The Activation of Magnesium Sintering by Zinc Addition

Abstract

1. Introduction

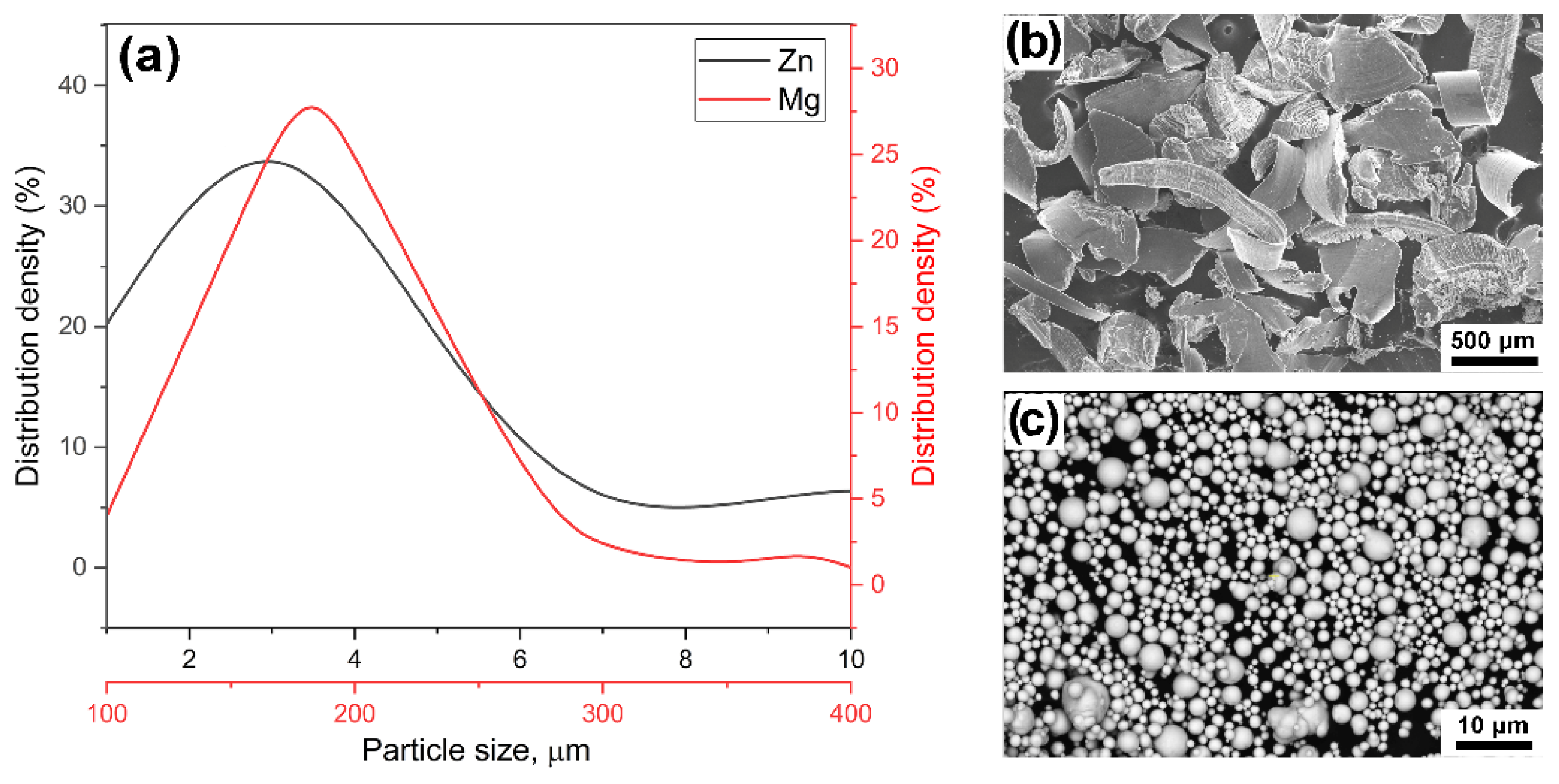

2. Materials and Methods

3. Results

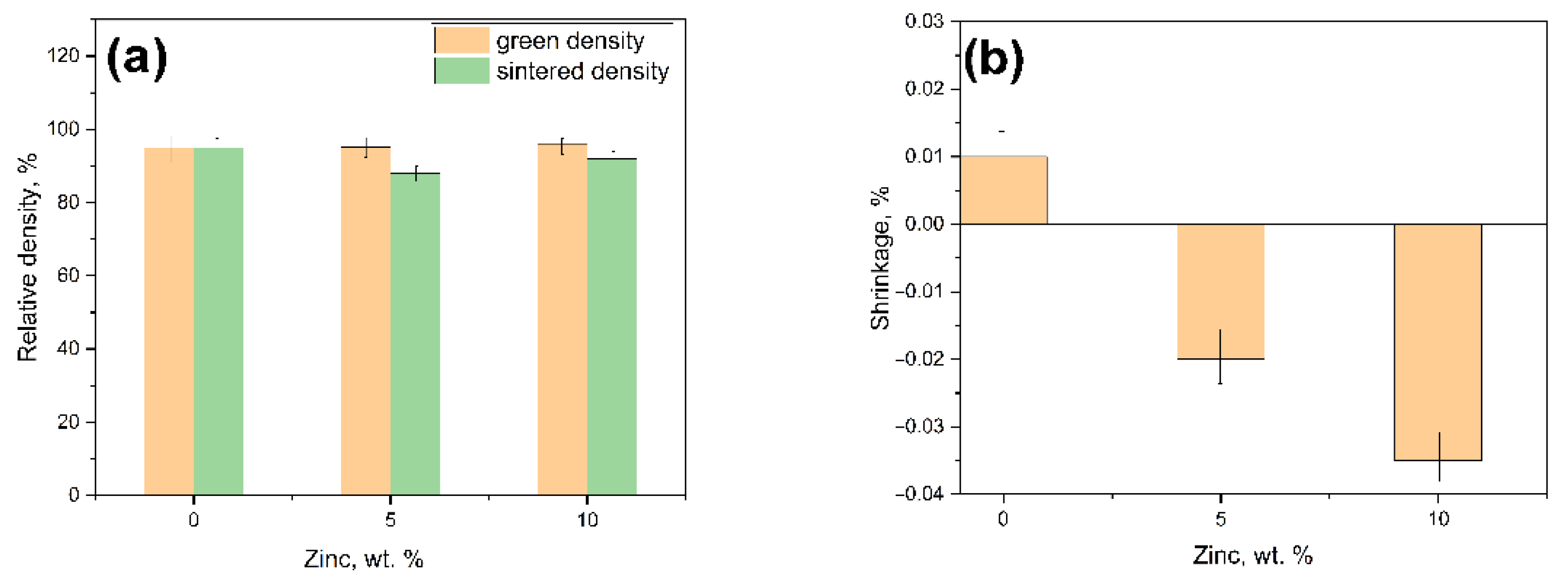

3.1. Pressing and Sintering

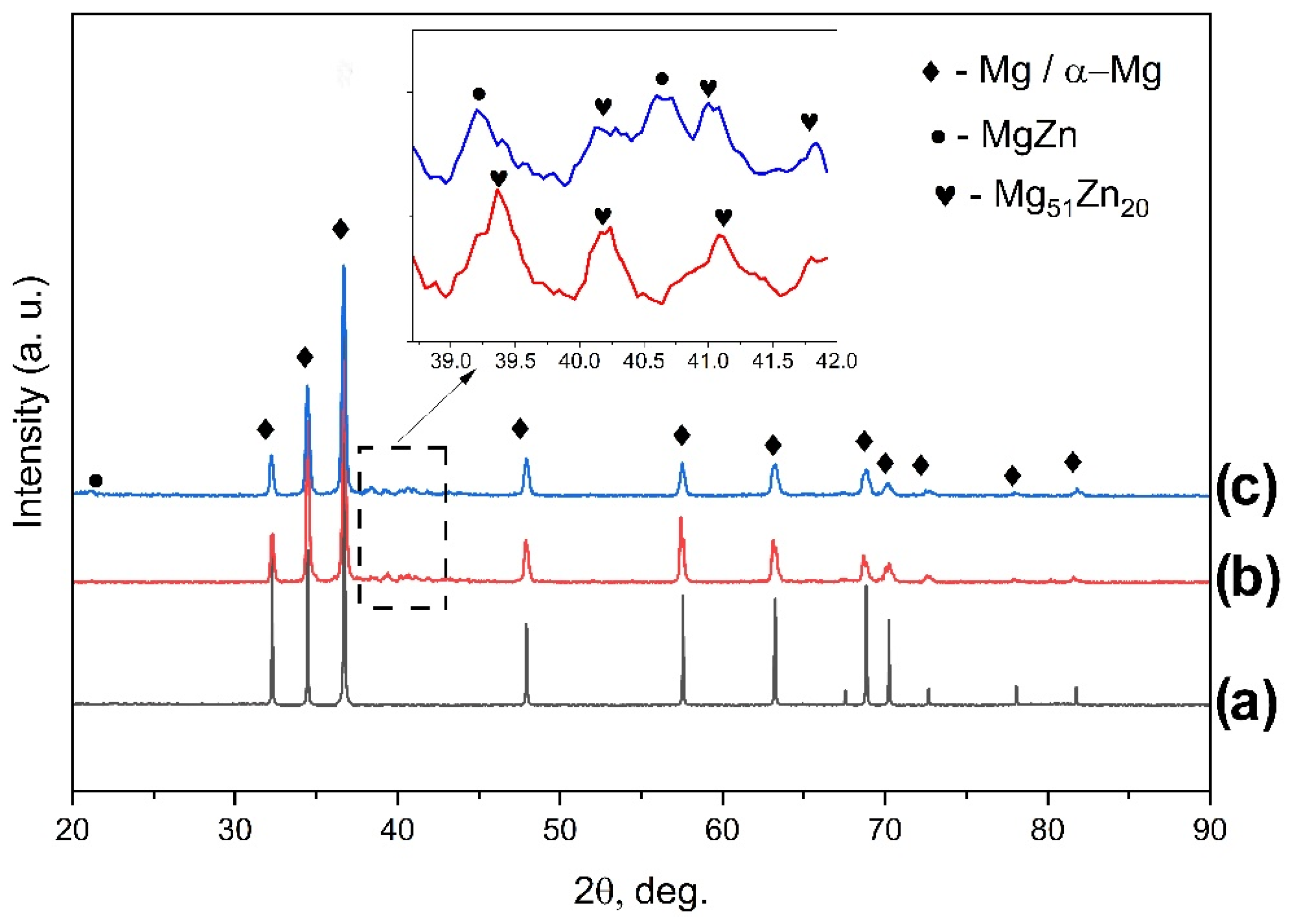

