1. Introduction

With fossil fuel prices at historic highs [

1], Tanzania is challenged to raise momentum in consuming its huge reserve of natural gas (NG) [

2], especially in the area of transportation. While the country is a zonal leader in NG production, a number of factors, including Tanzania’s sluggish economy, political upheaval on recognizing NG as an alternative road transportation fuel [

1], and growing concern of gas explosion, are threatening the widespread adoption of natural gas vehicles (NGVs). On the other hand, the alarming levels of global warming and environmental degradation as a result of tailpipe emission [

1,

3,

4] as well as the need to obey the Kyoto agreement restrict Tanzania to using clean road fuels. New fuel technologies such as acetylene [

5], biofuels [

6], and vegetable oils (palm, soybean, sunflower, peanut, and olive) [

7,

8] have been developed to mitigate road emissions. Several merits have been revealed when employing new fuel technologies, for instance, better performance, emission, and combustion characteristics for acetylene as a low reactivity fuel [

5] and the least black smoke and increase in specific fuel consumption for a biodiesel blend [

9]. However, due to its abundance, NG remains the prominent candidate in Tanzania. Therefore, Tanzania’s government is urged to seek alternative measures to facilitate the use of its NG so as to curtail tailpipe emissions, as well as reduce the dependence on imported fossil fuel.

Compressed natural gas (CNG) is the potential alternative fuel in Tanzania’s road sector due to its plentiful and environmental benefits. Despite the anomalous spike in road oil prices (6% from December 2020 to March 2021; 12% from March 2021 to June 2021; 10% from June 2021 and December 2021; and 16% from December 2021 and June 2022) that led to financial burden among Tanzanian residents, the shift to NGVs is not promising. Moreover, around 350 four-wheelers in 2018, 450 four-wheelers in 2020 [

1,

10], and 1500 four-wheelers were converted to use CNG, accounting for 0.08% of its 1.92 million vehicles (2022). Comparatively, the global commercialization of NGVs hits around 27.4 million (2018), 28.5 million (2019) [

1,

11], and above 30 million units (2021) [

12]. The global NGV records could alternatively indicate that Tanzania is not putting much emphasis on fighting against volatile oil prices and appalling issues of road emissions.

Governments around the world are implementing stringent regulations for reducing greenhouse gas emissions and sustaining ecofriendliness. In Asian-Pacific countries, for instance, Thailand implemented road pollution mitigation measures [

13] in two phases [

14]. Phase one involved the establishment of the natural gas pipeline in the greater Bangkok, as well as the conversion of public buses to use NG while increasing the in-city filling stations. Phase two involved promoting the use of NG throughout the country by supplying CNG and liquified natural gas (LNG) in the areas with and without NG pipelines, respectively [

14]. In India, New Delhi and Mumbai are the first major cities to use NG in their transportation sector primarily driven by environmental and public health imperatives. The NG programs targeted the most polluting segments on Indian roads such as diesel buses, light-duty commercial vehicles, taxis, and three-wheelers [

15]. Up to 2010, India had about 10,000 km of the NG pipeline network, owned in proportion by different companies and connected around 30 Indian cities. In the European Union (EU), NG is within the EU strategy for the future of transport. The EU Transport 2050 roadmap sets a big shift to cleaner cars and cleaner fuels for urban mobility—a 50% shift away from conventionally fueled cars by 2030, phasing them out of cities by 2050 [

16]. In an attempt to abate the issues of transport energy scarcity and increased road emission, the Nigerian government introduced the use of CNG in its policies as an automobile fuel to improve urban air and reduce adverse health effects [

17]. To improve its gas utilization capacity, Nigeria introduced several projects such as liquefied natural gas (LNG), gas to liquids (GTL), natural gas to power, and compressed natural gas (CNG) [

17]. The Egyptian government, through the Ministry of Petroleum, supported the NG programs by initiating the CNG commercialization process, stimulating the growth of the CNG market by providing a five-year tax exemption for CNG-approved companies, and introducing high-tech solutions such as the “Gas Card” system. Furthermore, to accelerate the rate of vehicle conversion to use NG, the Egyptian government in 2006 prepared the CNG Master Plan that would affect the CNG activities for the next twenty years [

18]. Tanzania is among the countries in sub-Saharan Africa in which the majority of its citizens have low income [

19,

20] and reside in rural areas. Despite the plentiful NG reserve, to date, Tanzania and other sub-Saharan countries have had sluggish transitions to NGVs. Moreover, there is a scarcity of knowledge to reveal the barriers and address the challenges in Tanzania and sub-Saharan countries so as to accelerate the evolution of NGVs.

The aim of this paper is to assess the technologies deployed to make NGVs plausible in Tanzania’s environment as well as barriers hindering their success to compete at international levels. The contributions are the following:

- -

The technical performance of technologies employed to convert gasoline- and diesel-fueled vehicles to use CNG in Tanzania’s road transportation sector is assessed.

- -

The economic savings as a result of retrofitting conventional vehicles to use CNG are evaluated in order to understand their payback characteristics in Tanzania’s road transportation sector.

- -

The social, technological, economic, and regulatory barriers that are still in place in the country as well as the prospects of NGV development are highlighted.

