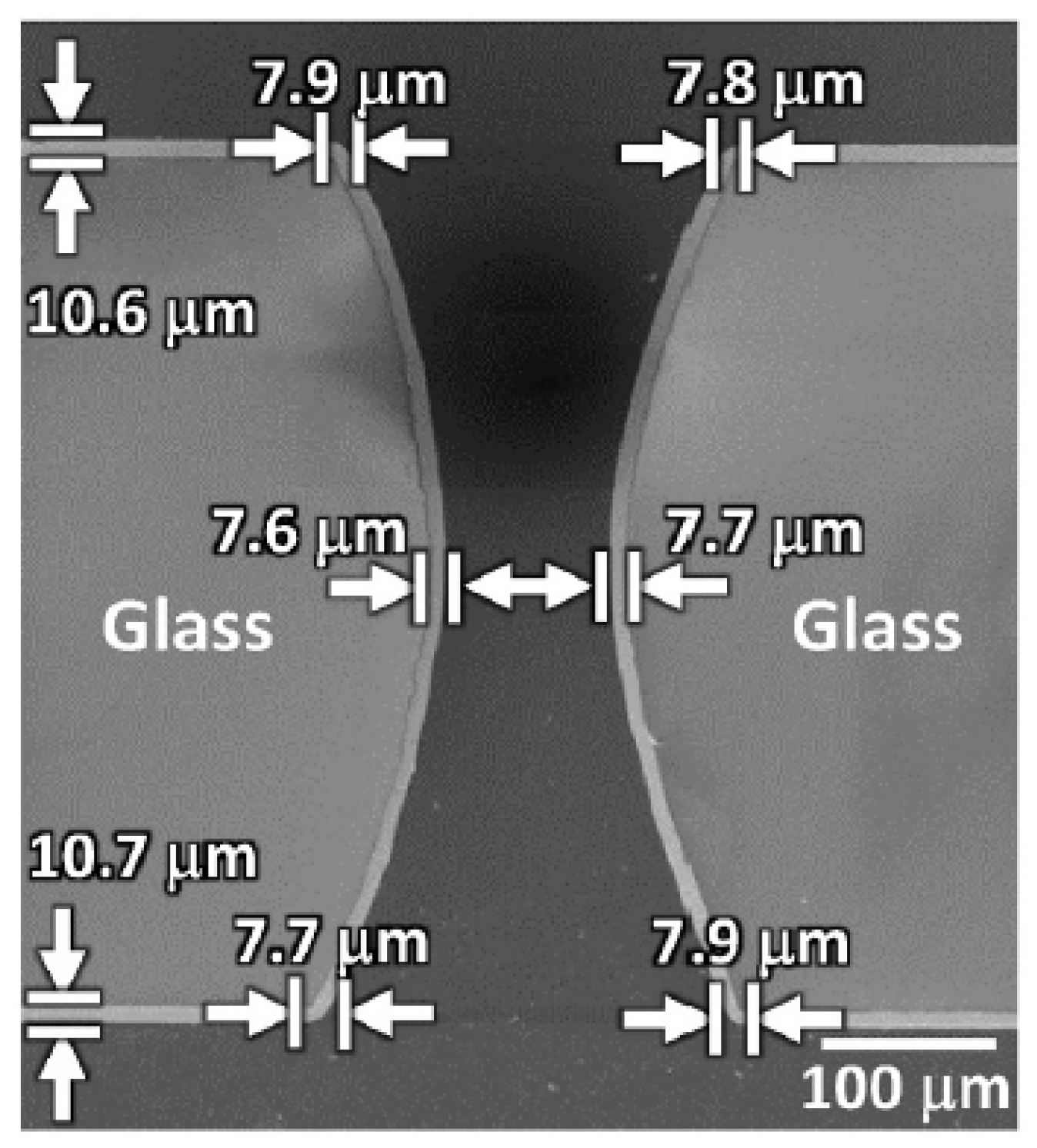

2.1. Through Glass Vias

2.1.1. Via Formation

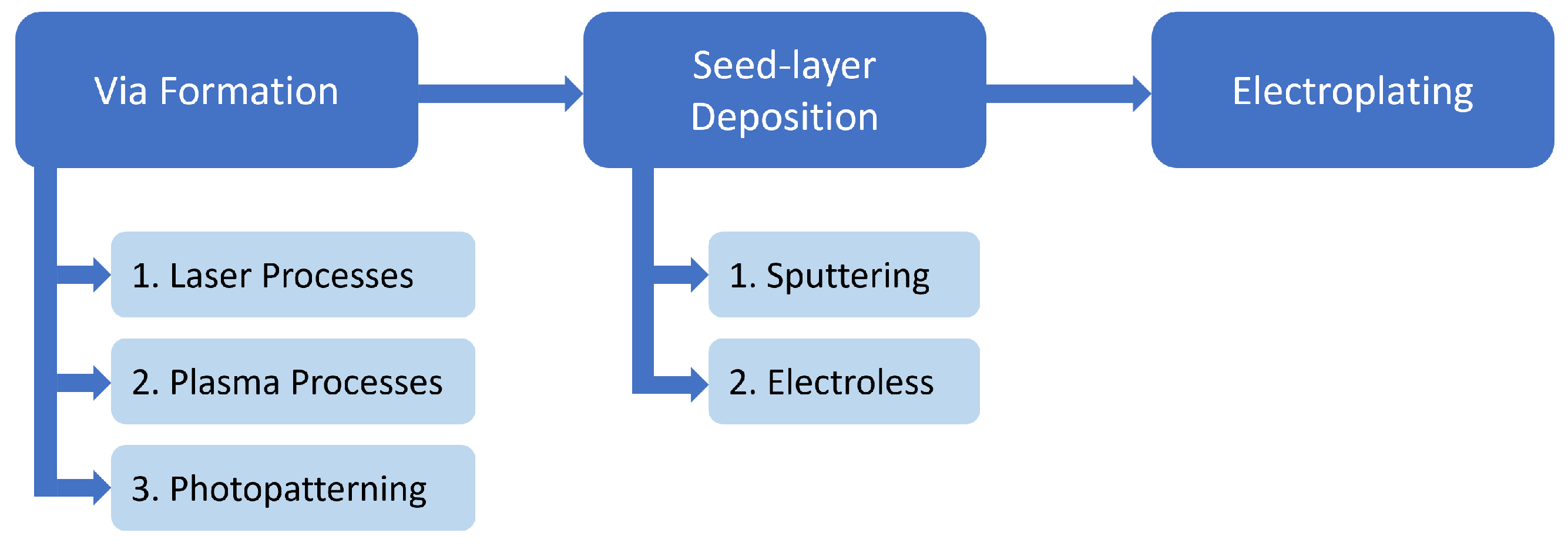

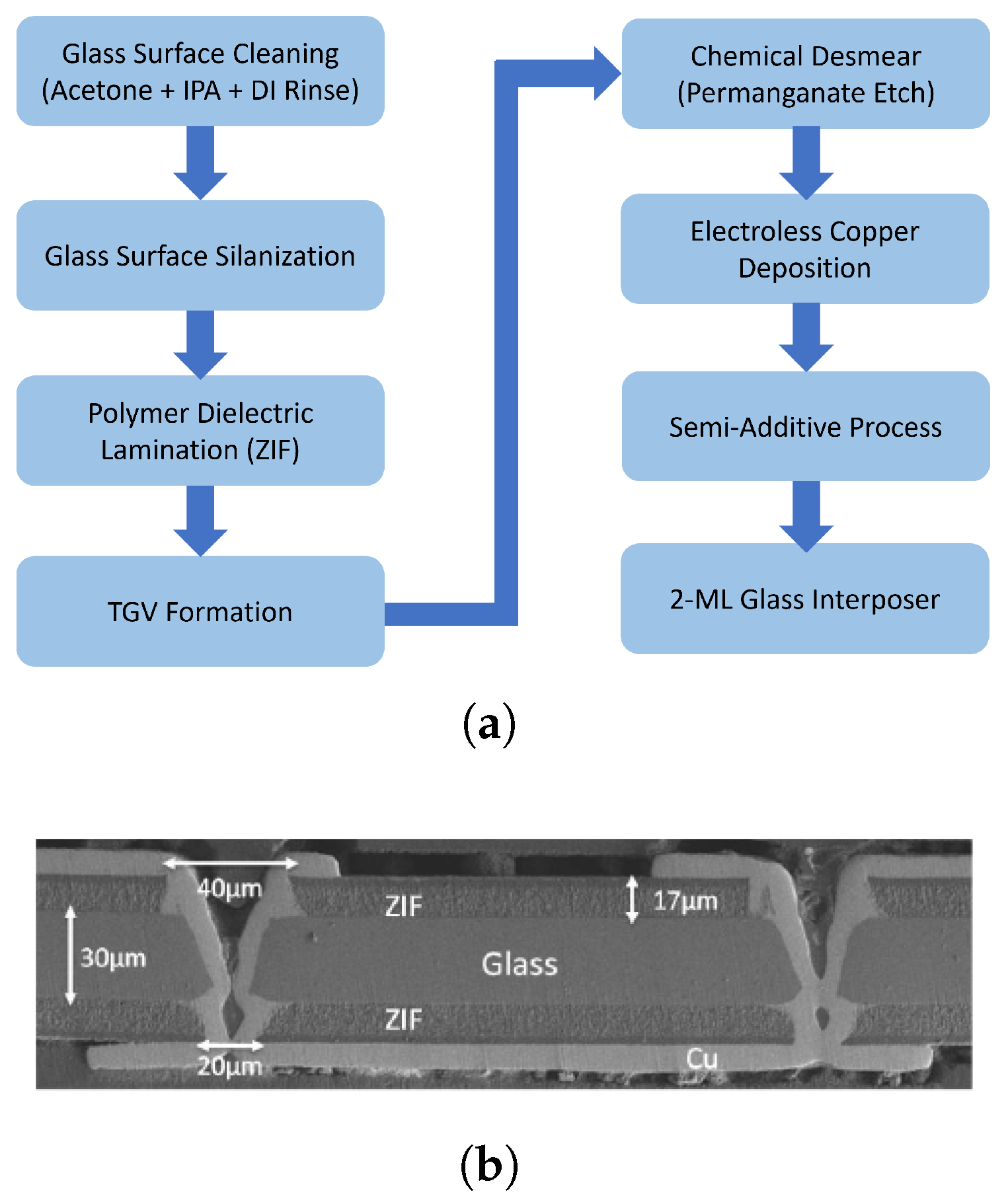

2.1.2. TGV Metallization

2.1.3. Commercial TGV Capabilities

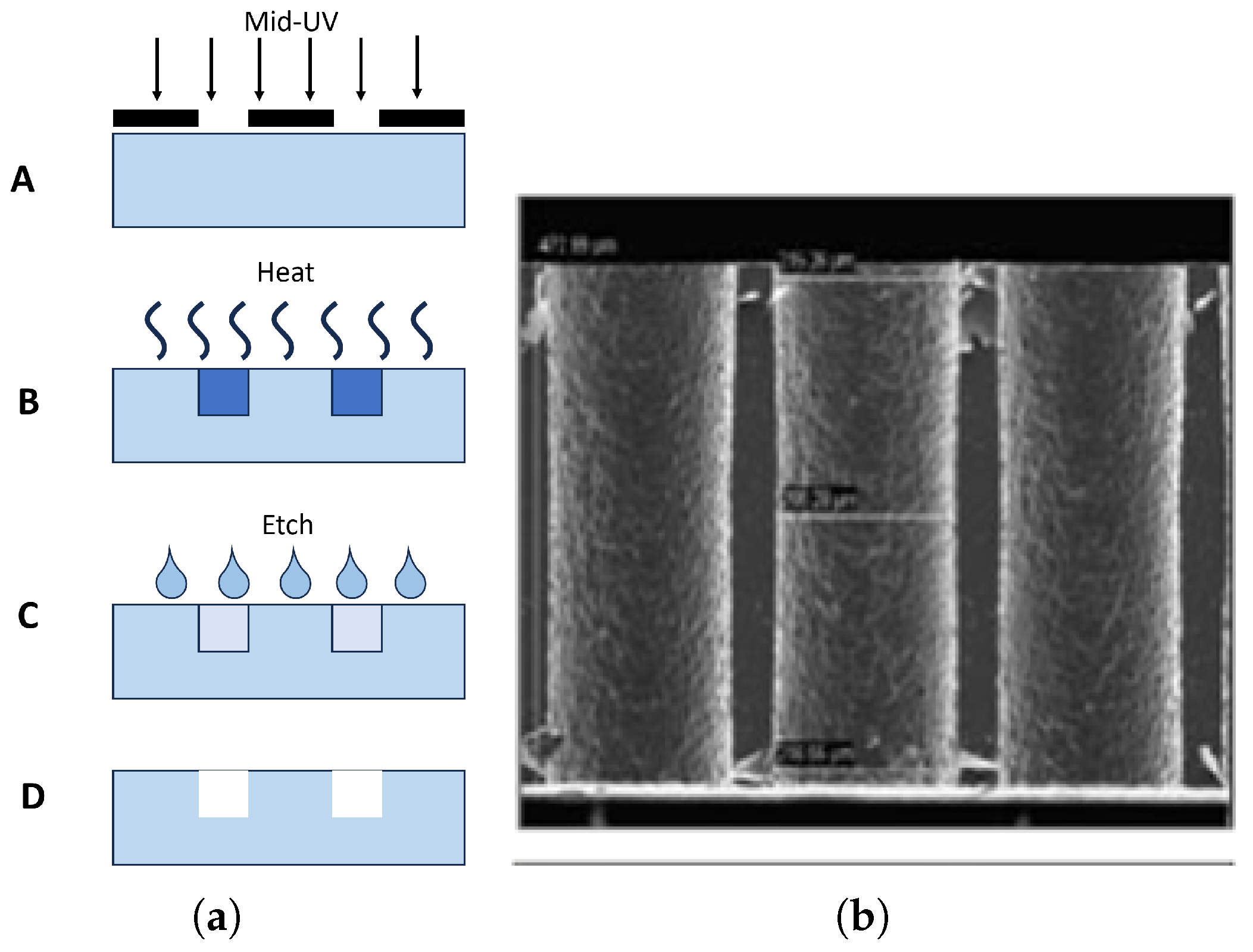

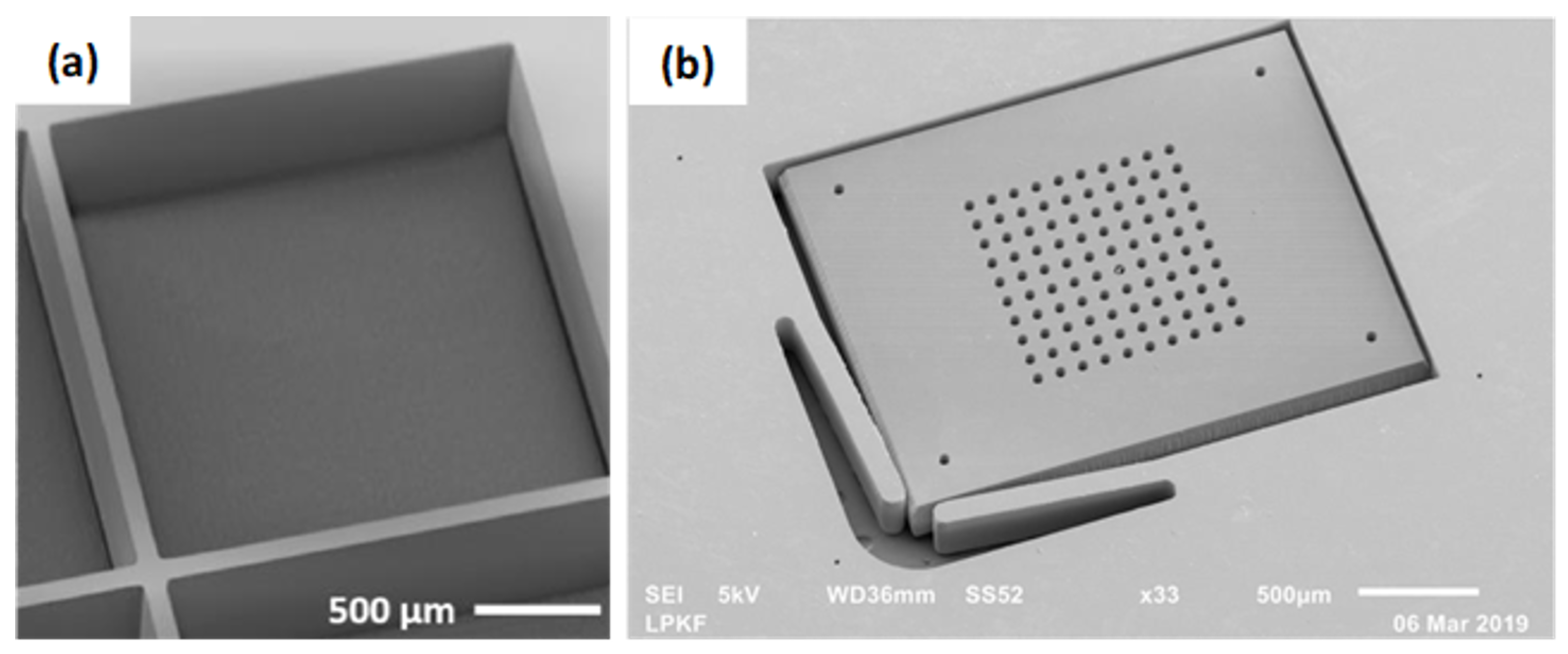

2.2. Formation of Glass Cavities and Embedding

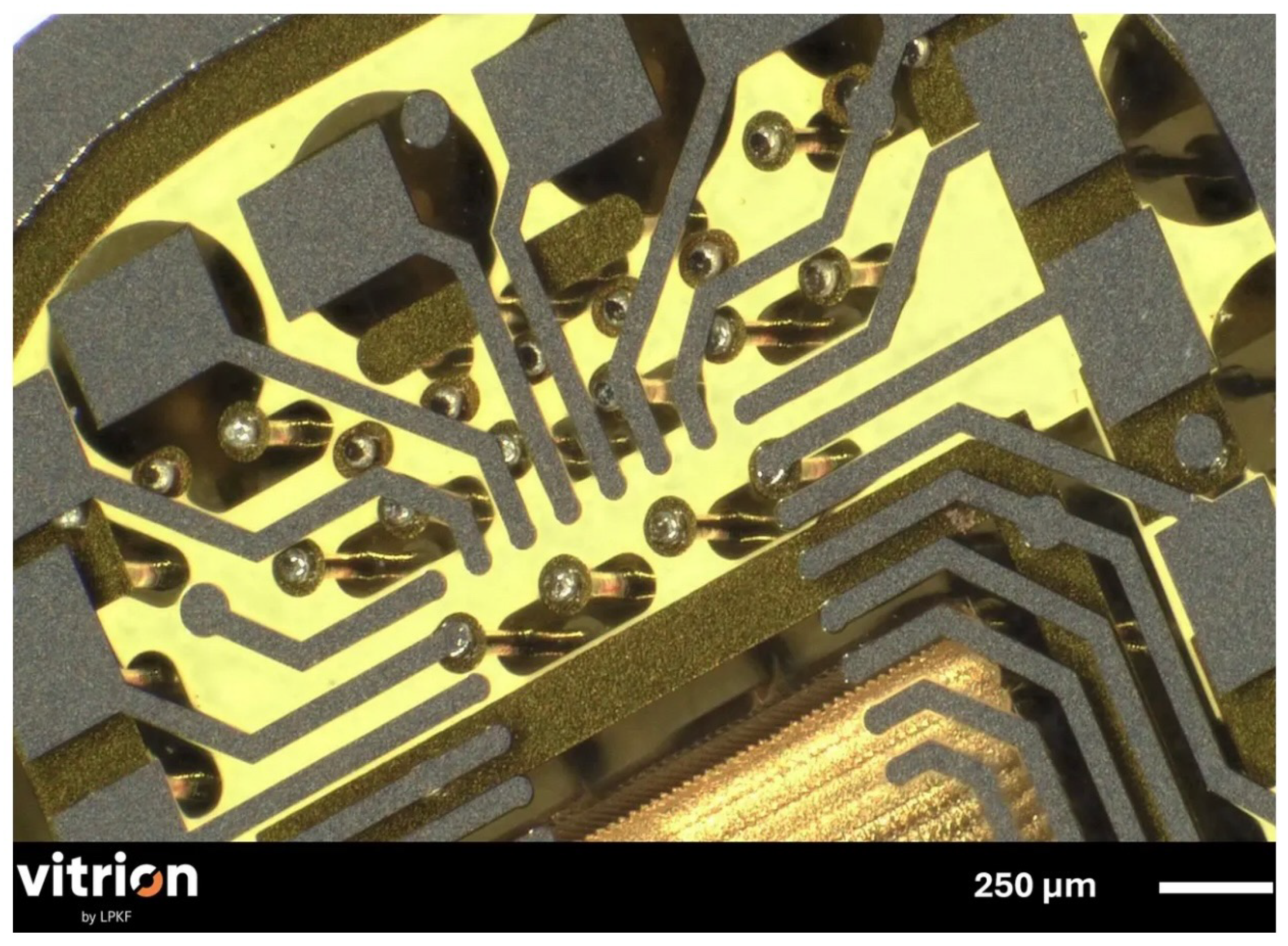

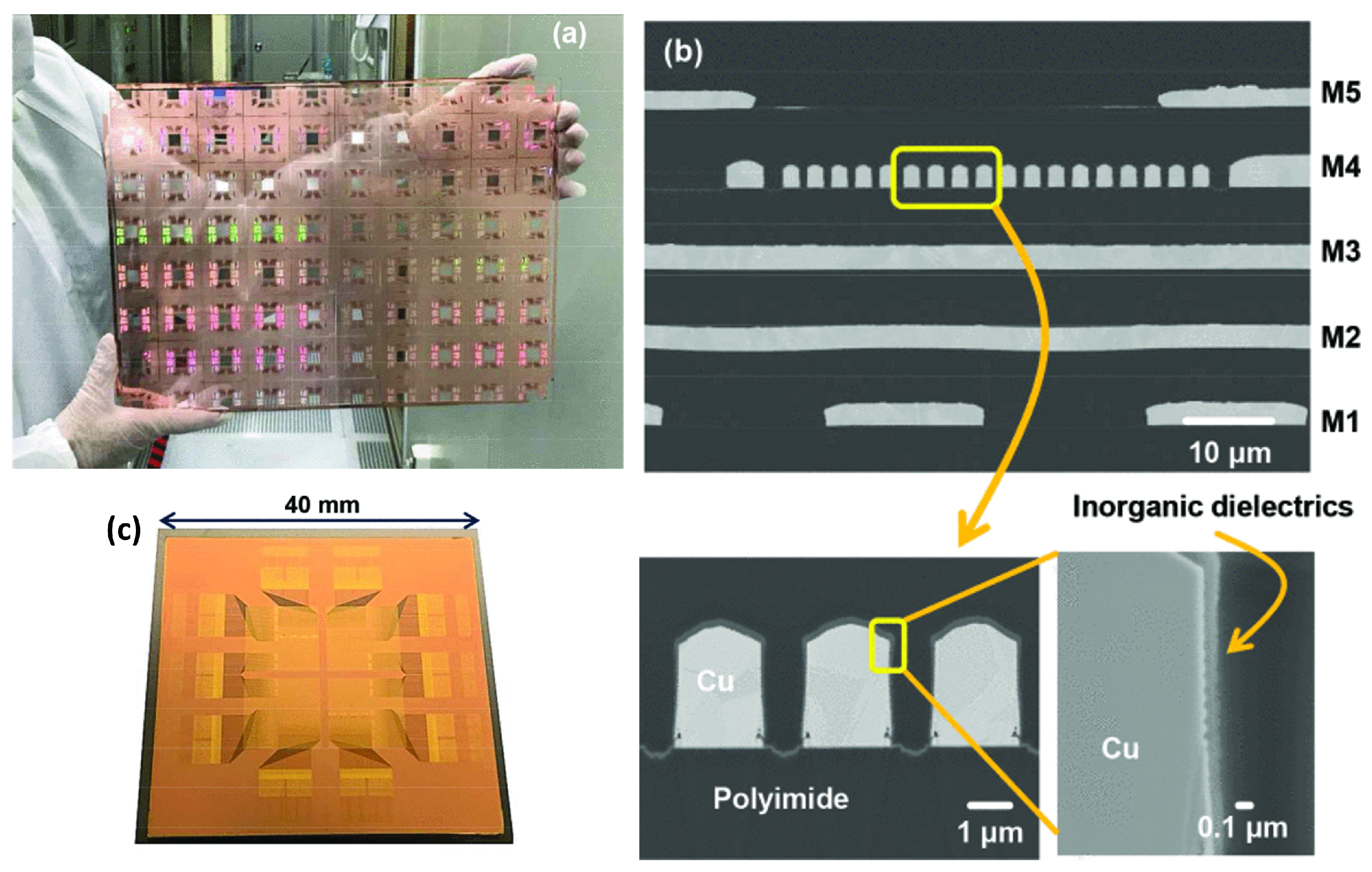

2.3. Fine Line RDL on Glass

2.4. Reliability Studies

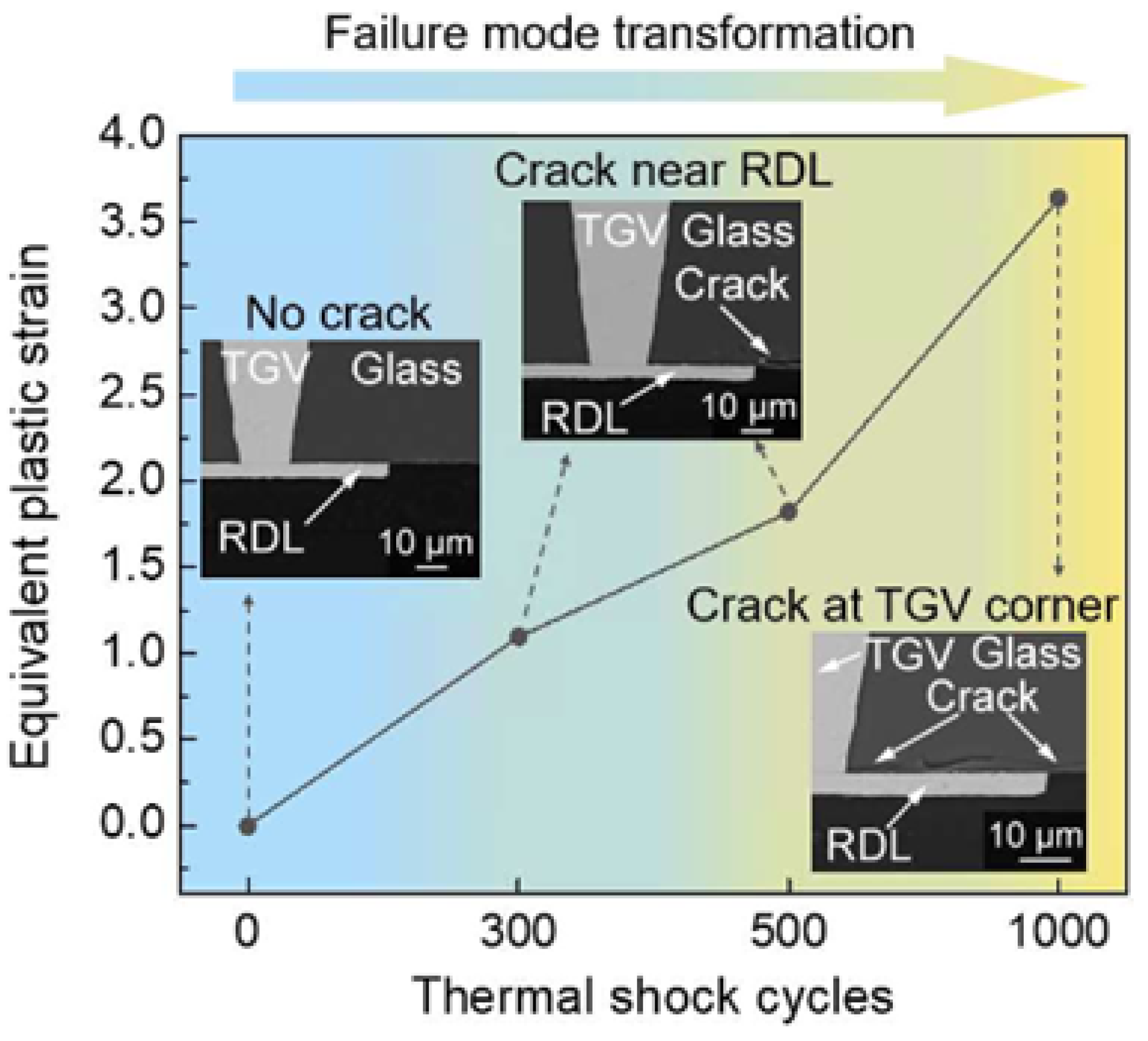

2.4.1. TGV Reliability

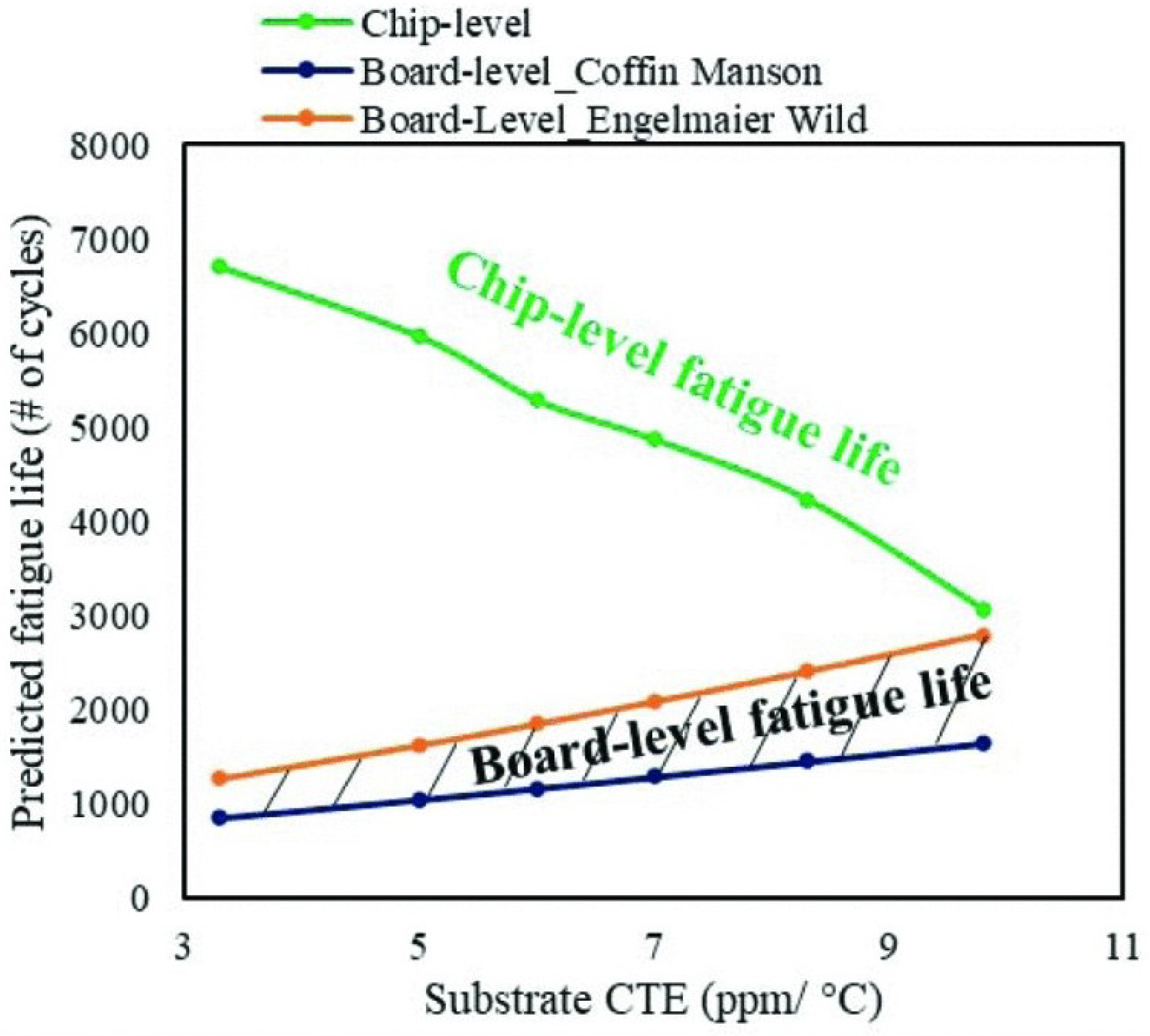

2.4.2. BGA Reliability

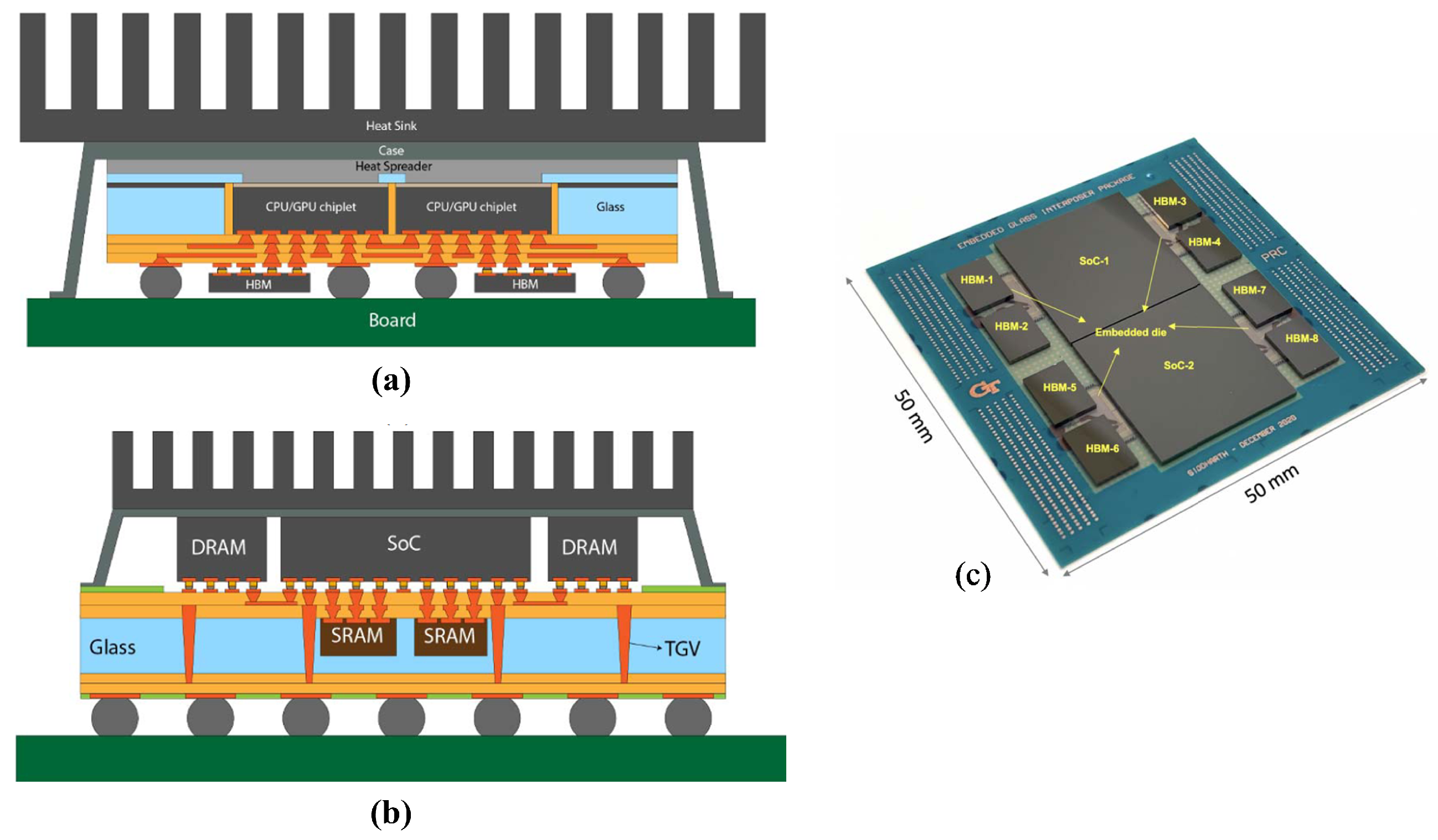

3. Architectures and Novel Integration Approaches

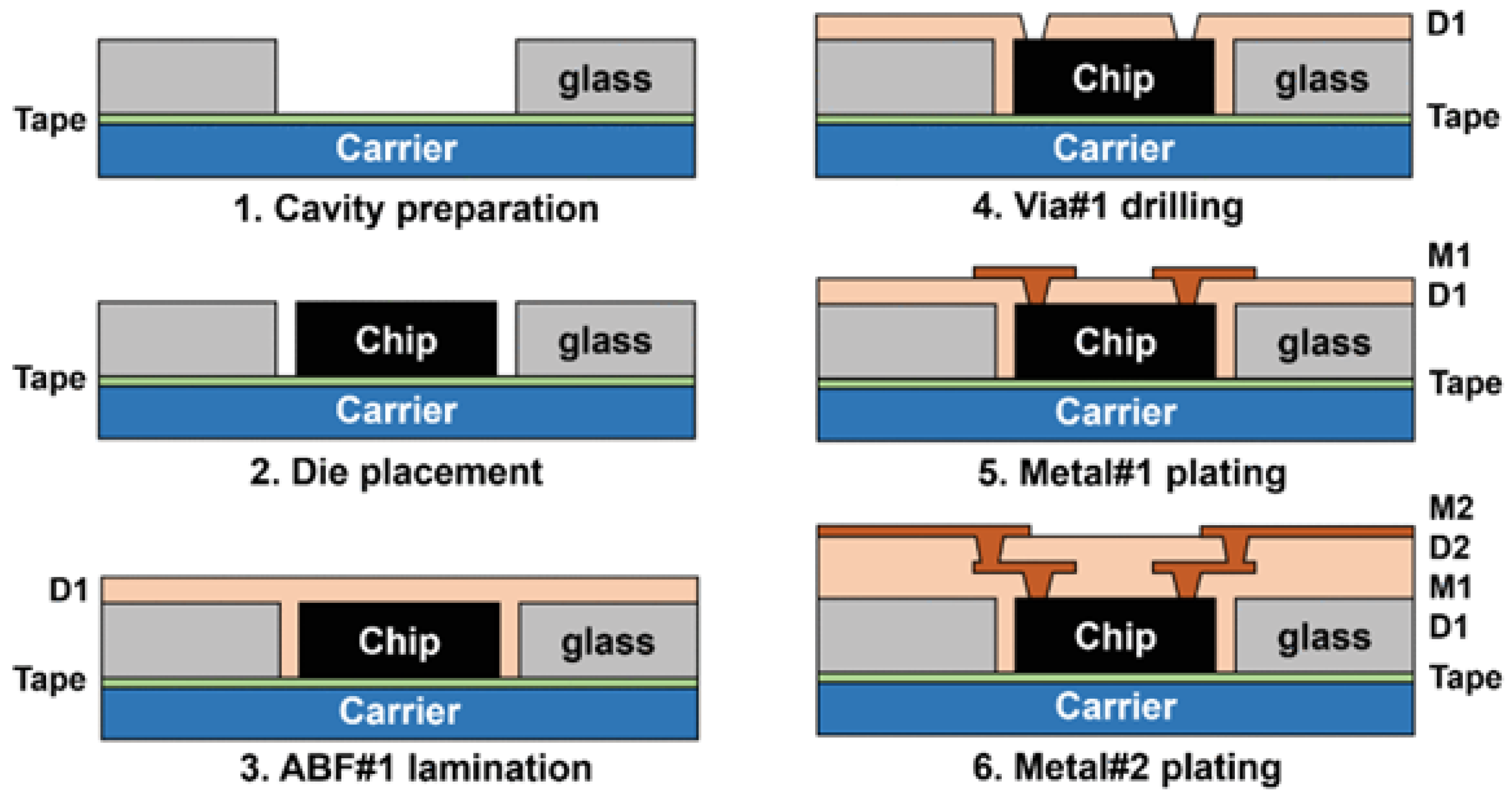

3.1. Glass Panel Embedding (GPE)

3.2. Optics Integration

3.3. mmWave Passives and Interconnects

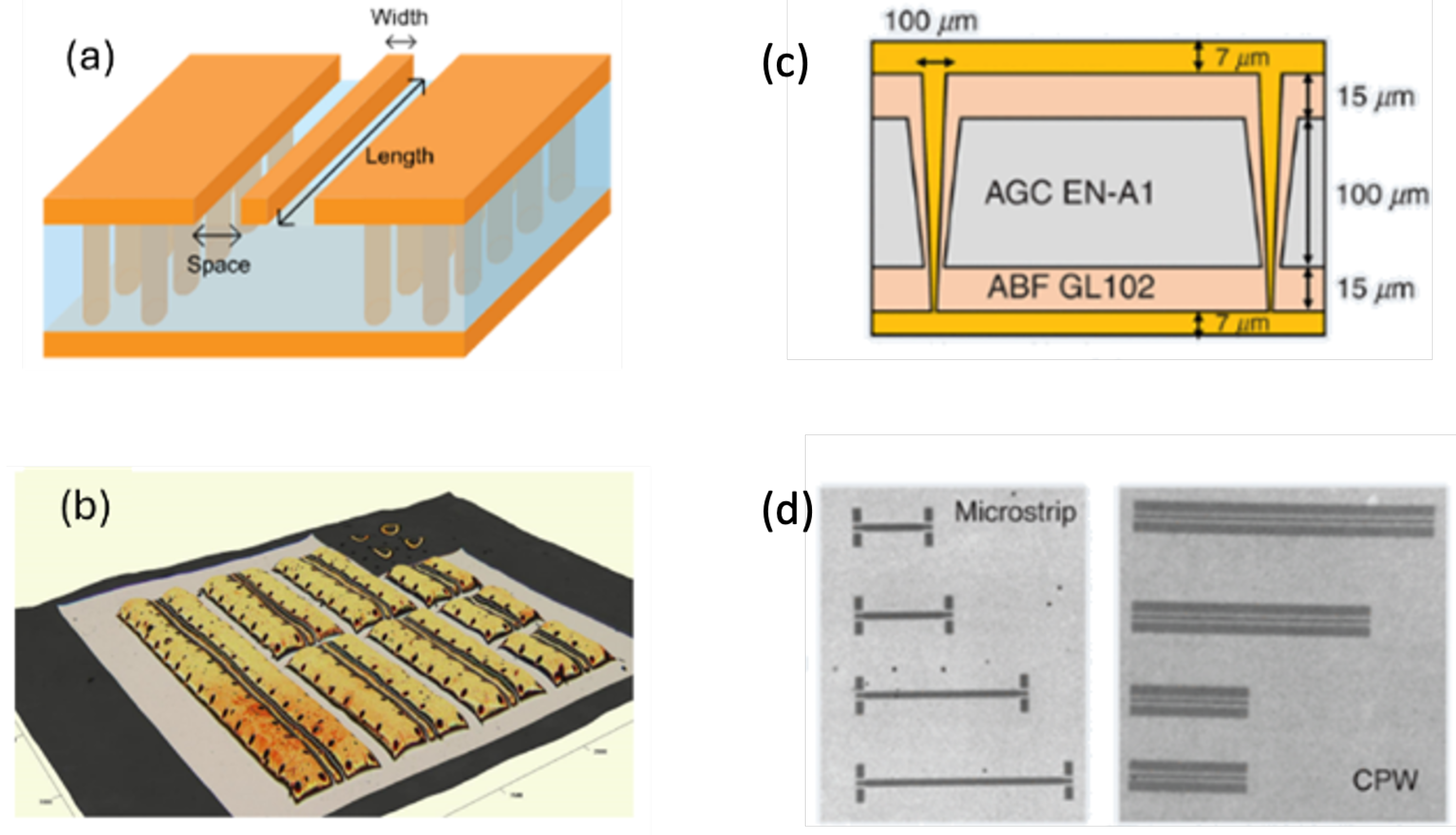

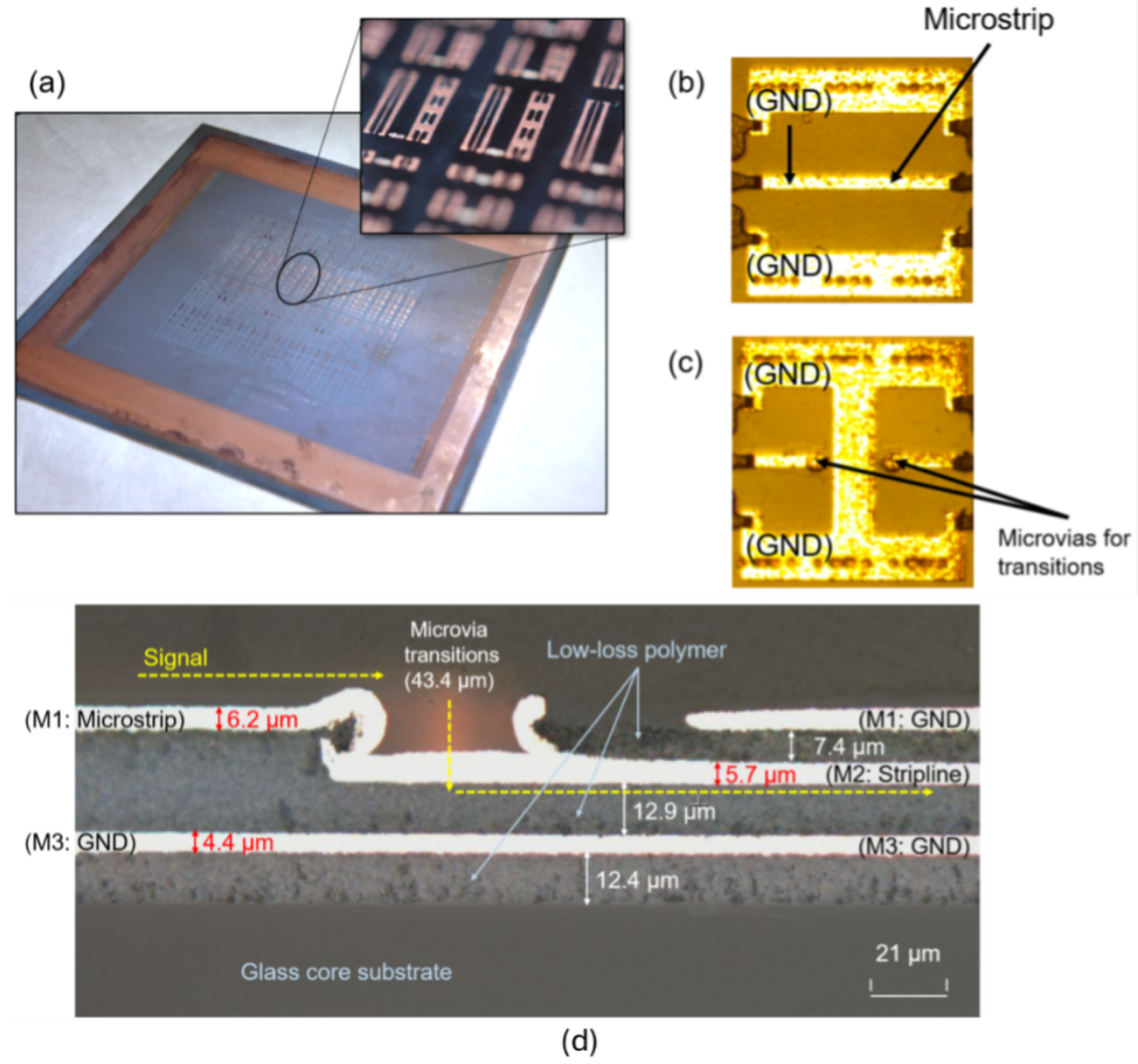

3.3.1. Interconnects

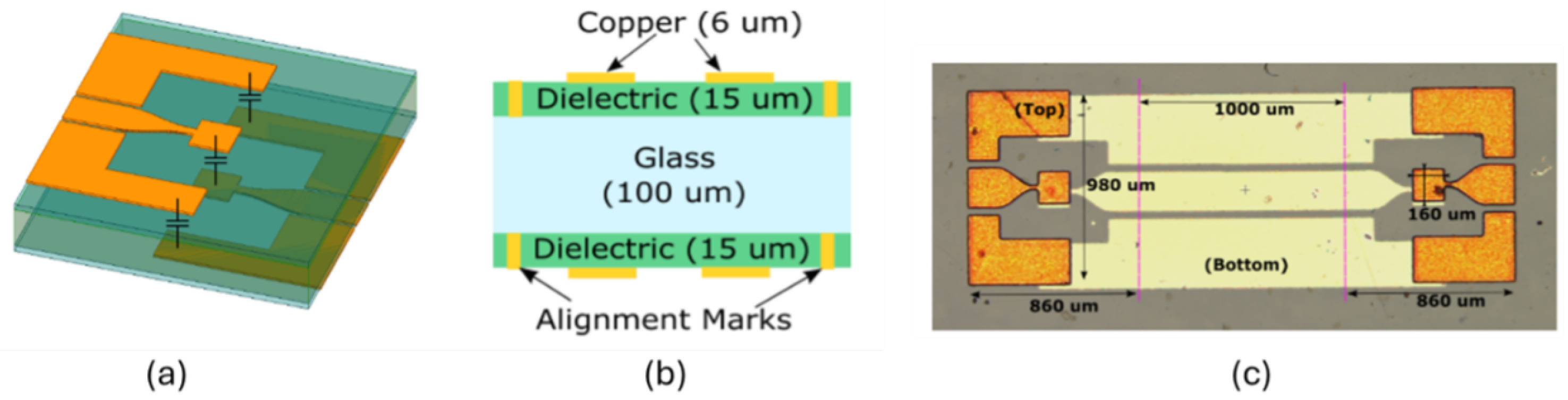

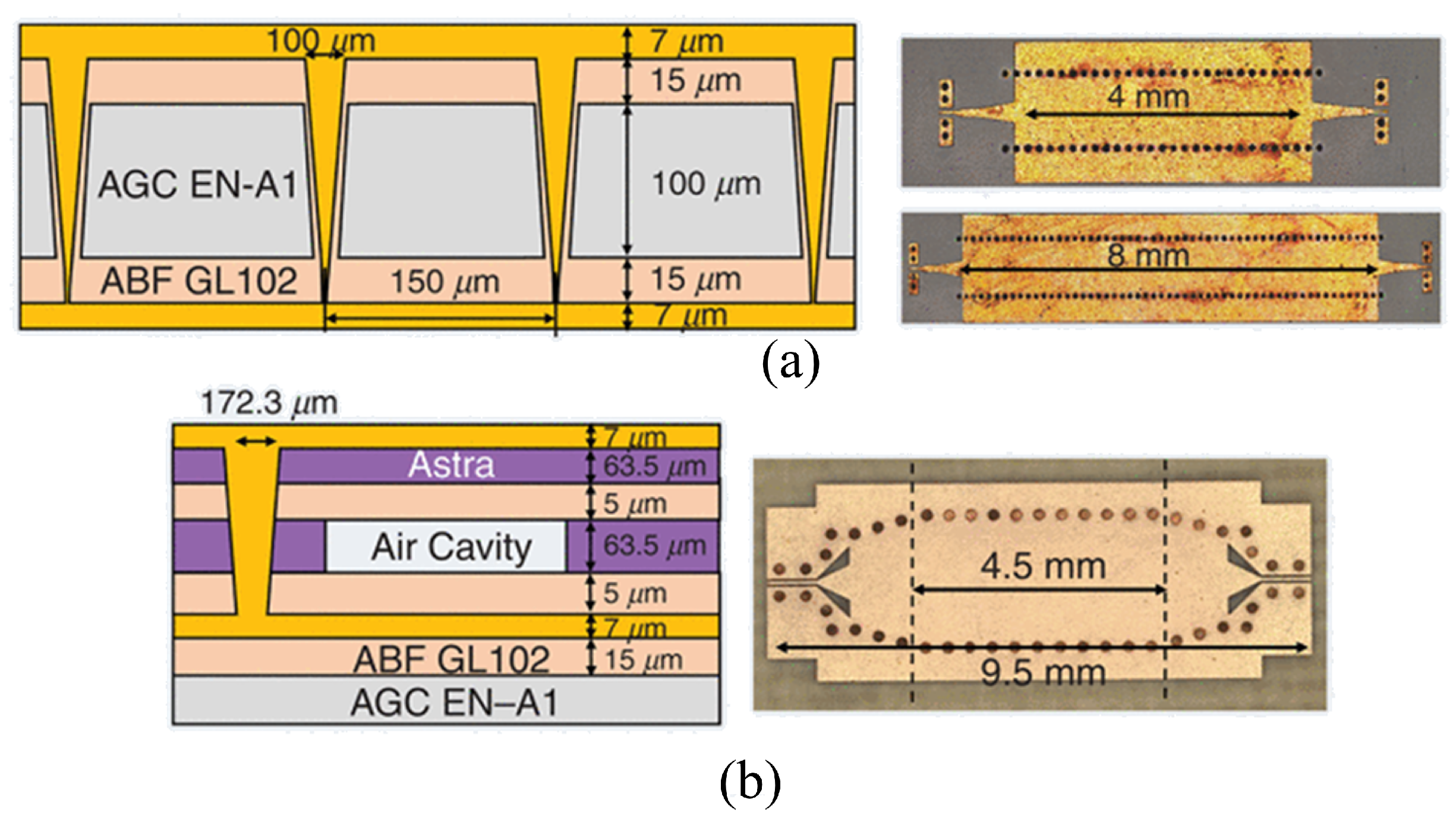

3.3.2. Substrate Integrated Waveguides (SIW)

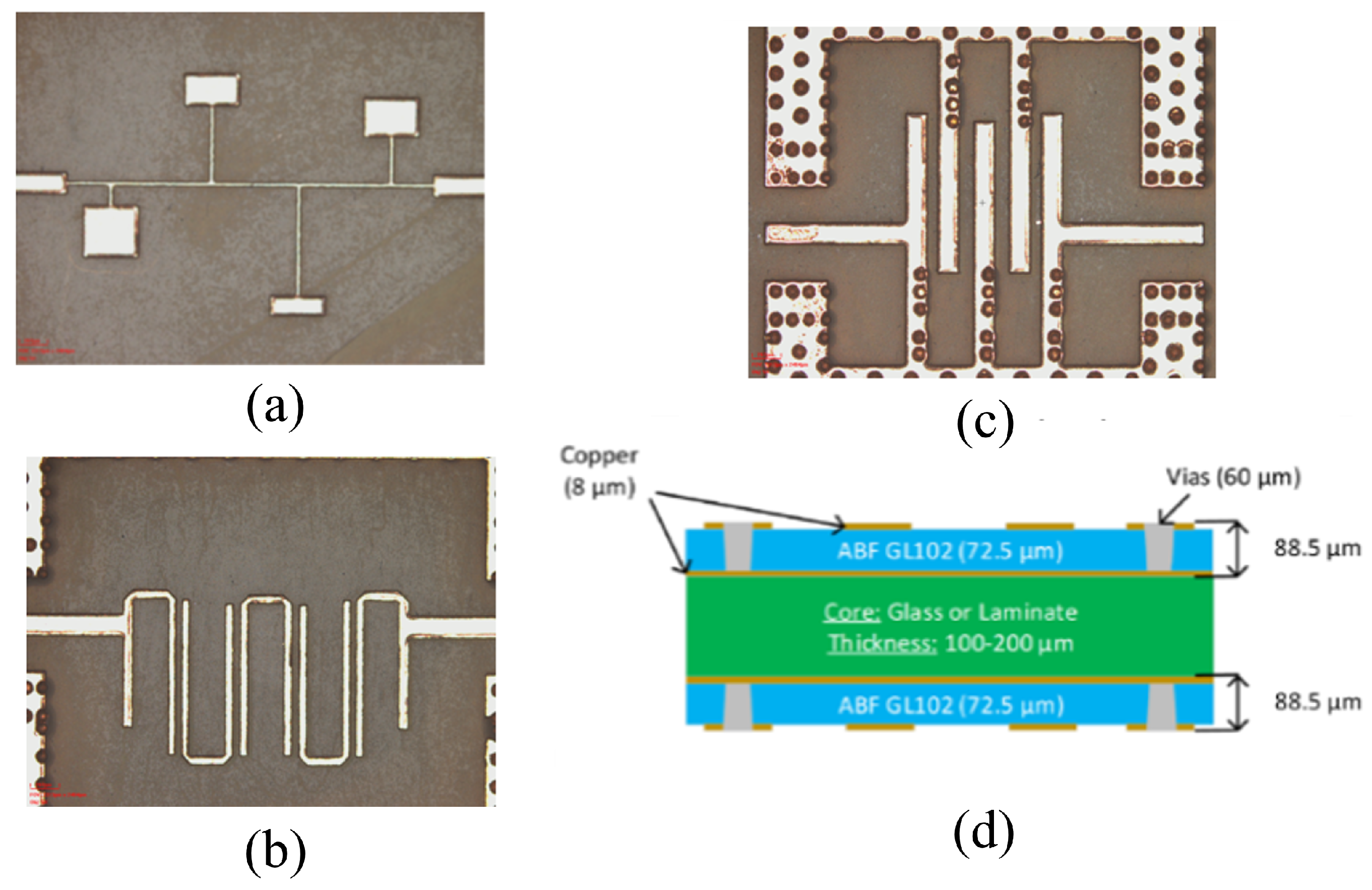

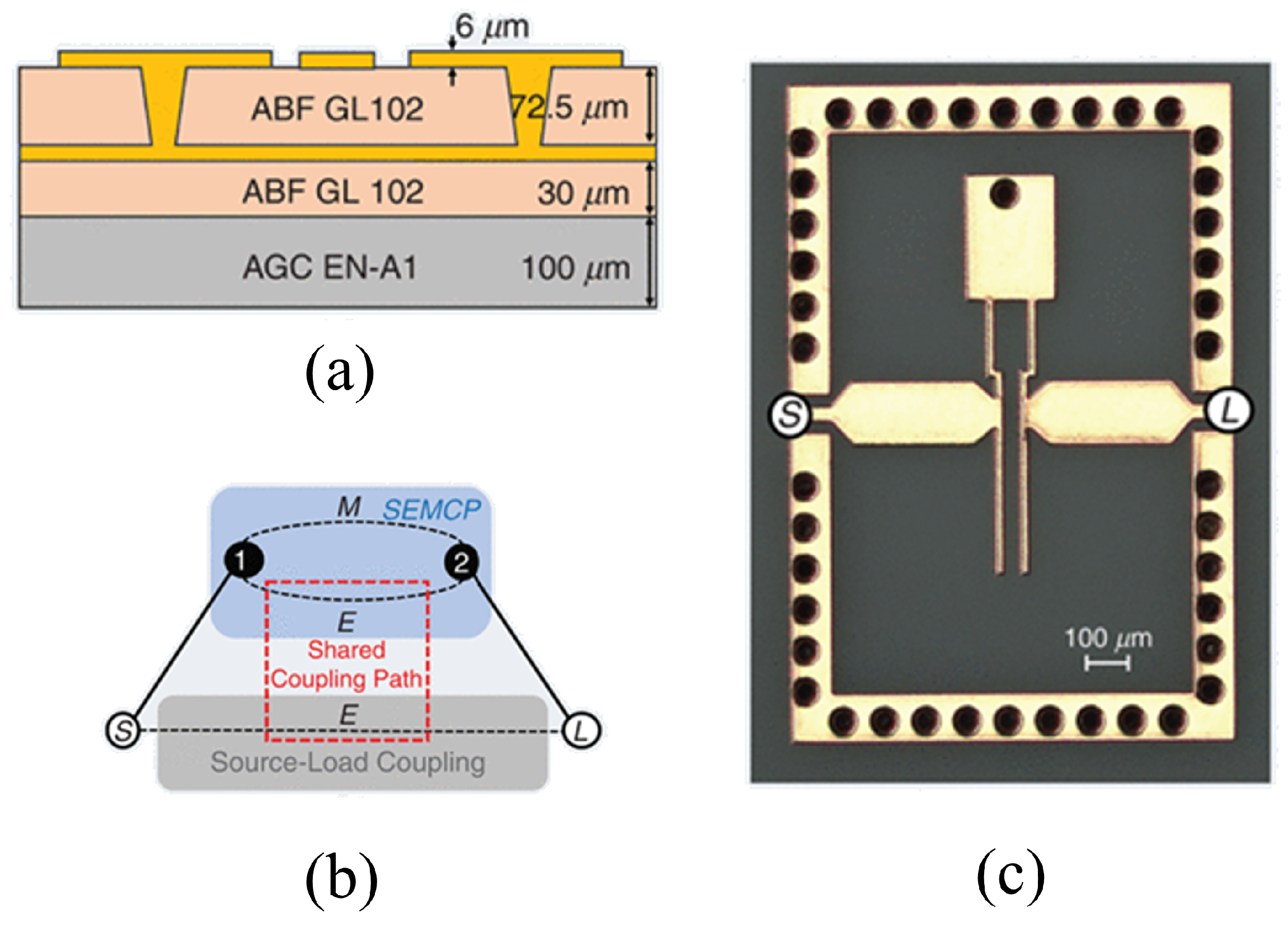

3.3.3. Filters

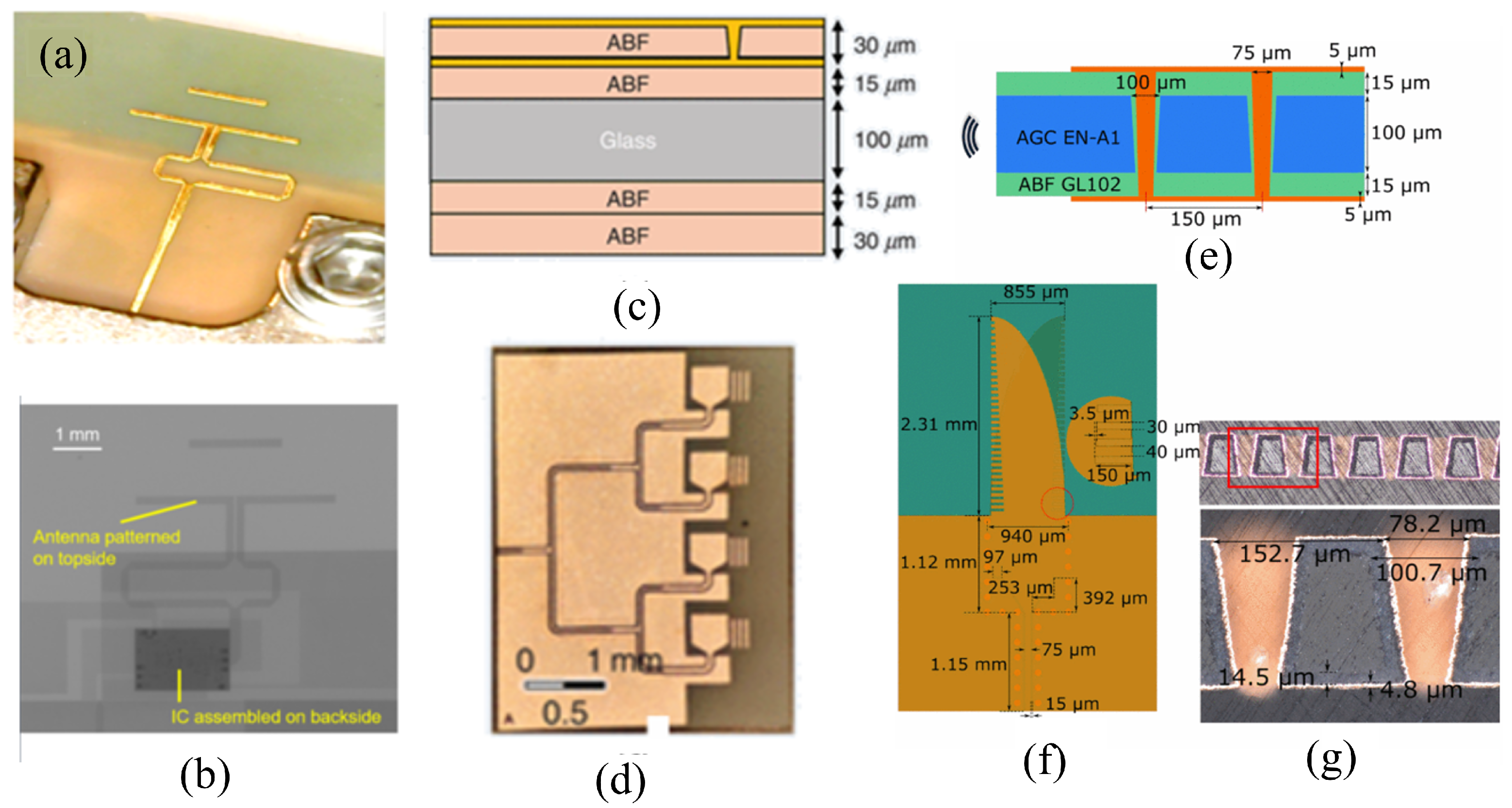

3.3.4. Antenna in Package (AiP)

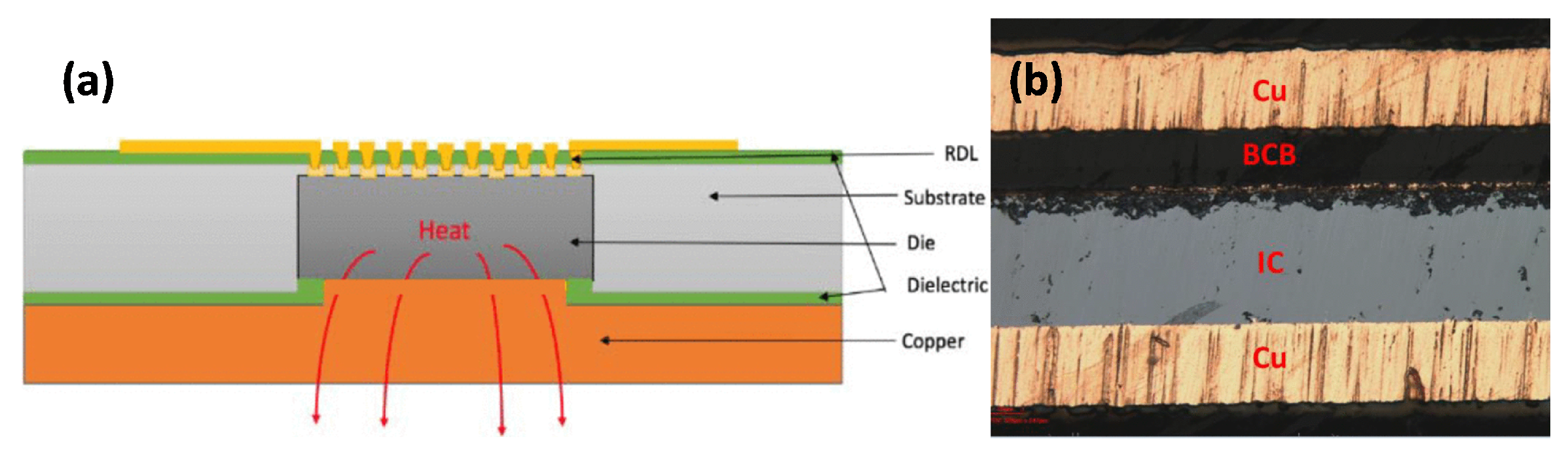

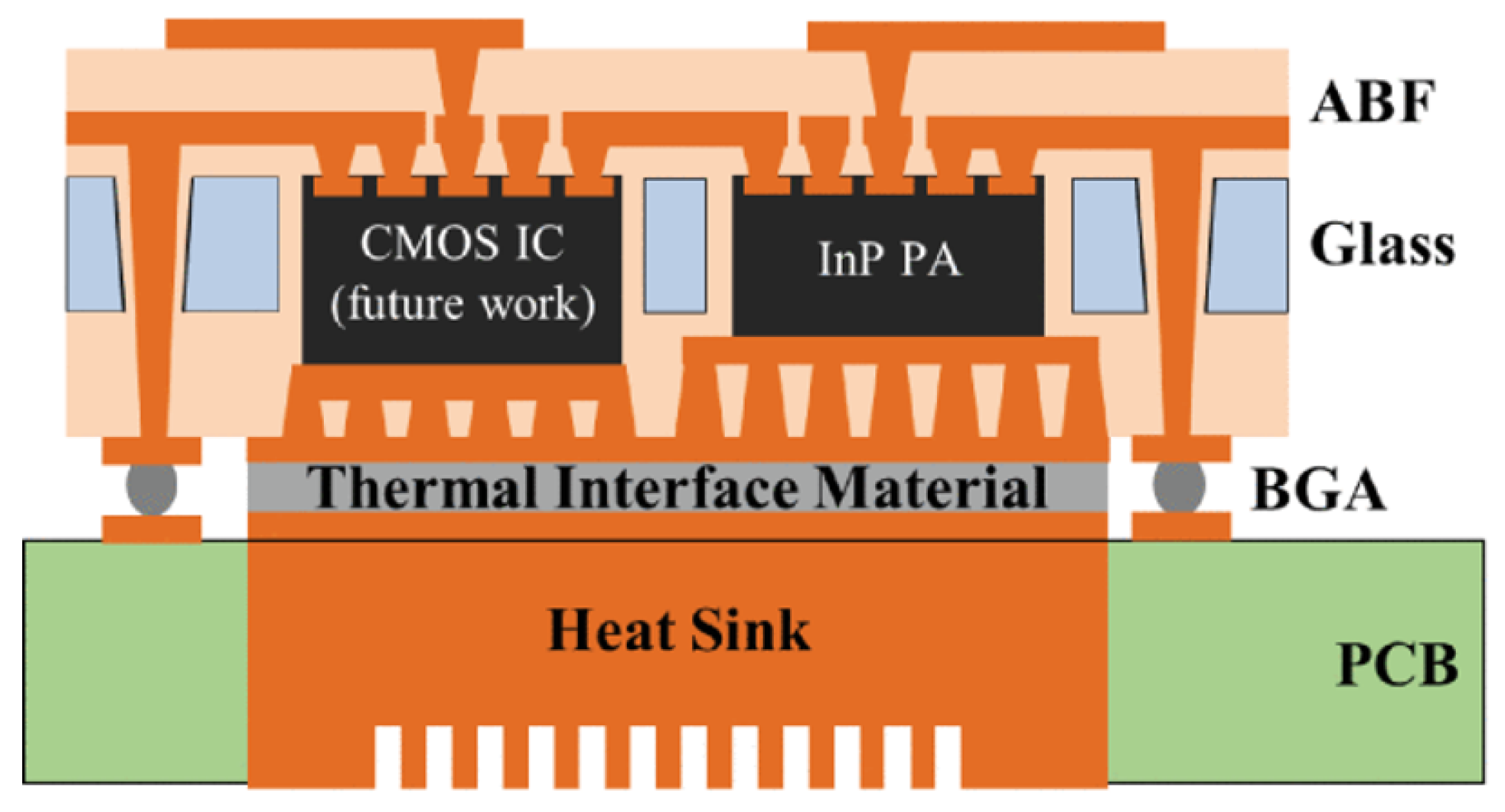

3.4. Thermal Management

4. Manufacturing Challenges

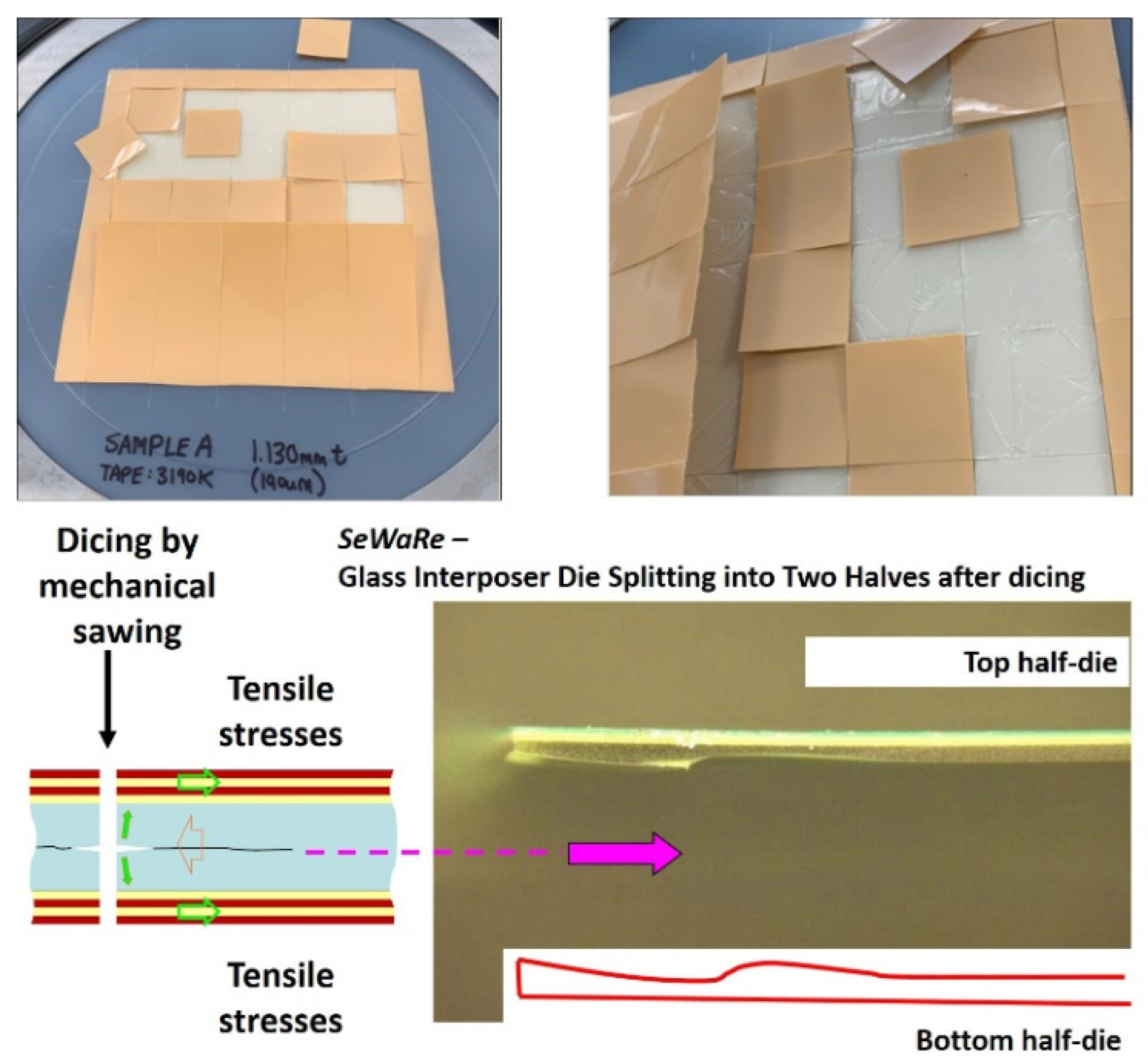