3.2. Microstructural and Phase Analysis

3.3. Compressive Strength of Mg-Zn Alloys

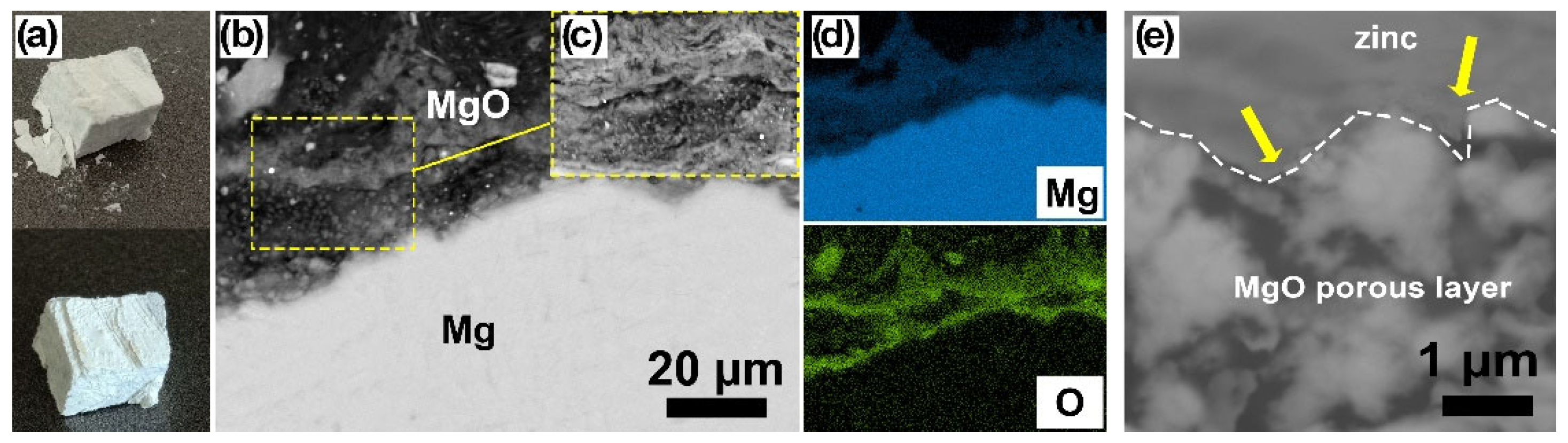

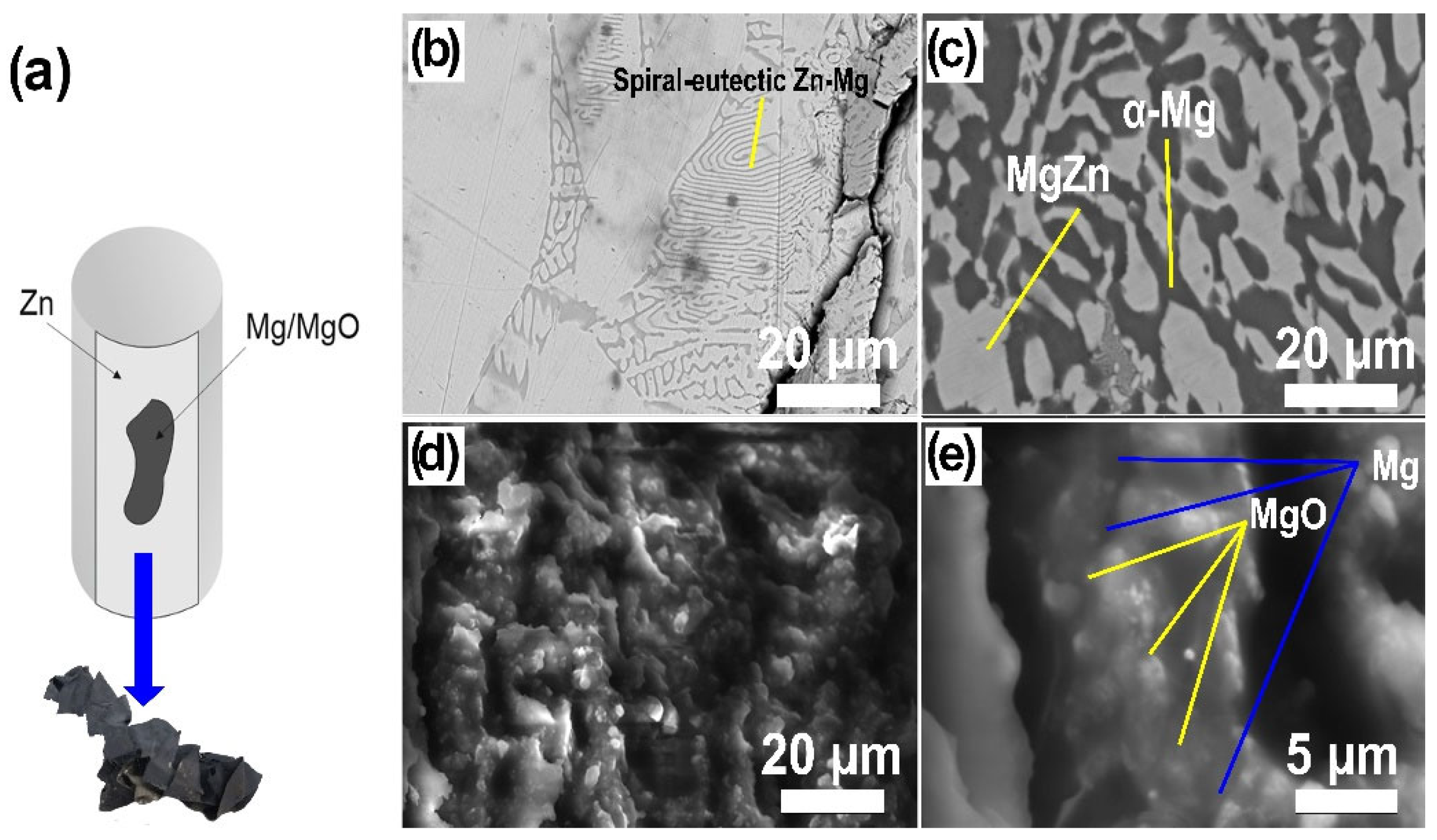

3.4. Interaction at Mg/MgO/Zn Interfaces

4. Discussions

5. Conclusions

- (1)

- The relative density of Mg and Mg–5, 10 wt. % Zn alloys after sintering in an argon environment at 430 °C and holding for 30 min are 95%, 88% and 92%, respectively. Growth during the sintering of Mg–5Zn and Mg–10Zn is due to the crystallization of phases with larger volumes and the action of the Frenkel effect.

- (2)

- In the structure of pure magnesium, an oxide was found, which accumulated at the boundaries between the particles, resisting sintering. Zinc additives from 5 to 10 wt. % contributed to the formation of α–Mg, MgZn, and Mg51Zn20.

