Non-Conventional, Non-Permanent Magnet Wind Generator Candidates

Abstract

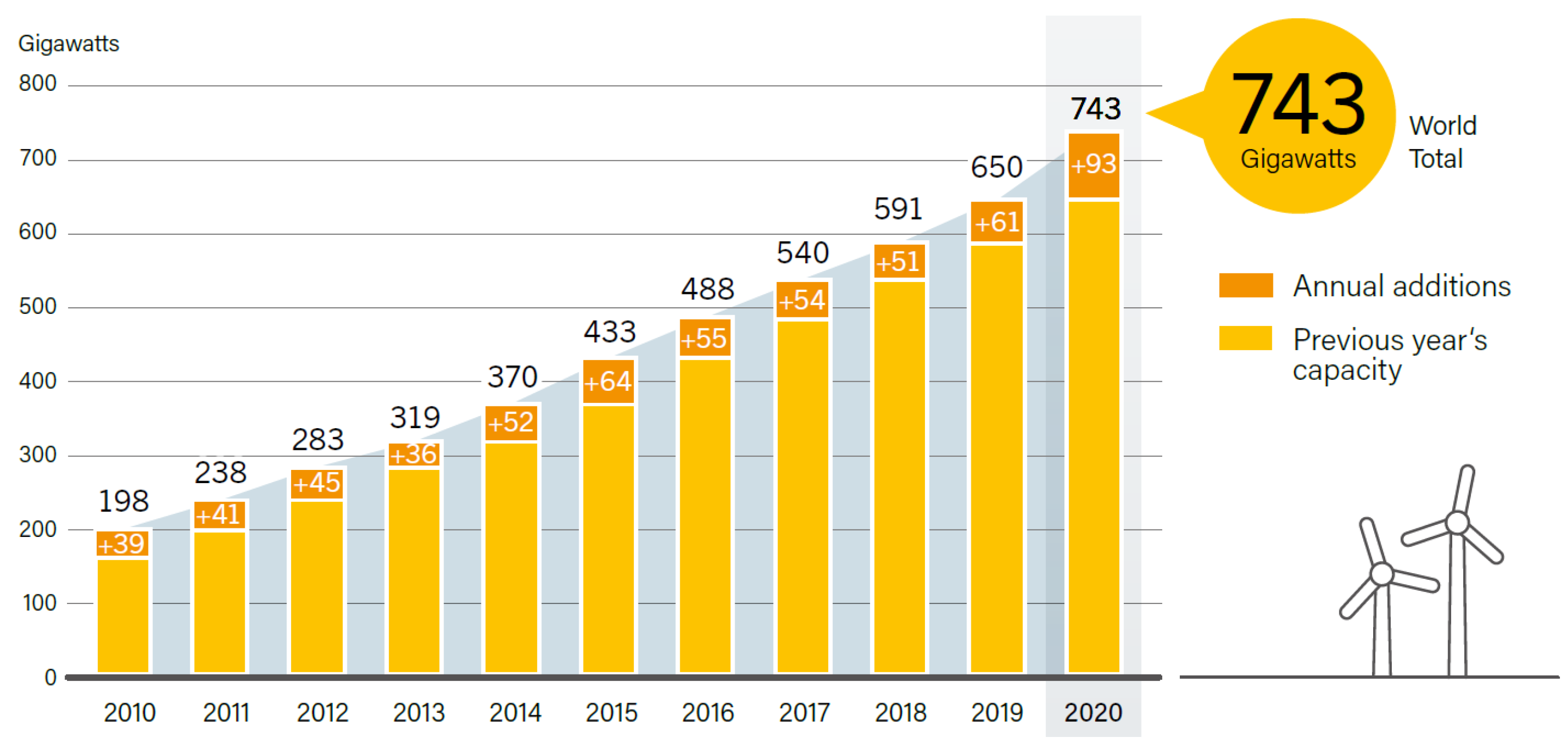

:1. Introduction

- Firstly, a robust hub structure that would overcome gusty wind conditions;

- Secondly, an economical size that favours larger offshore wind turbines capacities within the range of 5–10 MW;

- Thirdly, the use of a variable speed design that improves operation efficiency compared to that of fixed speed wind turbines which only operate efficiently at a particular peak speed;

- Fourthly, the elimination of gearboxes in the design of wind turbines to alleviate maintenance costs;

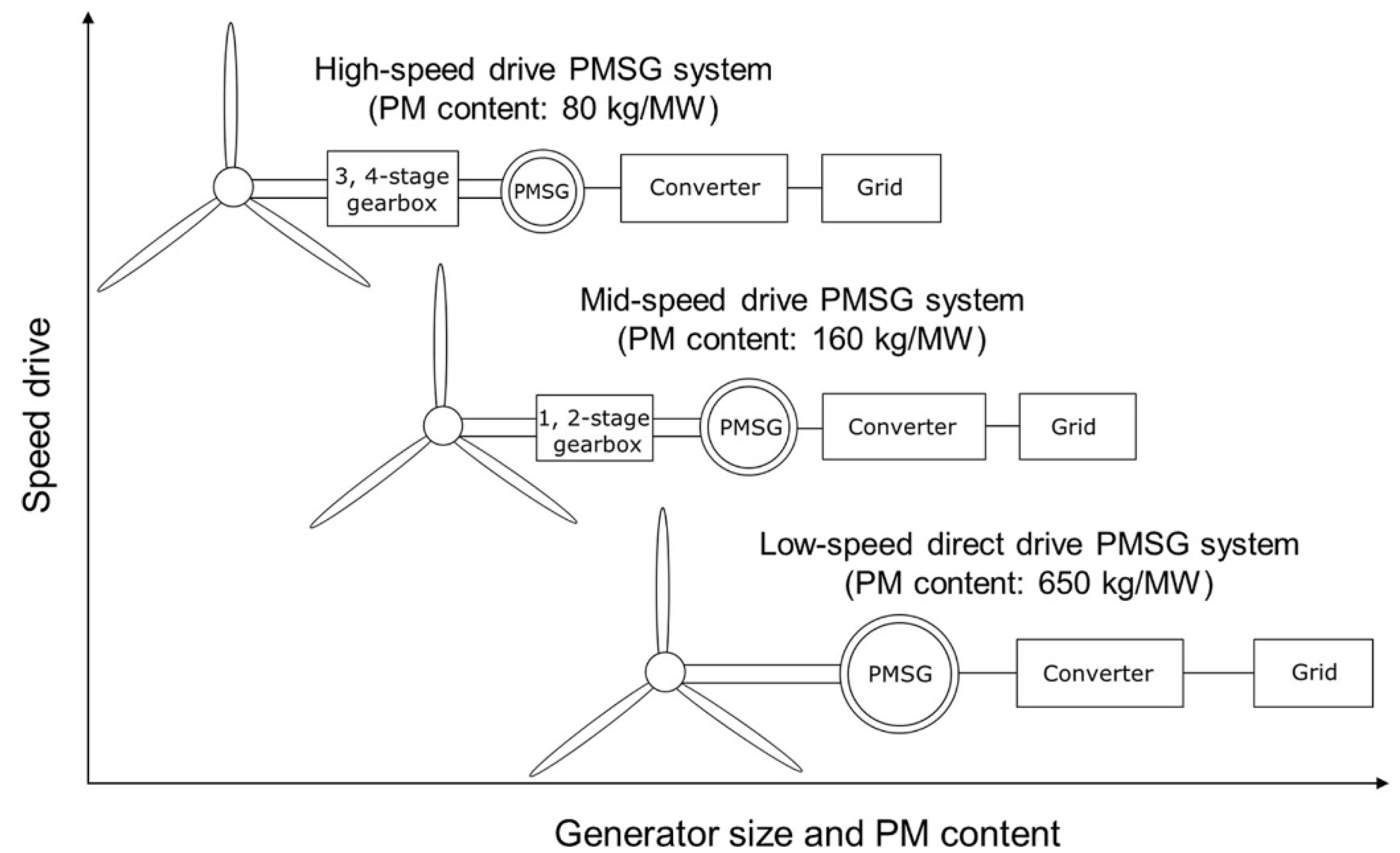

- Fifthly, the use of permanent magnets (PMs), which are constituted of the rare-earth materials—Neodymium-based powerful magnets used for manufacturing of the more efficient and high-torque density wind generators;

- Lastly, the use of superconductors or advance materials/design technologies to reduce the size and mass of wind generators, hence improving the levelized cost of energy (LCOE).

