Characterising Ultrasint PP Nat 01 Polypropylene to Examine Its Feasibility in Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Powder Morphology and Particle Size Distribution

2.2.2. Tapped and Bulk Density Testing

2.2.3. Melt Flow Index Testing (MFI)

2.2.4. Differential Scanning Calorimetry (DSC)

2.2.5. Thermogravimetric Analysis (TGA)

2.2.6. Fourier Transform Infrared (FTIR) Spectroscopy

2.2.7. Hot-Stage Microscopy

3. Results

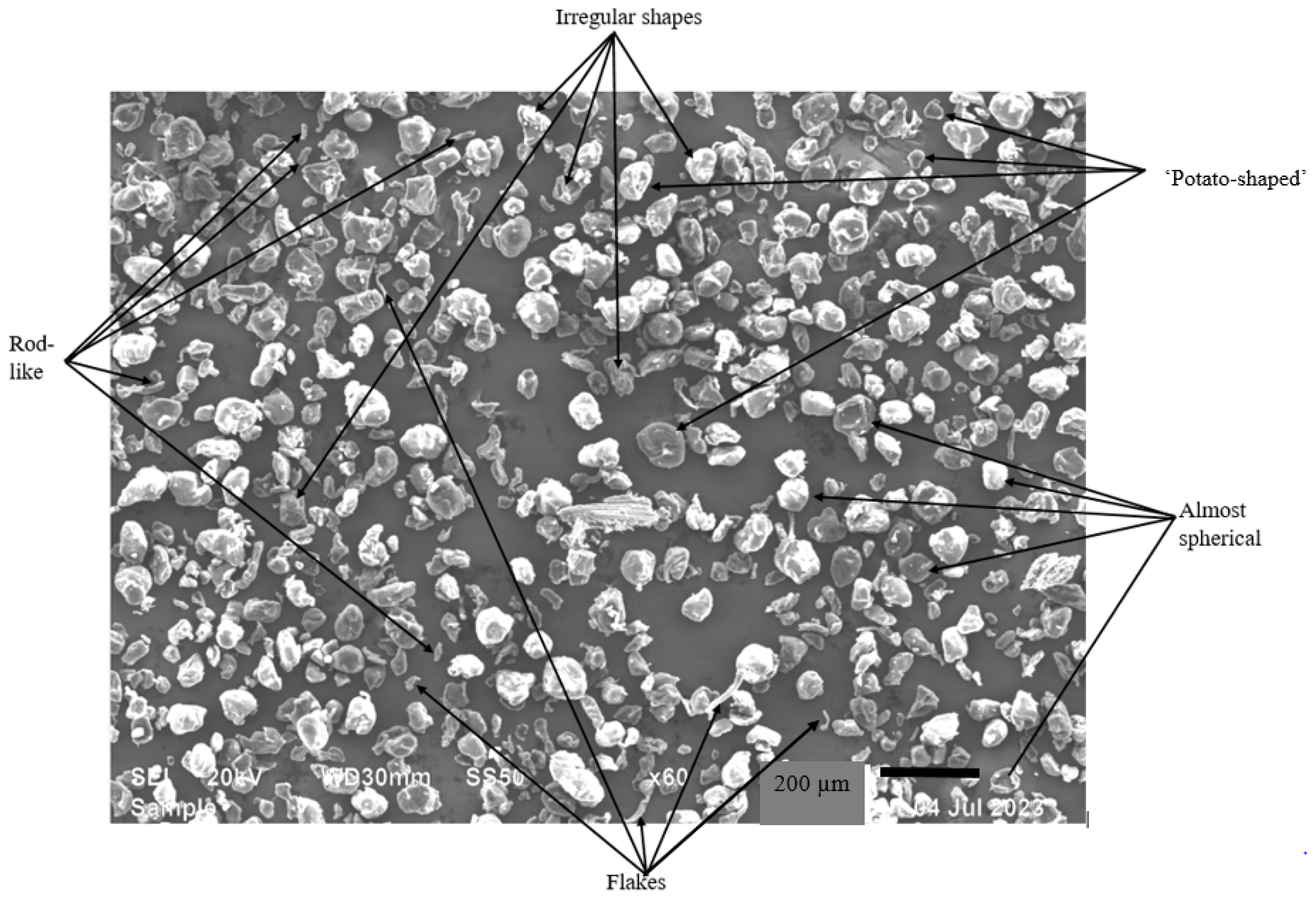

3.1. Powder Particle Shape, Morphology, and Particle Size Distribution

3.2. Hausner Ratio

3.3. Melt Flow Index Testing

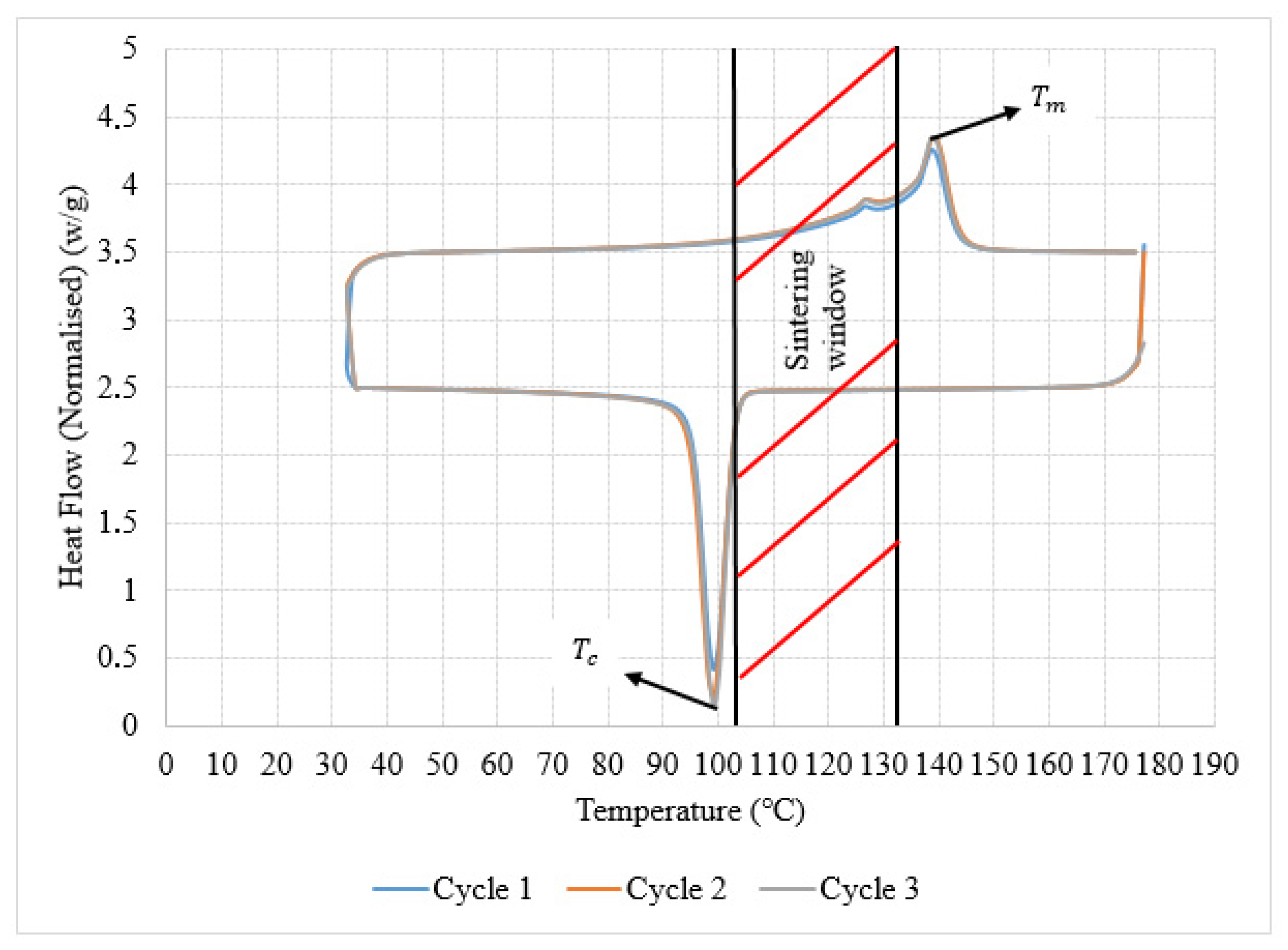

3.4. Differential Scanning Calorimetry

- = degree of crystallinity;

- = enthalpy of melting (65.8 J/g);

- = heat of melting of 100% (HDPE) (207 J/g) [40].