4.1. Glass Cracking

4.2. TGV Process Control and Yield

5. Current State of Commercialization

6. Future Needs

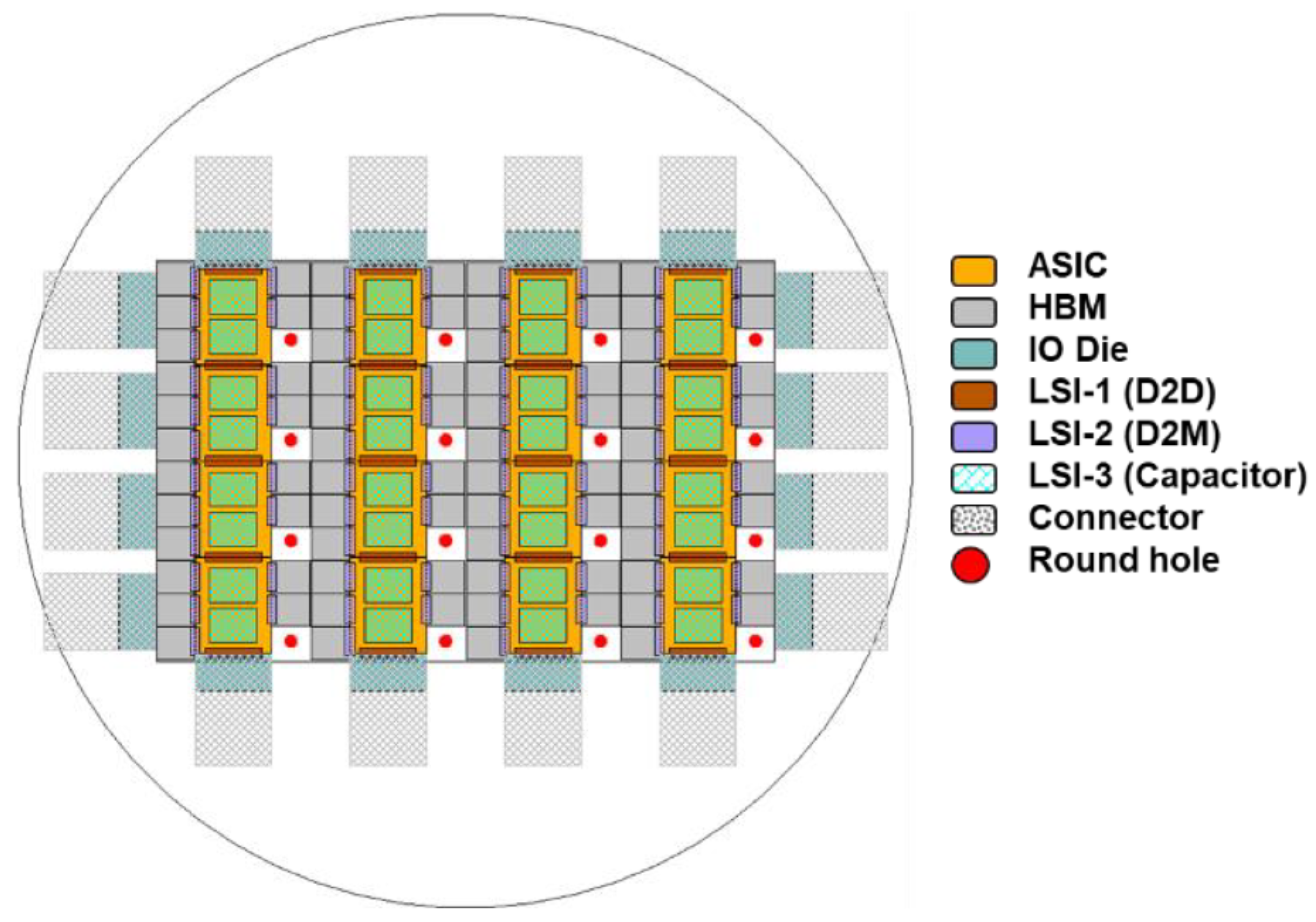

6.1. System on Panel

6.2. Low-Stress Materials and Processes

6.3. Sub-Micron Tolerances and Standardization of Large Panels

6.4. Better Handling, Inspection, and Cleanliness

Funding

Conflicts of Interest

Abbreviations

| GPU | Graphics Processing Unit |

| HBM | High Bandwidth Memory |

| RDL | Redistribution Layer |

| TSMC | Taiwan Semiconductor Manufacturing Company |

| CoWoS | Chip-on-Wafer-on-Substrate |

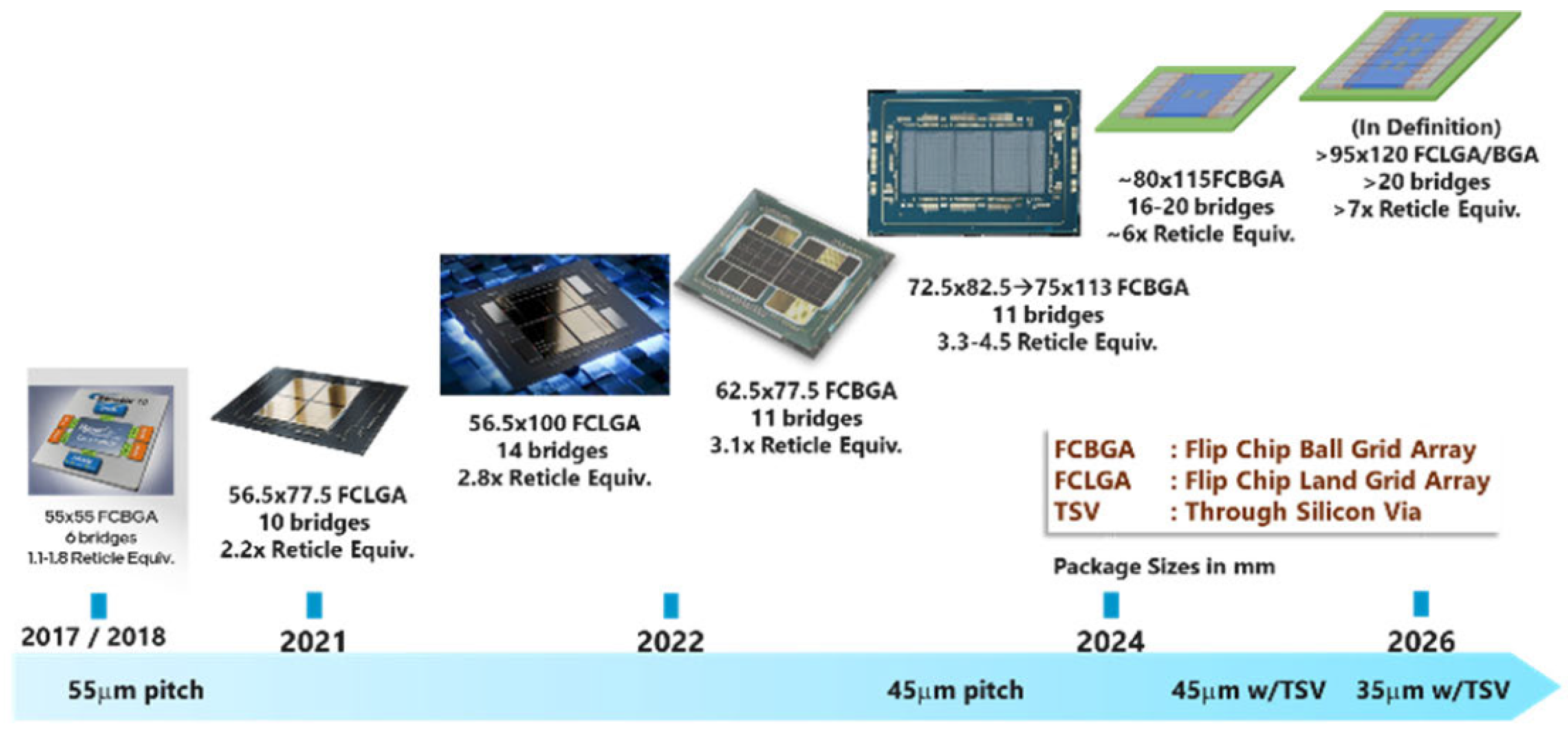

| EMIB | Embedded Multi-die Interconnect Bridge |

| BEOL | Back-End-Of-Line |

| UCIe | Universal Chiplet Interconnect Express |

| ASIC | Application-Specific Integrated Circuit |

| LSI | Local Silicon Interconnect |

| CTE | Coefficient of Thermal Expansion |

| EMC | Epoxy Mold Compound |

| TGV | Through Glass Via |

| ICP RIE | Inductively Coupled Plasma Reactive Ion Etching |

| DC | Direct Current |

| LIDE | Laser Induced Deep Etching |

| RF | Radio Frequency |

| MEMS | Micro-Electro-Mechanical Systems |

| SEM | Scanning Electron Microscope |

| WLFO | Wafer-Level Fan-Out |

| SAP | Semi-Additive Process |

| BGA | Ball Grid Array |

| PCB | Printed Circuit Board |

| C4 | Controlled Collapse Chip Connection |

References