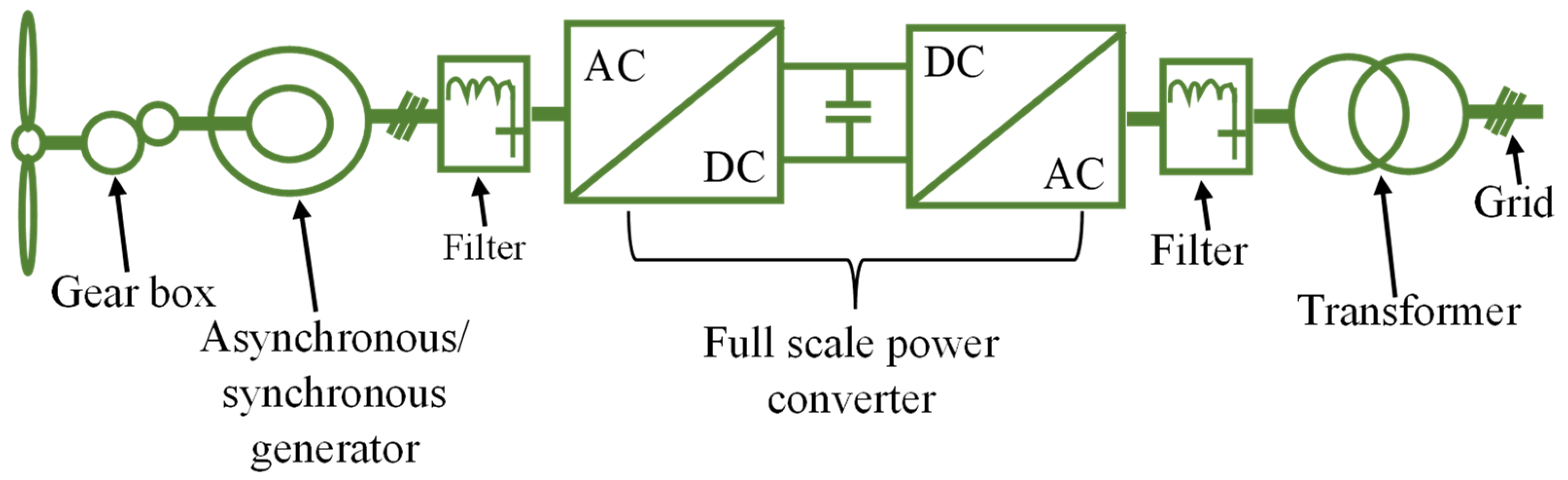

2. Conventional Non-PM Wind Generators

2.1. Squirrel Cage Induction Generators (SCIG)

2.2. Wound Rotor Induction Generators (WRIGs)

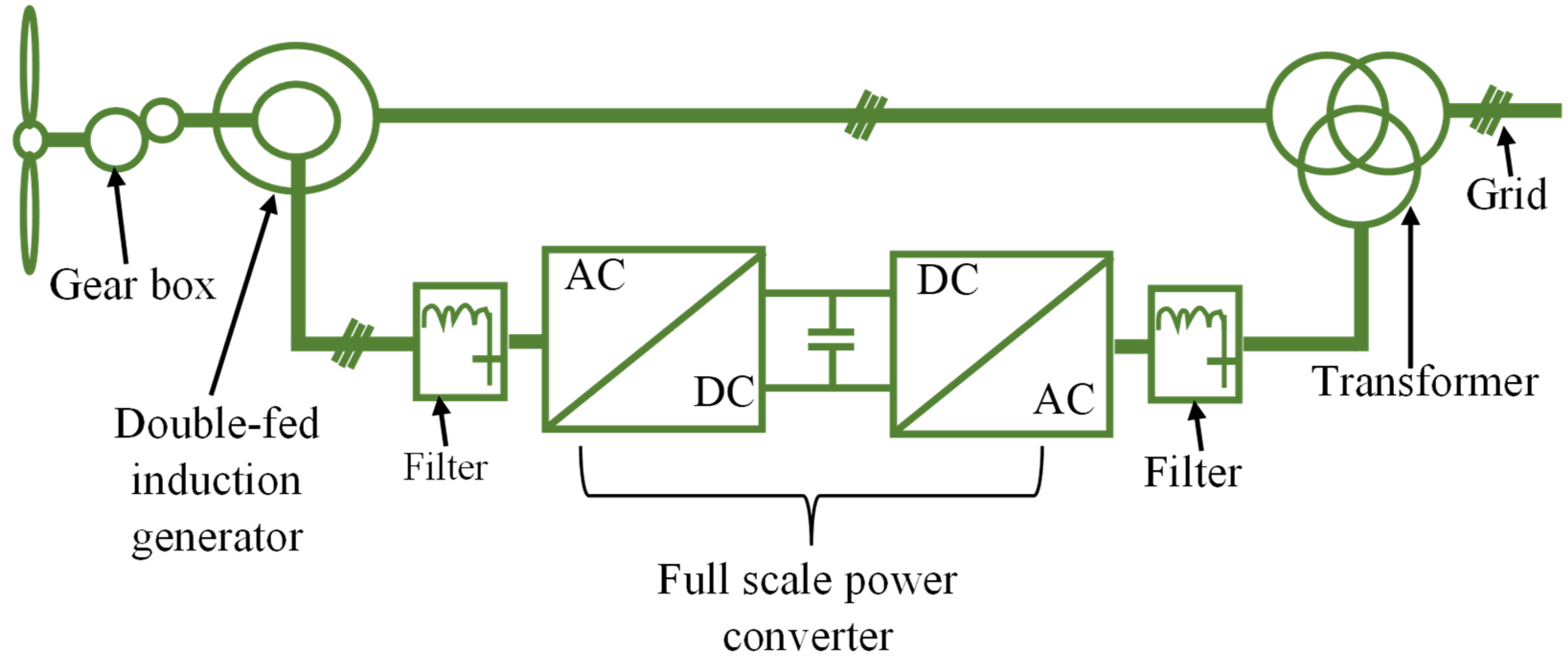

2.3. Doubly Fed Induction Generators (DFIG)

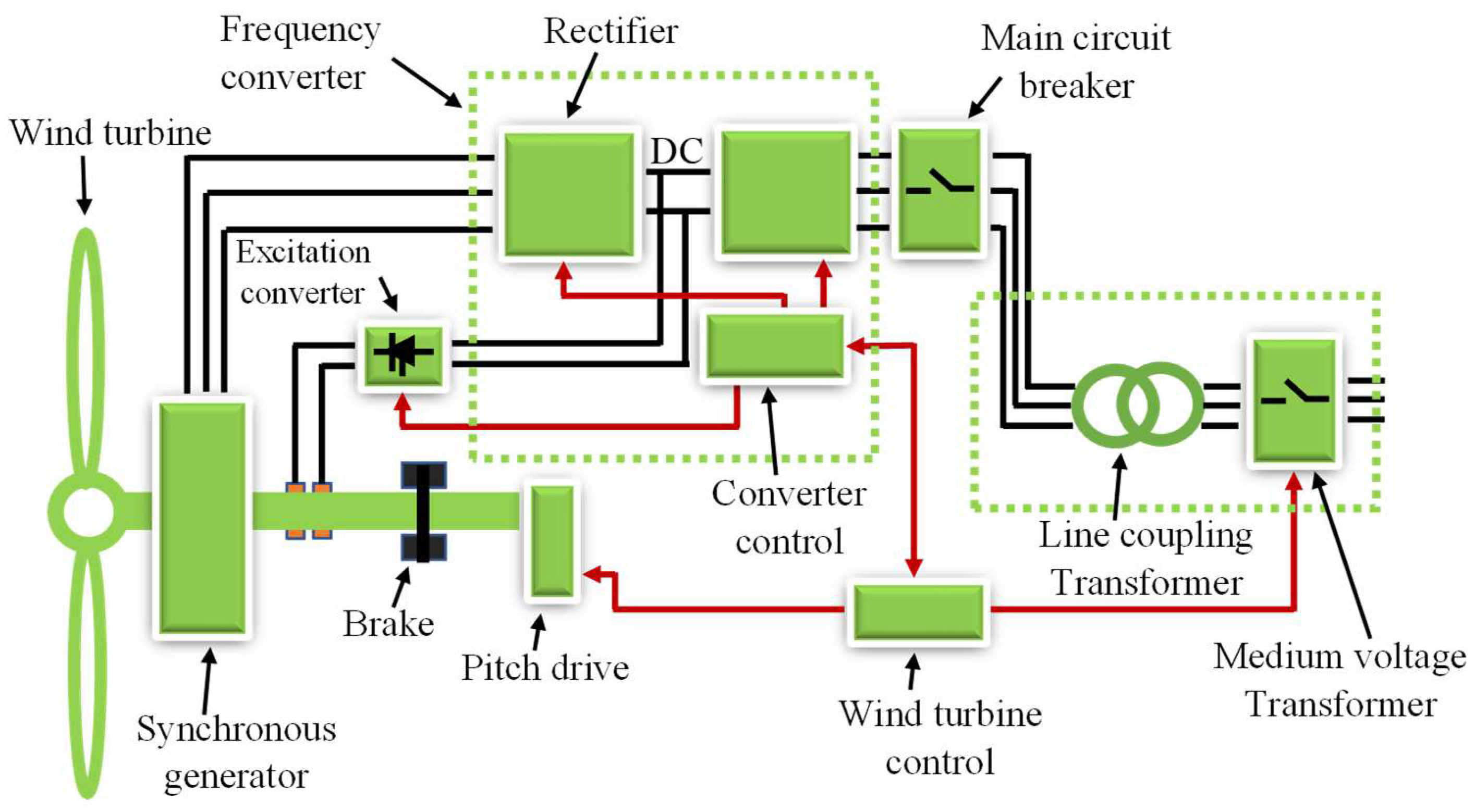

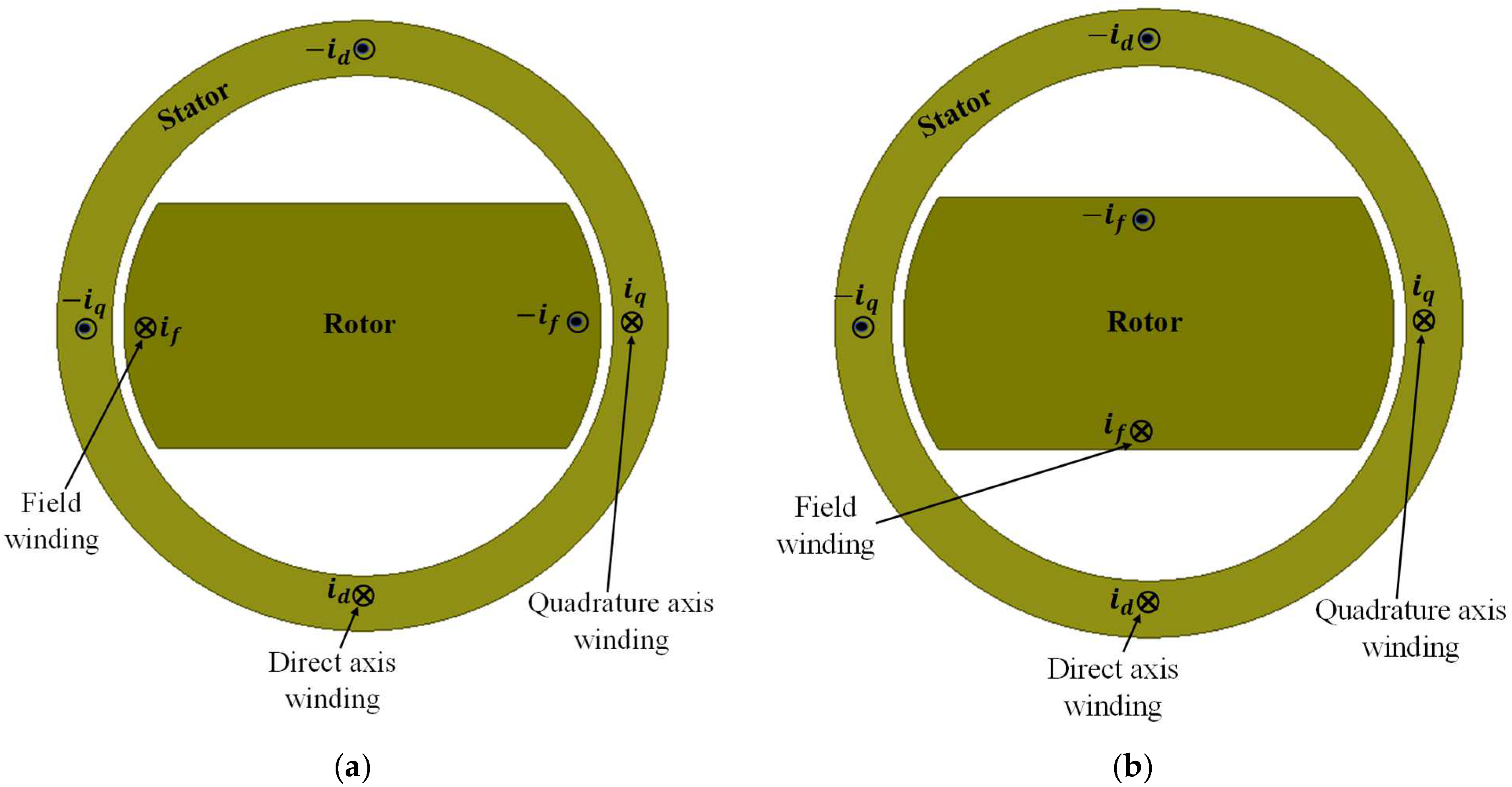