3.5. Thermogravimetric Analysis

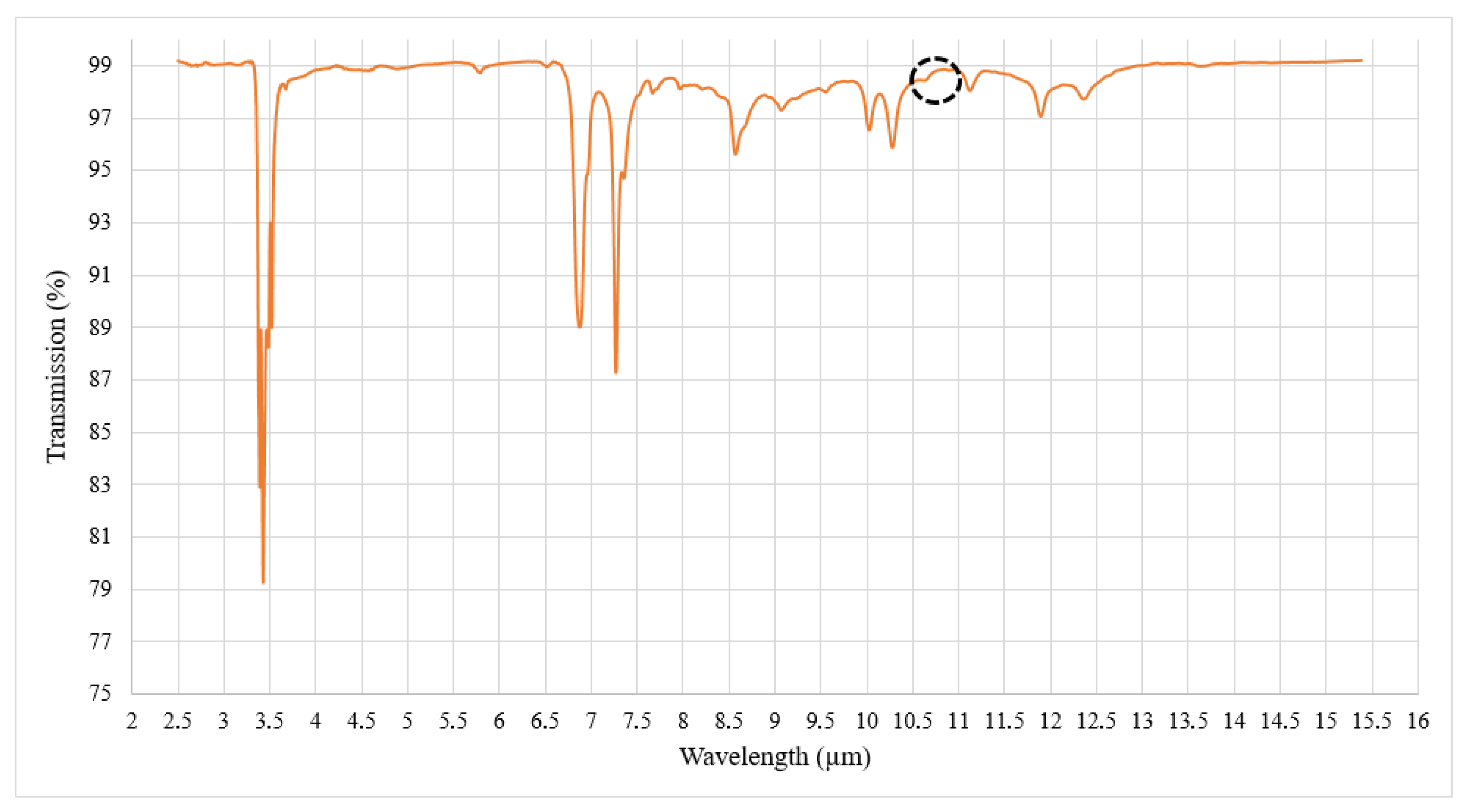

3.6. Results from Fourier Transform Infrared (FTIR) Spectroscopy

3.7. Results from Hot-Stage Microscopy

3.7.1. Effects of High Packing Density and Uniformity of a Powder Bed on a Built Layer After Melting and Cooling Powder Particles

3.7.2. Fusion of Particles During Sintering

3.7.3. Impact of Different Cooling Rates on Formed Layers

4. Conclusions

- Ultrasint PP nat 01 has a powder particle size distribution in the range of 20–80 µm, which is suitable for PLS. The material has a wide range of particle shapes, ranging from rod-like, “potato-shaped”, and almost spherical, to flakes and regularly shaped particles of powder. “Potato-shaped” and almost spherical particles were found to be in the majority, the latter of which is ideal for good flowability.

- The Hausner ratio, as well as the tapped density and bulk density of the material, were calculated and measured as 1.230 ± 0.05, 0.455 ± 0.02 g/cm3, and 0.370 ± 0.03 g/cm3, respectively. The value of the Hausner ratio confirmed good flowability of the material, which is pertinent for PLS.

- The initial melting point of Ultrasint PP nat 01 was measured as 133.8 °C, which indicated that the build chamber temperature for the PLS of the powder should be varied between 130 and 133 °C.

- Ultrasint PP nat 01 was found to have a relatively high sintering window of 30.7 °C, which makes the material good for printing using PLS, as it is expected to have reduced cases of curling and shrinkage.