- Duan, G.; Zhang, Y.; Gunawan, A.; Fang, Y.; Mousavi, J.; Apte, A.A.; Ahmed, N.; Sharma, S.; Alur, S.; Chandolu, A.; et al. EMIB-TSV Advanced Packaging Technology—EMIB’s Next Evolution. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27–30 May 2025. [Google Scholar]

- Mahajan, R.; Manepalli, R.; Aygün, K.; Radhakrishnan, K.; Sharan, S. Scaling EMIB—A Comprehensive Architecture Portfolio for Localized Interconnects. IEEE Trans. Electron Devices 2025, 72, 3911–3914. [Google Scholar] [CrossRef]

- Shih, P.C.; Su, A.J.; Tam, K.H.; Huang, T.C.; Chuang, K.; Yeh, J. SoW-X: A Novel System-on-Wafer Technology for Next Generation AI Server Application. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27–30 May 2025. [Google Scholar]

- Kim, Y. Electrical Performance Analysis of High-Speed Interconnection and Power Delivery Network (PDN) in Low-Loss Glass Substrate-Based Interposers. Micromachines 2023, 14, 1880. [Google Scholar] [CrossRef]

- Sawyer, B.M.D.; Suzuki, Y.; Furuya, R.; Nair, C.; Huang, T.C.; Smet, V.; Panayappan, K.; Sundaram, V.; Tummala, R. Design and Demonstration of a 2.5-D Glass Interposer BGA Package for High Bandwidth and Low Cost. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 552–562. [Google Scholar] [CrossRef]

- Vanna-Iampikul, P.; Woo, S.; Erdogan, S.; Zhu, L.; Kathaperumal, M.; Agarwal, R.; Gupta, R.; Rinebold, K.; Swaminathan, M.; Kyu Lim, S. Glass Interposer Integration of Logic and Memory Chiplets: PPA and Power/Signal Integrity Benefits. IEEE Trans. -Comput.-Aided Des. Integr. Circuits Syst. 2025, 44, 1954–1967. [Google Scholar] [CrossRef]