2.4. Electrically Excited Synchronous Generators (EESG)

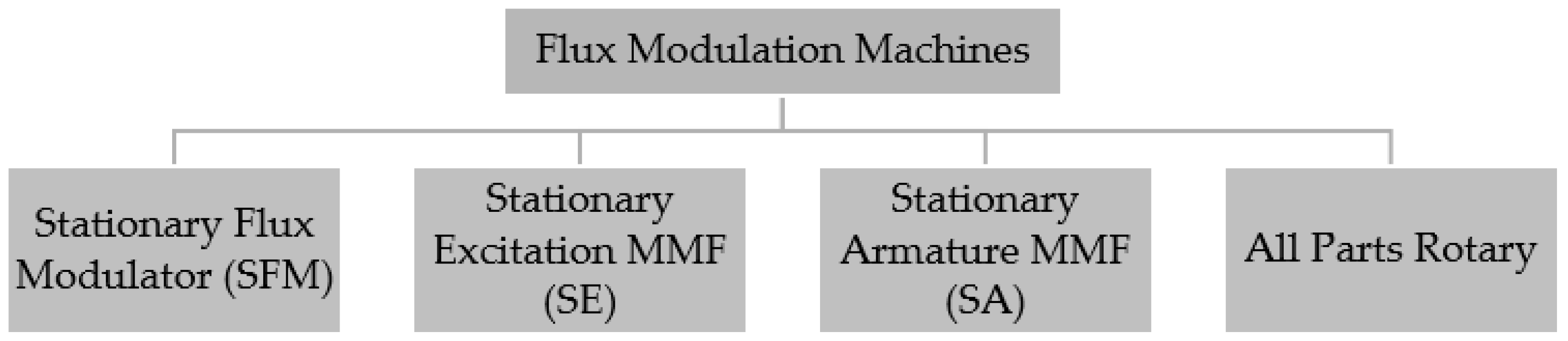

3. Non-Conventional Non-PM Electrical Machines

3.1. Reluctance Synchronous Machine (RSM)

3.1.1. Torque Ripple

3.1.2. Power Factor

3.1.3. Control

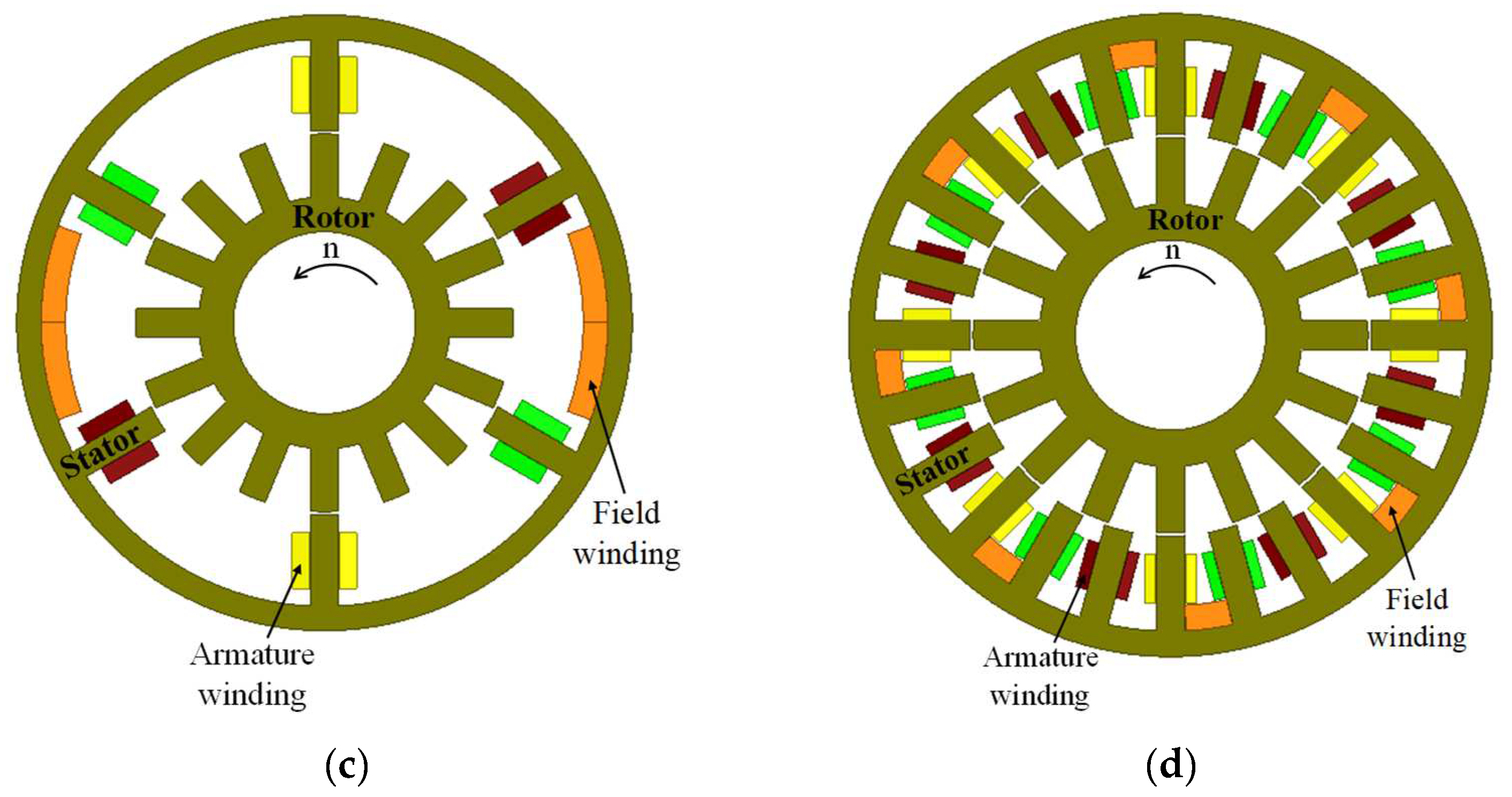

3.2. DC-Excited Vernier Reluctance Machine (DC-VRM)

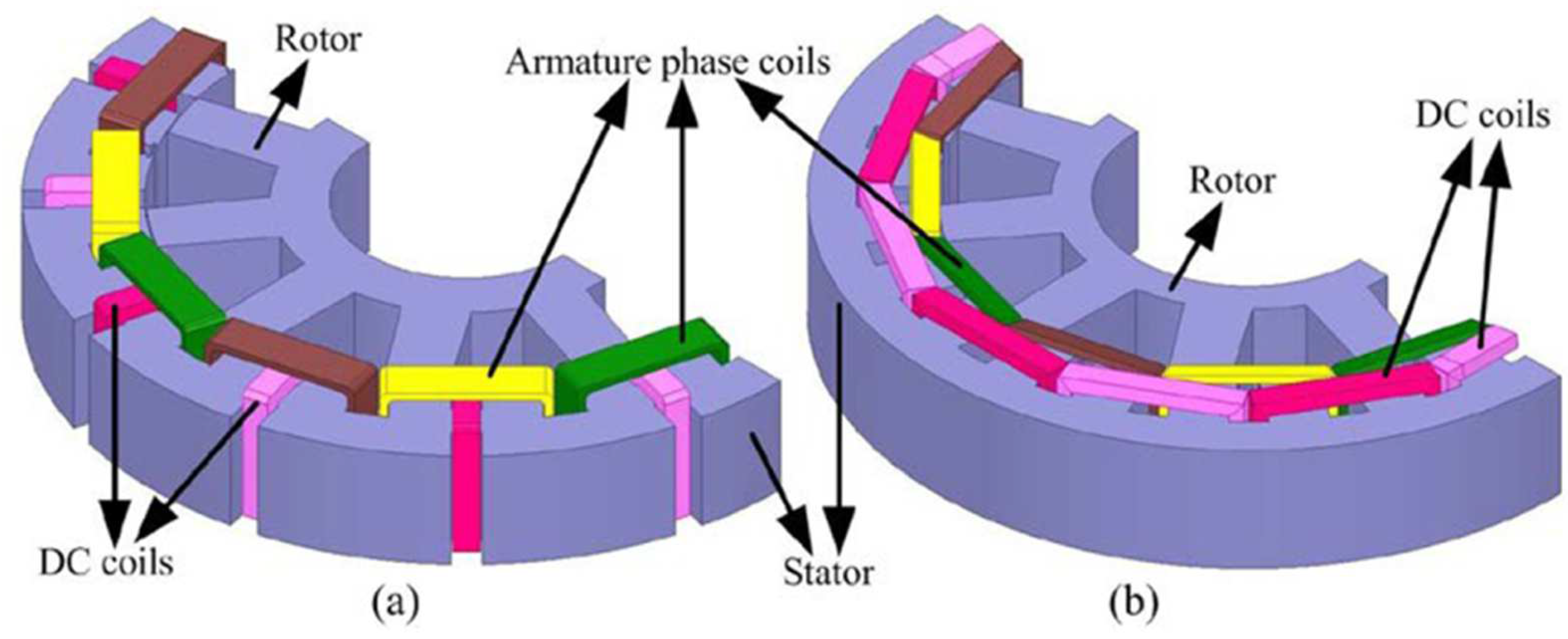