3. Implementation

3.1. Technologies for Conversion of Vehicles to NGVs

The CNG systems fitted in vehicles consist of a CNG cylinder and a conversion kit. A CNG cylinder stores pressurized gas. It falls into four types, namely, Type 1, 2, 3, and 4. The type of a CNG cylinder is based on the design and production techniques, including the liner material. Type 1 has no liner; Type 2 is lined by carbon fiber; Type 3 is lined by carbon fiber; and Type 4 is wholly wrapped by an aluminum liner. The liner materials regulate the in-cylinder temperature and therefore affect the quantity of CNG that it can contain based on the defined limits. For instance, carbon fiber tanks retain more heat compared to steel tanks and may reduce the capacity of the CNG due to the molecule expansion under hot conditions. A conversion kit falls into two types, namely, the venturi and sequential kit. The venturi kit is equipped with neither sensors nor an electronic control unit (ECU). This makes it affordable and easier for it to be installed in any type of vehicle. However, the absence of sensors and an ECU makes the operation of the venturi kit unpredictable as it cannot regulate the flow of CNG into the engine. This irregularity causes a lot of stalling and pickup loss as well in the engine. Moreover, as a result of this, the kit and engine need frequent tuning and cleaning—something that requires a certain amount of expertise. On the contrary, the sequential kit comprises a number of sensors and wires that are slightly more complex to install. The sequential kit works properly on vehicles that are equipped with electronic fuel injection systems. The ECU in the sequential kit monitors the flow and controls the combustion of CNG in the engine, which results in better performance and mileage of the vehicle. Moreover, the sequential kit can be an open-loop or closed-loop system. The closed-loop sequential kit consists of oxygen or lambda sensor(s) that are mounted in the vehicle’s exhaust to collect the emissions data and pass them to the ECU to check if they are within acceptable levels. This feedback information provides better control of CNG flow and prevention of excessive pollution. With the increasingly stringent environmental regulations, the sequential kits could be more useful, user-friendly, and even durable for users to switch their kits to another vehicle while benefiting from emission cutdowns.

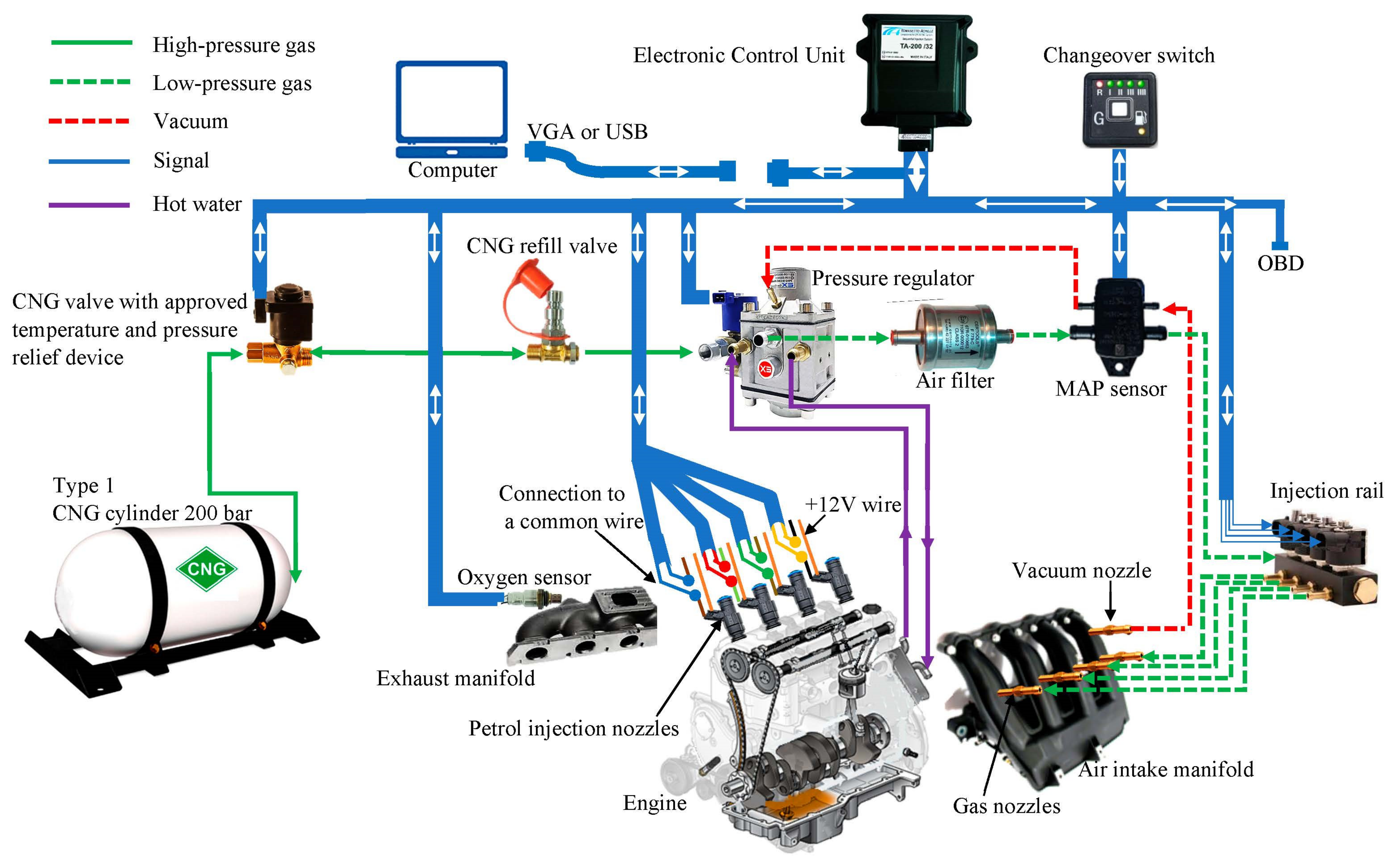

The CNG components for retrofitting petrol-powered vehicles are shown in

Figure 1. The natural gas is compressed into a CNG cylinder through a receptacle to a working pressure of 200 bar. The high-pressure gas is transferred to the pressure regulator through the high-pressure pipe. The pressure regulator reduces the pressure to a level that is compatible with the engine fuel injection system. Then, CNG mixes with air in the intake manifold before the mixture enters the combustion chamber for compression. The spark plug ignites the air–gas mixture to produce mechanical power. Once the changeover switch is pressed to allow CNG to operate, the ECU opens the CNG valve and pressure regulator to allow CNG to flow to the injector rail via the gas filter and mean absolute pressure (MAP) sensor while blocking petrol nozzles. The oxygen sensor monitors the amount of oxygen in the exhaust and transmits that information to the ECU, which regulates the air-to-fuel ratio accordingly.