- Du, K.; Shi, P. Subsurface precision machining of glass substrates by innovative lasers. Glass Sci. Technol. 2003, 76, 90–95. [Google Scholar]

- Bernd, K.; Horst, E.; Udo, L.; Thomas, K. Drilling of glass by excimer laser mask projection technique. J. Laser Appl. 2000, 12, 189–193. [Google Scholar] [CrossRef]

- Sukumaran, V.; Kumar, G.; Ramachandran, K.; Suzuki, Y.; Demir, K.; Sato, Y.; Seki, T.; Sundaram, V.; Tummala, R.R. Design, Fabrication, and Characterization of Ultrathin 3-D Glass Interposers with Through-Package-Vias at Same Pitch as TSVs in Silicon. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 786–795. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Ming, X.; Yin, C. Optimization of Laser-induced Deep Etching for TGV Fabrication in Fused Silica. In Proceedings of the 2023 24th International Conference on Electronic Packaging Technology (ICEPT), Shihezi City, China, 8–11 August 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Sandström, N.; Brandt, L.; Sandoz, P.A.; Zambarda, C.; Guldevall, K.; Schulz-Ruhtenberg, M.; Rösener, B.; Krüger, R.A.; Önfelt, B. Live single cell imaging assays in glass microwells produced by laser-induced deep etching. Lab Chip 2022, 22, 2107–2121. [Google Scholar] [CrossRef] [PubMed]

- Santos, R.; Delrue, J.P.; Ambrosius, N.; Ostholt, R.; Schmidt, S. Processing Glass Substrate for Advanced Packaging using Laser Induced Deep Etching. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 1922–1927. [Google Scholar] [CrossRef]