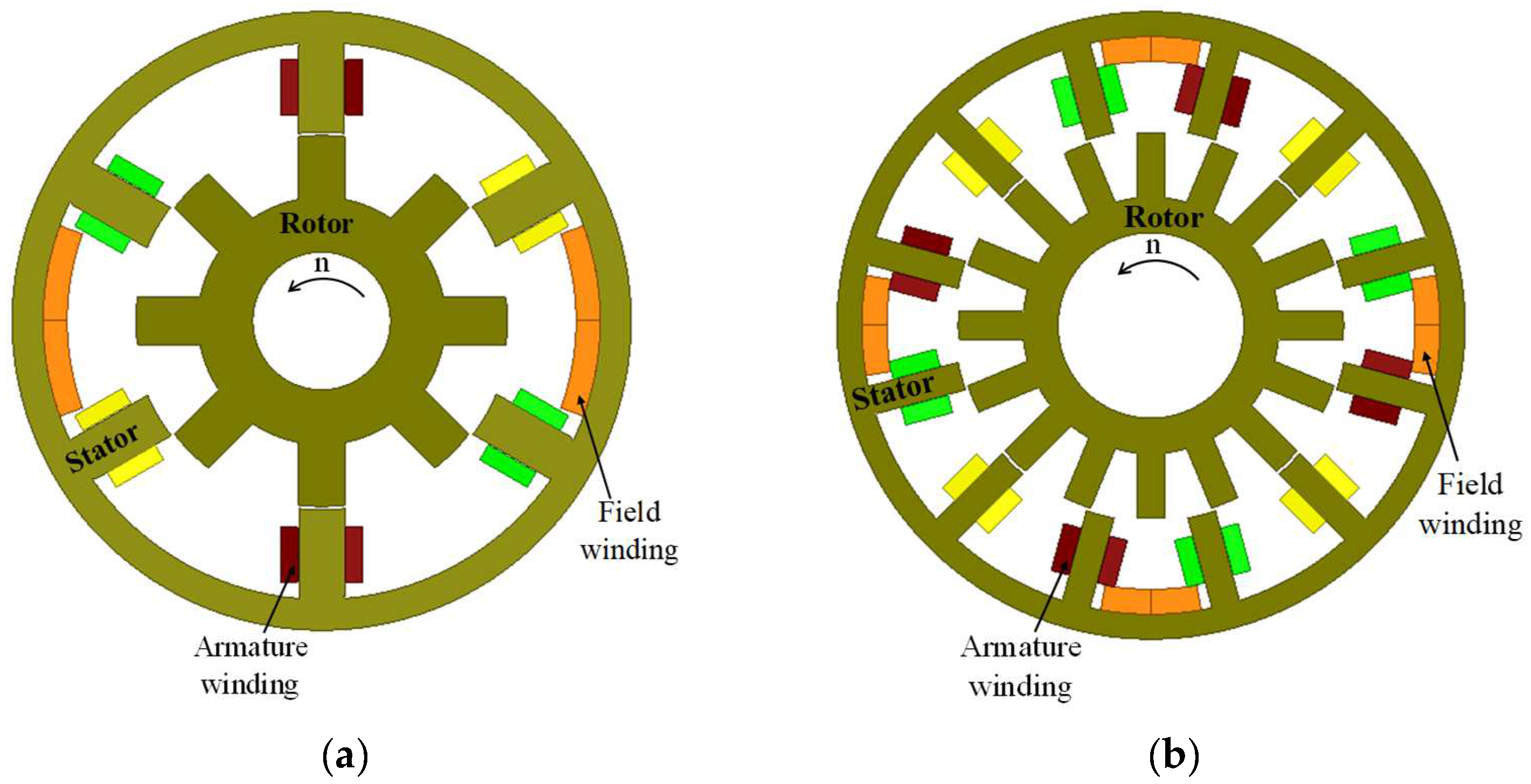

3.3. Wound-Field Flux Switching Machine (WF-FSM)

3.4. Double-Salient DC Machine (DSDCM)

3.5. DC-Field Excited Flux Reversal Machine (DC-FRM)

3.6. Brushless Doubly-Fed Machines

4. Comparative Analysis of Non-Conventional Non-PM Electrical Machines

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFDSM | Axial Flux Doubly Salient Machine |