- The material was found to have a high thermal stability of around 461.52 °C, thus making it suitable for use in PLS.

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soundararajan, B.; Sofia, D.; Barletta, D.; Poletto, M. Review on modeling techniques for powder bed fusion processes based on physical principles. Addit. Manuf. 2021, 47, 102336. [Google Scholar] [CrossRef]

- Mwania, F.M.; Maringa, M.; van der Walt, J.G. A review of the techniques used to characterize laser sintering of polymeric powders for use and re-use in additive manufacturing. Manuf. Rev. 2021, 8, 14. [Google Scholar] [CrossRef]

- Rudloff, J.; Lang, M.; Mohseni-Mofidi, S.; Bierwisch, C. Experimental investigations for improved modelling of the laser sintering process of polymers. Procedia CIRP 2020, 94, 80–84. [Google Scholar] [CrossRef]

- Drummer, D.; Wudy, K.; Kühnlein, F.; Drexler, M. Polymer blends for selective laser sintering: Material and process requirements. Phys. Procedia 2012, 39, 509–517. [Google Scholar] [CrossRef]

- Lexow, M.M.; Drummer, D. New materials for SLS: The use of antistatic and flow agents. J. Powder Technol. 2016, 2016, 4101089. [Google Scholar] [CrossRef]

- Mearns, C.; Potgieter, J.; Dirven, S.; Le Guen, M.J. Experimental analysis of the effectiveness of current modelling methods for SLS parameter determination. In Proceedings of the 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; pp. 1–5. [Google Scholar]