- (3)

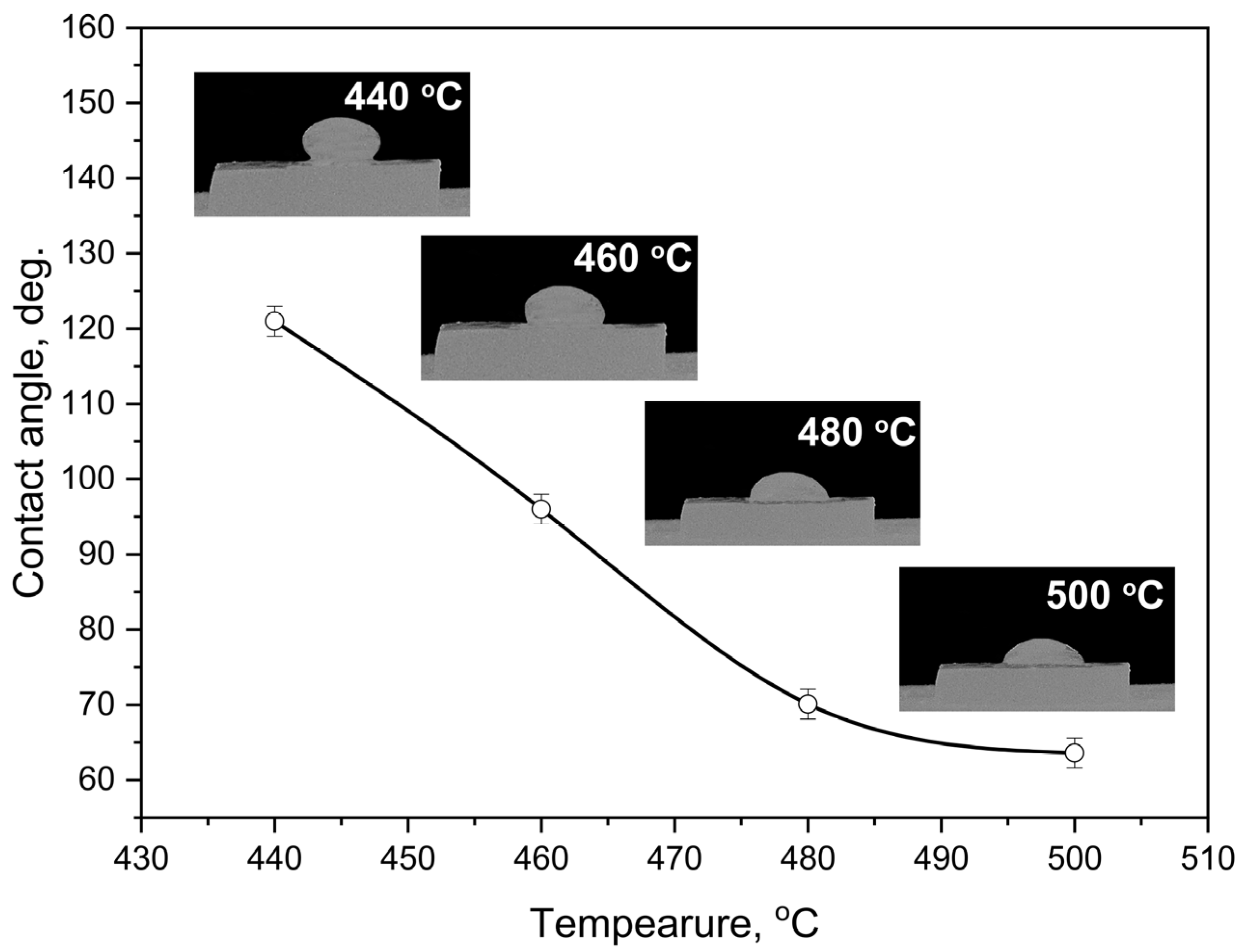

- The contact angle between the zinc melt and the MgO substrate was 120° at 440 °C and decreased to 65° at 500 °C. The reactions between the melt and the substrate were not identified.

- (4)

- The mechanism of magnesium sintering with zinc addition is shown. The mechanism is based on the following stages: the penetration of zinc to oxide-free surfaces; reactions to form a solid solution, intermetallics; the removal of magnesium oxide from the particle surface due to a change in the crystallographic orientation of the base phase and low wettability of the zinc melt; oxide particles were deposited on the surface of the sample in the form of slag.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, J.; Ramakrishna, S.; Camacho, A.M.; Berto, F. Applications of Magnesium and Its Alloys: A Review. Appl. Sci. 2021, 11, 6861. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Banerjee, P.C.; Al-Saadi, S.; Choudhary, L.; Harandi, S.E.; Singh, R. Magnesium Implants: Prospects and Challenges. Materials 2019, 12, 136. [Google Scholar] [CrossRef] [PubMed]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Vyas, A.V.; Sutaria, M.P. Investment Castings of Magnesium Alloys: A Road Map and Challenges. Arch. Foundry Eng. 2022, 22, 19–23. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, J.; Wang, J.; Jin, P.; Li, P. Significant strain hardening ability of AZ91 magnesium alloy fabricated by spark plasma sintering. Mater. Today Commun. 2023, 35, 105670. [Google Scholar] [CrossRef]