| ARSM | Assisted Reluctance Synchronous Machine |

| ASP | Asymmetric Stator Pole |

| BDFIM | Brushless Doubly-Fed Induction Machines |

| BDFRM | Brushless Doubly-Fed Reluctance Machines |

| BLAC | Brushless Alternating Current |

| BLDC | Brushless Direct Current |

| BSMM | Brushless Stator Mounted Machine |

| CPSR | Constant Power Speed Range |

| CRSM | Compensated Reluctance Synchronous Machine |

| DC | Direct Current |

| DFIG | Doubly Fed Induction Generator |

| DSDCM | Double-Salient Direct Current Machine |

| DSM | Double-Salient Machine |

| DSPM | Double-Salient Permanent Magnet Machine |

| EESG | Electrically Excited Synchronous Generator |

| EMF | Electromotive Force |

| FEM | Finite Element Method |

| FMM | Flux Modulation Machine |

| FRM | Flux Reversal Machine |

| FRT | Fault Ride Through |

| FSG | Flux Switching Generator |

| FSM | Flux Switching Machine |

| HS | High Speed |

| HTS | High Temperature Superconducting |

| HVDC | High Voltage Direct Current |

| kW | Kilowatt |

| LCOE | Levelized Cost of Energy |

| MFB | Multiple Flux Barriers |

| MW | Megawatt |

| OBD | Optimized Benchmark Design |

| PM | Permanent Magnet |

| PMSG | Permanent Magnet Synchronous Generator |

| RSG | Reluctance Synchronous Generator |

| RSM | Reluctance Synchronous Machine |

| SCIG | Squirrel Cage Induction Generator |

| SRM | Switched Reluctance Machine |

| UMF | Unbalanced Magnetic Force |

| USD | US Dollar |

| VRM | Vernier Reluctance Machine |

| WECS | Wind Energy Conversion System |

| WF | Wound Field |

| WRIG | Wound Rotor Induction Generator |

| WRSM | Wound Rotor Synchronous Machine |

References

- REN21. Renewables 2021 Global Status Report; REN21 Secretariat: Paris, France, 2021; ISBN 978-3-948393-03-8. [Google Scholar]

- Mantashe, S.G. Integrated Resource Plan 2019. Department of Mineral Resource and Energy, South Africa, Pretoria. 17 October 2019. Available online: http://www.energy.gov.za/IRP/2019/IRP-2019.pdf (accessed on 31 March 2022).

- Department of Energy. The South African Energy Sector Report 2021; Department of Mineral Resources & Energy, South Africa, 2022; ISBN 978-1-920435-18-9. Available online: http://www.energy.gov.za/files/media/explained/2021-South-African-Energy-Sector-Report.pdf (accessed on 31 March 2022).

- Shaun, I. Wind Energy and Its Application. Available online: https://www.yourarticlelibrary.com/paragraphs/wind-energy-and-its-application/47799 (accessed on 31 March 2022).

- Ragheb, M. Modern Wind Generators; University of Illinois: Champaign, IL, USA, 2019. [Google Scholar]

- Moore, S.K. Rough Seas for the Superconducting Wind Turbine: To Keep Offshore Turbines Light, Engineers Look beyond Superconductors to a New Permanent-Magnet Tech. IEEE Spectr. 2018, 55, 32–39. [Google Scholar] [CrossRef]

- De Vries, E. Wind Turbine Drive Systems: A Commercial Overview; Woodhead Publishing Limited: Sawston, UK, 2013; ISBN 9781845697839. [Google Scholar]

- NREL. Advanced Wind Turbine Drivetrain Concepts. Work. Rep. 2010, 1–31. Available online: https://www.nrel.gov/docs/fy11osti/50043.pdf (accessed on 31 March 2022).

- Pavel, C.C.; Lacal-Arántegui, R.; Marmier, A.; Schüler, D.; Tzimas, E.; Buchert, M.; Jenseit, W.; Blagoeva, D. Substitution Strategies for Reducing the Use of Rare Earths in Wind Turbines. Resour. Policy 2017, 52, 349–357. [Google Scholar] [CrossRef]

- Chen, H.; Zuo, Y.; Chau, K.T.; Zhao, W.; Lee, C.H.T. Modern Electric Machines and Drives for Wind Power Generation: A Review of Opportunities and Challenges. IET Renew. Power Gener. 2021, 15, 1864–1887. [Google Scholar] [CrossRef]

- Tahanian, H.; Aliahmadi, M.; Faiz, J. Ferrite Permanent Magnets in Electrical Machines: Opportunities and Challenges of a Non-Rare-Earth Alternative. IEEE Trans. Magn. 2020, 56, 1–20. [Google Scholar] [CrossRef]

- Ishikawa, T.; Igarashi, N.; Kurita, N. Failure Diagnosis for Demagnetization in Interior Permanent Magnet Synchronous Motors. Int. J. Rotating Mach. 2017, 2017, 2716814. [Google Scholar] [CrossRef] [Green Version]

- Watson, S.; Moro, A.; Reis, V.; Baniotopoulos, C.; Barth, S.; Bartoli, G.; Bauer, F.; Boelman, E.; Bosse, D.; Cherubini, A.; et al. Future Emerging Technologies in the Wind Power Sector: A European Perspective. Renew. Sustain. Energy Rev. 2019, 113, 109270. [Google Scholar] [CrossRef]

- Bensalah, A.; Benhamida, M.A.; Barakat, G.; Amara, Y. Large Wind Turbine Generators: State-of-the-Art Review. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2205–2211. [Google Scholar] [CrossRef]

- Li, D.; Qu, R.; Li, J. Topologies and Analysis of Flux-Modulation Machines. In Proceedings of the ECCE 2015: IEEE Energy Conversion Congress and Exposition, Montreal, QC, Canada, 20–24 September 2015; pp. 2153–2160. [Google Scholar] [CrossRef]

- Qu, R.; Zhou, Y.; Li, D. Milestones, hotspots and trends in the development of electric machines. iEnergy 2022, 1, 88–99. [Google Scholar] [CrossRef]

- Cheng, M.; Han, P.; Du, Y.; Wen, H.; Li, X. A Tutorial on General Air-Gap Field Modulation Theory for Electric Machines. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 10, 1712–1732. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Novel Experimentation of a 10 KW Geared Medium-Speed Wound-Field Flux Switching Wind Generator Drive. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 6492–6498. [Google Scholar]

- Szabo, L. A Survey on Modular Variable Reluctance Generators for Small Wind Turbines. IEEE Trans. Ind. Appl. 2019, 55, 2548–2557. [Google Scholar] [CrossRef]

- Liao, Y.; Liang, F.; Lipo, T.A. A Novel Permanent Magnet Motor with Doubly Salient Structure. IEEE Trans. Ind. Appl. 1995, 31, 1069–1078. [Google Scholar] [CrossRef]

- Deodhar, R.P.; Andersson, S.; Boldea, I.; Miller, T.J.E. The Flux-Reversal Machine: A New Brushless Doubly-Salient Permanent-Magnet Machine. IEEE Trans. Ind. Appl. 1997, 33, 925–934. [Google Scholar] [CrossRef]

- Hoang, E.; Ben-Ahmed, A.H.; Lucidarme, J. Switching Flux Permanent Magnet Poly-Phased Synchronous Machines. In Proceedings of the 7th European Conference on Power Electronics and Applications, Trondheim, Norway, 8–10 September 1997; Volume 3, pp. 903–908. [Google Scholar]

- Zhu, D.; Qiu, X.; Zhou, N.; Yan, Y. A Novel Five Phase Fault Tolerant Doubly Salient Electromagnetic Generator for Direct Driven Wind Turbine. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 2418–2422. [Google Scholar]

- Lee, C.H.T.; Chau, K.T.; Liu, C. Design and Analysis of a Cost-Effective Magnetless Multiphase Flux-Reversal DC-Field Machine for Wind Power Generation. IEEE Trans. Energy Convers. 2015, 30, 1565–1573. [Google Scholar] [CrossRef] [Green Version]

- Polinder, H.; Van Der Pijl, F.F.A.; De Vilder, G.J.; Tavner, P.J. Comparison of Direct-Drive and Geared Generator Concepts for Wind Turbines. IEEE Trans. Energy Convers. 2006, 21, 725–733. [Google Scholar] [CrossRef] [Green Version]

- Duong, M.Q.; Grimaccia, F.; Leva, S.; Mussetta, M.; Ogliari, E. Pitch Angle Control Using Hybrid Controller for All Operating Regions of SCIG Wind Turbine System. Renew. Energy 2014, 70, 197–203. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B.; Sen, P.C.; Kouro, S.; Narimani, M. High-Power Wind Energy Conversion Systems: State-of-the-Art and Emerging Technologies. Proc. IEEE 2015, 103, 740–788. [Google Scholar] [CrossRef]

- Movahednasab, A.; Madani, S.M.; Shahbazi, M.M. Modeling of a Squirrel Cage Induction Generator. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008; pp. 4267–4271. [Google Scholar]

- Blaabjerg, F.; Ma, K. Wind Energy Systems. Proc. IEEE 2017, 105, 2116–2131. [Google Scholar] [CrossRef] [Green Version]