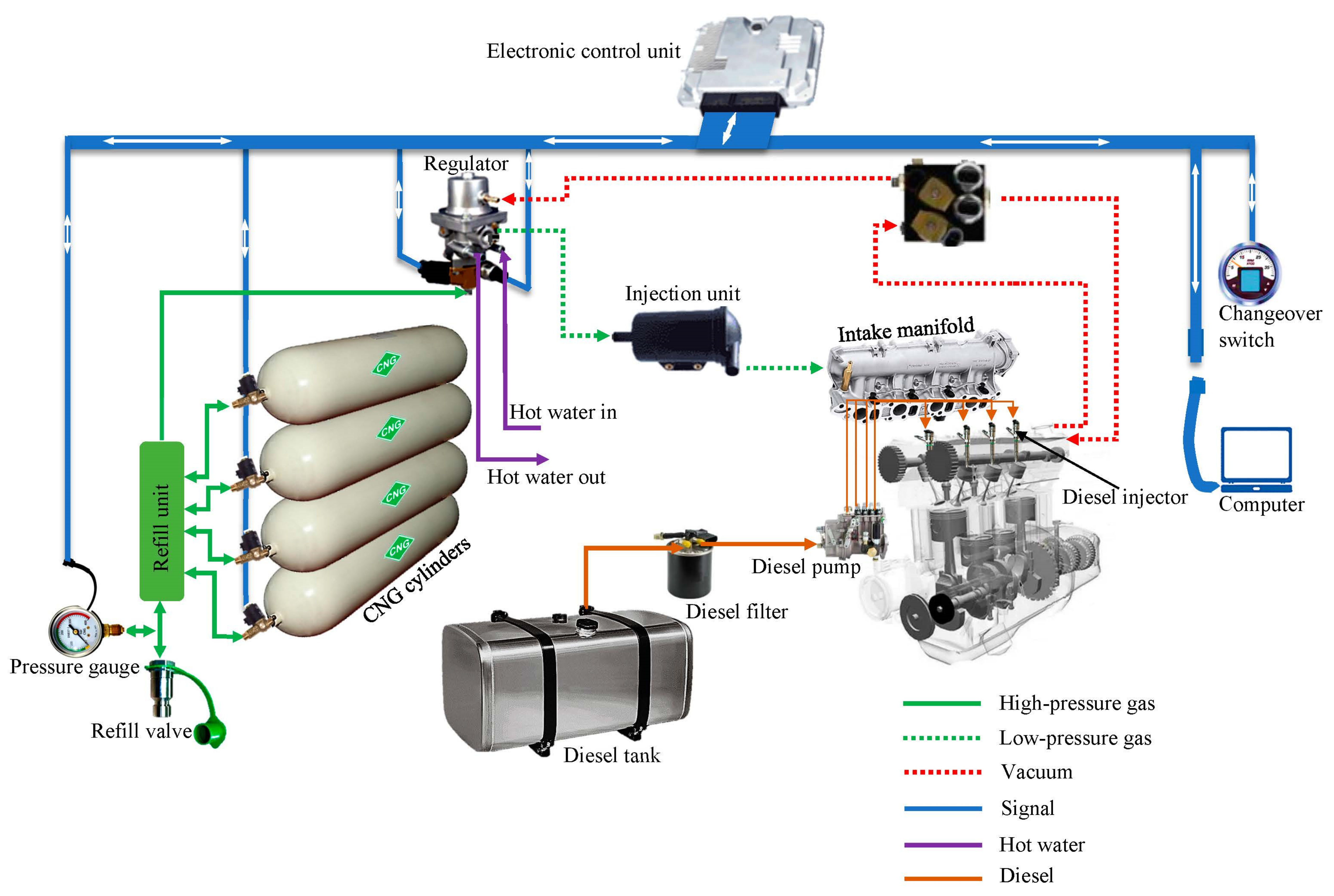

Figure 2 depicts the CNG components for retrofitting diesel-powered vehicles. The pressurized gas is transferred from the CNG cylinder to the pressure regulator, where it is decreased to the level required in the combustion chamber. In the intake manifold, the low-pressure gas combines with the bulky air and is transferred to the combustion chambers for compression. The presence of an air–gas mixture in an engine’s intake air is expected to cause a significant decrease in feed mixture temperature, resulting in the air–gas mixture failing to ignite during the compression stage.

Due to the lack of spark plugs in the combustion chamber, diesel fuel serves as an igniter of the air–gas mixture. Meanwhile, the pressure inside the combustion chamber is already high, obstructing the flow of diesel into the chamber. As a result, little diesel enters, creating a powerful spark to ignite the air–gas mixture during compression. In these engines, diesel provides ignition and natural gas provides power. The CNG used in both retrofitted gasoline and diesel-fueled vehicles has the same quality. According to the Energy and Water Utilities Regulatory Authority (EWURA) [

21], the natural gas in the pipeline contains approximately 98 % methane, to which all CNG-filling stations are linked. As a result, all NGVs considered in this study used the same CNG quality.

3.2. Technical Performance of NGVs

For petrol-fueled vehicles, technical performance is evaluated by four parameters, namely, engine performance, speed drop, engine fuel enhancement, and fuel savings. The engine performance is evaluated by the following parameters, namely, vehicle mileage (

MiCNG) and fuel consumption (

Fcons).

MiCNG is the mileage obtained when the vehicle is operated on CNG.

Fcons is the amount of CNG consumed by the NGV over a distance; see Equation (1).

where

Fcons is the amount of CNG consumed by the NGV over a distance (kg/km),

QCNG is the total amount of CNG consumed by the NGV or CNG cylinder capacity (kg), and

MiCNG is the mileage when the vehicle is operated on CNG (km).