- Hrapkowicz, B.; Lesz, S.; Karolus, M.; Garbiec, D.; Wiśniewski, J.; Rubach, R.; Gołombek, K.; Kremzer, M.; Popis, J. Microstructure and Mechanical Properties of Spark Plasma Sintered Mg-Zn-Ca-Pr Alloy. Metals 2022, 12, 375. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantaş, K.; Der, O.; Yalçın, B.; Şimşir, E.; Aamir, M. Microstructural and Mechanical Behavior Investigations of Nb-Reinforced Mg–Sn–Al–Zn–Mn Matrix Magnesium Composites. Metals 2023, 13, 1097. [Google Scholar] [CrossRef]

- Bryan, B.S.J.; Fong, K.S.; Wah, C.B.; Tekumalla, S.; Kwak, M.K.; Park, E.S.; Gupta, M. Enhancing Mechanical and Biocorrosion Response of a MgZnCa Bulk Metallic Glass through Variation in Spark Plasma Sintering Time. Metals 2023, 13, 1487. [Google Scholar] [CrossRef]

- Soderlind, J.; Cihova, M.; Schäublin, R.; Risbud, S.; Löffler, J.F. Towards refining microstructures of biodegradable magnesium alloy WE43 by spark plasma sintering. Acta Biomater. 2019, 98, 67–80. [Google Scholar] [CrossRef]

- Minárik, P.; Stráský, J.; Veselý, J.; Lukáč, F.; Hadzima, B.; Král, R. AE42 magnesium alloy prepared by spark plasma sintering. J. Alloys Compd. 2018, 742, 172–179. [Google Scholar] [CrossRef]

- Mondet, M.; Barraud, E.; Lemonnier, S.; Guyon, J.; Allain, N.; Grosdidier, T. Microstructure and mechanical properties of AZ91 magnesium alloy developed by Spark Plasma Sintering. Acta Mater. 2016, 119, 55–67. [Google Scholar] [CrossRef]

- Wolff, M.; Ebel, T.; Dahms, M. Sintering of Magnesium. Adv. Eng. Mater. 2010, 12, 829–836. [Google Scholar] [CrossRef]

- Wolff, M.; Schaper, J.G.; Suckert, M.R.; Dahms, M.; Feyerabend, F.; Ebel, T.; Willumeit-Römer, R.; Klassen, T. Metal Injection Molding (MIM) of Magnesium and Its Alloys. Metals 2016, 6, 118. [Google Scholar] [CrossRef]

- Nabilla, M.S.S.; Zuraidawani, C.D.; Derman, M.N.B. Effect of Sintering Temperature on Different Ca Content in Mg-Ca Composite Using Powder Metallurgy Technique. Appl. Mech. Mater. 2015, 754–755, 907–911. [Google Scholar] [CrossRef]

- Golmohammadi, P.; Saljooghi, F.; Bahmani, A.; Parvin, N.; Nayebi, B. On the synthesis and sintering behavior of a novel Mg-Ca alloy, Part I: Mechanical alloying. Synth. Sinter. 2022, 2, 131–137. [Google Scholar] [CrossRef]

- Jiang, P.; Blawert, C.; Zheludkevich, M.L. The Corrosion Performance and Mechanical Properties of Mg-Zn Based Alloys—A Review. Corros. Mater. Degrad. 2020, 1, 7. [Google Scholar] [CrossRef]

- Tsakiris, V.; Tardei, C.; Clicinschi, F.M. Biodegradable Mg alloys for orthopedic implants—A review. J. Magnes. Alloys 2021, 9, 1884–1905. [Google Scholar] [CrossRef]

- Kirkland, N.T.; Lespagnol, J.; Birbilis, N.; Staiger, M.P. A survey of bio-corrosion rates of magnesium alloys. Corros. Sci. 2010, 52, 287–291. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, X.; Qiao, Y.; Wang, X.; Lin, Q. Preparation of medical Mg–Zn alloys and the effect of different zinc contents on the alloy. J. Mater. Sci. Mater. Med. 2022, 33, 9. [Google Scholar] [CrossRef]

- Kapinos, D.; Augustyn, B.; Szymanek, M. Methods of Introducing Alloying Elements into Liquid Magnesium. Metall. Foundry Eng. 2014, 40, 141. [Google Scholar] [CrossRef]

- ASTM B962-23; Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle. ASTM: West Conshohocken, PA, USA, 2023.