- Domínguez-García, J.L.; Gomis-Bellmunt, O.; Trilla-Romero, L.; Junyent-Ferré, A. Indirect Vector Control of a Squirrel Cage Induction Generator Wind Turbine. Comput. Math. Appl. 2012, 64, 102–114. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Tutelea, L.; Boldea, I.; Ionel, D.M.; Blaabjerg, F. Power Electronic Drives, Controls, and Electric Generators for Large Wind Turbines–An Overview. Electr. Power Compon. Syst. 2015, 43, 1406–1421. [Google Scholar] [CrossRef]

- Hansen, L.H.; Helle, L.; Blaabjerg, F.; Ritchie, E.; Bindner, H.; Sørensen, P.; Munk-Nielsen, S.; Bindner, H.; Sorensen, P.; Bak-Jensen, B. Conceptual Survey of Generators and Power Electronics for Wind Turbines; Risoe National Lab: Roskilde, Denmark, 2001; Volume 1205, p. 108. [Google Scholar]

- Wu, B.; Lang, Y.; Zargari, N.; Kouro, S. Power Converters in Wind Energy Conversion Systems. In Power Conversion and Control of Wind Energy Systems; Wiley-IEEE Press: Hoboken, NJ, USA, 2011; pp. 87–152. [Google Scholar]

- Khadraoui, M.R.; Elleuch, M. Comparison between OptiSlip and Fixed Speed Wind Energy Conversion Systems. In Proceedings of the 5th International Multi-Conference on Systems, Signals and Devices, Amman, Jordan, 20–22 July 2008. [Google Scholar] [CrossRef]

- Dubois, M.; Polinder, H.; Ferreira, J.A. Comparison of Generator Topologies for Direct-Drive Wind Turbines. In Proceedings of the Nordic Countries Power and Industrial Electronics Conference (NORPIE), Aalborg, Denmark, 13–16 June 2000. [Google Scholar]

- Chatterjee, S.; Chatterjee, S. Review on the Techno-Commercial Aspects of Wind Energy Conversion System. IET Renew. Power Gener. 2018, 12, 1581–1608. [Google Scholar] [CrossRef]

- Liserre, M.; Cárdenas, R.; Molinas, M.; Rodriguez, J. Overview of Multi-MW Wind Turbines and Wind Parks. IEEE Trans. Ind. Electron. 2011, 58, 1081–1095. [Google Scholar] [CrossRef]

- Cardenas, R.; Pena, R.; Alepuz, S.; Asher, G. Overview of Control Systems for the Operation of DFIGs in Wind Energy Applications. IEEE Trans. Ind. Electron. 2013, 60, 2776–2798. [Google Scholar] [CrossRef]

- Ekanayake, J.B.; Holdsworth, L.; Wu, X.; Jenkins, N. Dynamic Modeling of Doubly Fed Induction Generator Wind Turbines. IEEE Trans. POWER Syst. 2003, 18, 803–809. [Google Scholar] [CrossRef] [Green Version]

- Mojumdar, M.R.R.; Himel, M.S.; Rahman, M.S.; Hossain, S. Electric Machines & Their Comparative Study for Wind Energy Conversion Systems (WECSs). J. Clean Energy Technol. 2015, 4, 290–294. [Google Scholar] [CrossRef] [Green Version]

- European Wind Energy Association Large Commercial Wind Turbines. Available online: https://www.wind-energy-the-facts.org/large-commercial-wind-turbines.html (accessed on 11 May 2022).

- Morren, J.; de Haan, S.W.H. Ridethrough of Wind Turbines with Doubly-Fed Induction Generator during a Voltage Dip. IEEE Trans. Energy Convers. 2005, 20, 435–441. [Google Scholar] [CrossRef] [Green Version]

- Aguemon, D.P.; Agbokpanzo, R.G.; Dubas, F.; Vianou, A.; Chamagne, D.; Espanet, C. A Comprehensive Analysis and Review on Electrical Machines in Wind Energy Conversion Systems. Adv. Eng. Forum 2020, 35, 77–93. [Google Scholar] [CrossRef]

- Boldea, I.; Tutelea, L.; Blaabjerg, F. High Power Wind Generator Designs with Less or No PMs: An Overview. In Proceedings of the 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014. [Google Scholar] [CrossRef]

- Jensen, B.B. A Large Electrically Excited Synchronous Generator. WO Patent WO2014198275A1, 4 June 2014. [Google Scholar]

- Keysan, O. Future Electrical Generator Technologies for Offshore Wind Turbines. Eng. Technol. Ref. 2015, 1, 1–14. [Google Scholar] [CrossRef]

- Goudarzi, A.; Ghayoor, F. Modelling of Wind Turbine Power Curves (WTPCs) Based on the Sum of the Sine Functions and Improved Version of Particle Swarm Optimization (IPSO). In Proceedings of the 2020 International SAUPEC/RobMech/PRASA Conference, Cape Town, South Africa, 29–31 January 2020; pp. 1–6. [Google Scholar]

- Amirat, Y.; Benbouzid, M.; Bensaker, B.; Wamkeue, R. The State of the Art of Generators for Wind Energy Conversion Systems. Electromotion 2007, 14, 163–172. [Google Scholar]

- Quéval, L.; Ohsaki, H. Back-to-Back Converter Design and Control for Synchronous Generator-Based Wind Turbines. In Proceedings of the 2012 International Conference on Renewable Energy Research and Applications (ICRERA), Nagasaki, Japan, 11–14 November 2012; pp. 1–6. [Google Scholar]

- Alnajjar, M.; Gerling, D. Medium-Speed Synchronous Reluctance Generator as Efficient, Reliabile and Low-Cost Solution for Power Generation in Modern Wind Turbines. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 1233–1238. [Google Scholar]

- Wang, Y.; Bianchi, N. Investigation of Self-Excited Synchronous Reluctance Generators. IEEE Trans. Ind. Appl. 2018, 54, 1360–1369. [Google Scholar] [CrossRef]

- Kostko, J.K. Polyphase Reaction Synchronous Motors. J. Am. Inst. Electr. Eng. 2013, 42, 1162–1168. [Google Scholar] [CrossRef]

- Cruickshank, A.J.O.; Menzies, R.W.; Anderson, A.F. Axially Laminated Anisotropic Rotors for Reluctance Motors. Proc. Inst. Electr. Eng. 1966, 113, 2058. [Google Scholar] [CrossRef]

- Krause, P.C.; Lipo, T.A. Analysis and Simplified Representations of a Rectifier-Inverter Induction Motor Drive. IEEE Trans. Power Appar. Syst. 1969, PAS-88, 588–596. [Google Scholar] [CrossRef]

- Honsinger, V.B. The Inductances Ld and Lq of Reluctance Machines. IEEE Trans. Power Appar. Syst. 1971, PAS-90, 298–304. [Google Scholar] [CrossRef]

- Barta, J.; Ondrusek, C. Rotor Design and Optimization of Synchronous Reluctance Machine. MM Sci. J. 2015, 2015, 555–559. [Google Scholar] [CrossRef]

- Palmieri, M.; Perta, M.; Cupertino, F.; Pellegrino, G. Effect of the Numbers of Slots and Barriers on the Optimal Design of Synchronous Reluctance Machines. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Brasov, Romania, 22–24 May 2014; pp. 260–267. [Google Scholar]

- Nagrial, M.; Rizk, J.; Hellany, A. Analysis and Performance of High Efficiency Synchronous Reluctance Machine. Int. J. Energy Environ. 2011, 2, 247–254. [Google Scholar]

- Štumberger, G.; Hadžiselimović, M.; Štumberger, B.; Miljavec, D.; Dolinar, D.; Zagradišnik, I. Comparison of Capabilities of Reluctance Synchronous Motor and Induction Motor. J. Magn. Magn. Mater. 2006, 304, 835–837. [Google Scholar] [CrossRef]

- Kamper, M.J.; Volsdhenk, A.F. Effect of Rotor Dimensions and Cross Magnetisation on Ld and Lq Inductances of Reluctance Synchronous Machine with Cageless Flux Barrier Rotor. IEE Proc.-Electr. Power Appl. 1994, 141, 213–220. [Google Scholar] [CrossRef]

- Vagati, A. The Synchronous Reluctance Solution: A New Alternative in AC Drives. In Proceedings of the IECON’94—20th Annual Conference of IEEE Industrial Electronics, Bologna, Italy, 5–9 September 1994; Volume 1, pp. 1–13. [Google Scholar]

- Howard, E.; Kamper, M.J. Reluctance Synchronous Wind Generator Design Optimisation in the Megawatt, Medium Speed Range. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition ECCE 2017, Cincinnati, OH, USA, 1–5 October 2017; pp. 1864–1871. [Google Scholar] [CrossRef]

- Howard, E. Design Optimisation of Reluctance Synchronous Machines: A Motor and Generator Study. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2017. [Google Scholar]

- Dippenaar, J.; Kamper, M.J. A Robust 5 MW Split-Pole Reluctance Synchronous Wind Generator. In Proceedings of the Proceedings—2020 International Conference on Electrical Machines, ICEM 2020, Gothenburg, Sweden, 23–26 August 2020; pp. 1841–1847. [Google Scholar]