Speed drop is evaluated in two moments: as a difference in engine speed when running on petrol and CNG in idling mode—termed

Sdrop-idle (Equation (2)).

where

Sdrop-idle is the drop in engine speed during idling mode when shifting from petrol to CNG (rpm),

Spetrol-idle is the engine speed when running on petrol during idling mode (rpm), and

SCNG-idle is the engine speed when running on CNG during idling mode (rpm).

Engine fuel enhancement (

Fenh) is the dimensionless factor defined as the ratio of mileage covered by a full tank of CNG to that of gasoline which is equivalent to CNG fuel; see Equation (3).

where

Fenh is the engine fuel enhancement (dimensionless).

Fuel saving (

Fsaving) defines the quantity of petrol fuel saved by running the vehicle on CNG. It is quantified by equalizing the energy quantities of petrol and CNG on the same vehicle, same engine condition, same route distance, and fuel price. It is then taken as a difference between the petrol fuel consumed by the vehicle before conversion to the petrol quantity equivalent to the CNG used on the same vehicle; see Equation (4).

where

Fsaving is the amount of petrol saved by running on CNG (L),

Fpetrol is the amount of petrol consumed during driving (L), and

FCNG is the amount of petrol that is equivalent to CNG consumed during driving (L).

For diesel vehicles, technical performance is assessed by two parameters, namely, vehicle mileage (

Midual) and fuel cutdown (

Fcutdown).

Midual is the mileage obtained when the vehicle is operated on dual fuel (diesel + CNG).

Fcutdown refers to the amount of diesel fuel cut down when using dual fuel over a distance; see Equation (5).

where

Fcutdown is the amount of diesel saved by running on dual fuel (L) and

Fdiesel is amount of diesel consumed during driving on diesel (L).

To assess the technical performance, a set of data was collected from the NGV users. The information collected was vehicle maker/model, make year, engine capacity, daily mileage (km), amount of petrol to cover the daily mileage (L), CNG cylinder capacity (kg), and maximum mileage obtained per CNG cylinder capacity in city and highway driving (km).

3.3. Economic Assessment of Conversion to NGVs

3.3.1. Conversion Cost, CC

The initial cost covers the import cost (

CI) and overhead cost (

COH). The import cost covers the cost of purchasing, shipping, port charges, and inland clearing. The

COH covers the cost of installation, first filling, and inspection costs. For petrol-fueled vehicles, CNG cylinders are Type 2 with 80 L or 11 kg and 110 L or 17 kg capacity and are mostly accepted by light-duty and medium-duty vehicle users. Hence, the conversion costs are based on these two sizes. Therefore, the conversion cost based on the vehicle model and size of the cylinder is computed as expressed in Equation (6). It should be noted that

COH also varies with the vehicle category.

for different vehicle types and cylinders is indicated in

Section 4.2.

where

is the cost of conversion for a vehicle with category

i and cylinder size

j (USD),

is the import cost for a vehicle with category

i and cylinder size

j (USD), and

is the overhead cost for a vehicle with category

i and cylinder size

j (USD).

Assumptions:

To facilitate computation of the conversion cost, the following assumptions are made:

- -

All costs are computed in TZS and USD currencies as of June 2022.

- -

The fuel costs refer to the Dar es Salaam region.

- -

An NG substitution ratio of 70% is used for all dual fuel vehicles.

- -

Table 1 indicates the properties of fuels used in the current study.

3.3.2. Fuel Cost Saving, FCsaving

Another important parameter to be evaluated is the percentage of fuel cost saved for a vehicle with category

i over a number of days after conversion to NGV (%

FCsaving, i). It is computed as a ratio of the difference between petrol and CNG costs and petrol cost as indicated in Equation (7).

where %

FCsaving,i is the percentage of fuel saved for a vehicle with category

i over a number of days after conversion to NGV (TZS),

FCpetrol,i is the cost of petrol incurred by a vehicle of category

i over a number of days (TZS), and

FCCNG,i is the cost of CNG incurred by a vehicle of category

i over a number of days (TZS).

For diesel vehicles, the fuel saving is computed as the difference in the cost of diesel and fuel cost when using dual fuel and is expressed as shown in Equation (8).

where

FCsaving,i,j is the fuel saving for a vehicle with category

i and cylinder size (USD),

FCdiesel,i is the cost of fuel when a vehicle is run on diesel (USD), and

FCdiesel+CNG,i,j is the cost of fuel when a vehicle runs on dual fuel (diesel and CNG).

3.3.3. Payback, PB

Another important parameter to be evaluated is the percentage of fuel cost saved by a vehicle of category

i over a specified number of days after conversion to NGV (%

FCsaving,i). It is computed as a ratio of the difference between petrol and CNG costs and petrol cost as indicated in Equation (9).

where

PBp,i,j is the payback period for a vehicle with category

i and cylinder type

j (months).

Payback distance (

PBd,i,j) is the distance beyond which the conversion costs begin to be paid off.

PBd,i,j is expressed as shown in Equation (10).

where

PBdistance,i,j is the payback distance for a vehicle with category

i and cylinder type

j (km) and

CNGkm,CNG,i,j is the cost per km when driving a vehicle of category

i and cylinder type

j on CNG, obtained as a ratio of refilling cost and

MiCNG (TZS/km).

5. Barriers to Widespread Adoption of NGVs in Tanzania

5.1. Social Barriers

Lack of public awareness: The conversion of vehicles to use CNG in Tanzania commenced early in 2018. Despite there being plenty of locally available natural gas, the conversion rate is still unpromising even on a regional level. Among the major reasons is the lack of knowledge regarding the benefits of transiting to NGVs. The majority of the residents cannot distinguish between CNG and domestically used liquified petroleum gas (LPG). When they recall some cases where LPG erupted in domestic houses, they become afraid to use CNG in their vehicles. Others think that NGVs can ignite when parked under the sun. Thus, the government needs to take measures to reduce social barriers.