- Kingery, W.D. Densification during Sintering in the Presence of a Liquid Phase. I. Theory. J. Appl. Phys. 1959, 30, 301–306. [Google Scholar] [CrossRef]

- Ristić, M.M.; Milosević, S.D. Frenkel’s theory of sintering. Sci. Sinter. 2006, 38, 7–11. [Google Scholar] [CrossRef]

- Skorokhod, V.V. Development of the ideas of Ya. I. Frenkel’ in the contemporary rheological theory of sintering. Powder Metall. Met. Ceram. 1996, 34, 521–527. [Google Scholar] [CrossRef]

- Rathore, S.S.; Dabhade, V.V. Dimensional Change During Sintering of Fe–Cu–C Alloys: A Comparative Study. Trans. Indian Inst. Met. 2016, 69, 991–998. [Google Scholar] [CrossRef]

- Yang, L.; Yuan, Y.; Li, Q.; Wu, J.; Chen, T.; Wang, J.; Zuo, X.; Tang, A.; Zhang, L.; Moelans, N.; et al. Interdiffusion and atomic mobility of the Mg–Sn–Zn system. Calphad 2023, 80, 102524. [Google Scholar] [CrossRef]

- Das, S.K.; Kim, Y.M.; Ha, T.K.; Jung, I.H. Investigation of anisotropic diffusion behavior of Zn in hcp Mg and interdiffusion coefficients of intermediate phases in the Mg–Zn system. Calphad 2013, 42, 51–58. [Google Scholar] [CrossRef]

- De Oro Calderon, R.; Gierl-Mayer, C.; Danninger, H. Fundamentals of Sintering: Liquid Phase Sintering. Encycl. Mater. Met. Alloys 2022, 3, 481–492. [Google Scholar] [CrossRef]

- Ohno, M.; Schmid-Fetzer, R. Mg-rich phase equilibria of Mg-Mn-Zn alloys analyzed by computational thermochemistry. Int. J. Mater. Res. 2006, 97, 526–532. [Google Scholar] [CrossRef]

- Zhu, G.; Lyu, S.; Shen, G.; Tian, L.; Chen, M. Effect of the microstructure parameters on the mechanical properties and corrosion behavior of Mg alloys with high Zn or Ca content. J. Mater. Sci. 2023, 58, 12373–12390. [Google Scholar] [CrossRef]

- Lin, Y.; Fu, X.; Zhong, Q.; Xu, Z.; Tan, J. Rapid solid-state thermal diffusion fabrication of MgZn intermetallic layer for hardening surface and improving corrosion resistance of AZ31 alloy. Surf. Coat. Technol. 2024, 489, 131017. [Google Scholar] [CrossRef]

- Yao, H.B.; Li, Y.; Wee, A.T.S. An XPS investigation of the oxidation/corrosion of melt-spun Mg. Appl. Surf. Sci. 2000, 158, 112–119. [Google Scholar] [CrossRef]

- Okamoto, H. Comment on Mg-Zn (magnesium-zinc). J. Phase Equilibria 1994, 15, 129–130. [Google Scholar] [CrossRef]

- Geng, L.; Zhang, B.P.; Li, A.B.; Dong, C.C. Microstructure and mechanical properties of Mg–4.0Zn–0.5Ca alloy. Mater. Lett. 2009, 63, 557–559. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium Based Intermetallics. In Titanium; Engineering Materials, Processes; Springer: Berlin/Heidelberg, Germany, 2007; pp. 337–366. [Google Scholar] [CrossRef]

- Teslia, S.; Stepanchuk, A. Microstructural evolution of Al–15Fe alloy produced by mechanical milling and centrifugal atomization. Intermetallics 2022, 149, 107671. [Google Scholar] [CrossRef]

- Teslia, S.; Teslia, M.; Sun, Q.; Stepanchuk, A. Investigation of microstructural evolution and mechanical properties Al13Fe4 produced by casting and spark-plasma sintering. Vacuum 2023, 218, 112590. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Idris, M.H.; Abdul-Kadir, M.R.; Ourdjini, A.; Medraj, M.; Daroonparvar, M.; Hamzah, E. Mechanical and bio-corrosion properties of quaternary Mg–Ca–Mn–Zn alloys compared with binary Mg–Ca alloys. Mater. Des. 2014, 53, 283–292. [Google Scholar] [CrossRef]