- Yang, Y.; Chien, J.; Lyu, S.; Wei, T. Development of Straight, Small-Diameter, High-Aspect Ratio Copper-Filled Through-Glass Vias (TGV) for High-Density 3D Interconnections. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27–30 May 2025; pp. 1036–1042. [Google Scholar] [CrossRef]

- Kolari, K. Deep plasma etching of glass with a silicon shadow mask. Sens. Actuators A 2008, 41, 677–684. [Google Scholar] [CrossRef]

- Brokmann, U.; Weigel, C.; Altendorf, L.M.; Strehle, S.; Rädlein, E. Wet Chemical and Plasma Etching of Photosensitive Glass. Solids 2023, 4, 213–234. [Google Scholar] [CrossRef]

- Huang, T.; Sundaram, V.; Raj, P.M.; Sharma, H.; Tummala, R. Adhesion and reliability of direct Cu metallization of through-package vias in glass interposers. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; pp. 2266–2270. [Google Scholar] [CrossRef]

- Pandey, H.; Pawar, K.; Dixit, P. Localized surface roughening to improve adhesion of electroless seed layer in through-glass vias. Mater. Sci. Semicond. Process. 2024, 183, 108757. [Google Scholar] [CrossRef]

- Hunegnaw, S.; Liu, Z.; Fu, H.; Wang, J.; Merschky, M.; Mukai, K.; Magaya, T. VitroCoat GI - Ultra-thin adhesive layer for metallization of glass interposer. In Proceedings of the 2015 10th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 21–23 October 2015; pp. 149–152. [Google Scholar] [CrossRef]