- Schmidt, J.; Dechet, M.A.; Gómez Bonilla, J.S.; Hesse, N.; Bück, A.; Peukert, W. Characterization of polymer powders for selective laser sintering. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- Mwania, F.; Maringa, M.; Van der Walt, K. Powder characterization for a new selective laser sintering polypropylene material (Laser PP CP 60) after single print cycle degradation. IJERT 2020, 13, 3342–3358. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process phenomena and material properties in selective laser sintering of polymers: A review. Materials 2022, 15, 183. [Google Scholar] [CrossRef]

- Li, J.; Yuan, S.; Zhu, J.; Li, S.; Zhang, W. Numerical model and experimental validation for laser sinterable semi-crystalline polymer: Shrinkage and warping. Polymers 2020, 12, 1373. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.H.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. Comptes Rendus Mécanique 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

- Olivier, C.M.; Oosthuizen, G.A.; Sacks, N. Improving the R&D process efficiency of the selective laser sintering industry through numerical thermal modeling. Procedia Manuf. 2019, 33, 131–138. [Google Scholar] [CrossRef]

- Mwania, F.M.; Maringa, M.; van der Walt, J. Analytical and numerical modelling of laser powder bed fusion (L-PBF) of polymers–a review of the key areas of focus of the process. MATEC Web Conf. 2022, 370, 06001–06020. [Google Scholar] [CrossRef]

- ISO 60:2023; Plastics—Determination of Apparent Density of Material that Can be Poured from a Specified Funnel. iTeh Standards: Geneva, Switzerland, 2023. Available online: https://cdn.standards.iteh.ai/samples/85747/80cd7f37764f4aa691145165dbf59c03/ISO-60-2023.pdf (accessed on 10 September 2025).

- ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. iTeh Standards: Geneva, Switzerland, 2022. Available online: https://cdn.standards.iteh.ai/samples/83905/b73b8c6de9404b659e7598977762f9d7/ISO-1133-1-2022.pdf (accessed on 10 September 2025).

- ISO 61:2023; Plastics—Determination of Apparent Density of Moulding Material that Cannot be Poured from a Specified Funnel. iTeh Standards: Geneva, Switzerland, 2023. Available online: https://cdn.standards.iteh.ai/samples/85748/4464b234b4024137ae9b3e01531f761b/ISO-61.pdf (accessed on 10 September 2025).

- ISO 11357-1:2016; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. iTeh Standards: Geneva, Switzerland, 2016. Available online: https://cdn.standards.iteh.ai/samples/70024/4eeac42fae96493190707ae5d8c2b4a7/ISO-11357-1-2016.pdf (accessed on 10 September 2025).

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. iTeh Standards: Geneva, Switzerland, 2012. Available online: https://cdn.standards.iteh.ai/samples/56046/c5c3ec20cc0741289bf6def861e0a40b/ISO-527-2-2012.pdf (accessed on 10 September 2025).

- Wu, L.; Mwania, F.M.; Van der Walt, J.G.; Koen, W. An evaluation of the suitability of a new polypropylene powder for powder bed fusion additive manufacturing. MATEC Web Conf. 2023, 388, 06003–06011. [Google Scholar] [CrossRef]

- ASTM D7481-18; Standard Test Methods for Determining Loose and Tapped Bulk Densities of Powders Using a Graduated Cylinder. iTeh Standards: Geneva, Switzerland, 2023. Available online: https://www.pmda.go.jp/files/000233964.pdf (accessed on 10 September 2025).

- ASTM D1238; Melt Flow Rate Determination on Plastics. Zwick/Roell: Ulm, Germany, 2023. Available online: https://www.zwickroell.com/industries/plastics/thermoplastics-and-thermosetting-molding-materials/determination-of-melt-flow-rate-astm-d1238/ (accessed on 10 September 2025).