- Sedlacek, R.; Suchy, T.; Padovec, Z. Biodegradation Behavior of Magnesium Alloy During Exposure to the Conditions of Human Body Environment. IFMBE Proc. 2020, 76, 1792–1795. [Google Scholar] [CrossRef]

- Khorashadizade, F.; Abazari, S.; Rajabi, M.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Sharif, S.; Ramakrishna, S.; Berto, F. Overview of magnesium-ceramic composites: Mechanical, corrosion and biological properties. J. Mater. Res. Technol. 2021, 15, 6034–6066. [Google Scholar] [CrossRef]

- Cheng, X.; Qu, Y.; Kang, C.; Kang, M.; Dong, R.; Zhao, J. Development of new medical Mg-Zn-Ca-Y alloy and in-vitro and in-vivo evaluations of its biological characteristics. Mater. Today Commun. 2021, 26, 102002. [Google Scholar] [CrossRef]

- Panasyuk, A.; Fomenno, V.; Glebova, G.; Kislyj, P. Resistance of Non-Metallic Materials in Melts: Handbook; Naukova Dumka: Kiev, Ukraine, 1986. [Google Scholar]

- German, R. Liquid Phase Sintering; Plenum Press: New York, NY, USA, 1985. [Google Scholar]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, K. Influence of substrate crystallographic orientation on the wettability and adhesion of α-Al2O3 single crystals by liquid Al and Cu. J. Mater. Sci. 2005, 40, 2329–2333. [Google Scholar] [CrossRef]

- Stringer, J.; Wood, G.C. The Adhesion of Growing Oxides to Metallic Substrates. MRS Online Proc. Libr. 1988, 119, 185. [Google Scholar] [CrossRef]

- Vora, S.B. Evaporation and Condensation of Zinc; University of Missouri: Columbia, MO, USA, 1971. [Google Scholar]

- Horky, J.; Ghaffar, A.; Werbach, K.; Mingler, B.; Pogatscher, S.; Schäublin, R.; Setman, D.; Uggowitzer, P.J.; Löffler, J.F.; Zehetbauer, M.J. Exceptional Strengthening of Biodegradable Mg-Zn-Ca Alloys through High Pressure Torsion and Subsequent Heat Treatment. Materials 2019, 12, 2460. [Google Scholar] [CrossRef] [PubMed]

- Minárik, P.; Zemková, M.; Veselý, J.; Lukáč, F.; Bohlen, J.; Knapek, M.; Král, R. Synergic effect of high temperature and high pressure on consolidation of Mg-4Y-3Nd powder by spark plasma sintering. Mater. Lett. 2021, 292, 129647. [Google Scholar] [CrossRef]

- Ma, L.; Ma, L.; Jin, P.; Feng, Z.; Jia, L. Effect of sintering temperature on microstructures and mechanical properties of ZK60 magnesium alloys. Mater. Res. Express 2022, 9, 016514. [Google Scholar] [CrossRef]

| Point | Elements, wt. % | ||

|---|---|---|---|

| Mg | Zn | O | |

| 1, 8 | 50.8 | - | 49.2 |

| 2 | 99.17 | - | 0.83 |

| 3 | 91.8 | 7.2 | 1.0 |

| 4 | 47.4 | 49.4 | 3.2 |

| 5 | 48.8 | 48.8 | 2.4 |

| 6 | 89.8 | 7.6 | 2.3 |

| 7 | 20.7 | 75.6 | 3.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teslia, S.; Kovalenko, M.; Teslia, M.; Vterkovskiy, M.; Solodkyi, I.; Loboda, P.; Soloviova, T. The Activation of Magnesium Sintering by Zinc Addition. Alloys 2024, 3, 178-189. https://doi.org/10.3390/alloys3030011

Teslia S, Kovalenko M, Teslia M, Vterkovskiy M, Solodkyi I, Loboda P, Soloviova T. The Activation of Magnesium Sintering by Zinc Addition. Alloys. 2024; 3(3):178-189. https://doi.org/10.3390/alloys3030011

Chicago/Turabian StyleTeslia, Serhii, Mykyta Kovalenko, Mariia Teslia, Mykhailo Vterkovskiy, Ievgen Solodkyi, Petro Loboda, and Tetiana Soloviova. 2024. "The Activation of Magnesium Sintering by Zinc Addition" Alloys 3, no. 3: 178-189. https://doi.org/10.3390/alloys3030011

APA StyleTeslia, S., Kovalenko, M., Teslia, M., Vterkovskiy, M., Solodkyi, I., Loboda, P., & Soloviova, T. (2024). The Activation of Magnesium Sintering by Zinc Addition. Alloys, 3(3), 178-189. https://doi.org/10.3390/alloys3030011