- Liu, Z.; Hunegnaw, S.; Fu, H.; Wang, J.; Magaya, T.; Merschky, M.; Bernhard, T.; Shorey, A.; Yun, H. A metal oxide adhesion layer prepared with water based coating solution for wet Cu metallization of glass interposer. In International Symposium on Microelectronics; International Microelectronics Assembly and Packaging Society: Pittsburgh, PA, USA, 2015; Volume 2015, pp. 000365–000369. [Google Scholar]

- Xu, L.; Liu, G.L.; Zhang, H.W.; Wang, Y.; Feng, Z.S. Nano-silver Doped Zinc Oxides Adhesion Layer for Wet Copper Metallization of Glass Substrates. J. Electrochem. Soc. 2025, 172, 012507. [Google Scholar] [CrossRef]

- Chang, Y.H.; Lin, Y.M.; Lee, C.Y.; Hsu, P.C.; Chen, C.M.; Ho, C.E. Through glass via (TGV) copper metallization and its microstructure modification. J. Mater. Res. Technol. 2024, 31, 1008–1016. [Google Scholar] [CrossRef]

- Jarrett, S.; McWethy, K.; Flemming, J. Implementing Photosensitive Glass as a Solution in Thermal Management Applications. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 21–23 July 2020; pp. 647–653. [Google Scholar] [CrossRef]

- Kanungo, M.; Vaddi, R.; Okoro, C.; Pollard, S.; Mazumder, P. Metallization of Helium-Hermetic and Thermo-Mechanically Reliable Through Glass Vias (TGV) by Conformal Pinched Via (CPV) Approach. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27 May 2025; pp. 1043–1046. [Google Scholar] [CrossRef]

- Through Glass Via (TGV). Available online: https://www.agc.com/en/products/electoric/detail/tgv.html (accessed on 2 July 2025).