Overexpectation of citizens: Despite the small number of conversion centers and long queues in the existing centers, vehicle owners still expect a one-day service. For the operating NGVs, some owners/drivers expect too much savings in a short driving period or no use of gasoline at all. Overcomplications were raised by some vehicle owners who did not want the CNG cylinder to be publicly seen, who wanted to fit a big CNG cylinder while maintaining sufficient boot space for luggage, and who wanted NGVs to maintain the same performance over years of operation.

5.2. Financial Barriers

Low per capita income: Most vehicle owners cannot afford the initial cost of conversion. After switching to an NGV, some economize CNG usage by not even allowing 1 km of driving on petrol before switching to CNG for optimum vehicle performance.

Increased taxes: The NGV technologies are still immature in Tanzania’s road transportation sector. CNG cylinders were exempted between 2018 and early 2020s while conversion kits were yet to be exempted. Despite the partial exemption on CNG cylinders and no exemption on conversion kits, the conversion rate was accelerated and increased the number of converted vehicles in the country as well. In the middle of 2022, the government of Tanzania withdrew the exemption on CNG cylinders, which resulted in a full tax on CNG systems. As a result, the conversion cost increased, which in turn drastically dropped the conversion rate.

5.3. Technical Barriers

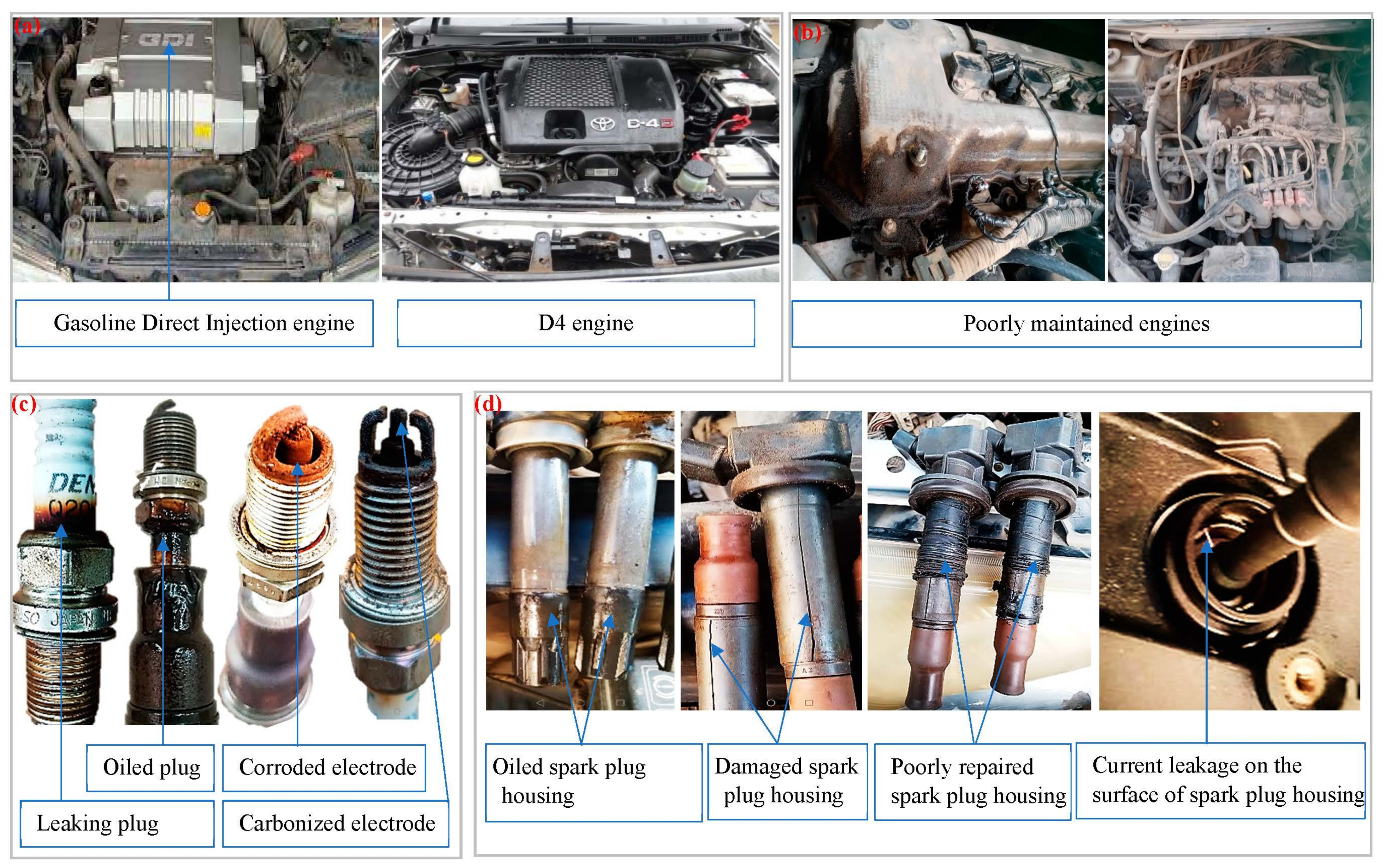

Incompatible engine technologies: During the vehicle inspection prior to the installation of the conversion kit, the engine’s fuel injection technology was inspected to check for its suitability with the kit. The inspected vehicles were made between 1990 and 2010. Technologies such as D4 and gasoline direct injection (GDI) were found to be incompatible with the sequential kit except for variable valve timing intelligence (VVTI) technology; see examples of GDI and D4 engines in

Figure 7a. Some of the vehicles were poorly maintained; hence, they were not accepted on time for conversion; see examples in

Figure 7b–d.