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powders for additive manufacturing processes: Characterization techniques and effects on part properties. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2016. [Google Scholar]

- Berretta, S.; Ghita, O.; Evans, K.E. Morphology of polymeric powders in Laser Sintering (LS): From Polyamide to new PEEK powders. Eur. Polym. J. 2014, 59, 218–229. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive manufacturing: Polymers applicable for laser sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Sommereyns, A.; Hupfeld, T.; Gökce, B.; Barcikowski, S.; Schmidt, M. Evaluation of essential powder properties through complementary particle size analysis methods for laser powder bed fusion of polymers. Procedia CIRP 2020, 94, 116–121. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Van den Eynde, M.; Kruth, J.P.; Goderis, B.; Van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Parteli, E.J.R. DEM simulation of particles of complex shapes using the multisphere method: Application for additive manufacturing. AIP Conf. Proc. 2013, 1542, 185–188. [Google Scholar] [CrossRef]

- Tan, P.; Zhou, M.; Tang, C.; Su, Y.; Qi, H.J.; Zhou, K. Multiphysics modelling of powder bed fusion for polymers. Virtual Phys. Prototyp. 2023, 18, 2257191–2257208. [Google Scholar] [CrossRef]

- Saw, H.Y.; Davies, C.E.; Paterson, A.H.; Jones, J.R. Correlation between powder flow properties measured by shear testing and Hausner ratio. Procedia Eng. 2015, 102, 218–225. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Sagar, K.; Zhou, K. Comparative study on the selective laser sintering of polypropylene homopolymer and copolymer: Processability, crystallization kinetics, crystal phases and mechanical properties. Addit. Manuf. 2021, 37, 101610–101623. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.U.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- Santomaso, A.; Lazzaro, P.; Canu, P. Powder flowability and density ratios: The impact of granules packing. Chem. Eng. Sci. 2003, 58, 2857–2874. [Google Scholar] [CrossRef]

- Berretta, S.; Wang, Y.; Davies, R.; Ghita, O.R. Polymer viscosity, particle coalescence and mechanical performance in high-temperature laser sintering. J. Mater. Sci. 2016, 51, 4778–4794. [Google Scholar] [CrossRef]

- Yaagoubi, H.; Abouchadi, H.; Taha Janan, M. Mathematical modelling and numerical thermal simulation of the selective laser sintering process of the polyamide 12. IJTPE 2021, 13, 162–169. [Google Scholar]

- Grünewald, M.; Popp, K.; Rudloff, J.; Lang, M.; Sommereyns, A.; Schmidt, M.; Mohseni-Mofidi, S.; Bierwisch, C. Experimental, numerical and analytical investigation of the polyamide 12 powder bed fusion with the aim of building dimensionless characteristic numbers. Mater. Des. 2021, 201, 109470–109482. [Google Scholar] [CrossRef]

- Wencke, Y.L.; Luinstra, G.A.; Duchateau, R.; Proes, F.; Imgrund, P.; Evenson, J.S.; Emmelmann, C. Disentangled UHMWPE@ silica powders for potential use in power bed fusion based additive manufacturing. Eur. Polym. J. 2022, 163, 110936. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Dusunceli, N.; Colak, O.U. Modelling effects of degree of crystallinity on mechanical behavior of semicrystalline polymers. Int. J. Plast. 2008, 24, 1224–1242. [Google Scholar] [CrossRef]

- TA Instruments, Applications Note TN048. Polymer Heats of Fusion. Available online: https://www.tainstruments.com/pdf/literature/TN048.pdf (accessed on 1 August 2024).

- Khalil, Y.; Hopkinson, N.; Kowalski, A.; Fairclough, J.P.A. Characterisation of UHMWPE polymer powder for laser sintering. Materials 2019, 12, 3496. [Google Scholar] [CrossRef]

- Morano, C.; Pagnotta, L. Additive manufactured parts produced by selective laser sintering technology: Porosity formation mechanisms. J. Polym. Eng. 2023, 43, 57–555. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001–122029. [Google Scholar] [CrossRef]

- Lee, A.; Wynn, M.; Quigley, L.; Salviato, M.; Zobeiry, N. Effect of temperature history during additive manufacturing on crystalline morphology of PEEK. Advan. Ind. Manuf. Eng. 2022, 4, 100085–100108. [Google Scholar]