- Shorey, A. Glass Package and Through Glass Via (TGV) for MEMS. In Proceedings of the IMAPS 19th Conference on DEVICE PACKAGING, Fountain Hills, AZ, USA, 13–16 March 2023; pp. 995–1018. [Google Scholar] [CrossRef]

- Through-Glass Vias. Available online: https://www.3dgsinc.com/through-glass-vias (accessed on 2 July 2025).

- LPKF Vitrion TGV Solutions. Available online: https://vitrion.lpkf.com/en/company (accessed on 2 July 2025).

- Plan Optik Packaging Wafers. Available online: https://planoptik.com/products/packaging-wafers/ (accessed on 2 July 2025).

- LPKF Vitrion. RF and mmWave Applications—Glass Substrates for Advanced Packaging. 2025. Available online: https://vitrion.lpkf.com/en/applications-products/radio-frequencies (accessed on 2 July 2025).

- NSC Anaake Glass Solutions. Available online: https://nsc-net.co.jp/en/anaake/ (accessed on 2 July 2025).

- DNP Through Glass Via News. Available online: https://www.global.dnp/news/detail/20169052_4126.html (accessed on 2 July 2025).

- Tecnisco TGV Technology. Available online: https://www.tecnisco.com/en/en_product/en_glass/en_tgv.html (accessed on 2 July 2025).

- High-Quality Borosilicate Glass TGV. Available online: https://www.galliumnitridewafer.com/sale-44812469-tgv-through-glass-via-technology-high-quality-borosilicate-glass-quartz.html (accessed on 2 July 2025).

- SkySemi TGV Services. Available online: https://www.sky-semi.com/tgvjs (accessed on 2 July 2025).

- Lante Semiconductor Applications. Available online: https://www.lante.com.cn/en/product/semiconductor-applications-103.html (accessed on 2 July 2025).

- Spierings, G. Wet chemical etching of silicate glasses in hydrofluoric acid based solutions. J. Mater. Sci. 1993, 28, 6261–6273. [Google Scholar] [CrossRef]

- Iliescu, C.; Chen, B.; Miao, J. On the wet etching of Pyrex glass. Sens. Actuators Phys. 2008, 143, 154–161. [Google Scholar] [CrossRef]

- Park, J.; Lee, N.E.; Lee, J.; Park, J.; Park, H. Deep dry etching of borosilicate glass using SF6 and SF6/Ar inductively coupled plasmas. Microelectron. Eng. 2005, 82, 119–128. [Google Scholar] [CrossRef]

- Iliescu, C.; Tan, K.L.; Tay, F.E.; Miao, J. Deep wet and dry etching of Pyrex glass: A review. In Proceedings of the ICMAT (Symposium F), Singapore, 8–10 May 2005; pp. 75–78. [Google Scholar]

- Moore, A.F.; Frantz, J.A.; Busse, L.E.; Sanghera, J.S. A Review of Reactive Ion Etching of Glass Materials. 2021. Available online: https://apps.dtic.mil/sti/citations/AD1150342 (accessed on 2 July 2025).

- Jia, X.; Li, X.; Erdogan, S.; Moon, K.S.; Kim, J.W.; Huang, K.Q.; Jordan, M.B.; Swaminathan, M. Antenna with embedded die in glass interposer for 6G wireless applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 219–229. [Google Scholar] [CrossRef]

- Cheng, H.C.; Chung, C.H.; Chen, W.H. Die Shift Assessment of Reconstituted Wafer for Fan-Out Wafer-Level Packaging. IEEE Trans. Device Mater. Reliab. 2020, 20, 136–145. [Google Scholar] [CrossRef]

- Ravichandran, S.; Yamada, S.; Park, G.; Chen, H.W.; Shi, T.; Buch, C.; Liu, F.; Smet, V.; Sundaram, V.; Tummala, R. 2.5 D glass panel embedded (GPE) packages with better I/O density, performance, cost and reliability than current silicon interposers and high-density fan-out packages. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 625–630. [Google Scholar]

- Ravichandran, S. Design and Demonstration of 3D Glass Panel Embedded (GPE) Package for Superior Bandwidth and Power-Efficiency. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2021. [Google Scholar]

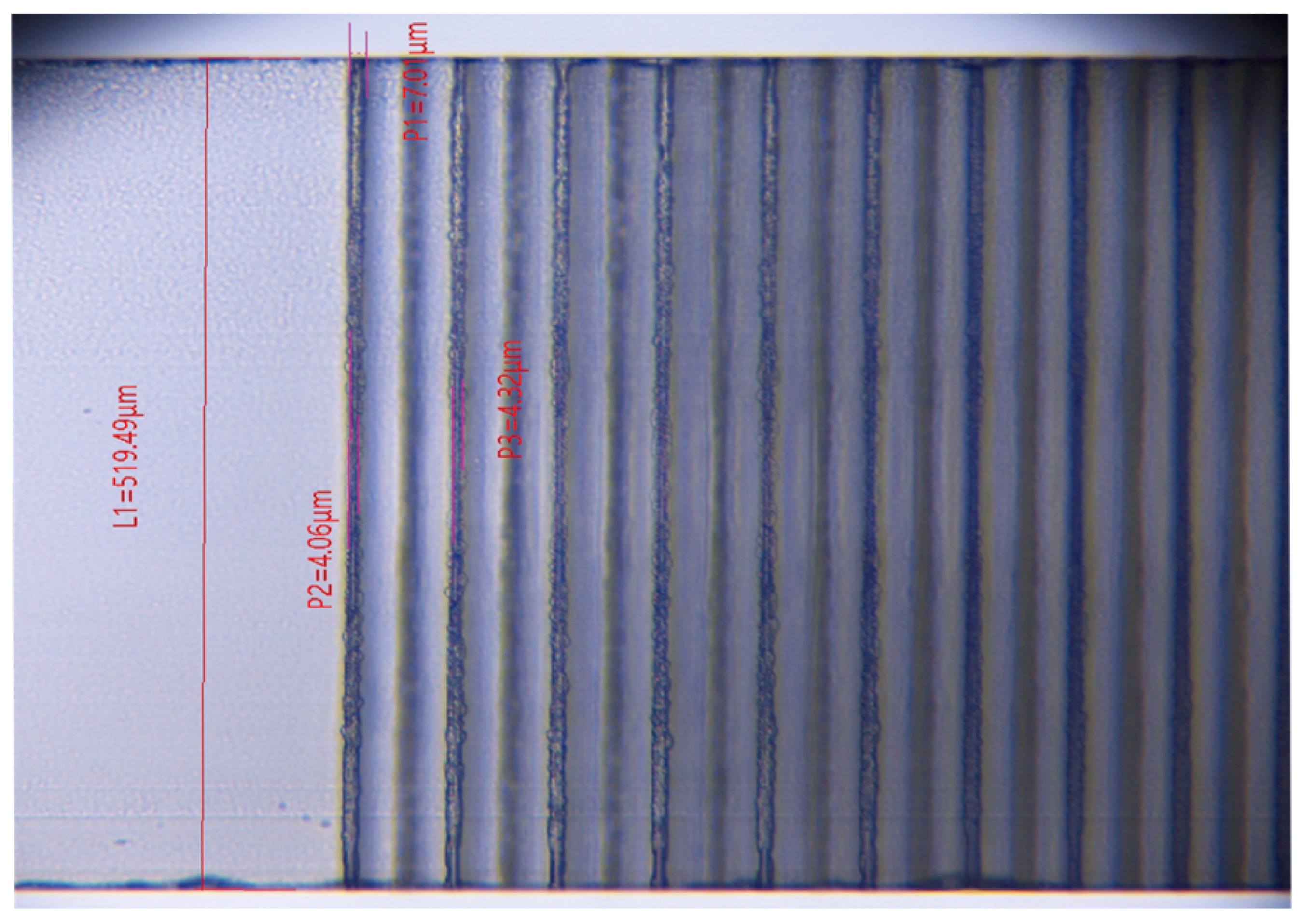

- Lu, H.; Furuya, R.; Sawyer, B.M.; Nair, C.; Liu, F.; Sundaram, V.; Tummala, R.R. Design, Modeling, Fabrication and Characterization of 2-5-μm Redistribution Layer Traces by Advanced Semiadditive Processes on Low-Cost Panel-Based Glass Interposers. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 959–967. [Google Scholar] [CrossRef]

- Liu, F.; Nimbalkar, P.; Aslani-Amoli, N.; Kathaperumal, M.; Tummala, R.; Swaminathan, M. A Critical Review of Lithography Methodologies and Impacts of Topography on 2.5-D/3-D Interposers. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 291–299. [Google Scholar] [CrossRef]

- Nimbalkar, P.; Bhaskar, P.; Blancher, C.; Kathaperumal, M.; Swaminathan, M.; Tummala, R. Novel zero side-etch process for <1μm package redistribution layers. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 2168–2173. [Google Scholar] [CrossRef]

- Kudo, H.; Takano, T.; Tanaka, M.; Mawatari, H.; Kitayama, D.; Tai, T.; Tsunoda, T.; Kuramochi, S. Panel-based large-scale RDL Interposer fabricated using 2-μm-pitch semi-additive process for chiplet-based integration. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May 2022–3 June 2022; pp. 836–844. [Google Scholar]

- Demir, K.; Armutlulu, A.; Sundaram, V.; Raj, P.M.; Tummala, R.R. Reliability of Copper Through-Package Vias in Bare Glass Interposers. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 829–837. [Google Scholar] [CrossRef]

- Ahmed, O.; Jalilvand, G.; Pollard, S.; Okoro, C.; Jiang, T. The interfacial reliability of through-glass vias for 2.5D integrated circuits. Microelectron. Int. 2020, 37, 181–188. [Google Scholar] [CrossRef]

- Pan, K.; Xu, J.; Lai, Y.; Park, S.; Okoro, C.; Joshi, D.; Pollard, S. In-situ temperature-dependent characterization of copper through glass via (TGV). Microelectron. Reliab. 2022, 129, 114487. [Google Scholar] [CrossRef]

- Wang, H.; Lai, C.; Ma, B.; Jian, X.; Chen, S.; Chen, H.; Fang, L.; Yang, X. Failure Mechanisms Investigation of Through Glass via (TGV) Under Thermal Annealing and Shock. In Proceedings of the 2024 25th International Conference on Electronic Packaging Technology (ICEPT), Shanghai, China, 7–9 August 2024; pp. 1–6. [Google Scholar]

- Fujimoto, K.; Okawa, Y.; Tai, T.; Kuramochi, S. Development of Glass core substrate with the stress analysis, transmission characteristics and reliability. In Proceedings of the 2024 IEEE 74th Electronic Components and Technology Conference (ECTC), Denver, CO, USA, 28–31 May 2024; pp. 546–550. [Google Scholar] [CrossRef]

- Okoro, C.; Maurey, P.; Davis, R.; Pollard, S. Evaluation of the helium hermeticity reliability of copper through-glass vias. Microelectron. Reliab. 2022, 137, 114783. [Google Scholar] [CrossRef]

- Lau, J.H.; Liu, N.; Ma, M.; Tseng, T.J. Solder joint reliability-glass core substrate versus organic core substrate. Microelectron. Reliab. 2025, 168, 115701. [Google Scholar] [CrossRef]

- JEDEC Standard-Thermal Shock JESD22-A106B. Available online: https://www.jedec.org/sites/default/files/docs/22a106b.pdf (accessed on 21 August 2025).

- Jayaram, V.; Gupte, O.; Smet, V. Modeling and Design for System-Level Reliability and Warpage Mitigation of Large 2.5D Glass BGA Packages. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 12 July 2022; pp. 1060–1067. [Google Scholar] [CrossRef]

- Jayaram, V.; McCann, S.; Singh, B.; Pulugurtha, R.; Smet, V.; Tummala, R.; Matsuura, H.; Takagi, Y. Analysis of system-level reliability of single-chip glass BGA packages with advanced solders and polymer collars. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; pp. 1405–1412. [Google Scholar]

- JEDEC Standard-Board Level Drop Test Method of Components for Handheld Electronic Products JESD22-B111A.01. Available online: https://www.jedec.org/standards-documents/docs/jesd-22-b111 (accessed on 21 August 2025).

- Singh, B.; Menezes, G.; McCann, S.; Jayaram, V.; Ray, U.; Sundaram, V.; Pulugurtha, R.; Smet, V.; Tummala, R. Board-level thermal cycling and drop-test reliability of large, ultrathin glass BGA packages for smart mobile applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 726–733. [Google Scholar] [CrossRef]

- Erdogan, S.; Ravichandran, S.; Jia, X.; Swaminathan, M. Characterization of Chip-to-Package Interconnects for Glass Panel Embedding (GPE) for Sub-THz Wireless Communications. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021; pp. 2328–2333. [Google Scholar] [CrossRef]

- Broquin, J.E.; Honkanen, S. Integrated Photonics on Glass: A Review of the Ion-Exchange Technology Achievements. Appl. Sci. 2021, 11, 4472. [Google Scholar] [CrossRef]

- Will, M.; Nolte, S.; Chichkov, B.N.; Tünnermann, A. Optical properties of waveguides fabricated in fused silica by femtosecond laser pulses. Appl. Opt. 2002, 41, 4360–4364. [Google Scholar] [CrossRef]

- Osellame, R.; Taccheo, S.; Marangoni, M.; Ramponi, R.; Laporta, P.; Polli, D.; Silvestri, S.D.; Cerullo, G. Femtosecond writing of active optical waveguides with astigmatically shaped beams. J. Opt. Soc. Am. B 2003, 20, 1559–1567. [Google Scholar] [CrossRef]

- Ross-Adams, A.; Fernandez, T.T.; Withford, M.; Gross, S. Low bend loss, high index, composite morphology ultra-fast laser written waveguides for photonic integrated circuits. Light Adv. Manuf. 2024, 5, 52–61. [Google Scholar] [CrossRef]

- Schröder, H.; Kirsch, O.; Weber, D.; Thiem, H. Photonic system integration by applying microelectronic packaging approaches using glass substrates. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 216–223. [Google Scholar] [CrossRef]

- Grenier, J.R.; Brusberg, L.; Wieland, K.A.; Matthies, J.; Terwilliger, C.C. Ultrafast laser processing of glass waveguide substrates for multi-fiber connectivity in co-packaged optics. Adv. Opt. Technol. 2023, 12, 1244009. [Google Scholar] [CrossRef]

- Brusberg, L.; Dejneka, M.J.; Okoro, C.A.; McEnroe, D.J.; Zakharian, A.R.; Terwilliger, C.C. Ultra Low-Loss Ion-Exchange Waveguides in Optimized Alkali Glass for Co-Packaged Optics. In Proceedings of the 2024 IEEE 74th Electronic Components and Technology Conference (ECTC), Denver, CO, USA, 28–31 May 2024; pp. 85–89. [Google Scholar]