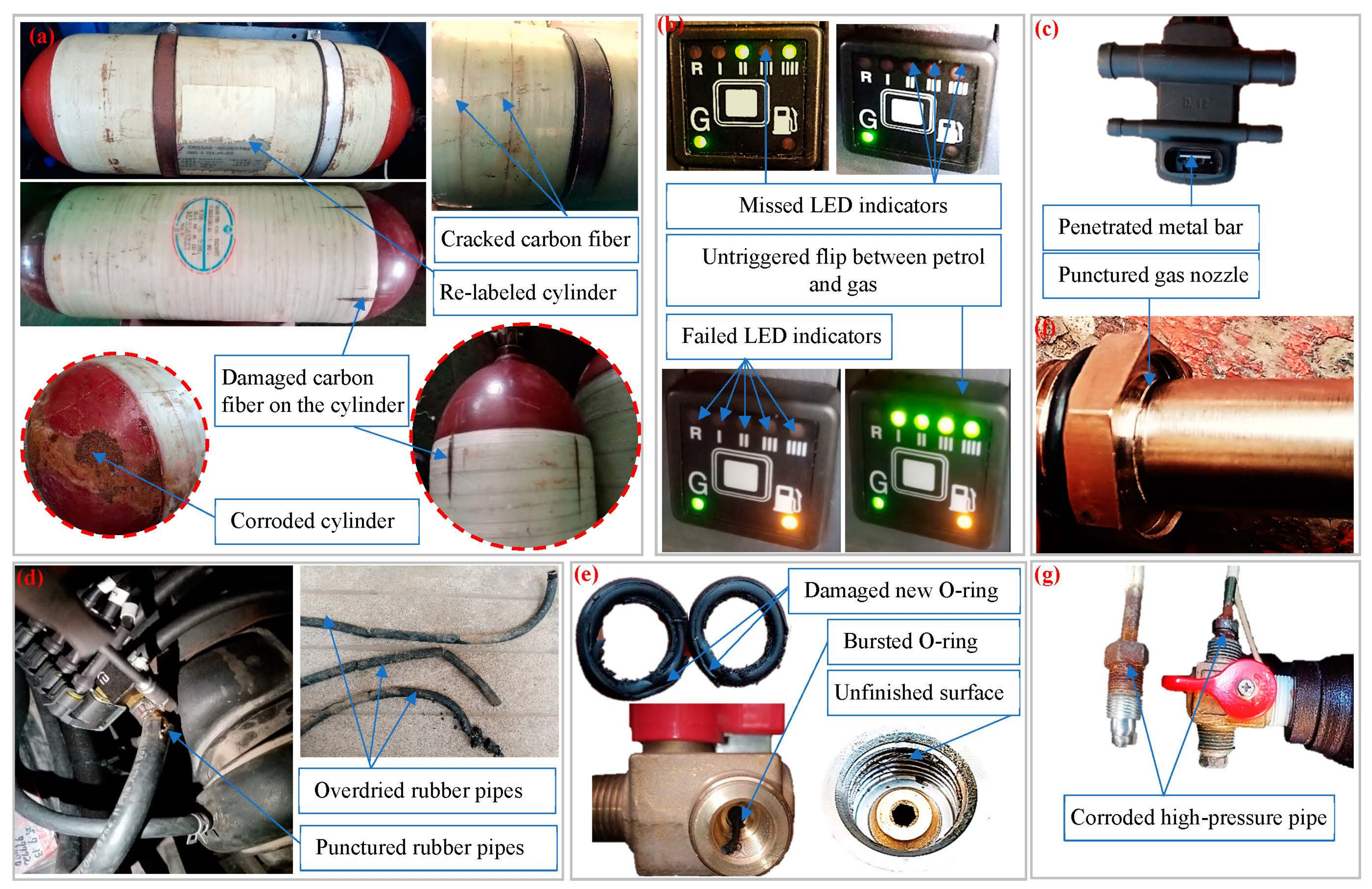

Low quality and malfunction of CNG system component(s): The presence of adulterous centers fitting second-hand CNG cylinders (

Figure 8a) or low-quality sequential kits lead to malfunctioning during on-road driving. Examples of malfunctioning components observed were CNG changeover switches (

Figure 8b), the electronic control unit (ECU), and mean absolute pressure (MAP) sensors. The MAP sensor rarely malfunctions due to the presence of an internal short-circuit (see

Figure 8c). Some of the CNG cylinders could not store the intended amount of CNG when refilled at any time in a day, so makers supplied low-quality hose pipes (

Figure 8d) and damaged O-rings in refill valves (

Figure 8e). Other issues involved cracking of CNG injection nozzles (

Figure 8f) and corrosion of the high-pressure CNG pipe (

Figure 8g).

Insufficient pool of NGV components and conversion centers across the country: Currently, all conversion kits are imported from Europe and far-East Asia. There are no readily available spare parts for servicing the NGVs in operation. Up to now, the conversion is only undertaken in Dar es Salaam, where there is a network of NG pipelines. However, the region suffers from a low conversion rate.

Inadequate CNG and NG pipeline infrastructures: There is a limited NG pipeline network. The shortage of the NG pipeline network hinders the expansion of CNG infrastructure, which in turn slows the conversion rate. Currently, only the NG pipeline is routed in the Dar es Salaam region, and there is only one mother and one daughter station.

5.4. Regulatory Barriers

NG is not considered an alternative fuel for vehicles: Tanzania’s current natural gas policy 2013 does not specify CNG as a vehicular fuel. This introduces other issues, for instance, the insurance act of 2015 to recognize only petrol and diesel as vehicle fuels in Tanzania. As a result, NGVs are yet to be insured as petrol or diesel vehicles. Moreover, CNG is seen as a source of fire during fire accidents, resulting in no insurance coverage.