- Benedetti, L.; Brulé, B.; Decreamer, N.; Evans, K.E.; Ghita, O. Shrinkage behaviour of semi-crystalline polymers in laser sintering: PEKK and PA12. Mater. Des. 2019, 181, 107906–107915. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

| Properties | Value | Unit | Test Method |

|---|---|---|---|

| Average particle size D50 | 60–70 | μm | Laser Diffraction |

| Bulk density | 330 | kg/m3 | DIN EN ISO 60 [14] |

| Melt volume flow rate | 14 | cm3/10 min | ISO 1133 (230 °C, 2.16 kg) [15] |

| Printed part density | 890 | kg/m3 | ISO 61 [16] |

| Melting temperature | 140 | °C | ISO 11357 (10 K/min) [17] |

| Crystallisation temperature | 100 | °C | ISO 11357 (10 K/min) |

| Tensile strength (X-, Z-direction) | 28 | MPa | ISO 527-2 [18] |

| Tensile modulus (X-, Z-direction) | 1400 | MPa | ISO 527-2 |

| Tensile elongation at break | 30 (x-direction) 10 (z-direction) | % | ISO 527-2 |

| # | Flowability | Hausner Number |

|---|---|---|

| 1 | Non-flowing | >1.4 |

| 2 | Cohesive | >1.4 |

| 3 | Fairly free-flowing | 1.25–1.4 |

| 4 | Free-flowing | 1–1.25 |

| 5 | Excellent flowing | 1–1.25 |

| 6 | Aerated | 1–1.25 |

| # | MFI (g/10 min) |

|---|---|

| Trial 1 | 14.8 |

| Trial 2 | 15.0 |

| Trial 3 | 15.6 |

| Trial 4 | 16.7 |

| Trial 5 | 17.1 |

| Average | 15.8 |

| Standard deviation | 0.102 |

| Sample 1 | Sample 2 | Sample 3 | Average | |

|---|---|---|---|---|

| Initial point of crystallisation (°C) | 103.1 | 103.1 | 103.1 | 103.1 |

| Terminal point of crystallisation (°C) | 95.3 | 95.0 | 95.3 | 95.2 |

| Crystallisation point (peak value), (°C) | 99.3 | 99.0 | 99.4 | 99.2 |

| Enthalpy of crystallisation (J/g) | −73.4 | −82.9 | −76.1 | −77.5 |

| Initial point of melting (°C) | 133.7 | 133.8 | 133.8 | 133.8 |

| Terminal point of melting (°C) | 143.4 | 143.9 | 143.6 | 143.6 |

| Melting point (peak value), (°C) | 138.9 | 139.2 | 139.0 | 139.0 |

| Enthalpy of melting (J/g) | 60.5 | 71.1 | 65.8 | 65.8 |

| Parameter | Value |

|---|---|

| Onset | 407.4 (°C) |

| End | 461.52 (°C) |

| Peak | 434.47 (°C) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mwania, F.; Maringa, M.; van der Walt, J. Characterising Ultrasint PP Nat 01 Polypropylene to Examine Its Feasibility in Powder Bed Fusion. Powders 2025, 4, 26. https://doi.org/10.3390/powders4030026

Mwania F, Maringa M, van der Walt J. Characterising Ultrasint PP Nat 01 Polypropylene to Examine Its Feasibility in Powder Bed Fusion. Powders. 2025; 4(3):26. https://doi.org/10.3390/powders4030026

Chicago/Turabian StyleMwania, Fredrick, Maina Maringa, and Jacobus van der Walt. 2025. "Characterising Ultrasint PP Nat 01 Polypropylene to Examine Its Feasibility in Powder Bed Fusion" Powders 4, no. 3: 26. https://doi.org/10.3390/powders4030026

APA StyleMwania, F., Maringa, M., & van der Walt, J. (2025). Characterising Ultrasint PP Nat 01 Polypropylene to Examine Its Feasibility in Powder Bed Fusion. Powders, 4(3), 26. https://doi.org/10.3390/powders4030026