- Brusberg, L.; Grenier, J.R.; Zakharian, A.R.; Yeary, L.W.; Seok, S.H.; Noh, J.H.; Kim, Y.G.; Matthies, J.; Terwilliger, C.C.; Paddock, B.J.; et al. Glass platform for co-packaged optics. IEEE J. Sel. Top. Quantum Electron. 2023, 29, 6000210. [Google Scholar] [CrossRef]

- Brusberg, L.; Zakharian, A.R.; Kocabaş, Ş.E.; Yeary, L.W.; Grenier, J.R.; Terwilliger, C.C.; Bellman, R.A. Glass substrate with integrated waveguides for surface mount photonic packaging. J. Light. Technol. 2020, 39, 912–919. [Google Scholar] [CrossRef]

- Yeary, L.; Brusberg, L.; Kim, C.; Seok, S.H.; Noh, J.; Rozenvax, A. Co-packaged optics on glass substrates for 102.4 Tb/s data center switches. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 224–227. [Google Scholar]

- Chou, B.C.; Vis, W.; Khan, B.; Furuya, R.; Liu, F.; Sundaram, V.; Tummala, R. Design and demonstration of micro-mirrors and lenses for low loss and low cost single-mode fiber coupling in 3D glass photonic interposers. In Proceedings of the 2016 IEEE 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016; pp. 497–503. [Google Scholar]

- Vis, W.; Chou, B.C.; Sundaram, V.; Tummala, R. Self-Aligned Chip-to-Chip Optical Interconnections in Ultra-Thin 3D Glass Interposers. In Proceedings of the 2015 Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 26–29 May 2015. [Google Scholar]

- Swaminathan, M.; Li, X.; Kumar, L.N.V.; Jia, X.; Erdogan, S.; ur Rehman, M.; Huang, K.Q.; Kim, J.W.; Al-Juwhari, M.; Ahamed, M. Glass Packaging for 6G Applications. IEEE Microw. Mag. 2025, 26, 46–64. [Google Scholar] [CrossRef]

- Lin, T.; Raj, P.M.; Watanabe, A.; Sundaram, V.; Tummala, R.; Tentzeris, M.M. Nanostructured Miniaturized Artificial Magnetic Conductors (AMC) for High-Performance Antennas in 5G, IoT, and Smart Skin Applications. In Proceedings of the 2017 IEEE 17th International Conference on Nanotechnology (IEEE-NANO), Pittsburgh, PA, USA, 25–28 July 2017; pp. 911–915. [Google Scholar]

- Rehman, M.U.; Ravichandran, S.; Watanabe, A.O.; Erdogan, S.; Swaminathan, M. Characterization of ABF/Glass/ABF Substrates for mmWave Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 384–394. [Google Scholar] [CrossRef]

- Watanabe, A.O.; Lin, T.H.; Ogawa, T.; Raj, P.M.; Sundaram, V.; Tentzeris, M.M.; Tummala, R.R. Design and demonstration of ultra-thin 3D glass-based 5G modules with low-loss interconnects. In Proceedings of the 2018 International Conference on Electronics Packaging and iMAPS All Asia Conference (ICEP-IAAC), Kuwana, Mie, Japan, 17–21 April 2018; pp. 180–183. [Google Scholar]

- Watanabe, A.O.; Ali, M.; Tehrani, B.; Hester, J.; Matsuura, H.; Ogawa, T.; Raj, P.M.; Sundaram, V.; Tentzeris, M.M.; Tummala, R.R. First demonstration of 28 GHz and 39 GHz transmission lines and antennas on glass substrates for 5G modules. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; pp. 236–241. [Google Scholar]

- Watanabe, A.; Lin, T.H.; Raj, P.M.; Sundaram, V.; Tentzeris, M.M.; Tummala, R.R.; Ogawa, T. Leading-edge and ultra-thin 3D glass-polymer 5G modules with seamless antenna-to-transceiver signal transmissions. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 29 May–1 June 2018; pp. 2026–2031. [Google Scholar]

- Kumar, L.N.V.; Moon, K.S.; Swaminathan, M.; Kanno, K.; Ito, H.; Ogawa, T.; Hasegawa, K. Demonstration and Comparison of Vertical Via-less Interconnects in Laminated Glass Panels from 40-170 GHz. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 12 July 2022; pp. 2281–2286. [Google Scholar]

- Rehman, M.U.; Watanabe, A.; Ravichandran, S.; Swaminathan, M. Substrate Integrated Waveguides in Glass Interposers for mmWave Applications. In Proceedings of the IEEE MTT-S International Microwave Symposium (IMS), Atlanta, GA, USA, 16–21 June 2021; pp. 339–341. [Google Scholar]

- Rehman, M.U.; Kumar, L.N.V.; Erdogan, S.; Swaminathan, M. Air-Filled SIWs Using Laminate Dielectrics on Glass Substrate for D-Band Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2024, 14, 98–105. [Google Scholar] [CrossRef]

- Ali, M.; Liu, F.; Watanabe, A.; Raj, P.M.; Sundaram, V.; Tentzeris, M.M.; Tummala, R.R. First demonstration of compact, ultra-thin low-pass and bandpass filters for 5G small-cell applications. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 1110–1112. [Google Scholar] [CrossRef]

- Ali, M. Modeling, Design and Fabrication of Miniaturized, High Performance and Integrated Passive Components for 5G and mm-Wave Applications. Ph.D. Thesis, School of Electrical and Computer Engineering, Georgia Institute of Technology, Atlanta, GA, USA, 2020. [Google Scholar]

- Li, X.; Jia, X.; Erdogan, S.; Swaminathan, M. Design and Characterization of Bandpass Filter with Multiple Zeros on Glass Interposer for 6G Applications. In Proceedings of the IEEE Radio and Wireless Symposium (RWS), Las Vegas, NV, USA, 22 January 2023; pp. 98–100. [Google Scholar]

- Bartlett, C.; Malavé, A.; Letz, M.; Höft, M. Structured-Glass Waveguide Technology for High-Performance Millimetre-Wave Components and Systems. IEEE J. Microw. 2022, 2, 307–315. [Google Scholar] [CrossRef]

- de Kok, M.; Smolders, A.B.; Johannsen, U. A review of design and integration technologies for D-band antennas. IEEE Open J. Antennas Propag. 2021, 2, 746–758. [Google Scholar] [CrossRef]

- Huang, K.Q.; Swaminathan, M. Antenna Array on Glass Interposer for 6G Wireless Communications. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 211–218. [Google Scholar] [CrossRef]

- Watanabe, A.O.; Lin, T.H.; Ali, M.; Wang, Y.; Smet, V.; Raj, P.M.; Tentzeris, M.M.; Tummala, R.R.; Swaminathan, M. Ultrathin antenna-integrated glass-based millimeter-wave package with through-glass vias. IEEE Trans. Microw. Theory Tech. 2020, 68, 5082–5092. [Google Scholar] [CrossRef]

- Erdogan, S.; Moon, K.S.J.; Kathaperumal, M.; Swaminathan, M. D-Band Integrated and Miniaturized Quasi-Yagi Antenna Array in Glass Interposer. IEEE Trans. Terahertz Sci. Technol. 2023, 13, 270–279. [Google Scholar] [CrossRef]

- Narasimha, L.; Kumar, V.; Swaminathan, M. Ultra-Wide Bandwidth Substrate Integrated Waveguide Fed Vivaldi Antenna in D-Band Using Glass Interposer. In Proceedings of the IEEE Radio and Wireless Symposium (RWS), Las Vegas, NV, USA, 22 January 2023; pp. 150–152. [Google Scholar]

- Nedumthakady, N.; DeProspo, B.; Raj, P.M.; Sundaram, V.; Tummala, R.; Byers, K.; Garrison, S.; Gibson, C.; Elsbury, M. Integrated copper heat spreaders in glass panel embedded packages with near-zero thermal interface resistance. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 2013–2018. [Google Scholar]

- Wong, R.; Ravichandran, S.; Lee, H.; Smet, V. Thermal Management of Glass Panel Embedded Packages: Package Architecture vs. Power Density. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 2105–2106. [Google Scholar] [CrossRef]

- Jia, X.; Li, X.; Kim, J.W.; Moon, K.s.; Rodwell, M.J.; Swaminathan, M. Antenna-Integrated and PA-Embedded Glass Substrates for D-Band InP Power Amplifier Modules. IEEE Trans. Compon. Packag. Manuf. Technol. 2025, 15, 782–791. [Google Scholar] [CrossRef]

- Cho, S.; Sundaram, V.; Tummala, R.R.; Joshi, Y.K. Impact of copper through-package vias on thermal performance of glass interposers. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1075–1084. [Google Scholar] [CrossRef]

- McCann, S.; Singh, B.; Smet, V.; Sundaram, V.; Tummala, R.R.; Sitaraman, S.K. Process Innovations to Prevent Glass Substrate Fracture From RDL Stress and Singulation Defects. IEEE Trans. Device Mater. Reliab. 2016, 16, 622–630. [Google Scholar] [CrossRef]

- McCann, S.; Sato, Y.; Sundaram, V.; Tummala, R.R.; Sitaraman, S.K. Prevention of Cracking From RDL Stress and Dicing Defects in Glass Substrates. IEEE Trans. Device Mater. Reliab. 2016, 16, 43–49. [Google Scholar] [CrossRef]

- Wei, F.; Frederick, A. Comprehensive Die Strengths Comparisons for Glass-Core Advanced Packaging Substrates Using Different Singulation Methods. In Proceedings of the 2025 IEEE 75th Electronic Components and Technology Conference (ECTC), Dallas, TX, USA, 27–30 May 2025. [Google Scholar]

- Best, K. The Long Climb: Bringing Through-Glass Vias (TGV) to High-Volume Manufacturing. 2024. Available online: https://semiengineering.com/the-long-climb-bringing-through-glass-vias-tgv-to-high-volume-manufacturing/ (accessed on 2 July 2025).

- The Elec. News Article on Glass Substrate Development. 2025. Available online: https://www.thelec.net/news/articleView.html?idxno=5254 (accessed on 2 July 2025).

- Basler AG. TGV Inspection with Basler Vision Systems. 2025. Available online: https://www.baslerweb.com/en/use-cases/tgv-inspection/?srsltid=AfmBOopWjLfjQ08phATo... (accessed on 2 July 2025).

- Toray Engineering. Announcement from Toray Engineering (18 February 2025). Available online: https://www.toray-eng.com/news/2025/20250218.html (accessed on 2 July 2025).

- Tokyo Electron Device. Glass Wafer Defect Inspection System. 2025. Available online: https://us.teldevice.com/product/glass-wafer-defect-inspection-system/ (accessed on 2 July 2025).

- Reuters. US Plans $75 Million Grant for Absolics Advanced Chip Packaging. 2024. Available online: https://www.reuters.com/technology/us-plans-75-million-grant-absolics-advanced-chip-packaging-2024-05-23/ (accessed on 1 July 2025).

- AP News. SK Group affiliate Absolics Opens Glass Substrate Facility in Georgia. 2024. Available online: https://apnews.com/article/dcf574a21293e3d6d53b89b594d72fcd (accessed on 1 July 2025).

- AT&S Newsroom. AT&S Building World-Class R&D Facility at Leoben HQ. 2024. Available online: https://ats.net/en/ats-building-world-class-rd-facility-at-leoben-hq/ (accessed on 1 July 2025).

- DNP. Development of Glass Core Substrate for Semiconductor Packages. 2023. Available online: https://www.global.dnp/news/detail/20169052_4126.html (accessed on 1 July 2025).

- AnandTech. Intel Shows Off Glass-Core Substrate Plans. 2023. Available online: https://www.anandtech.com/show/20058/intel-shows-off-glass-core-substrate-plans-deployment-late-decade (accessed on 1 July 2025).

- Digitimes. LG Innotek Preparing Sample Production for Glass Substrates. 2025. Available online: https://www.digitimes.com/news/a20250331PD204/lg-innotek-expansion-camera-module-manufacturing-technology.html (accessed on 1 July 2025).

- Fierce Electronics. Glass Substrates Maker Absolics on Track for $75M CHIPS Act. 2024. Available online: https://www.fierceelectronics.com/electronics/glass-substrates-maker-absolics-track-75m-chips-act (accessed on 24 June 2025).

- FICT. FICT Demonstrates Multilayer Glass-Core G-ALCS Technology. 2024. Available online: https://www.fict-g.com/en/news/2024/11/e20241101.html (accessed on 1 July 2025).

- IMAPS. Glass-Core Substrates for RF Heterogeneous Integrated Packages. 2023. Available online: https://imapsource.org/api/v1/articles/94295-glass-core-substrates-for-rf-heterogeneous-integrated-packages.pdf (accessed on 1 July 2025).

- 3D Glass Solutions. 3D Glass Solutions Closes $30 Million Series C Funding Round. 2023. Available online: https://www.businesswire.com/news/home/20230419005269/en/3D-Glass-Solutions-Closes-%2430-Million-Series-C-Funding-Round (accessed on 24 June 2025).

- Ibiden IR. Q2 FY2024 Financial and R&D Update. 2024. Available online: https://www.ibiden.com/ir/items/en_kessannsetsumei2024Q2.pdf (accessed on 21 July 2025).

- Business Korea. Samsung Electro-Mechanics and Group Affiliates Exploring Glass Substrates. 2024. Available online: https://www.businesskorea.co.kr/news/articleView.html?idxno=212906 (accessed on 1 July 2025).

- Tummala, R.; Deprospo, B.; Dwarakanath, S.; Ravichandran, S.; Nimbalkar, P.; Nedumthakady, N.; Swaminathan, M. Glass panel packaging, as the most leading-edge packaging: Technologies and applications. In Proceedings of the 2020 Pan Pacific Microelectronics Symposium (Pan Pacific), Kohala Coast, HI, USA, 10–13 February 2020; pp. 1–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nimbalkar, P.; Bhaskar, P.; Vijay Kumar, L.N.; Narayanan, M.; Torres, E.; Ambi Venkataramanan, S.S.; Kathaperumal, M. A Review of Glass Substrate Technologies. Chips 2025, 4, 37. https://doi.org/10.3390/chips4030037

Nimbalkar P, Bhaskar P, Vijay Kumar LN, Narayanan M, Torres E, Ambi Venkataramanan SS, Kathaperumal M. A Review of Glass Substrate Technologies. Chips. 2025; 4(3):37. https://doi.org/10.3390/chips4030037

Chicago/Turabian StyleNimbalkar, Pratik, Pragna Bhaskar, Lakshmi Narasimha Vijay Kumar, Meghna Narayanan, Emanuel Torres, Sai Saravanan Ambi Venkataramanan, and Mohanalingam Kathaperumal. 2025. "A Review of Glass Substrate Technologies" Chips 4, no. 3: 37. https://doi.org/10.3390/chips4030037

APA StyleNimbalkar, P., Bhaskar, P., Vijay Kumar, L. N., Narayanan, M., Torres, E., Ambi Venkataramanan, S. S., & Kathaperumal, M. (2025). A Review of Glass Substrate Technologies. Chips, 4(3), 37. https://doi.org/10.3390/chips4030037