Conflict of interest: The government greatly relies on fossil fuels as a major source of revenue. Oil importers, suppliers, and entrepreneurs consider NG/CNG as a threat to the oil business, which is not the case. On the other hand, energy regulators over-rely on oil for generating income used in some governmental projects. Moreover, NG producers and energy regulators who are responsible for licensing and promoting NG usage in Tanzania are not doing enough, resulting in a void of information and bureaucracy in providing licenses for the establishment of CNG-filling stations. Consequently, from 2018 when the conversion commenced to date, there is only one mother station and one daughter station feeding only 1 out of 30 regions. Yet, no measures have been established to replace the loss of revenue post-transition to NG.

Absence of bodies to promote and secure NGVs: An NGV association is yet to be established, which is crucial to promote the use of NG in the country, link the government and NGV users, provide the best advice to the government on the use of NG in the country, and represent the country in the regional development meetings. The petroleum act of Tanzania of 2015 requires retrofitted vehicles to be re-registered in other bodies. However, it is neither the Tanzania Revenue Authority (TRA), Tanzania Insurance Regulatory Authority (TIRA), nor Land and Air Transport Regulatory Authority (LATRA) that has executed the task. Furthermore, there is no governmental body responsible for dealing with accidental issues of NGVs.

7. Conclusions and Recommendations

The aim of this study is to assess the technologies deployed to make NGVs plausible in Tanzania’s environment as well as barriers hindering their success to compete at international levels. The technical and economic assessments of natural gas vehicles against their gasoline and diesel counterparts were evaluated. To undertake the analyses, a set of data was collected from the conversion centers and NGV users. Based on the analyses of this study, the following conclusions were made:

- -

The technologies for converting gasoline and diesel engines of road vehicles used in Tanzania’s transportation sector have been successfully implemented through the use of sequential conversion kits integrated with either Type 1 or Type 2 CNG cylinders.

- -

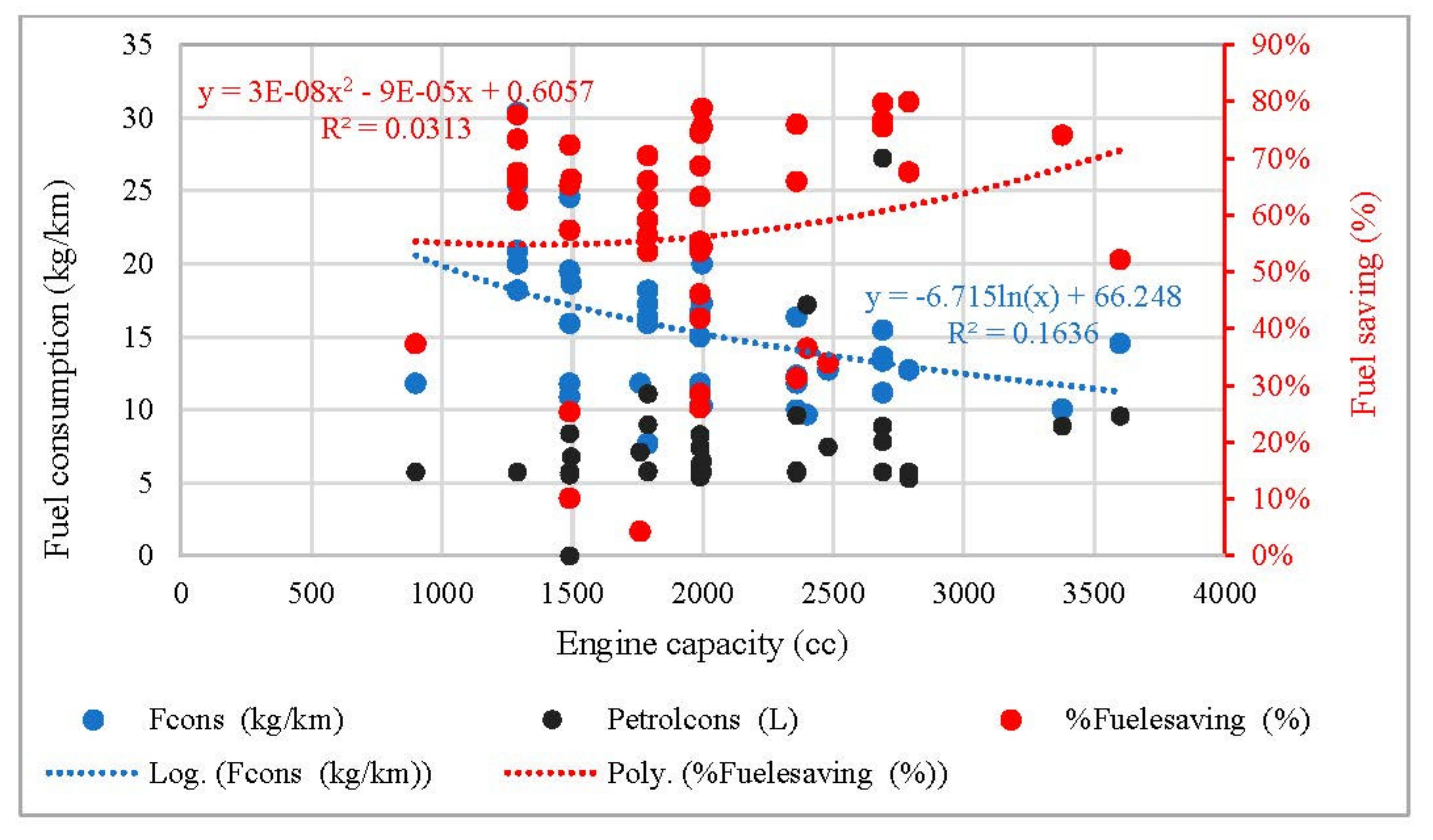

The technical analyses of gasoline retrofitted NGVs indicated an average mileage of 100 to 500 km per CNG filling, depending on the CNG cylinder size, and the mileage decreased with increasing engine capacity. The NGVs attained significant engine enhancement, ranging between 1.9 and 3.9, indicating that more mileage could be covered on CNG. In terms of fuel savings, NGVs can save between 71 and 78% of gasoline fuel, with insignificant effects on vehicle applications. With a proportion of 30:70 diesel-CNG fuel, the NGV (heavy-duty truck) could reach 1300 km, saving about 440 L, which is 78.6%. For a medium passenger car with 30:70 diesel-CNG fuel, 15 kg of CNG could reach 350 km, with fuel savings of about 75%.