- Dmitrievskii, V.A.; Prakht, V.A.; Kazakbaev, V.M. Ultra Premium Efficiency (IE5 Energy-Efficiency Class) Synchronous Reluctance Motor with Fractional Slot Winding. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1015–1020. [Google Scholar]

- Loubser, A.T.; Kamper, M.J. Design Optimisation of Reluctance Synchronous Machine for Drive System Efficiency. In Proceedings of the 2015 IEEE Workshop on Electrical Machines Design, Control and Diagnosis, WEMDCD 2015, Torino, Italy, 26–27 March 2015; pp. 60–65. [Google Scholar]

- Maroufian, S.S.; Pillay, P. Self-Excitation Criteria of the Synchronous Reluctance Generator in Stand-Alone Mode of Operation. IEEE Trans. Ind. Appl. 2018, 54, 1245–1253. [Google Scholar] [CrossRef]

- Hubert, T.; Reinlein, M.; Kremser, A.; Herzog, H.-G. Torque Ripple Minimization of Reluctance Synchronous Machines by Continuous and Discrete Rotor Skewing. In Proceedings of the 2015 5th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–16 September 2015; pp. 1–7. [Google Scholar]

- Tsuchiya, J.; Mishima, K.; Kimura, G. A Study on Torque Ripple Reduction of Synchronous Reluctance Motor. In Proceedings of the 4th IEEE International Conference on Power Electronics and Drive Systems. IEEE PEDS 2001—Indonesia. Proceedings (Cat. No.01TH8594), Denpasar, Indonesia, 25 October 2001; Volume 2, pp. 452–455. [Google Scholar]

- Fratta, A.; Troglia, G.P.; Vagati, A.; Villata, F. Evaluation of Torque Ripple in High Performance Synchronous Reluctance Machines. In Conference Record of the 1993 IEEE Industry Applications Conference Twenty-Eighth IAS Annual Meeting; IEEE: Piscataway, NJ, USA, 1993; Volume 1, pp. 163–170. [Google Scholar] [CrossRef]

- Lubin, T.; Hamiti, T.; Razik, H.; Rezzoug, A. Comparison Between Finite-Element Analysis and Winding Function Theory for Inductances and Torque Calculation of a Synchronous Reluctance Machine. IEEE Trans. Magn. 2007, 43, 3406–3410. [Google Scholar] [CrossRef] [Green Version]

- Moghaddam, R.R. Synchronous Reluctance Machine (SynRM) in Variable Speed Drives (VSD) Applications—Theoretical and Experimental Reevaluation; Royal Institute of Technology: Stockholm, Sweden, 2011. [Google Scholar]

- Moghaddam, R.-R.; Magnussen, F.; Sadarangani, C. Novel Rotor Design Optimization of Synchronous Reluctance Machine for Low Torque Ripple. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 720–724. [Google Scholar]

- Bomela, X.B.; Kamper, M.J. Effect of Stator Chording and Rotor Skewing on Performance of Reluctance Synchronous Machine. IEEE Trans. Ind. Appl. 2002, 38, 91–100. [Google Scholar] [CrossRef]

- Dabija, O.; Simion, A.; Livadaru, L.; Irimia, N. Study of a Skewed Rotor Cage Synchronous Reluctance Motor Using Finite Element Analysis. In Proceedings of the 2013 8th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 May 2013. [Google Scholar]

- Howard, E.; Kamper, M.J. Weighted Factor Multiobjective Design Optimization of a Reluctance Synchronous Machine. IEEE Trans. Ind. Appl. 2016, 52, 2269–2279. [Google Scholar] [CrossRef]

- Kamper, M.J. Design Optimisation of Cageless Flux Barrier Rotor Reluctance Synchronous Machine; Stellenbosch University: Stellenbosch, South Africa, 1996; pp. 58–62. [Google Scholar]

- Kamper, M.J.; Villet, W.T. Design and Performance of Compensated Reluctance Synchronous Machine Drive with Extended Constant Power Speed Range. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 4330–4337. [Google Scholar]

- Landsmann, P.; Kennel, R.; de Kock, H.W.; Kamper, M.J. Fundamental Saliency Based Encoderless Control for Reluctance Synchronous Machines. In Proceedings of the The XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–7. [Google Scholar]

- Landsmann, P.; Paulus, D.; Stolze, P.; Kennel, R. Reducing the Parameter Dependency of Encoderless Predictive Torque Control for Reluctance Machines. In Proceedings of the 2010 First Symposium on Sensorless Control for Electrical Drives, Padova, Italy, 9–10 July 2010; pp. 93–99. [Google Scholar]

- Boldea, I.; Fu, Z.X.; Nasar, S.A. Torque Vector Control (Tvc) of Axially-Laminated Anisotropic (Ala) Rotor Reluctance Synchronous Motors. Electr. Mach. Power Syst. 1991, 19, 527–531. [Google Scholar] [CrossRef]

- Lagerquist, R.; Boldea, I.; Miller, T.J.E. Sensorless-Control of the Synchronous Reluctance Motor. IEEE Trans. Ind. Appl. 1994, 30, 673–682. [Google Scholar] [CrossRef] [Green Version]

- Bolognani, S.; Peretti, L.; Zigliotto, M. Online MTPA Control Strategy for DTC Synchronous-Reluctance-Motor Drives. IEEE Trans. Power Electron. 2011, 26, 20–28. [Google Scholar] [CrossRef]

- Chikhi, A.; Djarallah, M.; Chikhi, K. A Comparative Study of Field-Oriented Control and Direct-Torque Control of Induction Motors Using an Adaptive Flux Observer. Serbian J. Electr. Eng. 2010, 7, 41–55. [Google Scholar] [CrossRef]

- Matsuo, T.; Lipo, T.A. Field Oriented Control of Synchronous Reluctance Machine. In Proceedings of the IEEE Power Electronics Specialist Conference—PESC ’93, Seattle, WA, USA, 20–24 June 1993; pp. 425–431. [Google Scholar]

- Xu, L.; Xu, X.; Lipo, T.A.; Novotny, D.W. Vector Control of a Synchronous Reluctance Motor Including Saturation and Iron Loss. IEEE Trans. Ind. Appl. 1991, 27, 977–985. [Google Scholar] [CrossRef]

- Betz, R.E.; Lagerquist, R.; Jovanovic, M.; Miller, T.J.E.; Middleton, R.H. Control of Synchronous Reluctance Machines. IEEE Trans. Ind. Appl. 1993, 29, 1110–1122. [Google Scholar] [CrossRef]

- Rashad, E.M.; Radwan, T.S.; Rahman, M.A. A Maximum Torque per Ampere Vector Control Strategy for Synchronous Reluctance Motors Considering Saturation and Iron Losses. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, 2004. 39th IAS Annual Meeting; IEEE: Piscataway, NJ, USA, 2004; Volume 4, pp. 2411–2417. [Google Scholar]

- Wu, F.; El-Refaie, A. Permanent Magnet Vernier Machine: A Review. IET Electr. Power Appl. 2019, 13, 127–137. [Google Scholar] [CrossRef]

- Tlali, P.M.; Wang, R.J.; Gerber, S.; Botha, C.D.; Kamper, M.J. Design and Performance Comparison of Vernier and Conventional PM Synchronous Wind Generators. IEEE Trans. Ind. Appl. 2020, 56, 2570–2579. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, Z.Q. Stator/Rotor Pole Combinations and Winding Configurations of Variable Flux Reluctance Machines. IEEE Trans. Ind. Appl. 2014, 50, 3675–3684. [Google Scholar] [CrossRef]

- Mabhula, M.; Akuru, U.B.; Kamper, M.J. Cross-Coupling Inductance Parameter Estimation for More Accurate Performance Evaluation of Wound-Field Flux Modulation Machines. Electronics 2020, 9, 1748. [Google Scholar] [CrossRef]

- Jia, S.; Qu, R.; Li, J. Analysis of the Power Factor of Stator DC-Excited Vernier Reluctance Machines. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Jia, S.; Qu, R.; Li, J.; Li, D.; Lu, H. Comparison of Stator DC Current Excited Vernier Reluctance Machines with Different Field Winding Configurations. IEEE Trans. Magn. 2017, 53, 16–19. [Google Scholar] [CrossRef]

- Lin, M.; Qu, R.; Li, J.; Jia, S.; Lu, Y. Torque Ripple Reduction Techniques for Stator DC Winding Excited Vernier Reluctance Machines. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Akuru, U.B.; Kamper, M.J.; Mabhula, M. Optimisation and Design Performance of a Small-Scale DC Vernier Reluctance Machine for Direct-Drive Wind Generator Drives. In Proceedings of the ECCE 2020—IEEE Energy Conversion Congress and Exposition, Detroit, MI, USA, 11–15 October 2020; pp. 2965–2970. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Optimisation and Design Comparison of 10-KW and 3-MW PM Flux-Switching Machines for Geared Medium-Speed Wind Power Generators. Electr. Eng. 2018, 100, 2509–2525. [Google Scholar] [CrossRef]