- -

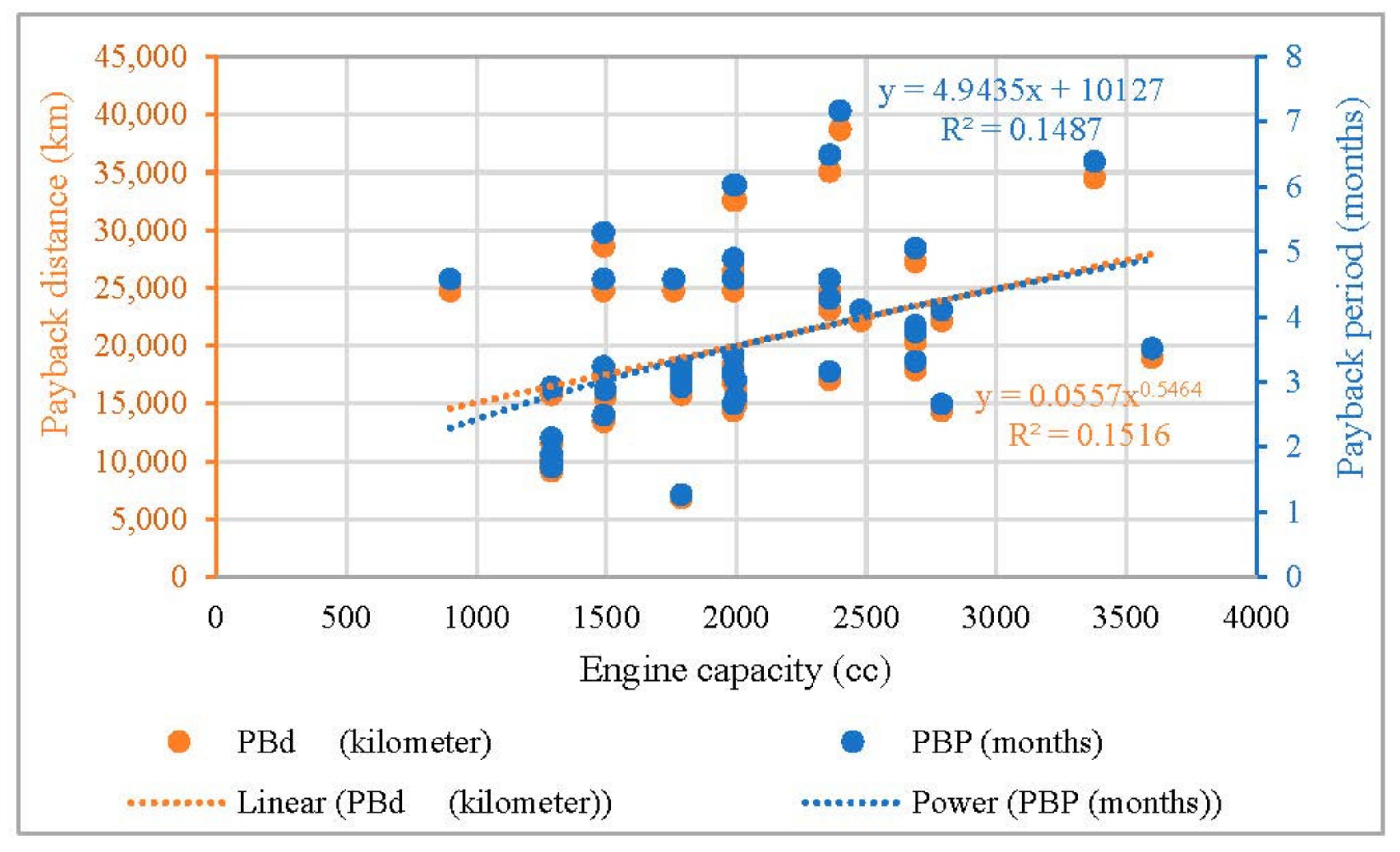

On the economic side, gasoline retrofitted NGVs cost about 50 to 200 km TZS/km, depending on the size of the CNG cylinder. This presents a fuel cost saving of up to 79%. After retrofitting to NGVs, gasoline vehicles start to pay off between 2 and 7 months or 10,000 and 40,000 km, depending on the engine capacity. Considering dual fuel, the heavy-duty truck consumes about 496 TZS/km while saving about 62.3% of diesel fuel. Additionally, the vehicles could start to pay off after 2.5 months or 29,304 km.

- -

Lack of proper information regarding socio–technical–economic benefits of NGVs, exclusion of NG as a vehicular fuel in existing policies, rigid and outdated policies, lack of dedicated bodies to promote NGVs, and financial difficulties are among the barriers hindering the wide penetration of NGVs in Tanzania.

It is recommended that, each year, new technologies, global regulations, strategies, and business scenarios are developed and introduced in the market. If Tanzania’s government does not address the existing barriers and employ green policies to speed up the use of its NG in the next few years, it will become obsolete over the other cleaner fuels. Most of the NGVs in Tanzania are not dedicated, and the government could find new ways of compensating the oil shares on NGV revenues. Sequential kits could be very user-friendly and durable for users to switch their kits to other vehicles while appealing to the government to create a more pocket-friendly price for gas in view of the numerous benefits associated with CNG.