- Khan, F.; Sulaiman, E.; Ahmad, Z.; Husin, Z.A. Design and Analysis of Wound Field Three-Phase Flux Switching Machine with Non-Overlap Windings and Salient Rotor. Int. J. Electr. Eng. Inform. 2015, 7, 323–333. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J. Comparative Advantage of Flux Switching PM Machines for Medium-Speed Wind Drives. In Proceedings of the 2015 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 31 March–1 April 2015; pp. 149–154. [Google Scholar]

- Cardenas, R.; Pena, R.; Perez, M.; Clare, J.; Asher, G.; Wheeler, P. Control of a Switched Reluctance Generator for Variable-Speed Wind Energy Applications. IEEE Trans. Energy Convers. 2005, 20, 781–791. [Google Scholar] [CrossRef]

- Cao, W.; Xie, Y.; Tan, Z. Wind Turbine Generator Technologies. Adv. Wind Power 2012, 1, 177–204. [Google Scholar] [CrossRef] [Green Version]

- Selema, A. Development of a Three-Phase Dual-Rotor Magnetless Flux Switching Generator for Low Power Wind Turbines. IEEE Trans. Energy Convers. 2020, 35, 828–836. [Google Scholar] [CrossRef]

- Yu, C.; Niu, S. Development of a Magnetless Flux Switching Machine for Rooftop Wind Power Generation. IEEE Trans. Energy Convers. 2015, 30, 1703–1711. [Google Scholar] [CrossRef]

- Abrahamsen, A.B.; Mijatovic, N.; Seiler, E.; Sørensen, M.P.; Koch, M.; Nørgård, P.B.; Pedersen, N.F.; Træholt, C.; Andersen, N.H.; Østergård, J. Design Study of 10 KW Superconducting Generator for Wind Turbine Applications. IEEE Trans. Appl. Supercond. 2009, 19, 1678–1682. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Chau, K.T.; Member, S.; Li, W.; Member, S. Loss Analysis of Permanent Magnet Hybrid Brushless Machines with and Without HTS Field Windings. IEEE Trans. Appl. Supercond. 2010, 20, 1077–1080. [Google Scholar]

- Wang, Y.; Sun, J.; Zou, Z.; Wang, Z.; Chau, K.T. Design and Analysis of a HTS Flux-Switching Machine for Wind Energy Conversion. IEEE Trans. Appl. Supercond. 2013, 23, 3–6. [Google Scholar] [CrossRef]

- Cheng, M.; Ning, X.; Zhu, X.; Wang, Y. Selection of Excitation Operating Points of 10 MW HTS Exciting Double Stator Direct-Drive Wind Generators Having Single and Double Polarity Inner Stator. J. Polytech. 2020, 23, 537–545. [Google Scholar] [CrossRef] [Green Version]

- Akuru, U.B.; Kamper, M.J. Potentials of Locally Manufactured Wound-Field Flux Switching Wind Generator in South Africa. J. Energy South. Afr. 2019, 30, 110–117. [Google Scholar] [CrossRef] [Green Version]

- Garner, K.S.; Akuru, U.B.; Kamper, M.J. Optimization and Performance Evaluation of Non-Overlap Wound-Field Converter-Fed and Direct-Grid Wind Generators. IEEE Access 2022, 10, 40587–40595. [Google Scholar] [CrossRef]

- Akuru, U.B.; Kamper, M.J.; Member, S. Intriguing Behavioural Characteristics of Rare—Earth—Free Flux Switching Wind Generators at Small—And Large—Scale Power Levels. IEEE Trans. Ind. Appl. 2018, 54, 5772–5782. [Google Scholar] [CrossRef]

- Gong, Y.; Chau, K.T.; Jiang, J.Z.; Yu, C.; Li, W. Design of Doubly Salient Permanent Magnet Motors With Minimum Torque Ripple. IEEE Trans. Magn. 2009, 45, 4704–4707. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.; Chau, K.T.; Chan, C.C. Design and Analysis of a New Doubly Salient Permanent Magnet Motor. IEEE Trans. Magn. 2001, 37, 3012–3020. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Zhu, D.; Li, Y.; Qin, Y. A Novel Doubly Salient Electromagnetic Generator. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011; pp. 1–4. [Google Scholar]

- Zhang, Z.; Yan, Y.; Tao, Y. A New Topology of Low Speed Doubly Salient Brushless DC Generator for Wind Power Generation. IEEE Trans. Magn. 2012, 48, 1227–1233. [Google Scholar] [CrossRef]

- Li, D.; Gao, Y.; Qu, R.; Li, J.; Huo, Y.; Ding, H. Design and Analysis of a Flux Reversal Machine With Evenly Distributed Permanent Magnets. IEEE Trans. Ind. Appl. 2018, 54, 172–183. [Google Scholar] [CrossRef]

- Cheng, M.; Hua, W.; Zhang, J.; Zhao, W. Overview of Stator-Permanent Magnet Brushless Machines. IEEE Trans. Ind. Electron. 2011, 58, 5087–5101. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, Y.; Shen, Y.; Xing, S. Effective Methods of Reducing Cogging Torque in Flux Reversal Machine. J. Iron Steel Res. Int. 2006, 13, 444–449. [Google Scholar] [CrossRef]

- Gao, Y.; Qu, R.; Li, J.; Li, D.; Wu, L. Power Factor of Three-Phase Flux Reversal Machines. In Proceedings of the 2015 IEEE International Magnetics Conference (INTERMAG), Beijing, China, 11–15 May 2015; p. 1. [Google Scholar]

- Olubamiwa, O.I.; Gule, N. A Review of the Advancements in the Design of Brushless Doubly Fed Machines. Energies 2022, 15, 725. [Google Scholar] [CrossRef]

- Han, P.; Cheng, M.; Ademi, S.; Jovanović, M.G. Brushless Doubly-Fed Machines: Opportunities and Challenges. Chin. J. Electr. Eng. 2018, 4, 1–17. [Google Scholar] [CrossRef]

- Potgieter, J.H.J.; Kamper, M.J. Double PM-Rotor, Toothed, Toroidal-Winding Wind Generator: A Comparison with Conventional Winding Direct-Drive PM Wind Generators over a Wide Power Range. IEEE Trans. Ind. Appl. 2016, 52, 2881–2891. [Google Scholar] [CrossRef]

| Items | PM-FRM | DC-FRM | |

|---|---|---|---|

| No. of armature phases | 3 | 4 | 4 |

| Power (kW) | 58 | 64 | 22 |

| Power Density (MW/m3) | 1.98 | 2.10 | 0.71 |

| Flux Controllability | Low | Low | High |

| Material Cost (USD) | 1245 | 1398 | 308 |

| Cost-effectiveness | 46.6 | 45.8 | 71.4 |

| Type | Torque Density (kNm/m3) | Average Torque (Nm) | Torque Ripple (%) | Power Factor | Cost | Efficiency (%) | Speed (r/min) |

|---|---|---|---|---|---|---|---|

| RSG [64] | 18.5 | 97.7 × 103 | 4.92 | 0.54 | Low | 97.94 | 500 |

| DC-VRM [85] | 17.39 | 732.0 | 8.5 | 0.8 | Low | 87.4 | 200 |

| WF-FSM [110] | 31.6 | 77.8 × 103 | 3.74 | 0.8 | Low | 97.0 | 360 |

| DSDCM [113] | 3.92 | 38.22 | 7.46 | - | Low | 89.3 | 500 |

| DC-FRM [24] | 6.68 | 179.9 | 6.28 | - | Low | 72.5 | 900 |

| PMSG (kW) [90] | 24.01 | 1011.1 | 3.42 | 0.97 | High | 94.4 | 150 |

| PMSG (MW) [121] | 109.25 | 2789 × 103 | 2.06 | 0.94 | High | 95.0 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udosen, D.; Kalengo, K.; Akuru, U.B.; Popoola, O.; Munda, J.L. Non-Conventional, Non-Permanent Magnet Wind Generator Candidates. Wind 2022, 2, 429-450. https://doi.org/10.3390/wind2030023

Udosen D, Kalengo K, Akuru UB, Popoola O, Munda JL. Non-Conventional, Non-Permanent Magnet Wind Generator Candidates. Wind. 2022; 2(3):429-450. https://doi.org/10.3390/wind2030023

Chicago/Turabian StyleUdosen, David, Kundanji Kalengo, Udochukwu B. Akuru, Olawale Popoola, and Josiah L. Munda. 2022. "Non-Conventional, Non-Permanent Magnet Wind Generator Candidates" Wind 2, no. 3: 429-450. https://doi.org/10.3390/wind2030023

APA StyleUdosen, D., Kalengo, K., Akuru, U. B., Popoola, O., & Munda, J. L. (2022). Non-Conventional, Non-Permanent Magnet Wind Generator Candidates. Wind, 2(3), 429-450. https://doi.org/10.3390/wind2030023